Additive Manufacture of Small-Scale Metamaterial Structures for Acoustic and Ultrasonic Applications

Abstract

:1. Introduction

1.1. Overview

1.2. Additive Manufacturing

1.3. Acoustic Metamaterials

1.4. Scope of Review

2. Acoustic Metamaterials

2.1. Background

2.2. Types of AMM

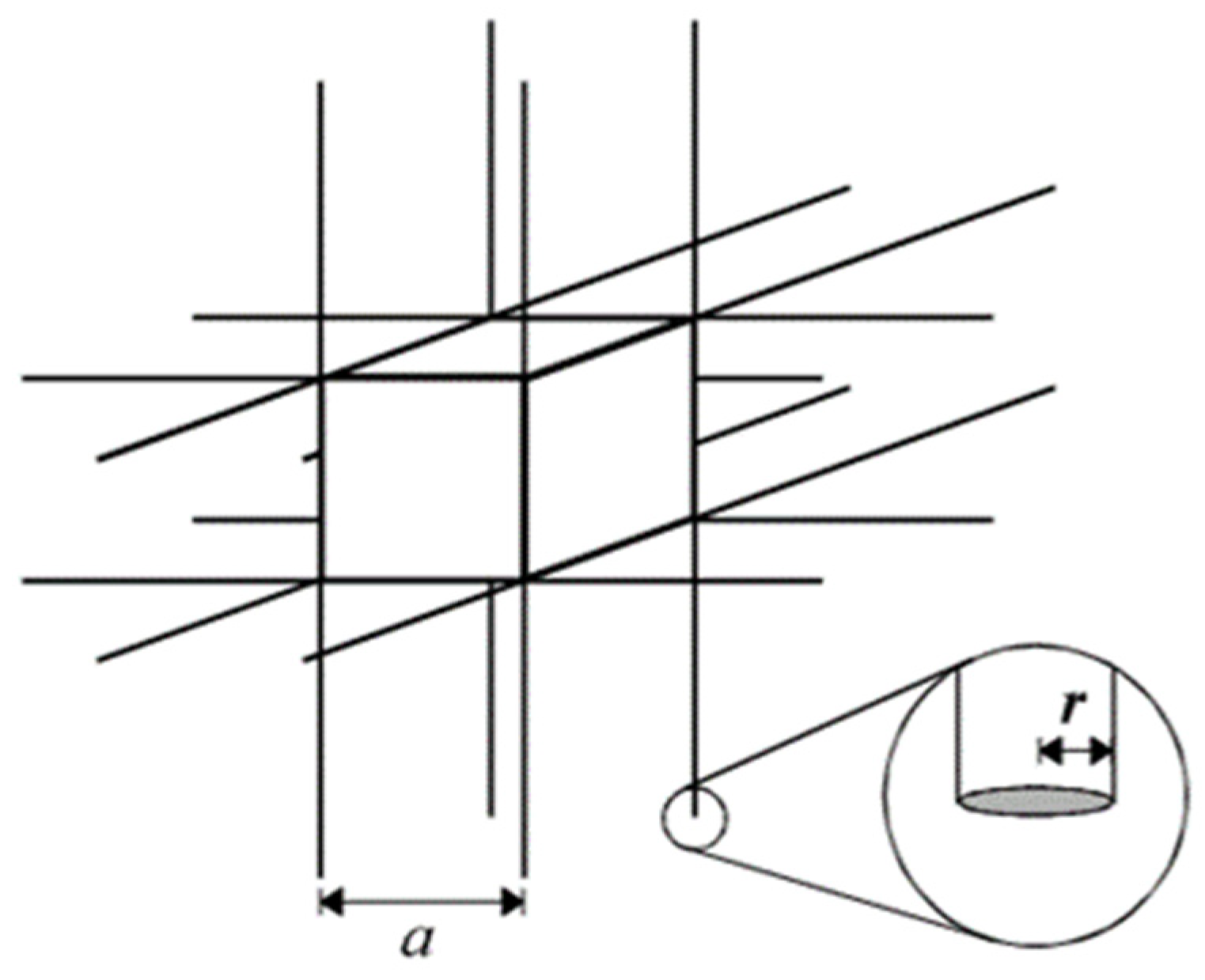

2.2.1. Periodic/Lattice Metamaterials

2.2.2. Coiled Structures and Metasurfaces

2.2.3. Active Metamaterials

3. Additive Manufacturing Methods

3.1. Vat Polymerization Techniques

3.1.1. Stereolithography (SLA)

3.1.2. Digital Light Processing (DLP)

3.1.3. Multi-Photon Polymerization (MPP)

3.1.4. Summary/Manufacture of AMMs

3.2. Powder Bed Fusion Techniques

3.2.1. Selected Laser Sintering/Melting (SLS/SLM)

3.2.2. Multi Jet Fusion (MJF)

3.2.3. Electron Beam Melting (EBM)

3.2.4. Summary/Manufacture of AMMs

3.3. Extrusion/Deposition Techniques

3.3.1. Fused Deposition Modelling (FDM)

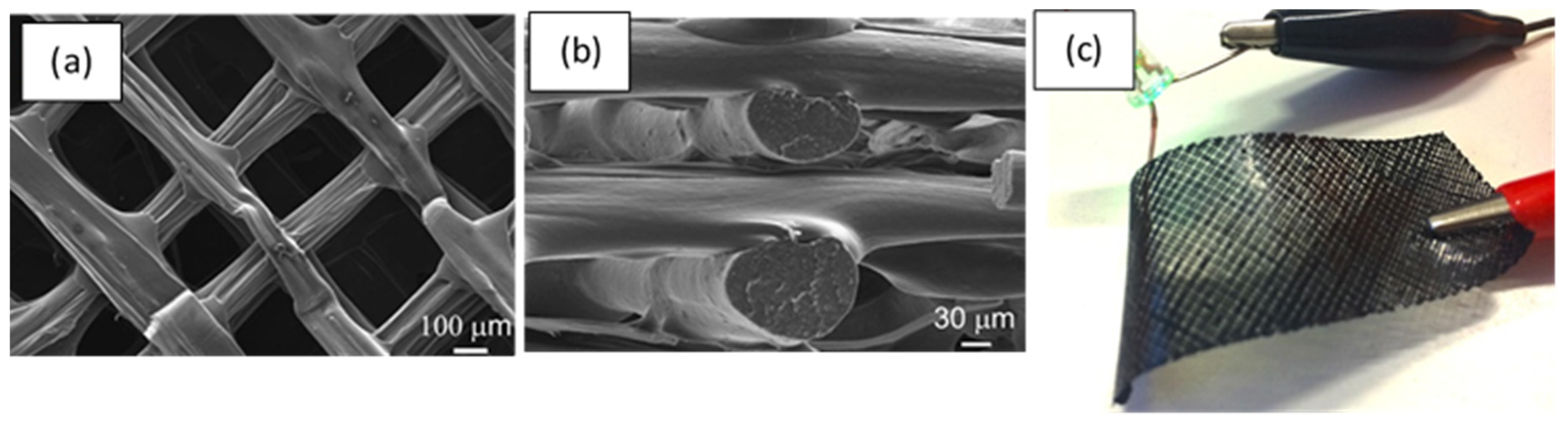

3.3.2. Direct Ink Writing (DIW)

3.3.3. Jetting Systems

3.3.4. Summary/Manufacture of AMMs

3.4. Hybrid Techniques

4. Discussion and Outlook

Funding

Conflicts of Interest

References

- Olsson Iii, R.H.; El-Kady, I. Microfabricated phononic crystal devices and applications. Meas. Sci. Technol. 2008, 20, 012002. [Google Scholar] [CrossRef]

- Fritzler, K.B.; Prinz, V.Y. 3D printing methods for micro- and nanostructures. Phys. Uspekhi 2019, 62, 54–69. [Google Scholar] [CrossRef]

- Lee, D.; Nguyen, D.M.; Rho, J. Acoustic wave science realized by metamaterials. Nano Converg. 2017, 4, 3. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Panda, D.; Mohanty, A.R. Sonic crystals for highway noise reduction. In Recent Developments in Acoustics; Singh, M., Rafat, Y., Eds.; Springer: Singapore, 2021; pp. 119–128. [Google Scholar]

- Acoustic Metamaterials Group. Acousticmetamaterials.org. Available online: https://acousticmetamaterials.org/ (accessed on 13 April 2021).

- MetAcoustic. Metacoustic.com. Available online: https://metacoustic.com/ (accessed on 13 April 2021).

- Mao, M.; Mao, M.; He, J.; Li, X.; Zhang, B.; Lei, Q.; Liu, Y.; Li, D. The emerging frontiers and applications of high-resolution 3D printing. Micromachines 2017, 8, 113. [Google Scholar] [CrossRef]

- Kjar, A.; Huang, Y. Application of micro-scale 3D printing in pharmaceutics. Pharmaceutics 2019, 11, 390. [Google Scholar] [CrossRef] [Green Version]

- Ahn, S.-H.; Yoon, H.-S.; Jang, K.-H.; Kim, E.-S.; Lee, H.-T.; Lee, G.-Y.; Kim, C.-S.; Cha, S.-W. Nanoscale 3D printing process using aerodynamically focused nanoparticle (AFN) printing, micro-machining, and focused ion beam (FIB). CIRP Ann. 2015, 64, 523–526. [Google Scholar] [CrossRef]

- Liu, Z.; Zhan, J.; Fard, M.; Davy, J.L. Acoustic measurement of a 3D printed micro-perforated panel combined with a porous material. Measurement 2017, 104, 233–236. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An overview on 3D printing technology: Technological, materials, and applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Savini, A.; Savini, G.G. A short history of 3D printing, a technological revolution just started. In Proceedings of the 2015 ICOHTEC/IEEE International History of High-Technologies and their Socio-Cultural Contexts Conference (HISTELCON), Tel-Aviv, Israel, 18–19 August 2015; pp. 1–8. [Google Scholar] [CrossRef]

- Paoletti, I.; Ceccon, L. The evolution of 3D printing in AEC: From experimental to consolidated techniques. In 3D Printing; IntechOpen: London, UK, 2018. [Google Scholar]

- Noorani, R. 3D Printing: Technology, Applications, and Selection; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Goral, J.; Deo, M. Nanofabrication of synthetic nanoporous geomaterials: From nanoscale-resolution 3D imaging to nano-3D-printed digital (shale) rock. Sci. Rep. 2020, 10, 21596. [Google Scholar] [CrossRef] [PubMed]

- Audoly, C. Acoustic metamaterials and underwater acoustics applications. Fundam. Appl. Acoust. Metamaterials 2019, 263–285. [Google Scholar] [CrossRef]

- Laureti, S. Acoustic Metamaterials for Medical Ultrasound and Non-Destructive Evaluation. Ph.D. Thesis, School of Engineering, University of Warwick, Coventry, UK, 2016. Available online: http://webcat.warwick.ac.uk/record=b3093046~S1 (accessed on 14 April 2021).

- Kan, W.; Liang, B.; Li, R.; Jiang, X.; Zou, X.-Y.; Yin, L.-L.; Cheng, J. Three-dimensional broadband acoustic illusion cloak for sound-hard boundaries of curved geometry. Sci. Rep. 2016, 6, 36936. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, J.J.; Ma, F.; Zhang, S.; Shen, L. Application of acoustic metamaterials in low-frequency vibration and noise reduction. J. Mech. Eng. 2016, 52, 68–78. [Google Scholar] [CrossRef]

- Ma, G.; Sheng, P. Acoustic metamaterials: From local resonances to broad horizons. Sci. Adv. 2016, 2, e1501595. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fok, L.; Ambati, M.; Zhang, X. Acoustic metamaterials. MRS Bull. 2008, 33, 931–934. [Google Scholar] [CrossRef]

- Zangeneh-Nejad, F.; Fleury, R. Active times for acoustic metamaterials. Rev. Phys. 2019, 4, 100031. [Google Scholar] [CrossRef]

- Gan, W.S. New acoustics based on metamaterials. In Acoustical Imaging: Techniques and Applications for Engineers; Wiley Online Books: Hoboken, NJ, USA, 2012; Chapter 15; pp. 369–406. [Google Scholar]

- Craster, R.V. Chapter 1: Fundamentals of acoustic metamaterials. In Acoustic Metamaterials: Negative Refraction, Imaging, Lensing and Cloaking; Guenneau, S., Ed.; Springer: Dordrecht, The Netherlands, 2013; Chapter 1; p. 2. [Google Scholar]

- Alster, M. Improved calculation of resonant frequencies of helmholtz resonators. J. Sound Vib. 1972, 24, 63–85. [Google Scholar] [CrossRef]

- Dalela, S.; Balaji, P.S.; Jena, D.P. A review on application of mechanical metamaterials for vibration control. Mech. Adv. Mater. Struct. 2021, 1–26. [Google Scholar] [CrossRef]

- Akl, W.; Baz, A. Active acoustic metamaterial with simultaneously programmable density and bulk modulus. J. Vib. Acoust. 2013, 135, 031001. [Google Scholar] [CrossRef]

- Akl, W.; Baz, A. Multi-cell active acoustic metamaterial with programmable bulk modulus. J. Intell. Mater. Syst. Struct. 2010, 21, 541–556. [Google Scholar] [CrossRef]

- Xia, B.; Chen, N.; Xie, L.; Qin, Y.; Yu, D. Temperature-controlled tunable acoustic metamaterial with active band gap and negative bulk modulus. Appl. Acoust. 2016, 112, 1–9. [Google Scholar] [CrossRef]

- Baz, A. The structure of an active acoustic metamaterial with tunable effective density. New J. Phys. 2009, 11, 123010. [Google Scholar] [CrossRef]

- Baz, A.M. An active acoustic metamaterial with tunable effective density. J. Vib. Acoust. 2010, 132, 041011. [Google Scholar] [CrossRef]

- Akl, W.; Baz, A. Experimental characterization of active acoustic metamaterial cell with controllable dynamic density. J. Appl. Phys. 2012, 112, 084912. [Google Scholar] [CrossRef]

- Chen, Z.; Xue, C.; Fan, L.; Zhang, S.-Y.; Li, X.-J.; Zhang, H.; Ding, J. A tunable acoustic metamaterial with double-negativity driven by electromagnets. Sci. Rep. 2016, 6, 30254. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Lee, H.P. Recent advances in active acoustic metamaterials. Int. J. Appl. Mech. 2019, 11. [Google Scholar] [CrossRef]

- Chen, S.; Fan, Y.; Fu, Q.; Wu, H.; Jin, Y.; Zheng, J.; Zhang, F. A review of tunable acoustic metamaterials. Appl. Sci. 2018, 8, 1480. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Guo, X.; Wu, J.; Fang, D.; Zhang, Y. Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci. Adv. 2018, 4, eaar8535. [Google Scholar] [CrossRef] [Green Version]

- Baz, A. Active acoustic metamaterial with tunable effective density using a disturbance rejection controller. J. Appl. Phys. 2019, 125, 074503. [Google Scholar] [CrossRef]

- Akl, W.; Baz, A. Analysis and experimental demonstration of an active acoustic metamaterial cell. J. Appl. Phys. 2012, 111, 044505. [Google Scholar] [CrossRef]

- Kumar, S.; Lee, H.P. Recent advances in acoustic metamaterials for simultaneous sound attenuation and air ventilation performances. Crystals 2020, 10, 686. [Google Scholar] [CrossRef]

- Nejad, F.Z.; Fleury, R. Potential applications of high-index acoustic metamaterials. J. Acoust. Soc. Am. 2018, 144, 1675. [Google Scholar] [CrossRef]

- Fedotov, V. Metamaterials. In Springer Handbook of Electronic and Photonic Materials; Kasap, S., Capper, P., Eds.; Springer International Publishing AG: Cham, Switzerland, 2017; Chapter 56.1.2. [Google Scholar]

- Veselago, V.G. The electrodynamics of substances with simultaneously negative values of ϵ and μ. Sov. Phys. Uspekhi 1968, 10, 509–514. [Google Scholar] [CrossRef]

- Pendry, J.B.; Holden, A.J.; Stewart, W.J.; Youngs, I. Extremely low frequency plasmons in metallic mesostructures. Phys. Rev. Lett. 1996, 76, 4773–4776. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sigalas, M.; Economou, E. Band structure of elastic waves in two dimensional systems. Solid State Commun. 1993, 86, 141–143. [Google Scholar] [CrossRef]

- Espinosa, F.R.M.D.; Jimeniz, E.; Torres, M. Experimental assessment of an ultrasonic band gap in a periodic two-dimensional composite. In Proceedings of the 1997 IEEE Ultrasonics Symposium Proceedings. An International Symposium (Cat. No.97CH36118), Toronto, ON, Canada, 5–8 October 1997; Volume 1, pp. 537–540. [Google Scholar]

- Sugimoto, N. Propagation of nonlinear acoustic waves in a tunnel with an array of helmholtz resonators. J. Fluid Mech. 1992, 244, 55. [Google Scholar] [CrossRef] [Green Version]

- Khelif, A.; Adibi, A. Phononic Crystals: Fundamentals and Applications; Springer: New York, NY, USA, 2015; pp. 1–245. [Google Scholar]

- Wang, G.; Yu, D.; Wen, J.; Liu, Y.; Wen, X. One-dimensional phononic crystals with locally resonant structures. Phys. Lett. A 2004, 327, 512–521. [Google Scholar] [CrossRef]

- Pennec, Y.; Vasseur, J.O.; Djafari-Rouhani, B.; Dobrzyński, L.; Deymier, P.A. Two-dimensional phononic crystals: Examples and applications. Surf. Sci. Rep. 2010, 65, 229–291. [Google Scholar] [CrossRef]

- Khelif, A.; Hsiao, F.-L.; Choujaa, A.; Benchabane, S.; Laude, V. Octave omnidirectional band gap in a three-dimensional phononic crystal. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2010, 57, 1621–1625. [Google Scholar] [CrossRef]

- Armenise, M.N.; Campanella, C.E.; Ciminelli, C.; Dell’Olio, F.; Passaro, V.M. Phononic and photonic band gap structures: Modelling and applications. Phys. Procedia 2010, 3, 357–364. [Google Scholar] [CrossRef] [Green Version]

- Olsson, R.H.; Griego, S.X.; El-Kady, I.; Su, M.; Soliman, Y.; Goettler, D.; Leseman, Z. Ultra high frequency (UHF) phononic crystal devices operating in mobile communication bands. In Proceedings of the 2009 IEEE International Ultrasonics Symposium, Rome, Italy, 20–23 September 2009; pp. 1150–1153. [Google Scholar] [CrossRef]

- Lucklum, R. Phononic crystals and metamaterials—Promising new sensor platforms. Procedia Eng. 2014, 87, 40–45. [Google Scholar] [CrossRef] [Green Version]

- Torrent, D.; Sánchez-Dehesa, J. Acoustic cloaking in two dimensions: A feasible approach. New J. Phys. 2008, 10, 063015. [Google Scholar] [CrossRef] [Green Version]

- Cummer, S.; Schurig, D. One path to acoustic cloaking. New J. Phys. 2007, 9, 45. [Google Scholar] [CrossRef]

- Zhang, S.; Xia, C.; Fang, N. Broadband acoustic cloak for ultrasound waves. Phys. Rev. Lett. 2011, 106, 024301. [Google Scholar] [CrossRef]

- Zigoneanu, L.; Popa, B.-I.; Cummer, S.A. Three-dimensional broadband omnidirectional acoustic ground cloak. Nat. Mater. 2014, 13, 352–355. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.; Chen, T.; Song, X.; Chen, C.; Liu, Z.; Zhang, J. Three-dimensional large-scale acoustic invisibility cloak with layered metamaterials for underwater operation. Phys. Scr. 2019, 94, 115003. [Google Scholar] [CrossRef]

- Elford, D.P.; Chalmers, L.; Kusmartsev, F.V.; Swallowe, G.M. Matryoshka locally resonant sonic crystal. J. Acoust. Soc. Am. 2011, 130, 2746–2755. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pennec, Y.; Djafari-Rouhani, B. Fundamental properties of phononic crystal. In Phononic Crystals: Fundamentals and Applications; Khelif, A., Adibi, A., Eds.; Springer: New York, NY, USA, 2016; pp. 23–50. [Google Scholar]

- Krushynska, A.; Miniaci, M.; Bosia, F.; Pugno, N. Coupling local resonance with bragg band gaps in single-phase mechanical metamaterials. Extrem. Mech. Lett. 2017, 12, 30–367. [Google Scholar] [CrossRef] [Green Version]

- Lu, M.-H.; Feng, L.; Chen, Y.-F. Phononic crystals and acoustic metamaterials. Mater. Today 2009, 12, 34–42. [Google Scholar] [CrossRef]

- Kushwaha, M.S.; Halevi, P. Giant acoustic stop bands in two-dimensional periodic arrays of liquid cylinders. Appl. Phys. Lett. 1996, 69, 31–33. [Google Scholar] [CrossRef]

- Kushwaha, M.S.; Djafari-Rouhani, B. Giant sonic stop bands in two-dimensional periodic system of fluids. J. Appl. Phys. 1998, 84, 4677–4683. [Google Scholar] [CrossRef]

- Sigalas, M.M. Defect states of acoustic waves in a two-dimensional lattice of solid cylinders. J. Appl. Phys. 1998, 84, 3026–3030. [Google Scholar] [CrossRef]

- Li, J.; Chan, C.T. Double-negative acoustic metamaterial. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2004, 70, 055602. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Zhang, X.; Mao, Y.; Zhu, Y.Y.; Yang, Z.; Chan, C.T.; Sheng, P. Locally resonant sonic materials. Science 2000, 289, 1734–1736. [Google Scholar] [CrossRef] [PubMed]

- Jena, D.; Dandsena, J.; Jayakumari, V. Demonstration of effective acoustic properties of different configurations of helmholtz resonators. Appl. Acoust. 2019, 155, 371–382. [Google Scholar] [CrossRef]

- Fang, N.; Xi, D.; Xu, J.; Ambati, M.; Srituravanich, W.; Sun, C.; Zhang, X. Ultrasonic metamaterials with negative modulus. Nat. Mater. 2006, 5, 452–456. [Google Scholar] [CrossRef]

- Kim, S.-H.; Lee, S.-H. Air transparent soundproof window. AIP Adv. 2014, 4, 117123. [Google Scholar] [CrossRef]

- Kumar, S.; Bhushan, P.; Prakash, O.; Bhattacharya, S. Double negative acoustic metastructure for attenuation of acoustic emissions. Appl. Phys. Lett. 2018, 112, 101905. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, C.M.; Seo, Y.M.; Wang, Z.G.; Kim, C.K. Composite acoustic medium with simultaneously negative density and modulus. Phys. Rev. Lett. 2010, 104, 054301. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Wu, J.H.; Cai, Y.; Ma, F. Investigation on dynamic effective parameters of perforated thin-plate acoustic metamaterials. J. Phys. D Appl. Phys. 2019, 52, 405301. [Google Scholar] [CrossRef]

- Tan, K.T.; Huang, H.H.; Sun, C.T. Optimizing the band gap of effective mass negativity in acoustic metamaterials. Appl. Phys. Lett. 2012, 101, 241902. [Google Scholar] [CrossRef]

- Su, H.; Zhou, X.; Xu, X.; Hu, G. Experimental study on acoustic subwavelength imaging of holey-structured metamaterials by resonant tunneling. J. Acoust. Soc. Am. 2014, 135, 1686–1691. [Google Scholar] [CrossRef]

- Chen, Y.; Zhu, R.; Nguyen, H.Q.; Huang, G. Chapter 3 Membrane-type acoustic metamaterials: Theory, design, and application. In Theory and Design of Acoustic Metamaterials; Pai, P., Huang, G., Eds.; SPIE: Washington, DC, USA, 2015; Chapter 3; pp. 53–56. [Google Scholar]

- Huang, T.-Y.; Shen, C.; Jing, Y. Membrane- and plate-type acoustic metamaterials. J. Acoust. Soc. Am. 2016, 139, 3240–3250. [Google Scholar] [CrossRef] [Green Version]

- Naify, C.J.; Chang, C.-M.; McKnight, G.; Nutt, S.R. Transmission loss of membrane-type acoustic metamaterials with coaxial ring masses. J. Appl. Phys. 2011, 110, 124903. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Yu, X.; Lau, S.-K.; Khoo, B.C.; Cui, F. Membrane-type acoustic metamaterial with eccentric masses for broadband sound isolation. Appl. Acoust. 2020, 157, 107003. [Google Scholar] [CrossRef]

- Naify, C.J.; Chang, C.-M.; McKnight, G.; Nutt, S.R. Scaling of membrane-type locally resonant acoustic metamaterial arrays. J. Acoust. Soc. Am. 2012, 132, 2784–2792. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Casarini, C.; Romero-Garcia, V.; Groby, J.-P.; Tiller, B.; Windmill, J.F.C.; Jackson, J.C.; Tiller, B. Fabrication and characterization of 3D printed thin plates for acoustic metamaterials applications. IEEE Sens. J. 2019, 19, 10365–10372. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Liang, B.; Gu, Z.-M.; Zou, X.-Y.; Cheng, J.-C. Reflected wavefront manipulation based on ultrathin planar acoustic metasurfaces. Sci. Rep. 2013, 3, srep02546. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Zhang, X.; Fang, Y.; Fattah, R. Manipulating reflected acoustic wave via Helmholtz resonators with varying-length extended necks. J. Appl. Phys. 2018, 124, 104902. [Google Scholar] [CrossRef]

- Liang, Z.; Feng, T.; Lok, S.; Liu, F.; Ng, K.B.; Chan, C.H.; Wang, J.; Han, S.; Lee, S.; Li, J. Space-coiling metamaterials with double negativity and conical dispersion. Sci. Rep. 2013, 3, srep01614. [Google Scholar] [CrossRef] [Green Version]

- Maurya, S.K.; Pandey, A.; Shukla, S.; Saxena, S. Double negativity in 3D space coiling metamaterials. Sci. Rep. 2016, 6, 33683. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, T.; Jiao, J.; Yu, D. Enhanced broadband acoustic sensing in gradient coiling up metamaterials. J. Phys. D Appl. Phys. 2020, 54, 085501. [Google Scholar] [CrossRef]

- Song, G.Y.; Cheng, Q.; Huang, B.; Dong, H.Y.; Cui, T.J. Broadband fractal acoustic metamaterials for low-frequency sound attenuation. Appl. Phys. Lett. 2016, 109, 131901. [Google Scholar] [CrossRef]

- Akl, W.; Baz, A. Active control of the dynamic density of acoustic metamaterials. Appl. Acoust. 2021, 178, 108001. [Google Scholar] [CrossRef]

- Baz, A. Active synthesis of a gyroscopic-nonreciprocal acoustic metamaterial. J. Acoust. Soc. Am. 2020, 148, 1271–1288. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Païdoussis, M.P.; Wen, J.; Yu, D.; Cai, L.; Wen, X. Acoustic cloak/anti-cloak device with realizable passive/active metamaterials. J. Phys. D Appl. Phys. 2012, 45, 285401. [Google Scholar] [CrossRef]

- Bacigalupo, A.; de Bellis, M.L.; Misseroni, D. Design of Active Acoustic Metamaterials with Periodic Piezoelectric Microstructure. arXiv Prepr. 2019, arXiv:1912.11508. [Google Scholar]

- Hedayati, R.; Lakshmanan, S. Pneumatically-actuated acoustic metamaterials based on helmholtz resonators. Materials 2020, 13, 1456. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Ma, C.; He, Q.; Lin, S.; Chen, Y.; Zhang, Y.; Fang, N.X.; Zhao, X. Metagel with broadband tunable acoustic properties over air–water–solid ranges. Adv. Funct. Mater. 2019, 29, 1903699. [Google Scholar] [CrossRef]

- Fraternali, F.; Senatore, L.; Daraio, C. Solitary waves on tensegrity lattices. J. Mech. Phys. Solids 2012, 60, 1137–1144. [Google Scholar] [CrossRef]

- Fraternali, F.; Carpentieri, G.; Amendola, A.; Skelton, R.E.; Nesterenko, V.F. Multiscale tunability of solitary wave dynamics in tensegrity metamaterials. Appl. Phys. Lett. 2014, 105, 201903. [Google Scholar] [CrossRef] [Green Version]

- Spadoni, A.; Daraio, C. Generation and control of sound bullets with a nonlinear acoustic lens. Proc. Natl. Acad. Sci. USA 2010, 107, 7230–7234. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vangelatos, Z.; Micheletti, A.; Grigoropoulos, C.P.; Fraternali, F. Design and testing of bistable lattices with tensegrity architecture and nanoscale features fabricated by multiphoton lithography. Nanomaterials 2020, 10, 652. [Google Scholar] [CrossRef] [Green Version]

- Skelton, R.E.; de Oliveira, M.C. Tensegrity Systems; Springer: Berlin/Heidelberg, Germany, 2009; pp. 26–29. [Google Scholar]

- Akl, W.; Baz, A. Stability analysis of active acoustic metamaterial with programmable bulk modulus. Smart Mater. Struct. 2011, 20, 125010. [Google Scholar] [CrossRef]

- Liang, Z.; Willatzen, M.; Li, J.; Christensen, J. Tunable acoustic double negativity metamaterial. Sci. Rep. 2012, 2, srep00859. [Google Scholar] [CrossRef] [Green Version]

- Ning, L.; Wang, Y.-Z.; Wang, Y.-S. Active control of elastic metamaterials consisting of symmetric double helmholtz resonator cavities. Int. J. Mech. Sci. 2019, 153–154, 287–298. [Google Scholar] [CrossRef]

- Muguruza, A.; Bo, J.B.; Gómez, A.; Minguella-Canela, J.; Fernandes, J.; Ramos, F.; Xuriguera, E.; Varea, A.; Cirera, A. Development of a multi-material additive manufacturing process for electronic devices. Procedia Manuf. 2017, 13, 746–753. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Z.; Tian, X.; Song, X. Engineering materials with light: Recent progress in digital light processing based 3D printing. J. Mater. Chem. C 2020, 8, 13896–13917. [Google Scholar] [CrossRef]

- Cvetkovic, C.; Raman, R.; Chan, V.; Williams, B.J.; Tolish, M.; Bajaj, P.; Sakar, M.S.; Asada, H.H.; Saif, M.T.A.; Bashir, R. Three-dimensionally printed biological machines powered by skeletal muscle. Proc. Natl. Acad. Sci. USA 2014, 111, 10125–10130. [Google Scholar] [CrossRef] [Green Version]

- Bagheri, A.; Jin, J. Photopolymerization in 3D printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Uzcategui, A.C.; Muralidharan, A.; Ferguson, V.L.; Bryant, S.J.; McLeod, R.R. Understanding and improving mechanical properties in 3D printed parts using a dual-cure acrylate-based resin for stereolithography. Adv. Eng. Mater. 2018, 20, 1800876. [Google Scholar] [CrossRef] [PubMed]

- Fleming, A.J.; Ghalehbeygi, O.T.; Routley, B.S.; Wills, A.G. Experimental scanning laser lithography with exposure optimization. IFAC-PapersOnLine 2017, 50, 8662–8667. [Google Scholar] [CrossRef]

- Casarini, C.; Windmill, J.F.C.; Jackson, J.C. 3D printed small-scale acoustic metamaterials based on Helmholtz resonators with tuned overtones. In Proceedings of the 2017 IEEE Sensors, Glasgow, UK, 29 October–1 November 2017; pp. 1–3. [Google Scholar] [CrossRef] [Green Version]

- Asiga.com. Asiga Products—MAX X. Available online: https://www.asiga.com/products/printers/max_series/max_x/ (accessed on 11 February 2021).

- Daly, P.; Windmill, J.F.C.; Jackson, J.; Vasilev, M. An in-air ultrasonic acoustic beam shifter metamaterial. In Proceedings of the IEEE IUS Symposium, Glasgow, UK, 6–9 October 2019. [Google Scholar]

- Maruyama, T.; Hirata, H.; Furukawa, T.; Maruo, S. Multi-material microstereolithography using a palette with multicolor photocurable resins. Opt. Mater. Express 2020, 10, 2522–2532. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, Z.; Ragonese, A.; Zhu, T.; Khuje, S.; Li, C.; Grossman, J.C.; Zhou, C.; Nouh, M.; Ren, S. A 3D-printed molecular ferroelectric metamaterial. Proc. Natl. Acad. Sci. USA 2020, 117, 27204–27210. [Google Scholar] [CrossRef] [PubMed]

- Ge, Q.; Li, Z.; Wang, Z.; Kowsari, K.; Zhang, W.; He, X.; Zhou, J.; Fang, N.X. Projection micro stereolithography based 3D printing and its applications. Int. J. Extrem. Manuf. 2020, 2, 022004. [Google Scholar] [CrossRef]

- Ertugrul, I. The fabrication of micro beam from photopolymer by digital light processing 3D printing technology. Micromachines 2020, 11, 518. [Google Scholar] [CrossRef]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Zhou, C.; Chen, Y.; Yang, Z.; Khoshnevis, B. Development of a multi-material mask-image-projection-based stereolithography for the fabrication of digital materials. In Proceedings of the 22nd Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 1 January 2011; pp. 65–80. [Google Scholar]

- Kowsari, K.; Akbari, S.; Wang, D.; Fang, N.X.; Ge, Q. High-efficiency high-resolution multimaterial fabrication for digital light processing-based three-dimensional printing. 3D Print. Addit. Manuf. 2018, 5, 185–193. [Google Scholar] [CrossRef]

- Han, D.; Yang, C.; Fang, N.X.; Lee, H. Rapid multi-material 3D printing with projection micro-stereolithography using dynamic fluidic control. Addit. Manuf. 2019, 27, 606–615. [Google Scholar] [CrossRef]

- Han, D.; Lu, Z.; Chester, S.A.; Lee, H. Micro 3D printing of a temperature-responsive hydrogel using projection micro-stereolithography. Sci. Rep. 2018, 8, 1963. [Google Scholar] [CrossRef]

- Schwartz, J.J.; Boydston, A.J. Multimaterial actinic spatial control 3D and 4D printing. Nat. Commun. 2019, 10, 791. [Google Scholar] [CrossRef]

- Khatri, B.; Frey, M.; Raouf-Fahmy, A.; Scharla, M.-V.; Hanemann, T. Development of a multi-material stereolithography 3D printing device. Micromachines 2020, 11, 532. [Google Scholar] [CrossRef]

- Loterie, D.; Delrot, P.; Moser, C. High-resolution tomographic volumetric additive manufacturing. Nat. Commun. 2020, 11, 852. [Google Scholar] [CrossRef]

- Maruo, S.; Nakamura, O.; Kawata, S. Three-dimensional microfabrication with two-photon-absorbed photopolymerization. Opt. Lett. 1997, 22, 132–134. [Google Scholar] [CrossRef] [Green Version]

- Yahya, B.; El, I.Y.; Imad, M.; Zouheir, S. Direct laser writing of submicrometric voxels in two-photon photopolymerization. In Proceedings SPIE 11098, Molecular and Nano Machines II; International Society for Optics and Photonics: Bellingham, WA, USA, 2019; Volume 110980G. [Google Scholar] [CrossRef]

- Huang, Z.; Tsui, G.C.-P.; Deng, Y.; Tang, C.-Y. Two-photon polymerization nanolithography technology for fabrication of stimulus-responsive micro/nano-structures for biomedical applications. Nanotechnol. Rev. 2020, 9, 1118–1136. [Google Scholar] [CrossRef]

- Haske, W.; Chen, V.W.; Hales, J.M.; Dong, W.; Barlow, S.; Marder, S.R.; Perry, J.W. 65 Nm feature sizes using visible wavelength 3-D multiphoton lithography. Opt. Express 2007, 15, 3426–3436. [Google Scholar] [CrossRef] [Green Version]

- Tan, D.; Li, Y.; Qi, F.; Yang, H.; Gong, Q.; Dong, X.; Duan, X. Reduction in feature size of two-photon polymerization using SCR500. Appl. Phys. Lett. 2007, 90, 071106. [Google Scholar] [CrossRef]

- Ovsianikov, A.; Viertl, J.; Chichkov, B.; Oubaha, M.; MacCraith, B.; Sakellari, I.; Giakoumaki, A.; Gray, D.; Vamvakaki, M.; Farsari, M.; et al. Ultra-low shrinkage hybrid photosensitive material for two-photon polymerization microfabrication. ACS Nano 2008, 2, 2257–2262. [Google Scholar] [CrossRef]

- Yeung, K.-W.; Dong, Y.; Chen, L.; Tang, C.-Y.; Law, W.-C.; Tsui, G.C.-P.; Engstrøm, D.S. Printability of photo-sensitive nanocomposites using two-photon polymerization. Nanotechnol. Rev. 2020, 9, 418–426. [Google Scholar] [CrossRef]

- Nguyen, A.K.; Narayan, R.J. Two-photon polymerization for biological applications. Mater. Today 2017, 20, 314–322. [Google Scholar] [CrossRef]

- Gottmann, J.; Hoerstmann-Jungemann, M.; Hermans, M.; Beckmann, D. High speed and high precision fs-laser writing using a scanner with large numerical aperture. JLMN 2009, 4, 192–196. [Google Scholar] [CrossRef]

- Pearre, B.W.; Michas, C.; Tsang, J.-M.; Gardner, T.J.; Otchy, T.M. Fast micron-scale 3D printing with a resonant-scanning two-photon microscope. Addit. Manuf. 2019, 30, 100887. [Google Scholar] [CrossRef]

- Carlotti, M.; Mattoli, V. Functional materials for two-photon polymerization in microfabrication. Small 2019, 15, e1902687. [Google Scholar] [CrossRef]

- Tudor, A.; Delaney, C.; Zhang, H.; Thompson, A.J.; Curto, V.F.; Yang, G.-Z.; Higgins, M.J.; Diamond, D.; Florea, L. Fabrication of soft, stimulus-responsive structures with sub-micron resolution via two-photon polymerization of poly(ionic liquid)s. Mater. Today 2018, 21, 807–816. [Google Scholar] [CrossRef]

- Xing, J.-F.; Zheng, M.-L.; Duan, X.-M. Two-photon polymerization microfabrication of hydrogels: An advanced 3D printing technology for tissue engineering and drug delivery. Chem. Soc. Rev. 2015, 44, 5031–5039. [Google Scholar] [CrossRef] [Green Version]

- Weisgrab, G.; Guillaume, O.; Guo, Z.; Heimel, P.; Slezak, P.; Poot, A.; Grijpma, D.; Ovsianikov, A. 3D printing of large-scale and highly porous biodegradable tissue engineering scaffolds from poly(trimethylene-carbonate) using two-photon-polymerization. Biofabrication 2020, 12, 045036. [Google Scholar] [CrossRef]

- Raimondi, M.T.; Eaton, S.M.; Nava, M.M.; Laganà, M.; Cerullo, G.; Osellame, R. Two-photon laser polymerization: From fundamentals to biomedical application in tissue engineering and regenerative medicine. J. Appl. Biomater. Funct. Mater. 2012, 10, 56–66. [Google Scholar] [CrossRef] [PubMed]

- Amato, L.; Gu, Y.; Bellini, N.; Eaton, S.M.; Cerullo, G.; Osellame, R. Integrated three-dimensional filter separates nanoscale from microscale elements in a microfluidic chip. Lab Chip 2012, 12, 1135–1142. [Google Scholar] [CrossRef]

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder bed fusion process in additive manufacturing: An overview. Mater. Today Proc. 2020, 26, 3058–3070. [Google Scholar] [CrossRef]

- Yang, W.; Bai, X.; Zhu, W.; Kiran, R.; An, J.; Chua, C.K.; Zhou, K. 3D printing of polymeric multi-layer micro-perforated panels for tunable wideband sound absorption. Polymers 2020, 12, 360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Claeys, C.; Deckers, E.; Pluymers, B.; Desmet, W. A Lightweight vibro-acoustic metamaterial demonstrator: Numerical and experimental investigation. Mech. Syst. Signal Process. 2016, 70–71, 853–880. [Google Scholar] [CrossRef] [Green Version]

- Yuan, S.; Shen, F.; Bai, J.; Chua, C.K.; Wei, J.; Zhou, K. 3D soft auxetic lattice structures fabricated by selective laser sintering: TPU powder evaluation and process optimization. Mater. Des. 2017, 120, 317–327. [Google Scholar] [CrossRef]

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of micro selective laser melting: The state of the art and future perspectives. Engineering 2019, 5, 702–720. [Google Scholar] [CrossRef]

- Fischer, J.; Kniepkamp, M.; Abele, E. Micro laser melting: Analyses of current potentials and restrictions for the additive manufacturing of micro structures. In Proceedings of the 25th Annual International Solid Freeform Fabrication Symposium—An additive Manufacturing Conference, Austin, TX, USA, 4–6 August 2014; pp. 22–35. [Google Scholar]

- Gieseke, M.; Senz, V.; Vehse, M.; Fiedler, S.; Irsig, R.; Hustedt, M.; Sternberg, K.; Nölke, C.; Kaierle, S.; Wesling, V.; et al. Additive manufacturing of drug delivery systems. Biomed. Eng. Biomed. Tech. 2012, 57, 398–401. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, X.; Chen, Z.; Jiang, Y.; Cao, X.; Fang, S.; Zhao, T.; Li, Y.; Fang, D. Numerical and experimental studies on compressive behavior of gyroid lattice cylindrical shells. Mater. Des. 2020, 186, 108340. [Google Scholar] [CrossRef]

- Cao, X.; Jiang, Y.; Zhao, T.; Wang, P.; Wang, Y.; Chen, Z.; Li, Y.; Xiao, D.; Fang, D. Compression experiment and numerical evaluation on mechanical responses of the lattice structures with stochastic geometric defects originated from additive-manufacturing. Compos. Part B Eng. 2020, 194, 108030. [Google Scholar] [CrossRef]

- Zhang, L.; Song, B.; Fu, J.; Wei, S.; Yang, L.; Yan, C.; Li, H.; Gao, L.; Shi, Y. Topology-optimized lattice structures with simultaneously high stiffness and light weight fabricated by selective laser melting: Design, manufacturing and characterization. J. Manuf. Process. 2020, 56, 1166–1177. [Google Scholar] [CrossRef]

- He, J.; Jiang, X.; Ta, D.; Wang, W. Experimental demonstration of underwater ultrasound cloaking based on metagrating. Appl. Phys. Lett. 2020, 117, 091901. [Google Scholar] [CrossRef]

- Xu, Z.; Wang, Y.; Wu, D.; Ananth, K.P.; Bai, J. The process and performance comparison of polyamide 12 manufactured by multi jet fusion and selective laser sintering. J. Manuf. Process. 2019, 47, 419–426. [Google Scholar] [CrossRef]

- Roca, D.; Pamies, T.; Cante, J.; Valls, O.L.; Oliver, J. Experimental and numerical assessment of local resonance phenomena in 3D-printed acoustic metamaterials. J. Vib. Acoust. 2020, 142, 1–19. [Google Scholar] [CrossRef]

- Wang, P.; Li, X.; Jiang, Y.; Nai, M.L.S.; Ding, J.; Wei, J. Electron beam melted heterogeneously porous microlattices for metallic bone applications: Design and investigations of boundary and edge effects. Addit. Manuf. 2020, 36, 101566. [Google Scholar] [CrossRef]

- Novak, N.; Krstulović-Opara, L.; Ren, Z.; Vesenjak, M. Mechanical properties of hybrid metamaterial with auxetic chiral cellular structure and silicon filler. Compos. Struct. 2020, 234, 111718. [Google Scholar] [CrossRef]

- Yang, H.; Yang, S.; Chi, X.; Evans, J.R.G. Fine ceramic lattices prepared by extrusion freeforming. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 79, 116–121. [Google Scholar] [CrossRef] [PubMed]

- Hirt, L.; Reiser, A.; Spolenak, R.; Zambelli, T. Additive manufacturing of metal structures at the micrometer scale. Adv. Mater. 2017, 29, 1604211. [Google Scholar] [CrossRef] [PubMed]

- Udofia, E.N.; Zhou, W. Microextrusion based 3D printing—A review. In Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 13–15 August 2018; pp. 13–18. [Google Scholar]

- Abeykoon, C.; Sri-Amphorn, P.; Fernando, A. Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int. J. Lightweight Mater. Manuf. 2020, 3, 284–297. [Google Scholar] [CrossRef]

- Vaezi, M.; Sejo, Z.; Humphrey, V.; Yang, S. Feasibility study of printing acoustic metamaterials using extrsuion freeforming method. In Proceedings of the 1st International Conference on Progress in Additive Manufacturing, Singapore, 26–28 May 2014; pp. 364–369. [Google Scholar]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos. Part A Appl. Sci. Manuf. 2015, 76, 110–114. [Google Scholar] [CrossRef]

- Jiang, P.; Ji, Z.; Zhang, X.; Liu, Z.; Wang, X. Recent advances in direct ink writing of electronic components and functional devices. Prog. Addit. Manuf. 2017, 3, 65–86. [Google Scholar] [CrossRef]

- Gratson, G.M.; García-Santamaría, F.; Lousse, V.; Xu, M.; Fan, S.; Lewis, J.A.; Braun, P.V. Direct-write assembly of three-dimensional photonic crystals: Conversion of polymer scaffolds to silicon hollow-woodpile structures. Adv. Mater. 2006, 18, 461–465. [Google Scholar] [CrossRef]

- Kolesky, D.B.; Homan, K.A.; Skylar-Scott, M.A.; Lewis, J.A. Three-dimensional bioprinting of thick vascularized tissues. Proc. Natl. Acad. Sci. USA 2016, 113, 3179–3184. [Google Scholar] [CrossRef] [Green Version]

- Vdovin, R.; Tomilina, T.; Smelov, V.; Laktionova, M. Implementation of the additive PolyJet technology to the development and fabricating the samples of the acoustic metamaterials. Procedia Eng. 2017, 176, 595–599. [Google Scholar] [CrossRef]

- Liashenko, I.; Rosell-Llompart, J.; Cabot, A. Ultrafast 3D printing with submicrometer features using electrostatic jet deflection. Nat. Commun. 2020, 11, 753. [Google Scholar] [CrossRef]

- Peng, X.; Kuang, X.; Roach, D.J.; Wang, Y.; Hamel, C.M.; Lu, C.; Qi, H.J. Integrating digital light processing with direct ink writing for hybrid 3D printing of functional structures and devices. Addit. Manuf. 2021, 40, 101911. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Zheng, X.; Chen, Z.; Zhou, Q.; Chen, Y. 3D-printed biomimetic super-hydrophobic structure for microdroplet manipulation and oil/water separation. Adv. Mater. 2018, 30, 1704912. [Google Scholar] [CrossRef] [PubMed]

- Laumer, T.; Stichel, T.; Amend, P.; Schmidt, M. Simultaneous laser beam melting of multimaterial polymer parts. J. Laser Appl. 2015, 27, 29204. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.; Laredo, E.; Ryan, O.; Yazdkhasti, A.; Kim, H.-T.; Ganye, R.; Horiuchi, T.; Yu, M. Ultrasound beam steering with flattened acoustic metamaterial luneburg lens. Appl. Phys. Lett. 2020, 116, 071902. [Google Scholar] [CrossRef] [Green Version]

- Kennedy, J.; Flanagan, L.; Dowling, L.; Bennett, G.J.; Rice, H.; Trimble, D. The influence of additive manufacturing processes on the performance of a periodic acoustic metamaterial. Int. J. Polym. Sci. 2019, 2019, 7029143. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gardiner, A.; Daly, P.; Domingo-Roca, R.; Windmill, J.F.C.; Feeney, A.; Jackson-Camargo, J.C. Additive Manufacture of Small-Scale Metamaterial Structures for Acoustic and Ultrasonic Applications. Micromachines 2021, 12, 634. https://doi.org/10.3390/mi12060634

Gardiner A, Daly P, Domingo-Roca R, Windmill JFC, Feeney A, Jackson-Camargo JC. Additive Manufacture of Small-Scale Metamaterial Structures for Acoustic and Ultrasonic Applications. Micromachines. 2021; 12(6):634. https://doi.org/10.3390/mi12060634

Chicago/Turabian StyleGardiner, Alicia, Paul Daly, Roger Domingo-Roca, James F. C. Windmill, Andrew Feeney, and Joseph C. Jackson-Camargo. 2021. "Additive Manufacture of Small-Scale Metamaterial Structures for Acoustic and Ultrasonic Applications" Micromachines 12, no. 6: 634. https://doi.org/10.3390/mi12060634

APA StyleGardiner, A., Daly, P., Domingo-Roca, R., Windmill, J. F. C., Feeney, A., & Jackson-Camargo, J. C. (2021). Additive Manufacture of Small-Scale Metamaterial Structures for Acoustic and Ultrasonic Applications. Micromachines, 12(6), 634. https://doi.org/10.3390/mi12060634