Perovskite Random Lasers, Process and Prospects

Abstract

:1. Introduction

2. Perovskite QD RLs

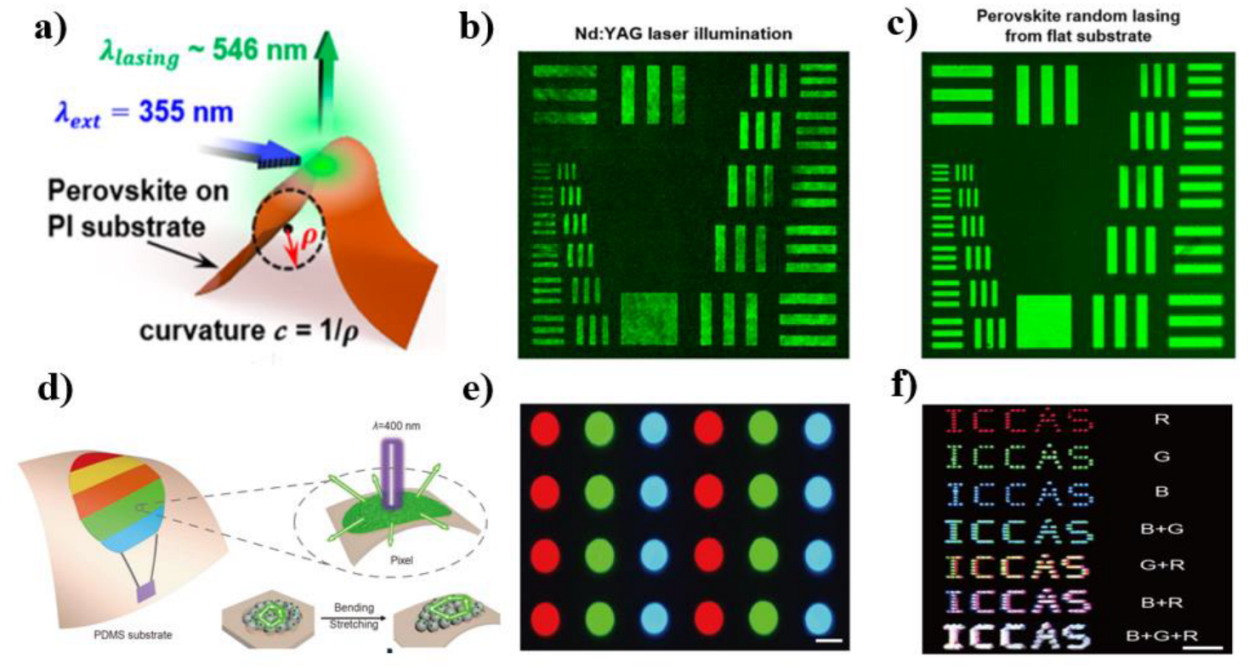

3. Perovskite Film RLs

4. Perovskite RL Applications

5. Conclusions and Outlook

Author Contributions

Funding

Conflicts of Interest

References

- Yu, S.F. Electrically Pumped Random Lasers. J. Phys. D Appl. Phys. 2015, 48, 483001. [Google Scholar] [CrossRef]

- Wiersma, D.S. The Physics and Applications of Random Lasers. Nat. Phys. 2008, 4, 359–367. [Google Scholar] [CrossRef]

- Luan, F.; Gu, B.; Gomes, A.S.L.; Yong, K.T.; Wen, S.; Prasad, P.N. Lasing in Nanocomposite Random Media. Nano Today 2015, 10, 168–192. [Google Scholar] [CrossRef]

- Gomes, A.S.L.; Moura, A.L.; de Araújo, C.B.; Raposo, E.P. Recent Advances and Applications of Random Lasers and Random Fiber Lasers. Prog. Quant. Electron. 2021, 78, 100343. [Google Scholar] [CrossRef]

- Azmi, A.N.; Wan Ismail, W.Z.; Abu Hassan, H.; Halim, M.M.; Zainal, N.; Muskens, O.L.; Wan Ahmad Kamil, W.M. Review of Open Cavity Random Lasers as Laser-Based Sensors. ACS Sens. 2022, 7, 914–928. [Google Scholar] [CrossRef] [PubMed]

- Song, Q.; Xu, Z.; Chio, S.H.; Sun, X.; Xiao, S.; Akkus, O.; Young, L.K. Detection of Nanoscale Structural Changes in Bone Using Random Lasers. Biomed. Opt. Express 2010, 1, 1401–1407. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liao, Y.M.; Liao, W.C.; Chang, S.W.; Hou, C.F.; Tai, C.T.; Su, C.Y.; Hsu, Y.T.; Wu, M.H.; Chou, R.J.; Lee, Y.H.; et al. Inkjet-Printed Random Lasers. Adv. Mater. Technol. 2018, 3, 1800214. [Google Scholar] [CrossRef]

- Pramanik, A.; Mondal, K.; Biswas, S.; Pal, S.K.; Ghosh, S.K.; Ganguly, T.; Kumbhakar, P. Sticky Note Paper-Based Plasmonic Random Laser for Artifact-Free Imaging. Appl. Phys. B 2022, 128, 167. [Google Scholar] [CrossRef]

- Ni, Y.; Wan, H.; Liang, W.; Zhang, S.; Xu, X.; Li, L.; Shao, Y.; Ruan, S.; Zhang, W. Random Lasing Carbon Dot Fibers for Multilevel Anti-Counterfeiting. Nanoscale 2021, 13, 16872–16878. [Google Scholar] [CrossRef]

- Lahoz, F.; Acebes, A.; González-Hernández, T.; de Armas-Rillo, S.; Soler-Carracedo, K.; Cuesto, G.; Mesa-Infante, V. Random Lasing in Brain Tissues. Org. Electron. 2019, 75, 105389. [Google Scholar] [CrossRef]

- Chang, S.W.; Liao, W.C.; Liao, Y.M.; Lin, H.I.; Lin, H.Y.; Lin, W.J.; Lin, S.Y.; Perumal, P.; Haider, G.; Tai, C.T.; et al. A White Random Laser. Sci. Rep. 2018, 8, 2720. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lawandy, N.M.; Balachandran, R.M.; Gomes, A.S.L.; Sauvaln, E. Laser Action in Strongly Scattering Media. Nature 1994, 368, 436–438. [Google Scholar] [CrossRef]

- Cao, H.; Zhao, Y.G.; Ho, S.T.; Seelig, E.W.; Wang, Q.H.; Chang, R.P.H. Random Laser Action in Semiconductor Powder. Phys. Rev. Lett. 1999, 82, 2278–2281. [Google Scholar] [CrossRef] [Green Version]

- Ning, S.; Wu, Z.; Dong, H.; Ma, L.; Jiao, B.; Ding, L.; Ding, L.; Zhang, F. The Enhanced Random Lasing from Dye-Doped Polymer Films with Different-Sized Silver Nanoparticles. Org. Electron. 2016, 30, 165–170. [Google Scholar] [CrossRef]

- Ziegler, J.; Djiango, M.; Vidal, C.; Hrelescu, C.; Klar, T.A. Gold Nanostars for Random Lasing Enhancement. Opt. Express 2015, 23, 15152–15159. [Google Scholar] [CrossRef]

- Zhu, J.L.; Li, W.H.; Sun, Y.; Lu, J.G.; Song, X.L.; Chen, C.Y.; Zhang, Z.; Su, Y. Random Laser Emission in A Sphere-Phase Liquid Crystal. Appl. Phys. Lett. 2015, 106, 191903. [Google Scholar] [CrossRef]

- Ismail, W.Z.W.; Vo, T.P.; Goldys, E.M.; Dawes, J.M. Plasmonic Enhancement of Rhodamine Dye Random Lasers. Laser Phys. 2015, 25, 085001. [Google Scholar] [CrossRef]

- Tolentino Dominguez, C.; Vieira, M.S.; Oliveira, R.M.; Ueda, M.; de Araújo, C.B.; Gomes, A.S.L. Three-Photon Excitation of An Upconversion Random Laser in ZnO-on-Si Nanostructured Films. J. Opt. Soc. Am. B 2014, 31, 1975. [Google Scholar] [CrossRef]

- Fujiwara, H.; Niyuki, R.; Ishikawa, Y.; Koshizaki, N.; Tsuji, T.; Sasaki, K. Low-Threshold and Quasi-single-mode Random Laser within A Submicrometer-sized ZnO Spherical Particle Film. Appl. Phys. Lett. 2013, 102, 061110. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Wang, M.; Yang, M.; Shi, L.J.; Deng, L.; Yang, H. Bichromatic Coherent Random Lasing from Dye-doped Polymer Stabilized Blue Phase Liquid Crystals Controlled by Pump Light Polarization. Chin. Phys. B 2016, 25, 094217. [Google Scholar] [CrossRef]

- Dai, G.; Wang, L.; Deng, L. Flexible Random Laser from Dye Doped Stretchable Polymer Film Containing Nematic Liquid Crystal. Opt. Mater. Express 2019, 10, 68–75. [Google Scholar] [CrossRef]

- Wang, Q.; Tong, Y.; Ye, H.; Liang, X.; Yang, K.; Xiang, W. Dual-Protective CsPbX3 Perovskite Nanocomposites with Improved Stability for Upconverted Lasing and Backlight Displays. ACS Sustain. Chem. Eng. 2021, 9, 11548–11555. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, S.; Huang, S.; Zhang, J.; Lyu, M.; Lu, H.; Zhu, J. Ligand-Mediated CsPbBrxI3−x/SiO2 Quantum Dots for Red, Stable and Low-Threshold Amplify Spontaneous Emission. Nanotechnology 2022, 33, 285201. [Google Scholar] [CrossRef] [PubMed]

- Dipold, J.; Magalhaes, E.S.; Bordon, C.D.S.; Kassab, L.R.P.; Wetter, N.U.; Digonnet, M.J.; Jiang, S. Emission Properties Study of a Nd3+-doped TZA Glass Random Laser. In Proceedings of the Optical Components and Materials XIX, San Francisco, CA, USA, 12 April 2022; p. 119970I. [Google Scholar]

- Wang, L.; Wan, Y.; Shi, L.; Zhong, H.; Deng, L. Electrically Controllable Plasmonic Enhanced Coherent Random Lasing from Dye-doped Nematic Liquid Crystals Containing Au Nanoparticles. Opt. Express 2016, 24, 17593–17602. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhong, H.; Chen, C.; Wu, X.G.; Hu, X.; Huang, H.; Han, J.; Zou, B.; Dong, Y. Brightly Luminescent and Color-Tunable Colloidal CH3NH3PbX3 (X = Br, I, Cl) Quantum Dots: Potential Alternatives for Display Technology. ACS Nano 2015, 9, 4533–4542. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Liu, T.; Burlingame, Q.; Liu, T.; Holley, R.; Cheng, G.; Yao, N.; Gao, F.; Loo, Y. Accelerated Aging of All-Inorganic, Interface-Stabilized Perovskite Solar Cells. Science 2022, 377, 307–310. [Google Scholar] [CrossRef] [PubMed]

- Protesescu, L.; Yakunin, S.; Bodnarchuk, M.I.; Krieg, F.; Caputo, R.; Hendon, C.H.; Yang, R.X.; Walsh, A.; Kovalenko, M.V. Nanocrystals of Cesium Lead Halide Perovskites (X = Cl, Br, and I): Novel Optoelectronic Materials Showing Bright Emission with Wide Color Gamut. Nano Lett. 2015, 15, 3692–3696. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dey, A.; Ye, J.; De, A.; Debroye, E.; Ha, S.K.; Bladt, E.; Kshirsagar, A.S.; Wang, Z.; Yin, J.; Wang, Y.; et al. State of the Art and Prospects for Halide Perovskite Nanocrystals. ACS Nano 2021, 15, 10775–10981. [Google Scholar] [CrossRef]

- Otero-Martinez, C.; Ye, J.; Sung, J.; Pastoriza-Santos, I.; Perez-Juste, J.; Xia, Z.; Rao, A.; Hoye, R.L.Z.; Polavarapu, L. Colloidal Metal-Halide Perovskite Nanoplatelets: Thickness-Controlled Synthesis, Properties, and Application in Light-Emitting Diodes. Adv. Mater. 2022, 34, 2107105. [Google Scholar] [CrossRef] [PubMed]

- Chang, S.; Bai, Z.; Zhong, H. In Situ Fabricated Perovskite Nanocrystals: A Revolution in Optical Materials. Adv. Opt. Mater. 2018, 6, 1800380. [Google Scholar] [CrossRef]

- Veldhuis, S.A.; Boix, P.P.; Yantara, N.; Li, M.; Sum, T.C.; Mathews, N.; Mhaisalkar, S.G. Perovskite Materials for Light-Emitting Diodes and Lasers. Adv. Mater. 2016, 28, 6804–6834. [Google Scholar] [CrossRef] [PubMed]

- Wu, T.; Qin, Z.; Wang, Y.; Wu, Y.; Chen, W.; Zhang, S.; Cai, M.; Dai, S.; Zhang, J.; Liu, J.; et al. The Main Progress of Perovskite Solar Cells in 2020-2021. Nanomicro Lett. 2021, 13, 152. [Google Scholar] [CrossRef]

- Wu, X.; Ji, H.; Yan, X.; Zhong, H. Industry Outlook of Perovskite Quantum Dots for Display Applications. Nat. Nanotechnol. 2022, 17, 813–816. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Liu, Y.; Li, Z.; Ji, Z.; Yan, G.; Zhao, C.; Mai, W. Achieving Dual-Color Imaging by Dual-Band Perovskite Photodetectors Coupled with Algorithms. J. Colloid Interface Sci. 2022, 625, 297–304. [Google Scholar] [CrossRef]

- Yang, G.; Fan, Q.; Chen, B.; Zhou, Q.; Zhong, H. Reprecipitation Synthesis of Luminescent CH3NH3PbBr3/NaNO3 Nanocomposites with Enhanced Stability. J. Mater. Chem. C 2016, 4, 11387–11391. [Google Scholar] [CrossRef]

- Yang, G.; Zhong, H. Organometal Halide Perovskite Quantum Dots: Synthesis, Optical properties, and Display applications. Chin. Chem. Lett. 2016, 27, 1124–1130. [Google Scholar] [CrossRef]

- Liu, X.; Li, J.; Zhang, P.; Lu, W.; Yang, G.; Zhong, H.; Zhao, Y. Perovskite Quantum Dot Microarrays: In Situ Fabrication via Direct Print Photopolymerization. Nano Res. 2022, 15, 7681–7687. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, G.; Li, F.; Shi, J.; Zhong, H. Direct in situ Photolithography of Perovskite Quantum Dots Based on Photocatalysis of Lead Bromide Complexes. Nat. Commun. 2022, 13, 6713. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, H.; Piotrowski, M.; Han, X.; Ge, Z.; Dong, L.; Wang, C.; Pinisetty, S.K.; Balguri, P.K.; Bandela, A.K.; et al. Cesium Lead Iodide Perovskites: Optically Active Crystal Phase Stability to Surface Engineering. Micromachines 2022, 13, 1318. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, X.; Song, J.; Xiao, L.; Zeng, H.; Sun, H. All-Inorganic Colloidal Perovskite Quantum Dots: A New Class of Lasing Materials with Favorable Characteristics. Adv. Mater. 2015, 27, 7101–7108. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.; Shang, Q.; Zhang, Q. Surface-Plasmon-Assisted Metal Halide Perovskite Small Lasers. Adv. Opt. Mater. 2019, 7, 1900279. [Google Scholar] [CrossRef]

- Mi, Y.; Zhong, Y.; Zhang, Q.; Liu, X. Continuous-Wave Pumped Perovskite Lasers. Adv. Opt. Mater. 2019, 7, 1900544. [Google Scholar] [CrossRef]

- Wang, K.; Wang, S.; Xiao, S.; Song, Q. Recent Advances in Perovskite Micro- and Nanolasers. Adv. Opt. Mater. 2018, 6, 1800278. [Google Scholar] [CrossRef]

- Liu, Z.; Li, C.; Shang, Q.Y.; Zhao, L.Y.; Zhong, Y.G.; Gao, Y.; Du, W.N.; Mi, Y.; Chen, J.; Zhang, S.; et al. Research Progress of Low-Dimensional Metal Halide Perovskites for Lasing Applications. Chin. Phys. B 2018, 27, 114209. [Google Scholar] [CrossRef]

- Chen, J.; Du, W.; Shi, J.; Li, M.; Wang, Y.; Zhang, Q.; Liu, X. Perovskite Quantum Dot Lasers. InfoMat 2020, 2, 170–183. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Su, R.; Du, W.; Liu, X.; Zhao, L.; Ha, S.T.; Xiong, Q. Advances in Small Perovskite-Based Lasers. Small Methods 2017, 1, 1700163. [Google Scholar] [CrossRef]

- Wang, L.; Meng, L.; Chen, L.; Huang, S.; Wu, X.; Dai, G.; Deng, L.; Han, J.; Zou, B.; Zhang, C.; et al. Ultralow-Threshold and Color-Tunable Continuous-Wave Lasing at Room-Temperature from In Situ Fabricated Perovskite Quantum Dots. J. Phys. Chem. Lett. 2019, 10, 3248–3253. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Dai, G.; Deng, L.; Zhong, H. Progress in Semiconductor Quantum Dots-Based Continuous-Wave Laser. Sci. Chin. Mater. 2020, 63, 1382–1397. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, C.; Xiao, S.; Wang, Y.; Fan, Y.; Liu, Y.; Zhang, N.; Qu, G.; Ji, H.; Han, J.; et al. Ultrafast Control of Vortex Microlasers. Science 2020, 367, 1018–1021. [Google Scholar] [CrossRef]

- Zhao, W.; Qin, Z.; Zhang, C.; Wang, G.; Huang, X.; Li, B.; Dai, X.; Xiao, M. Optical Gain from Biexcitons in CsPbBr3 Nanocrystals Revealed by Two-dimensional Electronic Spectroscopy. J. Phys. Chem. Lett. 2019, 10, 1251–1258. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Shang, Q.; Du, W.; Shi, J.; Wu, Z.; Mi, Y.; Chen, J.; Liu, F.; Li, Y.; Liu, M.; et al. Strong Exciton-Photon Coupling in Hybrid Inorganic-Organic Perovskite Micro/Nanowires. Adv. Opt. Mater. 2018, 6, 1701032. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, H. Advances and Prospects of Lasers Developed from Colloidal Semiconductor Nanostructures. Prog. Quant. Electron. 2018, 60, 1–29. [Google Scholar] [CrossRef]

- Pushkarev, A.; Korolev, V.; Markina, D.; Komissarenko, F.; Naujokaitis, A.; Drabavicius, A.; Pakstas, V.; Franckevicius, M.; Khubezhov, S.; Sannikov, D.; et al. A Few-Minute Synthesis of CsPbBr3 Nanolasers with a High Quality Factor by Spraying at Ambient Conditions. ACS Appl. Mater. Interface 2018, 11, 1040–1048. [Google Scholar] [CrossRef]

- Nagamine, G.; Rocha, J.O.; Bonato, L.G.; Nogueira, A.F.; Zaharieva, Z.; Watt, A.A.R.; de Brito Cruz, C.H.; Padilha, L.A. Two-Photon Absorption and Two-Photon-Induced Gain in Perovskite Quantum Dots. J. Phys. Chem. Lett. 2018, 9, 3478–3484. [Google Scholar] [CrossRef]

- Mathies, F.; Brenner, P.; Hernandez-Sosa, G.; Howard, I.A.; Paetzold, U.W.; Lemmer, U. Inkjet-Printed Perovskite Distributed Feedback Lasers. Opt. Express 2018, 26, 144–152. [Google Scholar] [CrossRef]

- Xing, G.; Mathews, N.; Lim, S.S.; Yantara, N.; Liu, X.; Sabba, D.; Gratzel, M.; Mhaisalkar, S.; Sum, T.C. Low-Temperature Solution-Processed Wavelength-Tunable Perovskites for Lasing. Nat. Mater. 2014, 13, 476–480. [Google Scholar] [CrossRef]

- Dang, C.; Lee, J.; Breen, C.; Steckel, J.S.; Coe-Sullivan, S.; Nurmikko, A. Red, Green and Blue Lasing Enabled by Single-Exciton Gain in Colloidal Quantum Dot Films. Nat. Nanotechnol. 2012, 7, 335–339. [Google Scholar] [CrossRef]

- Deschler, F.; Price, M.; Pathak, S.; Klintberg, L.E.; Jarausch, D.D.; Higler, R.; Huttner, S.; Leijtens, T.; Stranks, S.D.; Snaith, H.J.; et al. High Photoluminescence Efficiency and Optically Pumped Lasing in Solution-Processed Mixed Halide Perovskite Semiconductors. J. Phys. Chem. Lett. 2014, 5, 1421–1426. [Google Scholar] [CrossRef]

- Dhanker, R.; Brigeman, A.N.; Larsen, A.V.; Stewart, R.J.; Asbury, J.B.; Giebink, N.C. Random Lasing in Organo-Lead Halide Perovskite Microcrystal Networks. Appl. Phys. Lett. 2014, 105, 151112. [Google Scholar] [CrossRef]

- Yakunin, S.; Protesescu, L.; Krieg, F.; Bodnarchuk, M.I.; Nedelcu, G.; Humer, M.; De Luca, G.; Fiebig, M.; Heiss, W.; Kovalenko, M.V. Low-Threshold Amplified Spontaneous Emission and Lasing from Colloidal Nanocrystals of Caesium Lead Halide Perovskites. Nat. Commun. 2015, 6, 8056. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Sun, W.; Li, J.; Gu, Z.; Wang, K.; Xiao, S.; Song, Q. Random Lasing Actions in Self-Assembled Perovskite Nanoparticles. Opt. Eng. 2016, 55, 057102. [Google Scholar] [CrossRef] [Green Version]

- Hu, H.W.; Haider, G.; Liao, Y.M.; Roy, P.K.; Ravindranath, R.; Chang, H.T.; Lu, C.H.; Tseng, C.Y.; Lin, T.Y.; Shih, W.H.; et al. Wrinkled 2D Materials: A Versatile Platform for Low-Threshold Stretchable Random Lasers. Adv. Mater. 2017, 29, 1703549. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Chen, D.; Li, X.; Zhong, J.; Xu, X. In Situ Crystallization Synthesis of CsPbBr3 Perovskite Quantum Dot-Embedded Glasses with Improved Stability for Solid-State Lighting and Random Upconverted Lasing. ACS Appl. Mater. Interfaces 2018, 10, 18918–18926. [Google Scholar] [CrossRef]

- Roy, P.K.; Haider, G.; Lin, H.I.; Liao, Y.M.; Lu, C.H.; Chen, K.H.; Chen, L.C.; Shih, W.H.; Liang, C.T.; Chen, Y.F. Multicolor Ultralow-Threshold Random Laser Assisted by Vertical-Graphene Network. Adv. Opt. Mater. 2018, 6, 1800382. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, Z.; Shi, T.; Du, J.; Yang, J.; Zhang, Z.; Tang, X.; Leng, Y. Stable and Enhanced Frequency Up-Converted Lasing from CsPbBr3 Quantum Dots Embedded in Silica Sphere. Opt. Express 2019, 27, 9459–9466. [Google Scholar] [CrossRef]

- Tang, X.; Bian, Y.; Liu, Z.; Du, J.; Li, M.; Hu, Z.; Yang, J.; Chen, W.; Sun, L. Room-Temperature Up-Conversion Random Lasing from CsPbBr3 Quantum Dots with TiO2 Nanotubes. Opt. Lett. 2019, 44, 4706–4709. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Z.; Pi, M.; Lin, H.; Zeng, F.; Bian, Y.; Shi, T.; Du, J.; Leng, Y.; Tang, X. High Efficiency Up-Conversion Random Lasing from Formamidinium Lead Bromide/Amino-Mediated Silica Spheres Composites. Adv. Opt. Mater. 2020, 8, 2000290. [Google Scholar] [CrossRef]

- Zhu, Y.; Mu, Y.; Tang, F.; Du, P.; Ren, H. A Corona Modulation Device Structure and Mechanism Based on Perovskite Quantum Dots Random Laser Pumped Using an Electron Beam. Front. Optoelectron. 2020, 13, 291–302. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, X.; Gao, Z.; Hou, Y.; Wang, K.; Zhang, W.; Wang, Z.; Wang, X.; Xu, B.; Meng, X. Zero-Dimensional Perovskite Open Cavities for Low-Threshold Stimulated Emissions. J. Phys. Chem. C 2020, 124, 25499–25508. [Google Scholar] [CrossRef]

- Yang, L.; Wang, T.; Min, Q.; Pi, C.; Li, F.; Yang, X.; Li, K.; Zhou, D.; Qiu, J.; Yu, X.; et al. Ultrahigh Photo-Stable All-Inorganic Perovskite Nanocrystals and Their Robust Random Lasing. Nanoscale Adv. 2020, 2, 888–895. [Google Scholar] [CrossRef]

- Li, R.; Yu, J.; Wang, S.; Shi, Y.; Wang, Z.; Wang, K.; Ni, Z.; Yang, X.; Wei, Z.; Chen, R. Surface Modification of All-Inorganic Halide Perovskite Nanorods by a Microscale Hydrophobic Zeolite for Stable and Sensitive Laser Humidity Sensing. Nanoscale 2020, 12, 13360–13367. [Google Scholar] [CrossRef]

- Li, S.; Lei, D.; Ren, W.; Guo, X.; Wu, S.; Zhu, Y.; Rogach, A.L.; Chhowalla, M.; Jen, A.K. Water-Resistant Perovskite Nanodots Enable Robust Two-Photon Lasing in Aqueous Environment. Nat. Commun. 2020, 11, 1192. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, Y.; Zhou, Z.; Zhang, C.; Tang, J.; Fan, Y.; Xu, F.F.; Zhao, Y.S. Full-Color Flexible Laser Displays Based on Random Laser Arrays. Sci. Chin. Mater. 2021, 64, 2805–2812. [Google Scholar] [CrossRef]

- Xu, B.; Gao, Z.; Yang, S.; Sun, H.; Song, L.; Li, Y.; Zhang, W.; Sun, X.; Wang, Z.; Wang, X.; et al. Multicolor Random Lasers Based on Perovskite Quantum Dots Embedded in Intrinsic Pb–MOFs. J. Phys. Chem. C 2021, 125, 25757–25764. [Google Scholar] [CrossRef]

- Xing, D.; Lin, C.C.; Won, P.; Xiang, R.; Chen, T.P.; Kamal, A.S.A.; Lee, Y.C.; Ho, Y.L.; Maruyama, S.; Ko, S.H.; et al. Metallic Nanowire Coupled CsPbBr3 Quantum Dots Plasmonic Nanolaser. Adv. Funct. Mater. 2021, 31, 2102375. [Google Scholar] [CrossRef]

- Gao, W.; Wang, T.; Xu, J.; Zeng, P.; Zhang, W.; Yao, Y.; Chen, C.; Li, M.; Yu, S.F. Robust and Flexible Random Lasers Using Perovskite Quantum Dots Coated Nickel Foam for Speckle-Free Laser Imaging. Small 2021, 17, 2103065. [Google Scholar] [CrossRef] [PubMed]

- Jin, M.; Gao, W.; Liang, X.; Fang, Y.; Yu, S.; Wang, T.; Xiang, W. The Achievement of Red Upconversion Lasing for Highly Stable Perovskite Nanocrystal Glasses with The Assistance of Anion Modulation. Nano Res. 2021, 14, 2861–2866. [Google Scholar] [CrossRef]

- Xiong, Q.; Huang, S.; Zhan, Z.; Du, J.; Tang, X.; Hu, Z.; Liu, Z.; Zhang, Z.; Chen, W.; Leng, Y. Surface Ligand Modified Cesium Lead Bromide/Silica Sphere Composites for Low-Threshold Upconversion Lasing. Photon. Res. 2022, 10, 628–636. [Google Scholar] [CrossRef]

- Kao, T.S.; Chou, Y.H.; Hong, K.B.; Huang, J.F.; Chou, C.H.; Kuo, H.C.; Chen, F.C.; Lu, T.C. Controllable Lasing Performance in Solution-Processed Organic-Inorganic Hybrid Perovskites. Nanoscale 2016, 8, 18483–18488. [Google Scholar] [CrossRef]

- Xu, L.; Meng, Y.; Xu, C.; Chen, P. Room Temperature Two-Photon-Pumped Random Lasers in FAPbBr3/Polyethylene Oxide (PEO) Composite Perovskite Thin Film. RSC Adv. 2018, 8, 36910–36914. [Google Scholar] [CrossRef]

- Weng, G.; Xue, J.; Tian, J.; Hu, X.; Bao, X.; Lin, H.; Chen, S.; Zhu, Z.; Chu, J. Picosecond Random Lasing Based on Three-Photon Absorption in Organometallic Halide CH3NH3PbBr3 Perovskite Thin Films. ACS Photon. 2018, 5, 2951–2959. [Google Scholar] [CrossRef]

- Safdar, A.; Wang, Y.; Krauss, T.F. Random Lasing in Uniform Perovskite Thin Films. Opt. Express 2018, 26, 75–84. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.C.; Li, H.; Hong, Y.H.; Hong, K.B.; Chen, F.C.; Hsu, C.H.; Lee, R.K.; Conti, C.; Kao, T.S.; Lu, T.-C. Flexible Organometal–Halide Perovskite Lasers for Speckle Reduction in Imaging Projection. ACS Nano 2019, 13, 5421–5429. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, W.; Xiao, S.; Zhang, N.; Fan, Y.; Qu, G.; Song, Q. Surface-Emitting Perovskite Random Lasers for Speckle-Free Imaging. ACS Nano 2019, 13, 10653–10661. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yan, S.; Tong, J.; Shi, X.; Zhang, S.; Chen, C.; Xiao, Y.; Han, C.; Zhai, T. Perovskite Random Lasers on Fiber Facet. Nanophotonics 2020, 9, 935–941. [Google Scholar] [CrossRef] [Green Version]

- Mallick, S.P.; Sung, Z. Holographic Image Denoising using Random Laser Illumination. Ann. Phys. 2020, 532, 2000323. [Google Scholar] [CrossRef]

- Hong, Y.H.; Kao, T.S. Room-Temperature Random Lasing of Metal-Halide Perovskites via Morphology-Controlled Synthesis. Nanoscale Adv. 2020, 2, 5833–5840. [Google Scholar] [CrossRef]

- Mallick, S.P.; Hong, Y.H.; Chen, L.R.; Kao, T.S.; Lu, T.C. Effect of Passivation Layer on the Thin Film Perovskite Random Lasers. Materials 2020, 13, 2322. [Google Scholar] [CrossRef]

- Bouteyre, P.; Son Nguyen, H.; Lauret, J.S.; Trippe-Allard, G.; Delport, G.; Ledee, F.; Diab, H.; Belarouci, A.; Seassal, C.; Garrot, D.; et al. Directing Random Lasing Emission using Cavity Exciton-Polaritons. Opt. Express 2020, 28, 39739–39749. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Chen, Y.Y.; Lin, L.J.; Hsu, H.C. Room-Temperature Near-Infrared Random Lasing with Tin-Based Perovskites Prepared by CVD Processing. J. Phys. Chem. C 2021, 125, 5180–5184. [Google Scholar] [CrossRef]

- Suárez, I.; Chirvony, V.S.; Sánchez-Díaz, J.; Sánchez, R.S.; Mora-Seró, I.; Martínez-Pastor, J.P. Directional and Polarized Lasing Action on Pb-free FASnI3 Integrated in Flexible Optical Waveguides. Adv. Opt. Mater. 2022, 10, 2200458. [Google Scholar] [CrossRef]

- Hu, J.; Zhang, X. Substrate Effects on the Random Lasing Performance of Solution-Processed Hybrid-Perovskite Multicrystal Film. Crystals 2022, 12, 334. [Google Scholar] [CrossRef]

- Tang, X.; Hu, Z.; Chen, W.; Xing, X.; Zang, Z.; Hu, W.; Qiu, J.; Du, J.; Leng, Y.; Jiang, X.; et al. Room Temperature Single-Photon Emission and Lasing for All-Inorganic Colloidal Perovskite Quantum Dots. Nano Energy 2016, 28, 462–468. [Google Scholar] [CrossRef]

- Piotrowski, M.; Ge, Z.; Wang, Y.; Bandela, A.K.; Thumu, U. Programmable Precise Kinetic Control over Crystal Phase, Size, and Equilibrium in Spontaneous Metathesis Reaction for Cs-Pb-Br Nanostructure Patterns at Room Temperature. Nanoscale 2022. [Google Scholar] [CrossRef] [PubMed]

- Kao, T.S.; Chou, Y.H.; Chou, C.H.; Chen, F.C.; Lu, T.C. Lasing Behaviors Upon Phase Transition in Solution-Processed Perovskite Thin Films. Appl. Phys. Lett. 2014, 105, 231108. [Google Scholar] [CrossRef] [Green Version]

- Weng, G.; Tian, J.; Chen, S.; Xue, J.; Yan, J.; Hu, X.; Chen, S.; Zhu, Z.; Chu, J. Giant Reduction of The Random Lasing Threshold in CH3NH3PbBr3 Perovskite Thin Films by Using a Patterned Sapphire Substrate. Nanoscale 2019, 11, 10636–10645. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Zang, Z.; Han, C.; Hu, Z.; Tang, X.; Du, J.; Leng, Y.; Sun, K. Highly compact CsPbBr3 Perovskite Thin Films Decorated by ZnO Nanoparticles for Enhanced Random Lasing. Nano Energy 2017, 40, 195–202. [Google Scholar] [CrossRef]

- Duan, Z.; Wang, S.; Yi, N.; Gu, Z.; Gao, Y.; Song, Q.; Xiao, S. Miscellaneous Lasing Actions in Organo-Lead Halide Perovskite Films. ACS Appl. Mater. Interfaces 2017, 9, 20711–20718. [Google Scholar] [CrossRef] [PubMed]

- Roy, P.K.; Ulaganathan, R.K.; Raghavan, C.M.; Mhatre, S.M.; Lin, H.I.; Chen, W.L.; Chang, Y.M.; Rozhin, A.; Hsu, Y.T.; Chen, Y.F.; et al. Unprecedented Random Lasing in 2D Organolead Halide Single-Crystalline Perovskite Microrods. Nanoscale 2020, 12, 18269–18277. [Google Scholar] [CrossRef]

- Murzin, A.O.; Stroganov, B.V.; Günnemann, C.; Hammouda, S.B.; Shurukhina, A.V.; Lozhkin, M.S.; Emeline, A.V.; Kapitonov, Y.V. Amplified Spontaneous Emission and Random Lasing in MAPbBr3 Halide Perovskite Single Crystals. Adv. Opt. Mater. 2020, 8, 2000690. [Google Scholar] [CrossRef]

- Li, Z.; Moon, J.; Gharajeh, A.; Haroldson, R.; Hawkins, R.; Hu, W.; Zakhidov, A.A.; Gu, Q. Room-Temperature Continuous-Wave Operation of Organometal Halide Perovskite Lasers. ACS Nano 2018, 12, 10968–10976. [Google Scholar] [CrossRef] [Green Version]

- Evans, T.J.S.; Schlaus, A.; Fu, Y.; Zhong, X.; Atallah, T.L.; Spencer, M.S.; Brus, L.E.; Jin, S.; Zhu, X.Y. Continuous-Wave Lasing in Cesium Lead Bromide Perovskite Nanowires. Adv. Opt. Mater. 2018, 6, 1700982. [Google Scholar] [CrossRef]

- Jiang, L.; Liu, R.; Su, R.; Yu, Y.; Xu, H.; Wei, Y.; Zhou, Z.K.; Wang, X. Continuous Wave Pumped Single-Mode Nanolasers in Inorganic Perovskites with Robust Stability and High Quantum Yield. Nanoscale 2018, 10, 13565–13571. [Google Scholar] [CrossRef] [PubMed]

- Brenner, P.; Bar-On, O.; Jakoby, M.; Allegro, I.; Richards, B.S.; Paetzold, U.W.; Howard, I.A.; Scheuer, J.; Lemmer, U. Continuous Wave Amplified Spontaneous Emission in Phase-Stable Lead Halide Perovskites. Nat. Commun. 2019, 10, 988. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Pelton, M.; Fedin, I.; Talapin, D.V.; Waks, E. A Room Temperature Continuous-Wave Nanolaser using Colloidal Quantum Wells. Nat. Commun. 2017, 8, 143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grim, J.Q.; Christodoulou, S.; Di Stasio, F.; Krahne, R.; Cingolani, R.; Manna, L.; Moreels, I. Continuous-Wave Biexciton Lasing at Room Temperature using Solution-Processed Quantum Wells. Nat. Nanotechnol. 2014, 9, 891–895. [Google Scholar] [CrossRef]

- Wu, K.; Park, Y.S.; Lim, J.; Klimov, V.I. Towards Zero-Threshold Optical Gain using Charged Semiconductor Quantum Dots. Nat. Nanotechnol. 2017, 12, 1140–1147. [Google Scholar] [CrossRef] [PubMed]

- Fan, F.; Voznyy, O.; Sabatini, R.P.; Bicanic, K.T.; Adachi, M.M.; McBride, J.R.; Reid, K.R.; Park, Y.S.; Li, X.; Jain, A.; et al. Continuous-Wave Lasing in Colloidal Quantum Dot Solids Enabled by Facet-Selective Epitaxy. Nature 2017, 544, 75–79. [Google Scholar] [CrossRef] [PubMed]

- Jia, Y.; Kerner, R.A.; Grede, A.J.; Rand, B.P.; Giebink, N.C. Continuous-Wave Lasing in an Organic–Inorganic Lead Halide Perovskite Semiconductor. Nat. Photon. 2017, 11, 784–788. [Google Scholar] [CrossRef]

- Sutherland, B.R.; Hoogland, S.; Adachi, M.M.; Wong, C.T.; Sargent, E.H. Conformal organohalide perovskites enable lasing on spherical resonators. ACS Nano 2014, 8, 10947–10952. [Google Scholar] [CrossRef] [PubMed]

- Sutherland, B.R.; Hoogland, S.; Adachi, M.M.; Kanjanaboos, P.; Wong, C.T.O.; McDowell, J.J.; Xu, J.; Voznyy, O.; Ning, Z.; Houtepen, A.J.; et al. Perovskite Thin Films via Atomic Layer Deposition. Adv. Mater 2015, 27, 53–58. [Google Scholar] [CrossRef] [PubMed]

| Authors | Description | Pump Type | Pump Wavelength | Emission Wavelength | Thresholds | FWHM | Operation Condition | Publication Date (Year) |

|---|---|---|---|---|---|---|---|---|

| Perovskite QD RLs | ||||||||

| Yakunin et al. [61] | CsPbBr3 QDs | fs | 400 nm | ~483 nm | ~5 μJ/cm2 | 0.14 nm | RT | 2015 |

| Liu et al. [62] | MAPbBr3 QDs | fs | 400 nm/800 nm | ~548 nm | 60 μJ/cm2/4.4 mJ/cm2 | 1 nm | RT | 2016 |

| Hu et al. [63] | MAPbBr3 QDs | ps | 374 nm | 540 nm | ~34.5 μJ/cm2 | 0.4 nm | RT | 2017 |

| Yuan et al. [64] | CsPbBr3 QD-embedded glass | fs | 800 nm | 530–540 nm | 200 μJ/cm2 | <1 nm | 77 K | 2018 |

| Roy et al. [65] | MAPbBr3 QDs/GNW composite | ps | 374 nm | 530 nm | 1 nJ/cm2 | 0.4 nm | RT | 2018 |

| Liu et al. [66] | CsPbBr3-SiO2 sphere | fs | 800 nm | 537 nm | 665 μJ/cm2 | <1 nm | RT | 2019 |

| Tang et al. [67] | CsPbBr3 QDs | fs | 800 nm | 540 nm | 9.54 mJ/cm2 | 0.49 nm | RT | 2019 |

| Yang et al. [68] | FAPbBr3/A-SiO2 composites | fs | 800 nm | ~550 nm | 413.9 μJ/cm2 | ~1307 | RT | 2020 |

| Zhu et al. [69] | CsPbBr3 QDs | electron beam | - | ~540 nm | 3kV | 0.9 nm | RT | 2020 |

| Liu et al. [70] | Cs4PbBr6 monolith ceramics | fs | 400 nm/800 nm | ~541 nm | 25.98 μJ/cm2 719 μJ/cm2 | <1 nm | RT | 2020 |

| Yang et al. [71] | CsPbBr3 QDs | fs | 800 nm | 535 nm | 254 μJ/cm2 | 0.3 nm | 77 K | 2020 |

| Li et al. [72] | CsPbBr3 nanorods | fs | 355 nm | 532 nm | 18.8 μJ/cm2 | 0.2 nm | RT | 2020 |

| Li et al. [73] | CsPbBr3 QD/SiO2 nanodots | fs | 800 nm | 533 nm | 0.91 mJ/cm2 | 0.3 nm | RT | 2020 |

| Hou et al. [74] | CsPbX3 QD/SiO2 composites | fs | 400 nm | RGB | 52.1–72.3 μJ/cm2 | - | RT | 2021 |

| Xu et al. [75] | MAPbX3 QDs@Pb-MOFs | ps | 490 nm | Multicolar 520–780 nm | 0.38 mJ/cm2 | 1.2 nm | RT | 2021 |

| Wang et al. [22] | CsPbX3@glass@ SEBS | fs | 800 nm | ~523 nm | 0.16 mJ/cm2 | - | RT | 2021 |

| Xing et al. [76] | Ag NW coupled CsPbBr3 QDs | fs | 400 nm | ~520 nm | ~34.5 μJ/cm2 | ~2.5 nm | RT | 2021 |

| Gao et al. [77] | CsPbBr3 QDs | fs | 800 nm | 537 nm | 190 μJ/cm2 | 1 nm | RT | 2021 |

| Jin et al. [78] | CsPb(Br/I)3 QD glasses | fs | 800 nm | 590 nm | 0.79 mJ/cm2 | 3 nm | 93 K | 2021 |

| Xiong et al. [79] | CsPbBr3 QD/SiO2 composites | fs | 800 nm | 527 nm | 79.81 μJ/cm2 | 0.4 nm | RT | 2022 |

| Perovskite film RLs | ||||||||

| Dhanker et al. [60] | MAPbI3 planar microcrystal networks | ns | 355 nm | ~785 nm | 200 μJ/cm2 | <0.5 nm | RT | 2014 |

| Kao et al. [80] | MAPbI3 film | ns | 355 nm | ~745 nm | ~230 μJ/cm2 | - | 77 K | 2016 |

| Xu et al. [81] | FAPbBr3/PEOcomposite film | ns | 1064 nm | 538 nm | 1.1 mJ/cm2 | 0.4 nm | RT | 2018 |

| Weng et al. [82] | MAPbBr3 film | fs | 1300 nm | ~547 nm | 27 mJ/cm2 | 5 nm | RT | 2018 |

| Safdar et al. [83] | MAPbI3 films | ns | 532 nm | 780 nm | 10 μJ/cm2 | 5 nm | RT | 2018 |

| Wang et al. [84] | MAPbBr3 film | ns | 355 nm | ~546 nm | 2.5 mJ/cm2 | 1.8 nm | RT | 2019 |

| Liu et al. [85] | MAPbBr3 film | ps | 400 nm | 540–560 nm | ~25 μJ/cm2 | <1 nm | RT | 2019 |

| Zhang et al. [86] | MAPbBr3 film on fiber facet | fs | 400 nm | 552 nm | 32.3 μJ/cm2 | 4 nm | RT | 2020 |

| Mallick et al. [87] | MAPbBr3 film | ns | 355 nm | ~550 nm | ~6.6 mJ/cm2 | <1 nm | RT | 2020 |

| Hong et al. [88] | MAPbBr3 films | ns | 355 nm | ~550 nm | 0.9 mJ cm2 | <1 nm | RT | 2020 |

| Mallick et al. [89] | MAPbBr3 films | ns | 355 nm | 546 nm | 2.6 mJ/cm2 | ~3 nm | RT | 2020 |

| Bouteyre et al. [90] | MAPbBr3 film | fs | 405 nm | 545 nm | 104 μW | 0.7 nm | RT | 2020 |

| Wu et al. [91] | γ-CsSnI3 films | ps | 355 nm | 950–960 nm | 18 mJ/cm2 | 0.3 nm | RT | 2021 |

| Suárez et al. [92] | FASnI3 films | ns | 532 nm | 890 nm | 300 nJ/cm2 | 0.8 nm | RT | 2022 |

| Hu et al. [93] | MAPbBr3 films | fs | 400 nm | ~550 nm | 12.3 μJ/cm2 | 7.7 nm | RT | 2022 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yang, M.; Zhang, S.; Niu, C.; Lv, Y. Perovskite Random Lasers, Process and Prospects. Micromachines 2022, 13, 2040. https://doi.org/10.3390/mi13122040

Wang L, Yang M, Zhang S, Niu C, Lv Y. Perovskite Random Lasers, Process and Prospects. Micromachines. 2022; 13(12):2040. https://doi.org/10.3390/mi13122040

Chicago/Turabian StyleWang, Lei, Mingqing Yang, Shiyu Zhang, Chunhui Niu, and Yong Lv. 2022. "Perovskite Random Lasers, Process and Prospects" Micromachines 13, no. 12: 2040. https://doi.org/10.3390/mi13122040