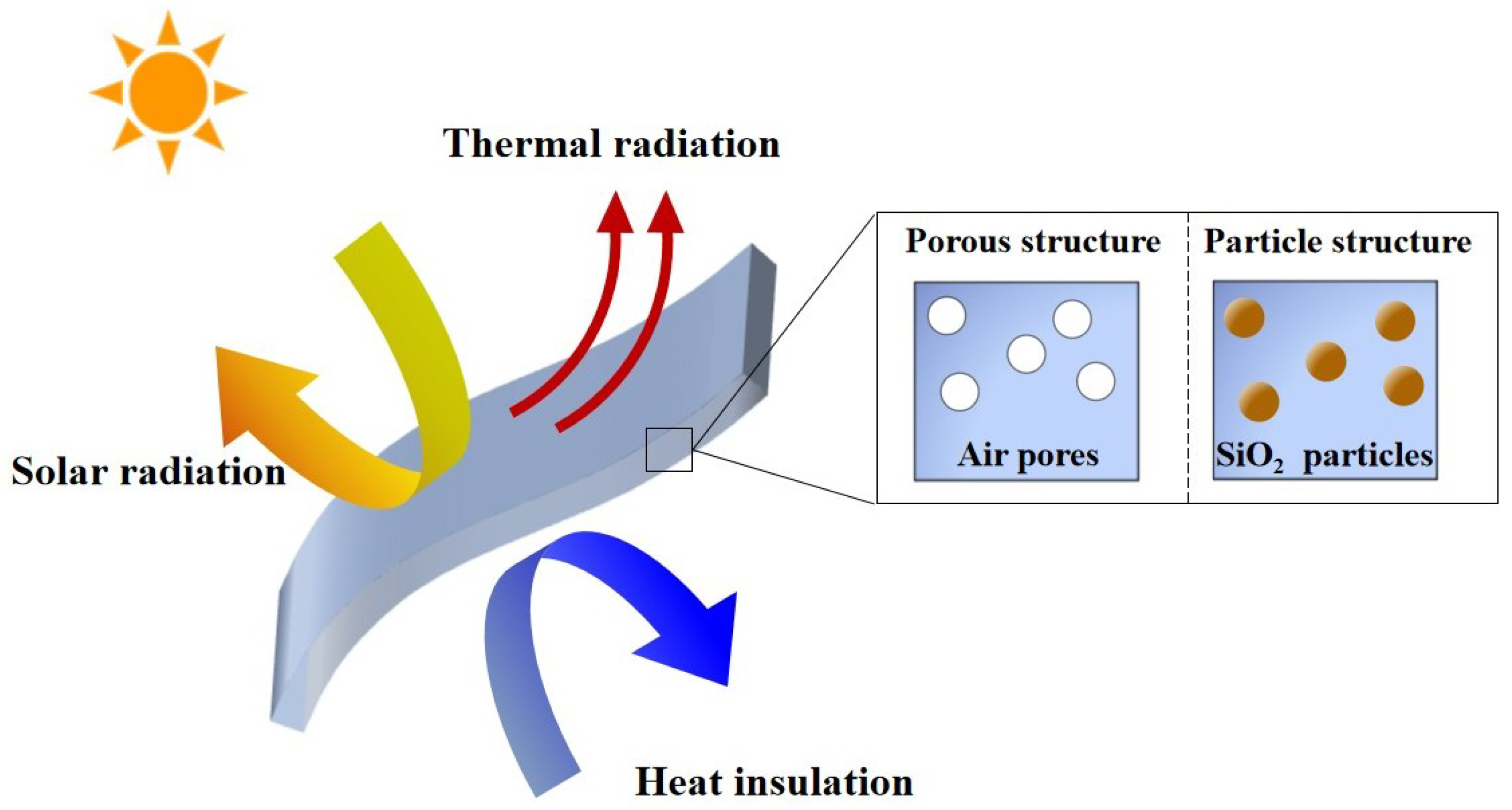

Structure Design of Polymer-Based Films for Passive Daytime Radiative Cooling

Abstract

1. Introduction

2. Methods

2.1. Radiative Properties of the Films

2.2. Radiative Transfer Model

2.3. Net Radiative Cooling Power

3. Results and Discussion

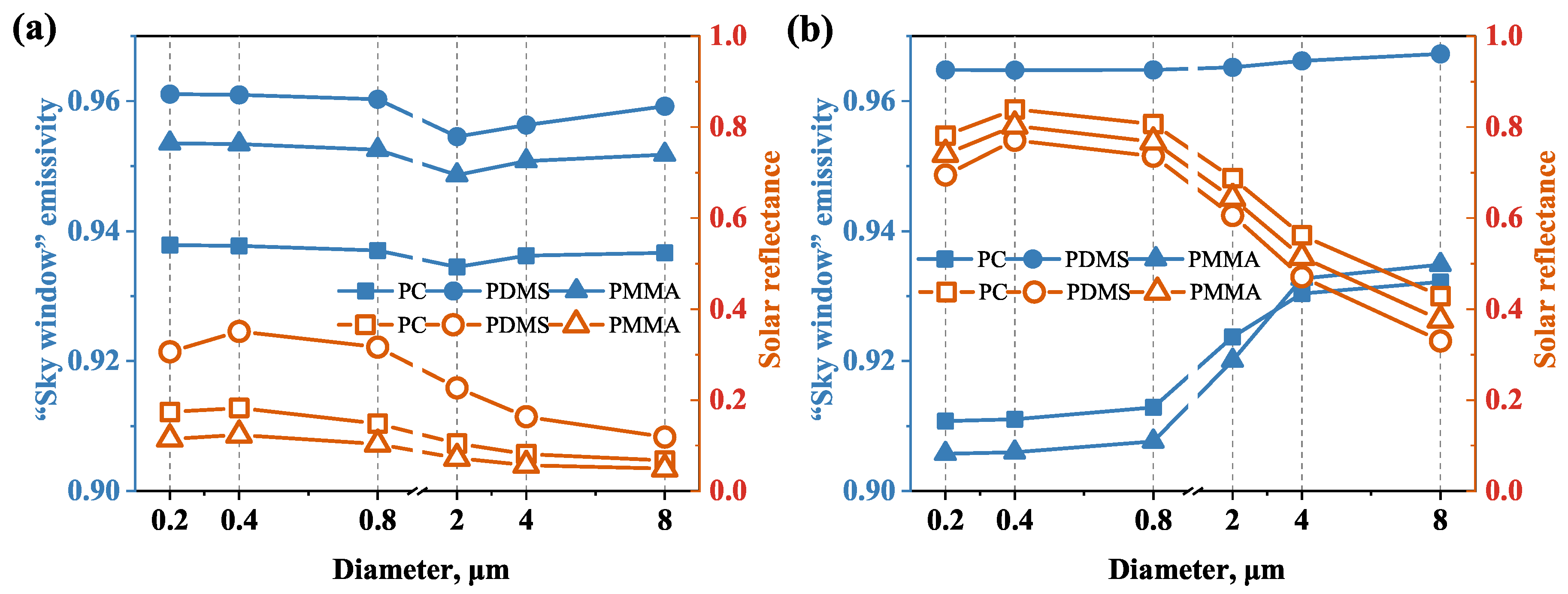

3.1. Effect of Diameter on Radiative Properties

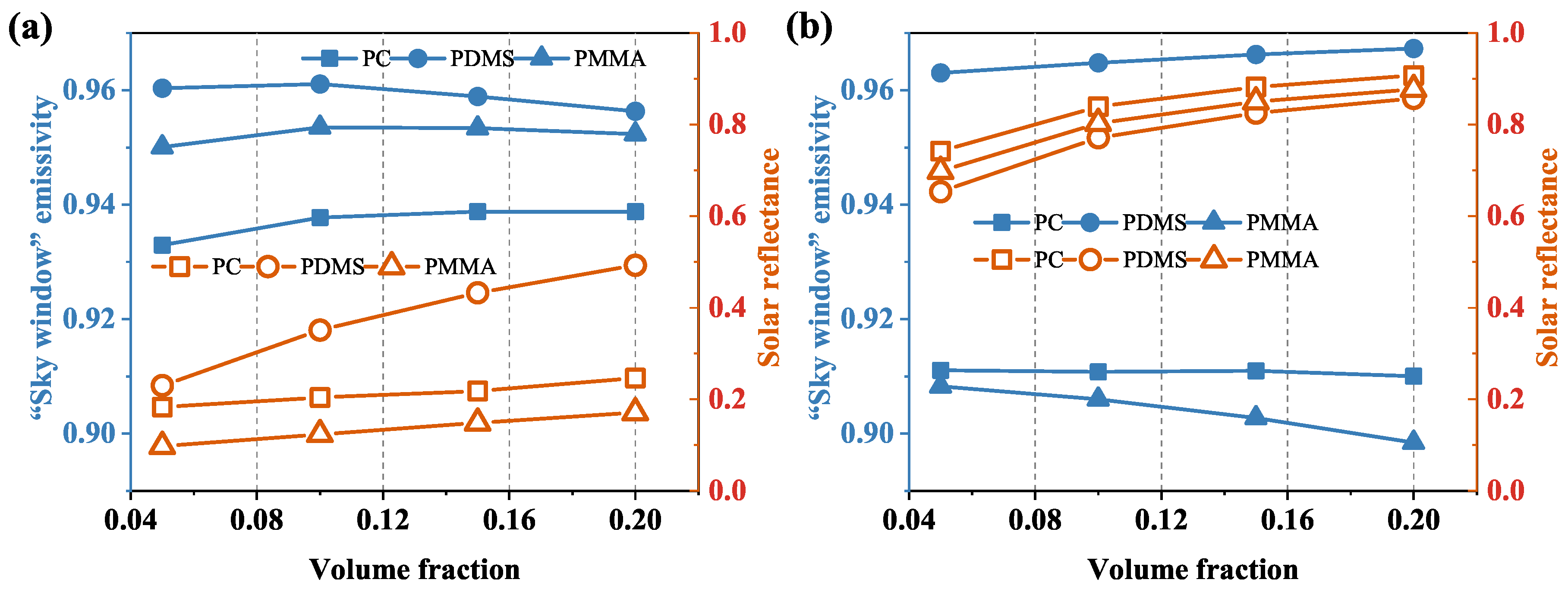

3.2. Effect of Volume Fraction on the Radiative Properties

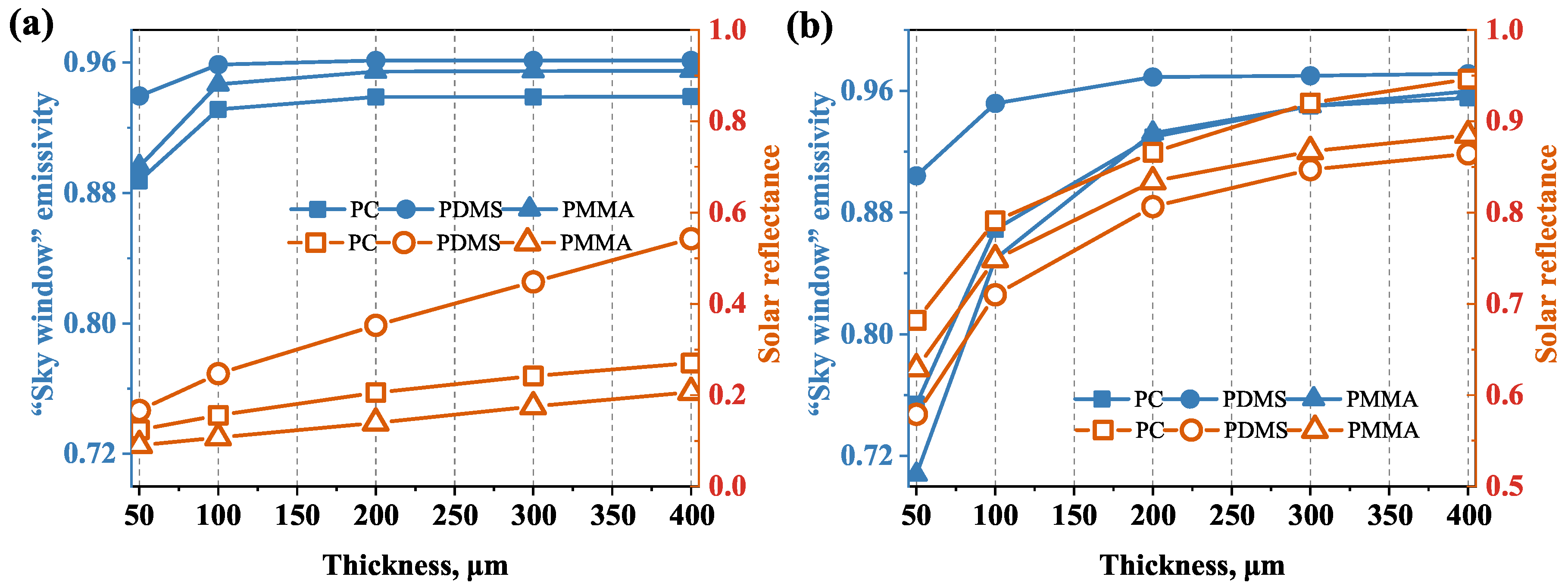

3.3. Effect of Thickness on the Radiative Properties

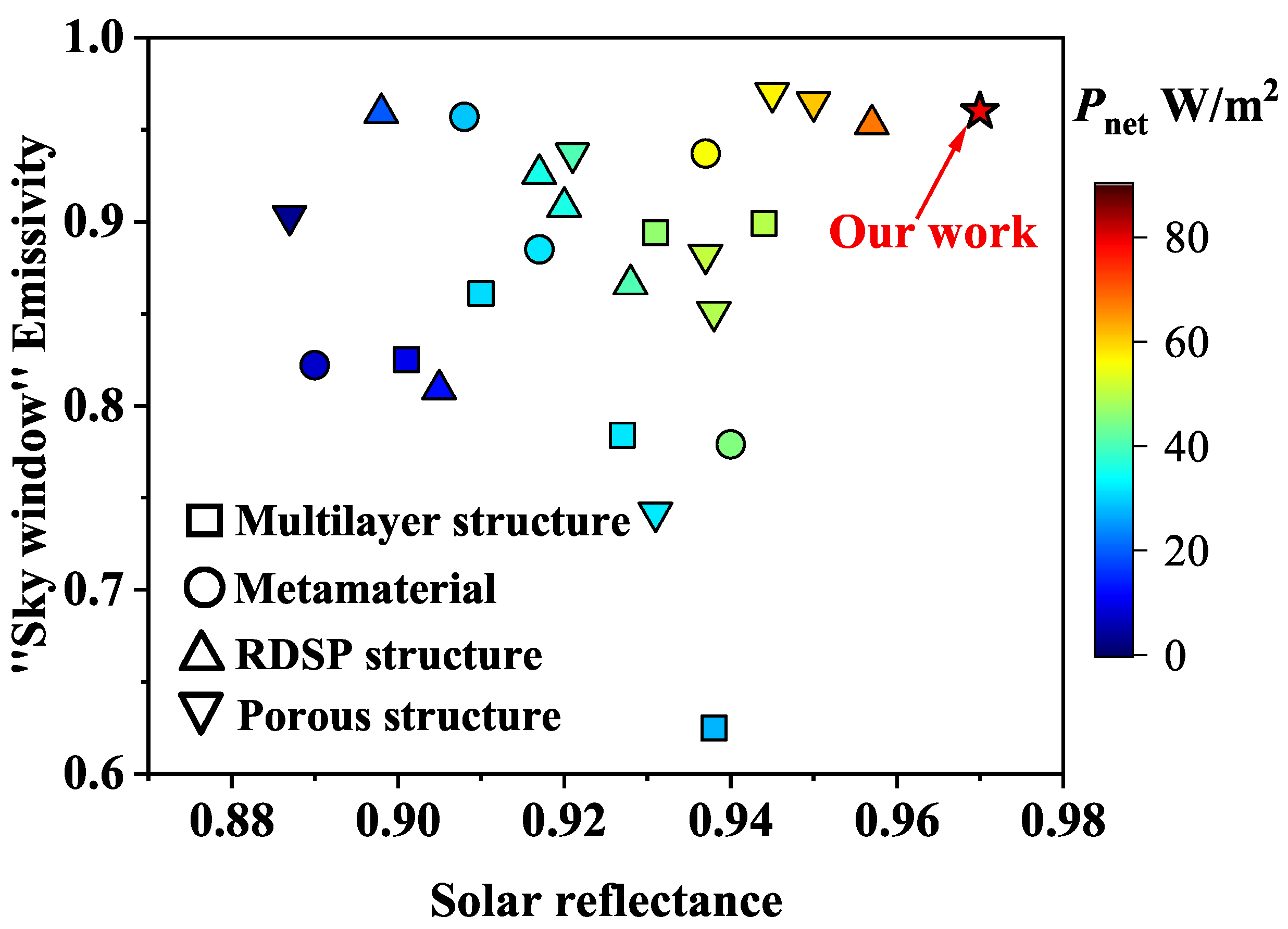

3.4. Effect of the Microstructure on Cooling Power

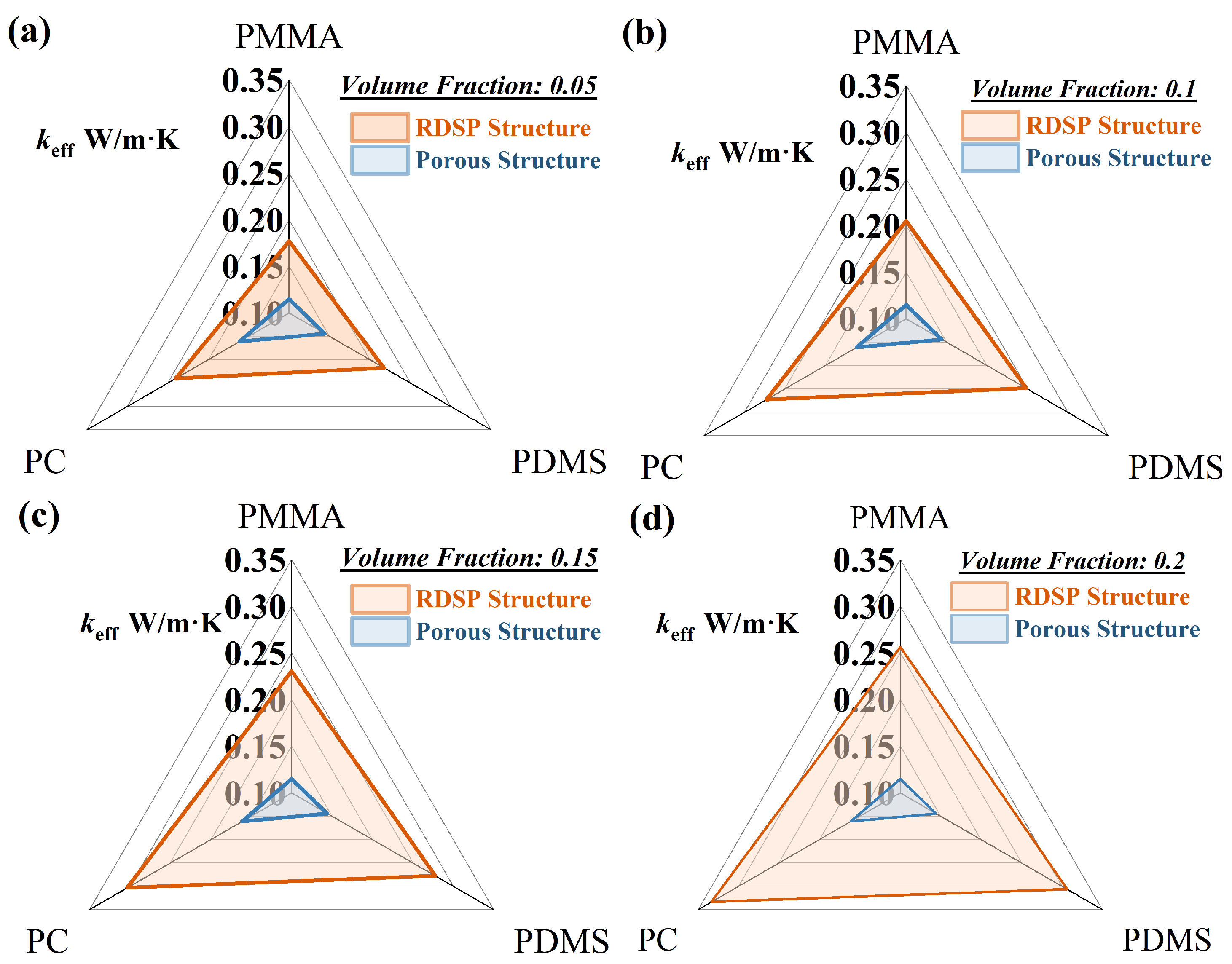

3.5. Influences of Different Structures on Thermal Insulation Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Mie scattering coefficient | |

| Mie scattering coefficient | |

| D | diameter of dispersed medium, m |

| particle volume fraction | |

| g | asymmetry factor |

| comprehensive non-radiative heat transfer coefficient | |

| AM1.5 spectral solar irradiance | |

| spectral intensity emitted by blackbody | |

| effective thermal conductivity, W/m·K | |

| m | complex refractive index, |

| normalized complex refractive index | |

| ambient radiation power, W/m | |

| daytime net cooling power, W/m | |

| thermal loss power, W/m | |

| the radiation power, W/m | |

| absorbed solar radiation energy, W/m | |

| extinction efficiency factor | |

| scattering efficiency factor | |

| spectral reflectance of film | |

| solar weighted reflectance | |

| T | temperature, K |

| t | thickness of films, m |

| Greek symbols | |

| spectral emittance of film | |

| extinction coefficient | |

| weighted emissivity | |

| total absorption coefficient | |

| absorption coefficient | |

| wavelength of radiation, m | |

| scattering coefficient | |

| total scattering coefficient | |

| Superscripts and subscripts | |

| amb | ambient |

| h | host medium |

| m | dispersed medium |

References

- Isaac, M.; Vuuren, D. Modeling global residential sector energy demand for heating and air conditioning in the context of climate change. Energy Policy 2009, 37, 507–521. [Google Scholar] [CrossRef]

- Huang, M.; Yu, X.; Wan, J.; Du, M.; Wang, X.; Sun, Q.; Tang, G. All-Day Effective Radiative Cooling by Optically Selective and Thermally Insulating Mesoporous Materials. Sol. Energy 2022, 235, 170–179. [Google Scholar] [CrossRef]

- Dong, M.; Zhu, L.; Jiang, B.; Fan, S.; Chen, Z. Concentrated radiative cooling and its constraint from reciprocity. Opt. Express 2022, 30, 275–285. [Google Scholar] [CrossRef] [PubMed]

- Brown, J.S.; Domanski, P. Review of alternative cooling technologies. Appl. Therm. Eng. 2014, 64, 252–262. [Google Scholar] [CrossRef]

- Zhong, H.; Li, Y.; Zhang, P.; Gao, S.; Liu, B.; Wang, Y.; Meng, T.; Zhou, Y.; Hou, H.; Xue, C.; et al. Hierarchically Hollow Microfibers as a Scalable and Effective Thermal Insulating Cooler for Buildings. Appl. Therm. Eng. 2021, 5, 10076–10083. [Google Scholar] [CrossRef]

- Nishijima, Y.; Kimura, S.; Takeshima, Y.; Juodkazis, S. Metasurfaces as Energy Valves for Sustainable Energy Management. Micromachines 2022, 13, 1769. [Google Scholar] [CrossRef]

- Yang, R.; Wang, M.; Du, M.; Wang, X.; Tang, G. Droplet effect on the infrared transmittance of radiative cooler for direct water condensation. Sol. Energy Mater. Sol. Cells 2022, 238, 111615. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, L.; Raman, A.; Fan, S. Radiative cooling to deep sub-freezing temperatures through a 24-h day-night cycle. Nat. Commun. 2016, 7, 13729. [Google Scholar] [CrossRef]

- Zhu, L.; Raman, A.; Fan, S. Color-preserving daytime radiative cooling. Appl. Phys. Lett. 2013, 103, 223902. [Google Scholar] [CrossRef]

- Kimball, B. Cooling performance and efficiency of night sky radiators. Sol. Energy 1985, 34, 19–33. [Google Scholar] [CrossRef]

- Berdahl, P. Radiative cooling with MgO and/or LiF layers. Appl. Opt. 1984, 23, 370. [Google Scholar] [CrossRef]

- NilssonGunnar, T.; Niklasson, A. Radiative cooling during the day: Simulations and experiments on pigmented polyethylene cover foils. Sol. Energy Mater. Sol. Cells 1995, 37, 93–118. [Google Scholar]

- Bartoli, B.; Catalanotti, S.; Coluzzi, B.; Cuomo, V.; Silvestrini, V.; Troise, G. Nocturnal and diurnal performances of selective radiators. Appl. Energy 1977, 3, 267–286. [Google Scholar] [CrossRef]

- Catalanotti, S.; Cuomo, V.; Piro, G.; Ruggi, D.; Silvestrini, V.; Troise, G. The radiative cooling of selective surfaces. Sol. Energy 1975, 17, 83–89. [Google Scholar] [CrossRef]

- Rephaeli, E.; Raman, A.; Fan, S. Ultrabroad band photonic structures to achieve high-performance daytime radiative cooling. Nano Lett. 2013, 13, 1457–1461. [Google Scholar] [CrossRef]

- Hsu, P.; Liu, C.; Song, A.; Zhang, Z.; Peng, Y.; Xie, J.; Liu, K.; Wu, C.; Catrysse, P.; Cai, L.; et al. Dual-mode Textile for Human Body Radiative Heating and Cooling. Sci. Adv. 2017, 3, 1700895. [Google Scholar] [CrossRef]

- Smith, G.; Granqvist, C. Green Nanotechnology: Solutions for Sustainability and Energy in the Built Environment; CRC Press: Boca Raton, FL, USA, 2011; Volume 5, pp. 303–359. [Google Scholar]

- Hossain, M.M.; Gu, M. Radiative Cooling: Principles, Progress, and Potentials. Adv. Sci. 2016, 3, 1500360. [Google Scholar] [CrossRef]

- Zhai, Y.; Ma, Y.; David, S.; Zhao, D.; Lou, R.; Tan, G.; Yang, R.; Yin, X. Scalablemanufactured randomized glass-polymer hybrid metamaterial for daytime radiative cooling. Science 2017, 355, 1062–1066. [Google Scholar] [CrossRef]

- Mandal, J.; Fu, Y.; Overvig, A.; Jia, M.; Sun, K.; Shi, N.; Zhou, H.; Xiao, X.; Yu, N.; Yang, Y. Hierarchically porous polymer coatings for highly efficient passive daytime radiative cooling. Science 2018, 362, 315–319. [Google Scholar] [CrossRef]

- Yang, R.; Niu, D.; Pu, J.; Tang, G.; Wang, X.; Du, M. Passive all-day freshwater harvesting through a transparent radiative cooling film. Appl. Energy 2022, 325, 119801. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, M.; Ao, X.; Pei, G. Performance evaluation of daytime radiative cooling under different clear sky conditions. Appl. Therm. Eng. 2019, 155, 660–666. [Google Scholar] [CrossRef]

- Huang, J.; Li, M.; Fan, D. Core-shell particles for devising high-performance full-day radiative cooling paint. Sol. Energy 2021, 25, 101209. [Google Scholar] [CrossRef]

- Wiersma, D. A bioinspired “skin” with cooperative thermo-optical effect for daytime radiative cooling. ACS Appl. Mater. Interfaces 2020, 5, 25286–25293. [Google Scholar]

- Baniassadi, A.; Sailor, D.; Ban-Weiss, G. Potential energy and climate benefits of super-cool materials as a rooftop strategy. Urban Clim. 2019, 29, 100495. [Google Scholar] [CrossRef]

- Mandal, J.; Yang, Y.; Yu, N.; Raman, A. Paints as a scalable and effective radiative cooling technology for buildings. Joule 2020, 4, 1350–1356. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, X.; Ma, Y.; Hu, B.; Zhou, J. Transparent polymer coatings for energy-efficient daytime window cooling. Cell Rep. Phys. Sci. 2020, 1, 100231. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, M.; Ao, X.; Xuan, Q.; Pei, G. Spectrally selective approaches for passive cooling of solar cells: A review. Appl. Energy 2020, 262, 114548. [Google Scholar] [CrossRef]

- Hsu, P.C.; Song, A.; Catrysse, P.; Liu, C.; Peng, Y.; Xie, J.; Fan, S.; Cui, Y. Radiative human body cooling by nanoporous polyethylene textile. Science 2016, 353, 1019–1023. [Google Scholar] [CrossRef]

- Ishii, S.; Dao, T.; Nagao, T. Radiative cooling for continuous thermoelectric power generation in day and night. Appl. Phys. Lett. 2020, 117, 013901. [Google Scholar] [CrossRef]

- Dong, M.; Zhang, Z.; Shi, Y.; Zhao, X.; Fan, S.; Chen, Z. Fundamental limits of the dew-harvesting technology. Nanoscale Microscale Thermophys. Eng. 2019, 3, 2679–2686. [Google Scholar] [CrossRef]

- Yu, X.; Huang, M.; Wang, X.; Sun, Q.; Tang, G.H.; Du, M. Toward optical selectivity aerogels by plasmonic nanoparticles doping. Renew. Energy 2022, 190, 741–751. [Google Scholar] [CrossRef]

- Yu, X.; Chan, J.; Chen, C. Review of Radiative Cooling Materials: Performance Evaluation and Design Approaches. Nano Energy 2021, 88, 106529. [Google Scholar] [CrossRef]

- Zhao, B.; Hu, M.; Ao, X.; Chen, N.; Pei, G. Radiative cooling: A review of fundamentals, materials, applications, and prospects. Appl. Energy 2019, 236, 489–513. [Google Scholar] [CrossRef]

- Bijarniya, J.; Sarkar, J.; Maiti, P. Review on passive daytime radiative cooling: Fundamentals, recent researches, challenges and opportunities. Renew. Sustain. Energy Rev. 2020, 133, 110263. [Google Scholar] [CrossRef]

- Li, D.; Liu, X.; Li, W.; Lin, Z.; Zhu, B.; Li, Z.; Li, J.; Li, B.; Fan, S.; Xie, J.; et al. Scalable and hierarchically designed polymer film as a selective thermal emitter for high performance all-day radiative cooling. Nat. Nanotechnol. 2021, 16, 153–158. [Google Scholar] [CrossRef]

- Zhao, H.; Sun, Q.; Zhou, J.; Deng, X.; Cui, J. Switchable cavitation in silicone coatings for energy-saving cooling and heating. Nat. Nanotechnol. 2020, 32, 2000870. [Google Scholar] [CrossRef]

- Zhao, D.; Aili, A.; Zhai, Y.; Lu, J.; Kidd, D.; Tan, G.; Yin, X.; Yang, R. Subambient cooling of water: Toward real-world applications of daytime radiative cooling. Joule 2019, 3, 111–123. [Google Scholar] [CrossRef]

- Li, X.; Peoples, J.; Yao, P.; Ruan, X. Ultrawhite BaSO4 paints and films for remarkable daytime subambient radiative cooling. ACS Appl. Mater. Interfaces 2021, 13, 21733–21739. [Google Scholar] [CrossRef]

- Chen, M.; Pang, D.; Chen, X.; Yan, H. Enhancing infrared emission behavior of polymer coatings for radiative cooling applications. J. Phys. D Appl. Phys. 2021, 54, 295501. [Google Scholar] [CrossRef]

- Modest, M. Radiative Heat Transfer, 3rd ed.; Academic Press: San Diego, CA, USA, 2013. [Google Scholar]

- Wen, S.; Qi, H.; Li, Y.; Ren, Y.; Ruan, L. An on-line extended Kalman filtering technique for reconstructing the transient heat flux and temperature field in twodimensional participating media. Int. J. Therm. Sci. 2020, 148, 106069. [Google Scholar] [CrossRef]

- Wang, F.; Wang, H.; Gong, D.; Cheng, Z.; Ma, L. Radiative transfer analysis of semitransparent medium with particles having non-uniform size distribution by differential-integration method. Int. J. Heat Mass Transf. 2019, 130, 342–355. [Google Scholar] [CrossRef]

- Kamiuto, K. Study of the Henyey-Greenstein approximation to scattering phase functions. J. Quant. Spectrosc. Radiat. Transf. 1987, 37, 411–413. [Google Scholar] [CrossRef]

- Chen, M.; Pang, D.; Mandal, J.; Chen, X.; Yan, H.; He, Y.; Yu, N.; Yang, Y. Designing Mesoporous Photonic Structures for High-Performance Passive Daytime Radiative Cooling. Nano Lett. 2021, 21, 1412–1418. [Google Scholar] [CrossRef] [PubMed]

- Raman, A.; Anoma, M.; Zhu, L.; Rephaeli, E.; Fan, S. Passive radiative cooling below ambient air temperature under direct sunlight. Nature 2014, 515, 540–544. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A Variational Approach to the Theory of the Effective Magnetic Permeability of Multiphase Materials. J. Appl. Phys. 1962, 33, 3125–3131. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, Y. Passive Daytime Radiative Cooling: Principle, Application, and Economic Analysis. MRS Energy Sustain. 2020, 7, 1–8. [Google Scholar] [CrossRef]

- Yu, X.Y.; Huang, M.Q.; Wang, X.Y.; Tang, G.H.; Du, M. Plasmon silica aerogel for improving high- temperature solar thermal conversion. Appl. Therm. Eng. 2023, 219, 119419. [Google Scholar] [CrossRef]

- Cheng, Z.M.; Wang, F.Q.; Liang, G.D.Y.H.X.; Shuai, Y. Low-cost radiative cooling blade coating with ultrahigh visible light transmittance and emission within an “atmospheric window”. Sol. Energy Mater. Sol. Cells 2020, 213, 110563. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, M.; Huang, M.; Yu, X.; Ren, X.; Sun, Q. Structure Design of Polymer-Based Films for Passive Daytime Radiative Cooling. Micromachines 2022, 13, 2137. https://doi.org/10.3390/mi13122137

Du M, Huang M, Yu X, Ren X, Sun Q. Structure Design of Polymer-Based Films for Passive Daytime Radiative Cooling. Micromachines. 2022; 13(12):2137. https://doi.org/10.3390/mi13122137

Chicago/Turabian StyleDu, Mu, Maoquan Huang, Xiyu Yu, Xingjie Ren, and Qie Sun. 2022. "Structure Design of Polymer-Based Films for Passive Daytime Radiative Cooling" Micromachines 13, no. 12: 2137. https://doi.org/10.3390/mi13122137

APA StyleDu, M., Huang, M., Yu, X., Ren, X., & Sun, Q. (2022). Structure Design of Polymer-Based Films for Passive Daytime Radiative Cooling. Micromachines, 13(12), 2137. https://doi.org/10.3390/mi13122137