Mold Size Effect in Microscale Laser Dynamic Flexible Bulging Assisted by Laser Pre-Shocking

Abstract

:1. Introduction

2. Experiment

2.1. Experimental Materials

2.2. Bulging Mold

2.3. Experimental Parameters and Equipment

3. Results and Discussion

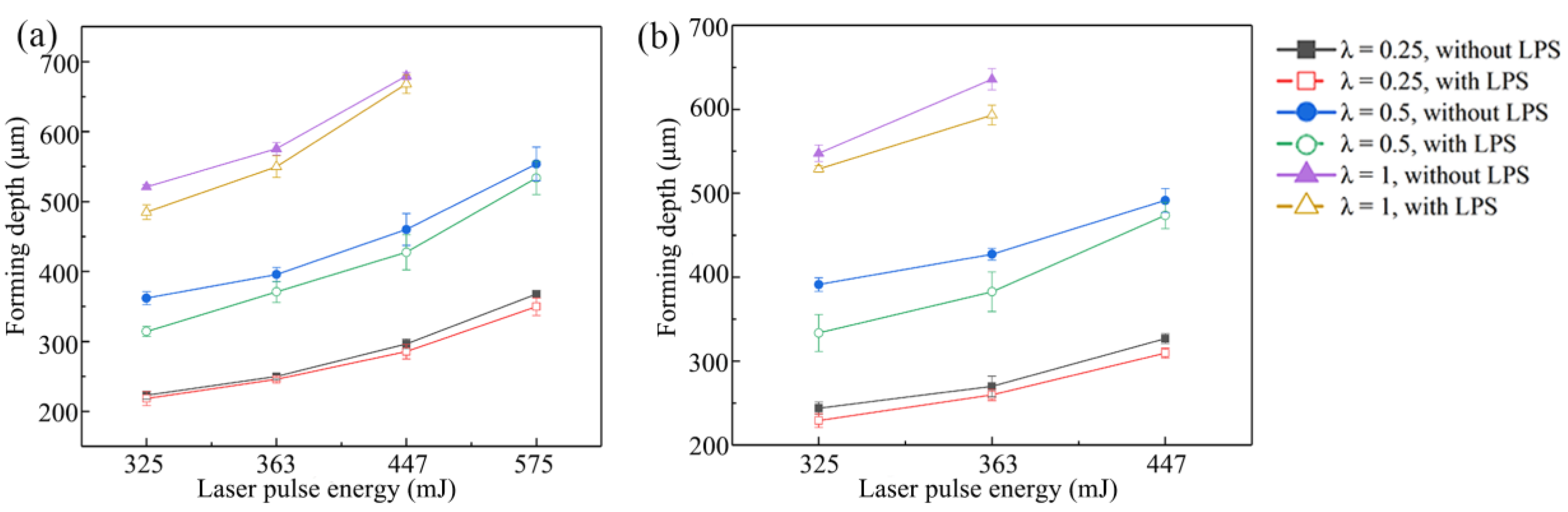

3.1. Forming Depth

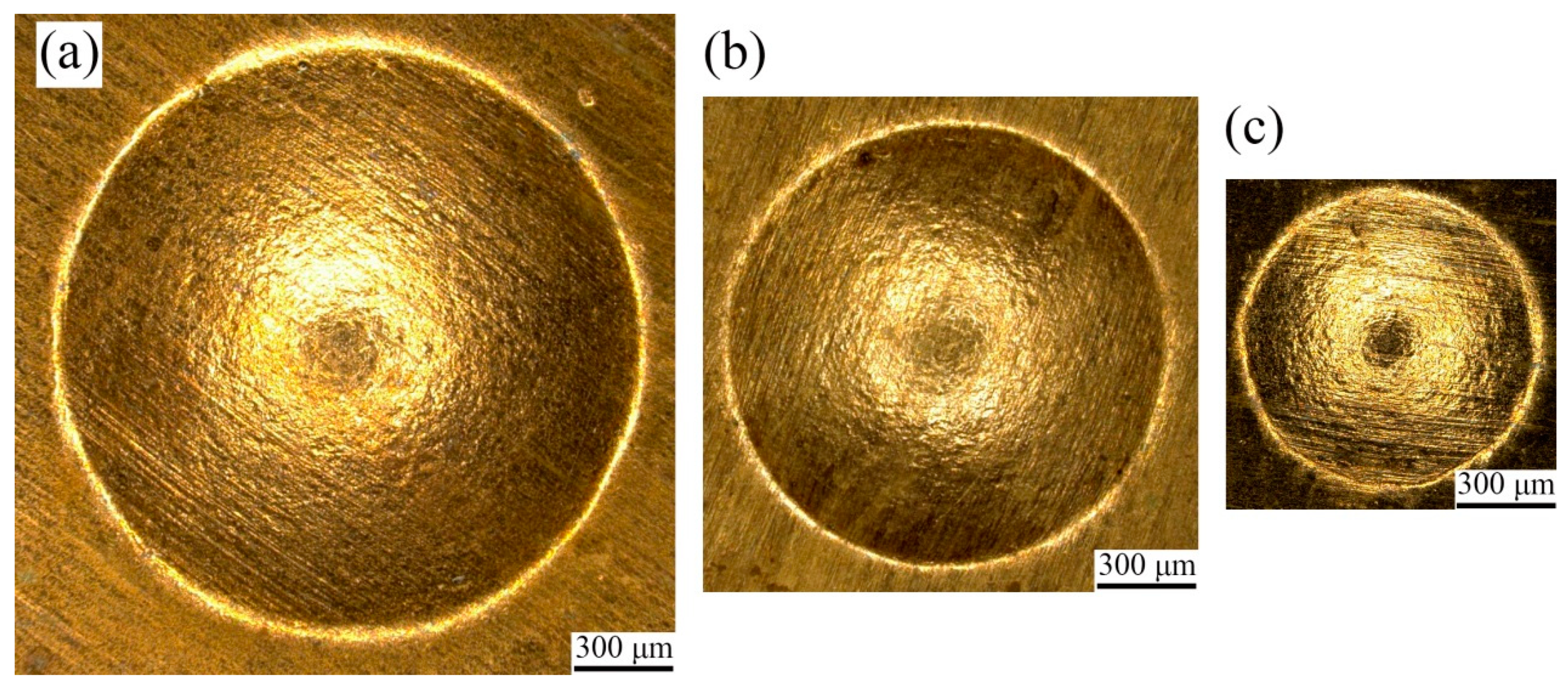

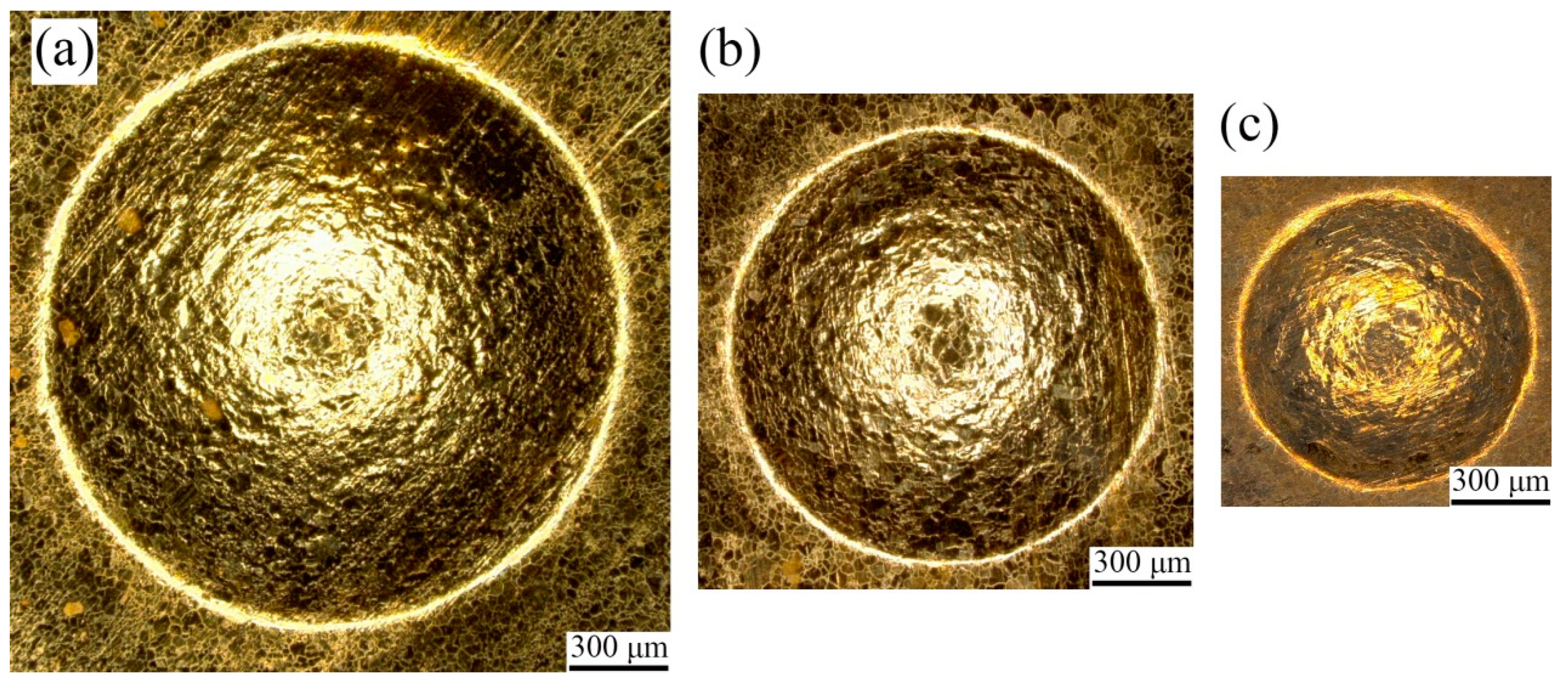

3.2. Surface Roughness

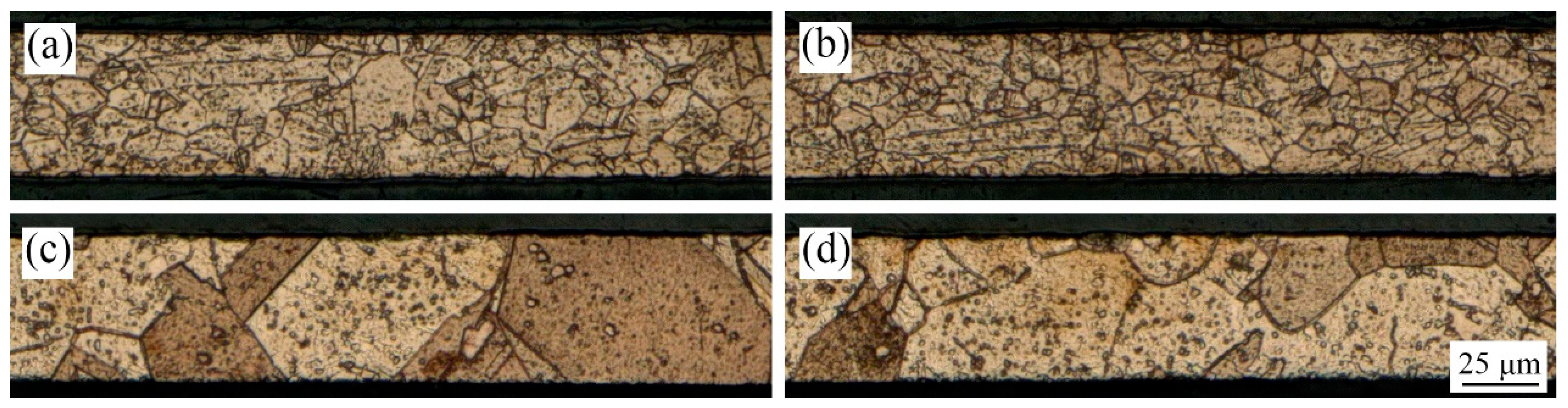

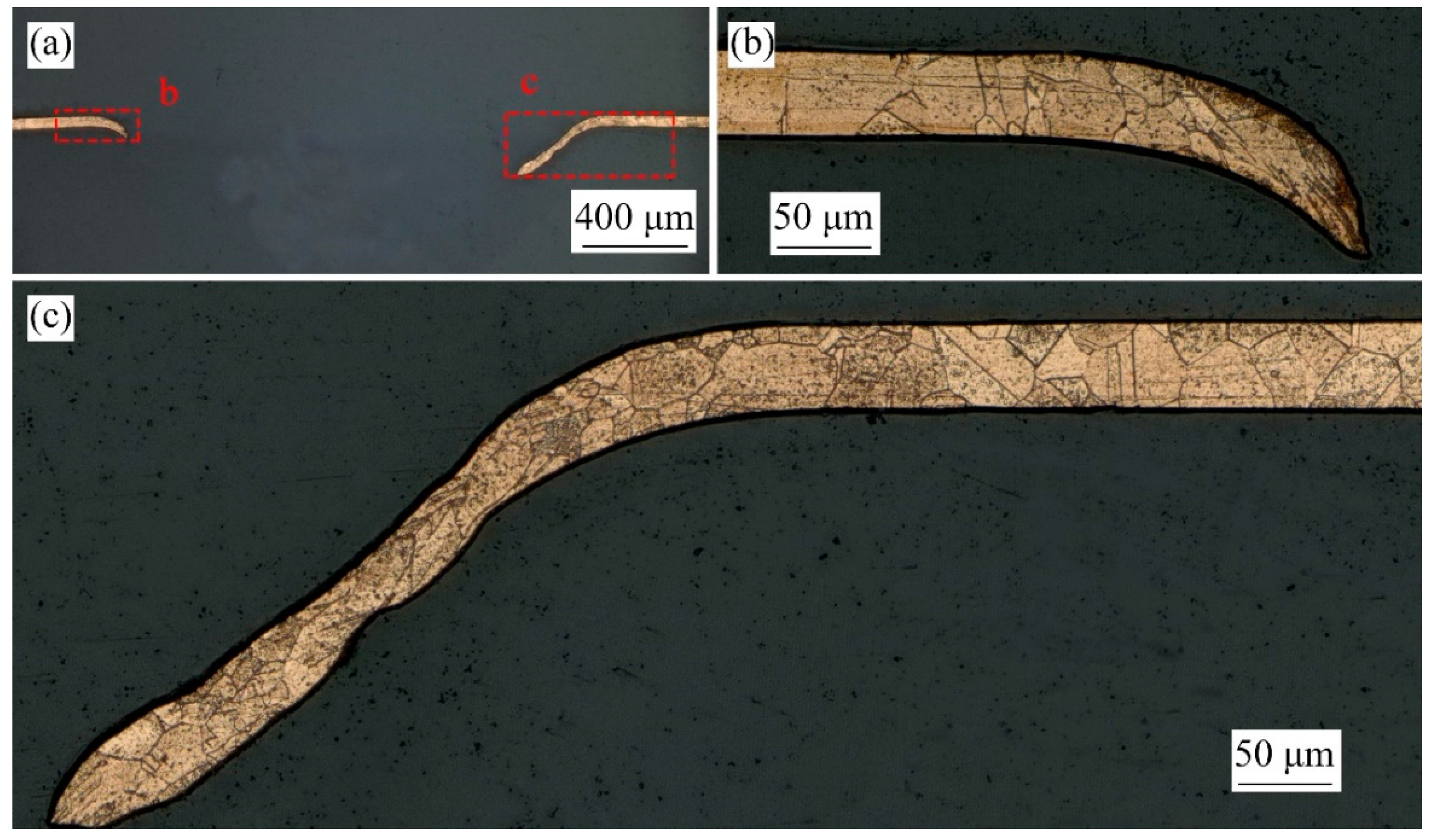

3.3. Microstructure Morphology

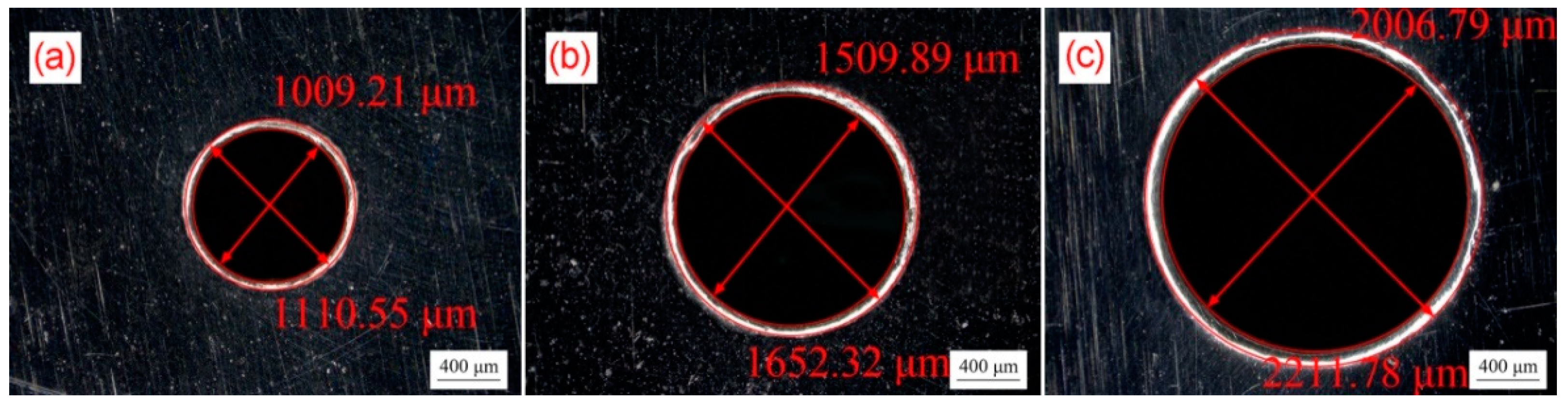

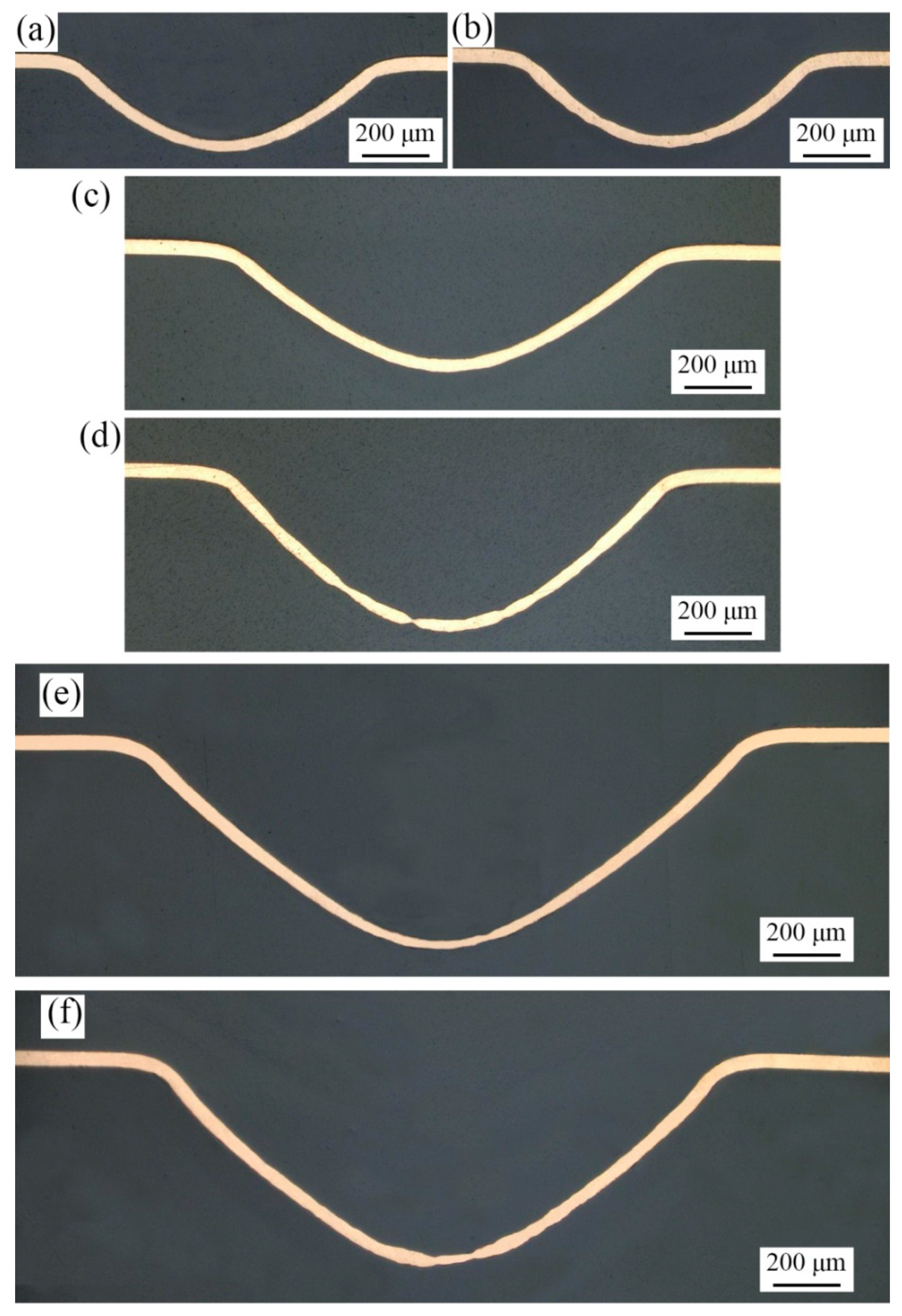

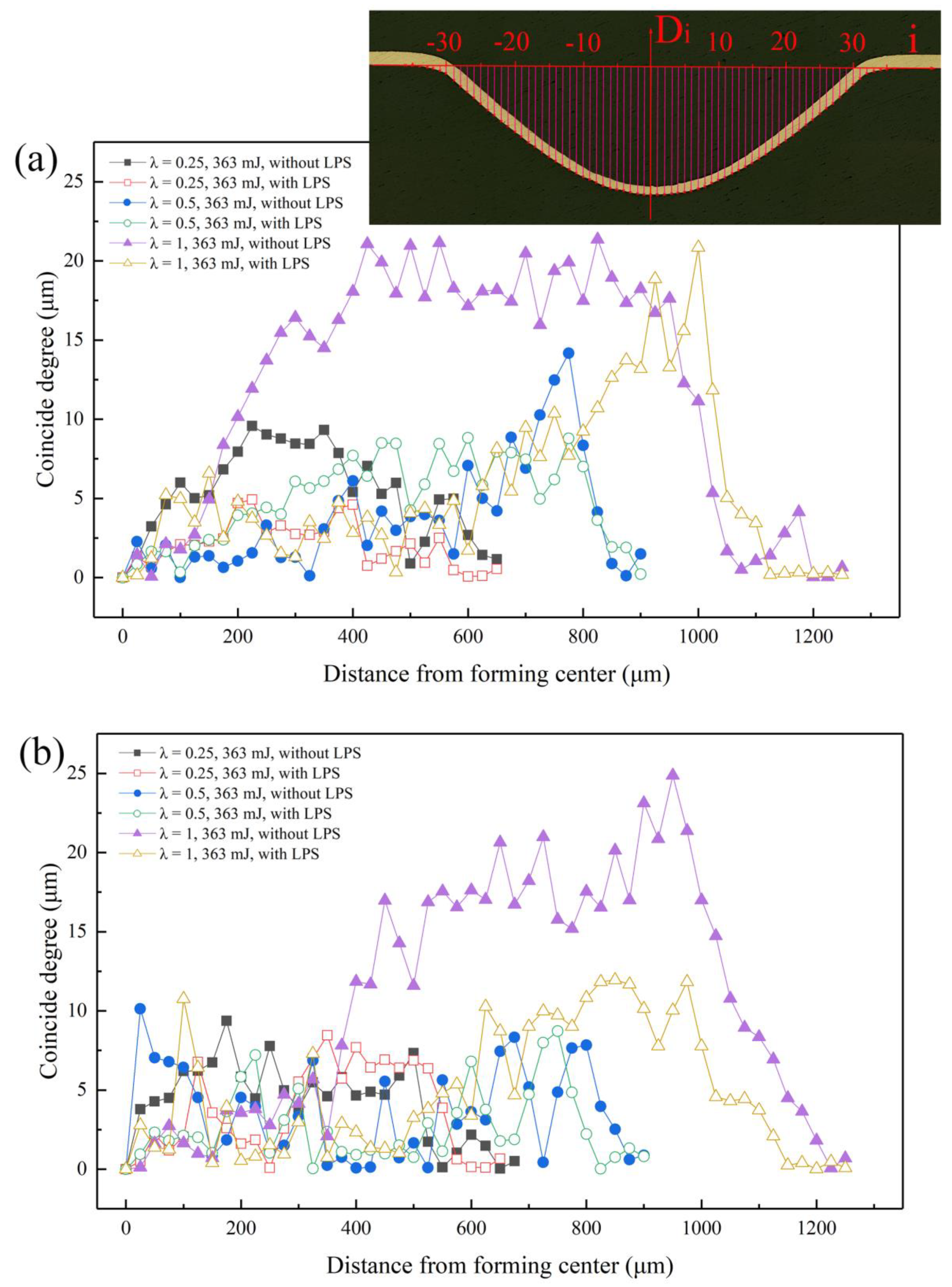

3.4. Forming Symmetry

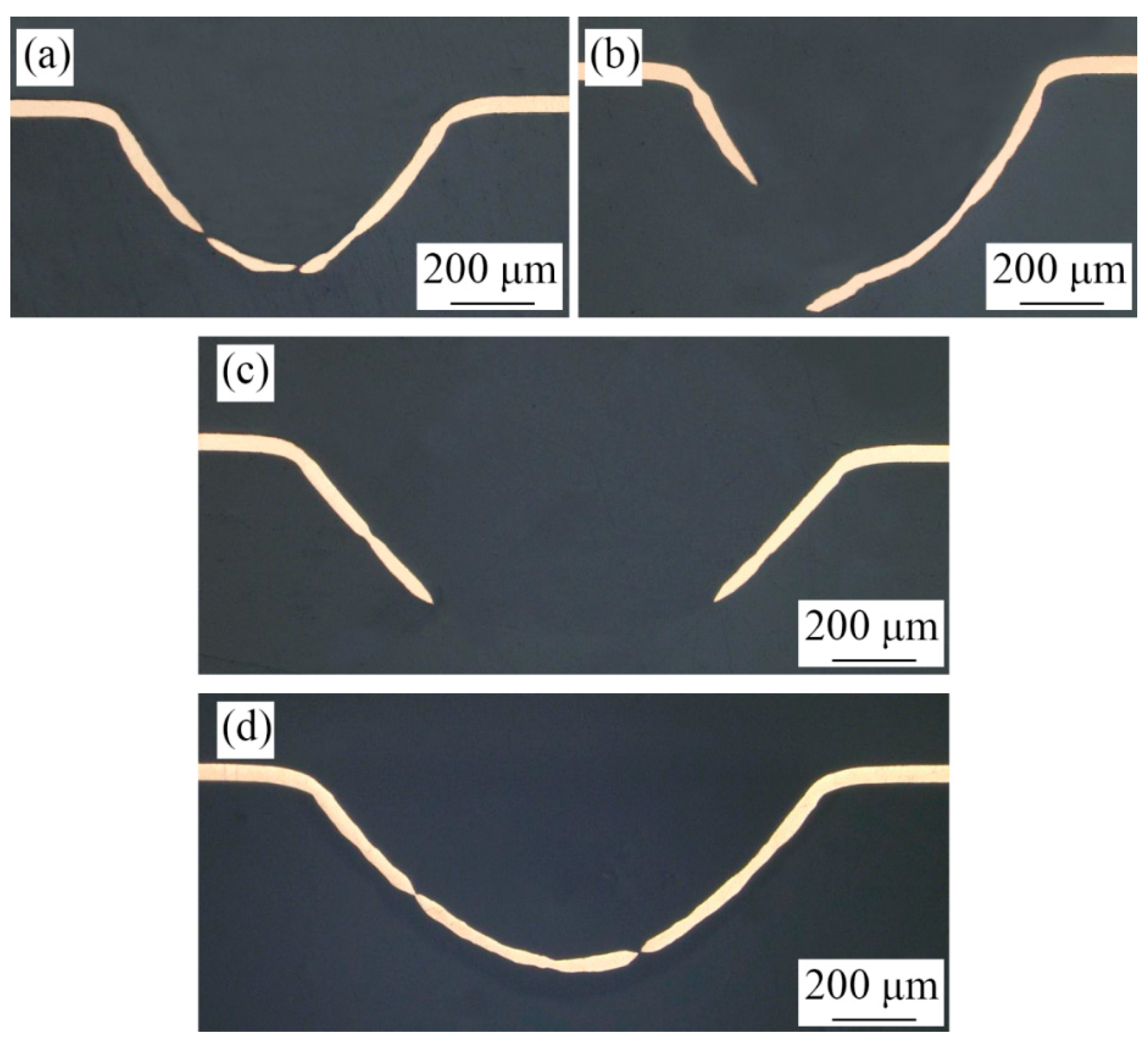

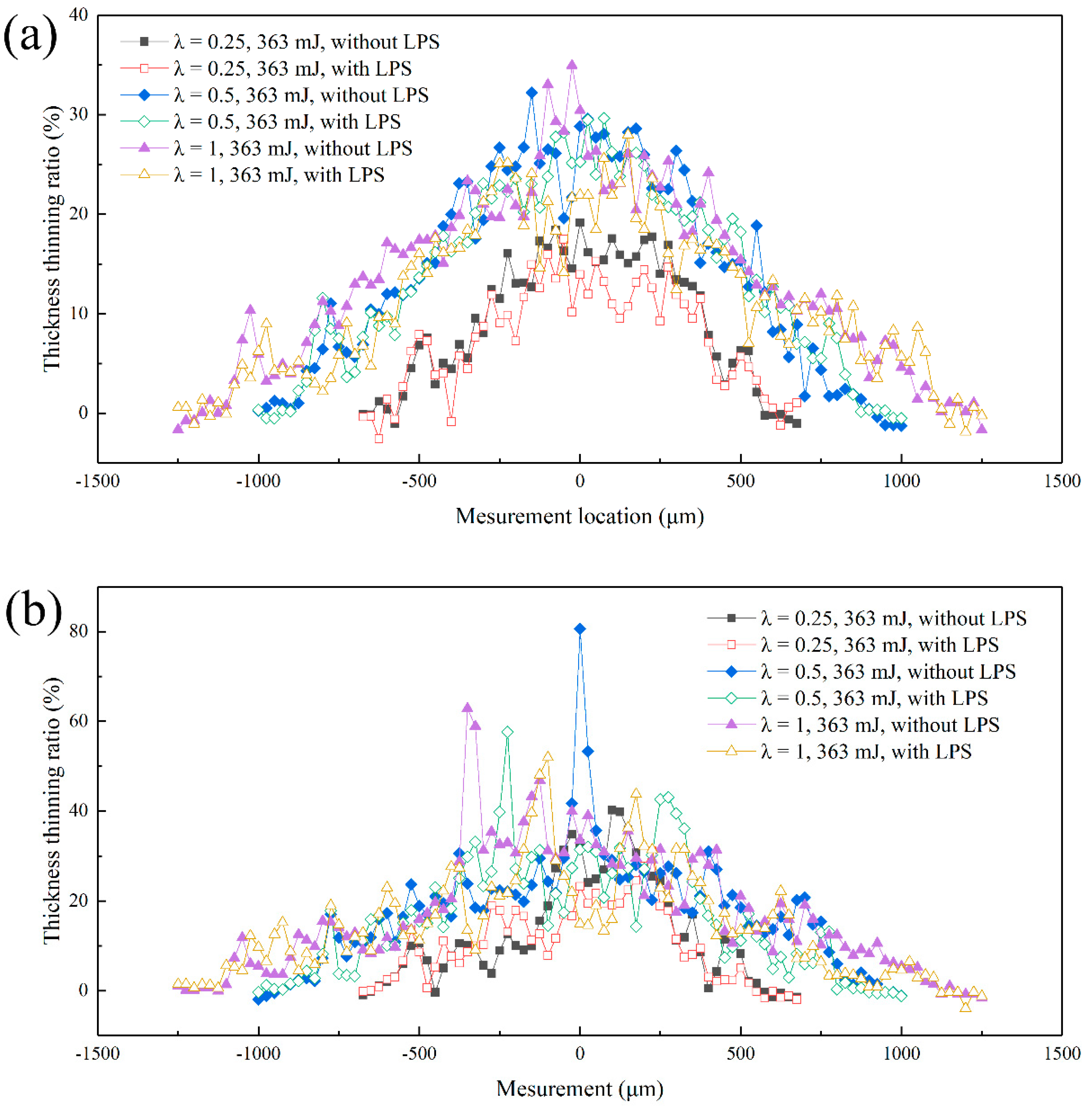

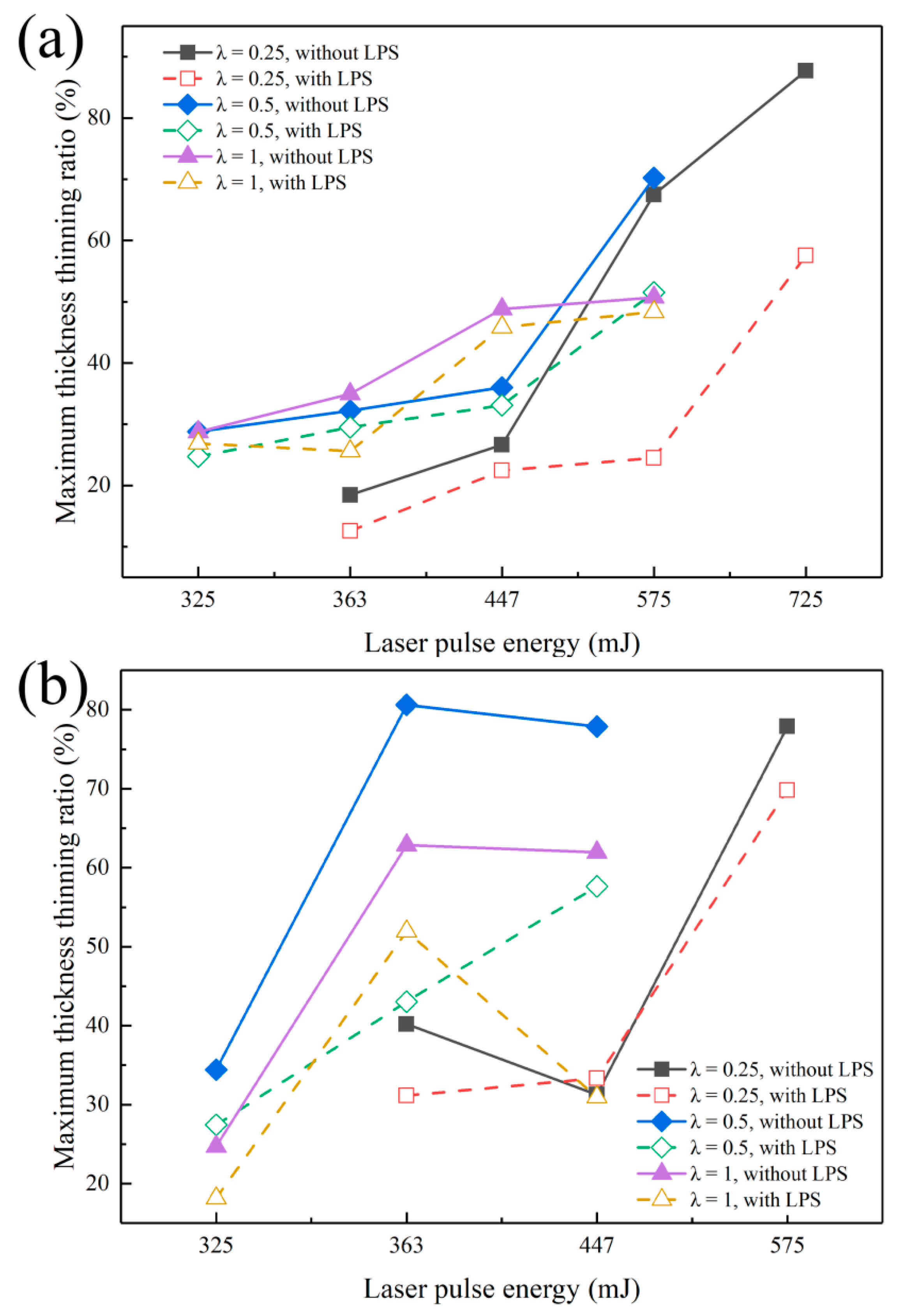

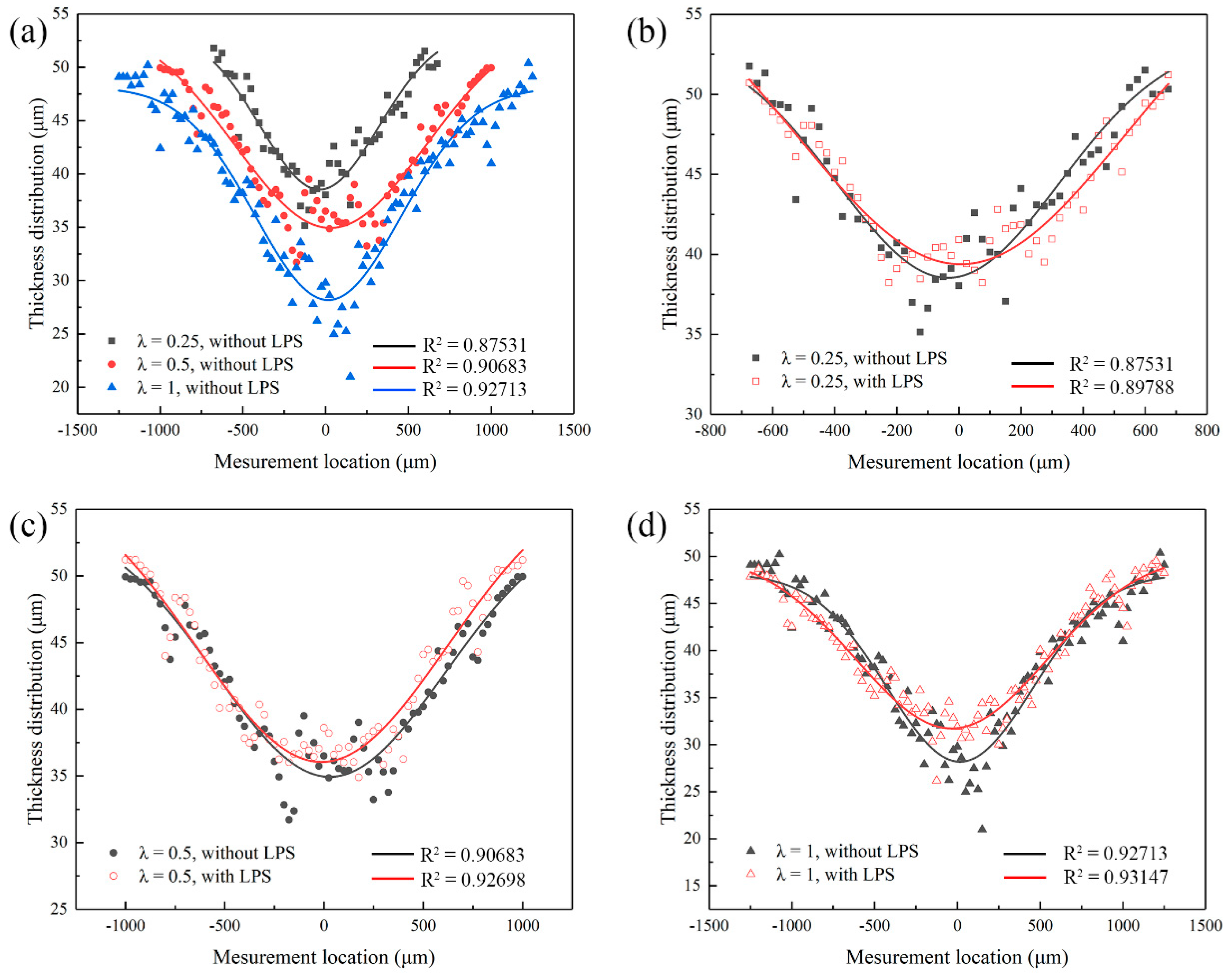

3.5. Forming Uniformity

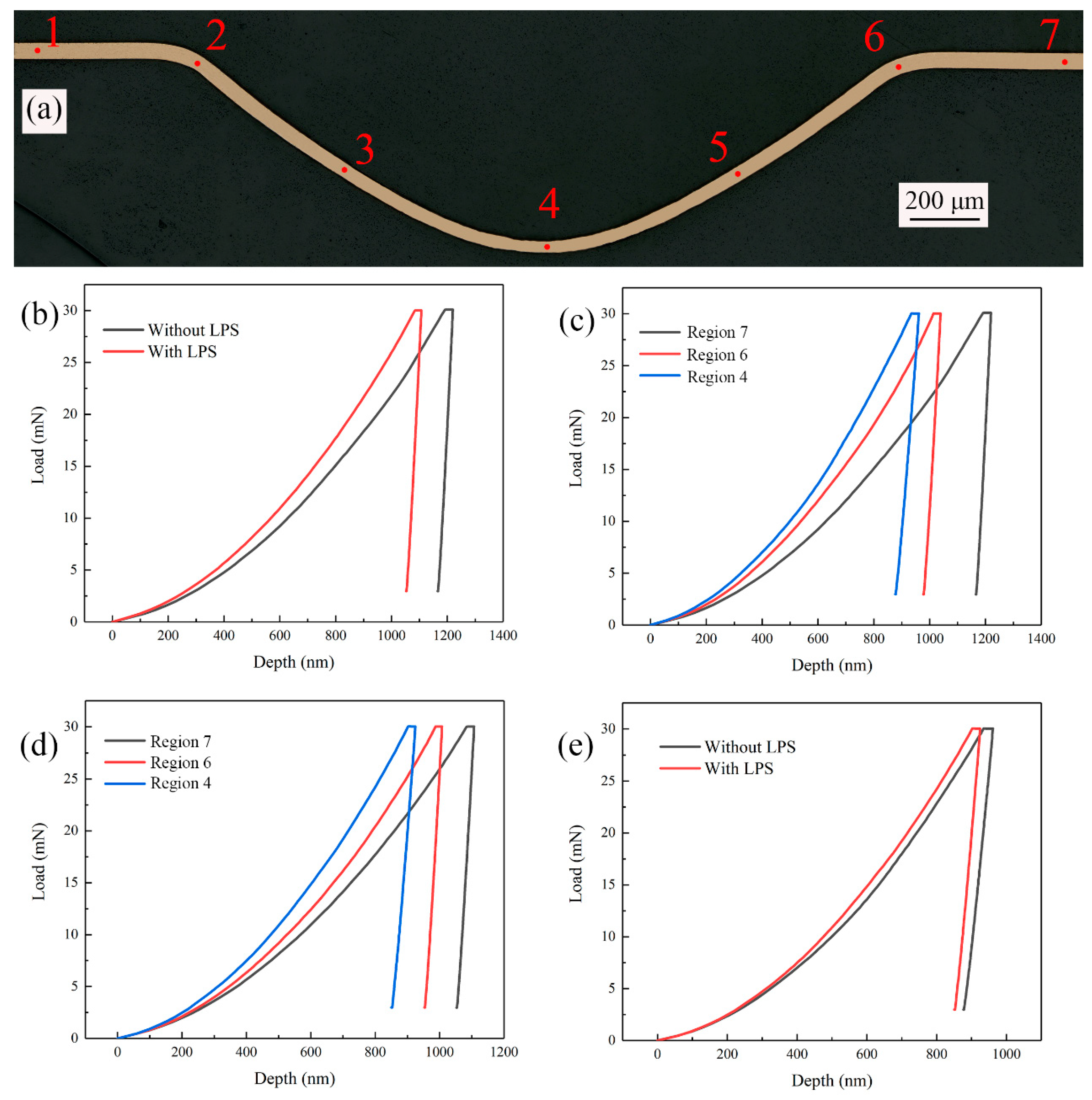

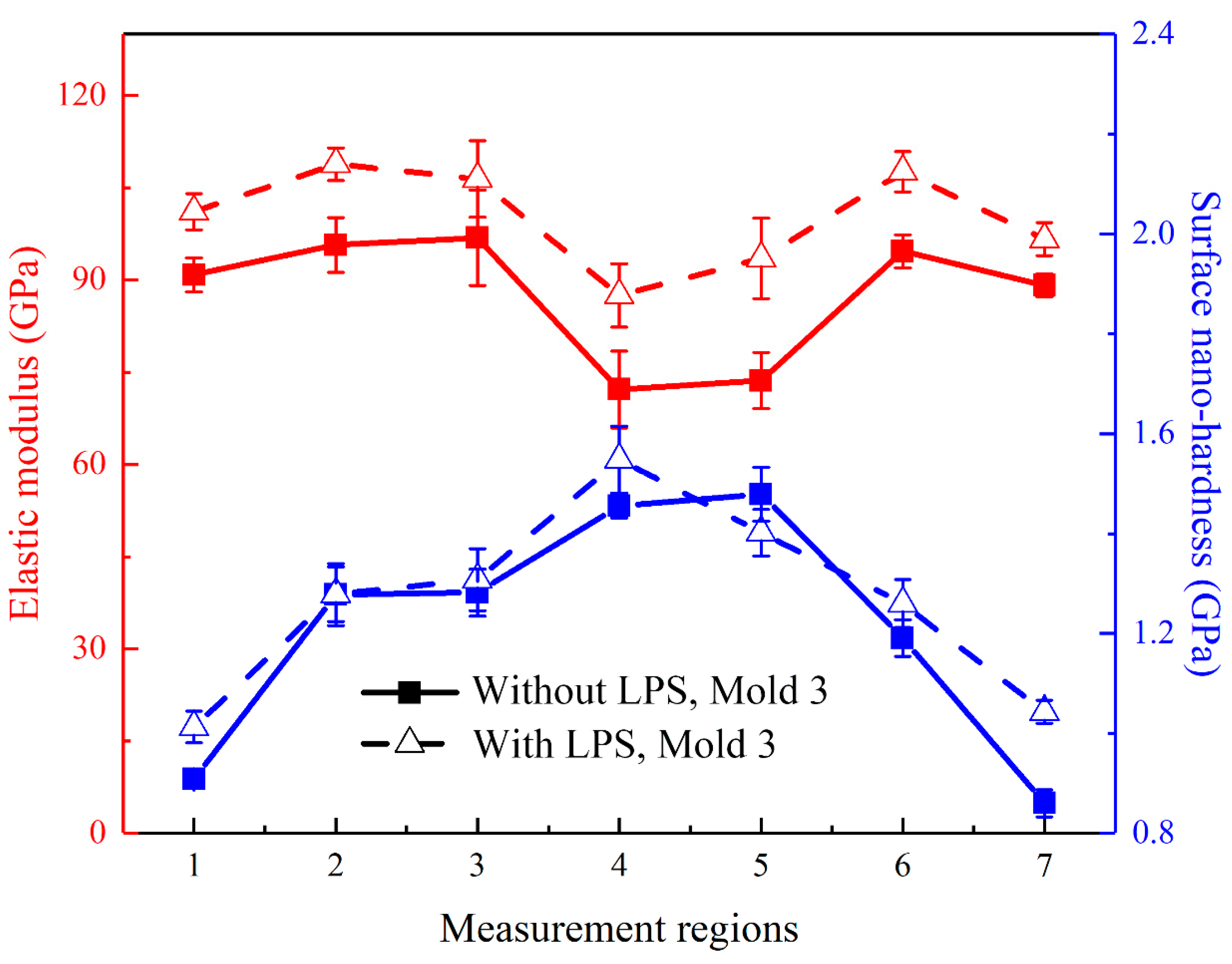

3.6. Nanoindentation Test

4. Conclusions

- (1)

- For copper foil with constant thickness, there is a suitable mold characteristic size to obtain better forming quality (the mold diameter is 1.5 mm in this paper). The surface quality of bulging parts is poor when the mold characteristic size is small (the mold diameter is 1.0 mm). However, the forming symmetry and forming uniformity of bulging samples are reduced when the mold characteristic size is large (the mold diameter is 2.0 mm).

- (2)

- The plastic strain increases with the increase of laser energy, and five stages can be observed: uniform plastic deformation, local necking, cracks in the bulging zone, complete fracture in the bulging zone and complete rupture at the mold entrance.

- (3)

- The increase of grain size and mold characteristic size leads to the increase of surface roughening rate and local necking, which is the precursor of crack. The fracture mode of bulging samples belongs to ductile fracture.

- (4)

- LPS plays a positive role in improving the surface quality and forming performance of bulging samples, which is mainly reflected in improving the forming symmetry and forming uniformity of bulging samples. The surface roughness of fine-grained bulging samples decreases from 2.267 to 1.797 μm with an increase of 20.7% (λ = 0.25, 363 mJ). Additionally, the maximum thinning rate of fine-grained bulging samples decreases from 67.5% to 24.5% (λ = 0.25, 575 mJ).

- (5)

- The nano-hardness and elastic modulus of bulging samples without LPS change abnormally due to their uneven microstructure in the bulging transition zone, but there is no such phenomenon in bulging samples with LPS, which indicates that LPS can effectively improve the forming uniformity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shen, Z.; Wang, X.; Liu, H.; Wang, Y.; Wang, C. Rubber-induced uniform laser shock wave pressure for thin metal sheets microforming. Appl. Surf. Sci. 2015, 327, 307–312. [Google Scholar] [CrossRef]

- Batani, D.; Balducci, A.; Nazarov, W.; Löwer, T.; Hall, T.; Koenig, M.; Faral, B.; Benuzzi, A.; Temporal, M. Use of low-density foams as pressure amplifiers in equation-of-state experiments with laser-driven shock waves. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2001, 63, 046410. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, J.; Wang, X.; Wang, C.; Yuan, L.; Guo, B. A Review on Micro/Nanoforming to Fabricate 3D Metallic Structures. Adv. Mater. 2021, 33, 2170044. [Google Scholar] [CrossRef]

- Janssen, P.J.M.; de Keijser, T.H.; Geers, M.G.D. An experimental assessment of grain size effects in the uniaxial straining of thin Al sheet with a few grains across the thickness. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2006, 419, 238–248. [Google Scholar] [CrossRef]

- Keller, C.; Hug, E.; Feaugas, X. Microstructural size effects on mechanical properties of high purity nickel. Int. J. Plast. 2011, 27, 635–654. [Google Scholar] [CrossRef]

- Chen, F.; Chen, S.; Dong, X.H.; Li, C.Y.; Hong, X.T.; Zhang, X.P. Size effects on tensile strength of aluminum–bronze alloy at room temperature. Mater. Des. 2015, 85, 778–784. [Google Scholar] [CrossRef]

- Miyazaki, S.; Shibata, K.; Fujita, H. Effect of specimen thickness on mechanical properties of polycrystalline aggregates with various grain sizes. Acta Mater. 1979, 27, 855–862. [Google Scholar] [CrossRef]

- Wang, C.; Wang, H.; Chen, G.; Zhu, Q.; Zhang, G.; Cui, L.; Zhang, P. Size effects affected uniaxial tensile properties and formability in rubber pad microforming process of pure nickel thin sheets. Int. J. Mech. Sci. 2020, 182, 105757. [Google Scholar] [CrossRef]

- Yuan, Z.; Tu, Y.; Yuan, T.; Zhang, Y.; Huang, Y. Size effects on mechanical properties of pure industrial aluminum sheet for micro/meso scale plastic deformation: Experiment and modeling. J. Alloys Compd. 2021, 859, 157752. [Google Scholar] [CrossRef]

- Ghassemali, E.; Jarfors, A.E.W.; Tan, M.-J.; Lim, S.C.V. On the microstructure of micro-pins manufactured by a novel progressive microforming process. Int. J. Mater. Form. 2013, 6, 65–74. [Google Scholar] [CrossRef]

- Kim, H.S.; Nam, J.S. Quantitative modeling and characterization of the size effects in microscale coining process of copper. Precis. Eng. 2018, 51, 490–498. [Google Scholar] [CrossRef]

- Raja, C.P.; Ramesh, T. Influence of size effects and its key issues during microforming and its associated processes—A review. Eng. Sci. Technol. Int. J. 2021, 24, 556–570. [Google Scholar] [CrossRef]

- Escobedo, J.P.; Denniskoller, D.; Cerreta, E.K.; Patterson, B.M.; Bronkhorst, C.A.; Hansen, B.L.; Tonks, D.L.; Lebensohn, R.A. Effects of grain size and boundary structure on the dynamic tensile response of copper. J. Appl. Phys. 2011, 110, 033513. [Google Scholar] [CrossRef] [Green Version]

- Zhu, C.; Xu, J.; Yu, H.; Shan, D.; Guo, B. Size effect on the high strain rate micro/meso-tensile behaviors of pure titanium foil. J. Mater. Res. Technol. 2021, 11, 2146–2159. [Google Scholar] [CrossRef]

- Fang, Z.; Jiang, Z.; Wang, X.; Zhou, C.; Wei, D.; Liu, X. Grain size effect of thickness/average grain size on mechanical behaviour, fracture mechanism and constitutive model for phosphor bronze foil. Int. J. Adv. Manuf. Technol. 2015, 79, 1905–1914. [Google Scholar] [CrossRef] [Green Version]

- Gu, X.; Wang, X.; Ma, Y.; Zhang, H.; Lu, J.; Wang, K.; Liu, H. Investigation on grain size effect and forming mechanism of laser shock hydraulic microforming of copper foil. Int. J. Adv. Manuf. Technol. 2021, 114, 1049–1064. [Google Scholar] [CrossRef]

- Yoshida, K. Effects of grain-scale heterogeneity on surface roughness and sheet metal necking. Int. J. Mech. Sci. 2014, 83, 48–56. [Google Scholar] [CrossRef]

- Cheng, C.; Wan, M.; Meng, B.; Fu, M.W. Characterization of the microscale forming limit for metal foils considering free surface roughening and failure mechanism transformation. J. Mater. Process. Technol. 2019, 272, 111–124. [Google Scholar] [CrossRef]

- Bong, H.J.; Lee, J. Crystal plasticity finite element–Marciniak-Kuczynski approach with surface roughening effect in predicting formability of ultra-thin ferritic stainless steel sheets. Int. J. Mech. Sci. 2021, 191, 106066. [Google Scholar] [CrossRef]

- Dai, F.; Zhou, J.; Lu, J.; Luo, X. A technique to decrease surface roughness in overlapping laser shock peening. Appl. Surf. Sci. 2016, 370, 501–507. [Google Scholar] [CrossRef]

- Lu, J.Z.; Wu, L.J.; Sun, G.F.; Luo, K.Y.; Zhang, Y.K.; Cai, J.; Cui, C.Y.; Luo, X.M. Microstructural response and grain refinement mechanism of commercially pure titanium subjected to multiple laser shock peening impacts. Acta Mater. 2017, 127, 252–266. [Google Scholar] [CrossRef]

- Zhang, J.; Shen, Z.; Lin, Y.; Liu, K.; Zhou, G.; Wang, Y.; Zhang, L.; Li, P.; Liu, H.; Wang, X. Improving the Forming Quality of Laser Dynamic Flexible Micropunching by Laser Pre-Shocking. Materials 2020, 13, 3667. [Google Scholar] [CrossRef] [PubMed]

- Shen, Z.; Zhang, L.; Zhang, J.; Li, P.; Zhen, X.; Liu, H.; Wang, X. Reducing surface roughening in microscale laser dynamic flexible bulging by using laser pre-shocking. J. Manuf. Process. 2021, 72, 274–293. [Google Scholar] [CrossRef]

- Gao, Z.; Peng, L.; Yi, P.; Lai, X. Grain and geometry size effects on plastic deformation in roll-to-plate micro/meso-imprinting process. J. Mater. Process. Technol. 2015, 219, 28–41. [Google Scholar] [CrossRef]

- Mahabunphachai, S.; Koç, M. Investigation of size effects on material behavior of thin sheet metals using hydraulic bulge testing at micro/meso-scales. Int. J. Mach. Tools Manuf. 2008, 48, 1014–1029. [Google Scholar] [CrossRef]

- Raulea, L.V.; Goijaerts, A.M.A.; Govaert, L.L.; Baaijens, F.F. Size effects in the processing of thin metal sheets. J. Mater. Process. Technol. 2001, 115, 44–48. [Google Scholar] [CrossRef]

- Hao, Y.; Jibin, Z.; Tianran, W. Research on a different method to reach the saturate limit of titanium aluminide alloy surface mechanical and fatigue properties by laser shock process. Optik 2019, 193, 162989. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Wan, Z.; Peng, P.; Zhang, H.; Sun, R.; Che, Z.; Guo, C.; Li, B.; Guo, W. Microstructure and mechanical properties of laser shock peened 38CrSi steel. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2020, 788, 139486. [Google Scholar] [CrossRef]

- Fu, M.W.; Yang, B.; Chan, W.L. Experimental and simulation studies of micro blanking and deep drawing compound process using copper sheet. J. Mater. Process. Technol. 2013, 213, 101–110. [Google Scholar] [CrossRef]

- Stoudt, M.R.; Ricker, R.E. The relationship between grain size and the surface roughening behavior of Al-Mg alloys. Metall. Mater. Trans. A 2002, 33, 2883–2889. [Google Scholar] [CrossRef]

- Stoudt, M.R.; Hubbard, J.B.; Leigh, S.D. On the Relationship between Deformation-Induced Surface Roughness and Plastic Strain in AA5052—Is it Really Linear? Metall. Mater. Trans. A 2011, 42, 2668–2679. [Google Scholar] [CrossRef]

- Li, Q.; Wang, L.; Teng, J.; Pang, X.; Han, X.; Zou, J. In-situ observation of cooperative grain boundary sliding and migration in the nano-twinned nanocrystalline-Au thin-films. Scr. Mater. 2020, 180, 97–102. [Google Scholar] [CrossRef]

- Shen, Z.; Zhang, L.; Li, P.; Liu, H.; Liu, K.; Lin, Y.; Zhou, G.; Wang, Y.; Zhang, J.; Wang, X. Altering the surface wettability of copper sheet using overlapping laser shock imprinting. Appl. Surf. Sci. 2021, 543, 148736. [Google Scholar] [CrossRef]

- Wang, Y.; Lei, J.; Bai, L.; Zhou, K.; Liu, Z. Effects of tensile strain rate and grain size on the mechanical properties of nanocrystalline T-carbon. Comput. Mater. Sci. 2019, 170, 109188. [Google Scholar] [CrossRef]

- Liu, H.; Sun, X.; Shen, Z.; Li, L.; Sha, C.; Ma, Y.; Gau, J.-T.; Wang, X. Experimental and Numerical Simulation Investigation on Laser Flexible Shock Micro-Bulging. Metals 2017, 7, 93. [Google Scholar] [CrossRef] [Green Version]

- Yakovtseva, O.; Tomas, A.; Mikhaylovskaya, A. Surface and internal structural markers for studying grain boundary sliding and grain rotation. Mater. Lett. 2020, 268, 127569. [Google Scholar] [CrossRef]

- Wang, X.; Ma, Y.; Shen, Z.; Gu, Y.; Zhang, D.; Qiu, T.; Liu, H. Size effects on formability in microscale laser dynamic forming of copper foil. J. Mater. Process. Technol. 2015, 220, 173–183. [Google Scholar] [CrossRef]

- Gao, H.; Cheng, G.J. Laser-Induced High-Strain-Rate Superplastic 3-D Microforming of Metallic Thin Films. J. Microelectromech. Syst. 2010, 19, 273–281. [Google Scholar] [CrossRef]

- Cheng, G.J.; Pirzada, D.; Ming, Z. Microstructure and mechanical property characterizations of metal foil after microscale laser dynamic forming. J. Appl. Phys. 2007, 101, 345–360. [Google Scholar] [CrossRef]

- Li, J.; Lu, B.; Zhang, Y.; Zhou, H.; Hu, G.; Xia, R. Nanoindentation response of nanocrystalline copper via molecular dynamics: Grain-size effect. Mater. Chem. Phys. 2020, 241, 122391. [Google Scholar] [CrossRef]

- Yoshida, F.; Uemori, T.; Fujiwara, K. Elastic–plastic behavior of steel sheets under in-plane cyclic tension–compression at large strain. Int. J. Plast. 2002, 18, 633–659. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, M.; Zhou, F.; Ma, E. High tensile ductility in a nanostructured metal. Nature 2002, 419, 912–915. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Wang, J.; Zhou, J. Characterization and analysis on micro-hardness and microstructure evolution of brass subjected to laser shock peening. Opt. Laser Technol. 2019, 115, 325–330. [Google Scholar] [CrossRef]

| Values | 450 °C Annealed, without LPS | 450 °C Annealed, with LPS | 650 °C Annealed, without LPS | 650 °C Annealed, with LPS |

|---|---|---|---|---|

| Grain size (μm) | 13.1 | 10.2 | 54.1 | 41.6 |

| N values | 3.8 | 4.9 | 0.9 | 1.2 |

| Number | Diameter (mm) | Fillet (mm) | Scale Factor λ |

|---|---|---|---|

| 1 | 1.0 | 0.10 | 0.25 |

| 2 | 1.5 | 0.15 | 0.5 |

| 3 | 2.0 | 0.20 | 1 |

| Parameters | Values |

|---|---|

| Laser pulse energy (mJ) | 80–1800 |

| Pulse width (ns) | 8 |

| Wave length (nm) | 1064 |

| Exit spot diameter (mm) | 9 |

| Parameters | Values |

|---|---|

| Spot diameter (mm) | 3 |

| Mold diameter (mm) | 1.0, 1.5, 2.0 |

| PMMA thickness (mm) | 3 |

| Black paint thickness (μm) | ~50 |

| Soft film thickness (μm) | 300 |

| Laser pulse energy (mJ) | 325, 363, 447, 575, 725, 1050, 1420 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, Y.; Li, P.; Zhen, X.; Zhang, J.; Shen, Z. Mold Size Effect in Microscale Laser Dynamic Flexible Bulging Assisted by Laser Pre-Shocking. Micromachines 2022, 13, 757. https://doi.org/10.3390/mi13050757

Fang Y, Li P, Zhen X, Zhang J, Shen Z. Mold Size Effect in Microscale Laser Dynamic Flexible Bulging Assisted by Laser Pre-Shocking. Micromachines. 2022; 13(5):757. https://doi.org/10.3390/mi13050757

Chicago/Turabian StyleFang, Yijun, Pin Li, Xijin Zhen, Jindian Zhang, and Zongbao Shen. 2022. "Mold Size Effect in Microscale Laser Dynamic Flexible Bulging Assisted by Laser Pre-Shocking" Micromachines 13, no. 5: 757. https://doi.org/10.3390/mi13050757