Dynamic Modeling and Flow Distribution of Complex Micron Scale Pipe Network

Abstract

:1. Introduction

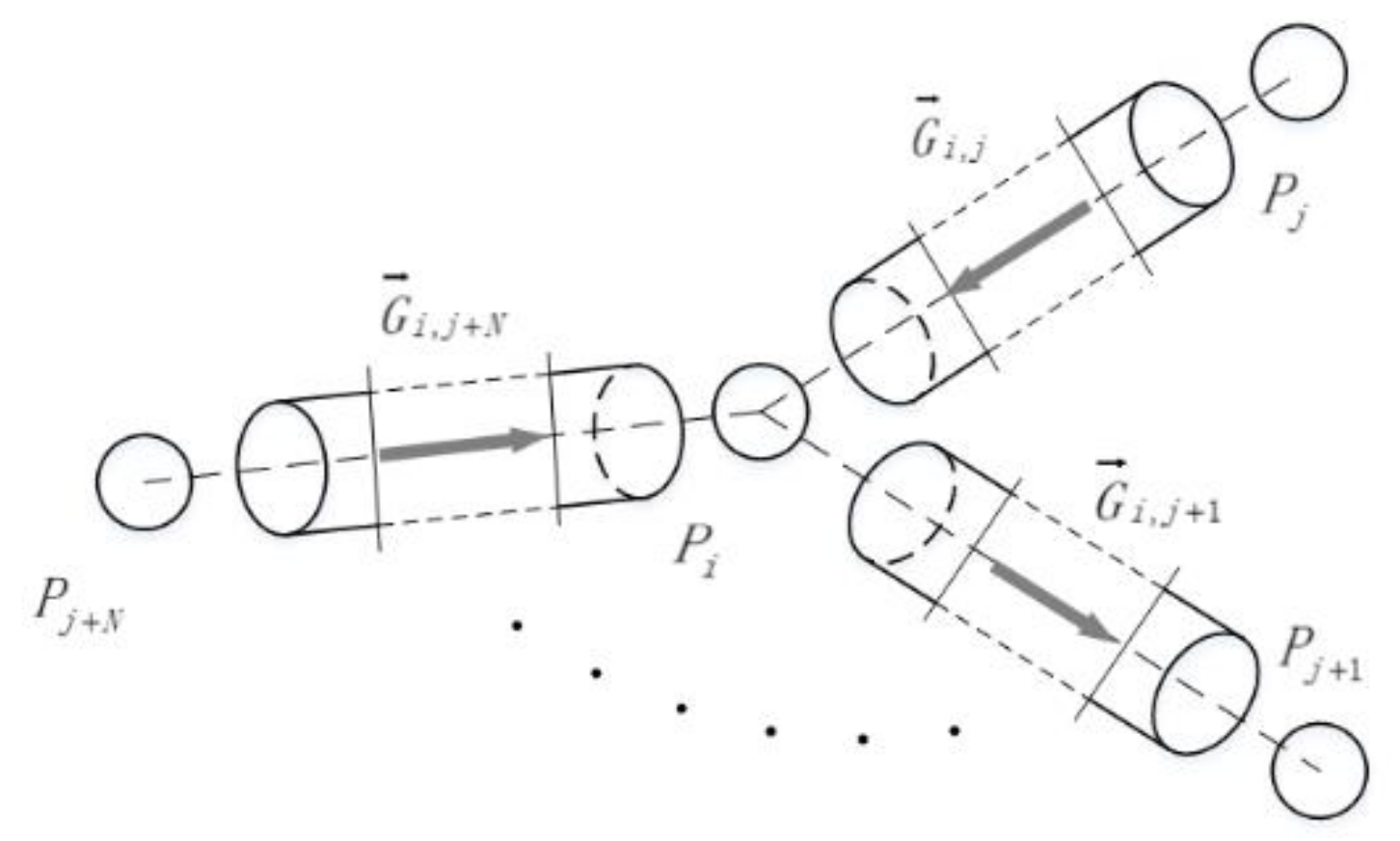

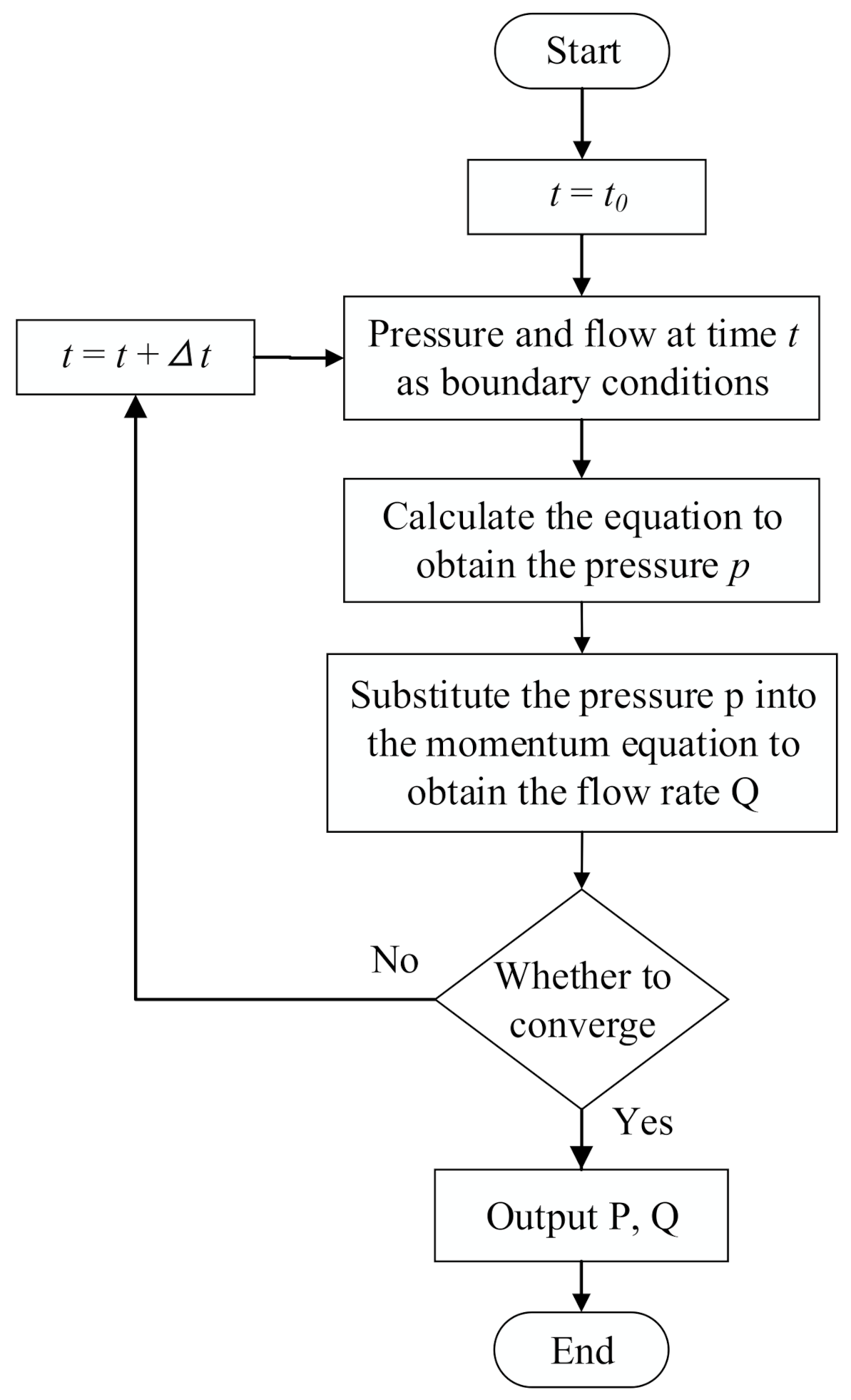

2. Model Development

- (a)

- No power source in the fluid network model.

- (b)

- The fluid state in the nodes is uniform (the internal pressure is equal).

- (c)

- The flow resistance only takes the equivalent frictional resistance along the pipeline into account and keeps the flow resistance coefficient constant.

- (d)

- The cross-sectional area in the same branch pipe remains unchanged, and the working medium parameters are represented by the weighted average of the connected node parameters.

- (a)

- Nodes, including pipe transitions and other essential components in the microfluidic network.

- (b)

- Branches, a connecting component between two nodes.

3. Results and Discussions

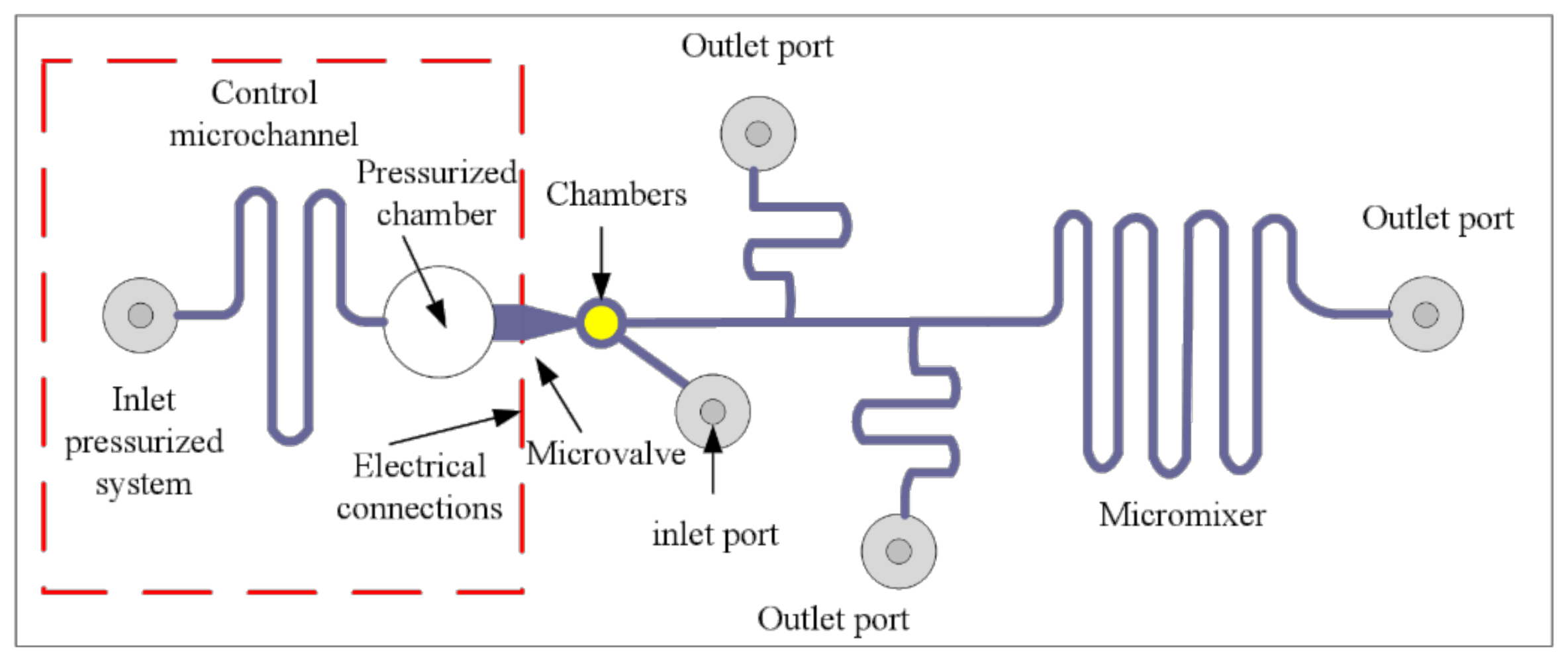

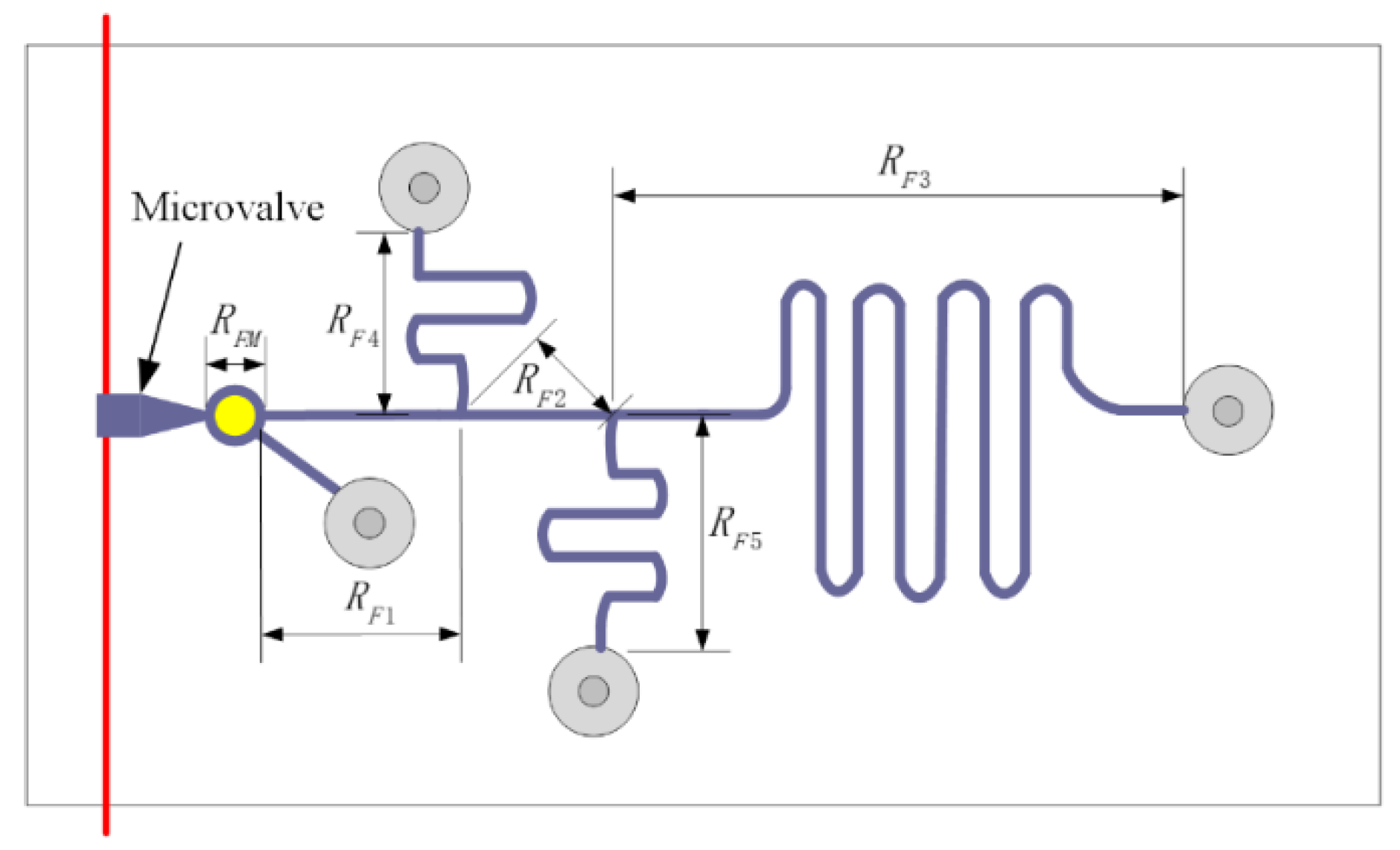

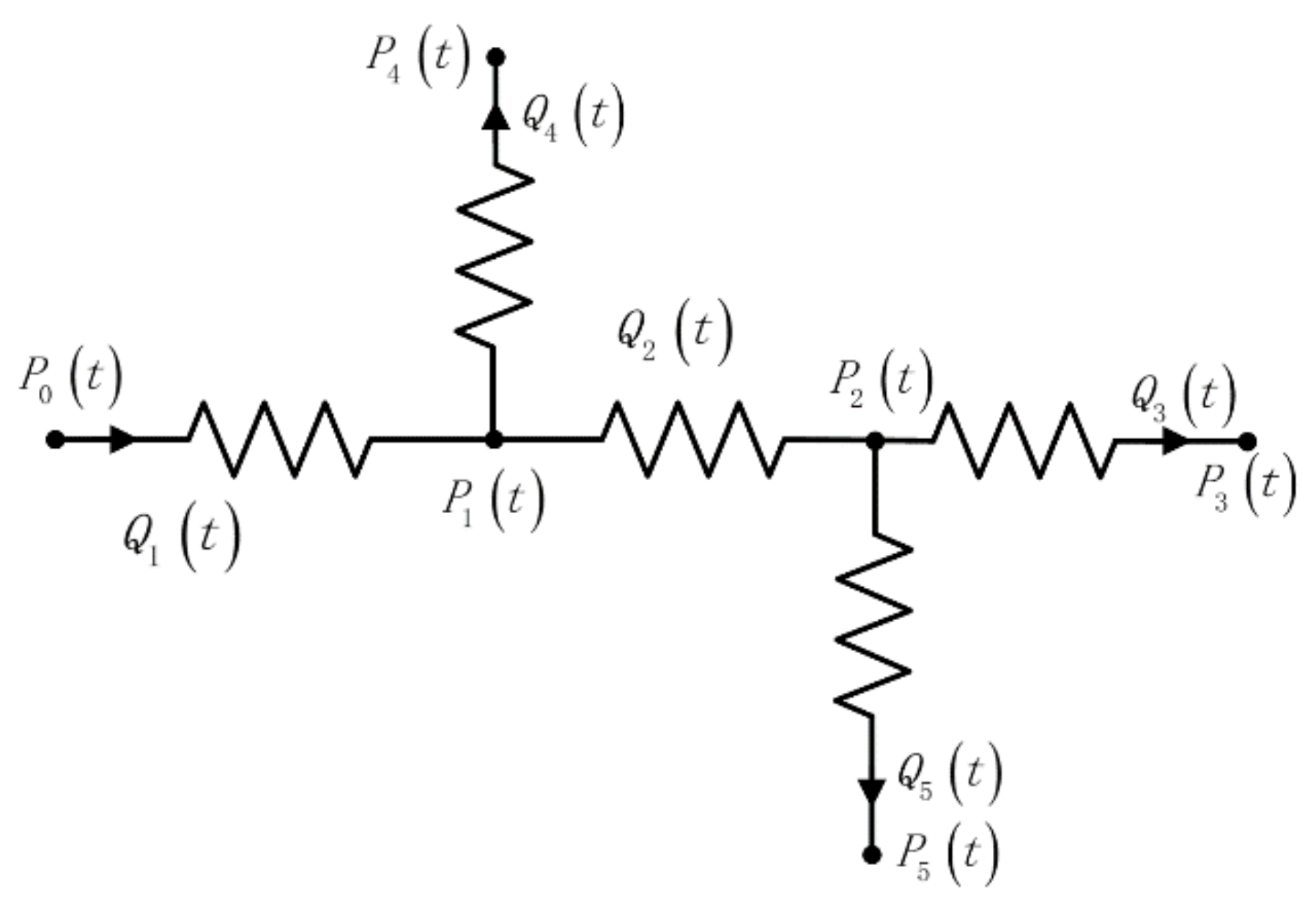

3.1. Model Design and Electrical Equivalent

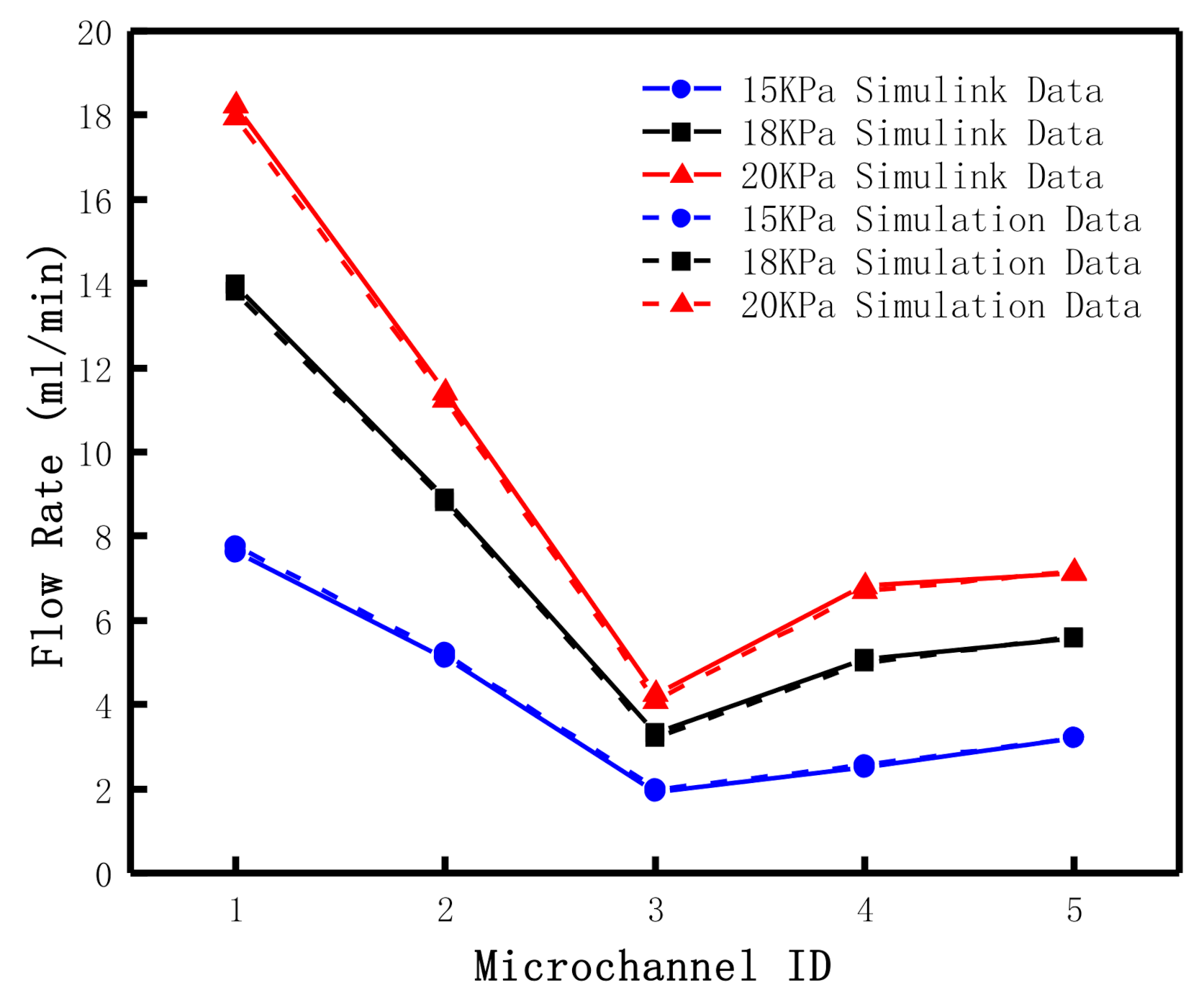

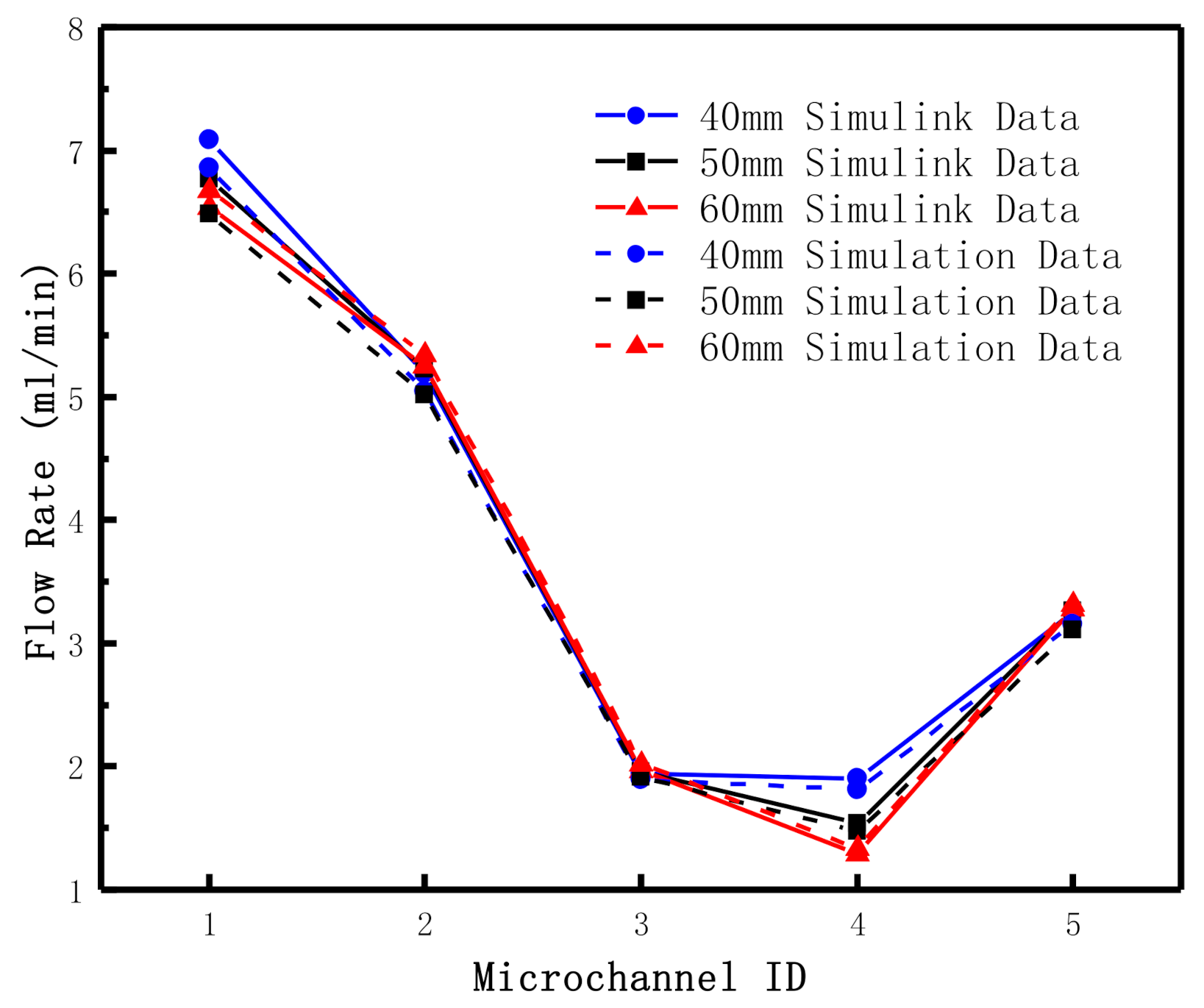

3.2. Model Calculation Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gou, Y.; Jia, Y.; Wang, P.; Sun, C. Progress of Inertial Microfluidics in Principle and Application. Sensors 2018, 18, 1762. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, K.; Jiang, L.; Gao, Z.; Zhai, C.; Yan, W.; Wu, S. Design and Numerical Study of Micropump Based on Induced Electroosmotic Flow. J. Nanotechnol. 2018, 2018, 4018503. [Google Scholar] [CrossRef] [Green Version]

- Aracil, C.; Perdigones, F.; Moreno, J.M.; Luque, A.; Quero, J.M. Portable Lab-on-PCB platform for autonomous micromixing. Microelectron. Eng. 2014, 131, 13–18. [Google Scholar] [CrossRef]

- Okkels, F.; Bruus, H. Design of Micro-Fluidic Bio-Reactors Using Topology Optimization. In Proceedings of the European Conference on Computational Fluid Dynamics, Mekelweg, The Netherlands, 5–8 September 2006. [Google Scholar]

- Mathew, B.; John, T.J.; Hegab, T.J. Effect of Manifold Design on Flow Distribution in Multichanneled Microfluidic Devices. In Proceedings of the Asme Fluids Engineering Division Summer Meeting, Vail, CO, USA, 2–6 August 2009. [Google Scholar]

- Delsman, E.R.; Pierik, A.; De Croon, M.H.J.M.; Kramer, G.J.; Schouten, J.C. Microchannel Plate Geometry Optimization for Even Flow Distribution at High Flow Rates. Chem. Eng. Res. Des. 2004, 82, 267–273. [Google Scholar] [CrossRef]

- Alharbi, A.Y.; Pence, D.V.; Cullion, R.N. Fluid Flow Through Microscale Fractal-Like Branching Channel Networks. J. Fluids Eng. 2003, 125, 1051–1057. [Google Scholar] [CrossRef]

- Jing, D.; Yi, S. Electroosmotic Flow in Tree-like Branching Microchannel Network. Fractals 2019, 9, 1950095. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, P. Heat transfer and pressure drop in fractal tree-like microchannel nets. Int. J. Heat Mass Transf. 2002, 45, 2643–2648. [Google Scholar] [CrossRef]

- Bassiouny, M.K.; Martin, H. Flow Distribution and Pressure Drop in Plate Heat Exchangers I U-Type Arrangement. Chem. Eng. Sci. 1984, 39, 693–700. [Google Scholar] [CrossRef]

- Bassiouny, M.K.; Martin, H. Flow distribution and pressure drop in plate heat exchangers II Z-type arrangement. Chem. Eng. Sci. 1984, 39, 701–704. [Google Scholar] [CrossRef]

- Kim, S.; Choi, E.; Cho, Y.I. The effect of header shapes on the flow distribution in a manifold for electronic packaging applications. Int. Commun. Heat Mass Transf. 1995, 22, 329–341. [Google Scholar] [CrossRef]

- Wang, J. Pressure drop and flow distribution in parallel-channel configurations of fuel cells: Z-type arrangement. Int. J. Hydrogen Energy 2010, 35, 5498–5509. [Google Scholar] [CrossRef]

- Idelchik, I.E. Handbook of Hydraulic Resistance, 4th Edition Revised and Augmented; Begell House Inc.: Moscow, Russia, 2008. [Google Scholar]

- Bruus, H. Theoretical Microfluidics; Oxford University Press: Oxford, UK, 2008. [Google Scholar]

| Parameter | |||||

|---|---|---|---|---|---|

| ) | 500 | 500 | 350 | 350 | 350 |

| ) | 500 | 500 | 350 | 350 | 350 |

| Length (mm) | 10 | 8 | 50 | 30 | 30 |

| ) | 4.64 | 3.71 | 96.6 | 57.9 | 57.9 |

| Entrance Pressure (KPa) | 15 | 18 | 20 | |

|---|---|---|---|---|

| (mL/min) | Simulink Data | 7.623 | 13.990 | 18.235 |

| Simulation Data | 7.767 | 13.812 | 17.945 | |

| Relative Error (%) | 1.883 | 1.272 | 1.585 | |

| (mL/min) | Simulink Data | 5.126 | 8.895 | 11.407 |

| Simulation Data | 5.217 | 8.802 | 11.246 | |

| Relative Error (%) | 1.772 | 1.054 | 1.414 | |

| (mL/min) | Simulink Data | 1.921 | 3.333 | 4.275 |

| Simulation Data | 2.000 | 3.211 | 4.086 | |

| Relative Error (%) | 4.100 | 3.671 | 4.421 | |

| (mL/min) | Simulink Data | 2.497 | 5.095 | 6.827 |

| Simulation Data | 2.550 | 5.011 | 6.700 | |

| Relative Error (%) | 2.111 | 1.653 | 1.871 | |

| (mL/min) | Simulink Data | 3.205 | 5.561 | 7.132 |

| Simulation Data | 3.217 | 5.590 | 7.160 | |

| Relative Error (%) | 0.378 | 0.515 | 0.388 | |

| Microchannel 4 Length (mm) | 40 | 50 | 60 | |

|---|---|---|---|---|

| ) | 7.73 | 9.66 | 11.6 | |

| (mL/min) | Simulink Data | 7.090 | 6.764 | 6.541 |

| Simulation Data | 6.855 | 6.488 | 6.680 | |

| Relative Error (%) | 3.305 | 4.078 | 2.104 | |

| (mL/min) | Simulink Data | 5.188 | 5.226 | 5.252 |

| Simulation Data | 5.047 | 5.016 | 5.342 | |

| Relative Error (%) | 2.733 | 4.014 | 1.721 | |

| (mL/min) | Simulink Data | 1.944 | 1.958 | 1.968 |

| Simulation Data | 1.894 | 1.912 | 2.026 | |

| Relative Error (%) | 2.580 | 2.369 | 2.943 | |

| (mL/min) | Simulink Data | 1.903 | 1.538 | 1.290 |

| Simulation Data | 1.81 | 1.472 | 1.337 | |

| Relative Error (%) | 4.863 | 4.297 | 3.663 | |

| Simulink Data | 3.244 | 3.267 | 3.284 | |

| Simulation Data | 3.152 | 3.104 | 3.316 | |

| Relative Error (%) | 2.825 | 5.000 | 0.989 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Zhang, K.; Guo, F.; Yang, M. Dynamic Modeling and Flow Distribution of Complex Micron Scale Pipe Network. Micromachines 2021, 12, 763. https://doi.org/10.3390/mi12070763

Zhao Y, Zhang K, Guo F, Yang M. Dynamic Modeling and Flow Distribution of Complex Micron Scale Pipe Network. Micromachines. 2021; 12(7):763. https://doi.org/10.3390/mi12070763

Chicago/Turabian StyleZhao, Yao, Kai Zhang, Fengbei Guo, and Mingyue Yang. 2021. "Dynamic Modeling and Flow Distribution of Complex Micron Scale Pipe Network" Micromachines 12, no. 7: 763. https://doi.org/10.3390/mi12070763

APA StyleZhao, Y., Zhang, K., Guo, F., & Yang, M. (2021). Dynamic Modeling and Flow Distribution of Complex Micron Scale Pipe Network. Micromachines, 12(7), 763. https://doi.org/10.3390/mi12070763