Positioning Accuracy Determination of the Servo Axes for Grinding Wavy-Tilt-Dam Seals Using a Four-Axis Grinder

Abstract

:1. Introduction

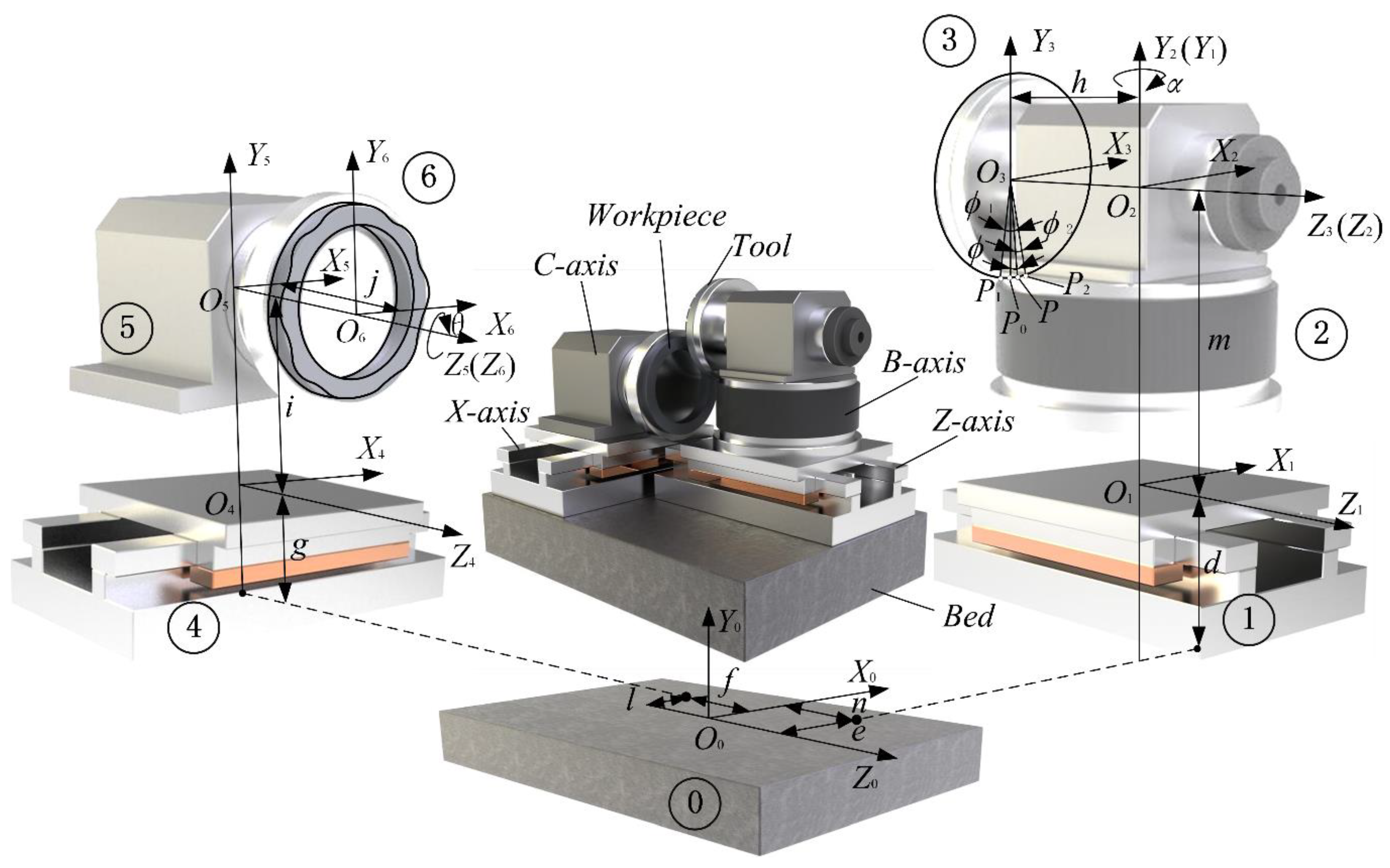

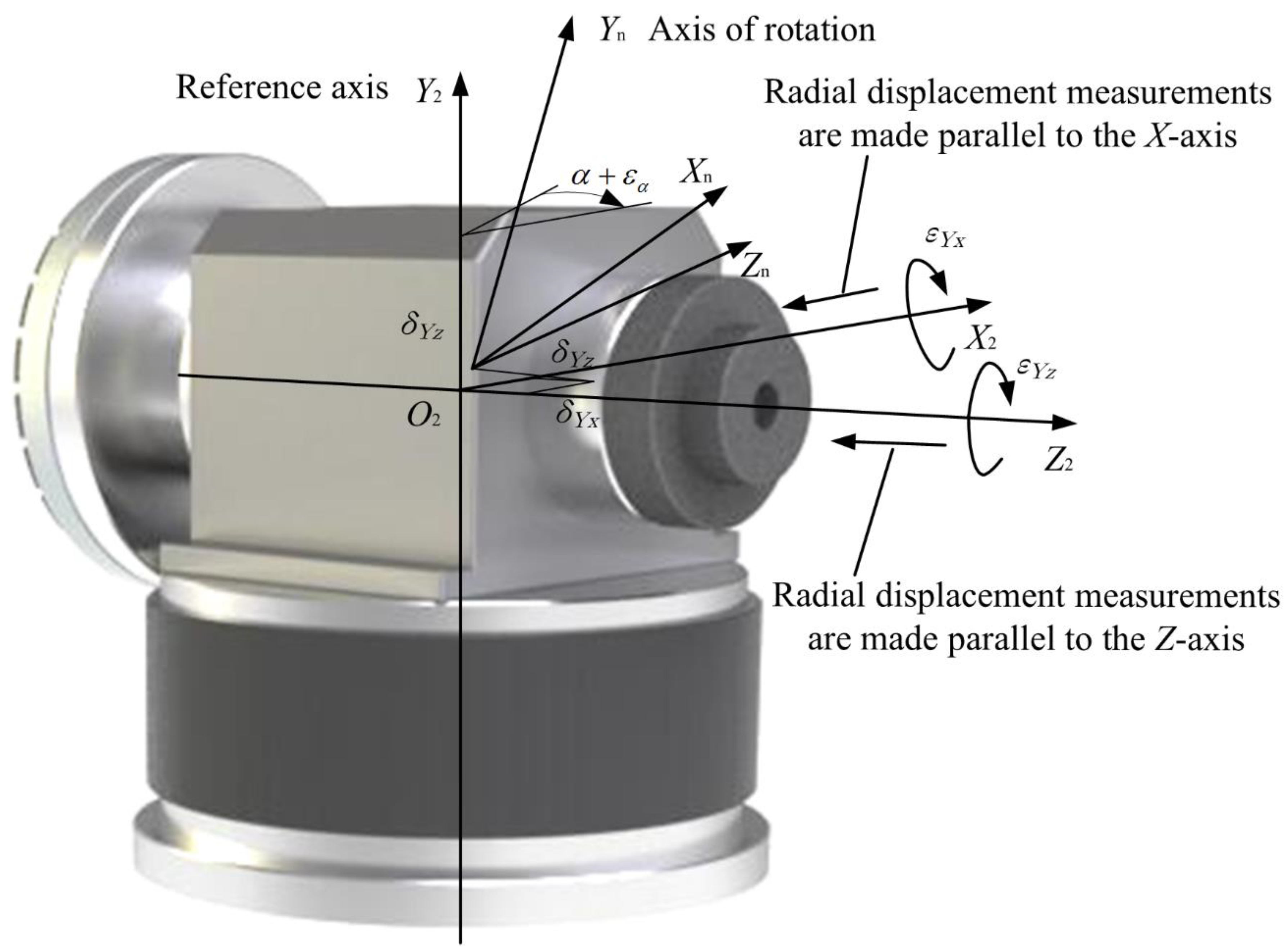

2. The Modelling of a Wavy Face Seal by a Four-Axis Grinder Using a Cup Wheel

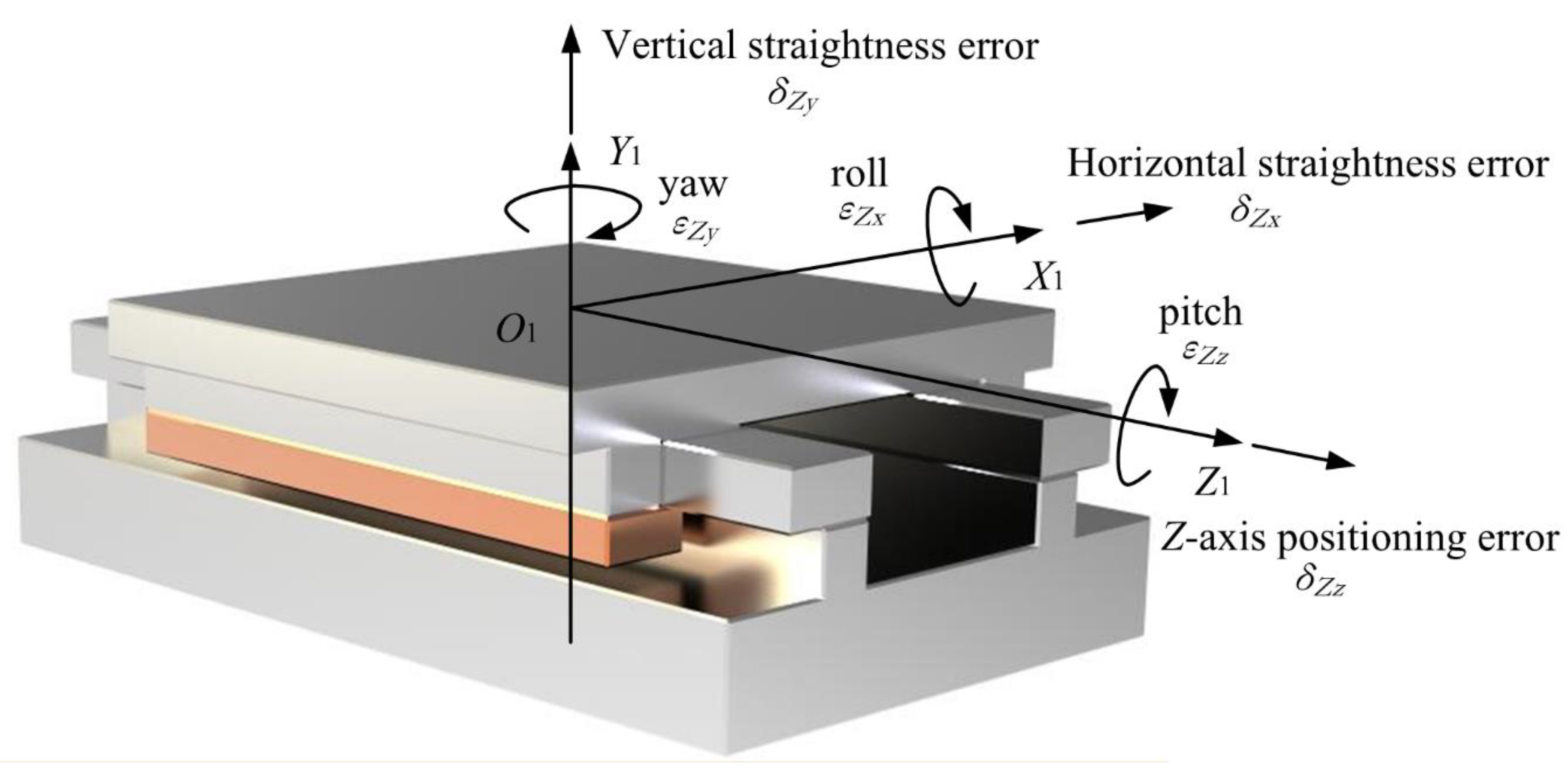

3. Form Error Calculations Concerning Geometric Errors of the Four Axes

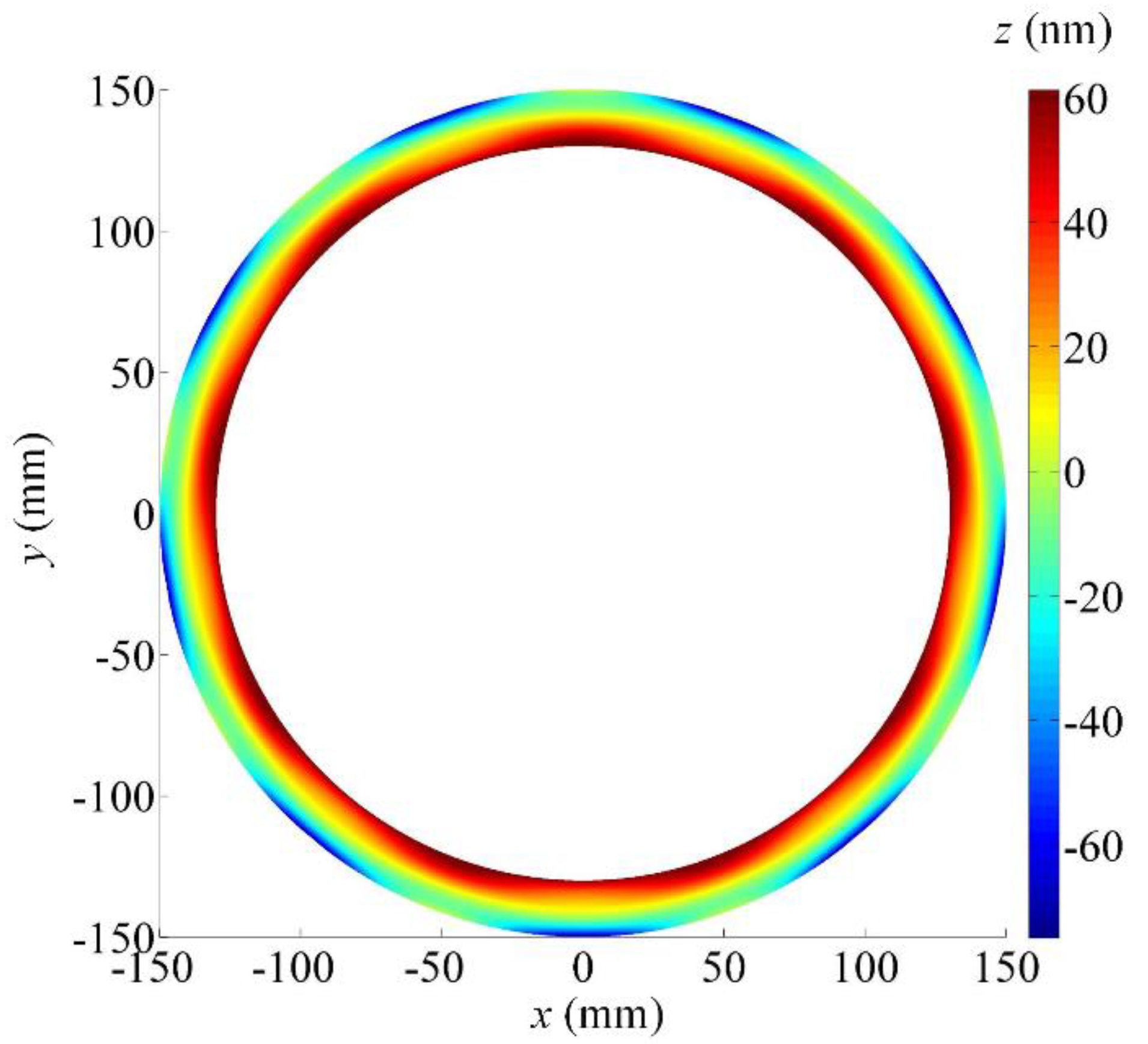

4. The Effects of the Positioning Errors on Form Error of the Ground Wavy Face

5. Positioning Accuracy Determination of the Servo Axes

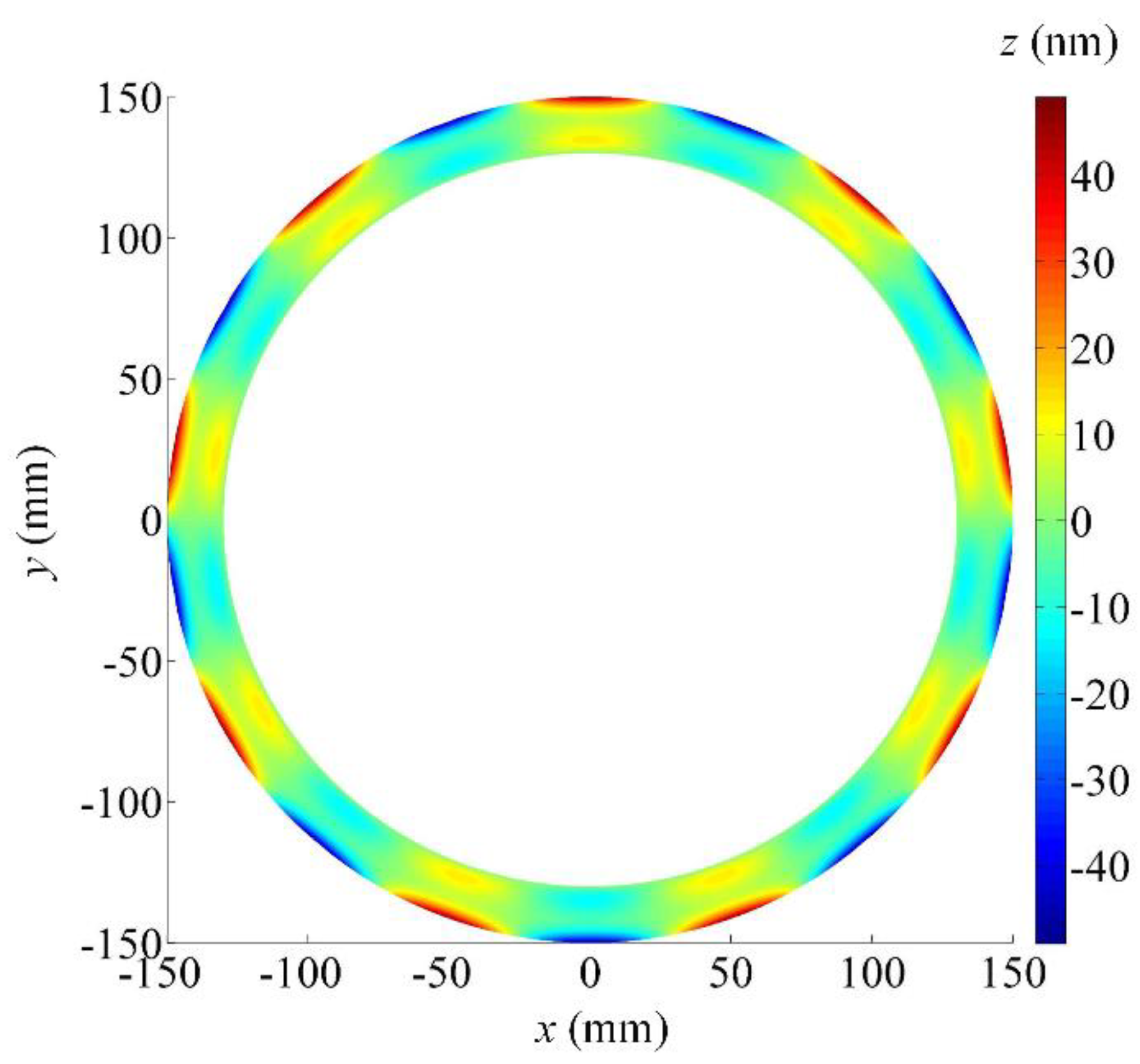

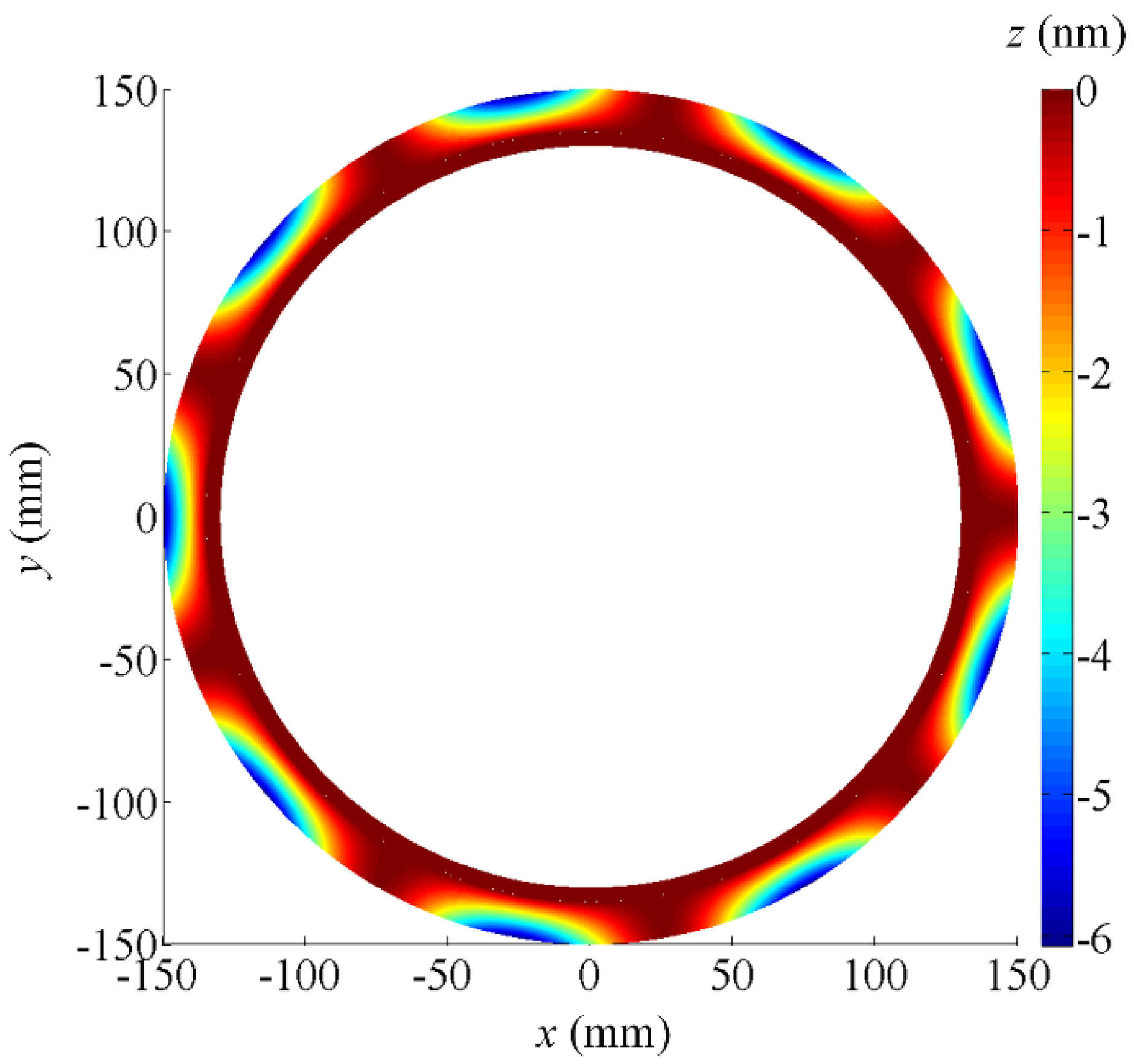

6. Effects of Four-Axis Geometric Errors on Form Error of the Ground Wavy Face

7. Discussion

8. Conclusions

- The Z-axis and B-axis are located in sensitive directions of the processing error while the X-axis and C-axis are located in insensitive directions. The positioning accuracy of the X-axis, Z-axis, B-axis and C-axis components is recommended to be within ±10 μm, ±0.1 μm, ±1 arcsec and ±60 arcsec, respectively.

- The ground form error of the wavy face is mainly affected by the positioning accuracy of the B-axis which can increase the form deviations, apparently. Therefore, the accuracy of the B-axis should be limited as low as the manufacturers can provide.

- Taking the geometric errors of all the four axes into consideration, the maximal amplitude of the ground wavy face is about 6.07 μm which is a little larger than the design value and the form error is only 109.74 nm which is far less than the allowable value of 580 nm.

- All the machine components with assumed geometric errors can be fabricated by modern manufacturing techniques and the calculated results can serve as a theoretical basis for the design and development of the four-axis grinder.

Author Contributions

Funding

Conflicts of Interest

References

- Allaire, P.E. Noncontacting face seals for nuclear applications-a literature review. Lubr. Eng. 1984, 40, 344–351. [Google Scholar]

- Salant, R.F.; Payne, J.W.; Johnson, W.R.; Boles, G. Simulation of a hydraulically controllable reactor coolant pump seal. Tribol. Int. 2018, 122, 163–168. [Google Scholar] [CrossRef]

- Su, W.T.; Li, Y.; Wang, Y.H.; Zhang, Y.N.; Li, X.B.; Ma, Y. Influence of structural parameters on wavy-tilt-dam hydrodynamic mechanical seal performance in reactor coolant pump. Renew. Energy 2020, 166, 210–221. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, W.T.; Jeong, J.H. Demand characteristics of component parts of Korean nuclear power plants depending on reactor type at the operation stage. Ann. Nucl. Energy 2021, 155, 108154. [Google Scholar] [CrossRef]

- Xu, R.; Hu, Y.Y.; Yin, G.L.; Zhang, G.T.; Wang, D.Z. A transient CFD research on the dynamic characteristics of liquid annular seals. Ann. Nucl. Energy 2018, 120, 528–533. [Google Scholar] [CrossRef]

- Francesc, P.R.; Roland, L.; Andreas, A. Modelling of leakage on metal-to-metal seals. Tribol. Int. 2016, 94, 421–427. [Google Scholar]

- Brunetière, N.; Rouillon, M. Fluid flow regime transition in water lubricated spiral grooved face seals. Tribol. Int. 2021, 153, 106605. [Google Scholar] [CrossRef]

- Blasiak, S. Time-fractional heat transfer equations in modeling of the non-contacting face seals. Int. J. Heat Mass Transf. 2016, 100, 79–88. [Google Scholar] [CrossRef]

- Xie, J.; Lu, Y.X. Study on axial-feed mirror finish grinding of hard and brittle materials in relation to micron-scale grain protrusion parameters. Int. J. Mach. Tools Manuf. 2011, 51, 84–93. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Mutlugünes, Y.; Klocke, F.; Aurich, J.C.; Shore, P.; Ohmori, H. Ultraprecision grinding. CIRP Ann. Manuf. Technol. 2010, 59, 652–671. [Google Scholar] [CrossRef]

- Agarwal, S.; Rao, P.V. Experimental investigation of surface/subsurface damage formation and material removal mechanisms in SiC grinding. Int. J. Mach. Tools Manuf. 2008, 48, 698–710. [Google Scholar] [CrossRef]

- Evans, C.J.; Paul, E.; Dornfeld, D.; Lucca, D.A.; Byrne, G.; Tricard, M.; Klocke, F.; Dambon, O.; Mullany, B.A. Material Removal Mechanisms in Lapping and Polishing. CIRP Ann. Manuf. Technol. 2003, 52, 611–633. [Google Scholar] [CrossRef] [Green Version]

- Popli, D.; Gupta, M. Experimental investigation of tool wear and machining rate in rotary ultrasonic machining of nickel alloy. Mach. Sci. Technol. 2018, 22, 427–453. [Google Scholar] [CrossRef]

- Osa, J.L.; Sánchez, J.A.; Ortega, N.; Iordanoff, I.; Charles, J.L. Discrete-element modelling of the grinding contact length combining the wheel-body structure and the surface-topography models. Int. J. Mach. Tools Manuf. 2016, 110, 43–54. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Li, B.Z.; Wu, C.J.; Kong, L.F.; Zheng, Y.H. Smoothed particle hydrodynamics simulation and experimental analysis of SiC ceramic grinding mechanism. Ceram. Int. 2018, 44, 12194–12203. [Google Scholar] [CrossRef]

- Magel, E.; Kalousek, J.; Caldwell, R. A numerical simulation of wheel wear. Wear 2005, 258, 1245–1254. [Google Scholar] [CrossRef] [Green Version]

- Lionel, A.; Young, B.; Key, R.; Philips, R.; Svendsten, S. Mechanical seals with laser machined wavy SiC faces for high duty boiler circulation and feedwater applications. Lubr. Eng. 2003, 59, 30–39. [Google Scholar]

- Feng, G.; Huo, F.W.; Guo, D.M.; Kang, R.K.; Jin, Z.J. Ultra-precision grinding of asymmetric curved surfaces by line contact with cup wheel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2013, 227, 111–119. [Google Scholar] [CrossRef]

- Feng, G.; Guo, D.M.; Huo, F.W.; Jin, Z.J.; Kang, R.K. Implementation strategies for high accuracy grinding of hydrodynamic seal ring with wavy face for reactor coolant pumps. Sci. China Technol. Sci. 2013, 56, 2403–2412. [Google Scholar] [CrossRef]

- Pezeshki, M.; Arezoo, B. Kinematic errors identification of three-axis machine tools based on machined work pieces. Precis. Eng. 2016, 43, 493–504. [Google Scholar] [CrossRef]

- Kvrgic, V.; Dimic, Z.; Cvijanovic, V.; Vidakovic, J.; Kablar, N. A control algorithm for improving the accuracy of five-axis machine tools. Int. J. Prod. Res. 2014, 52, 2983–2998. [Google Scholar] [CrossRef]

- Liu, X.L.; Zhang, X.D.; Fang, F.Z.; Liu, S.G. Identification and compensation of main machining errors on surface form accuracy in ultra-precision diamond turning. Int. J. Mach. Tools Manuf. 2016, 105, 45–57. [Google Scholar] [CrossRef]

- Zhong, G.Y.; Wang, C.Q.; Yang, S.F.; Zheng, E.L.; Ge, Y.Y. Position geometric error modeling, identification and compensation for large 5-axis machining center prototype. Int. J. Mach. Tools Manuf. 2015, 89, 142–150. [Google Scholar] [CrossRef]

- Fu, G.Q.; Fu, J.Z.; Xu, Y.T.; Chen, Z.C.; Lai, J.T. Accuracy enhancement of five-axis machine tool based on differential motion matrix: Geometric error modeling, identification and compensation. Int. J. Mach. Tools Manuf. 2015, 89, 170–181. [Google Scholar] [CrossRef]

- Lee, D.M.; Zhu, Z.K.; Lee, K.; Yang, S.H. Identification and measurement of geometric errors for a five-axis machine tool with a tilting head using a double ball-bar. Int. J. Precis. Eng. Manuf. 2011, 12, 337–343. [Google Scholar] [CrossRef]

- Zhu, S.W.; Ding, G.F.; Qin, S.F.; Lei, J.; Zhuang, L.; Yan, K.Y. Integrated geometric error modeling, identification and compensation of CNC machine tools. Int. J. Mach. Tools Manuf. 2012, 52, 24–29. [Google Scholar] [CrossRef]

- Wu, C.J.; Fan, J.W.; Wang, Q.H.; Chen, D.J. Machining accuracy improvement of non-orthogonal five-axis machine tools by a new iterative compensation methodology based on the relative motion constraint equation. Int. J. Mach. Tools Manuf. 2018, 124, 80–98. [Google Scholar] [CrossRef]

- Guo, S.J.; Jiang, G.D.; Mei, X.S. Investigation of sensitivity analysis and compensation parameter optimization of geometric error for five-axis machine tool. Int. J. Adv. Manuf. Technol. 2017, 93, 3229–3243. [Google Scholar] [CrossRef]

- Chen, J.X.; Lin, S.W.; He, B.W. Geometric error measurement and identification for rotary table of multi-axis machine tool using double ballbar. Int. J. Mach. Tools Manuf. 2014, 77, 47–55. [Google Scholar] [CrossRef]

- Lee, J.C.; Lee, H.H.; Yang, S.H. Total measurement of geometric errors of a three-axis machine tool by developing a hybrid technique. Int. J. Precis. Eng. Manuf. 2016, 17, 427–432. [Google Scholar] [CrossRef]

- Ramesh, R.; Mannan, M.A.; Poo, A.N. Error compensation in machine tools—A review: Part I: Geometric, cutting-force induced and fixture-dependent errors. Int. J. Mach. Tools Manuf. 2000, 40, 1235–1256. [Google Scholar] [CrossRef]

- Cheng, Q.; Zhang, Z.L.; Zhang, G.J.; Gu, P.H.; Cai, L.G. Geometric accuracy allocation for multi-axis CNC machine tools based on sensitivity analysis and reliability theory. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2014, 229, 1134–1149. [Google Scholar] [CrossRef]

| Axis Name | Positioning Error (μm) | Form Error (nm) |

|---|---|---|

| X-axis | 2 | 77.18 |

| −2 | 77.17 | |

| 5 | 77.20 | |

| −5 | 77.19 | |

| 10 | 77.29 | |

| −10 | 77.26 | |

| 20 | 77.62 | |

| −20 | 77.55 | |

| Z-axis | - | 57.88 |

| Axis Name | Positioning Error (arcsec) | Form Error (nm) |

|---|---|---|

| B-axis | 0.1 | 77.17 |

| −0.1 | 77.17 | |

| 0.5 | 90.88 | |

| −0.5 | 90.77 | |

| 1 | 136.09 | |

| −1 | 135.90 | |

| 2 | 232.80 | |

| −2 | 232.54 | |

| C-axis | 10 | 80.66 |

| −10 | 73.68 | |

| 30 | 87.64 | |

| −30 | 66.70 | |

| 60 | 98.11 | |

| −60 | 56.23 | |

| 120 | 119.06 | |

| −120 | 35.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, G.; Ma, X. Positioning Accuracy Determination of the Servo Axes for Grinding Wavy-Tilt-Dam Seals Using a Four-Axis Grinder. Micromachines 2021, 12, 388. https://doi.org/10.3390/mi12040388

Feng G, Ma X. Positioning Accuracy Determination of the Servo Axes for Grinding Wavy-Tilt-Dam Seals Using a Four-Axis Grinder. Micromachines. 2021; 12(4):388. https://doi.org/10.3390/mi12040388

Chicago/Turabian StyleFeng, Guang, and Xiaobao Ma. 2021. "Positioning Accuracy Determination of the Servo Axes for Grinding Wavy-Tilt-Dam Seals Using a Four-Axis Grinder" Micromachines 12, no. 4: 388. https://doi.org/10.3390/mi12040388

APA StyleFeng, G., & Ma, X. (2021). Positioning Accuracy Determination of the Servo Axes for Grinding Wavy-Tilt-Dam Seals Using a Four-Axis Grinder. Micromachines, 12(4), 388. https://doi.org/10.3390/mi12040388