Localized Characteristics of the First Three Typical Condensation Frosting Stages in the Edge Region of a Horizontal Cold Plate

Abstract

1. Introduction

2. Methodology

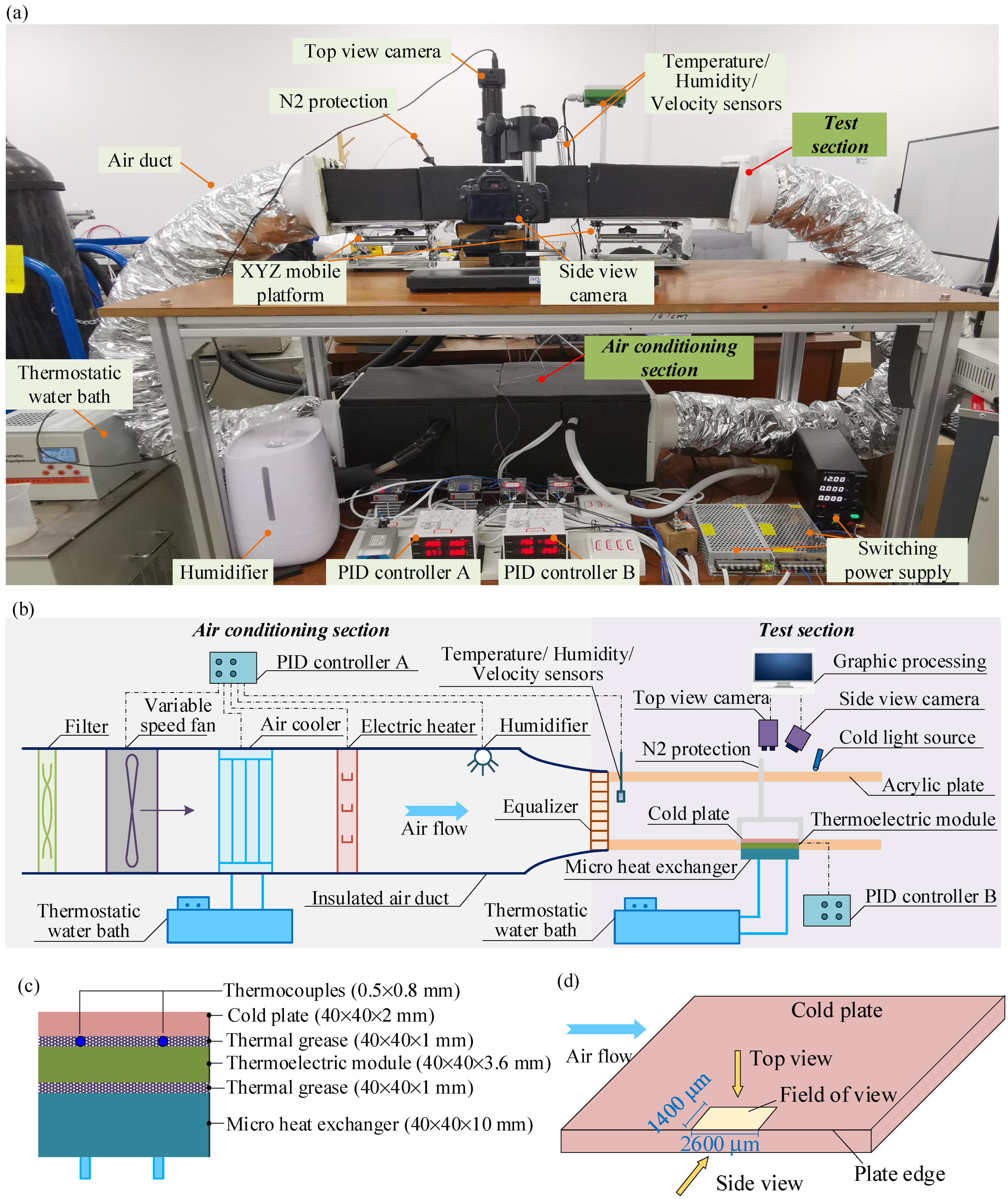

2.1. Experimental Set-Up

2.2. Experimental Procedure and Conditions

- Preparation: (1) adjust the air temperature, relative humidity, and velocity to the designated values, on the air conditioning unit; (2) place the N2 mask on the cold plate to avoid undesired condensation; (3) adjust the cold plate surface temperature to the designated value by the thermoelectric module;

- Frosting experiment: (1) remove the N2 mask to allow the processed humid air to directly contact with the cold plate; (2) maintain the air temperature, relative humidity and velocity, and cold plate surface temperature at the designated values;

- Defrosting experiment: (1) turn off the air conditioning unit when the frosting time reached the set value; (2) heat the cold plate by the thermoelectric module to melt frost; (3) wipe away the melted water on the cold plate and clean the cold plate with absolute ethyl alcohol.

2.3. Data Reductions and Error Analysis

3. Results and Discussion

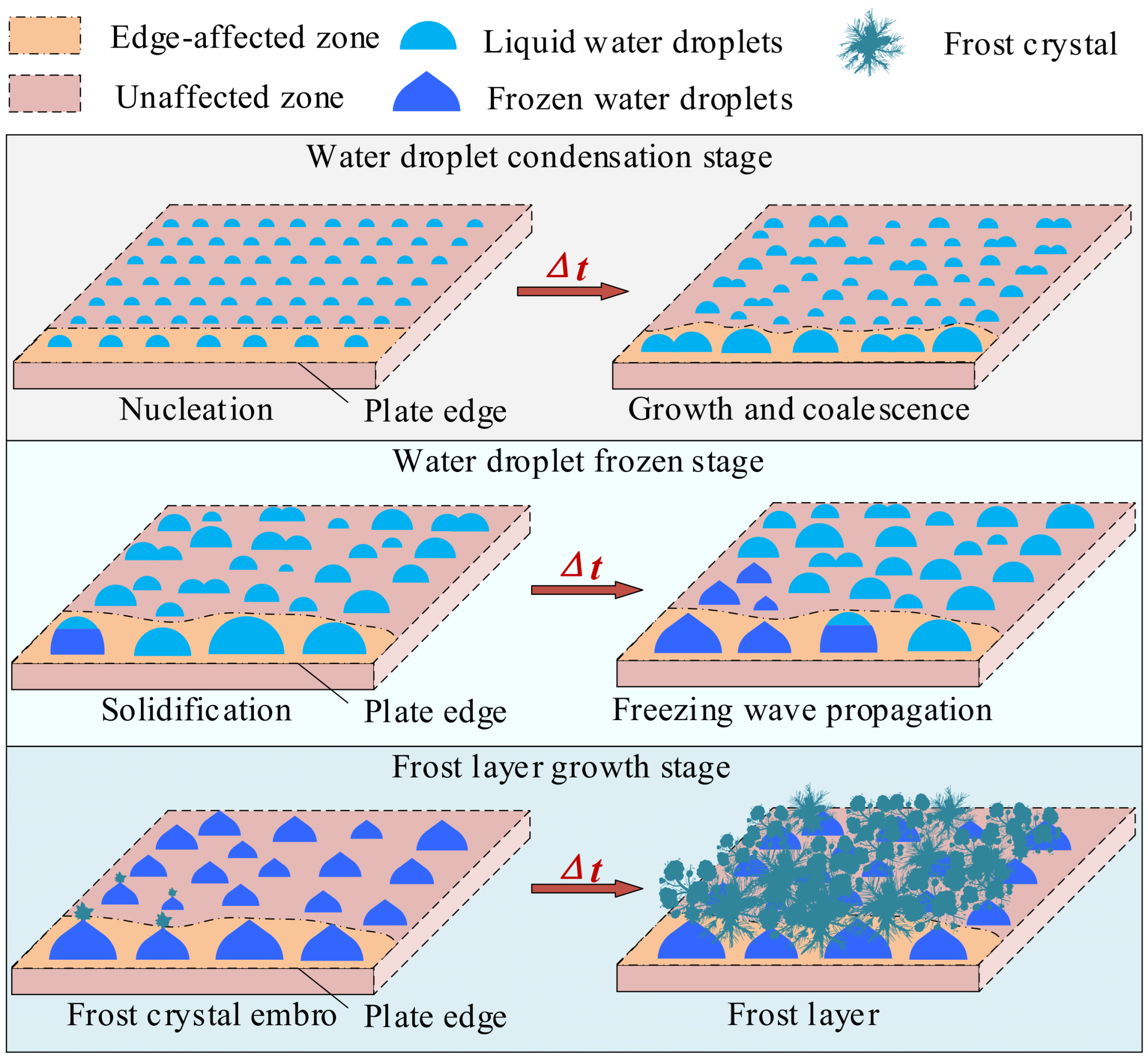

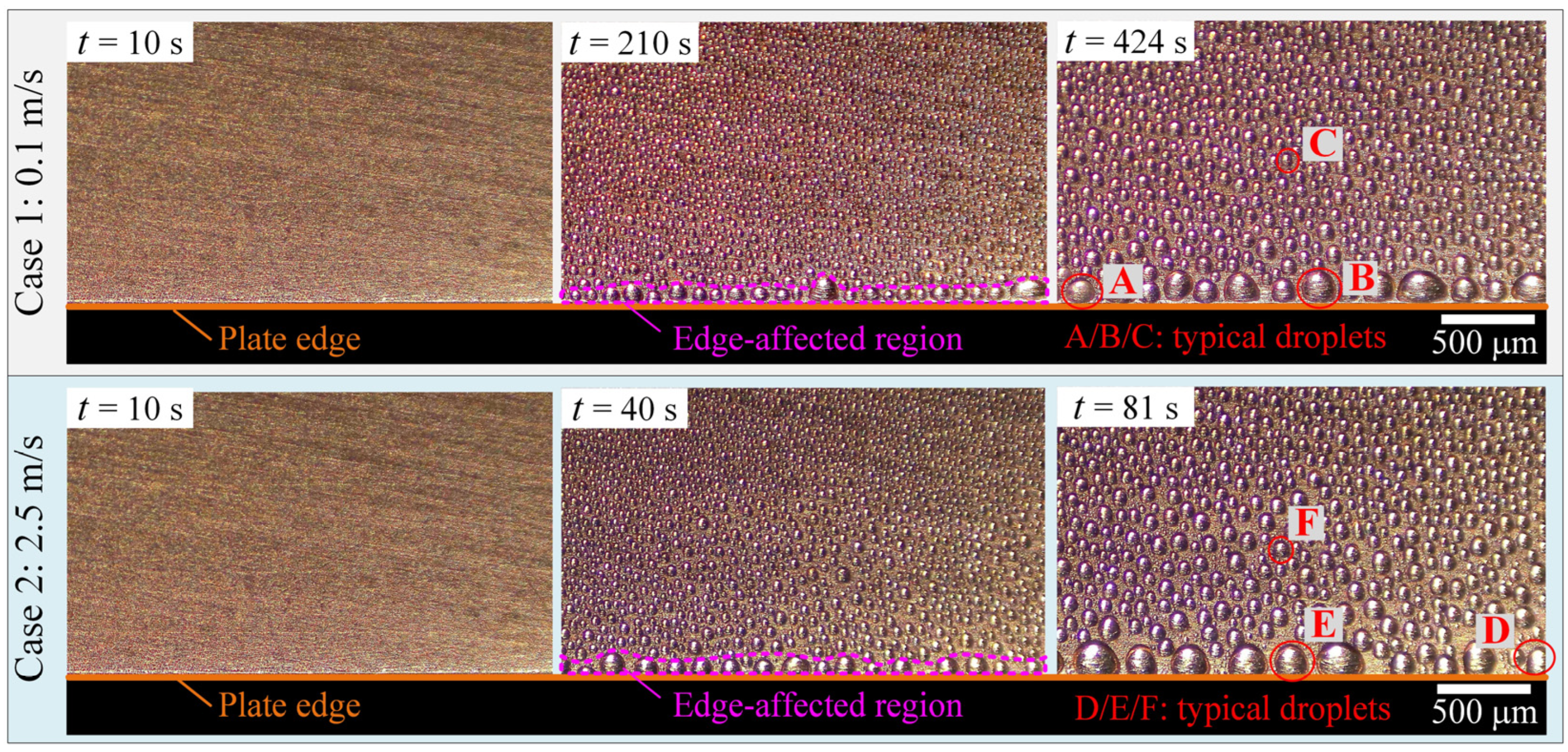

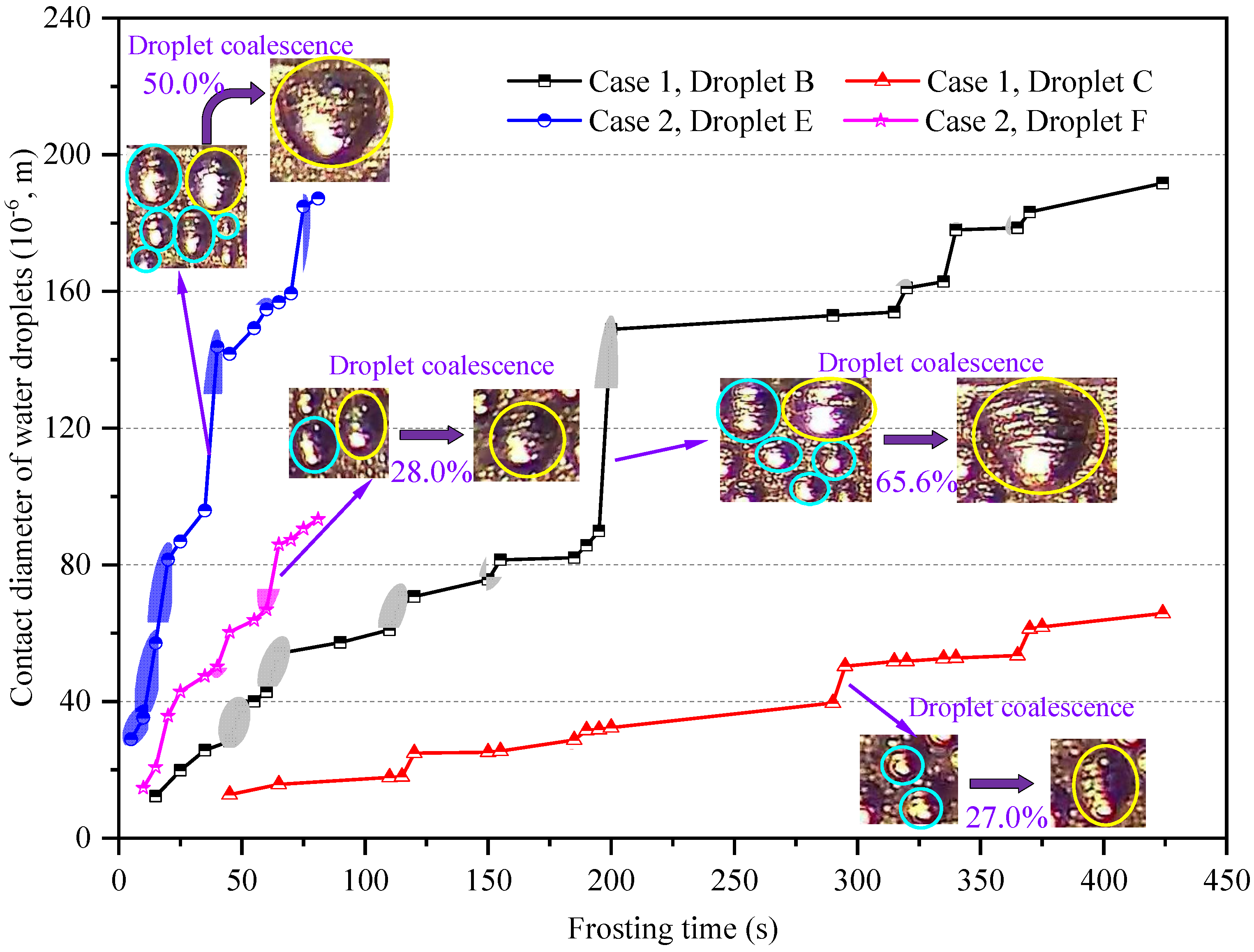

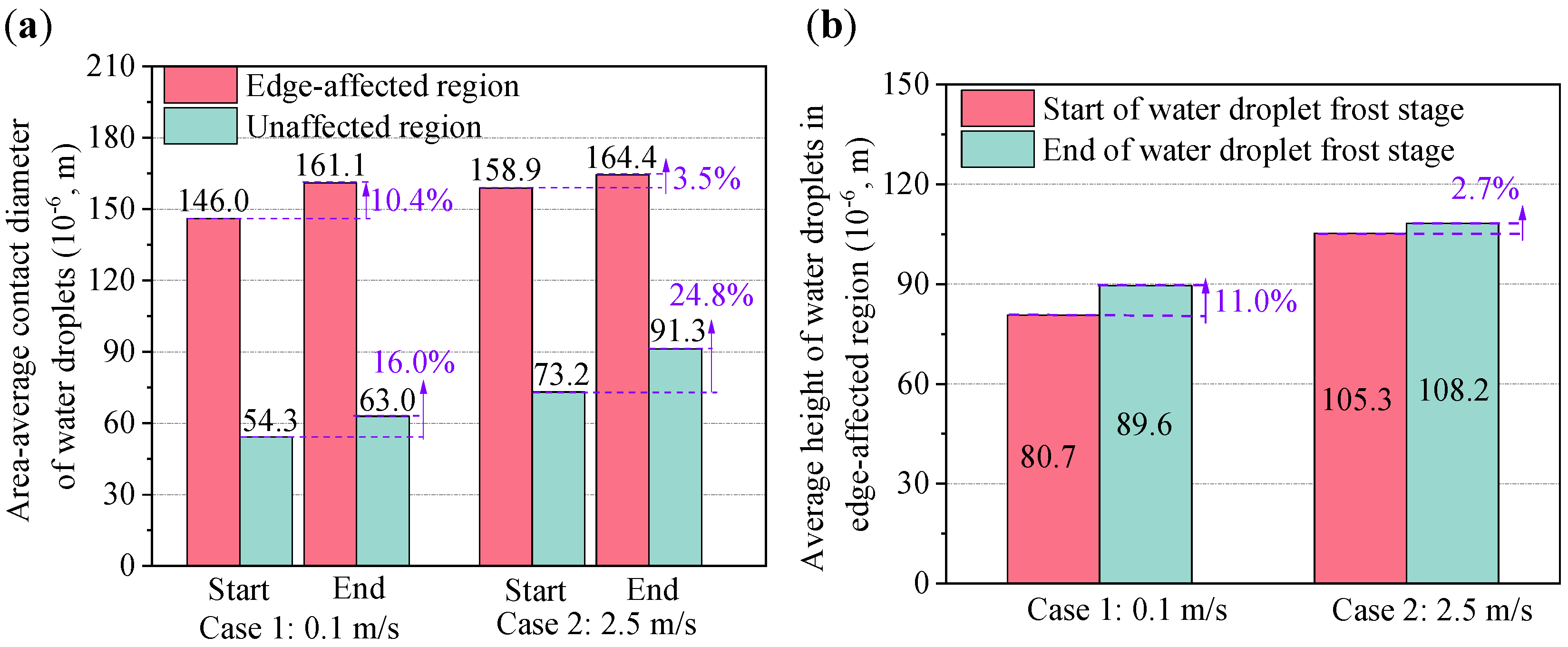

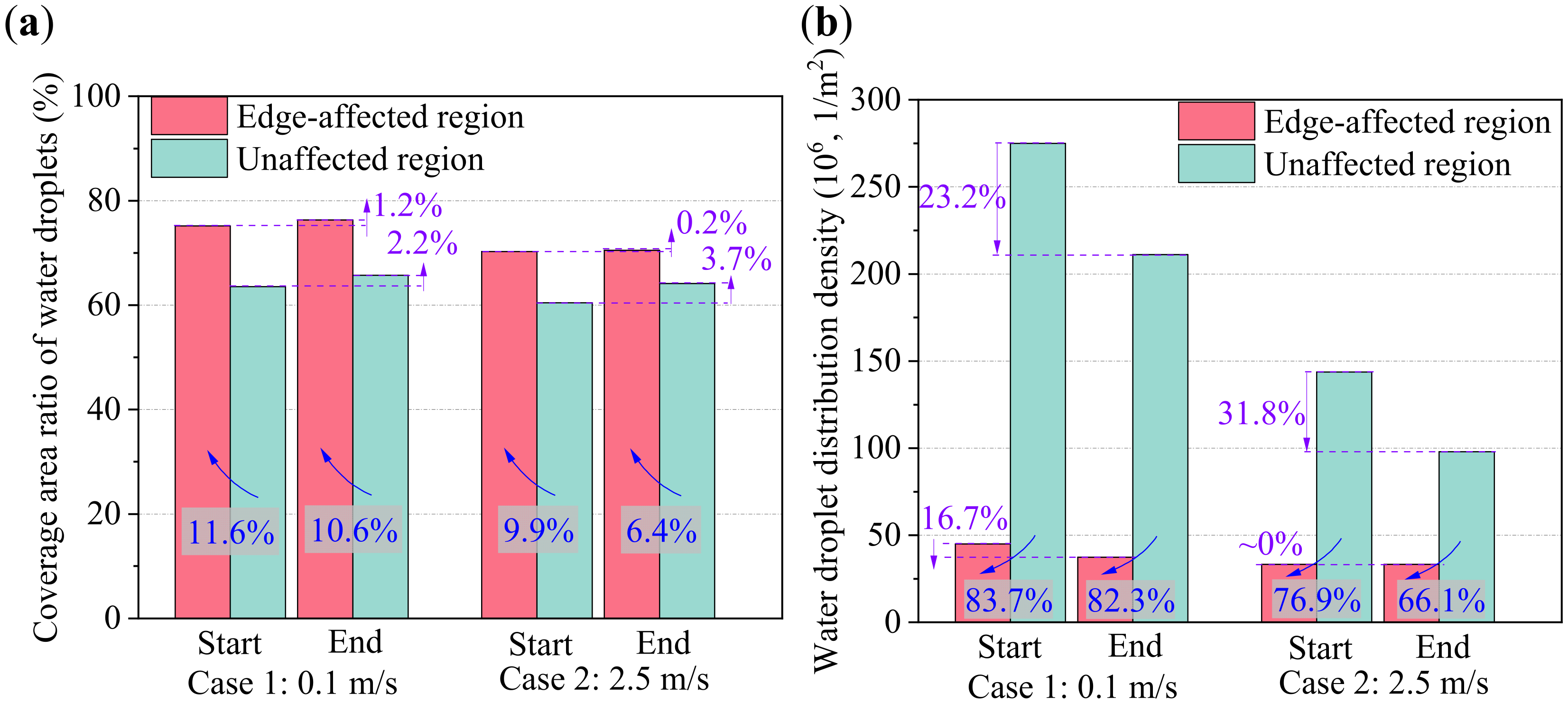

3.1. Localized Water Droplet Condensation Characteristics in Edge-Affected and Unaffected Regions

3.2. Localized Water Droplet Frozen Characteristics in Edge-Affected and Unaffected Regions

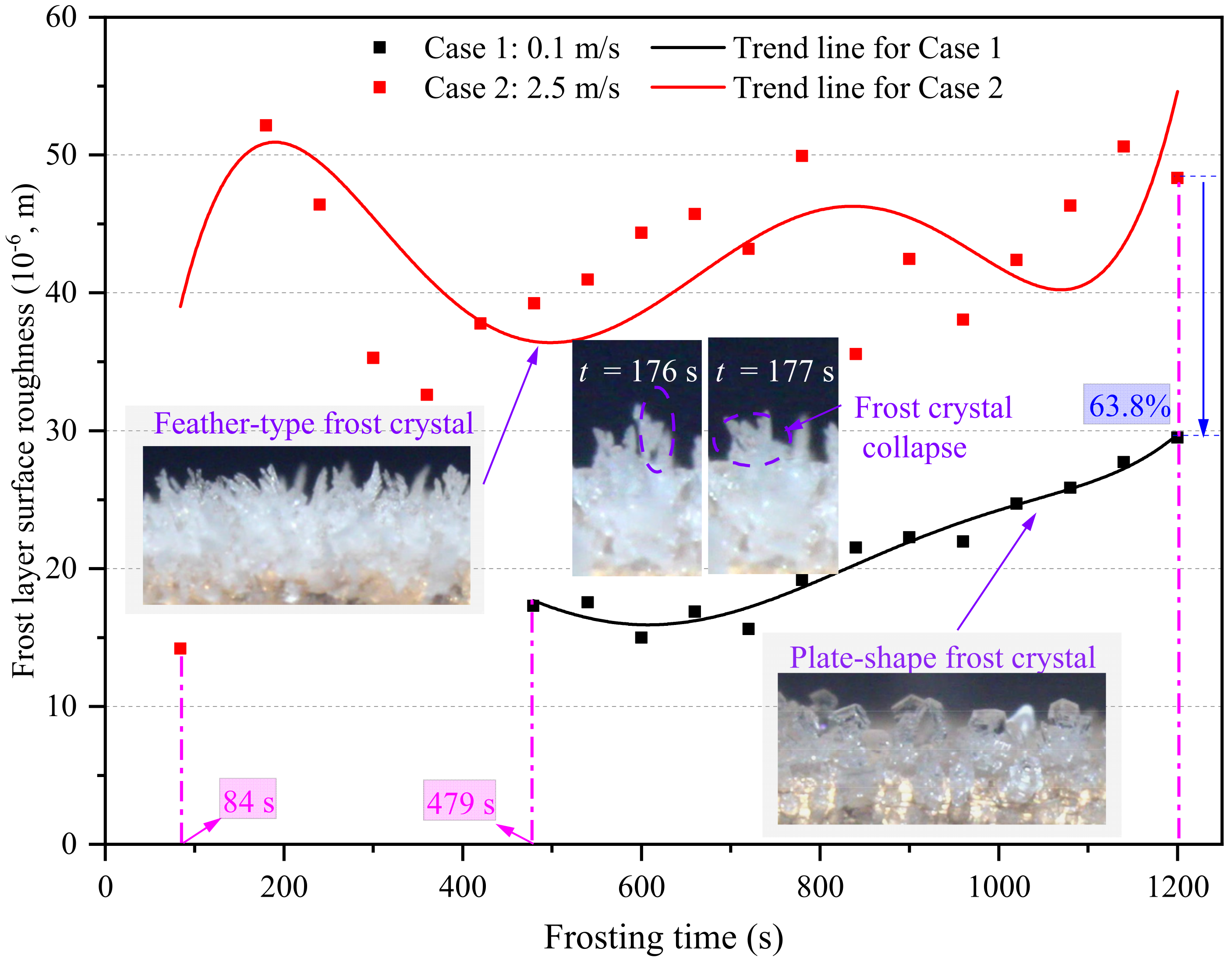

3.3. Localized Frost Layer Growth Characteristics in Edge-Affected Region

4. Conclusions

- (a)

- Forced convection may decrease the WDC stage duration and the influence area of the plate edge when compared with natural convection. The WDC stage duration was notably shortened from 424 to 81 s with a decrease of 80.9% when the air velocity increased from 0.1 to 2.5 m/s. The equivalent width of the edge-affected region under forced convection was 19.3% greater than under natural convection, at the end of their respective WDC stages;

- (b)

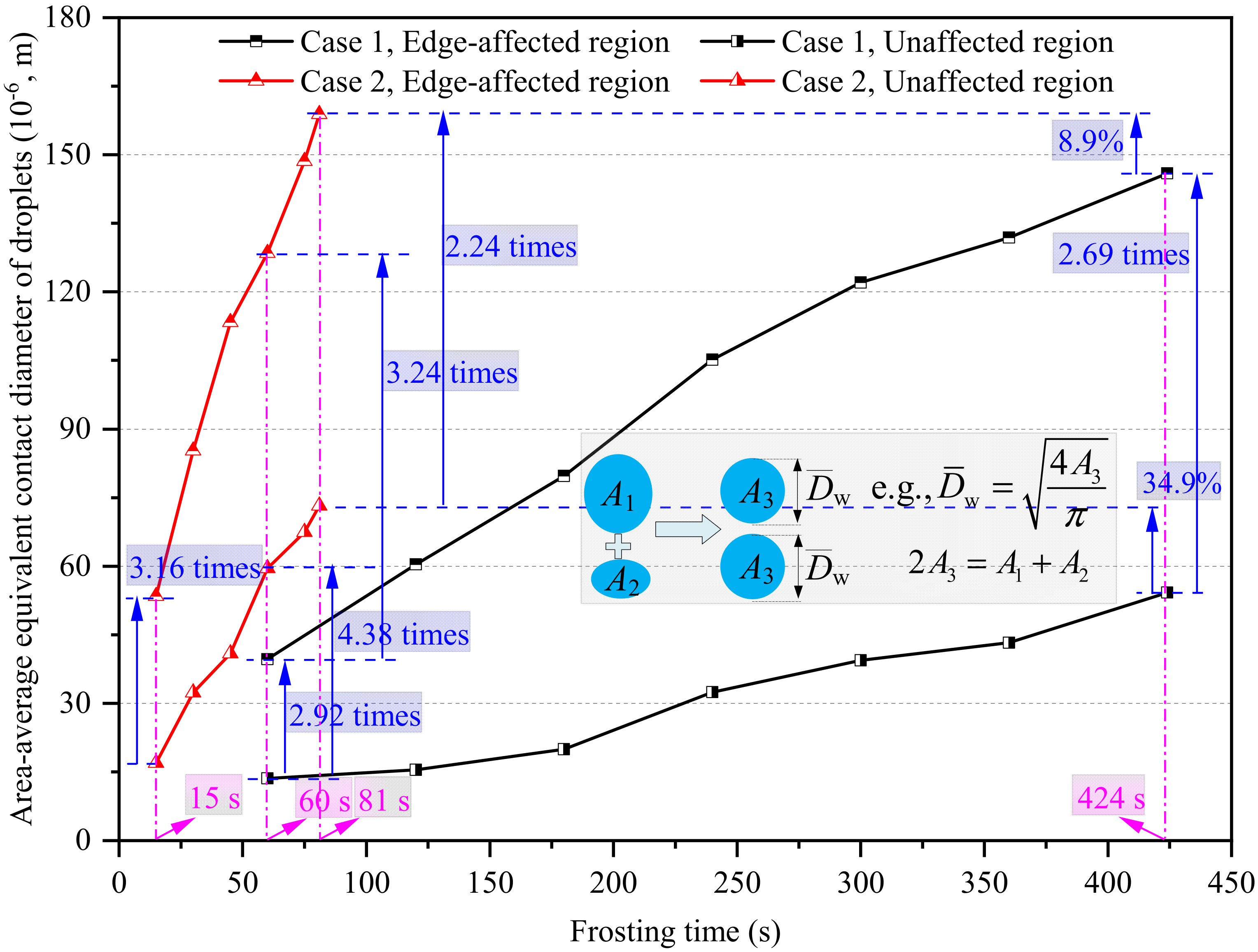

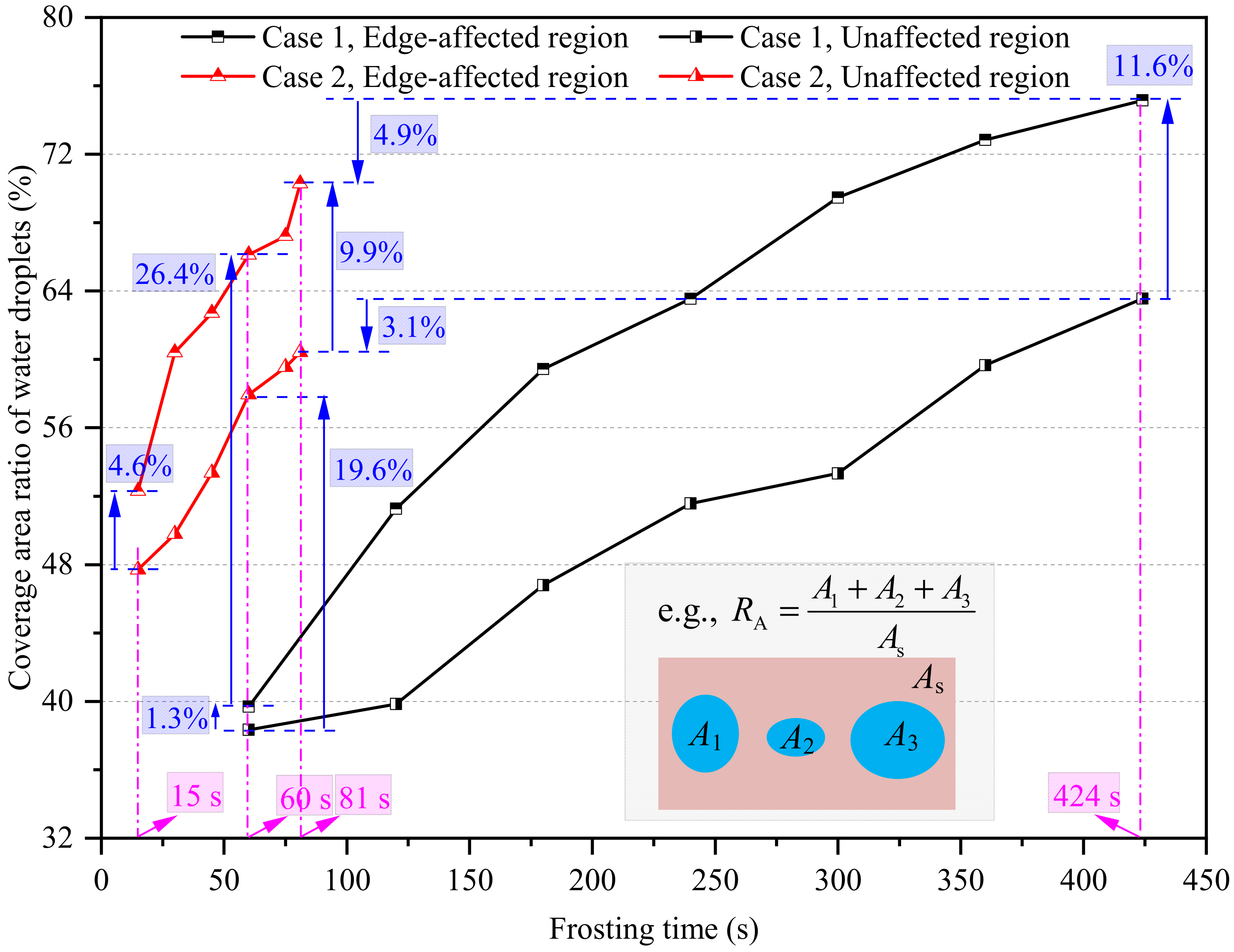

- The plate edge may facilitate the growth rate of water droplets, which increases their size and coverage area ratio at the early frosting stage. The number of droplet coalescence for water droplets in edge-affected regions was around 50% greater than in unaffected regions. At the end of their respective WDC stages, the area-average equivalent contact diameter and coverage area ratio of water droplets in edge-affected regions were 2.69 times and 11.6% greater than those in unaffected regions under natural convection, and the corresponding values were 2.24 times and 9.9% under forced convection;

- (c)

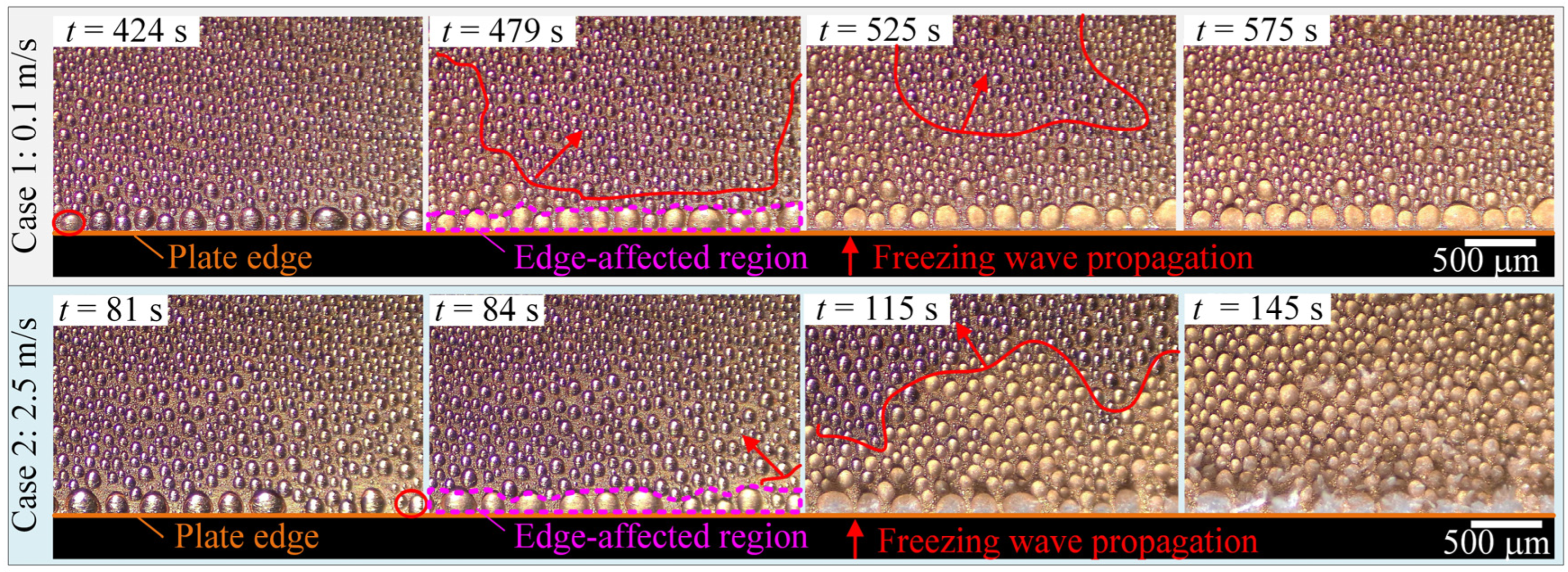

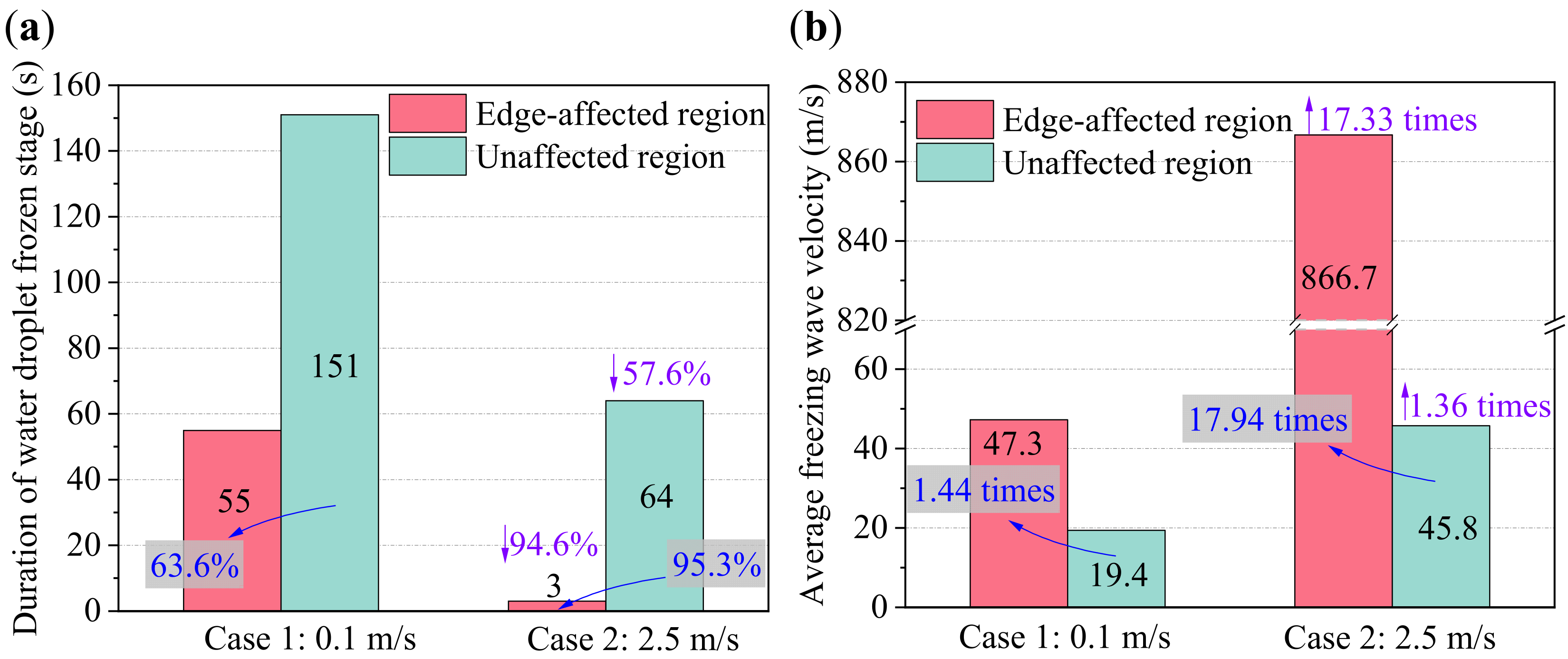

- Both the air velocity and plate edge positively impacted the propagation of the freezing wave at the WDF stage. Compared with the unaffected region, the WDF stage duration in edge-affected regions decreased by 63.6% under natural convection and 95.3% under forced convection, respectively. The average freezing wave propagation velocities in edge-affected and unaffected regions under natural convection were 47.3 × 10−6 and 19.4 ×10−6 m/s, and those under forced convection increased by 17.33 and 1.36 times, respectively. Compared with the unaffected region, the average freezing wave propagation velocities in edge-affected regions increased by 1.44 and 17.94 times under natural and forced convection, respectively.

- (d)

- The average frost layer thickness continued to increase at the later FLG stage, even though local reverse melting occurred for part of each frost crystal. The general variation trend in frost layer growth rate under natural convection first increased, and then decreased, while under forced convection it continued to decrease as time passed. The maximum frost layer growth rate under forced convection was 3.46 × 10−6 m/s at 84 s, which was 2.93 times larger than the maximum frost layer growth rate of 0.52 × 10−6 m/s under natural convection at 720 s. Additionally, the frost layer surface roughness under forced convection fluctuated more significantly than under natural convection, and feather-type and plate-type frost crystals were, respectively, observed in the former and latter.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| area (m2) | |

| equivalent diameter (m) | |

| area-average equivalent diameter (m) | |

| FLG | frost layer growth |

| FLFG | frost layer fully growth |

| growth rate (m/s) | |

| water droplet height (m) | |

| average water droplet height (m) | |

| equivalent distance in the corresponding region (m) | |

| length of the edged region (m) | |

| number | |

| coverage area ratio of droplets (%) | |

| root-mean-square roughness (m) | |

| uncertainty (%) | |

| velocity (m/s) | |

| W | equivalent width of the edge-affected region |

| WDC | water droplet condensation |

| WDF | water droplet frozen |

| Greek symbols | |

| thickness (m) | |

| average thickness (m) | |

| water droplet frozen stage duration (s) | |

| time interval used for measuring frost thickness (s) | |

| Subscripts | |

| f | frost |

| fw | freezing wave |

| p | pixel |

| p,in | pixels inside a water droplet |

| sp | sampling points |

| s | surface of the corresponding region |

| w | water |

References

- Azeez Mohammed Hussein, H.; Zulkifli, R.; Faizal Bin Wan Mahmood, W.M.; Ajeel, R.K. Structure parameters and designs and their impact on performance of different heat exchangers: A review. Renew. Sustain. Energy Rev. 2022, 154, 111842. [Google Scholar] [CrossRef]

- Moradkhani, M.A.; Hosseini, S.H.; Song, M.J. Robust and general predictive models for condensation heat transfer inside conventional and mini/micro channel heat exchangers. Appl. Therm. Eng. 2022, 201, 117737. [Google Scholar] [CrossRef]

- Lee, K.; Kim, W. The effects of design and operating factors on the frost growth and thermal performance of a flat plate fin-tube heat exchanger under the frosting condition. KSME Int. J. 1999, 13, 973–981. [Google Scholar] [CrossRef]

- Sadeghianjahromi, A.; Wang, C. Heat transfer enhancement in fin-and-tube heat exchangers—A review on different mechanisms. Renew. Sustain. Energy Rev. 2021, 137, 110470. [Google Scholar] [CrossRef]

- Hu, W.J.; Fan, J.; Song, M.J.; Jia, P.; Gao, Y. An experimental study on the frosting characteristic and performance of a micro-channel evaporator in an air source heat pump unit. Energy Build. 2020, 224, 110254. [Google Scholar] [CrossRef]

- Liu, X.; Yu, J.; Yan, G. An experimental study on the air side heat transfer performance of the perforated fin-tube heat exchangers under the frosting conditions. Appl. Therm. Eng. 2020, 166, 114634. [Google Scholar] [CrossRef]

- Da Silva, D.L.; Melo, C.; Hermes, C.J.L. Effect of frost morphology on the thermal-hydraulic performance of fan-supplied tube-fin evaporators. Appl. Therm. Eng. 2017, 111, 1060–1068. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.Q.; Dong, J.K.; Yao, Y.; Deng, S.M. A comparative study of frosting behavior on finned tube heat exchanger under different fan control modes. Appl. Therm. Eng. 2019, 160, 114063. [Google Scholar] [CrossRef]

- Moallem, E.; Cremaschi, L.; Fisher, D.E.; Hong, T. Effects of frost growth on louvered folded fins of microchannel heat exchangers on the time-dependent air side convective heat transfer coefficient. Exp. Therm. Fluid Sci. 2017, 88, 326–335. [Google Scholar] [CrossRef]

- Kim, K.; Lee, K.S. Frosting and defrosting characteristics of surface-treated louvered-fin heat exchangers: Effects of fin pitch and experimental conditions. Int. J. Heat Mass Transf. 2013, 60, 505–511. [Google Scholar] [CrossRef]

- Kim, K.; Kim, M.H.; Kim, D.R.; Lee, K.S. Thermal performance of microchannel heat exchangers according to the design parameters under the frosting conditions. Int. J. Heat Mass Transf. 2014, 71, 626–632. [Google Scholar] [CrossRef]

- Kim, M.H.; Kim, H.; Kim, D.R.; Lee, K.S. A novel louvered fin design to enhance thermal and drainage performances during periodic frosting/defrosting conditions. Energy Convers. Manag. 2016, 110, 494–500. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.Q.; Dong, J.K.; Yao, Y.; Deng, S.M. An experimental study of frost distribution and growth on finned tube heat exchangers used in air source heat pump units. Appl. Therm. Eng. 2018, 132, 38–51. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.Q.; Dong, J.K.; Yao, Y.; Deng, S.M. An experimental study on the effects of frosting conditions on frost distribution and growth on finned tube heat exchangers. Int. J. Heat Mass Transf. 2019, 128, 748–761. [Google Scholar] [CrossRef]

- Zhang, L.; Song, M.; Mao, N.; Dong, J. Temporal and spatial frost growth prediction of a tube-finned heat exchanger considering frost distribution characteristics. Int. J. Heat Mass Transf. 2022, 183, 122192. [Google Scholar] [CrossRef]

- Zhang, L.; Song, M.; Deng, S.; Shen, J.; Dang, C. Frosting mechanism and behaviors on surfaces with simple geometries: A state-of-the-art literature review. Appl. Therm. Eng. 2022, 215, 118984. [Google Scholar] [CrossRef]

- Choi, C.; Mittal, K.L. Ice Adhesion: Mechanism, Measurement, and Mitigation; John Wiley & Sons: Hoboken, NJ, USA, 2020. [Google Scholar]

- Walker, C.; Lerch, S.; Reininger, M.; Eghlidi, H.; Milionis, A.; Schutzius, T.M.; Poulikakos, D. Desublimation Frosting on Nanoengineered Surfaces. ACS Nano 2018, 12, 8288–8296. [Google Scholar] [CrossRef]

- Byun, S.; Jeong, H.; Hyeon, S.; Lee, K. Quantitative analysis of frosting characteristics at ultra-low temperatures under forced convection conditions. Energy Build. 2021, 248, 111186. [Google Scholar] [CrossRef]

- Qu, K.; Xu, X.; Duan, Z. Experimental study on behavior of initial frost crystal formation under lower water vapor pressures. Int. Commun. Heat Mass 2006, 33, 819–826. [Google Scholar] [CrossRef]

- Piucco, R.O.; Hermes, C.J.L.; Melo, C.; Barbosa, J.R. A study of frost nucleation on flat surfaces. Exp. Therm. Fluid Sci. 2008, 32, 1710–1715. [Google Scholar] [CrossRef]

- Guadarrama-Cetina, J.; Mongruel, A.; González-Viñas, W.; Beysens, D. Percolation-induced frost formation. Europhys. Lett. 2013, 101, 16009. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, Y. Early stage condensation frosting characteristics on plain and nano Al2O3-epoxy mixture-coated brass. Appl. Therm. Eng. 2019, 160, 113971. [Google Scholar] [CrossRef]

- Mengjie, S.; Shangwen, L.; Hosseini, S.H.; Xiaoyan, L.; Zhihua, W. An experimental study on the effect of horizontal cold plate surface temperature on frosting characteristics under natural convection. Appl. Therm. Eng. 2022, 211, 118416. [Google Scholar] [CrossRef]

- Sheng, W.; Pei, Y.; Li, X.; Ming, P.; Zhao, W. Effect of surface characteristics on condensate droplets growth. Appl. Therm. Eng. 2020, 173, 115260. [Google Scholar] [CrossRef]

- Boreyko, J.B.; Collier, C.P. Delayed Frost Growth on Jumping-Drop Superhydrophobic Surfaces. ACS Nano 2013, 7, 1618–1627. [Google Scholar] [CrossRef] [PubMed]

- Boreyko, J.B.; Chen, C. Self-propelled dropwise condensate on superhydrophobic surfaces. Phys. Rev. Lett. 2009, 103, 184501. [Google Scholar] [CrossRef]

- Shen, Y.; Zou, H.; Wang, S. Condensation Frosting on Micropillar Surfaces—Effect of Microscale Roughness on Ice Propagation. Langmuir 2020, 36, 13563–13574. [Google Scholar] [CrossRef]

- Lu, M.; Song, M.; Pang, X.; Dang, C.; Zhang, L. Modeling study on sessile water droplet during freezing with the consideration of gravity, supercooling, and volume expansion effects. Int. J. Multiph. Flow 2022, 147, 103909. [Google Scholar] [CrossRef]

- Dang, Q.; Song, M.J.; Dang, C.B.; Zhan, T.Z.; Zhang, L. Experimental study on solidification characteristics of sessile urine droplets on a horizontal cold plate surface under natural convection. Langmuir 2022, 38, 7846–7857. [Google Scholar] [CrossRef]

- Jung, S.; Tiwari, M.K.; Poulikakos, D. Frost halos from supercooled water droplets. Proc. Natl. Acad. Sci. USA 2012, 109, 16073–16078. [Google Scholar] [CrossRef]

- Graeber, G.; Dolder, V.; Schutzius, T.M.; Poulikakos, D. Cascade Freezing of Supercooled Water Droplet Collectives. ACS Nano 2018, 12, 11274–11281. [Google Scholar] [CrossRef] [PubMed]

- Léoni, A.; Mondot, M.; Durier, F.; Revellin, R.; Haberschill, P. State-of-the-art review of frost deposition on flat surfaces. Int. J. Refrig. 2016, 68, 198–217. [Google Scholar] [CrossRef]

- Lei, S.W.; Song, M.J.; Dang, C.B.; Xu, Y.J.; Shao, K.K. Experimental study on the effect of surface temperature on the frost characteristics of an inverted cold plate under natural convection. Appl. Therm. Eng. 2022, 211, 118470. [Google Scholar] [CrossRef]

- Moradkhani, M.A.; Hosseini, S.H.; Shangwen, L.; Mengjie, S. Intelligent computing approaches to forecast thickness and surface roughness of frost layer on horizontal plates under natural convection. Appl. Therm. Eng. 2022, 217, 119258. [Google Scholar] [CrossRef]

- Brèque, F.; Nemer, M. Frosting modeling on a cold flat plate: Comparison of the different assumptions and impacts on frost growth predictions. Int. J. Refrig. 2016, 69, 340–360. [Google Scholar] [CrossRef]

- Zhang, L.; Song, M.; Hosseini, S.H.; Shen, J.; Jiang, Y. A modeling study of spatial and temporal frost growth on the edge of windward fins for a tube-finned heat exchanger. Int. J. Heat Mass Transf. 2022, 183, 122093. [Google Scholar] [CrossRef]

- Rasul, S.B.; Kajal, A.M.; Khan, A.H. Quantifying Uncertainty in Analytical Measurements. J. Bangladesh Acad. Sci. 2018, 41, 145–163. [Google Scholar] [CrossRef]

- Zhang, L.; Song, M.; Chao, C.Y.H.; Shen, J. An experimental study on the dynamic frosting characteristics on the edge zone of a horizontal copper plate under forced convection. Int. J. Heat Mass Transf. 2023, 200, 123541. [Google Scholar] [CrossRef]

| No. | Item | Unit | Case 1 | Case 2 |

|---|---|---|---|---|

| 1 | Air velocity | m/s | 0.1 | 2.5 |

| 2 | Air temperature | °C | 20.0 | 20.0 |

| 3 | Air relative humidity | - | 50% | 50% |

| 4 | Cold plate surface temperature | °C | −15.0 | −15.0 |

| 5 | Frosting time | s | 1200 | 1200 |

| Characteristic Parameter | Uncertainty |

|---|---|

| Equivalent contact diameter of a water droplet | ±0.9% |

| Area-average equivalent contact diameter of water droplets | ±2.4% |

| Coverage area ratio of water droplets | ±1.1% |

| Average height of water droplets | ±2.8% |

| Frost layer thickness | ±3.7% |

| Frost layer growth rate | ±2.9% |

| Frost layer surface roughness | ±2.2% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Song, M.; Chao, C.Y.H.; Dang, C.; Shen, J. Localized Characteristics of the First Three Typical Condensation Frosting Stages in the Edge Region of a Horizontal Cold Plate. Micromachines 2022, 13, 1906. https://doi.org/10.3390/mi13111906

Zhang L, Song M, Chao CYH, Dang C, Shen J. Localized Characteristics of the First Three Typical Condensation Frosting Stages in the Edge Region of a Horizontal Cold Plate. Micromachines. 2022; 13(11):1906. https://doi.org/10.3390/mi13111906

Chicago/Turabian StyleZhang, Long, Mengjie Song, Christopher Yu Hang Chao, Chaobin Dang, and Jun Shen. 2022. "Localized Characteristics of the First Three Typical Condensation Frosting Stages in the Edge Region of a Horizontal Cold Plate" Micromachines 13, no. 11: 1906. https://doi.org/10.3390/mi13111906

APA StyleZhang, L., Song, M., Chao, C. Y. H., Dang, C., & Shen, J. (2022). Localized Characteristics of the First Three Typical Condensation Frosting Stages in the Edge Region of a Horizontal Cold Plate. Micromachines, 13(11), 1906. https://doi.org/10.3390/mi13111906