Study of Surface Integrity of Titanium Alloy (TC4) by Belt Grinding to Achieve the Same Surface Roughness Range

Abstract

:1. Introduction

2. Materials and Experimental Procedures

2.1. Materials

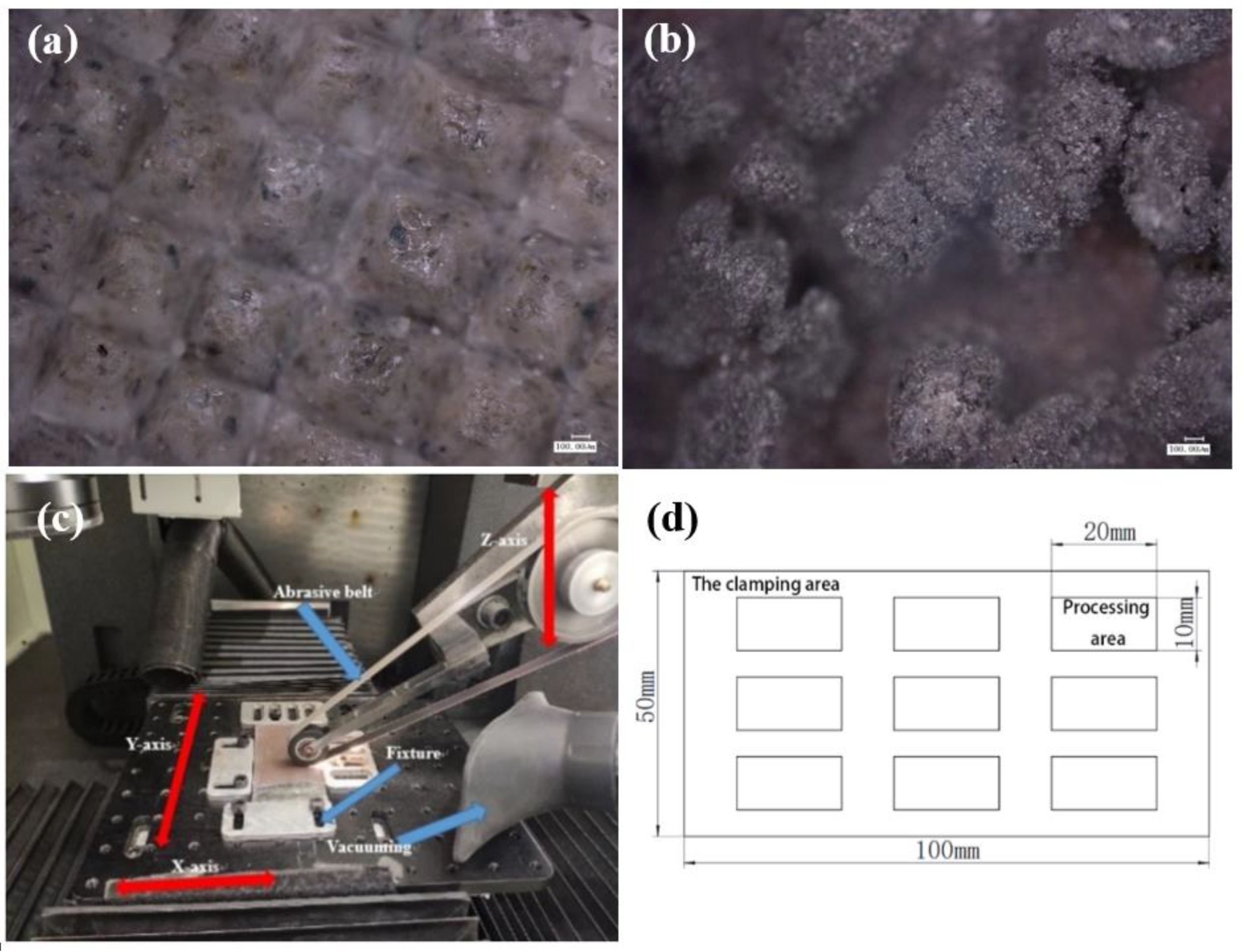

2.2. Experimental Procedure

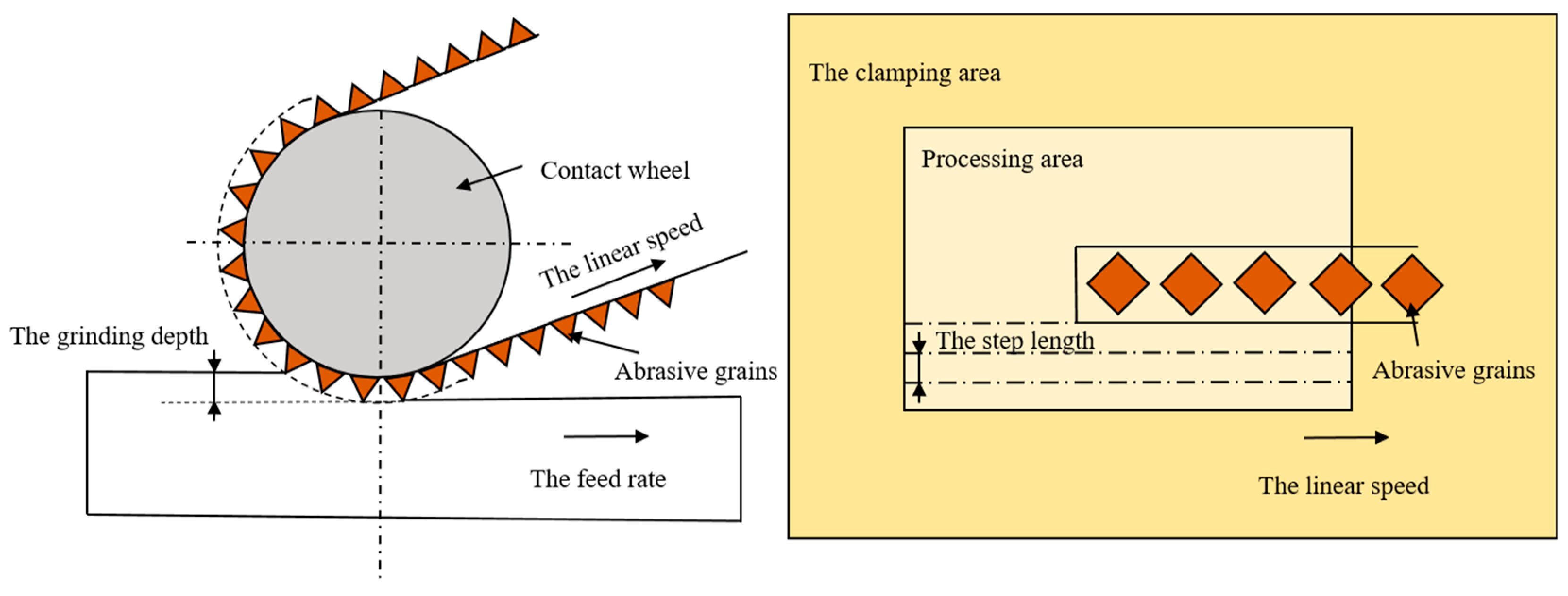

2.2.1. Surface Grinding

2.2.2. Surface Integrity Testing

3. Results

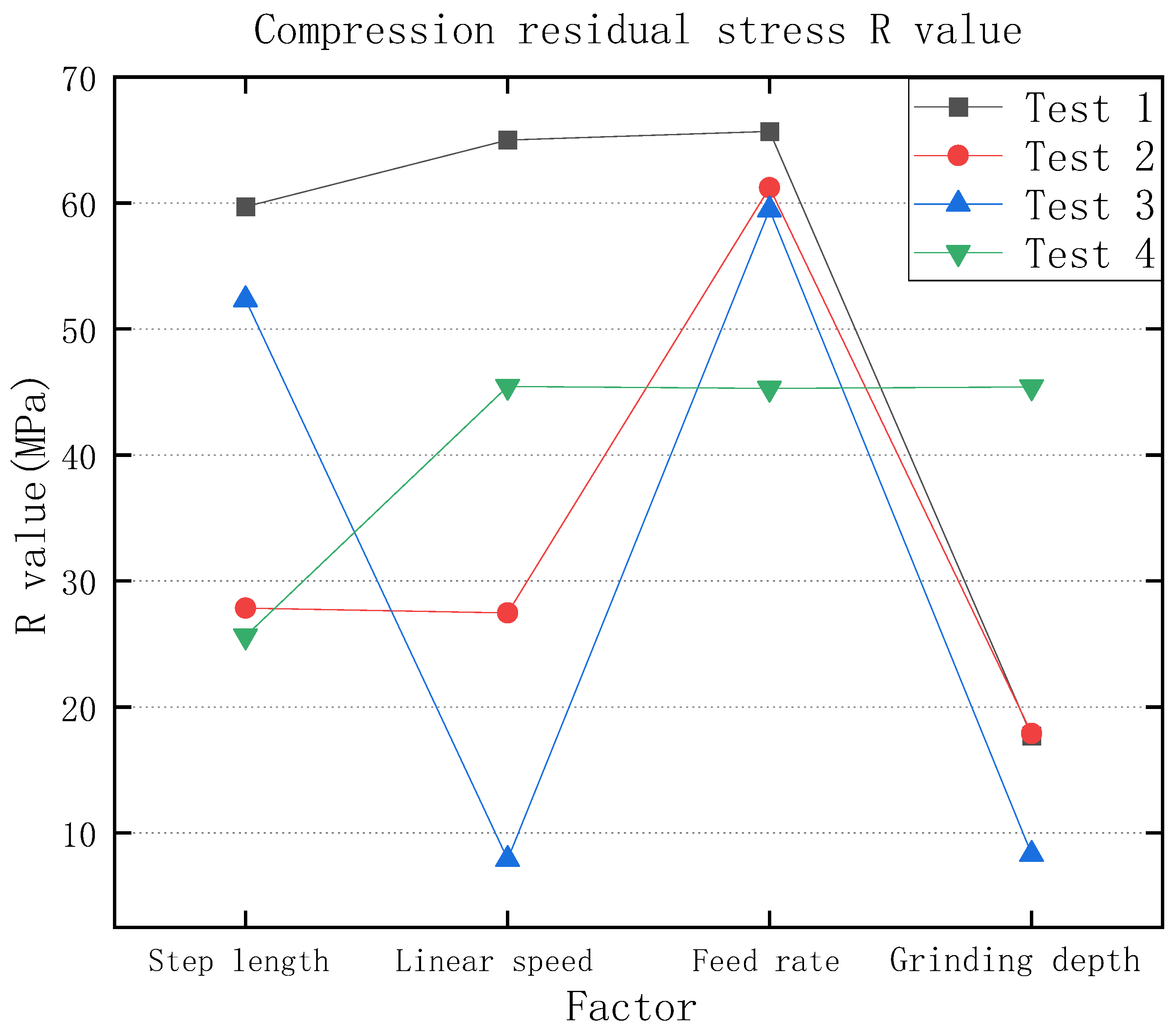

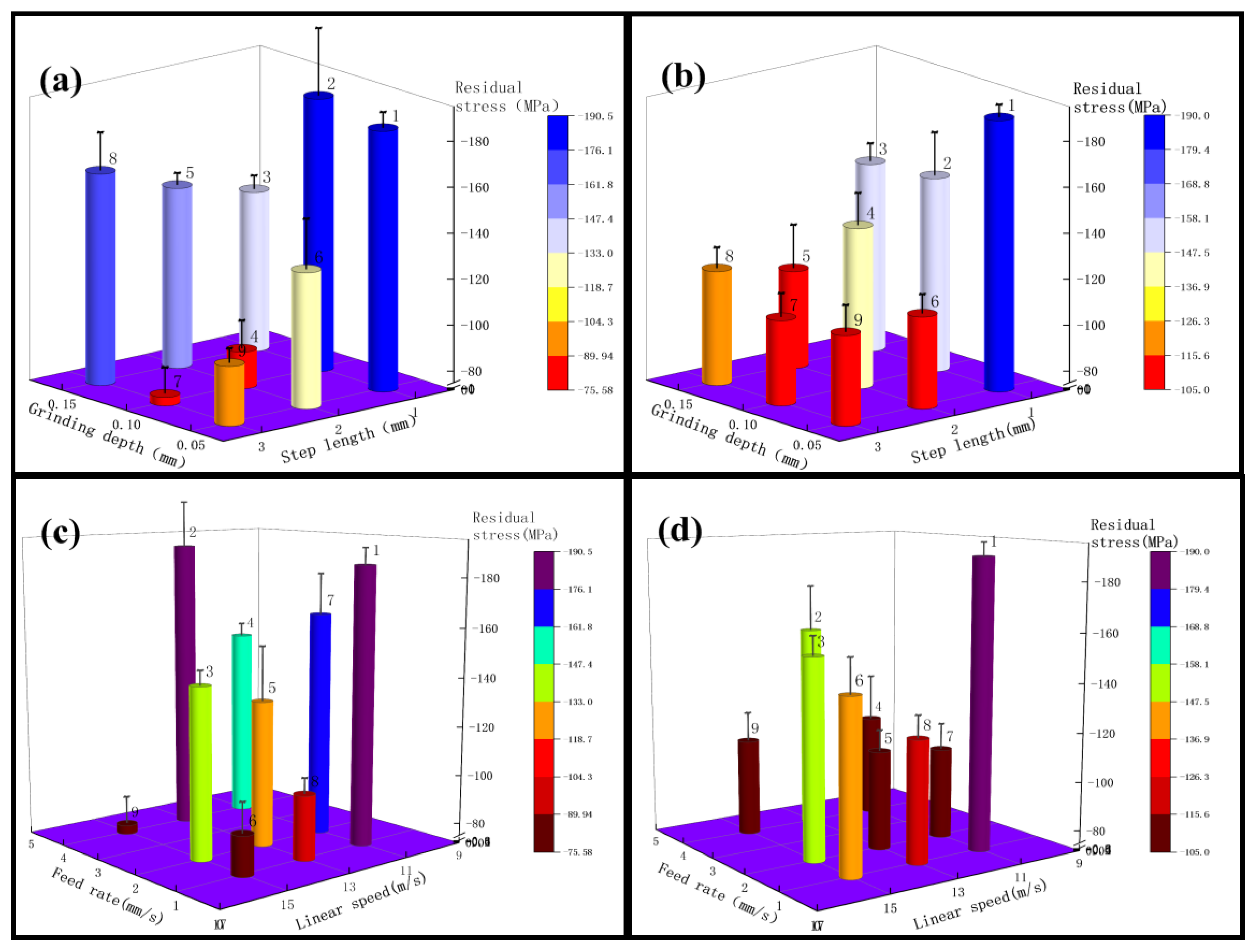

3.1. Effect of Grinding Parameters and Levels on Compression Residual Stresses

3.1.1. Roughness Ra 0.4 μm–0.2 μm Compression Residual Stress Analysis

3.1.2. Compression Residual Stress Analysis for the Roughness Ra of 0.2 μm or Less

3.2. The Effect of Grinding on Surface Hardness

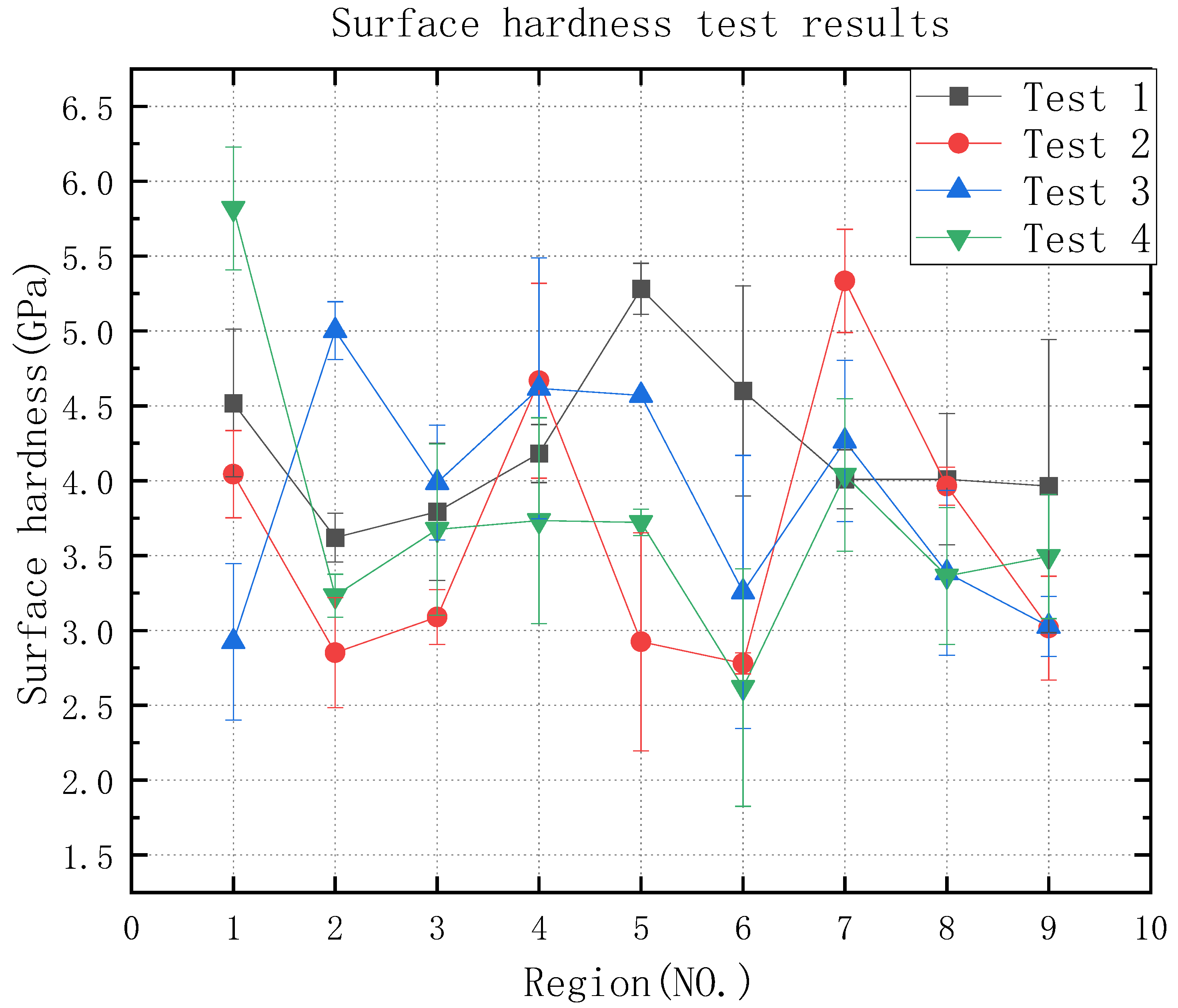

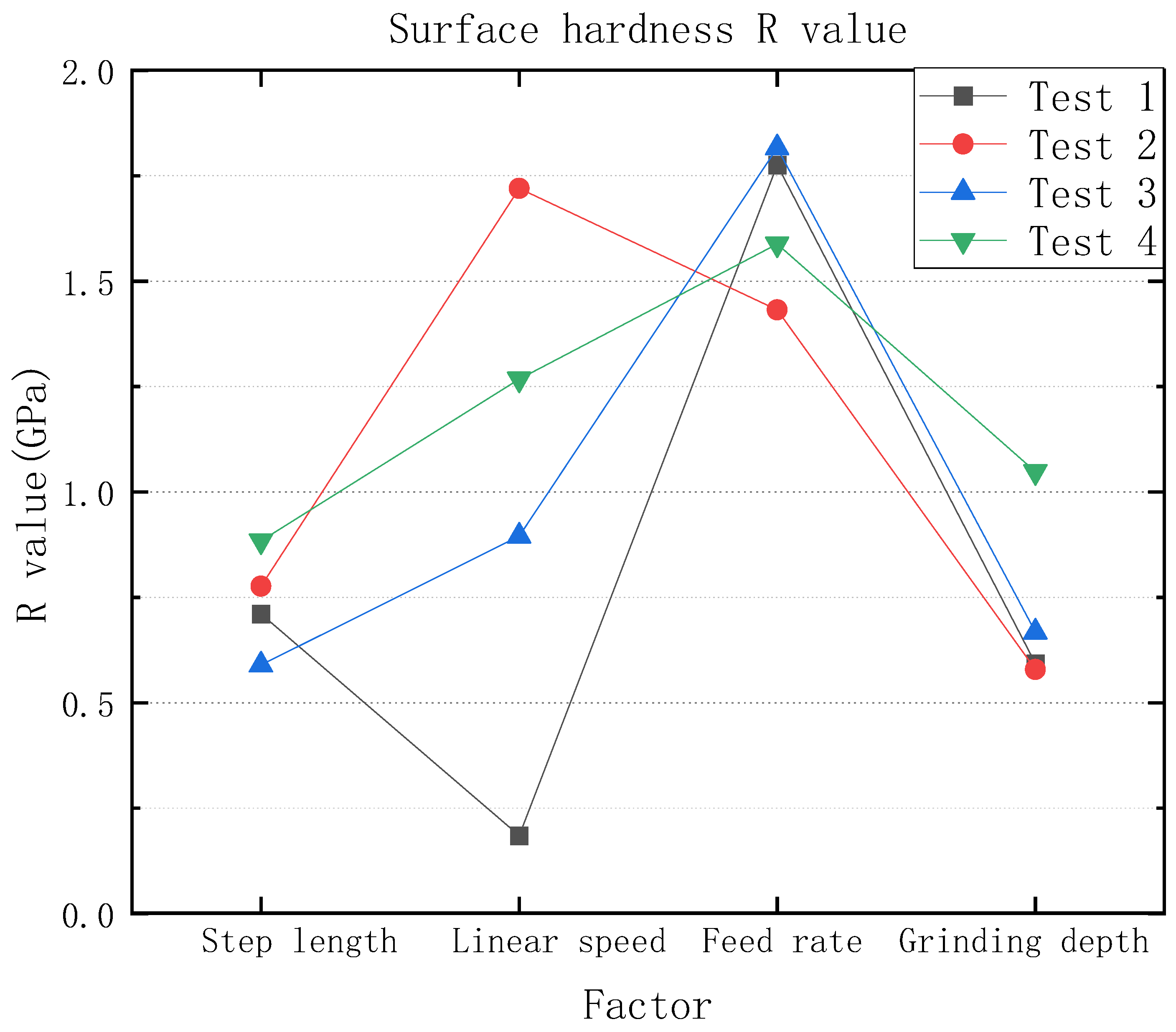

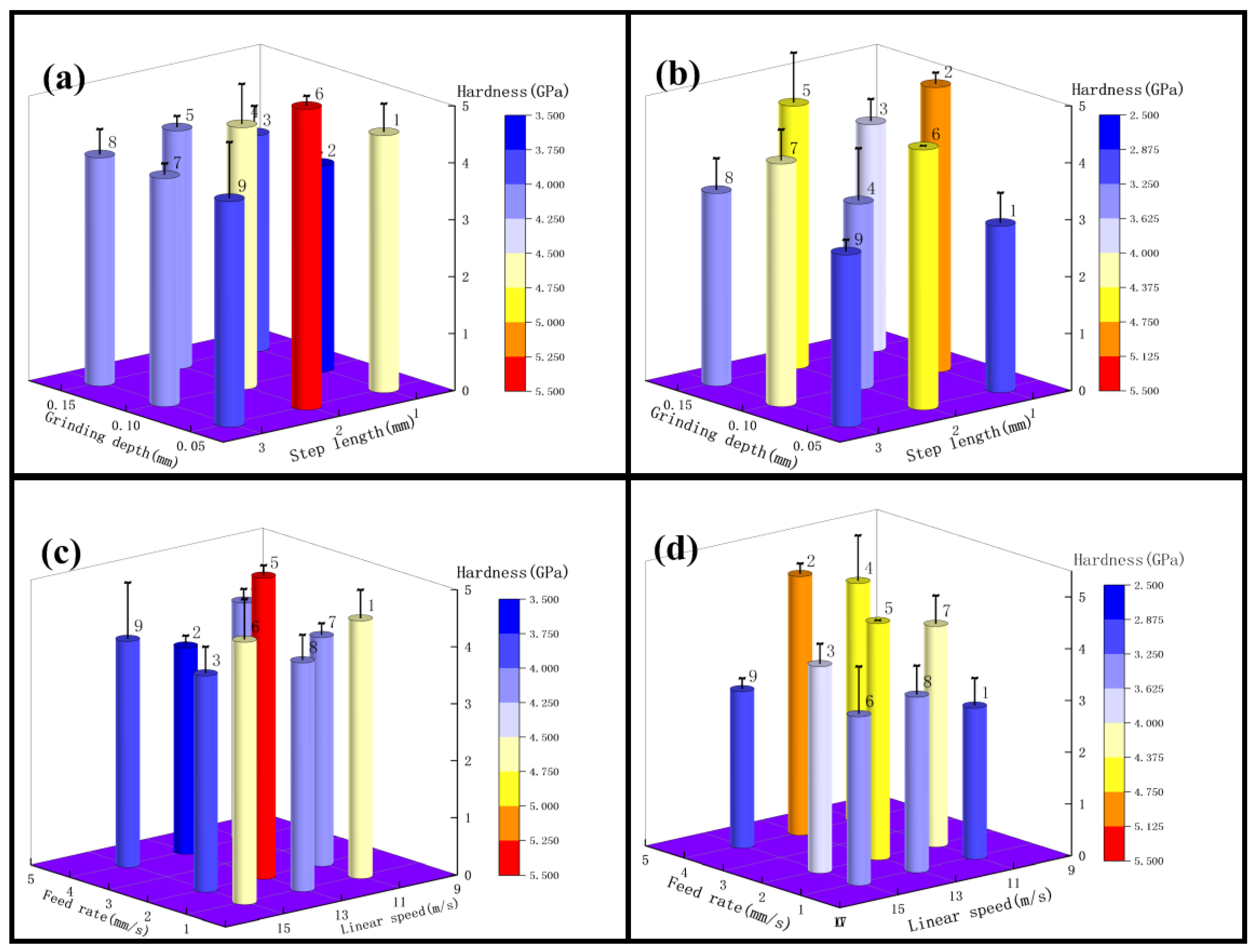

3.2.1. Surface Hardness Analysis for Roughness Ra 0.4 μm–0.2 μm

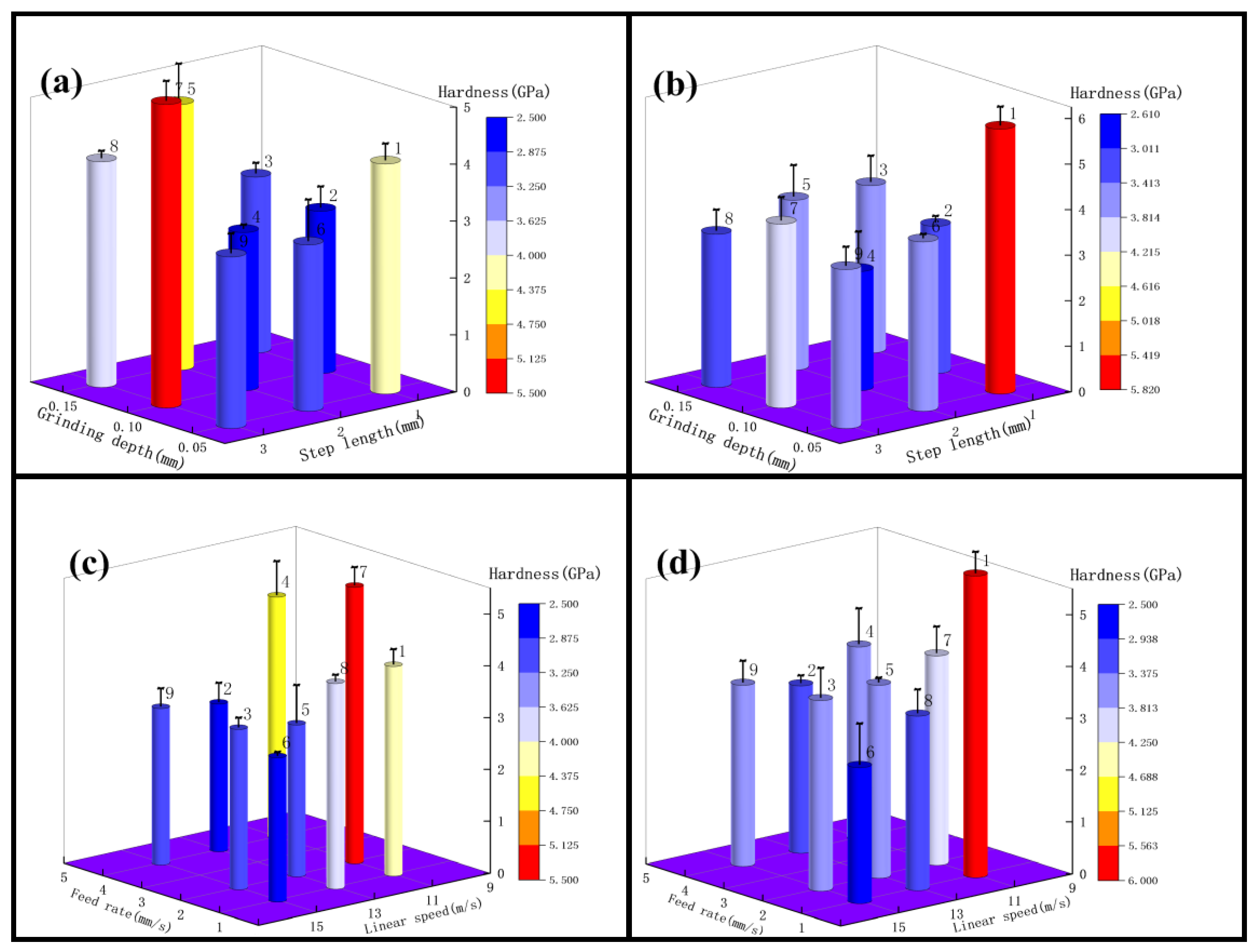

3.2.2. Surface Hardness Analysis for Roughness Ra below 0.2 μm

3.3. Effect of Grinding Parameters and Level on Surface Topography

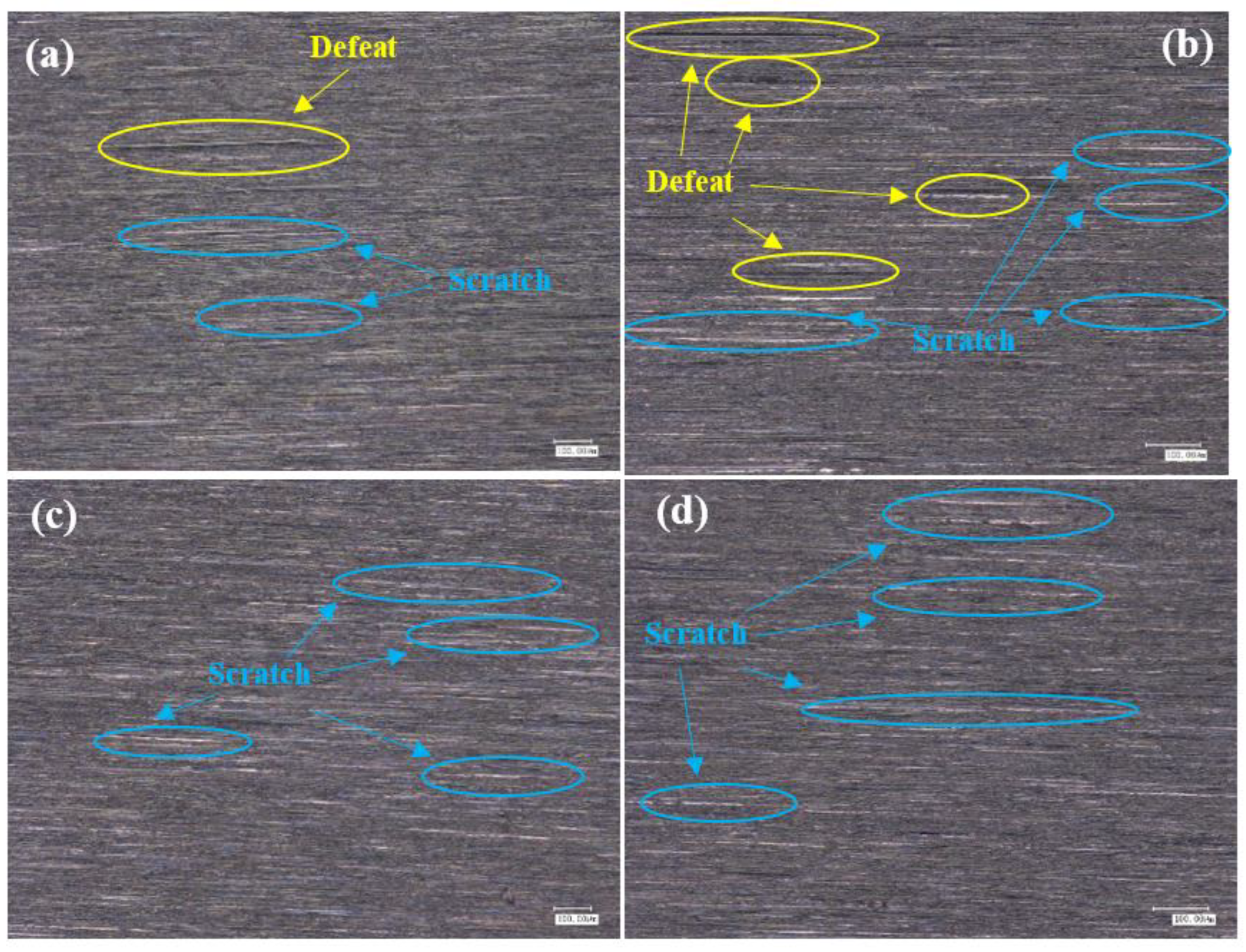

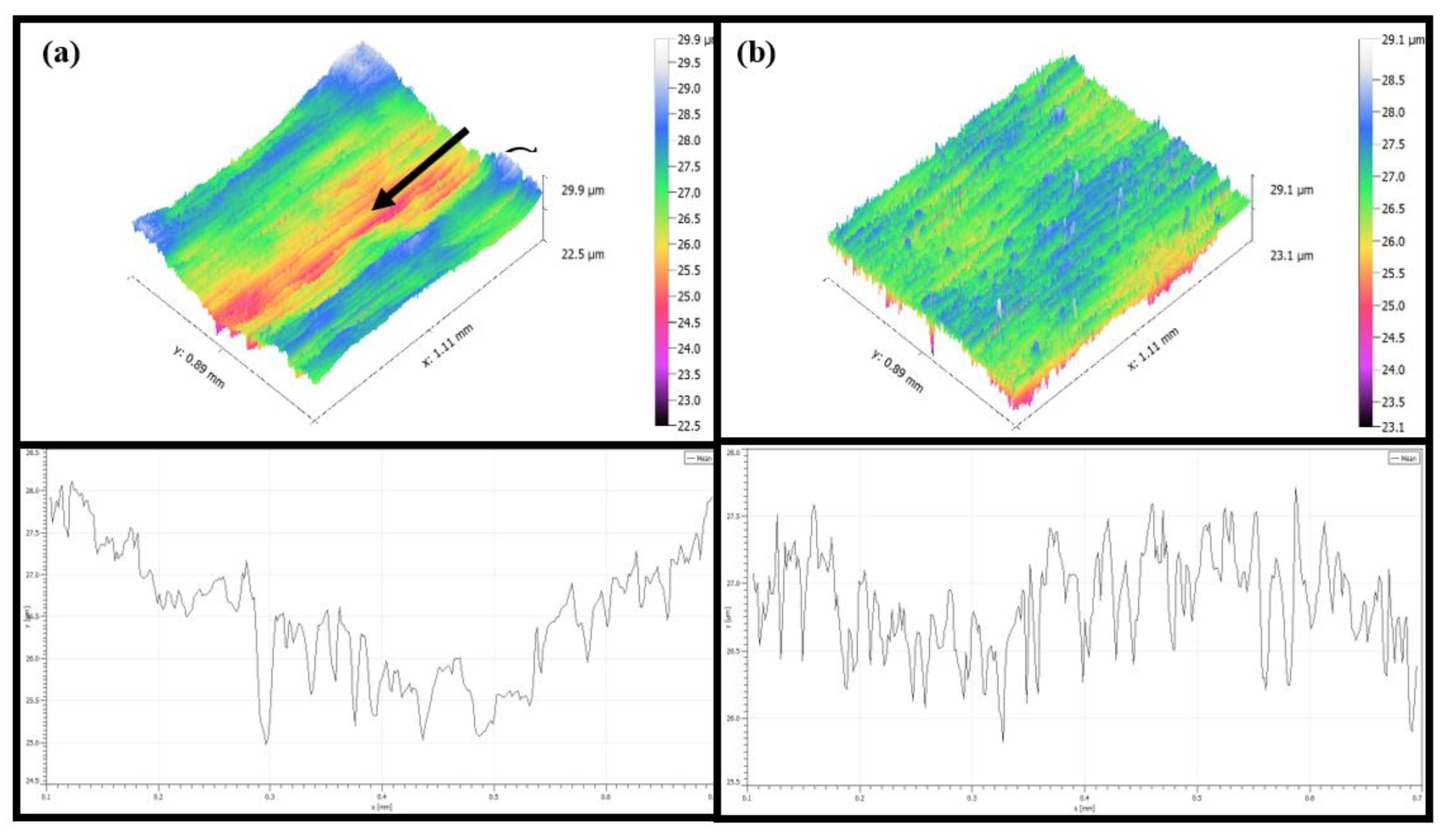

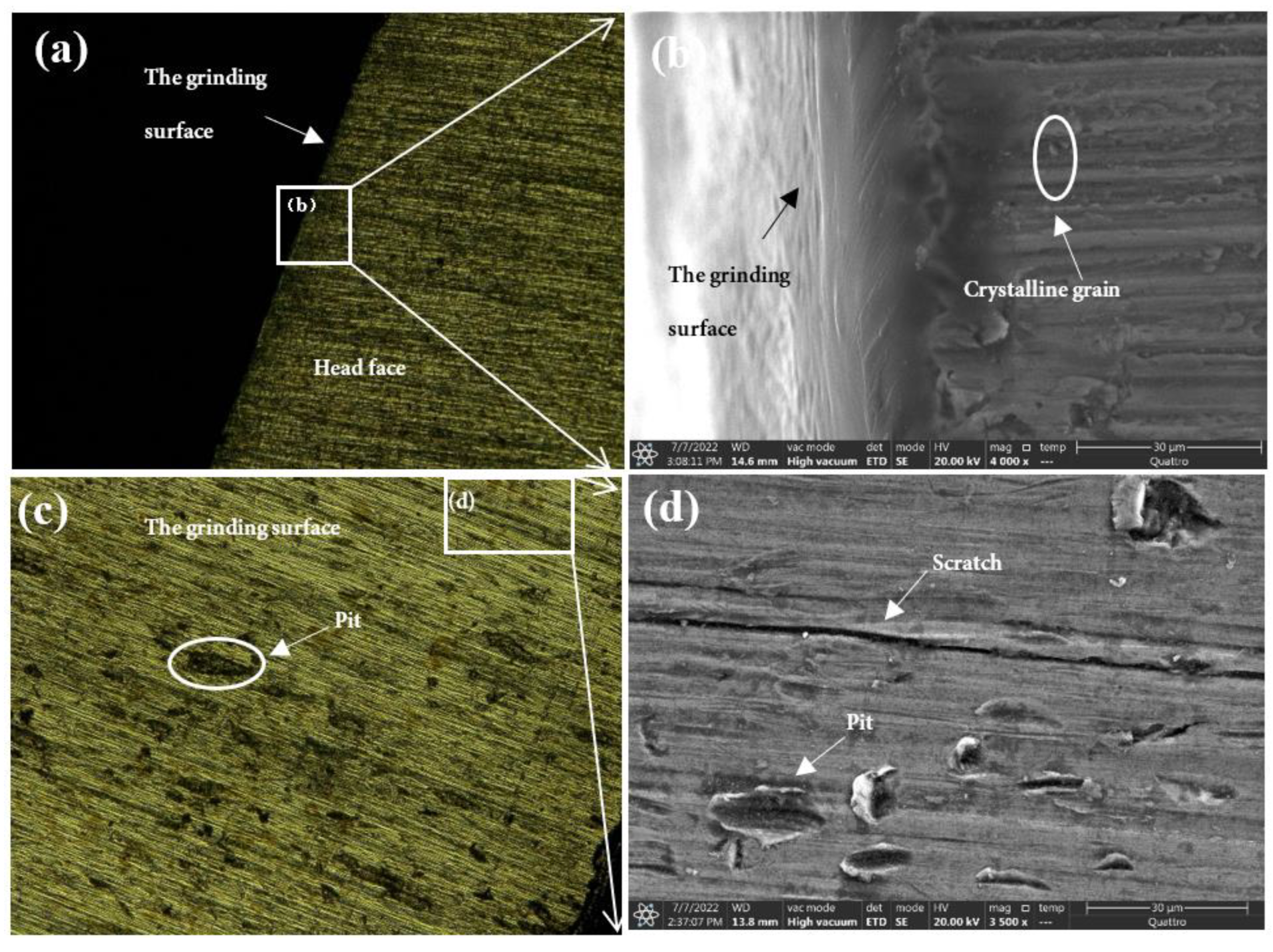

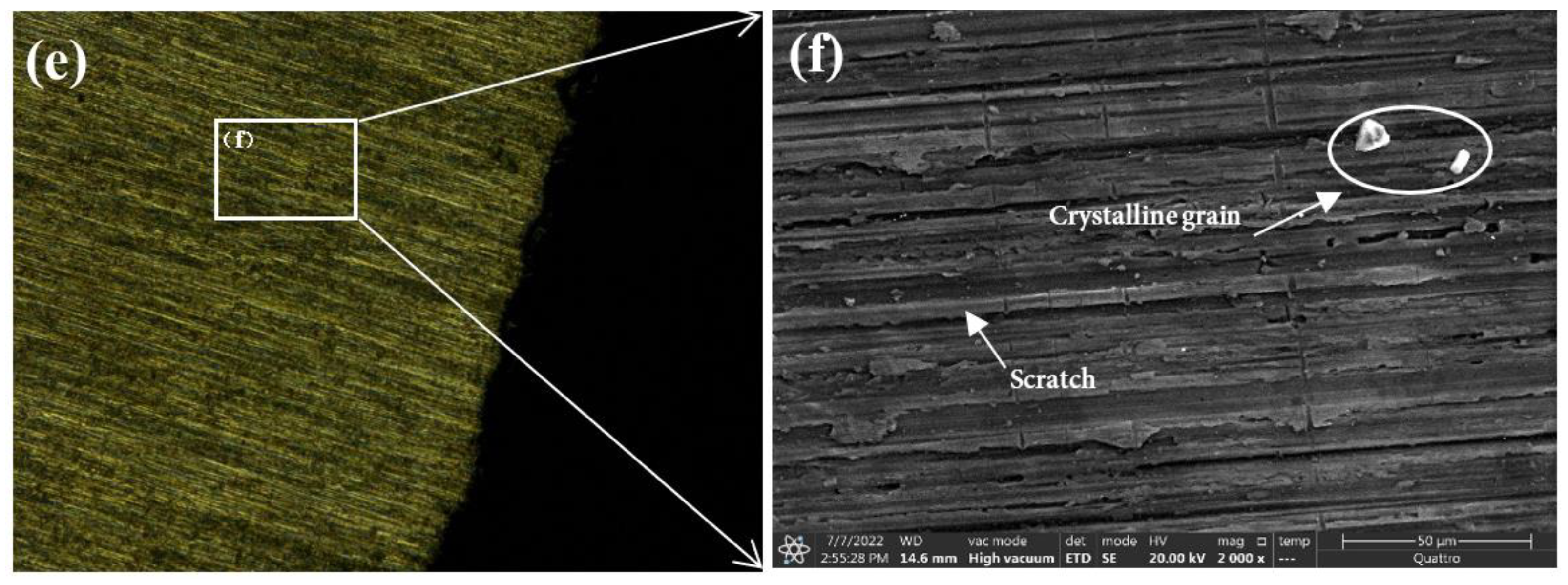

3.3.1. Roughness Ra 0.4 μm–0.2 μm Surface Topography Analysis

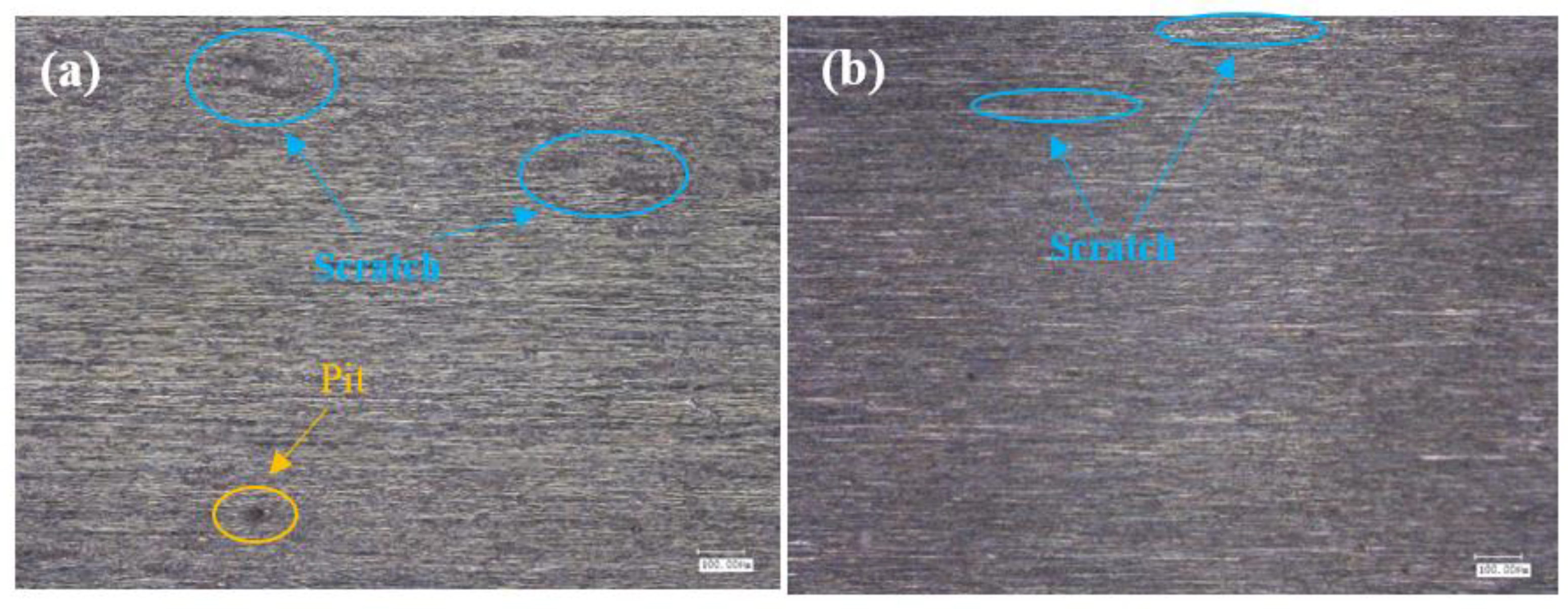

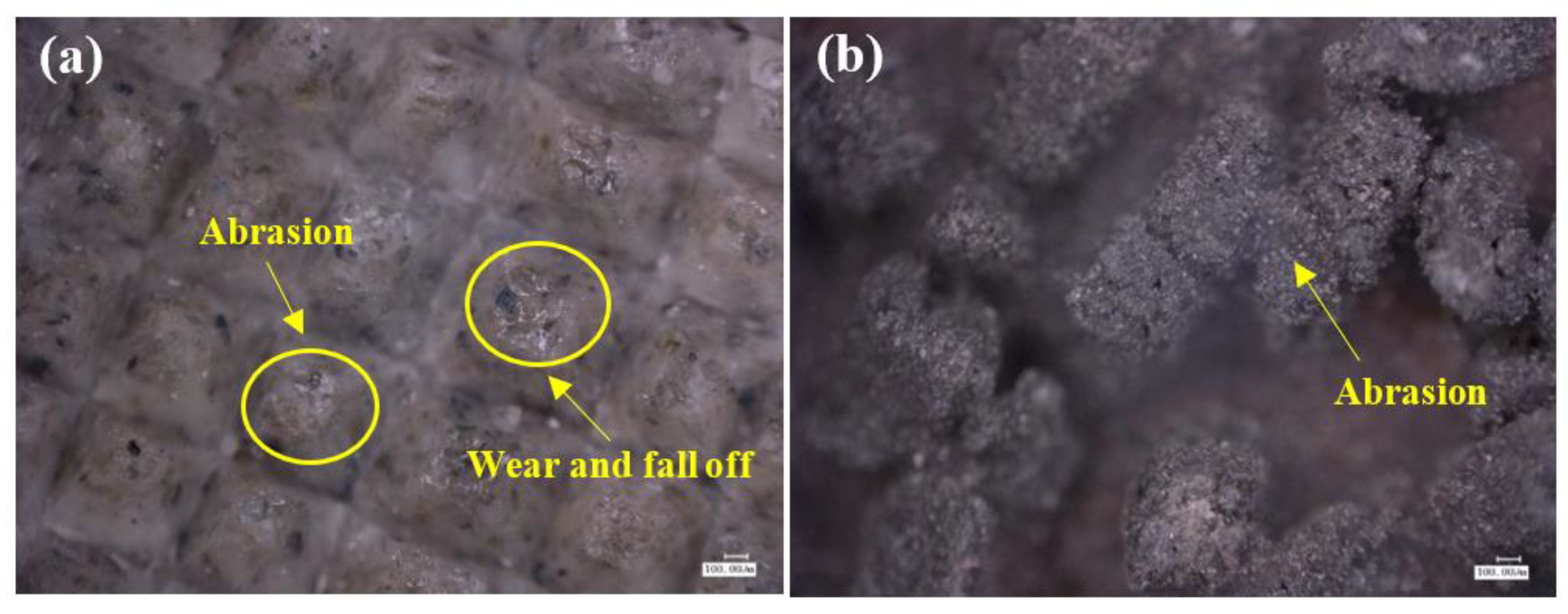

3.3.2. Surface Topography Analysis for Roughness Ra below 0.2 μm

4. Discussion

4.1. Mechanism of the Influence of Grinding Parameters and Levels on Compression Residual Stresses

4.2. Mechanism of the Influence of Grinding Parameters and Levels on Surface Hardness

4.3. Mechanism of the Influence of Grinding Parameters and Levels on Surface Topography

5. Conclusions

- At a roughness Ra of 0.4 μm–0.2 μm, tests 1 and 3, the compressive residual stress decreases with increasing linear speed and increases with increasing feed rate. The analysis shows that to increase the residual stresses in engineering, the grinding belt’s linear speed can be reduced, and a feed rate of 2 mm/s can be selected. At a roughness Ra of 0.2 μm or less, test 2,4, the compressive residual stress decreases with increasing linear speed and increases with increasing feed rate. The analysis leads to the engineering need to increase the residual stress, which requires reducing the grinding belt’s linear speed and selecting a feed rate of 2 mm/s. Even with different abrasive belts and different roughness, it can be seen from the test results that the residual stress decreases with increasing linear speed and increases with increasing feed rate, which is caused by the large amount of heat generated during the grinding process and thus the cooling of the substrate.

- Between a roughness Ra of 0.4 μm and 0.2 μm, the surface hardness of test 1 was maximum at a step length of 2 mm; the surface hardness decreased with increasing grinding depth. The surface hardness of test 3 increased with increasing step length and decreased with increasing grinding depth. At a roughness Ra of 0.2 μm or less, the surface hardness of test 2 decreased with the increase of linear speed and increased with the increase of grinding depth; the surface hardness of test 4 decreased with the increase of linear speed and decreased with the increase of step length. The analysis of the test results showed that the surface hardness did not show a good regularity when the roughness Ra was between 0.4 μm and 0.2 μm, while the influence of the linear speed and grinding depth was greater below 0.2 μm. Therefore, if the surface hardness needs to be increased in engineering, the linear speed can be reduced, or the grinding depth can be increased.

- At a roughness Ra of 0.4 μm or less, the surface topography of VSM belt grinding was better than that of 3M belt grinding, and VSM belt grinding can be chosen for grinding when better surface quality is needed. Using a 3M abrasive belt to grind titanium alloy surfaces produces larger residual stress, but the surface topography is poorer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, S.; Lu, S.; Zhang, B.; Cheung, C.F. Surface integrity and material removal mechanisms in high-speed grinding of Al/SiCp metal matrix composites. Int. J. Mach. Tools Manuf. 2022, 178, 103906. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Ye, C.; Zhang, P.; Mo, D.; Lu, X.; Yan, F.; Ge, X.; Jiang, P.; Cheng, Y. Dynamic response and microstructure evolution of titanium alloy plates under low-velocity impact. Thin-Walled Struct. 2022, 180, 109888. [Google Scholar] [CrossRef]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W.-M. High performance cutting of advanced aerospace alloys and composite materials. CIRP Ann. 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Wu, Z.; Kou, H.; Chen, N.; Xi, Z.; Fan, J.; Tang, B.; Li, J. Recent developments in cold dwell fatigue of titanium alloys for aero-engine applications: A review. J. Mater. Res. Technol. 2022, 20, 469–484. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog. Aerosp. Sci. 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Klocke, F.; Soo, S.L.; Karpuschewski, B.; Webster, J.A.; Novovic, D.; Elfizy, A.; Axinte, D.A.; Tönissen, S. Abrasive machining of advanced aerospace alloys and composites. CIRP Ann. 2015, 64, 581–604. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, D.; Wu, B.; Zhang, Y.; Luo, M. A path planning method for error region grinding of aero-engine blades with free-form surface. Int. J. Adv. Manuf. Technol. 2015, 81, 717–728. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, Z.; Jiang, R.; Jin, Q.; Zhang, Q.; Wang, W. Effect of creep feed grinding on surface integrity and fatigue life of Ni3Al based superalloy IC10. Chin. J. Aeronaut. 2021, 34, 438–448. [Google Scholar] [CrossRef]

- Yang, H.; Kano, S.; Shen, J.; McGrady, J.; Zhao, Z.; Duan, Z.; Abe, H. On the strength-hardness relationships in a Zr-Nb alloy plate with bimodal basal texture microstructure. Mater. Sci. Eng. A 2018, 732, 333–340. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Li, J.Y.; Fan, W.G.; Liu, Y.M.; Wang, W.X. Experimental and simulation research on residual stress for abrasive belt rail grinding. Int. J. Adv. Manuf. Technol. 2020, 109, 129–142. [Google Scholar] [CrossRef]

- Huang, Y.; Li, S.C.; Xiao, G.j.; Chen, B.Q.; Zhang, Y.D.; He, Y.; Song, K.K. Research progress of aero-engine blade materials and anti-fatigue grinding technology. J. Aeronaut. Mater. 2021, 41, 17–35. [Google Scholar] [CrossRef]

- Feng, B. Effects of surface roughness on scratch resistance and stress-strain fields during scratch tests. AIP Adv. 2017, 7, 035217. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Peng, W.; Yu, J.; Wang, J.; Ding, M.; Zhang, Y. Effect of surface roughness on the fatigue failure and evaluation of TC17 titanium alloy. Mater. Sci. Technol. 2021, 37, 301–313. [Google Scholar] [CrossRef]

- Zhu, D.; Xu, X.; Yang, Z.; Zhuang, K.; Yan, S.; Ding, H. Analysis and assessment of robotic belt grinding mechanisms by force modeling and force control experiments. Tribol. Int. 2018, 120, 93–98. [Google Scholar] [CrossRef]

- Zhao, C.; Li, J.; Wang, W. Forming mechanisms based simulation and prediction of grinding surface roughness for abrasive belt rail grinding. Procedia CIRP 2020, 87, 503–508. [Google Scholar] [CrossRef]

- Sun, J.; Zhou, P.; Wu, Y.H.; Zhang, K.; Zhang, L.X. Analysis on the Factors of Surface Morphologies on Si3N4 Ceramic Internal Grinding. Int. J. Eng. Res. Afr. 2017, 31, 44–52. [Google Scholar] [CrossRef]

- Tan, L.; Zhang, D.; Yao, C.; Wu, D.; Zhang, J. Evolution and empirical modeling of compressive residual stress profile after milling, polishing and shot peening for TC17 alloy. J. Manuf. Process. 2017, 26, 155–165. [Google Scholar] [CrossRef]

- Quan, F.; Chen, Z.; Ye, H.; Cui, C.; Cui, Y. Study of the effect of surface roughness on fatigue strength of GH4169 based on indirect evaluation of the notch root radius. Int. J. Fatigue 2021, 152, 106440. [Google Scholar] [CrossRef]

- Qiu, L.; Qi, L.; Liu, L.; Zhang, Z.; Xu, J. The blade surface performance and its robotic machining. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420914090. [Google Scholar] [CrossRef]

- Wu, C.; Guo, W.; Wu, Z.; Wang, Q.; Li, B. Ductility-oriented high-speed grinding of silicon carbide and process design for quality and damage control with higher efficiency. Int. J. Adv. Manuf. Technol. 2019, 105, 2771–2784. [Google Scholar] [CrossRef]

- Żak, K.; Grzesik, W. Metrological Aspects of Surface Topographies Produced by Different Machining Operations Regarding Their Potential Functionality. Metrol. Meas. Syst. 2017, 24, 325–335. [Google Scholar] [CrossRef]

- Guo, X.; Zhai, R.; Shi, Y.; Kang, R.; Jin, Z.; Guo, D. Study on influence of grinding depth and grain shape on grinding damage of K9 glass by SPH simulation. Int. J. Adv. Manuf. Technol. 2019, 106, 333–343. [Google Scholar] [CrossRef]

- Jia, Z.-Y.; Ye, T.; Ma, J.-W.; Cao, X.-K.; Liu, W.; Yu, W.-J.; Gao, J. Effect of Process Parameters on the Hardness of Laser Surface Textured 5A06 Aluminum Alloy. J. Mater. Eng. Perform. 2021, 30, 5858–5867. [Google Scholar] [CrossRef]

- Gao, S.; Liu, J.; Huang, S.; Lin, R. Effects of Heat Generated during Grind Hardening on Hardness and Microstructure of Alloy Metal: Optimal Process to Improve Efficiency. Sens. Mater. 2020, 32, 3383–3397. [Google Scholar] [CrossRef]

- Liu, S.; Yang, G.; Zheng, J.; Liu, X. Numerical and experimental studies on grind-hardening cylindrical surface. Int. J. Adv. Manuf. Technol. 2014, 76, 487–499. [Google Scholar] [CrossRef]

- Xiu, S.C.; Liu, M.H.; Wei, J.H.; Zhang, X.M. Study on grinding strengthening and hardening mechanism under small depth of cut conditions. Int. J. Surf. Sci. Eng. 2015, 9, 479–492. [Google Scholar] [CrossRef]

- Hariharan, K.; Prakash, R.V. Integrating effect of forming in fatigue life prediction: Review of present scenario and challenges. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 967–979. [Google Scholar] [CrossRef]

- Zheng, Q.; Wang, N.; Zhu, P.; Liu, J.; Ma, W. Fatigue Life Simulation and Analysis of Aluminum Alloy Sheet Self-piercing Riveting. Frat. Integrità Strutt. 2020, 14, 141–151. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Zuo, Z. Numerical Study of the Effects of Residual Stress on Fretting Fatigue Using XFEM. Materials 2015, 8, 7094–7105. [Google Scholar] [CrossRef]

- Yao, C.; Wang, T.; Ren, J.; Xiao, W. A comparative study of residual stress and affected layer in Aermet100 steel grinding with alumina and cBN wheels. Int. J. Adv. Manuf. Technol. 2014, 74, 125–137. [Google Scholar] [CrossRef]

- Zhao, M.; Mao, J.; Ji, X.; Feng, Y.; Liang, S.Y. Effect of crystallographic orientation on residual stress induced in micro-grinding. Int. J. Adv. Manuf. Technol. 2021, 112, 1271–1284. [Google Scholar] [CrossRef]

- Li, G.; Xu, H.; Zhou, H.; Jing, X.; Sun, Y. Experimental study of residual stresses of Cam produced by heat treatment and grinding processes. Int. J. Adv. Manuf. Technol. 2018, 100, 1355–1362. [Google Scholar] [CrossRef]

- Shen, S.; Li, B.; Guo, W. Experimental study on grinding-induced residual stress in C-250 maraging steel. Int. J. Adv. Manuf. Technol. 2019, 106, 953–967. [Google Scholar] [CrossRef]

- Denkena, B.; Grove, T.; Lucas, H. Influences of grinding with Toric CBN grinding tools on surface and subsurface of 1.3344 PM steel. J. Mater. Process. Technol. 2016, 229, 541–548. [Google Scholar] [CrossRef]

- Chen, J.; Fang, Q.; Zhang, L. Investigate on distribution and scatter of surface residual stress in ultra-high speed grinding. Int. J. Adv. Manuf. Technol. 2014, 75, 615–627. [Google Scholar] [CrossRef]

- Su, J.; Zhang, H.; Jiang, C.; Nie, S. Prediction and experimental study on thermal stress in multi-tooth form grinding of cycloid gear. Int. J. Adv. Manuf. Technol. 2021, 117, 187–198. [Google Scholar] [CrossRef]

- Cui, Y.; Cai, J.; Li, Z.; Jiao, Z.; Hu, L.; Hu, J. Effect of Porosity on Dynamic Response of Additive Manufacturing Ti-6Al-4V Alloys. Micromachines 2022, 13, 408. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Yu, T.; Zhao, J. Assessment and optimization of grinding process on AISI 1045 steel in terms of green manufacturing using orthogonal experimental design and grey relational analysis. J. Clean. Prod. 2020, 253, 119896. [Google Scholar] [CrossRef]

- Liu, S.; Xiao, G.; Lin, O.; He, Y.; Song, S. A new one-step approach for the fabrication of microgrooves on Inconel 718 surface with microporous structure and nanoparticles having ultrahigh adhesion and anisotropic wettability: Laser belt processing. Appl. Surf. Sci. 2022, 607, 155108. [Google Scholar] [CrossRef]

- Zhu, S.; Xiao, G.; He, Y.; Liu, G.; Song, S.; Jiahua, S. Tip vortex cavitation of propeller bionic noise reduction surface based on precision abrasive belt grinding. J. Adv. Manuf. Sci. Technol. 2022, 2, 2022003. [Google Scholar] [CrossRef]

- Li, C.; Hu, Y.; Zhang, F.; Geng, Y.; Meng, B. Molecular dynamics simulation of laser assisted grinding of GaN crystals. Int. J. Mech. Sci. 2022, 107856. [Google Scholar] [CrossRef]

- Camurri, C.; Carrasco, C.; Dille, J. Residual stress during heat treatment of steel grinding balls. J. Mater. Process. Technol. 2008, 208, 450–456. [Google Scholar] [CrossRef]

- Huang, Y.; Li, S.; Xiao, G.; Chen, B.; He, Y.; Song, K. Research on the fatigue failure behavior of 1Cr17Ni2 blades ground by abrasive belt with passivation treatment. Eng. Fail. Anal. 2021, 129, 105670. [Google Scholar] [CrossRef]

| Element | Al | V | Fe | O | C | N | H | Ti |

|---|---|---|---|---|---|---|---|---|

| wt% | 6.12 | 3.95 | 0.12 | 0.085 | 0.01 | 0.005 | 0.004 | Bal |

| Materials | Strength (MPa) | Compressive Strength (MPa) | Elastic Modulus (GPa) | Hardness (HRC) |

|---|---|---|---|---|

| TC4 | 1100 | 895 | 110 | 30 |

| NO. | Step Length (mm) | Linear Speed (m/s) | Feed Rate (mm/s) | Grinding Depth (mm) |

|---|---|---|---|---|

| 1 | 1 | 11 | 1 | 0.05 |

| 2 | 1 | 13 | 4 | 0.10 |

| 3 | 1 | 15 | 2 | 0.15 |

| 4 | 2 | 11 | 4 | 0.15 |

| 5 | 2 | 13 | 2 | 0.05 |

| 6 | 2 | 15 | 1 | 0.10 |

| 7 | 3 | 11 | 2 | 0.10 |

| 8 | 3 | 13 | 1 | 0.15 |

| 9 | 3 | 15 | 4 | 0.05 |

| NO. | Text 1 | Text 2 | Text 3 | Text 4 |

|---|---|---|---|---|

| 1 | 0.219 | 0.152 | 0.288 | 0.154 |

| 2 | 0.338 | 0.161 | 0.247 | 0.141 |

| 3 | 0.319 | 0.160 | 0.267 | 0.195 |

| 4 | 0.239 | 0.197 | 0.320 | 0.189 |

| 5 | 0.307 | 0.180 | 0.283 | 0.171 |

| 6 | 0.302 | 0.160 | 0.278 | 0.176 |

| 7 | 0.220 | 0.138 | 0.299 | 0.184 |

| 8 | 0.300 | 0.150 | 0.277 | 0.182 |

| 9 | 0.211 | 0.192 | 0.277 | 0.159 |

| NO. | Text 1 | Text 2 | Text 3 | Text 4 |

|---|---|---|---|---|

| 1 | −185.26 | −202.45 | −189.90 | −137.28 |

| 2 | −190.36 | −186.66 | −155.75 | −183.99 |

| 3 | −140.85 | −202.80 | −153.02 | −119.90 |

| 4 | −150.11 | −190.01 | −113.90 | −103.00 |

| 5 | −131.16 | −134.37 | −111.95 | −164.20 |

| 6 | −87.80 | −184.02 | −141.49 | −97.08 |

| 7 | −163.82 | −184.63 | −108.94 | −99.41 |

| 8 | −97.93 | −173.68 | −121.36 | −127.77 |

| 9 | −75.58 | −176.02 | −111.35 | −185.42 |

| NO. | Text 1 | Text 2 | Text 3 | Text 4 |

|---|---|---|---|---|

| 1 | 4.5185 | 4.0430 | 2.9239 | 5.8187 |

| 2 | 3.6199 | 2.8515 | 5.0026 | 3.2323 |

| 3 | 3.7923 | 3.0896 | 3.9876 | 3.6743 |

| 4 | 4.1818 | 4.6676 | 4.6170 | 3.7334 |

| 5 | 5.2813 | 2.9247 | 4.5702 | 3.7210 |

| 6 | 4.5999 | 2.7800 | 3.2572 | 2.6190 |

| 7 | 4.0087 | 5.3344 | 4.2639 | 4.0380 |

| 8 | 4.0101 | 3.9638 | 3.3852 | 3.3634 |

| 9 | 3.9644 | 3.0158 | 3.0266 | 3.4936 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, G.; Zhao, Z.; Xiao, G.; Li, S.; Chen, B.; Zhuo, X.; Zhang, J. Study of Surface Integrity of Titanium Alloy (TC4) by Belt Grinding to Achieve the Same Surface Roughness Range. Micromachines 2022, 13, 1950. https://doi.org/10.3390/mi13111950

Jiang G, Zhao Z, Xiao G, Li S, Chen B, Zhuo X, Zhang J. Study of Surface Integrity of Titanium Alloy (TC4) by Belt Grinding to Achieve the Same Surface Roughness Range. Micromachines. 2022; 13(11):1950. https://doi.org/10.3390/mi13111950

Chicago/Turabian StyleJiang, Guiyun, Zeyong Zhao, Guijian Xiao, Shaochuan Li, Benqiang Chen, Xiaoqin Zhuo, and Jie Zhang. 2022. "Study of Surface Integrity of Titanium Alloy (TC4) by Belt Grinding to Achieve the Same Surface Roughness Range" Micromachines 13, no. 11: 1950. https://doi.org/10.3390/mi13111950

APA StyleJiang, G., Zhao, Z., Xiao, G., Li, S., Chen, B., Zhuo, X., & Zhang, J. (2022). Study of Surface Integrity of Titanium Alloy (TC4) by Belt Grinding to Achieve the Same Surface Roughness Range. Micromachines, 13(11), 1950. https://doi.org/10.3390/mi13111950