Direct Writing of Cu Patterns on Polydimethylsiloxane Substrates Using Femtosecond Laser Pulse-Induced Reduction of Glyoxylic Acid Copper Complex

Abstract

:1. Introduction

2. Materials and Methods

2.1. Femtosecond Laser Direct Writing of Cu Wires

2.2. Evaluation of the Patterns

3. Results and Discussion

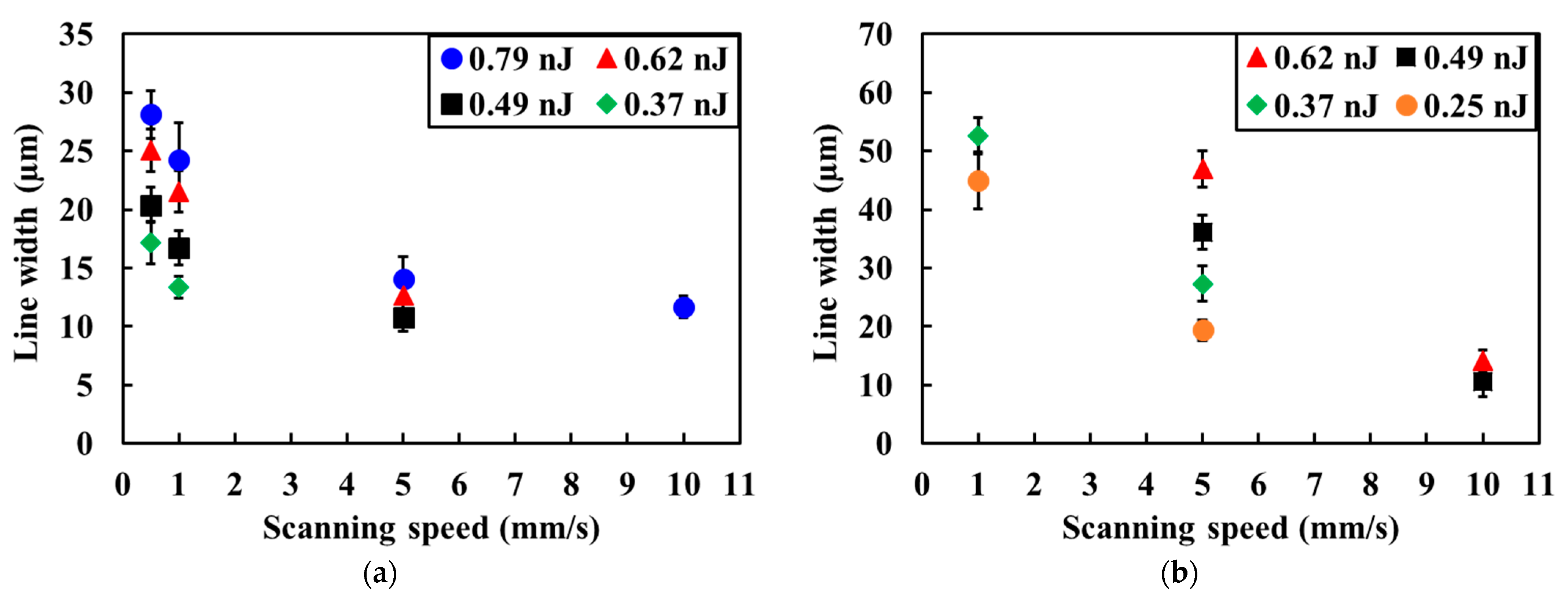

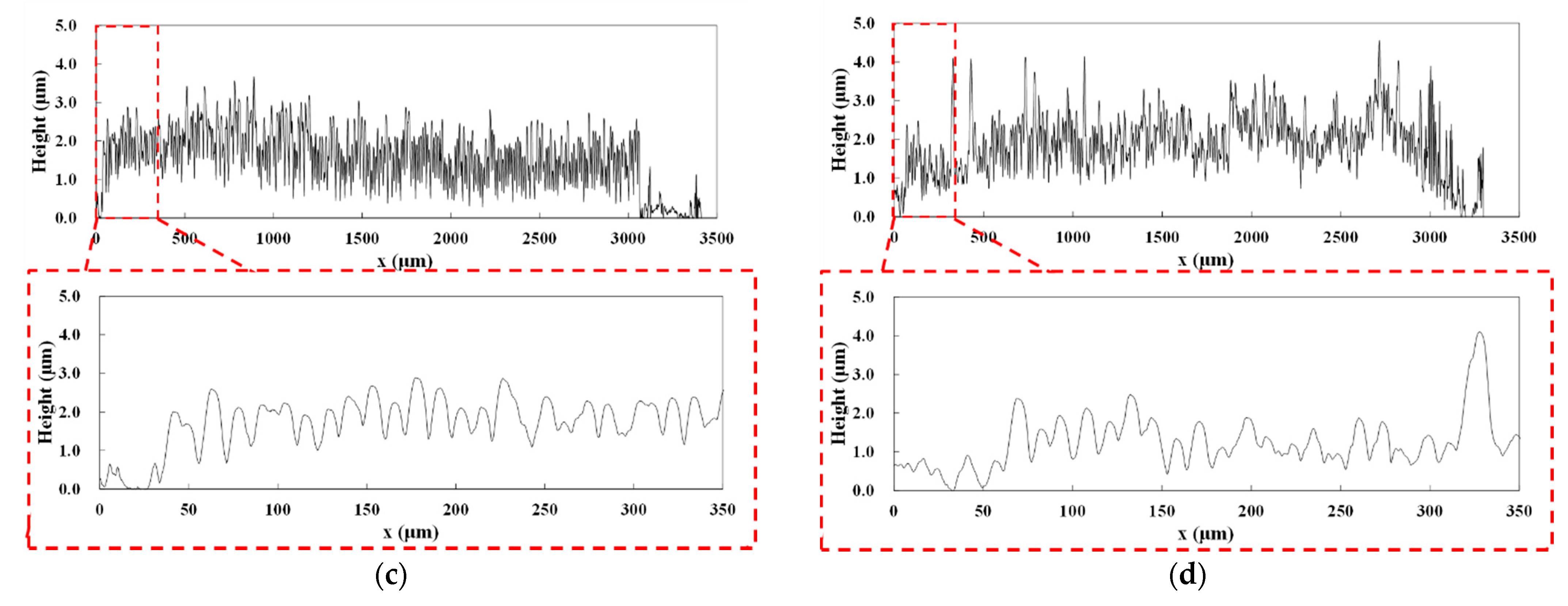

3.1. Morphology and Width of Line Patterns and on Glass and PDMS Substrates

3.2. XRD Spectra of the Patterns on Glass and PDMS Substrates

3.3. Resistivity of the Patterns on Glass and PDMS Substrates

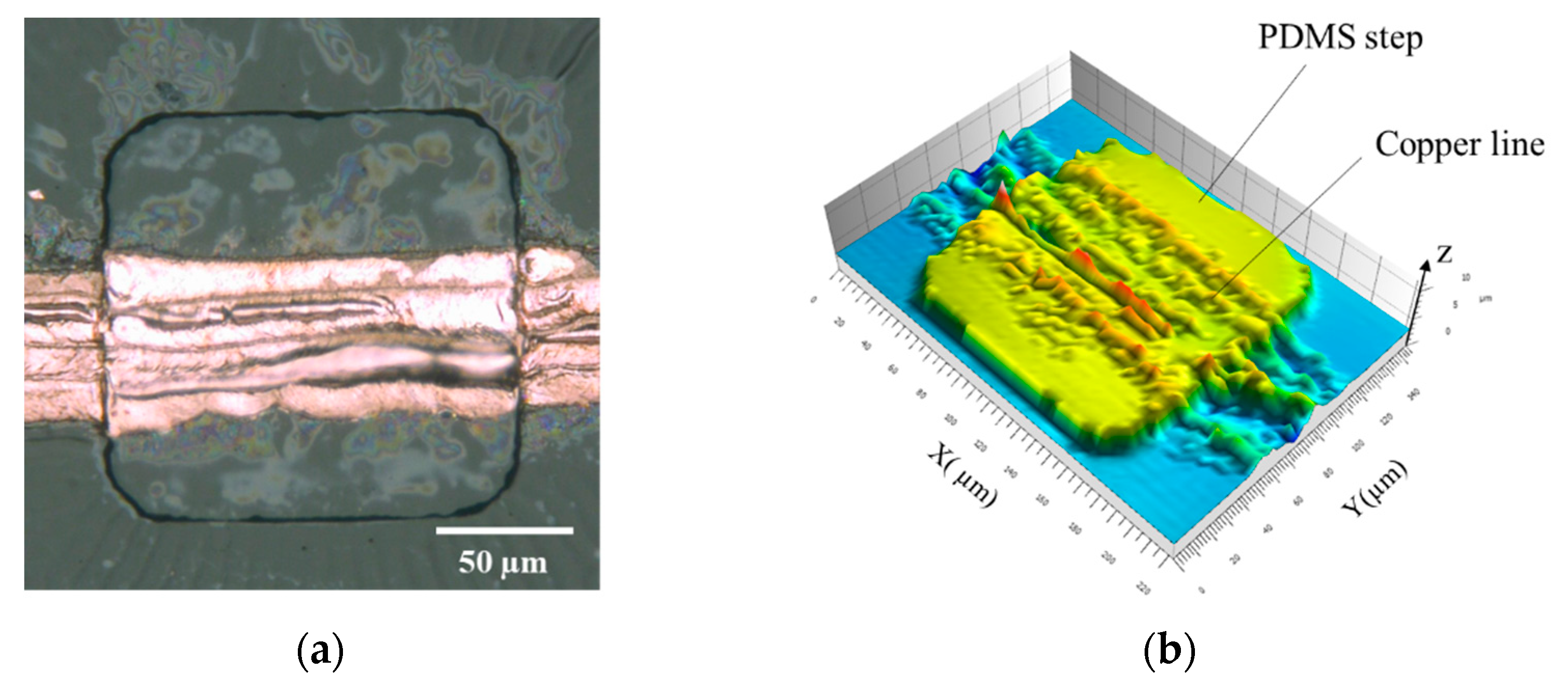

3.4. Cu Patterning on PDMS Step Structures

4. Conclusions

- The width of the line patterns formed on PDMS substrates was larger than that on glass substrates under the same conditions, such as laser scanning speed and pulse energy, which is attributable to heat accumulation on PDMS substrates induced by its lower thermal conductivity. The line width is expected to be reduced by decreasing the repetition frequency of the femtosecond laser pulses to inhibit heat accumulation.

- XRD peaks of the patterns fabricated on glass substrates corresponded to Cu without significant oxidation. By contrast, although Cu patterns were also formed on PDMS substrates at a scanning speed of 10 mm/s and pulse energy of 0.49 nJ, Cu2O was also generated under the overheating conditions at a scanning speed of 1 mm/s and pulse energy of 0.37 nJ.

- All the patterns exhibited electrical conductivity on glass and PDMS substrates. The minimum resistivity of the patterns on PDMS substrates is 1.4 × 10−5 Ωm, which is 10 times higher than that on glass substrates, indicating that microcracks formed by thermal shrinkage of the substrates during laser irradiation increase the resistivity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Zacharatos, F.; Theodorakos, I.; Karvounis, P.; Tuohy, S.; Braz, N.; Melamed, S.; Kabla, A.; De La Vega, F.; Andritsos, K.; Hatziapostolou, A.; et al. Selective Laser Sintering of Laser Printed Ag Nanoparticle Micropatterns at High Repetition Rates. Materials 2018, 11, 2142. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Halonen, E.; Heinonen, E.; Mäntysalo, M. The Effect of Laser Sintering Process Parameters on Cu Nanoparticle Ink in Room Conditions. Opt. Photonics J. 2013, 3, 40–44. [Google Scholar] [CrossRef]

- Yeo, J.; Hong, S.; Lee, D.; Hotz, N.; Lee, M.-T.; Grigoropoulos, C.P.; Ko, S.H. Next Generation Non-Vacuum, Maskless, Low Temperature Nanoparticle Ink Laser Digital Direct Metal Patterning for a Large Area Flexible Electronics. PLoS ONE 2012, 7, e42315. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kang, B.; Han, S.; Kim, J.; Ko, S.; Yang, M. One-Step Fabrication of Copper Electrode by Laser-Induced Direct Local Reduction and Agglomeration of Copper Oxide Nanoparticle. J. Phys. Chem. C 2011, 115, 23664–23670. [Google Scholar] [CrossRef]

- Paeng, D.; Lee, D.; Yeo, J.; Yoo, J.-H.; Allen, F.I.; Kim, E.; So, H.; Park, H.K.; Minor, A.M.; Grigoropoulos, C.P. Laser-Induced Reductive Sintering of Nickel Oxide Nanoparticles under Ambient Conditions. J. Phys. Chem. C 2015, 119, 6363–6372. [Google Scholar] [CrossRef]

- Lee, D.; Paeng, D.; Park, H.K.; Grigoropoulos, C.P. Vacuum-Free, Maskless Patterning of Ni Electrodes by Laser Reductive Sintering of NiO Nanoparticle Ink and Its Application to Transparent Conductors. ACS Nano 2014, 8, 9807–9814. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Yang, M. Effect of solvent and PVP on electrode conductivity in laser-induced reduction process. Appl. Phys. A 2015, 119, 317–323. [Google Scholar] [CrossRef]

- Lee, J.; Lee, B.; Jeong, S.; Kim, Y.; Lee, M. Microstructure and electrical property of laser-sintered Cu complex ink. Appl. Surf. Sci. 2014, 307, 42–45. [Google Scholar] [CrossRef]

- Ohishi, T.; Takahashi, N. Preparation and Properties of Copper Fine Wire on Polyimide Film in Air by Laser Irradiation and Mixed-Copper-Complex Solution Containing Glyoxylic Acid Copper Complex and Methylamine Copper Complex. Mater. Sci. Appl. 2018, 9, 859–872. [Google Scholar] [CrossRef] [Green Version]

- Ohishi, T.; Kimura, R. Fabrication of Copper Wire Using Glyoxylic Acid Copper Complex and Laser Irradiation in Air. Mater. Sci. Appl. 2015, 6, 799–808. [Google Scholar] [CrossRef] [Green Version]

- Mizoshiri, M.; Arakane, S.; Sakurai, J.; Hata, S. Direct writing of Cu-based micro-temperature detectors using femtosecond laser reduction of CuO nanoparticles. Appl. Phys. Express 2016, 9, 36701. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Ito, Y.; Arakane, S.; Sakurai, J.; Hata, S. Direct fabrication of Cu/Cu2O composite micro-temperature sensor using femtosecond laser reduction patterning. Jpn. J. Appl. Phys. 2016, 55, 06GP05. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Hata, S. Selective fabrication of p-type and n-type thermoelectric micropatterns by the reduction of CuO/NiO mixed nanoparticles using femtosecond laser pulses. Appl. Phys. A 2017, 124, 64. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Aoyama, K.; Uetsuki, A.; Ohishi, T. Direct Writing of Copper Micropatterns Using Near-Infrared Femtosecond Laser-Pulse-Induced Reduction of Glyoxylic Acid Copper Complex. Micromachines 2019, 10, 401. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martin, A.A.; Calta, N.P.; Hammons, J.A.; Khairallah, S.A.; Nielsen, M.H.; Shuttlesworth, R.M.; Sinclair, N.; Matthews, M.J.; Jeffries, J.R.; Willey, T.M.; et al. Ultrafast dynamics of laser-metal interactions in additive manufacturing alloys captured by in situ X-ray imaging. Mater. Today Adv. 2019, 1, 100002. [Google Scholar] [CrossRef]

| Irradiation Conditions | Resistivity (Ωm) | Resistance (Ω) | Cross-Section (µm2) | Length (mm) | Average Thickness (µm) |

|---|---|---|---|---|---|

| Patterns on glass substrates at a scanning speed of 5 mm/s and pulse energy of 0.49 nJ. | 7.3 × 10−6 | 9.4 | 195 | 0.25 | 0.65 |

| Patterns on glass substrates at a scanning speed of 0.5 mm/s and pulse energy of 0.74 nJ. | 1.4 × 10−2 | 4.5 × 104 | 163 | 0.25 | 0.54 |

| Patterns on PDMS substrates at a scanning speed of 10 mm/s and pulse energy of 0.49 nJ. | 1.4 × 10−5 | 16 | 4359 | 5.0 | 1.5 |

| Patterns on PDMS substrates at a scanning speed of 1 mm/s and pulse energy of 0.37 nJ. | 6.2 | 6.3 × 106 | 4950 | 5.0 | 1.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ha, N.P.; Ohishi, T.; Mizoshiri, M. Direct Writing of Cu Patterns on Polydimethylsiloxane Substrates Using Femtosecond Laser Pulse-Induced Reduction of Glyoxylic Acid Copper Complex. Micromachines 2021, 12, 493. https://doi.org/10.3390/mi12050493

Ha NP, Ohishi T, Mizoshiri M. Direct Writing of Cu Patterns on Polydimethylsiloxane Substrates Using Femtosecond Laser Pulse-Induced Reduction of Glyoxylic Acid Copper Complex. Micromachines. 2021; 12(5):493. https://doi.org/10.3390/mi12050493

Chicago/Turabian StyleHa, Nam Phuong, Tomoji Ohishi, and Mizue Mizoshiri. 2021. "Direct Writing of Cu Patterns on Polydimethylsiloxane Substrates Using Femtosecond Laser Pulse-Induced Reduction of Glyoxylic Acid Copper Complex" Micromachines 12, no. 5: 493. https://doi.org/10.3390/mi12050493

APA StyleHa, N. P., Ohishi, T., & Mizoshiri, M. (2021). Direct Writing of Cu Patterns on Polydimethylsiloxane Substrates Using Femtosecond Laser Pulse-Induced Reduction of Glyoxylic Acid Copper Complex. Micromachines, 12(5), 493. https://doi.org/10.3390/mi12050493