Study of Normally-Off AlGaN/GaN HEMT with Microfield Plate for Improvement of Breakdown Voltage

Abstract

:1. Introduction

2. Device Structure and Simulation Model

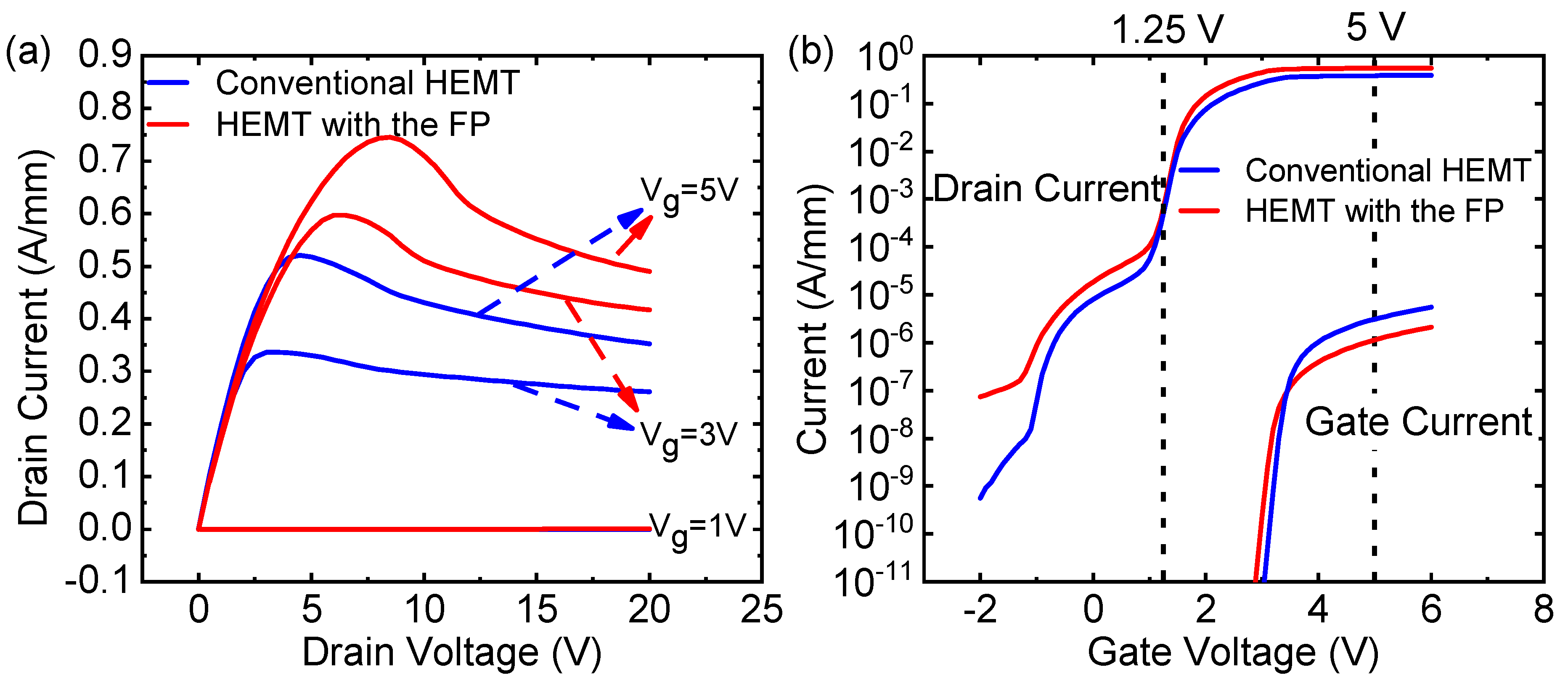

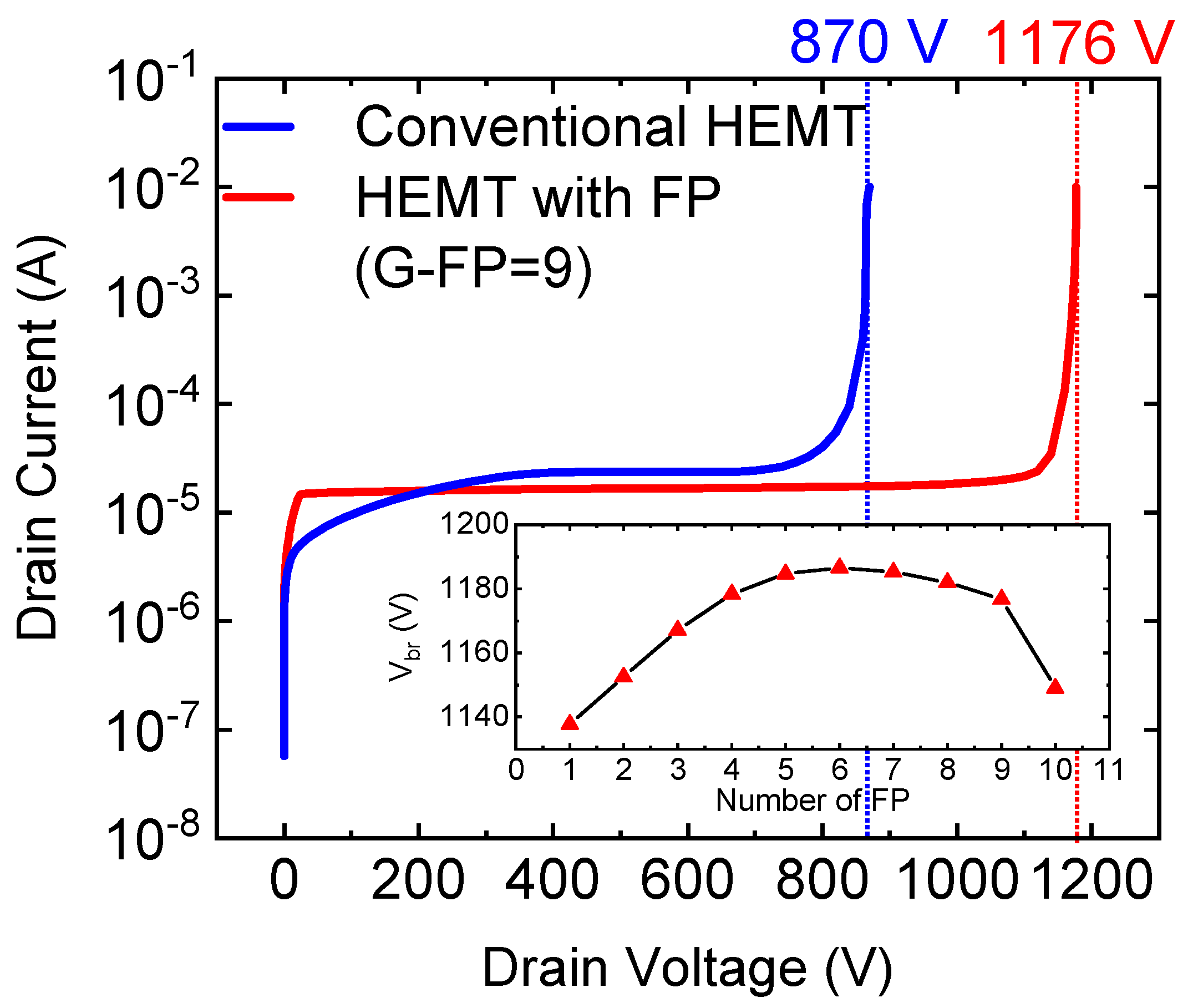

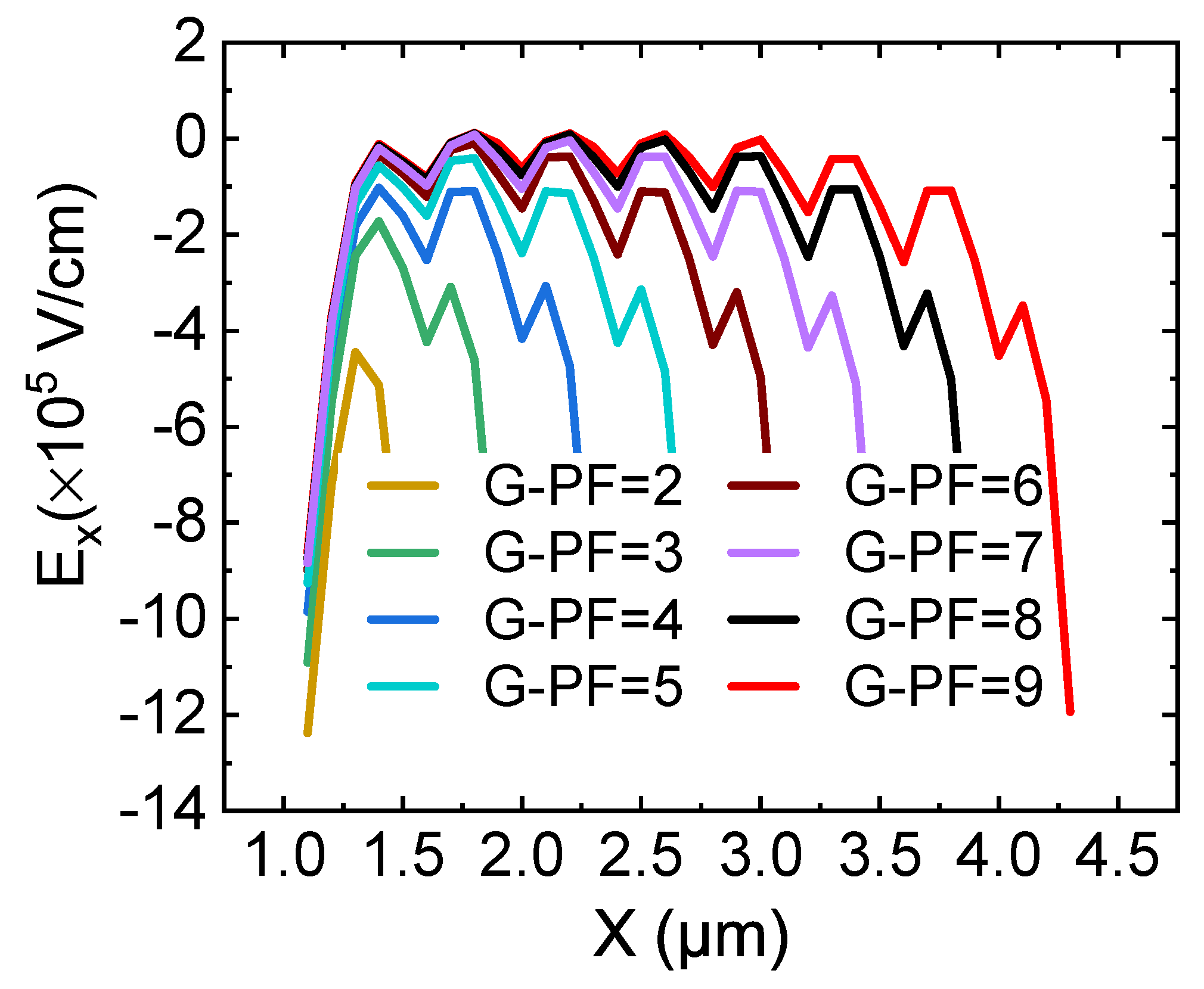

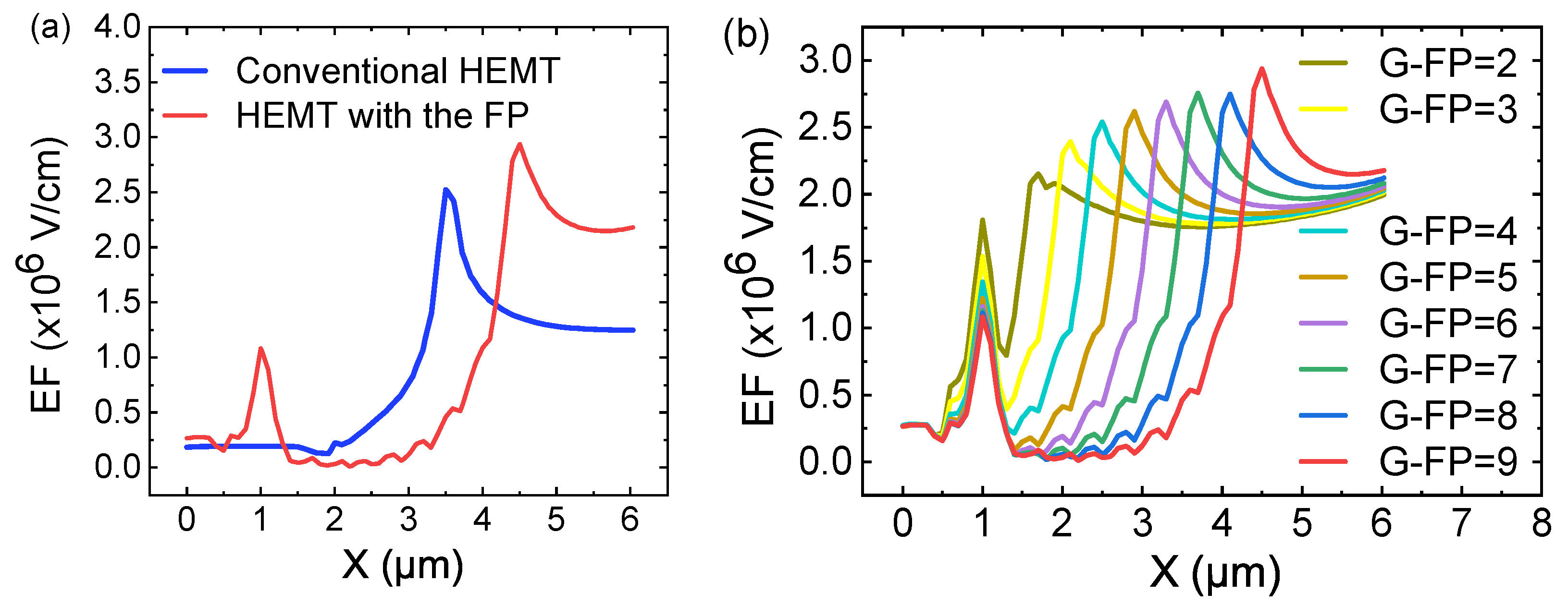

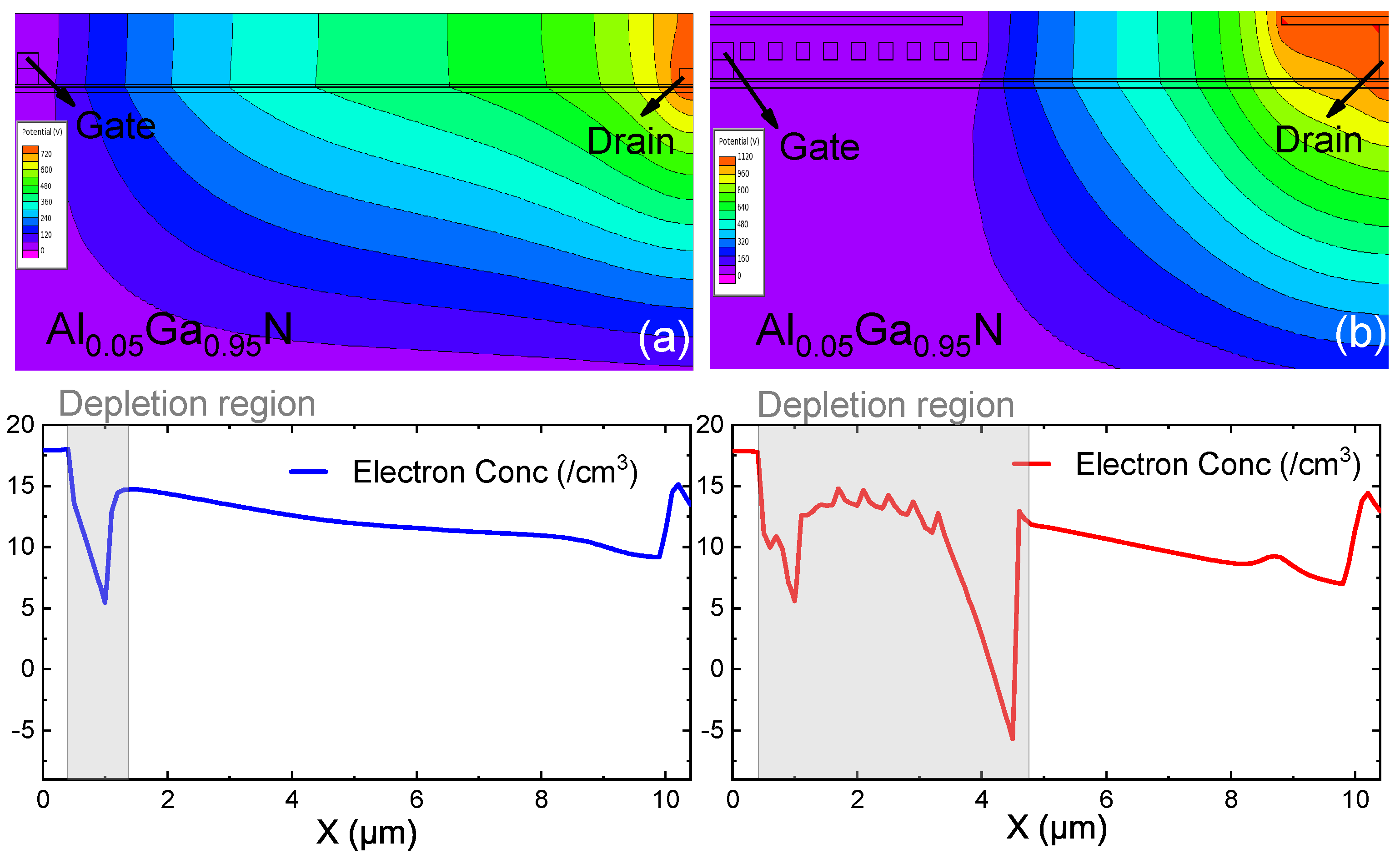

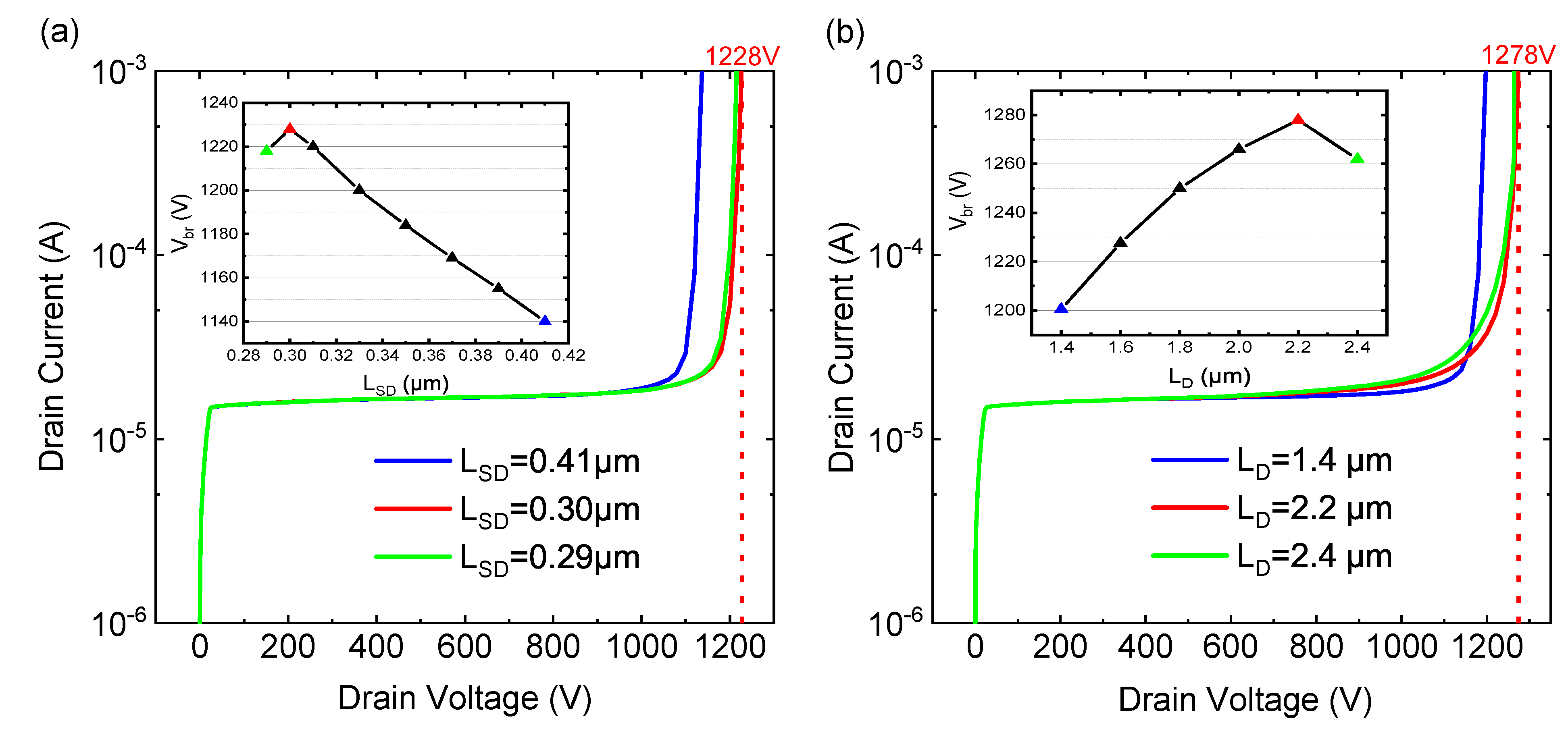

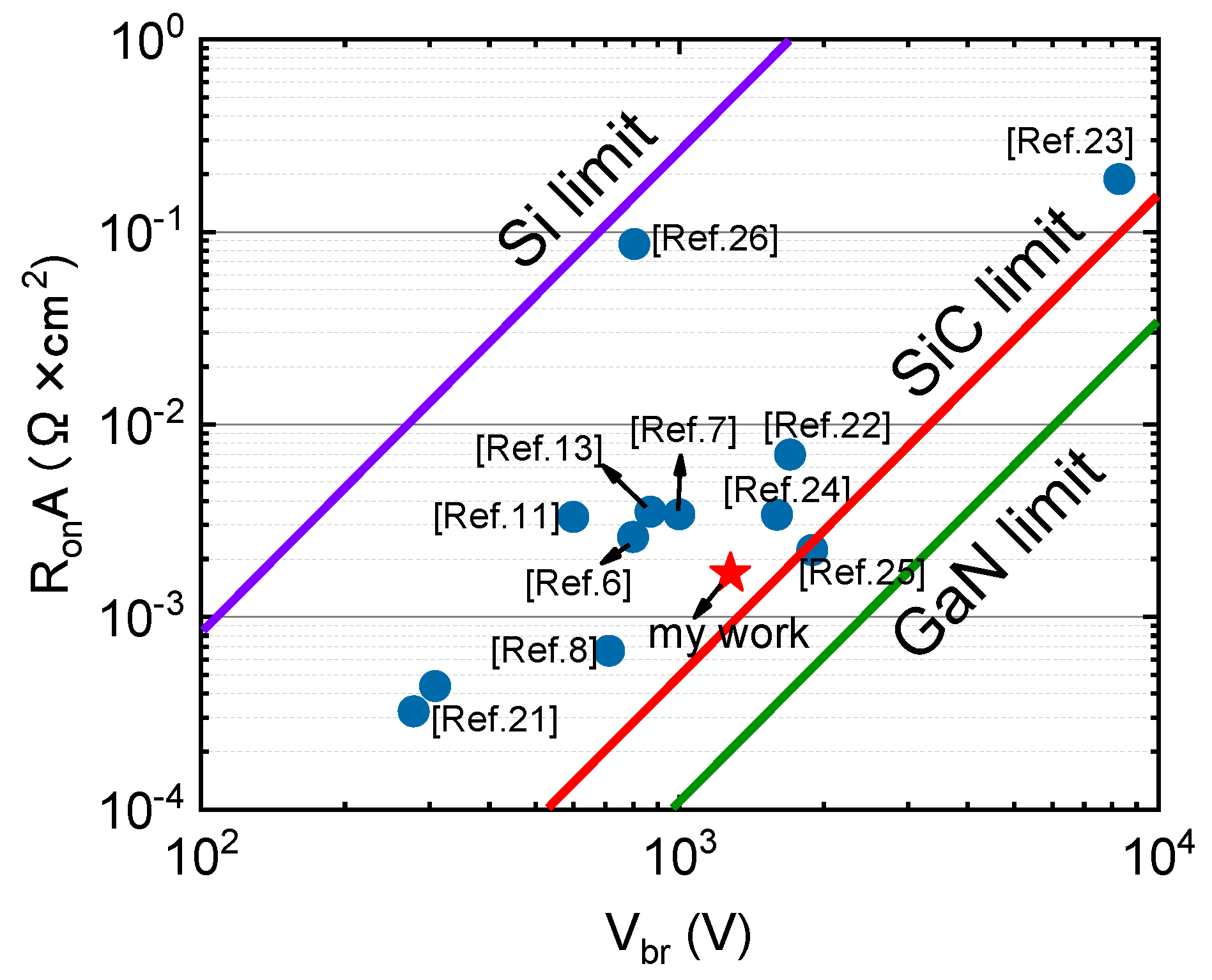

3. Simulation Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pasupuleti, K.S.; Reddeppa, M.; Park, B.-G.; Peta, K.R.; Oh, J.-E.; Kim, S.-G.; Kim, M.-D. Ag Nanowire-Plasmonic-Assisted Charge Separation in Hybrid Heterojunctions of Ppy-PEDOT: PSS/GaN Nanorods for Enhanced UV Photodetection. ACS Appl. Mater. Interfaces 2020, 12, 54181–54190. [Google Scholar] [CrossRef] [PubMed]

- Chu, R.; Corrion, A.; Chen, M.; Li, R.; Wong, D.; Zehnder, D.; Hughes, B.; Boutros, K. 1200-V normally off GaN-on-Si field-effect transistors with low dynamic on-resistance. IEEE Electron Device Lett. 2011, 32, 632–634. [Google Scholar]

- Binari, S.C.; Ikossi, K.; Roussos, J.A.; Kruppa, W.; Park, D.; Dietrich, H.B.; Koleske, D.D.; Wickenden, A.E.; Henry, R.L. Trapping effects and microwave power performance in AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2001, 48, 465–471. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Zhang, J.; Zhao, S.; Zhang, W.; Zhang, Y.; Duan, X.; Chen, J.; Hao, Y. More Than 3000 V Reverse Blocking Schottky-Drain AlGaN-Channel HEMTs With >230 MW/cm2 Power Figure-of-Merit. IEEE Electron Device Lett. 2019, 40, 1724–1727. [Google Scholar] [CrossRef]

- Chen, D.; Liu, Z.; Liang, J.; Wan, L.; Xie, Z.; Li, G. A sandwich-structured AlGaN/GaN HEMT with broad transconductance and high breakdown voltage. J. Mater. Chem. C 2019, 7, 12075–12079. [Google Scholar] [CrossRef]

- Uemoto, Y.; Hikita, M.; Ueno, H.; Matsuo, H.; Ishida, H.; Yanagihara, M.; Ueda, T.; Tanaka, T.; Ueda, D. Gate injection transistor (GIT)—A normally-off AlGaN/GaN power transistor using conductivity modulation. IEEE Trans. Electron Devices 2007, 54, 3393–3399. [Google Scholar] [CrossRef]

- Zeng, F.; Wang, Q.; Lin, S.; Wang, L.; Zhou, G.; Cheng, W.C.; He, M.; Jiang, Y.; Ge, Q.; Li, M.; et al. Study on the optimization of off-state breakdown performance of p-GaN HEMTs. In Proceedings of the 2020 4th IEEE Electron Devices Technology & Manufacturing Conference (EDTM), Penang, Malaysia, 16–18 March 2020; pp. 1–4. [Google Scholar]

- Bahat-Treidel, E.; Hilt, O.; Brunner, F.; Sidorov, V.; Würfl, J.; Tränkle, G. AlGaN/GaN/AlGaN DH-HEMTs breakdown voltage enhancement using multiple grating field plates (MGFPs). IEEE Trans. Electron Devices 2010, 57, 1208–1216. [Google Scholar] [CrossRef]

- Saito, W.; Takada, Y.; Kuraguchi, M.; Tsuda, K.; Omura, I.; Ogura, T. Design and Demonstration of High Breakdown Voltage GaN High Electron Mobility Transistor (HEMT) Using Field Plate Structure for Power Electronics Applications. Jpn. J. Appl. Phys. 2004, 43, 2239–2242. [Google Scholar] [CrossRef]

- Berzoy, A.; Lashway, C.R.; Moradisizkoohi, H.; Mohammed, O.A. Breakdown voltage improvement and analysis of GaN HEMTs through field plate inclusion and substrate removal. In Proceedings of the 2017 IEEE 5th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Albuquerque, NM, USA, 30 October–1 November 2017; pp. 138–142. [Google Scholar]

- Xing, H.; Dora, Y.; Chini, A.; Heikman, S.; Keller, S.; Mishra, U.K. High breakdown voltage AlGaN-GaN HEMTs achieved by multiple field plates. IEEE Electron Device Lett. 2004, 25, 161–163. [Google Scholar] [CrossRef] [Green Version]

- Wong, J.; Shinohara, K.; Corrion, A.L.; Brown, D.F.; Carlos, Z.; Williams, A.; Tang, Y.; Robinson, J.F.; Khalaf, I.; Fung, H.; et al. Novel asymmetric slant field plate technology for high-speed low-dynamic R on E/D-mode GaN HEMTs. IEEE Electr. Device Lett. 2017, 38, 95–98. [Google Scholar] [CrossRef]

- Hilt, O.; Knauer, A.; Brunner, F.; Bahat-Treidel, E.; Würfl, J. In Proceedings of the 2010 6th International Conference on Integrated Power Electronics Systems, Nuremberg, Germany, 16–18 March 2010; pp. 1–4.

- Fei, X.X.; Wang, Y.; Luo, X.; Bao, M.T.; Yu, C.H. TCAD simulation of a breakdown-enhanced double channel GaN metal-insulator-semiconductor field-effect transistor with a P-buried layer. Semicond. Sci. Technol. 2020, 35, 065012. [Google Scholar] [CrossRef]

- Efthymiou, L.; Murukesan, K.; Longobardi, G.; Udrea, F.; Shibib, A.; Terrill, K. Understanding the Threshold Voltage Instability During OFF-State Stress in p-GaN HEMTs. IEEE Electron Device Lett. 2019, 40, 1253. [Google Scholar] [CrossRef]

- Subramani, N.K.; Couvidat, J.; Hajjar, A.A.; Nallatamby, J.C.; Quéré, R. Low-frequency drain noise characterization and TCAD physical simulations of GaN HEMTs: Identification and analysis of physical location of traps. IEEE Electron Device Lett. 2018, 39, 107–110. [Google Scholar] [CrossRef] [Green Version]

- Miccoli, C.; Martino, V.C.; Reina, S.; Rinaudo, S. Trapping and Thermal Effects Analysis for AlGaN/GaN HEMTs by Means of TCAD Simulations. IEEE Electron Device Lett. 2013, 34, 1121. [Google Scholar] [CrossRef]

- Jones, E.A.; Wang, F.F.; Costinett, D. Review of commercial GaN power devices and GaN-based converter design challenges. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 707–719. [Google Scholar] [CrossRef]

- Hu, Q.; Zeng, F.; Cheng, W.-C.; Zhou, G.; Wang, Q.; Yu, H. Reducing dynamic on-resistance of p-GaN gate HEMTs using dual field plate configurations. In Proceedings of the 2020 IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), Singapore, 20–23 July 2020; pp. 1–4. [Google Scholar]

- Zhang, C.; Guo, H.; Chen, Z.; Yue, W.; Li, Y.; Zhang, L.; Liu, S.; Sun, W. Super Field Plate Technique That Can Provide Charge Balance Effect for Lateral Power Devices Without Occupying Drift Region. IEEE Trans. Electron Devices 2020, 67, 2218. [Google Scholar] [CrossRef]

- Treidel, E.B.; Hilt, O.; Brunner, F.; Würfl, J.; Tränkle, G. AlGaN/GaN/AlGaN double heterojunction HEMTs on n-type SiC substrates. In Proceedings of the 36th International Symposium on Compound Semiconductors (ISCS), Santa Barbara, CA, USA, 30 August–2 September 2009; pp. 2408–2411. [Google Scholar]

- Yagi, S.; Shimizu, M.; Okumura, H.; Ohashi, H.; Yano, Y.; Akutsu, N. High Breakdown Voltage AlGaN/GaN Metal-Insulator-Semiconductor High-Electron-Mobility Transistor with TiO2/SiN Gate Insulator. Jpn. J. Appl. Phys. 2007, 46, 2309. [Google Scholar] [CrossRef]

- Uemoto, Y.; Shibata, D.; Yanagihara, M.; Ishida, H.; Matsuo, H.; Nagai, S.; Batta, N.; Ueda, T.; Tanaka, T.; Ueda, D. 8300V Blocking Voltage AlGaN/GaN Power HFET with Thick Poly-AlN Passivation. In Proceedings of the 2007 IEEE International Electron Devices Meeting, Washington, DC, USA, 10–12 December 2007; pp. 861–864. [Google Scholar]

- Tipirneni, N.; Koudymov, A.; Adivarahan, V.; Yang, J.; Simin, G.; Khan, M.A. The 1.6-kV AlGaN/GaN HFETs. IEEE Electron Device Lett. 2006, 27, 716–719. [Google Scholar] [CrossRef]

- Dora, Y.; Chakraborty, A.; McCarthy, L.; Keller, S.; DenBaars, S.P.; Mishra, U.K. High Breakdown Voltage Achieved on AlGaN/GaN HEMTs With Integrated Slant Field Plates. IEEE Electron Device Lett. 2006, 27, 713. [Google Scholar] [CrossRef]

- Qiao, M.; Wang, Z.; Wang, Y.; Yu, L.; Xiao, Q.; Li, Z.; Zhang, B. 3-D Edge Termination Design and RON,sp-BV Model of A 700-V Triple RESURF LDMOS With N-Type Top Layer. IEEE Trans. Electron Devices 2017, 64, 2579. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, X.; Guo, Z.; Sun, H. Study of Normally-Off AlGaN/GaN HEMT with Microfield Plate for Improvement of Breakdown Voltage. Micromachines 2021, 12, 1318. https://doi.org/10.3390/mi12111318

Xia X, Guo Z, Sun H. Study of Normally-Off AlGaN/GaN HEMT with Microfield Plate for Improvement of Breakdown Voltage. Micromachines. 2021; 12(11):1318. https://doi.org/10.3390/mi12111318

Chicago/Turabian StyleXia, Xiaoyu, Zhiyou Guo, and Huiqing Sun. 2021. "Study of Normally-Off AlGaN/GaN HEMT with Microfield Plate for Improvement of Breakdown Voltage" Micromachines 12, no. 11: 1318. https://doi.org/10.3390/mi12111318