A Novel MEMS Capacitive Microphone with Semiconstrained Diaphragm Supported with Center and Peripheral Backplate Protrusions

Abstract

:1. Introduction

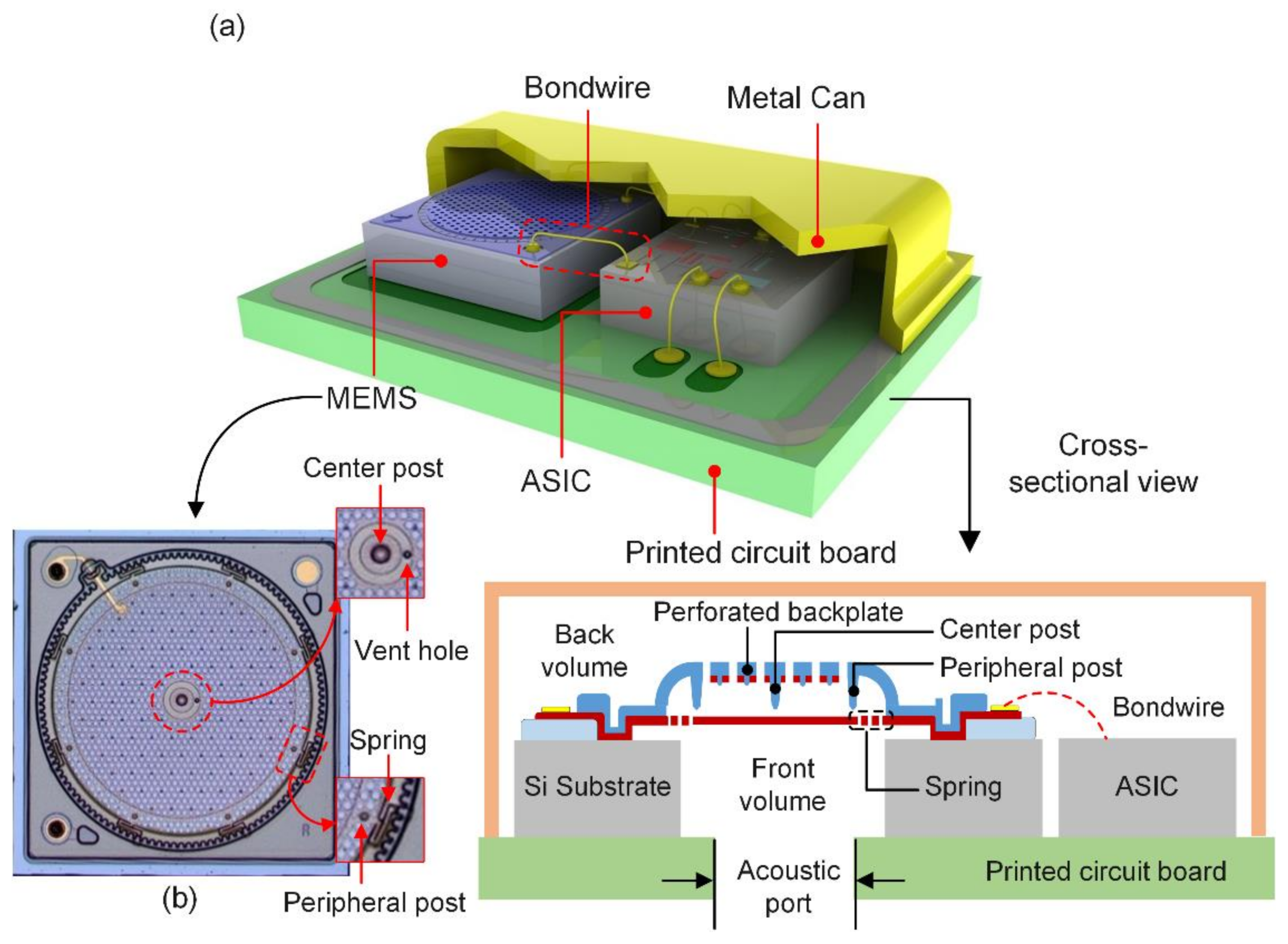

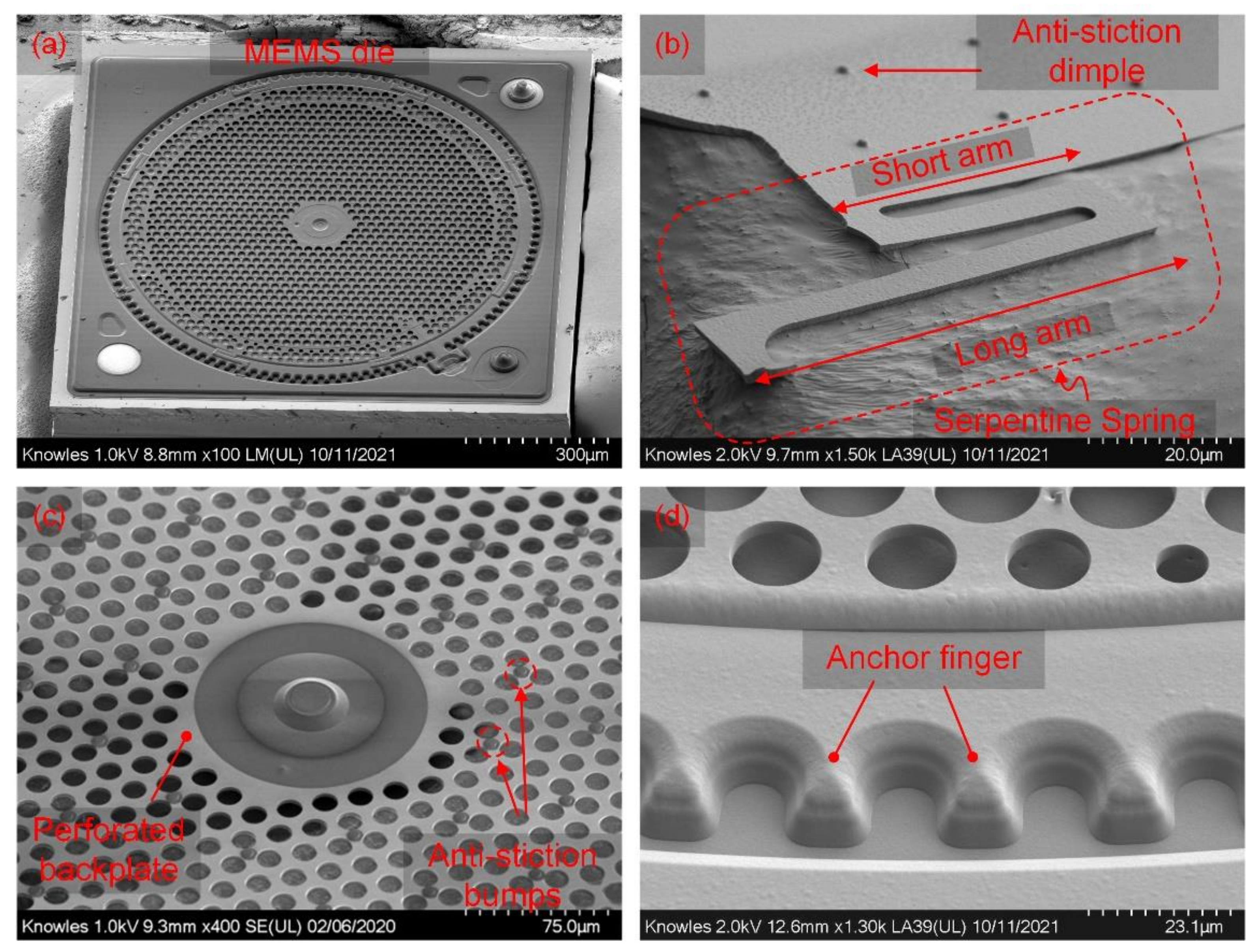

2. Microphone Structure and Design

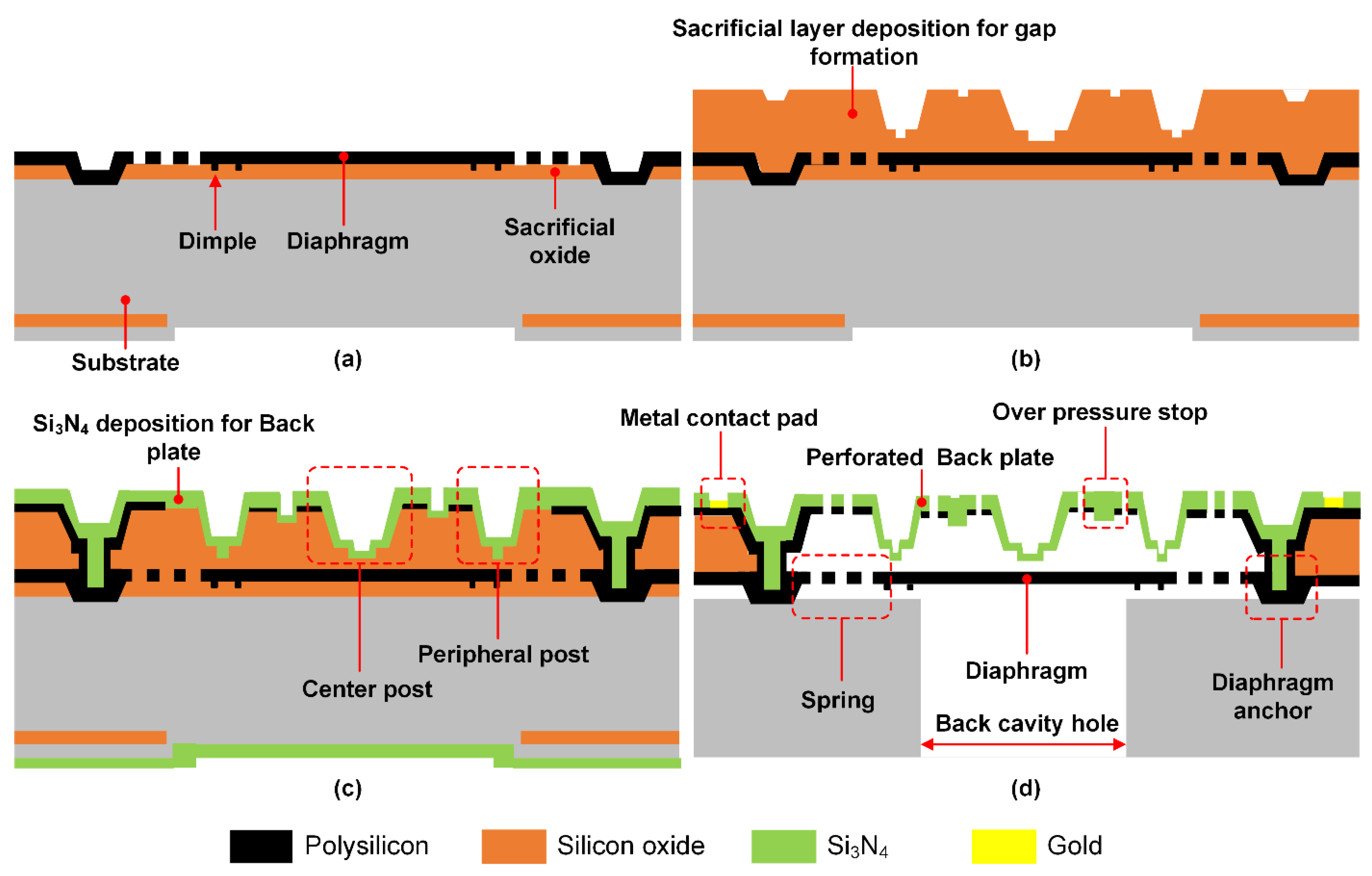

3. Microfabrication

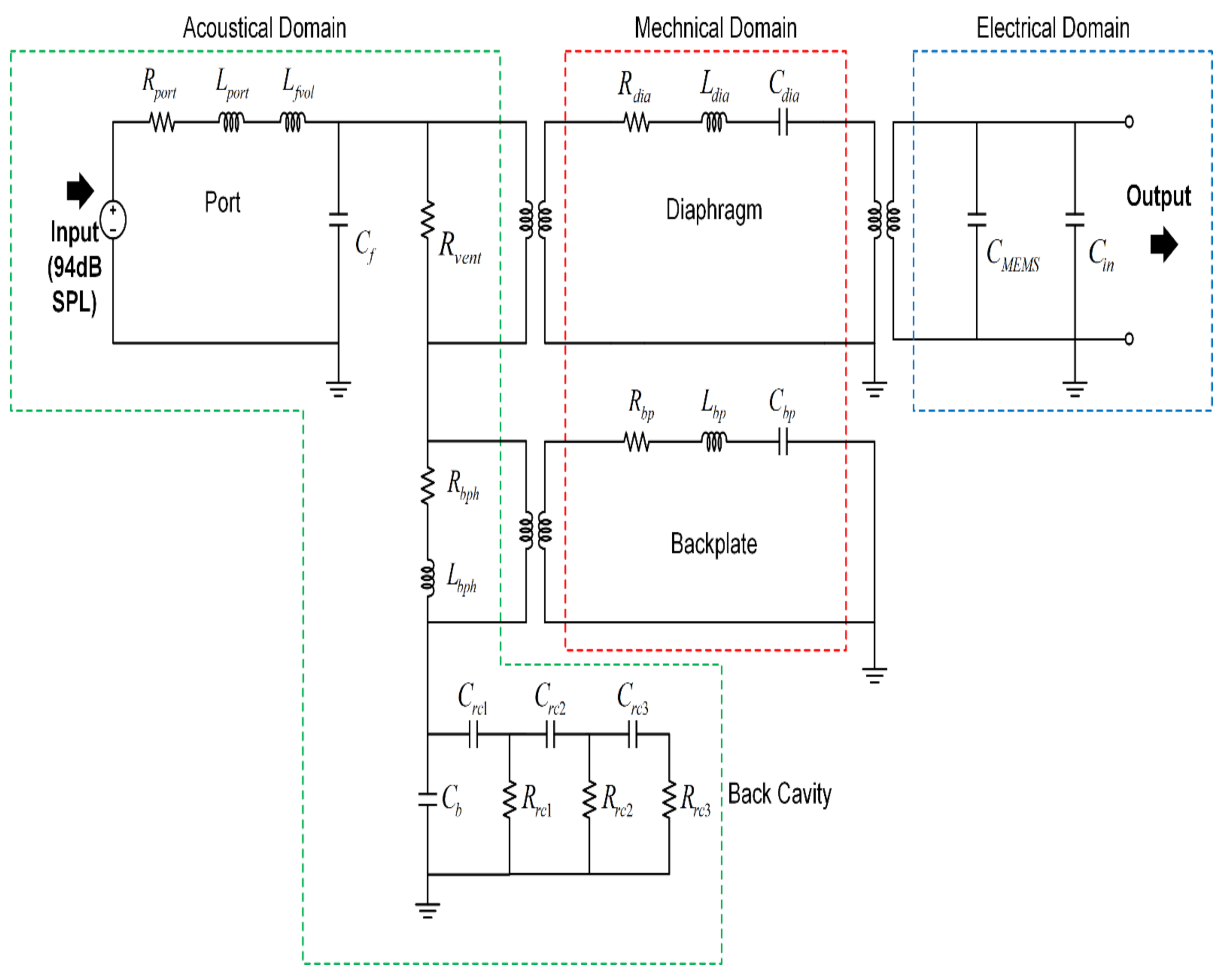

4. Reduced Order Modeling

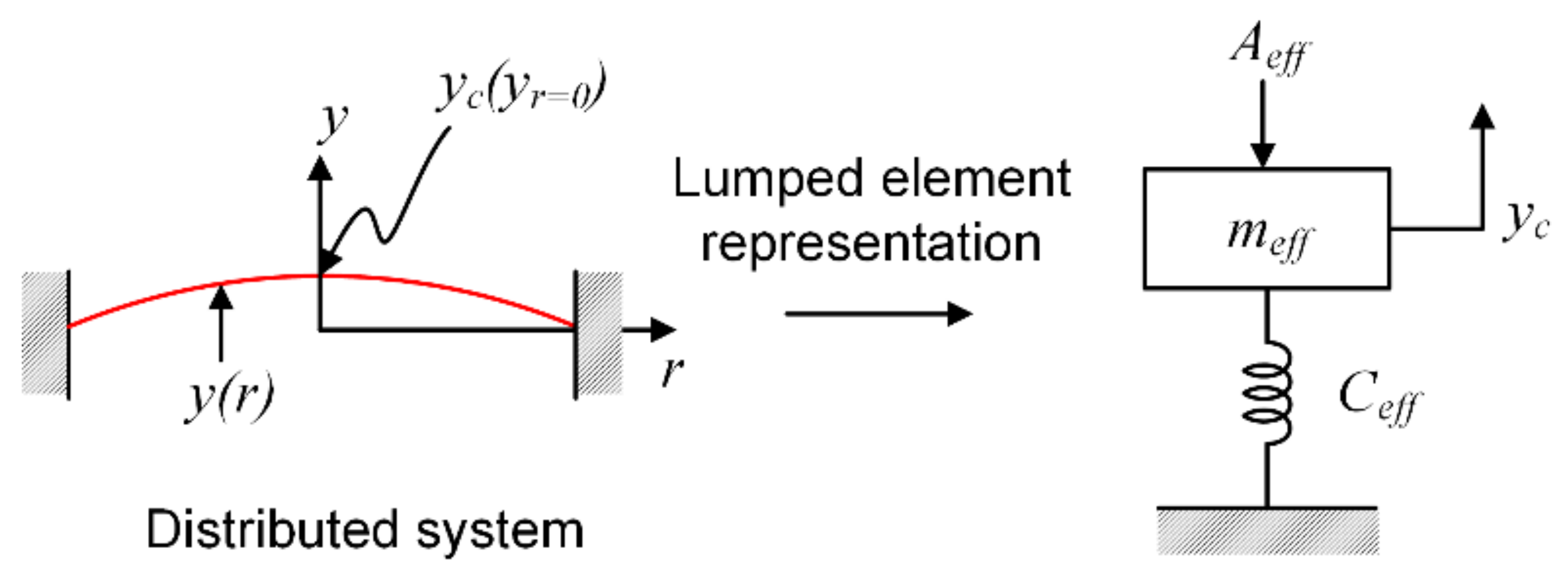

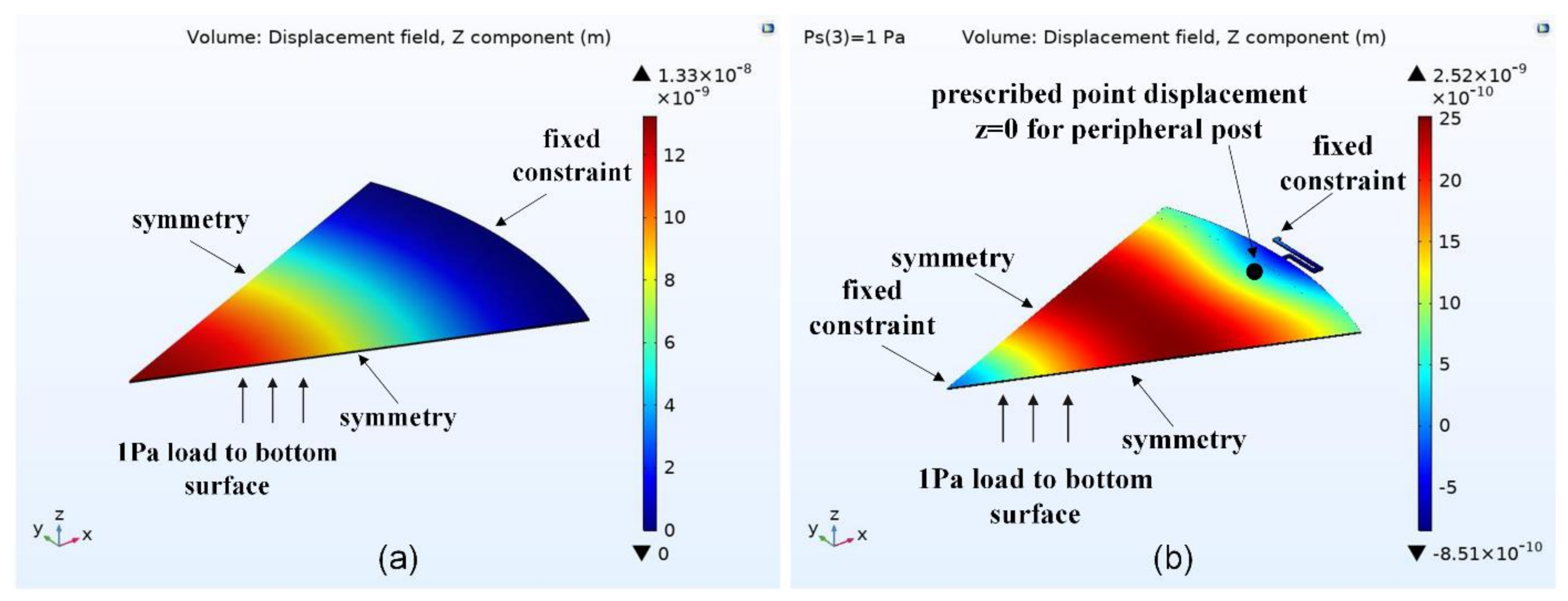

4.1. Diaphragm Effective Area (Acoustic-to-Mechanical Transformer Ratio)

4.2. Electrostatic Coupling Coefficient (Mechanical-to-Electrical Transformer Ratio)

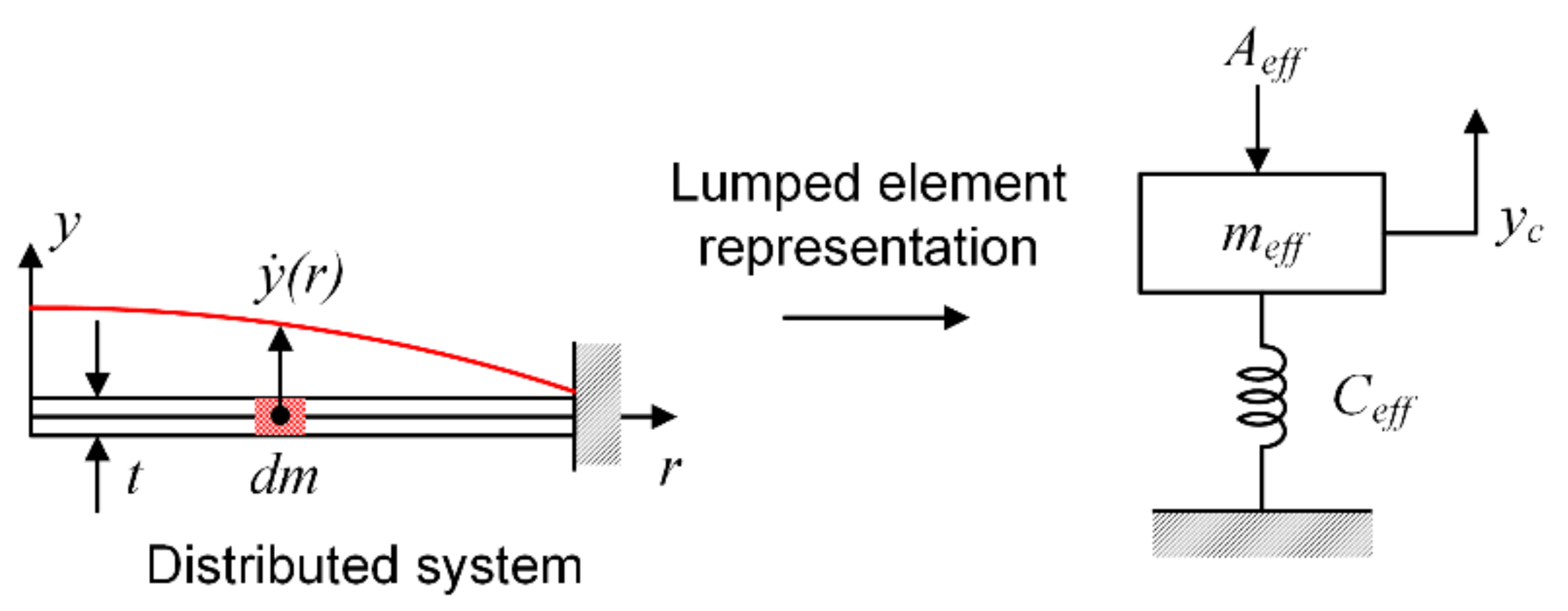

4.3. Effective Mass of the Diaphragm

4.4. Diaphragm Compliance

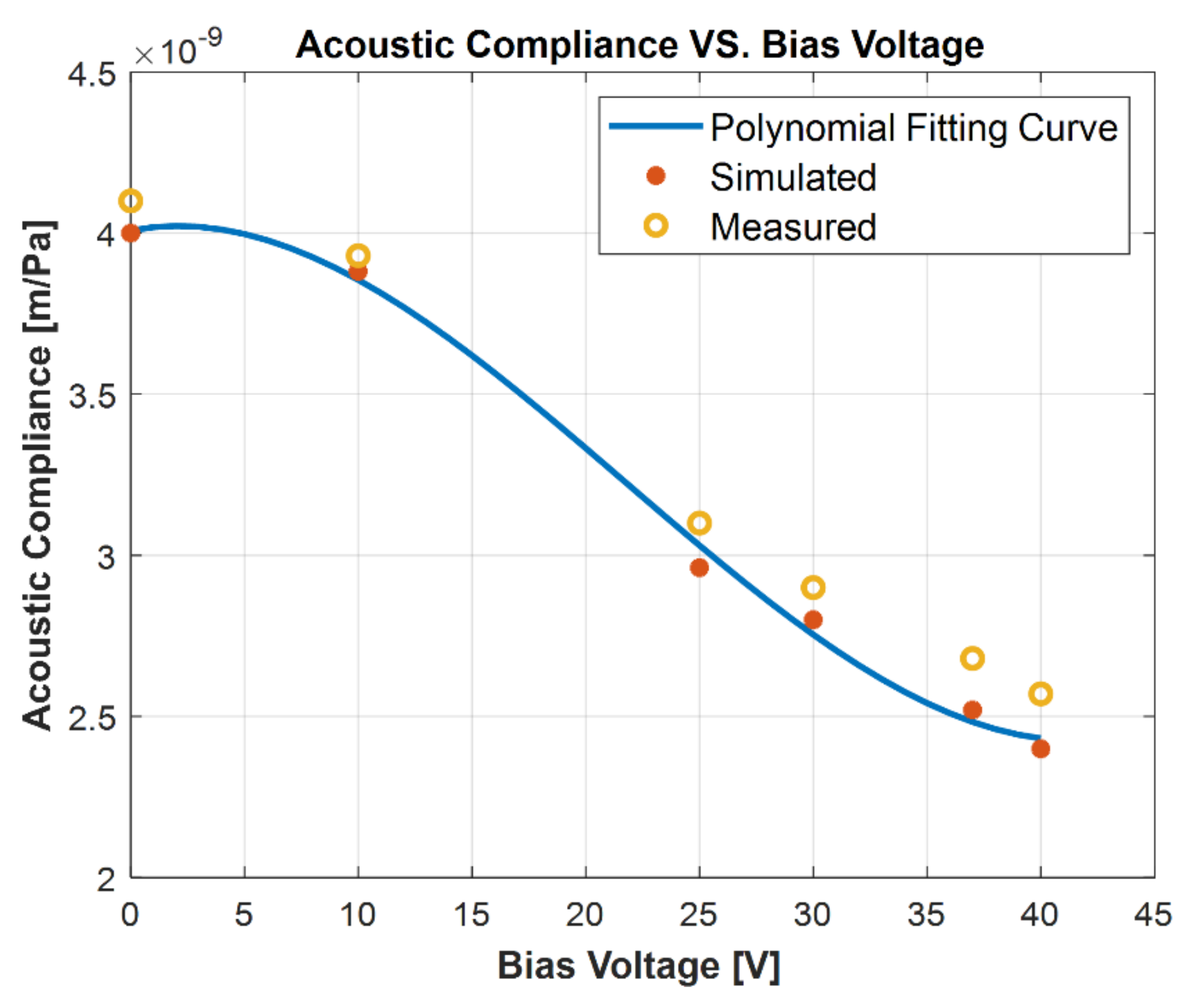

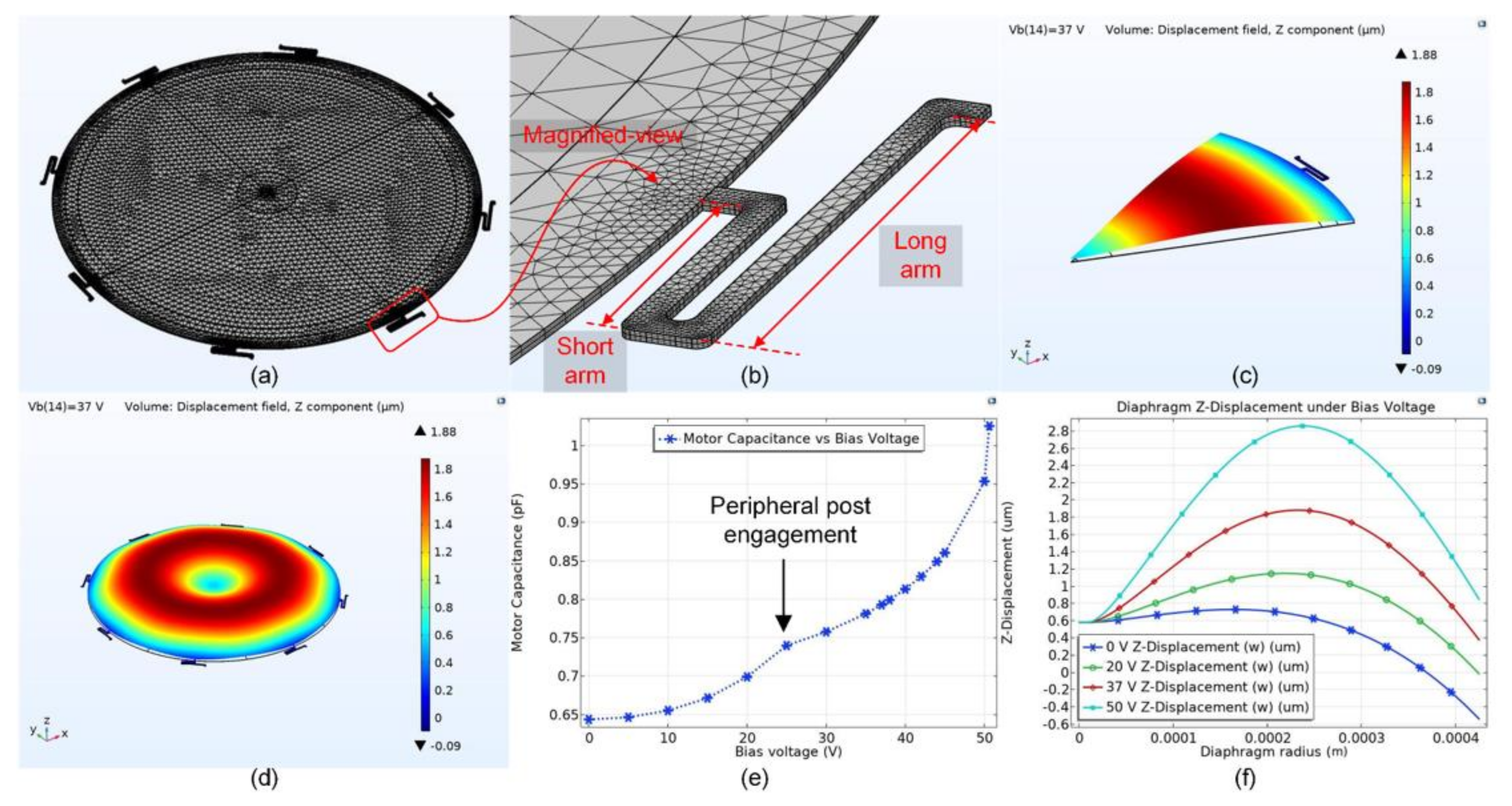

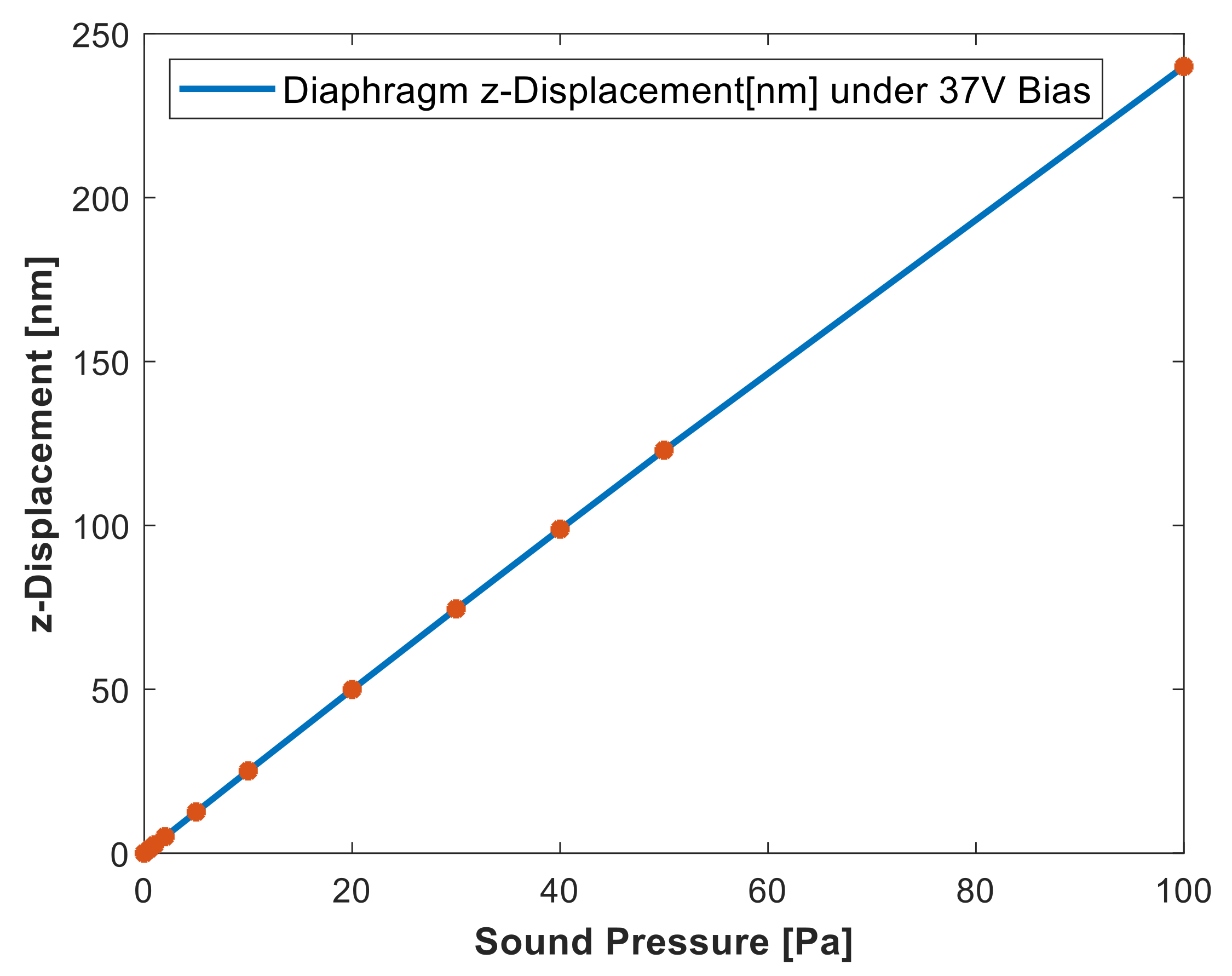

5. Diaphragm FEA Model

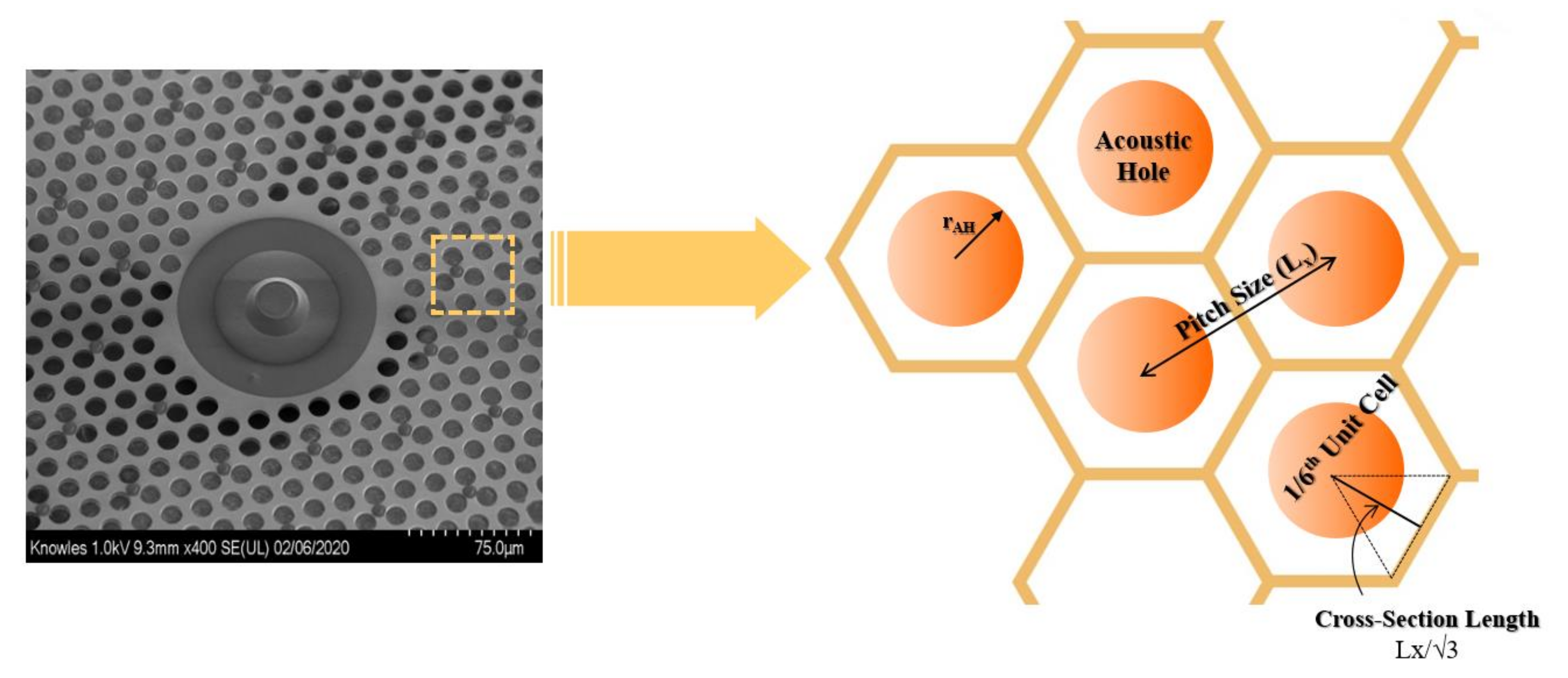

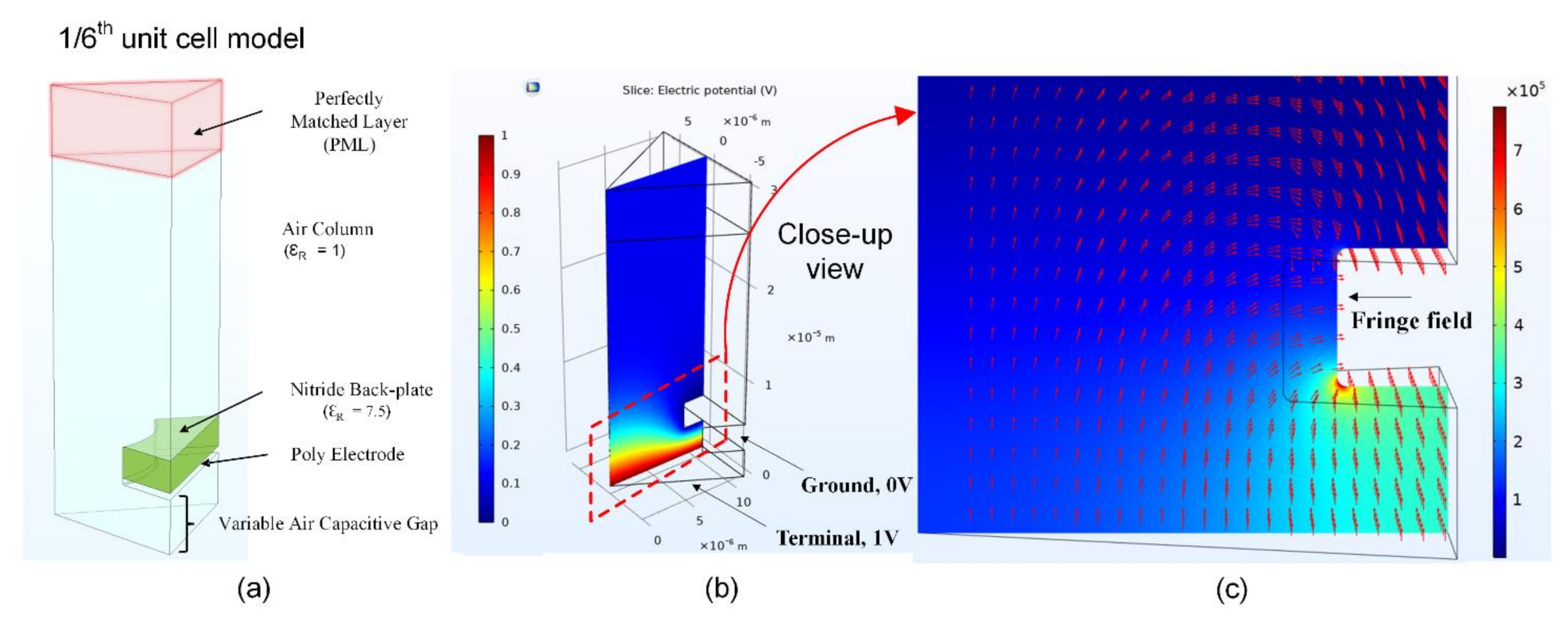

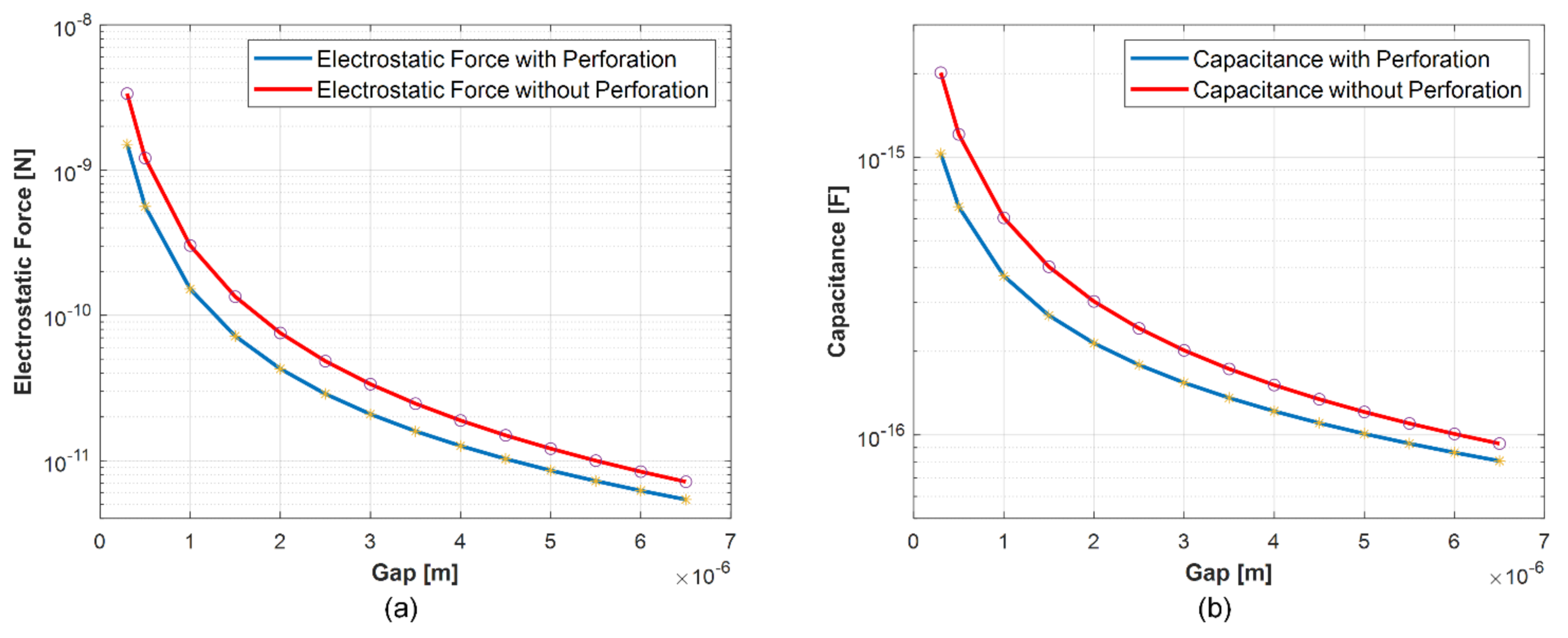

5.1. Unit Cell Capacitance Model

5.2. Electromechanical Model

5.3. Resonance Modes

6. Noise Sources in MEMS Microphone

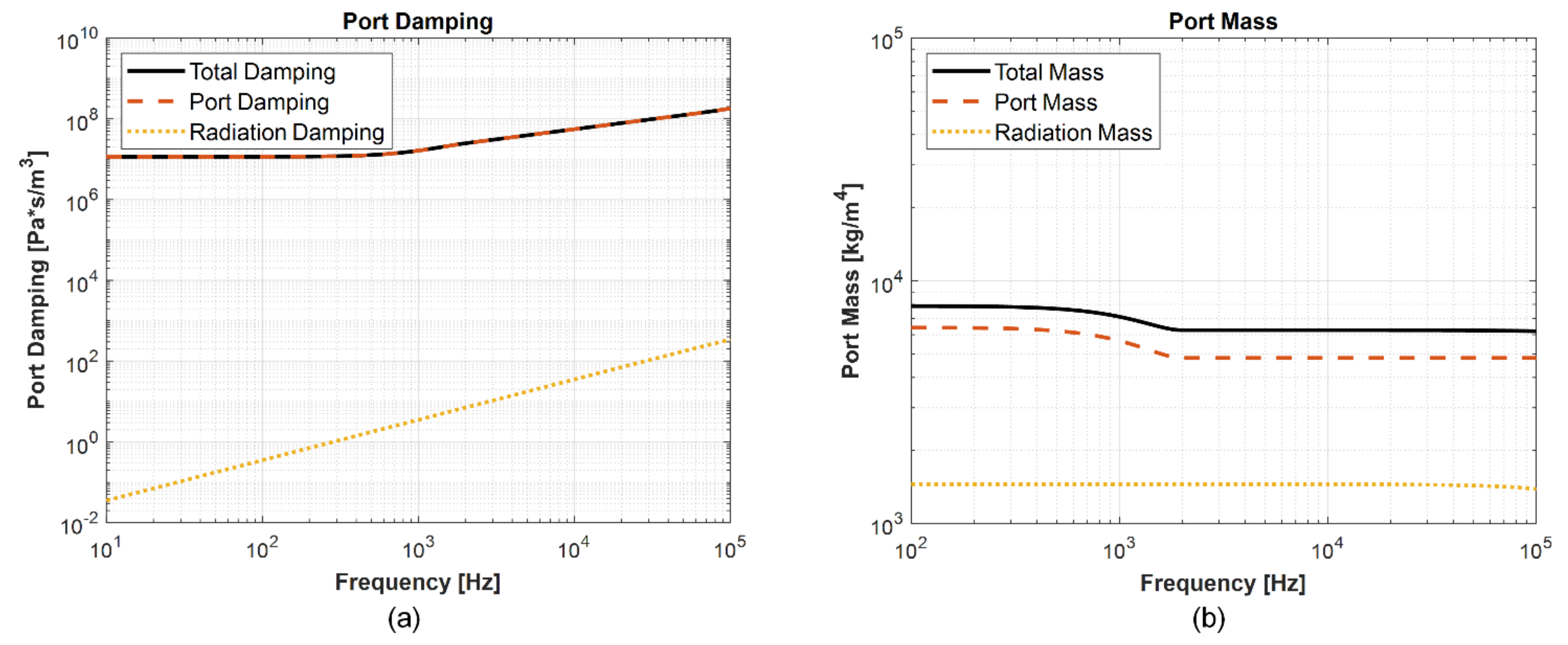

6.1. Analytical Calculation of Port and Cavity Acoustic Parameters

6.2. Calculation of Enclosure Impedance

6.3. Vent Resistance

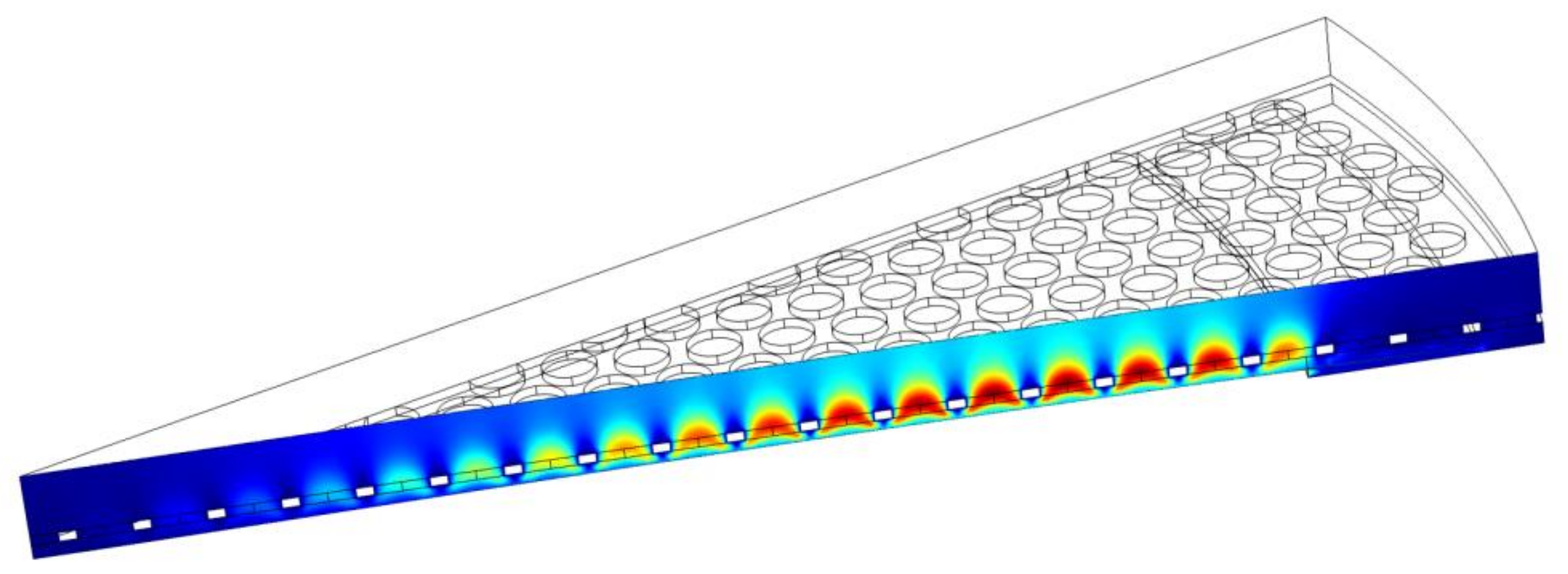

6.4. Backplate Damping

7. Microphone Performance

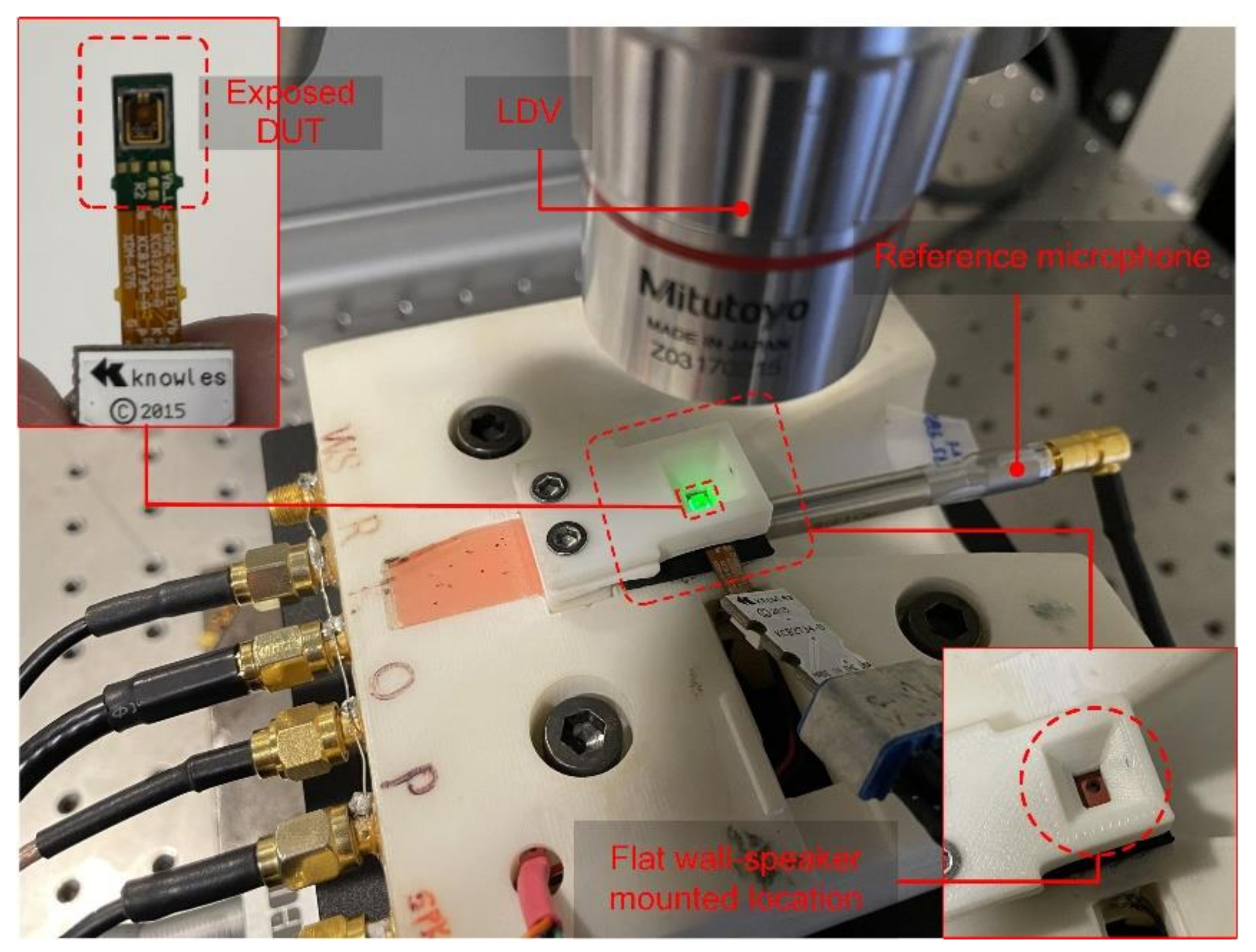

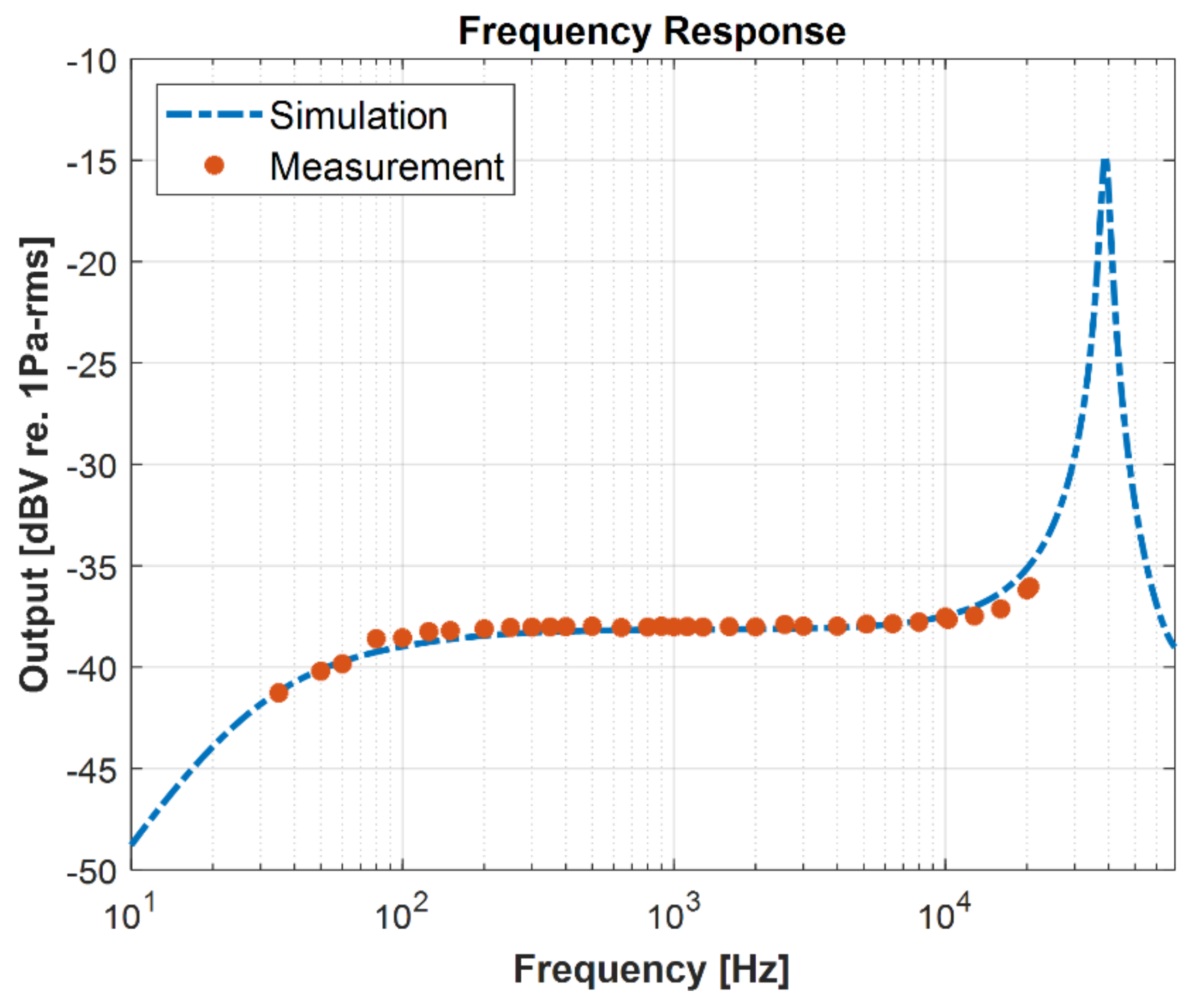

7.1. Microphone Sensitivity

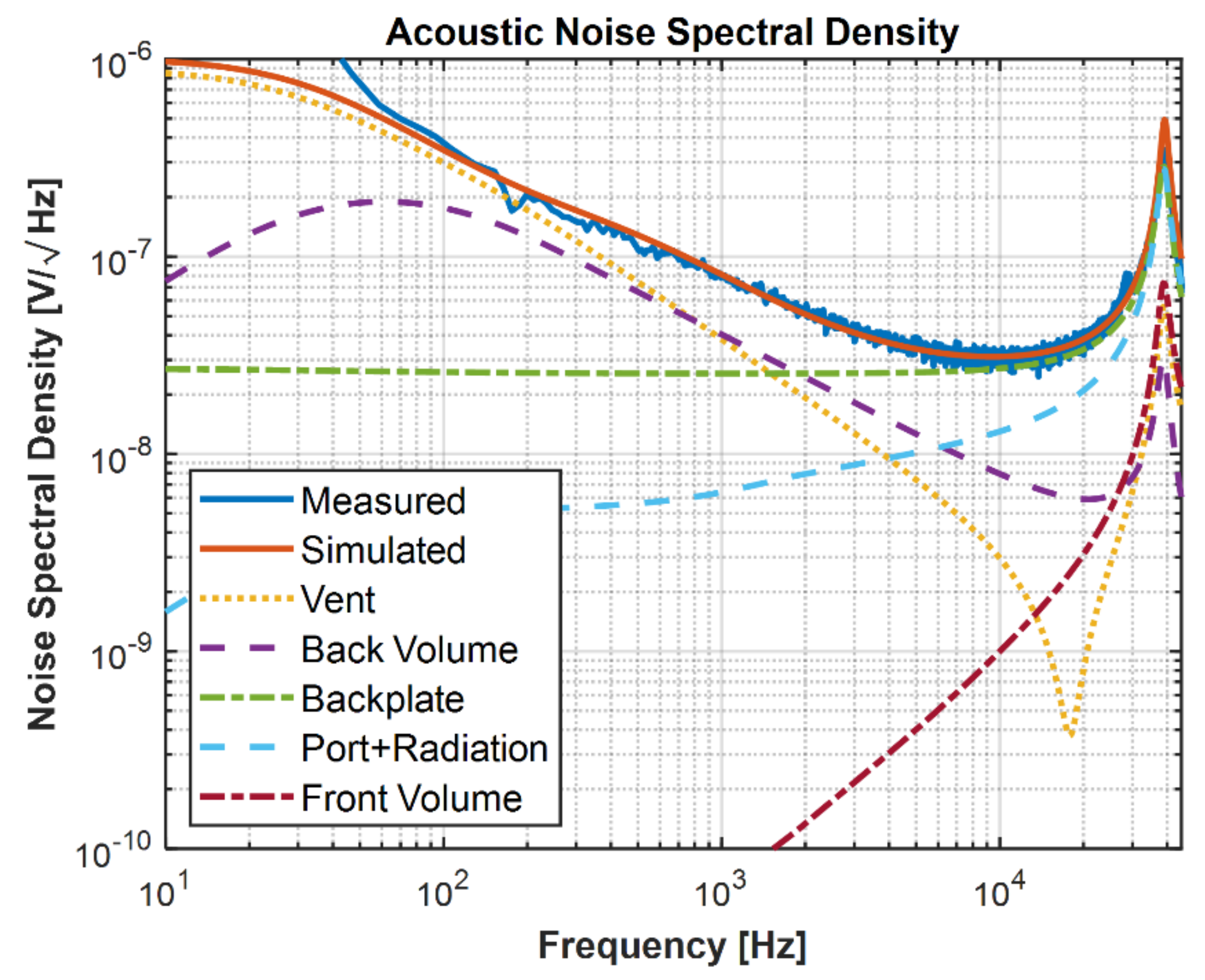

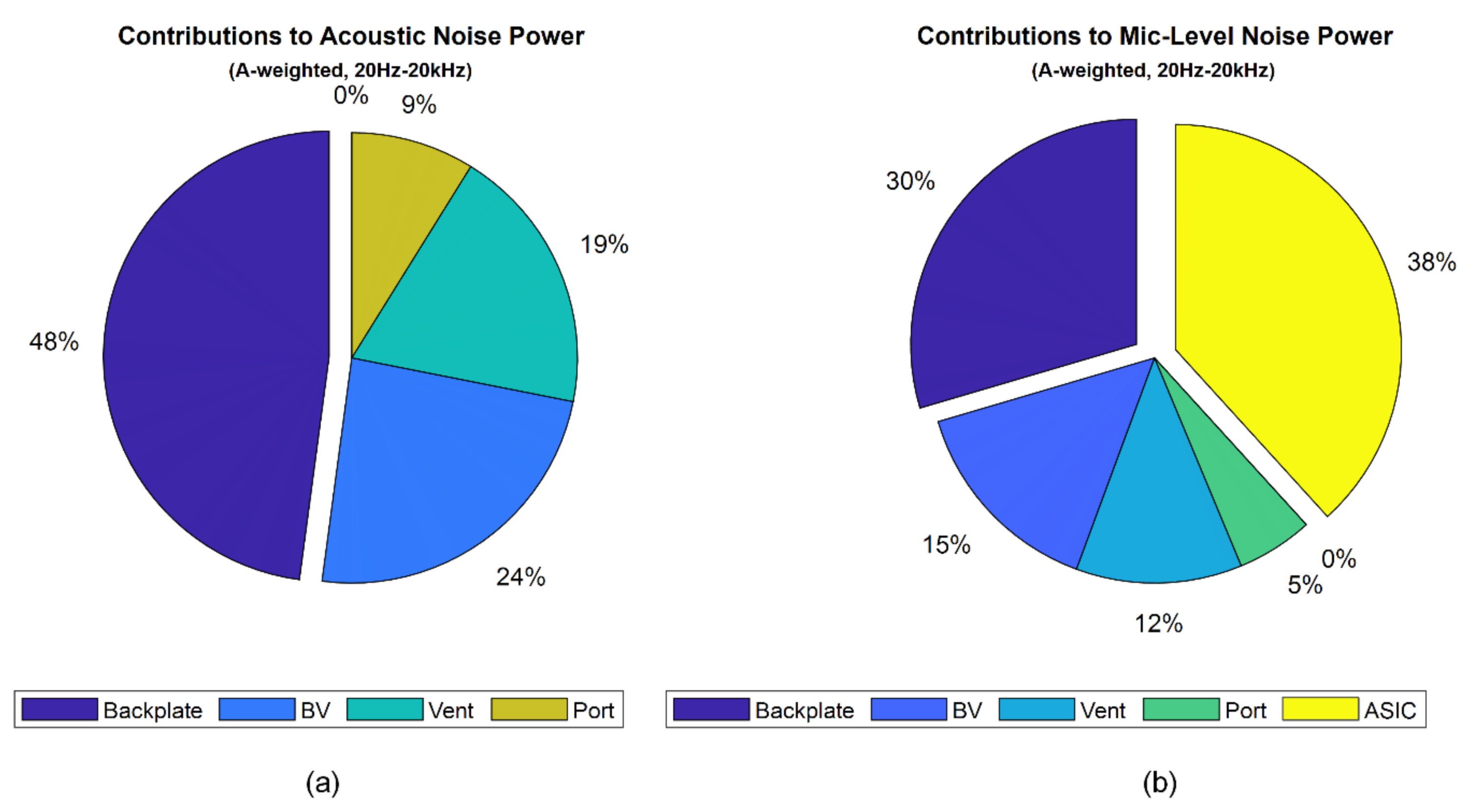

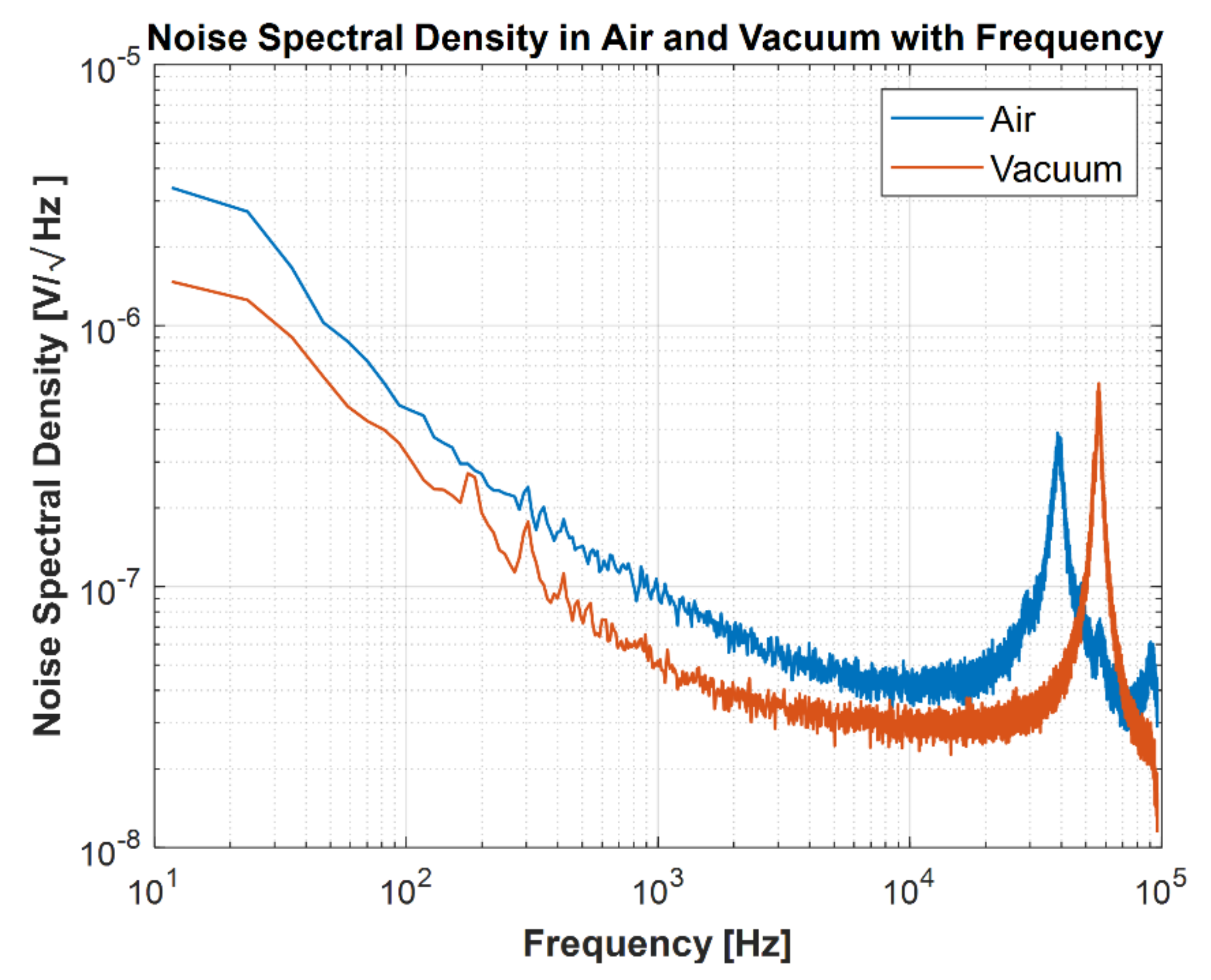

7.2. Noise

7.3. Resonance Peak

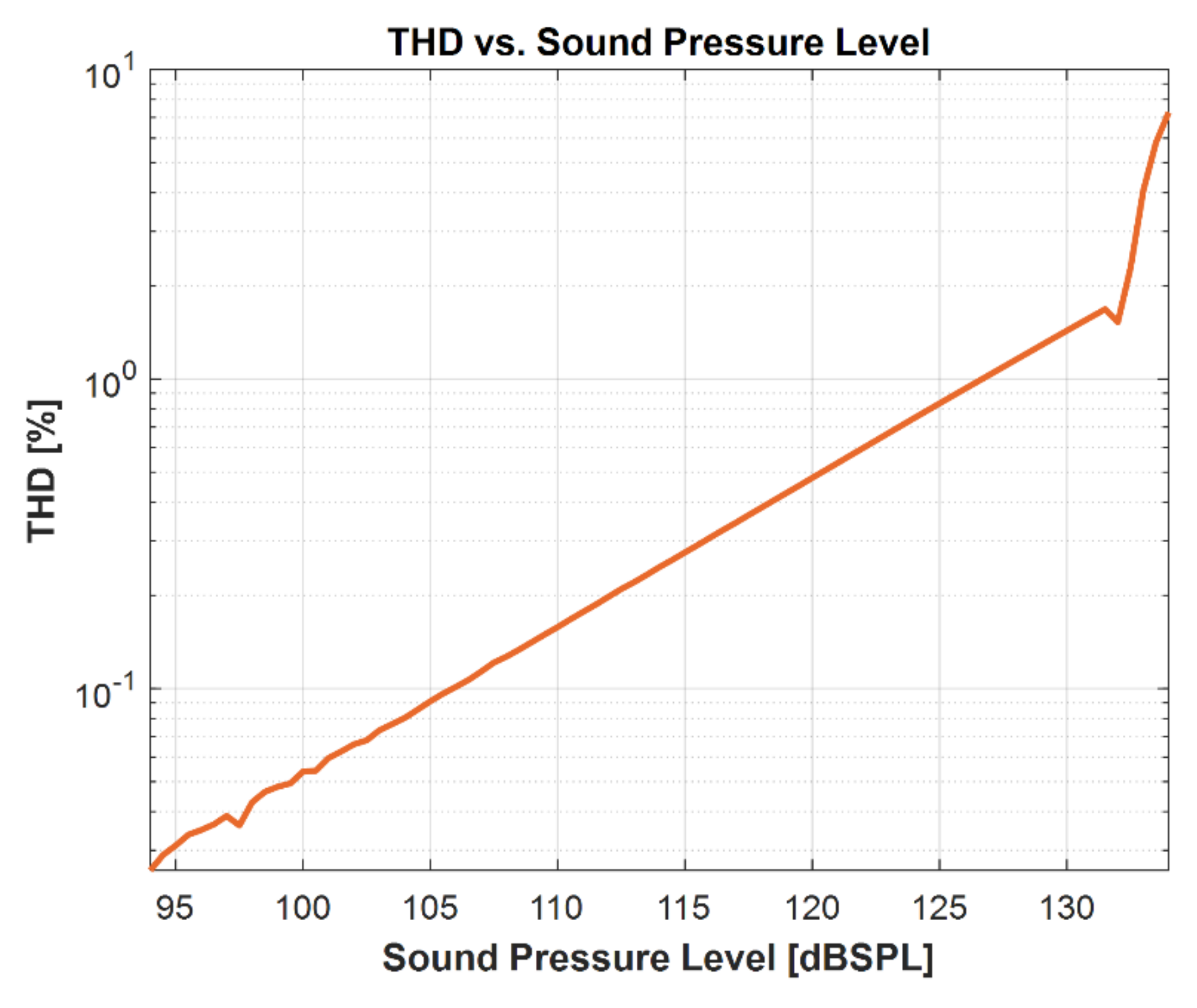

7.4. Total Harmonic Distortion

8. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Loeppert, P.V.; Lee, S.B. SiSonic™-The first commercialized MEMS microphone. In Proceedings of the Solid-State Sensors, Actuators, and Microsystems Workshop, Hilton Head, SC, USA, 5–9 June 2006; pp. 27–30. [Google Scholar]

- Kim, B.H.; Lee, H.S. Acoustical-thermal noise in a capacitive MEMS microphone. J. Sens. IEEE 2015, 15, 6853–6860. [Google Scholar] [CrossRef]

- Ganji, B.A.; Sedaghat, S.B.; Roncaglia, A.; Belsito, L.; Ansari, R. Design, modeling, and fabrication of crab-shape capacitive microphone using silicon-on-isolator wafer. J. Micro Nanolithogr. MEMS MOEMS 2018, 17, 015002. [Google Scholar] [CrossRef]

- Scheeper, P.R.; van der Donk, A.G.H.; Olthius, W.; Bergveld, P. A review of silicon microphones. Sens. Actuators A Phys. 1994, 44, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Tadigadapa, S.; Mateti, K. Piezoelectric MEMS sensors: State-of-the-art and perspectives. Meas. Sci. Technol. 2009, 20, 092001. [Google Scholar] [CrossRef]

- Papila, M.; Haftka, R.T.; Nishida, T.; Sheplak, M. Piezoresistive microphone design Pareto optimization: Tradeoff between sensitivity and noise floor. J. MEMS 2006, 15, 1632–1643. [Google Scholar] [CrossRef]

- Kon, S.; Oldham, K.; Horowitz, R. Piezoresistive and piezoelectric MEMS strain sensors for vibration detection. In Proceedings of the Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems 2007, Vancouver, BC, Canada, 10 April 2007. [Google Scholar]

- Hall, N.A.; Bicen, B.; Jeelani, M.K.; Lee, W.; Qureshi, S.; Degertekin, F.L. Micromachined microphones with diffraction-based optical displacement detection. J. Acoust. Soc. Am. 2005, 118, 3000–3009. [Google Scholar] [CrossRef]

- Kuntzman, M.L.; Garcia, C.T.; Onaran, A.G.; Avenson, B.; Kirk, K.D.; Hall, N.A. Performance and modeling of a fully packaged micromachined optical microphone. J. MEMS 2011, 20, 828–833. [Google Scholar] [CrossRef]

- Bernstein, J. A micromachined condenser hydrophone. In Proceedings of the Technical Digest IEEE Solid-State Sensor and Actuator Workshop, Hilton Head, SC, USA, 22–25 June 1992; pp. 161–165. [Google Scholar]

- Scheeper, P.R.; Olthuis, W.; and Bergveld, P. Improvement of the performance of microphones with a silicon nitride diaphragm and backplate. Sens. Actuators A Phys. 1994, 40, 179–186. [Google Scholar] [CrossRef] [Green Version]

- Yoo, I.; Sim, J.; Yang, S.; Kim, H. Development of capacitive MEMS microphone based on slit-edge for high signal-to-noise ratio. In Proceedings of the IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 1072–1075. [Google Scholar]

- Gharaei, H.; Koohsorkhi, J. Design and characterization of high sensitive MEMS capacitive microphone with fungous coupled diaphragm structure. Microsyst. Technol. 2016, 22, 401–411. [Google Scholar] [CrossRef]

- Fu, M.; Dehe, A.; Lerch, R. Analytical analysis and finite element simulation of advanced membranes for silicon microphones. J. Sens. IEEE 2005, 5, 857–863. [Google Scholar] [CrossRef]

- Shubham, S. Silicon Nitride Corrugated Membrane with High-Width-Aspect-Ratio for MEMS Microphones. In Proceedings of the COMSOL Conference, Boston, MA, USA, 7–8 October 2020. [Google Scholar]

- Ying, M.; Zou, Q.; Yi, S. Finite-element analysis of silicon condenser microphones with corrugated diaphragms. Finite Elem. Anal. Des. 1998, 30, 163–173. [Google Scholar] [CrossRef]

- Sedaghat, S.B.; Ganji, B.A. A novel MEMS capacitive microphone using spring-type diaphragm. Microsyst. Technol. 2019, 25, 217–224. [Google Scholar] [CrossRef]

- Sui, W.; Zhang, W.; Song, K.; Cheng, C.H.; Lee, Y.K. Breaking the size barrier of capacitive MEMS microphones from critical length scale. In Proceedings of the 19th International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Kaohsiung, Taiwan, 18–22 June 2017; pp. 946–949. [Google Scholar]

- Chan, C.K.; Lai, W.C.; Wu, M.; Wang, M.Y.; Fang, W. Design and implementation of a capacitive-type microphone with rigid diaphragm and flexible spring using the two poly silicon micromachining processes. J. Sens. IEEE 2011, 11, 2365–2371. [Google Scholar] [CrossRef]

- Lo, S.C.; Yeh, S.K.; Wang, J.J.; Wu, M.; Chen, R.; Fang, W. Bandwidth and SNR enhancement of MEMS microphones using two poly-Si micromachining processes. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 1064–1067. [Google Scholar]

- Rombach, P.; Müllenborn, M.; Klein, U.; Rasmussen, K. The first low voltage, low noise differential silicon microphone, technology development and measurement results. Sens. Actuators A Phys. 2002, 95, 196–201. [Google Scholar] [CrossRef]

- Martin, D.T.; Liu, J.; Kadirvel, K.; Fox, R.M.; Sheplak, M.; Nishida, T. A micromachined dual-backplate capacitive microphone for aeroacoustic measurements. J. MEMS 2007, 16, 1289–1302. [Google Scholar] [CrossRef]

- Martin, D.T. Design, Fabrication, and Characterization of a MEMS Dual-Backplate Capacitive Microphone. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2007. [Google Scholar]

- Martin, D.T.; Kadirvel, K.; Liu, J.; Fox, R.M.; Sheplak, M.; Nishida, T. Surface and bulk micromachined dual backplate condenser microphone. In Proceedings of the 18th IEEE International Conference on Micro Electro Mechanical Systems, Miami Beach, FL, USA, 30 January–3 February 2005; pp. 319–322. [Google Scholar]

- Naderyan, V.; Lee, S.; Sharma, A.; Wakefield, W.; Kuntzman, M.; Ma, Y.; da Silva, M.; Pedersen, M. MEMS microphone with 73dBA SNR in a 4 mm × 3 mm × 1.2 mm Package. In Proceedings of the 21st International Conference on Solid State Sensors, Actuators and Microsystems (Transducers), Orlando, FL, USA, 20–24 June 2021. [Google Scholar]

- Bay, J.; Hansen, O.; Bouwstra, S. Design of a silicon microphone with differential read-out of a sealed double parallel-plate capacitor. Sens. Actuators A Phys. 1996, 53, 232–236. [Google Scholar] [CrossRef]

- Wang, Z.; Zou, Q.; Song, Q.; Tao, J. The era of silicon MEMS microphone and look beyond. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Anchorage, AK, USA, 21–25 June 2015; pp. 375–378. [Google Scholar]

- Timoshenko, S. Theory of Plates and Shells; McGraw-Hill: New York, NY, USA, 1959. [Google Scholar]

- Hunt, F.V. Electroacoustics: The Analysis of Transduction, and Its Historical Background; American Institute of Physics: New York, NY, USA, 1982. [Google Scholar]

- Shubham, S.; Nawaz, M. Estimating Parasitic Capacitances in MEMS Microphones using Finite Element Modeling. In Proceedings of the COMSOL Conference, Boston, MA, USA, 2–4 October 2019. [Google Scholar]

- Beranek, L. Acoustics; American Institute of Physics: New York, NY, USA, 1954. [Google Scholar]

- Aarts, R.M.; Janssen, A.J.E.M. Approximation of the Struve function H1 occurring in impedance calculations. J. Acoust. Soc. Am. 2003, 113, 2635–2637. [Google Scholar] [CrossRef] [PubMed]

- Kuntzman, K.; LoPresti, J.; Du, Y.; Conklin, W.; Naderyan, V.; Lee, S.; Schafer, D.; Pedersen, M.; Loeppert, P. Thermal boundary layer limitations on the performance of micromachined microphones. J. Acoust. Soc. Am. 2018, 144, 2838–2846. [Google Scholar] [CrossRef] [PubMed]

- Naderyan, V.; Raspet, R.; Hickey, C. Thermo-viscous acoustic modeling of perforated micro-electro-mechanical systems (MEMS). J. Acoust. Soc. Am. 2020, 150, 2749–2756. [Google Scholar] [CrossRef] [PubMed]

- Naderyan, V.; Raspet, R.; Hickey, C. Analytical, computational, and experimental study of thermoviscous acoustic damping in perforated micro-electro-mechanical systems with flexible diaphragm. J. Acoust. Soc. Am. 2021, 148, 2376–2385. [Google Scholar] [CrossRef] [PubMed]

- Infineon Inside MEMS Microphone Partners. Available online: https://www.infineon.com/cms/en/product/sensor/mems-microphones/mems-microphones-for-consumer/infineon-inside/ (accessed on 8 November 2021).

- High SNR Microphone with Differential Output and Low Power Mode. Available online: https://invensense.tdk.com/products/analog/ics-40618/ (accessed on 8 November 2021).

- Analog MEMS Microphone. Available online: http://www.zilltek.com/en-us/Product (accessed on 8 November 2021).

- Wide Dynamic Range, High SNR, Small Package Analog Microphone. Available online: https://invensense.tdk.com/products/analog/t4078/ (accessed on 8 November 2021).

| Domain | Flow Variable | Effort Variable | Impedance | Units of Impedance |

|---|---|---|---|---|

| Acoustical | ||||

| Mechanical | ||||

| Electrical | Ω |

| Element | Mechanical Equivalent Model | Electrical Equivalent Model | Acoustical Equivalent Model |

|---|---|---|---|

| Mass | . (kg) | Inductance (H) | (kg/m4) |

| Spring | (m/N) | (F) | (m5/N) |

| Damper | (N.s/m) | (Ω) | (N·s/m5) |

| Category | Parameter | Description | Unit |

|---|---|---|---|

| Acoustical (Port and back cavity) | Acoustic port resistance | ||

| Acoustic port inductance | |||

| Front volume inductance | |||

| Front volume compliance | |||

| Acoustical (Vent) | Vent flow resistance | ||

| Acoustical (Backplate) | Backplate hole resistance | ||

| Backplate hole inductance | |||

| Acoustical (Back cavity volume) | Back volume compliance | ||

| TBL * compliance term #1, #2, and #3 | |||

| TBL damping term #1, #2, and #3 | |||

| Mechanical (Diaphragm) | Diaphragm mechanical damper | ||

| Diaphragm mechanical mass | |||

| Diaphragm mechanical compliance | |||

| Mechanical (Backplate) | Backplate mechanical damper | ||

| Backplate mechanical mass | |||

| Backplate mechanical compliance | |||

| Electrical (MEMS and ASIC) | Motor Capacitance (including MEMS parasitic capacitances) | ||

| ASIC input Capacitance |

| Diaphragm Boundary Condition | Volume Displacement, | Maximum (m) | Simulated Effective Area Coefficient, β |

|---|---|---|---|

| Constrained | 0.33 | ||

| Simply supported | 0.46 | ||

| Free plate with Peripheral Post | 0.41 | ||

| Free plate with Peripheral and Center Post | 0.61 | ||

| Semiconstrained with Peripheral Post | 0.41 | ||

| Semiconstrained with Peripheral Post and Center Post | 0.61 | ||

| Semiconstrained with Peripheral Post and Center Post under bias | 0.7 |

| Expression | Unit | Description |

|---|---|---|

| Specific Acoustic Impedance | ||

| Mechanical Impedance |

| Property | Value |

|---|---|

| Diaphragm diameter | ) |

| Diaphragm thickness | ) |

| Spring long arm length | ) |

| Spring short arm length | ) |

| Spring width | ) |

| Gap between springs | ) |

| Spring count | 8 |

| Category | Parameter | Description | Value | Unit |

|---|---|---|---|---|

| Package | Back cavity volume | |||

| Acoustic port length | ||||

| Acoustic port radius | ||||

| Front cavity volume | ||||

| MEMS | Diaphragm radius | |||

| Diaphragm thickness | ||||

| Acoustic hole radius | ||||

| Average gap after bias over electrode region | ||||

| Bias Voltage | ||||

| MEMS total capacitance | 0.9 | |||

| MEMS parasitic capacitance [30] | 0.12 | |||

| Diaphragm resonance in characterization package, measured in air | 39 | |||

| Diaphragm compliance | 2.5 | |||

| Low-frequency corner | 35 | |||

| Backplate damping | ||||

| Effective acoustic diaphragm mass | ||||

| α | Effective mass coefficient for simply supported plate | 0.296 | ||

| Effective diaphragm moving area | ||||

| β | Effective area coefficient | 0.7 | ||

| φ | Electrostatic coupling coefficient (Transduction factor) |

| Symbol | Description | Expression | Unit |

|---|---|---|---|

| Port mass | |||

| Port resistance | |||

| Front cavity compliance | |||

| Back cavity compliance |

| Property | Value |

|---|---|

| Sensitivity | −38 dBV/Pa |

| Signal-to-noise ratio (SNR) | 67 dBA |

| Total harmonic distortion (THD) | 7.2% at 134 dB SPL |

| Bandwidth | 35–10 kHz |

| Motor capacitance | 0.9 pF |

| Bias voltage | 37 V |

| Pull-in voltage | 50 V |

| Microphone | ASIC Interface | Sensitivity | SNR (dBA) | AOP (dB SPL) | Package Size (mm × mm × mm) |

|---|---|---|---|---|---|

| Knowles, Proposed design | Analog | −38 dBV/Pa | 67 | >134 | 3.25 × 1.90 × 0.9 |

| Infineon partner, MMA208-001 [36] | Analog | −38 dBV/Pa | 67 | 135 | 3.35 × 2.50 × 0.98 |

| Infineon partner, MMA208-W02 [36] | Analog | −38 dBV/Pa | 66 | 136 | 3.35 × 2.50 × 0.98 |

| Infineon partner, MA-ERA381-H43-1 [36] | Analog | −38 dBV/Pa | 65.5 | 137 | 3.35 × 2.50 × 0.98 |

| Infineon partner, S14OB381 [36] | Analog | −38 dBV/Pa | 65 | 135 | 3.35 × 2.50 × 0.98 |

| TDK InvenSense, ICS-40618 [37] | Analog | −38 dBV/Pa | 67 | 132 | 3.5 × 2.65 × 0.98 |

| ZillTek, ZTS6554 [38] | Analog | −37 dBV/Pa | 67 | 120 | 3.35 × 2.50 × 0.98 |

| ZillTek, ZTS6054 [38] | Analog | −38 dBV/Pa | 65 | 125 | 3.35 × 2.50 × 0.98 |

| TDK InvenSense, ICS-4078 [39] | Analog | −38 dBV/Pa | 66 | 135 | 3.35 × 2.50 × 0.98 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shubham, S.; Seo, Y.; Naderyan, V.; Song, X.; Frank, A.J.; Johnson, J.T.M.G.; da Silva, M.; Pedersen, M. A Novel MEMS Capacitive Microphone with Semiconstrained Diaphragm Supported with Center and Peripheral Backplate Protrusions. Micromachines 2022, 13, 22. https://doi.org/10.3390/mi13010022

Shubham S, Seo Y, Naderyan V, Song X, Frank AJ, Johnson JTMG, da Silva M, Pedersen M. A Novel MEMS Capacitive Microphone with Semiconstrained Diaphragm Supported with Center and Peripheral Backplate Protrusions. Micromachines. 2022; 13(1):22. https://doi.org/10.3390/mi13010022

Chicago/Turabian StyleShubham, Shubham, Yoonho Seo, Vahid Naderyan, Xin Song, Anthony J. Frank, Jeremy Thomas Morley Greenham Johnson, Mark da Silva, and Michael Pedersen. 2022. "A Novel MEMS Capacitive Microphone with Semiconstrained Diaphragm Supported with Center and Peripheral Backplate Protrusions" Micromachines 13, no. 1: 22. https://doi.org/10.3390/mi13010022

APA StyleShubham, S., Seo, Y., Naderyan, V., Song, X., Frank, A. J., Johnson, J. T. M. G., da Silva, M., & Pedersen, M. (2022). A Novel MEMS Capacitive Microphone with Semiconstrained Diaphragm Supported with Center and Peripheral Backplate Protrusions. Micromachines, 13(1), 22. https://doi.org/10.3390/mi13010022