Recent Progress in Thin-Film Transistors toward Digital, Analog, and Functional Circuits

Abstract

1. Introduction

2. Digital Thin-Film Circuits

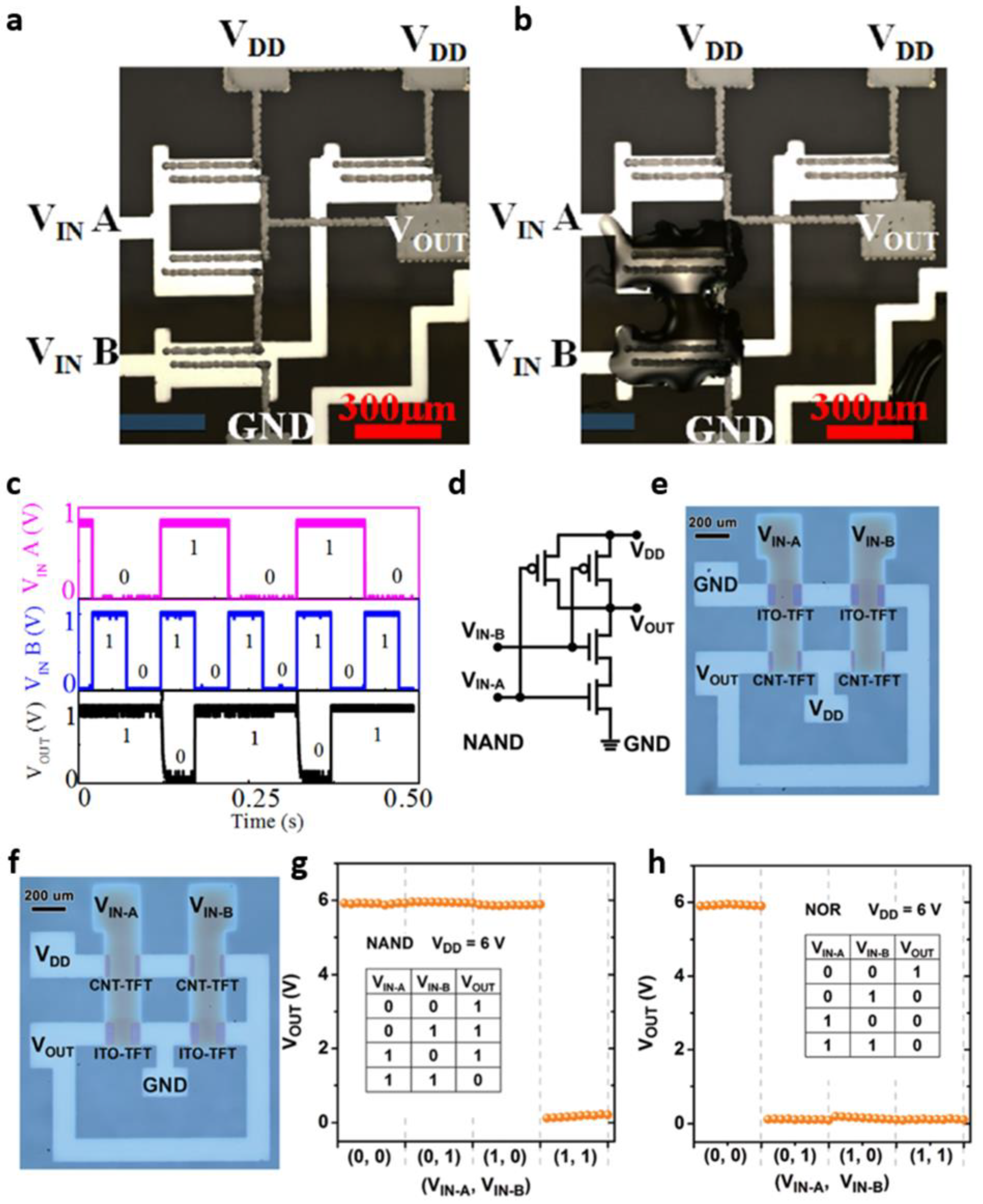

2.1. CNT-Based Thin-Film Digital Circuits

2.2. OECT-Based Thin-Film Digital Circuits

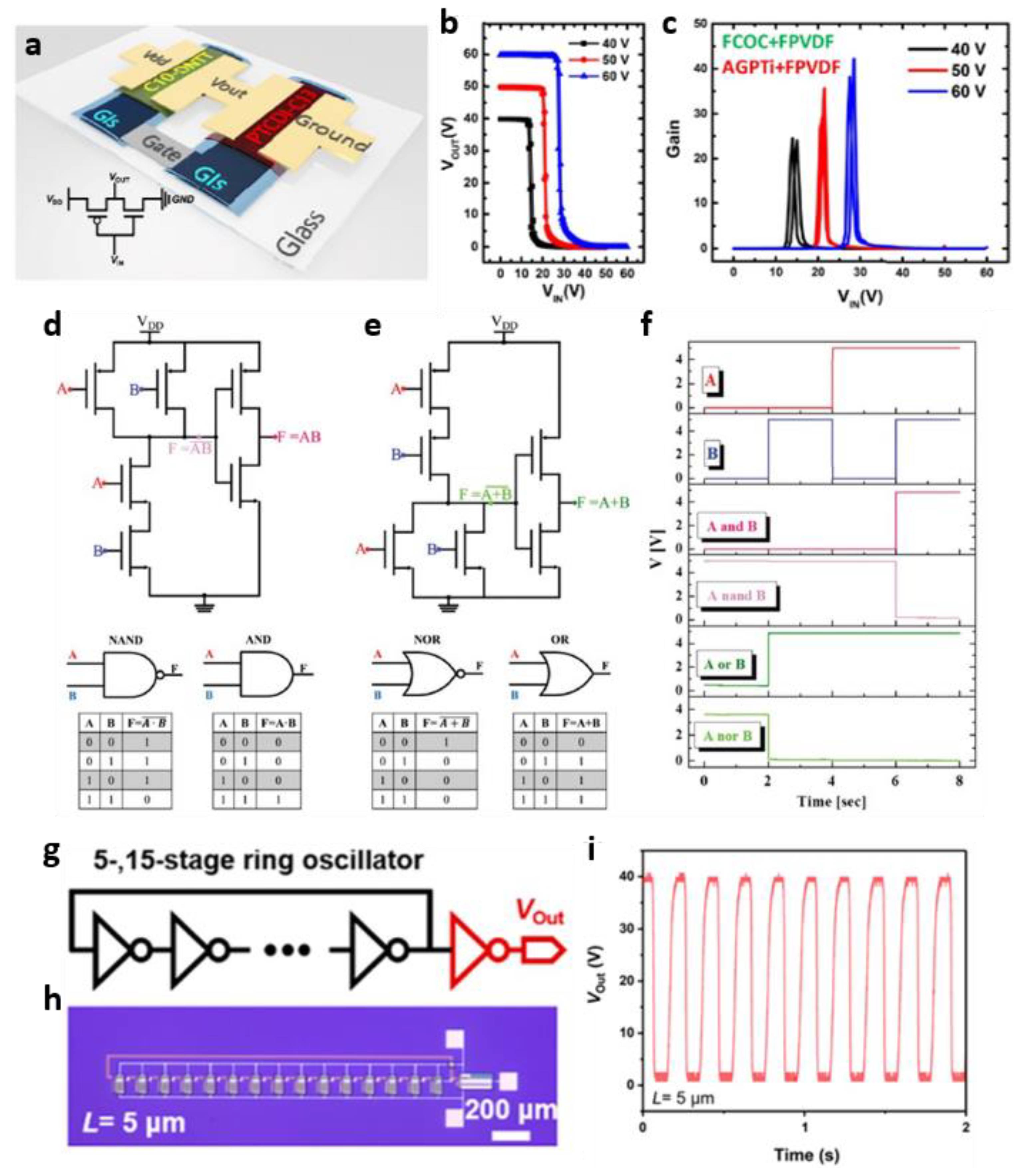

2.3. Organic-Based Thin-Film Digital Circuits

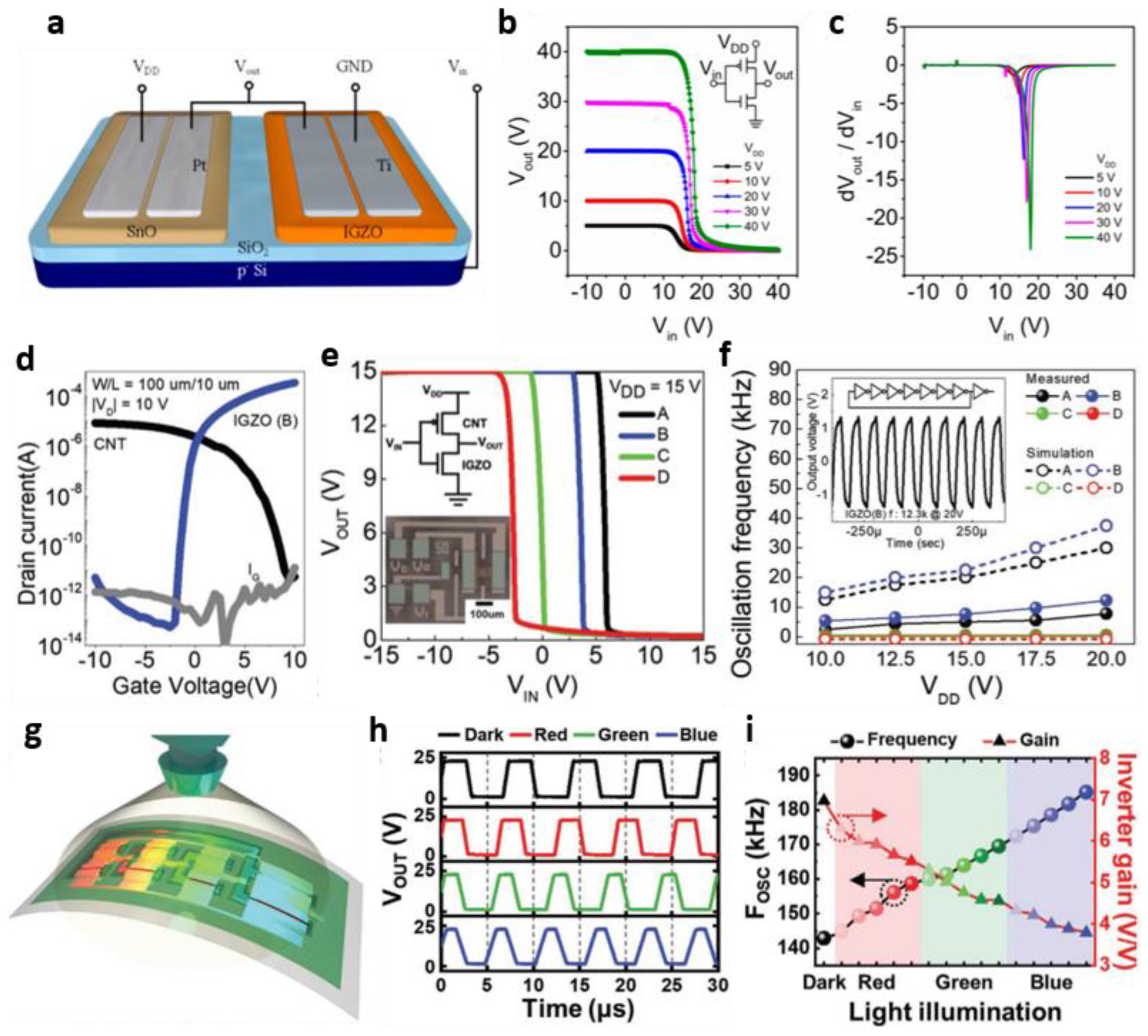

2.4. Metal-Oxide-Based Thin-Film Digital Circuits

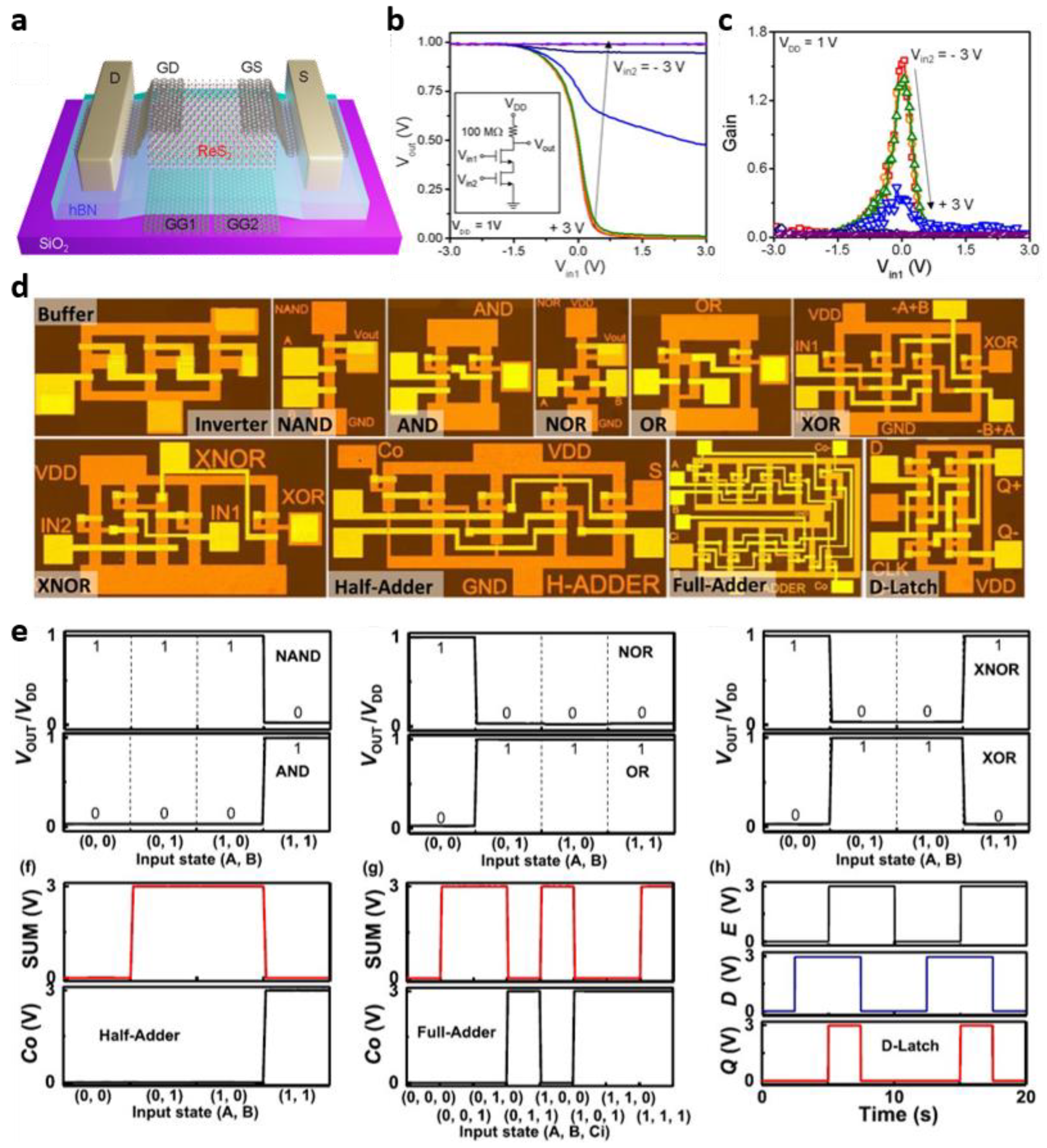

2.5. TMDs-Based Thin-Film Digital Circuits

3. Analog circuits

3.1. CNT-Based Thin-Film Analog Circuits

3.2. OECT-Based Thin-Film Analog Circuits

3.3. Organic-Based Thin-Film Analog Circuits

3.4. Metal-Oxide-Based Thin-Film Analog Circuits

3.5. TMD-Based Thin-Film Analog Circuits

4. Summary

Author Contributions

Funding

Conflicts of Interest

References

- Gedda, M.; Yengel, E.; Faber, H.; Paulus, F.; Kress, J.A.; Tang, M.C.; Zhang, S.; Hacker, C.A.; Kumar, P.; Naphade, D.R.; et al. Ruddlesden-popper-phase hybrid halide perovskite/small-molecule organic blend memory transistors. Adv. Mater. 2021, 33, e2003137. [Google Scholar] [CrossRef]

- Ho, D.; Vegiraju, S.; Choi, D.; Cho, C.-H.; Kwon, G.; Huang, P.-C.; Lee, G.-H.; Earmme, T.; Yau, S.L.; Chen, M.-C.; et al. Solution-processable small molecules for bulk heterojunction ambipolar thin-film transistors and complementary-like inverters. Dyes Pigments 2019, 163, 725–733. [Google Scholar] [CrossRef]

- Kwon, J.; Matsui, H.; Kim, W.; Tokito, S.; Jung, S. Static and dynamic response comparison of printed, single- and dual-gate 3-D complementary organic TFT inverters. IEEE Electron. Device Lett. 2019, 40, 1277–1280. [Google Scholar] [CrossRef]

- Miyata, R.; Inoue, S.; Nakajima, K.; Hasegawa, T. Insulating polymer blend organic thin-film transistors based on bilayer-type alkylated benzothieno[3,2-b]naphtho[2,3-b]thiophene. ACS Appl. Mater. Interfaces 2022, 14, 17719–17726. [Google Scholar] [CrossRef] [PubMed]

- Hur, J.S.; Kim, J.O.; Kim, H.A.; Jeong, J.K. Stretchable polymer gate dielectric by ultraviolet-assisted hafnium oxide doping at low temperature for high-performance indium gallium tin oxide transistors. ACS Appl. Mater. Interfaces 2019, 11, 21675–21685. [Google Scholar] [CrossRef]

- Kang, Y.H.; Min, B.K.; Kim, S.K.; Bae, G.; Song, W.; Lee, C.; Cho, S.Y.; An, K.S. Proton conducting perhydropolysilazane-derived gate dielectric for solution-processed metal oxide-based thin-film transistors. ACS Appl. Mater. Interfaces 2020, 12, 15396–15405. [Google Scholar] [CrossRef]

- Wang, P.; Yang, H.; Li, J.; Zhang, X.; Wang, L.; Xiao, J.; Zhao, B.; Zhang, S.; Lu, L. Synergistically enhanced performance and reliability of abrupt metal-oxide heterojunction transistor. Adv. Electron. Mater. 2022, 2200807. [Google Scholar] [CrossRef]

- Ippolito, S.; Kelly, A.G.; Furlan de Oliveira, R.; Stoeckel, M.A.; Iglesias, D.; Roy, A.; Downing, C.; Bian, Z.; Lombardi, L.; Samad, Y.A.; et al. Covalently interconnected transition metal dichalcogenide networks via defect engineering for high-performance electronic devices. Nat. Nanotechnol. 2021, 16, 592–598. [Google Scholar] [CrossRef]

- Lee, H.; Bak, S.; Kim, J.; Lee, H. The effect of the dopant’s reactivity for high-performance 2D MoS2 thin-film transistor. Nano Res. 2020, 14, 198–204. [Google Scholar] [CrossRef]

- Kim, M.; Mackenzie, D.M.A.; Kim, W.; Isakov, K.; Lipsanen, H. All-parylene flexible wafer-scale graphene thin film transistor. Appl. Surf. Sci. 2021, 551, 149410. [Google Scholar] [CrossRef]

- Yogeswaran, N.; Hosseini, E.S.; Dahiya, R. Graphene based low voltage field effect transistor coupled with biodegradable piezoelectric material based dynamic pressure sensor. ACS Appl. Mater. Interfaces 2020, 12, 54035–54040. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Lotfi, A.; Hesketh, P.J.; Kumar, S. Carbon nanotube thin-film-transistors for gas identification. Sens. Actuators B: Chem. 2019, 281, 1080–1087. [Google Scholar] [CrossRef]

- Cardenas, J.A.; Upshaw, S.; Williams, N.X.; Catenacci, M.J.; Wiley, B.J.; Franklin, A.D. Impact of morphology on printed contact performance in carbon nanotube thin-film transistors. Adv. Funct. Mater. 2018, 29, 1805727. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, A.; Shim, K.I.; Hong, J.; Han, J.W.; Noh, Y.Y. High-performance and reliable lead-free layered-perovskite transistors. Adv. Mater. 2020, 32, e2002717. [Google Scholar] [CrossRef] [PubMed]

- Liu, A.; Zhu, H.; Bai, S.; Reo, Y.; Zou, T.; Kim, M.-G.; Noh, Y.-Y. High-performance inorganic metal halide perovskite transistors. Nat. Electron. 2022, 5, 78–83. [Google Scholar] [CrossRef]

- Dou, W.; Tan, Y. Dual-gate low-voltage transparent electric-double-layer thin-film transistors with a top gate for threshold voltage modulation. RSC Adv. 2020, 10, 8093–8096. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Alim, N.; Hong, W.-C.; Li, G.; Reyes, P.I.; Wang, S.-Y.; Yu, F.; Lu, Y. MgZnO thin film transistors on glass with blocking voltage of 900 V. IEEE Electron. Device Lett. 2020, 41, 1352–1355. [Google Scholar] [CrossRef]

- Byun, H.-R.; You, E.-A.; Ha, Y.-G. Room-temperature solution-processed, ZrOx-based hybrid gate dielectrics for low-voltage organic thin-film transistors on plastic substrates. Appl. Phys. Lett. 2019, 114, 013301. [Google Scholar] [CrossRef]

- Hallani, R.K.; Moser, M.; Bristow, H.; Jenart, M.V.C.; Faber, H.; Neophytou, M.; Yarali, E.; Paterson, A.F.; Anthopoulos, T.D.; McCulloch, I. Low-temperature cross-linking benzocyclobutene based polymer dielectric for organic thin film transistors on plastic substrates. J. Org. Chem. 2020, 85, 277–283. [Google Scholar] [CrossRef]

- Borchert, J.W.; Peng, B.; Letzkus, F.; Burghartz, J.N.; Chan, P.K.L.; Zojer, K.; Ludwigs, S.; Klauk, H. Small contact resistance and high-frequency operation of flexible low-voltage inverted coplanar organic transistors. Nat. Commun. 2019, 10, 1119. [Google Scholar] [CrossRef]

- Yang, P.; Cai, G.; Wang, X.; Pei, Y. Electrolyte-gated indium oxide thin film transistor based biosensor with low operation voltage. IEEE Trans. Electron. Devices 2019, 66, 3554–3559. [Google Scholar] [CrossRef]

- Wang, N.; Yang, A.; Fu, Y.; Li, Y.; Yan, F. Functionalized organic thin film transistors for biosensing. Acc. Chem. Res. 2019, 52, 277–287. [Google Scholar] [CrossRef] [PubMed]

- Yang, A.; Yan, F. Flexible electrochemical biosensors for health monitoring. ACS Appl. Electron. Mater. 2020, 3, 53–67. [Google Scholar] [CrossRef]

- Mano, T.; Nagamine, K.; Ichimura, Y.; Shiwaku, R.; Furusawa, H.; Matsui, H.; Kumaki, D.; Tokito, S. Printed organic transistor-based enzyme sensor for continuous glucose monitoring in wearable healthcare applications. ChemElectroChem 2018, 5, 3881–3886. [Google Scholar] [CrossRef]

- Im, H.; Hong, S.; Lee, Y.; Lee, H.; Kim, S. A colorimetric multifunctional sensing method for structural-durability-health monitoring systems. Adv. Mater. 2019, 31, e1807552. [Google Scholar] [CrossRef]

- Wan, H.; Cao, Y.; Lo, L.W.; Zhao, J.; Sepulveda, N.; Wang, C. Flexible carbon nanotube synaptic transistor for neurological electronic skin applications. ACS Nano 2020, 14, 10402–10412. [Google Scholar] [CrossRef]

- Hu, W.; Wan, L.; Jian, Y.; Ren, C.; Jin, K.; Su, X.; Bai, X.; Haick, H.; Yao, M.; Wu, W. Electronic noses: From advanced materials to sensors aided with data processing. Adv. Mater. Technol. 2018, 4, 1800488. [Google Scholar] [CrossRef]

- Lee, C.-J.; Chang, Y.-C.; Wang, L.-W.; Wang, Y.-H. Biodegradable materials for organic field-effect transistors on a paper substrate. IEEE Electron. Device Lett. 2019, 40, 236–239. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, Z.-H.; Liu, H.; Chen, L.; Liu, X.-k.; Min, L.; Li, Z.-w.; Zhu, H.; Sun, Q.-Q. Feasibility of large-scale MoS2 thin-film transistors on a GaN substrate. ACS Appl. Electron. Mater. 2019, 1, 1418–1423. [Google Scholar] [CrossRef]

- Bolat, S.; Fuchs, P.; Knobelspies, S.; Temel, O.; Sevilla, G.T.; Gilshtein, E.; Andres, C.; Shorubalko, I.; Liu, Y.; Tröster, G.; et al. Inkjet-printed and deep-UV-annealed YAlOx dielectrics for high-performance IGZO thin-film transistors on flexible substrates. Adv. Electron. Mater. 2019, 5, 1800843. [Google Scholar] [CrossRef]

- Kim, D.; Woo, H.K.; Lee, Y.M.; Kim, Y.; Choi, J.-H.; Oh, S.J. Controllable doping and passivation of ZnO thin films by surface chemistry modification to design low-cost and high-performance thin film transistors. Appl. Surf. Sci. 2020, 509, 145289. [Google Scholar] [CrossRef]

- Duan, S.; Gao, X.; Wang, Y.; Yang, F.; Chen, M.; Zhang, X.; Ren, X.; Hu, W. Scalable fabrication of highly crystalline organic semiconductor thin film by channel-restricted screen printing toward the low-cost fabrication of high-performance transistor arrays. Adv. Mater. 2019, 31, e1807975. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.; Chen, S.; Tang, W.; Liang, J.; Ouyang, B.; Li, M.; Song, Y.; Shan, T.; Chen, C.-C.; Too, P.; et al. Low-temperature solution-processed all organic integration for large-area and flexible high-resolution imaging. IEEE J. Electron. Devices 2022, 10, 821–826. [Google Scholar] [CrossRef]

- Wang, R.; Kwon, H.-j.; Tang, X.; Ye, H.; Park, C.E.; Kim, J.; Kong, H.; Kim, S.H. Slot-die coating of sol–gel-based organic–inorganic nanohybrid dielectric layers for flexible and large-area organic thin film transistors. Appl. Surf. Sci. 2020, 529, 147198. [Google Scholar] [CrossRef]

- Liu, P.T.; Ruan, D.B.; Yeh, X.Y.; Chiu, Y.C.; Zheng, G.T.; Sze, S.M. Highly responsive blue light sensor with amorphous Indium-Zinc-Oxide thin-film transistor based architecture. Sci. Rep. 2018, 8, 8153. [Google Scholar] [CrossRef]

- Vishniakou, S.; Chen, R.; Ro, Y.G.; Brennan, C.J.; Levy, C.; Yu, E.T.; Dayeh, S.A. Improved performance of Zinc Oxide thin film transistor pressure sensors and a demonstration of a commercial chip compatibility with the new force sensing technology. Adv. Mater. Technol. 2018, 3, 1700279. [Google Scholar] [CrossRef]

- Yin, M.-J.; Li, Z.-R.; Lv, T.-R.; Yong, K.-T.; An, Q.-F. Low-voltage driven flexible organic thin-film transistor humidity sensors. Sens. Actuators B: Chem. 2021, 339, 129887. [Google Scholar] [CrossRef]

- Im, H.; AlMutairi, A.; Kim, S.; Sritharan, M.; Kim, S.; Yoon, Y. On MoS2 thin-film transistor design consideration for a NO2 gas sensor. ACS Sens. 2019, 4, 2930–2936. [Google Scholar] [CrossRef]

- Oh, H.; Kim, H.; Yoo, H.; Park, B.; Chung, S.; Lee, B.; Hong, Y. Inkjet-printing-based density profile engineering of single-walled carbon nanotube networks for conformable high-on/off-performance thin-film transistors. ACS Appl. Mater. Interfaces 2021, 13, 43163–43173. [Google Scholar] [CrossRef]

- Shin, H.; Park, S.-J.; Kang, B.-C.; Ha, T.-J. Comprehensive analysis of two-dimensional charge transport mechanism in thin-film transistors based on random networks of single-wall carbon nanotubes using transient measurements. Nano Res. 2021, 15, 1524–1531. [Google Scholar] [CrossRef]

- Zhang, Z.; Du, C.; Jiao, H.; Zhang, M. Polyvinyl alcohol/SiO2 hybrid dielectric for transparent flexible/stretchable all-carbon-nanotube thin-film-transistor integration. Adv. Electron. Mater. 2020, 6, 1901133. [Google Scholar] [CrossRef]

- Wei, M.; Robin, M.; Portilla, L.; Ren, Y.; Shao, S.; Bai, L.; Cao, Y.; Pecunia, V.; Cui, Z.; Zhao, J. Air-stable N-type printed carbon nanotube thin film transistors for CMOS logic circuits. Carbon 2020, 163, 145–153. [Google Scholar] [CrossRef]

- Zou, J.; Zhang, K.; Cai, W.; Chen, T.; Nathan, A.; Zhang, Q. Optical-reconfigurable carbon nanotube and indium-tin-oxide complementary thin-film transistor logic gates. Nanoscale 2018, 10, 13122–13129. [Google Scholar] [CrossRef] [PubMed]

- Zabihipour, M.; Lassnig, R.; Strandberg, J.; Berggren, M.; Fabiano, S.; Engquist, I.; Andersson Ersman, P. High yield manufacturing of fully screen-printed organic electrochemical transistors. npj Flex. Electron. 2020, 4, 15. [Google Scholar] [CrossRef]

- Jo, Y.J.; Kwon, K.Y.; Khan, Z.U.; Crispin, X.; Kim, T.I. Gelatin hydrogel-based organic electrochemical transistors and their integrated logic circuits. ACS Appl. Mater. Interfaces 2018, 10, 39083–39090. [Google Scholar] [CrossRef]

- Sun, H.; Vagin, M.; Wang, S.; Crispin, X.; Forchheimer, R.; Berggren, M.; Fabiano, S. Complementary logic circuits based on high-performance n-type organic electrochemical transistors. Adv. Mater. 2018, 30, 1704916. [Google Scholar] [CrossRef]

- Dai, F.; Liu, X.; Yang, T.; Qian, J.; Li, Y.; Gao, Y.; Xiong, P.; Ou, H.; Wu, J.; Kanehara, M.; et al. Fabrication of two-dimensional crystalline organic films by tilted spin coating for high-performance organic field-effect transistors. ACS Appl. Mater. Interfaces 2019, 11, 7226–7234. [Google Scholar] [CrossRef]

- Khound, S.; Sarmah, J.K.; Sarma, R. Hybrid La2O3-cPVP dielectric for organic thin film transistor applications. ECS J. Solid State Sci. Technol. 2022, 11, 013007. [Google Scholar] [CrossRef]

- Li, X.; Kim, K.; Oh, H.; Moon, H.C.; Nam, S.; Kim, S.H. Cone-jet printing of aligned silver nanowire/poly(ethylene oxide) composite electrodes for organic thin-film transistors. Org. Electron. 2019, 69, 190–199. [Google Scholar] [CrossRef]

- Singh, S.; Takeda, Y.; Matsui, H.; Tokito, S. Flexible inkjet-printed dual-gate organic thin film transistors and PMOS inverters: Noise margin control by top gate. Org. Electron. 2020, 85, 105847. [Google Scholar] [CrossRef]

- Tang, X.; Kwon, H.J.; Li, Z.; Wang, R.; Kim, S.J.; Park, C.E.; Jeong, Y.J.; Kim, S.H. Strategy for selective printing of gate insulators customized for practical application in organic integrated devices. ACS Appl. Mater. Interfaces 2021, 13, 1043–1056. [Google Scholar] [CrossRef] [PubMed]

- Siddiqui, G.U.; Rehman, M.M.; Choi, K.H. Enhanced resistive switching in all-printed, hybrid and flexible memory device based on perovskite ZnSnO3 via PVOH polymer. Polymer 2016, 100, 102–110. [Google Scholar] [CrossRef]

- Can, T.T.T.; Nguyen, T.C.; Choi, W.S. Patterning of high-viscosity silver paste by an electrohydrodynamic-jet printer for use in TFT applications. Sci. Rep. 2019, 9, 9180. [Google Scholar] [CrossRef] [PubMed]

- Casula, G.; Lai, S.; Matino, L.; Santoro, F.; Bonfiglio, A.; Cosseddu, P. Printed, low-voltage, all-organic transistors and complementary circuits on paper substrate. Adv. Electron. Mater. 2020, 6, 1901027. [Google Scholar] [CrossRef]

- Chen, R.; Yan, Y.; Wang, X.; Chang, C.; Zhao, Y.; Liu, Y.; Wei, D. Patterning an erosion-free polymeric semiconductor channel for reliable all-photolithography organic electronics. J. Phys. Chem. Lett. 2022, 13, 7673–7680. [Google Scholar] [CrossRef]

- Rahaman, A.; Chen, Y.; Hasan, M.M.; Jang, J. A high performance operational amplifier using coplanar dual gate a-IGZO TFTs. IEEE J. Electron. Devices 2019, 7, 655–661. [Google Scholar] [CrossRef]

- Xin, C.; Chen, L.; Li, T.; Zhang, Z.; Zhao, T.; Li, X.; Zhang, J. Highly sensitive flexible pressure sensor by the integration of microstructured PDMS film with a-IGZO TFTs. IEEE Electron. Device Lett. 2018, 39, 1073–1076. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, J.; Yang, Y.; Chen, Q.; Zhang, J. Artificial synapse emulated through fully aqueous solution-processed low-voltage In2O3 thin-film transistor with Gd2O3 solid electrolyte. ACS Appl. Mater. Interfaces 2020, 12, 980–988. [Google Scholar] [CrossRef]

- Magari, Y.; Kataoka, T.; Yeh, W.; Furuta, M. High-mobility hydrogenated polycrystalline In2O3 (In2O3:H) thin-film transistors. Nat. Commun. 2022, 13, 1078. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Y.; Qin, C.; Ding, X.; Zhang, J. Enhanced stability in Zr-doped ZnO TFTs with minor influence on mobility by atomic layer deposition. IEEE Trans. Electron. Devices 2019, 66, 1760–1765. [Google Scholar] [CrossRef]

- Rezk, A.; Saadat, I. High-performance ALD Al-doped ZnO thin-film transistors grown on flexible substrates. IEEE Electron. Device Lett. 2019, 40, 240–242. [Google Scholar] [CrossRef]

- Hsu, S.-M.; He, J.-C.; Li, Y.-S.; Su, D.-Y.; Tsai, F.-Y.; Cheng, I.C. Effect of mechanical strain on electrical performance of flexible P-type SnO thin-film transistors. IEEE Trans. Electron. Devices 2019, 66, 5183–5186. [Google Scholar] [CrossRef]

- Lee, A.W.; Le, D.; Matsuzaki, K.; Nomura, K. Hydrogen-defect termination in SnO for p-channel TFTs. ACS Appl. Electron. Mater. 2020, 2, 1162–1168. [Google Scholar] [CrossRef]

- Jang, J.; Chung, S.; Kang, H.; Subramanian, V. P-type CuO and Cu2O transistors derived from a sol–gel copper (II) acetate monohydrate precursor. Thin Solid Films 2016, 600, 157–161. [Google Scholar] [CrossRef]

- Zeng, X.; Zhukova, M.; Faniel, S.; Li, G.; Flandre, D. Room-temperature DC-sputtered p-type CuO accumulation-mode thin-film transistors gated by HfO2. Appl. Phys. Lett. 2022, 121, 133503. [Google Scholar] [CrossRef]

- Lin, C.-W.; Chung, W.-C.; Zhang, Z.-D.; Hsu, M.-C. P-channel transparent thin-film transistor using physical-vapor-deposited NiO layer. Jpn. J. Appl. Phys. 2018, 57, 01AE01. [Google Scholar] [CrossRef]

- Xu, W.; Zhang, J.; Li, Y.; Zhang, L.; Chen, L.; Zhu, D.; Cao, P.; Liu, W.; Han, S.; Liu, X.; et al. p-type transparent amorphous oxide thin-film transistors using low-temperature solution-processed nickel oxide. J. Alloys Compd. 2019, 806, 40–51. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, J.; Li, Y.; Wilson, J.; Ma, X.; Xin, Q.; Song, A. High performance complementary circuits based on p-SnO and n-IGZO thin-film transistors. Materials 2017, 10, 319. [Google Scholar] [CrossRef]

- Isakov, I.; Paterson, A.F.; Solomeshch, O.; Tessler, N.; Zhang, Q.; Li, J.; Zhang, X.; Fei, Z.; Heeney, M.; Anthopoulos, T.D. Hybrid complementary circuits based on p-channel organic and n-channel metal oxide transistors with balanced carrier mobilities of up to 10 cm2/Vs. Appl. Phys. Lett. 2016, 109, 263301. [Google Scholar] [CrossRef]

- Luo, M.; Zhu, M.; Wei, M.; Shao, S.; Robin, M.; Wei, C.; Cui, Z.; Zhao, J.; Zhang, Z. Radiation-hard and repairable complementary metal-oxide-semiconductor circuits integrating n-type indium oxide and p-type carbon nanotube field-effect transistors. ACS Appl. Mater. Interfaces 2020, 12, 49963–49970. [Google Scholar] [CrossRef]

- Kim, K.T.; Jeon, S.P.; Lee, W.; Jo, J.W.; Heo, J.S.; Kim, I.; Kim, Y.H.; Park, S.K. A site-specific charge carrier control in monolithic integrated amorphous oxide semiconductors and circuits with locally induced optical-doping process. Adv. Funct. Mater. 2019, 29, 1904770. [Google Scholar] [CrossRef]

- Jeong, J.; Seo, S.G.; Yu, S.M.; Kang, Y.; Song, J.; Jin, S.H. Flexible light-to-frequency conversion circuits built with Si-based frequency-to-digital converters via complementary photosensitive ring oscillators with p-type SWNT and n-type a-IGZO thin film transistors. Small 2021, 17, e2008131. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.; Shin, Y.; Kwon, H.; Lee, J.Y.; Park, H.; Watanabe, K.; Taniguchi, T.; Kim, J.; Lee, C.H.; Im, S.; et al. All-2D ReS2 transistors with split gates for logic circuitry. Sci. Rep. 2019, 9, 10354. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.; Chen, X.; Wang, X.; Bian, J.; Tong, L.; Chen, H.; Guo, X.; Xia, Y.; Zhang, X.; Xu, Z.; et al. Engineering top gate stack for wafer-scale integrated circuit fabrication based on two-dimensional semiconductors. ACS Appl. Mater. Interfaces 2022, 14, 11610–11618. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.; Jung, H.; Choi, B.; Yoon, J.; Yoo, H.B.; Kim, H.J.; Park, G.H.; Kim, D.M.; Kim, D.H.; Kang, M.H.; et al. Flexible carbon nanotube Schottky diode and its integrated circuit applications. RSC Adv. 2019, 9, 22124–22128. [Google Scholar] [CrossRef]

- Lei, T.; Shao, L.L.; Zheng, Y.Q.; Pitner, G.; Fang, G.; Zhu, C.; Li, S.; Beausoleil, R.; Wong, H.P.; Huang, T.C.; et al. Low-voltage high-performance flexible digital and analog circuits based on ultrahigh-purity semiconducting carbon nanotubes. Nat. Commun. 2019, 10, 2161. [Google Scholar] [CrossRef]

- Gaviria Rojas, W.A.; Beck, M.E.; Sangwan, V.K.; Guo, S.; Hersam, M.C. Ohmic-contact-gated carbon nanotube transistors for high-performance analog amplifiers. Adv. Mater. 2021, 33, e2100994. [Google Scholar] [CrossRef]

- Venkatraman, V.; Friedlein, J.T.; Giovannitti, A.; Maria, I.P.; McCulloch, I.; McLeod, R.R.; Rivnay, J. Subthreshold operation of organic electrochemical transistors for biosignal amplification. Adv. Sci. 2018, 5, 1800453. [Google Scholar] [CrossRef]

- Yang, C.Y.; Tu, D.; Ruoko, T.P.; Gerasimov, J.Y.; Wu, H.Y.; Harikesh, P.C.; Massetti, M.; Stoeckel, M.A.; Kroon, R.; Müller, C.; et al. Low-power/high-gain flexible complementary circuits based on printed organic electrochemical transistors. Adv. Electron. Mater. 2021, 8, 2100907. [Google Scholar] [CrossRef]

- Kondo, M.; Melzer, M.; Karnaushenko, D.; Uemura, T.; Yoshimoto, S.; Akiyama, M.; Noda, Y.; Araki, T.; Schmidt, O.; Sekitani, T. Imperceptible magnetic sensor matrix system integrated with organic driver and amplifier circuits. Sci. Adv. 2020, 6, eaay6094. [Google Scholar] [CrossRef]

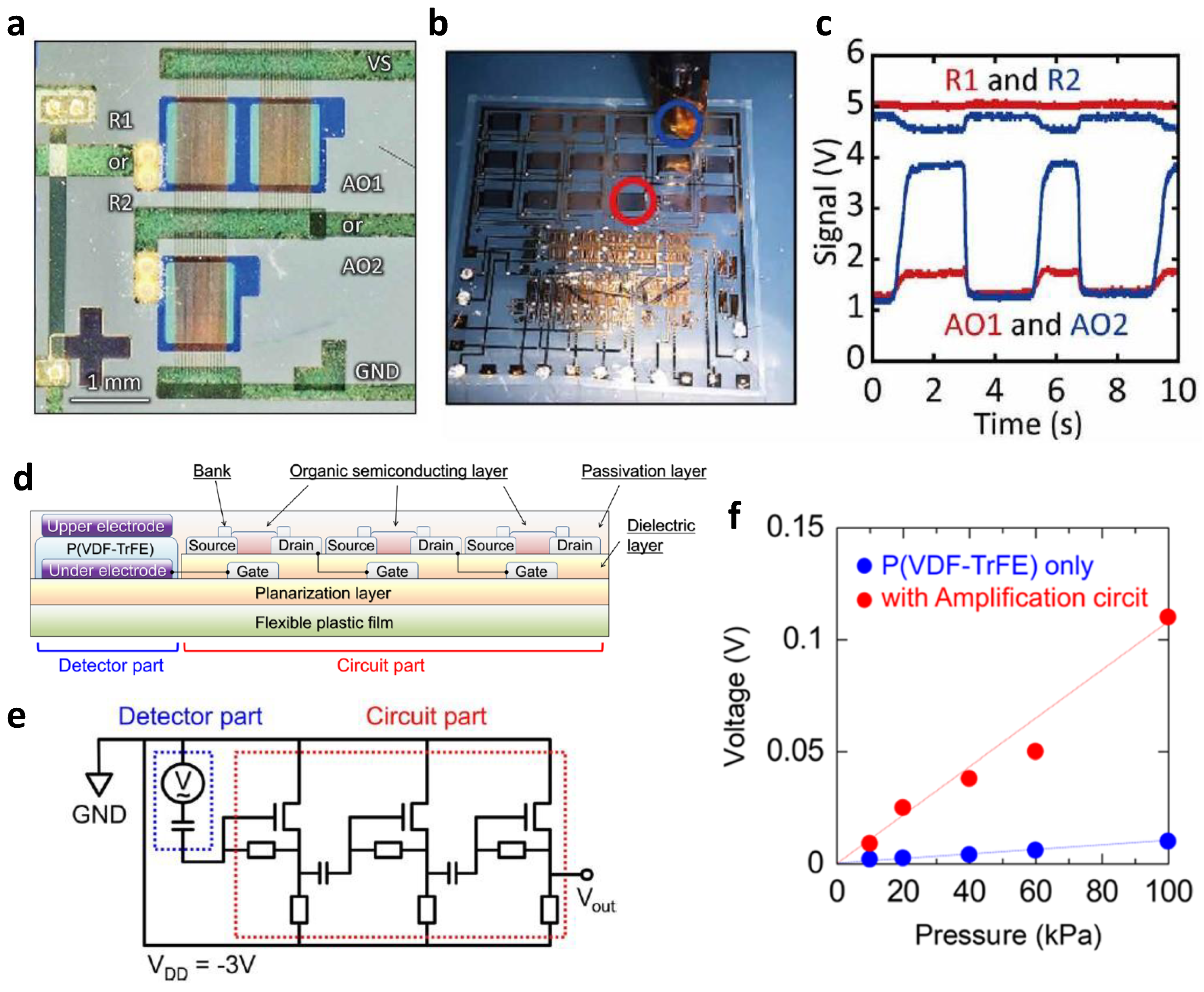

- Sekine, T.; Gaïtis, A.; Sato, J.; Miyazawa, K.; Muraki, K.; Shiwaku, R.; Takeda, Y.; Matsui, H.; Kumaki, D.; Domingues Dos Santos, F.; et al. Low operating voltage and highly pressure-sensitive printed sensor for healthcare monitoring with analogic amplifier circuit. ACS Appl. Electron. Mater. 2019, 1, 246–252. [Google Scholar] [CrossRef]

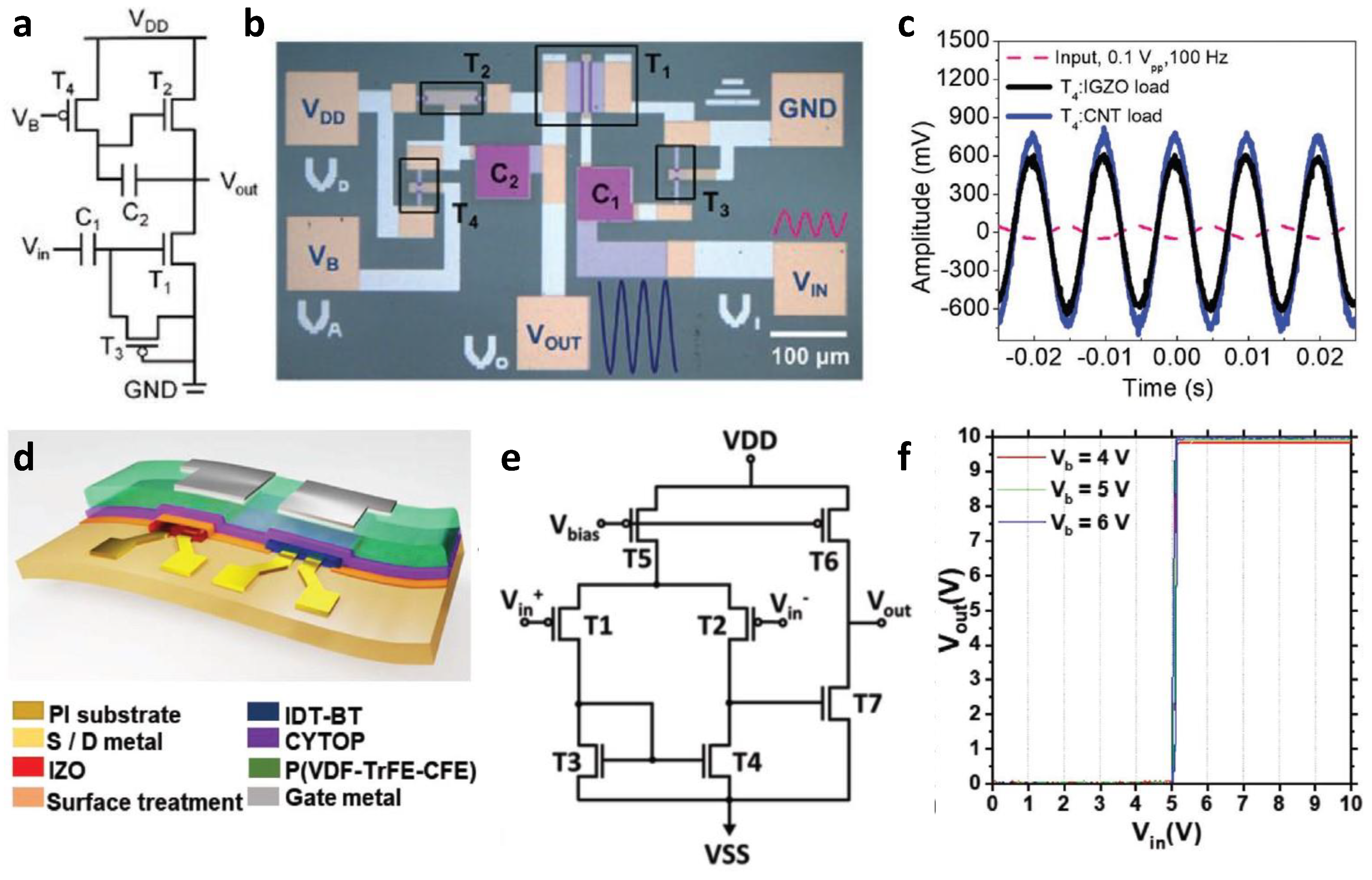

- Kim, K.T.; Kang, S.H.; Kim, J.; Heo, J.S.; Kim, Y.H.; Park, S.K. An ultra-flexible solution-processed metal-oxide/carbon nanotube complementary circuit amplifier with highly reliable electrical and mechanical stability. Adv. Electron. Mater. 2019, 6, 1900845. [Google Scholar] [CrossRef]

- Kang, M.H.; Armitage, J.; Andaji-Garmaroudi, Z.; Sirringhaus, H. Surface passivation treatment to improve performance and stability of solution-processed metal oxide transistors for hybrid complementary circuits on polymer substrates. Adv. Sci. 2021, 8, e2101502. [Google Scholar] [CrossRef] [PubMed]

- Sachid, A.B.; Tosun, M.; Desai, S.B.; Hsu, C.Y.; Lien, D.H.; Madhvapathy, S.R.; Chen, Y.Z.; Hettick, M.; Kang, J.S.; Zeng, Y. Monolithic 3D CMOS using layered semiconductors. Adv. Mater. 2016, 28, 2547–2554. [Google Scholar] [CrossRef] [PubMed]

- Polyushkin, D.K.; Wachter, S.; Mennel, L.; Paur, M.; Paliy, M.; Iannaccone, G.; Fiori, G.; Neumaier, D.; Canto, B.; Mueller, T. Analogue two-dimensional semiconductor electronics. Nat. Electron. 2020, 3, 486–491. [Google Scholar] [CrossRef]

- Liu, X.; Kuang, W.; Ni, H.; Tao, Z.; Chang, J.; Liu, Q.; Ge, J.; Li, C.; Dai, Q. High efficiency light-emitting transistor with vertical metal-oxide heterostructure. Small 2018, 14, e1800265. [Google Scholar] [CrossRef]

- Liu, C.; Li, X.; Luo, Y.; Wang, Y.; Hu, S.; Liu, C.; Liang, X.; Zhou, H.; Chen, J.; She, J.; et al. How materials and device factors determine the performance: A unified solution for transistors with nontrivial gates and transistor-diode hybrid integration. Adv. Sci. 2022, 9, e2104896. [Google Scholar] [CrossRef]

- Hu, S.; Shabani, F.; Liu, B.; Zhang, L.; Guo, M.; Lu, G.; Zhou, Z.; Wang, J.; Huang, J.C.; Min, Y.; et al. High-performance deep red colloidal quantum well light-emitting diodes enabled by the understanding of charge dynamics. ACS Nano 2022, 16, 10840–10851. [Google Scholar] [CrossRef]

- Yoo, H.; Park, H.; Yoo, S.; On, S.; Seong, H.; Im, S.G.; Kim, J.J. Highly stacked 3D organic integrated circuits with via-hole-less multilevel metal interconnects. Nat. Commun. 2019, 10, 2424. [Google Scholar] [CrossRef]

- Park, H.; Yoo, H.; Lee, C.; Kim, J.-J.; Im, S.G. Multi-stage organic logic circuits using via-hole-less metal interconnects. IEEE Electron. Device Lett. 2020, 41, 1685–1687. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, S.; Yoo, H. Recent Progress in Thin-Film Transistors toward Digital, Analog, and Functional Circuits. Micromachines 2022, 13, 2258. https://doi.org/10.3390/mi13122258

Kim S, Yoo H. Recent Progress in Thin-Film Transistors toward Digital, Analog, and Functional Circuits. Micromachines. 2022; 13(12):2258. https://doi.org/10.3390/mi13122258

Chicago/Turabian StyleKim, Seongjae, and Hocheon Yoo. 2022. "Recent Progress in Thin-Film Transistors toward Digital, Analog, and Functional Circuits" Micromachines 13, no. 12: 2258. https://doi.org/10.3390/mi13122258

APA StyleKim, S., & Yoo, H. (2022). Recent Progress in Thin-Film Transistors toward Digital, Analog, and Functional Circuits. Micromachines, 13(12), 2258. https://doi.org/10.3390/mi13122258