Evaluation of the Cross-Sectional Shape of μ–Grooves Produced in Stainless Steel 304 by Laser-Induced Etching Technique

Abstract

1. Introduction

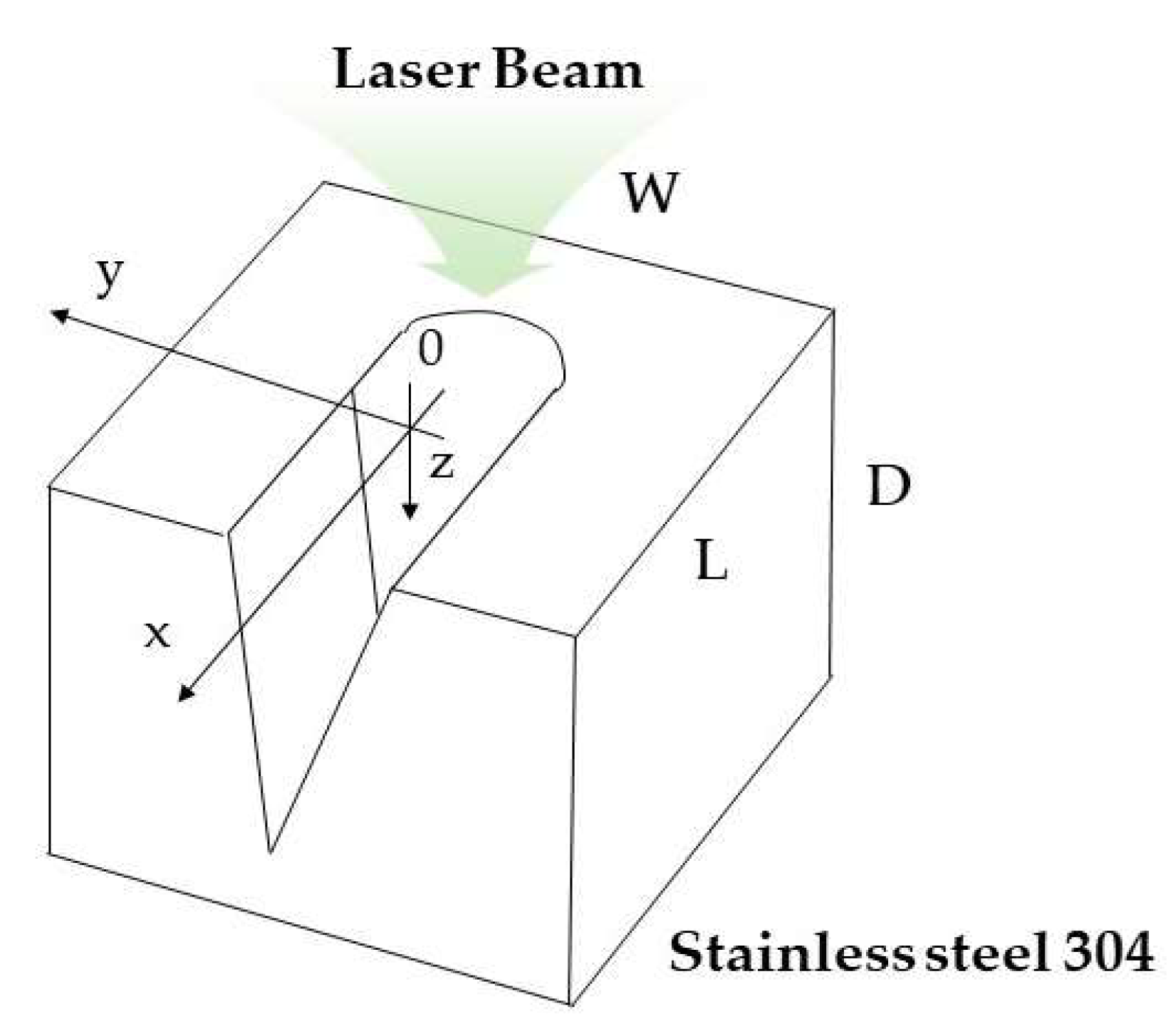

2. Materials and Methods

2.1. System Configuration

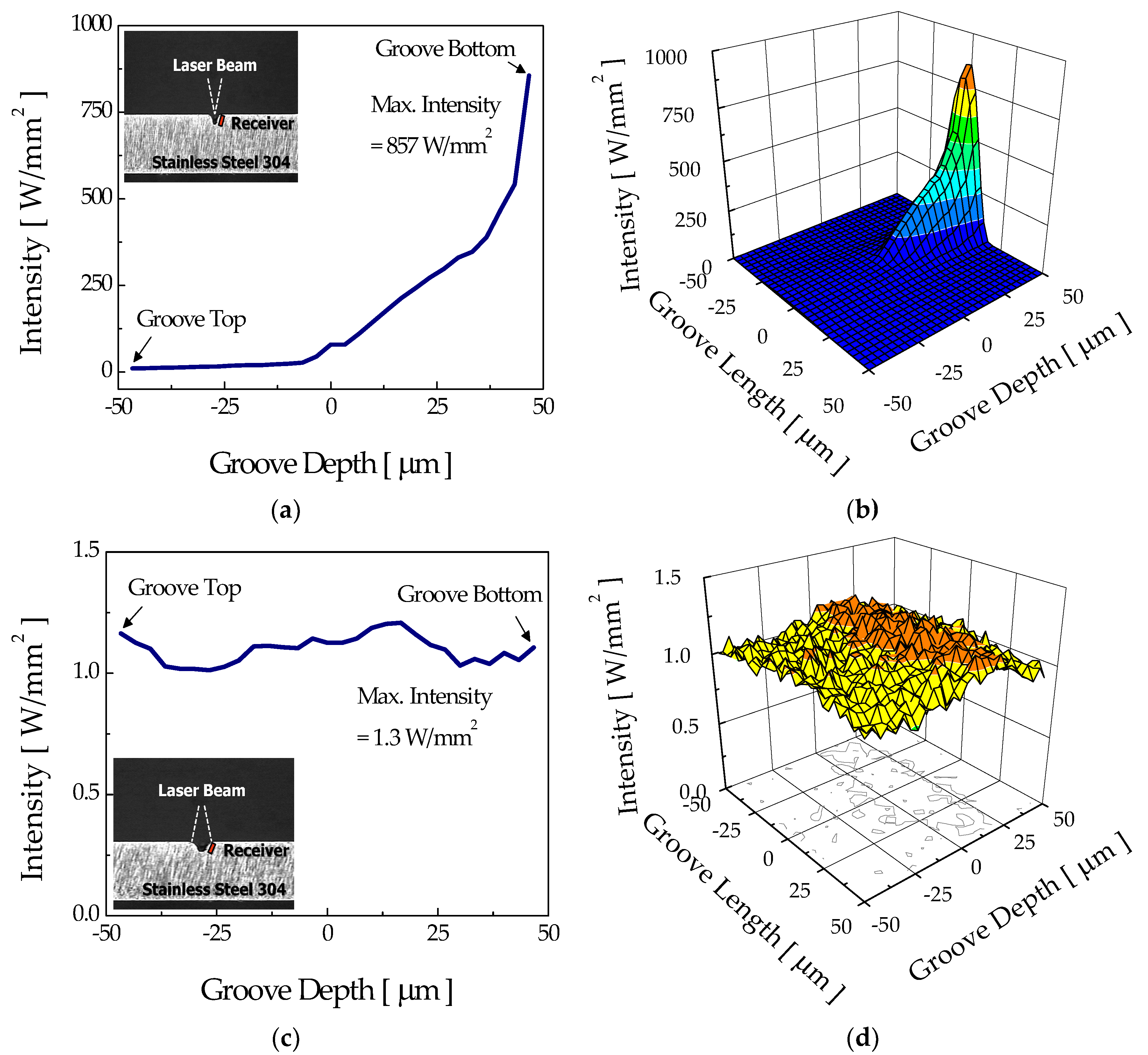

2.2. Modeling for Ray Tracing

3. Results and Discussion

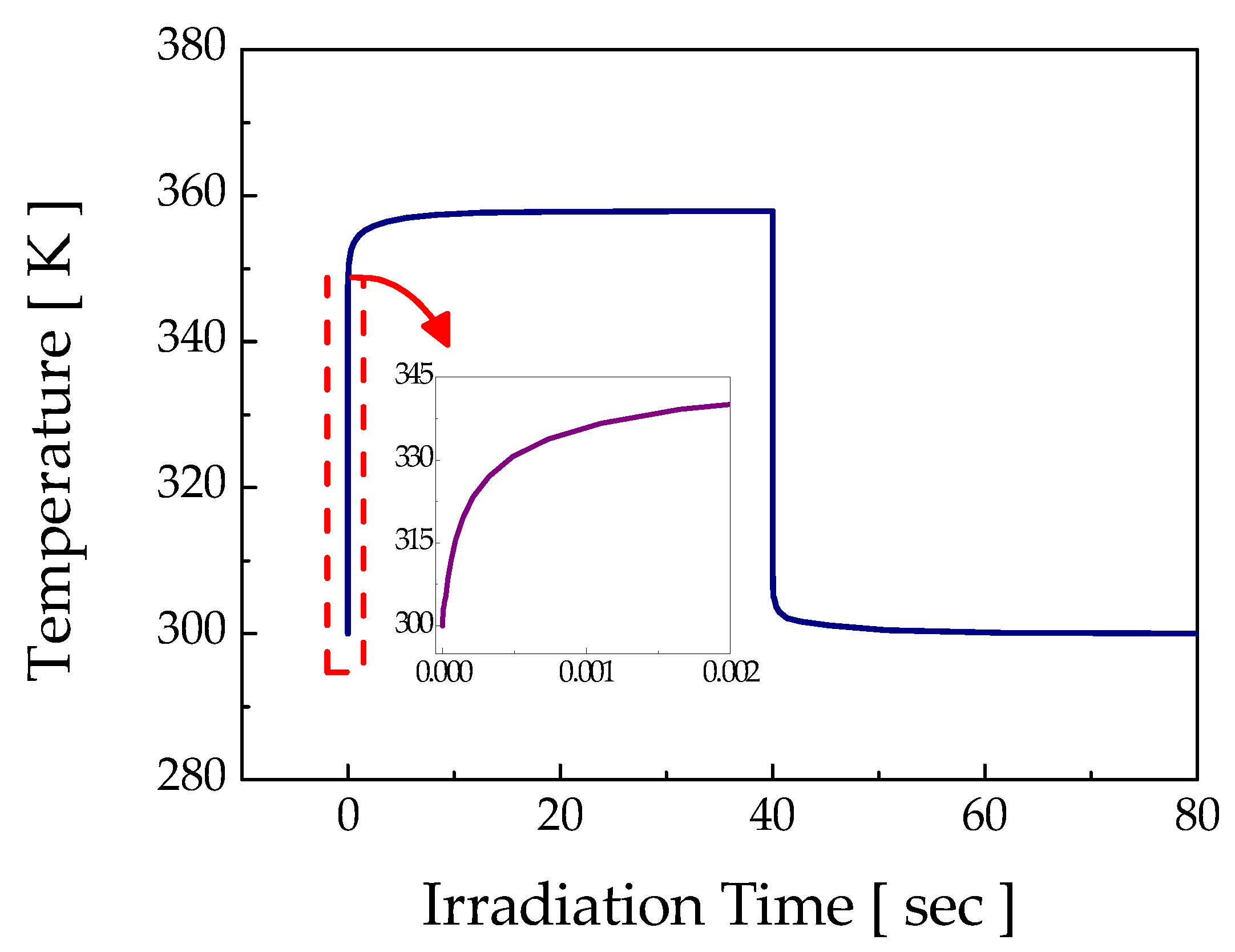

3.1. Etch Threshold Temperature

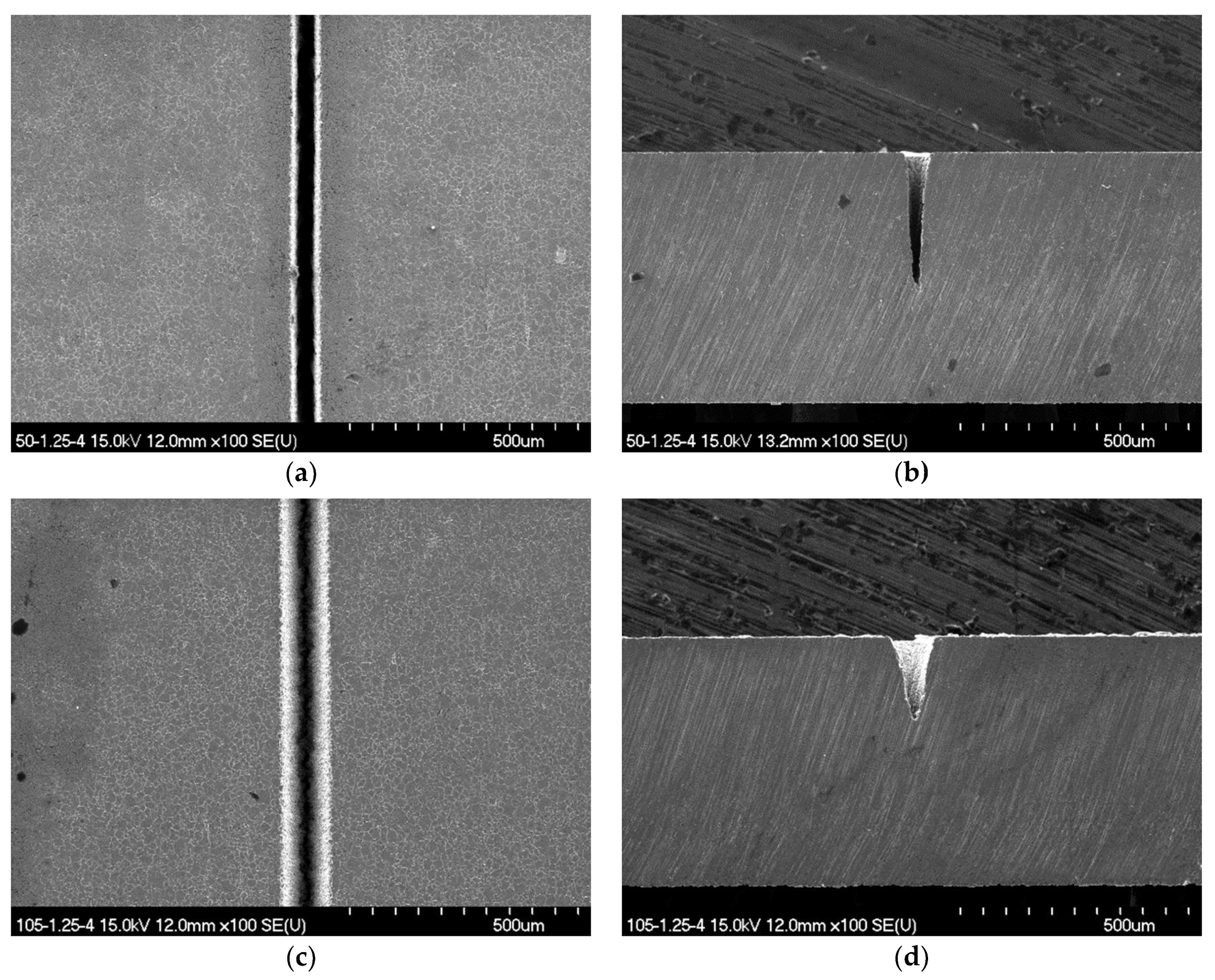

3.2. Comparison of Microgrooves Fabricated by Two Different Laser Irradiation Modes

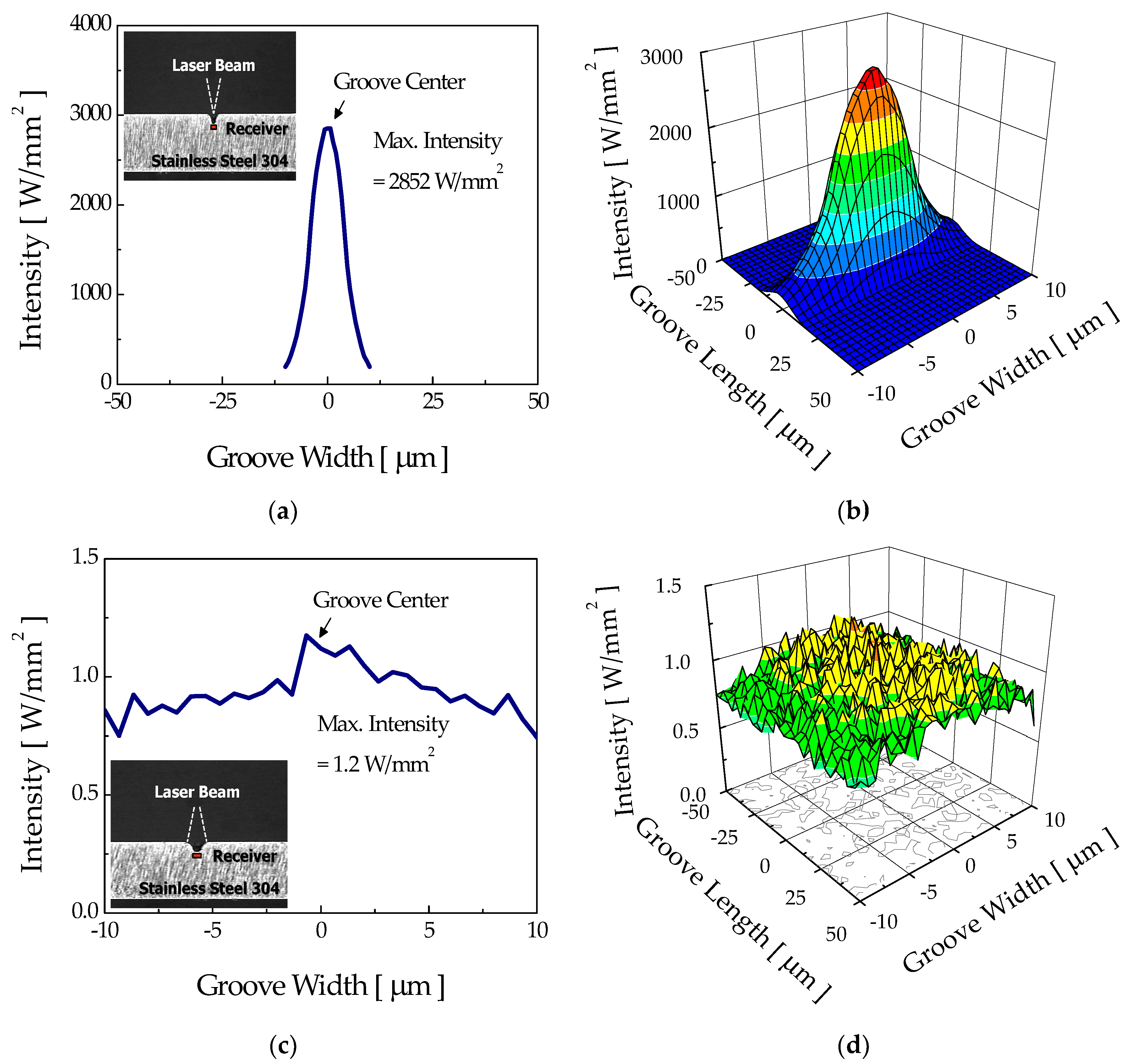

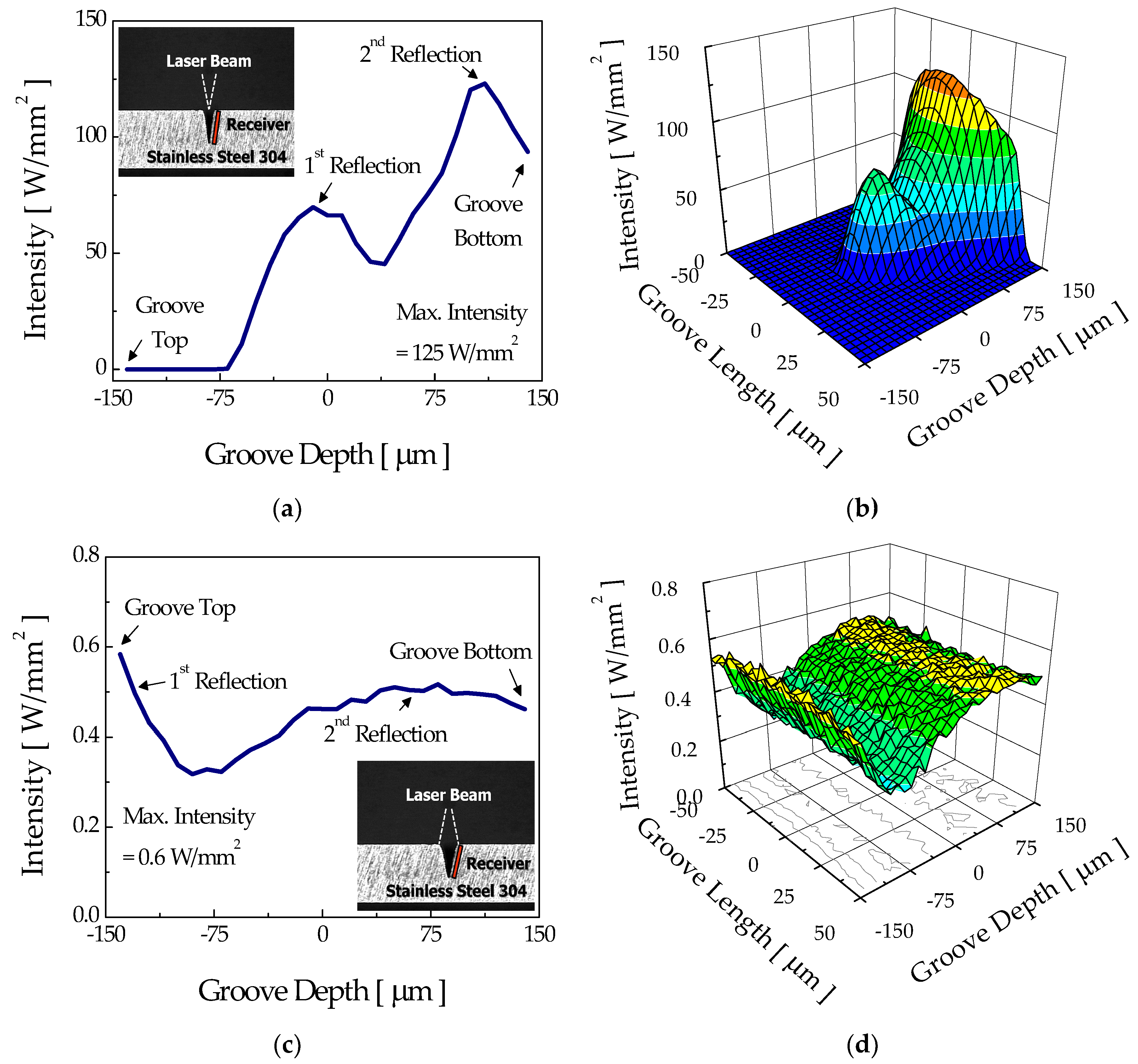

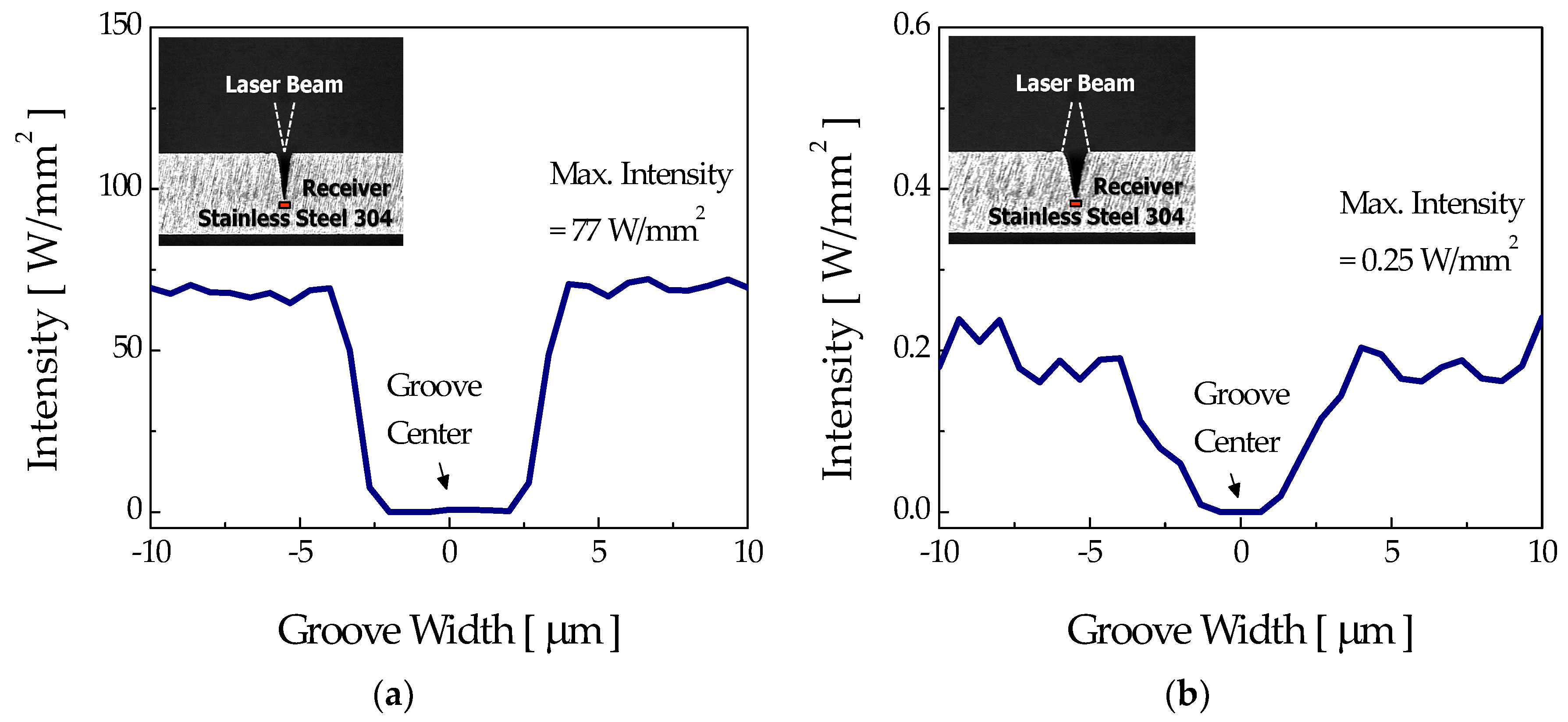

3.3. Optical Rendering

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hopkins, R.; Faghri, A.; Khrustalev, D. Flat miniature heat pipes with microcapillary grooves. J. Heat Transfer. 1999, 121, 102–199. [Google Scholar] [CrossRef]

- Cao, Y.; Gao, M.; Beam, J.E.; Donovan, B. Experiments and analyses of flat miniature heat pipes. J. Thermophys. Heat Transfer. 1997, 11, 158–164. [Google Scholar] [CrossRef]

- Suh, J.S.; Greif, R.; Grigoropoulos, C.P. Friction in micro-channel flows of a liquid and vapor in trapezoidal and sinusoidal grooves. Int. J. Heat Mass Transfer. 2001, 44, 3103–3109. [Google Scholar] [CrossRef]

- Takagi, H.; Maeda, R.; Ozaki, K.; Parameswaran, M.; Mehta, M. Phase transformation type micro pump. In Proceedings of the 5th International Symposium on Micro Machine and Human Science, Nagoya Congress Center, Nagoya, Japan, 2–4 October 1994. [Google Scholar]

- Du, S.; Manoochehri, S. Enhanced ac electrothermal fluidic pumping in microgrooved channels. J. Appl. Phys. 2008, 104, 064902. [Google Scholar] [CrossRef]

- Sabotin, I.; Tristo, G.; Valentinčič, J. Technical model of micro electrical discharge machining (EDM) milling suitable for bottom grooved micromixer design optimization. Micromachines 2020, 11, 594. [Google Scholar] [CrossRef]

- Ma, J.; Wang, Y.; Liu, J. Biomaterials meet microfluidics: From synthesis technologies to biological applications. Micromachines 2017, 8, 255. [Google Scholar] [CrossRef]

- Pattekar, A.V.; Kothare, M.V. Novel microfluidic interconnectors for high temperature and pressure applications. J. Micromech. Microeng. 2003, 13, 337–345. [Google Scholar] [CrossRef]

- Korin, N.; Bransky, A.; Khoury, M.; Levenberg, S. Design of well and groove microchannel bioreactors for cell culture. Biotechnol. Bioeng. 2009, 102, 1222–1230. [Google Scholar] [CrossRef]

- Lee, S.J.; Chang-Chien, A.; Cha, S.W.; O’Hayre, R.; Park, Y.I.; Saito, Y.; Prinz, F.B. Design and fabrication of a micro fuel cell array with ‘flip-flop’ interconnection. J. Power Sour. 2002, 112, 410–418. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A. 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Luft, A.; Franz, U.; Emsermann, A.; Kaspar, J. A study of thermal and mechanical effects on materials induced by pulsed laser drilling. Appl. Phys. A. 1996, 243, 93–101. [Google Scholar] [CrossRef]

- Tsao, J.Y.; Ehrlich, D.J. Laser-controlled chemical etching of aluminum. Appl. Phys. Lett. 1983, 43, 146–148. [Google Scholar] [CrossRef]

- Nowak, R.; Metev, S.; Sepold, G. Nd:YAG-laser-induced wet chemical etching of titanium and stainless steel. Sens. Actuator A. 1995, 51, 41–45. [Google Scholar] [CrossRef]

- Kordás, K.; Bali, K.; Leppävuori, S.; Uusimäki, A.; Nánai, L. Laser direct writing of copper on polyimide surfaces from solution. Appl. Surf. Sci. 2000, 154—155, 399–404. [Google Scholar] [CrossRef]

- Son, S.W.; Lee, M.K.; Oh, K.H.; Jeong, S.H. Fabrication of titanium microchannels using laser-assisted thermochemical wet etching. J. Laser Appl. 2006, 18, 131–137. [Google Scholar] [CrossRef]

- Oh, K.H.; Woo, S.S.; Jeong, H.S.; Yi, Y.W.; Jeong, S.H. Novel optical fiber-based laser direct writing process for micromachining of metal. Chin. Opt. Lett. 2012, 10, S21407. [Google Scholar] [CrossRef]

- Treyz, G.V.; Beach, R.; Osgood, R.M., Jr. Rapid direct writing of high-aspect-ratio trenches in silicon. Appl. Phys. Lett. 1987, 50, 475–477. [Google Scholar] [CrossRef]

- Yan, R.; Chen, J.; Chen, L.; Zhu, D. Deposition mitigation of the first mirrors exposed in EAST with metal and carbon mixed wall materials. Plasma Sci. Technol. 2014, 16, 885–889. [Google Scholar] [CrossRef][Green Version]

- Yoshida, N.; Ohtawa, Y.; Ebihara, A.; Akiyama, T.; Tokitani, M.; Ashikawa, N.; Kawahata, K. Reflectivity reduction of retro-reflector installed in LHD due to plasma surface interaction. In Proceedings of the 22nd IAEA Fusion Energy Conference, United Nations Office, Geneva, Switzerland, 13–18 October 2008. [Google Scholar]

- Oh, K.H.; Park, J.B.; Cho, S.I.; Im, H.D.; Jeong, S.H. Investigation of sidewall roughness of the microgrooves manufactured with laser-induced etching technique. Appl. Surf. Sci. 2009, 255, 9835–9839. [Google Scholar] [CrossRef]

- Chin, D.T.; Chang, H.H. On the conductivity of phosphoric acid electrolyte. J. Appl. Electrochem. 1989, 19, 95–99. [Google Scholar] [CrossRef]

- Shaltout, A.A.; Seoudi, R.; El-Ashkar, E.A.; Eid, K.A. Developed method for spectroscopic studies of viscous samples. Anal. Lett. 2008, 41, 3034–3048. [Google Scholar] [CrossRef]

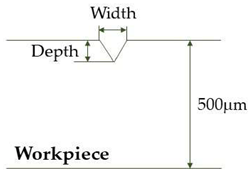

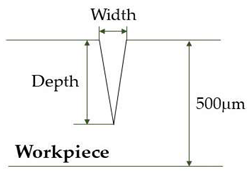

| Groove Geometry | Irradiation Mode | ||

|---|---|---|---|

| Focused Beam | Diverging Beam | ||

(Flat surface with no groove) | Width | 0 | 0 |

| Depth | 0 | 0 | |

(Intermediate stage groove) | Width | 30 μm | 100 μm |

| Depth | 85 μm | 85 μm | |

(Fully developed V-groove) | Width | 50 μm | 100 μm |

| Depth | 300 μm | 300 μm | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Oh, K.H. Evaluation of the Cross-Sectional Shape of μ–Grooves Produced in Stainless Steel 304 by Laser-Induced Etching Technique. Micromachines 2021, 12, 144. https://doi.org/10.3390/mi12020144

Kim J, Oh KH. Evaluation of the Cross-Sectional Shape of μ–Grooves Produced in Stainless Steel 304 by Laser-Induced Etching Technique. Micromachines. 2021; 12(2):144. https://doi.org/10.3390/mi12020144

Chicago/Turabian StyleKim, Jonghun, and Kwang H. Oh. 2021. "Evaluation of the Cross-Sectional Shape of μ–Grooves Produced in Stainless Steel 304 by Laser-Induced Etching Technique" Micromachines 12, no. 2: 144. https://doi.org/10.3390/mi12020144

APA StyleKim, J., & Oh, K. H. (2021). Evaluation of the Cross-Sectional Shape of μ–Grooves Produced in Stainless Steel 304 by Laser-Induced Etching Technique. Micromachines, 12(2), 144. https://doi.org/10.3390/mi12020144