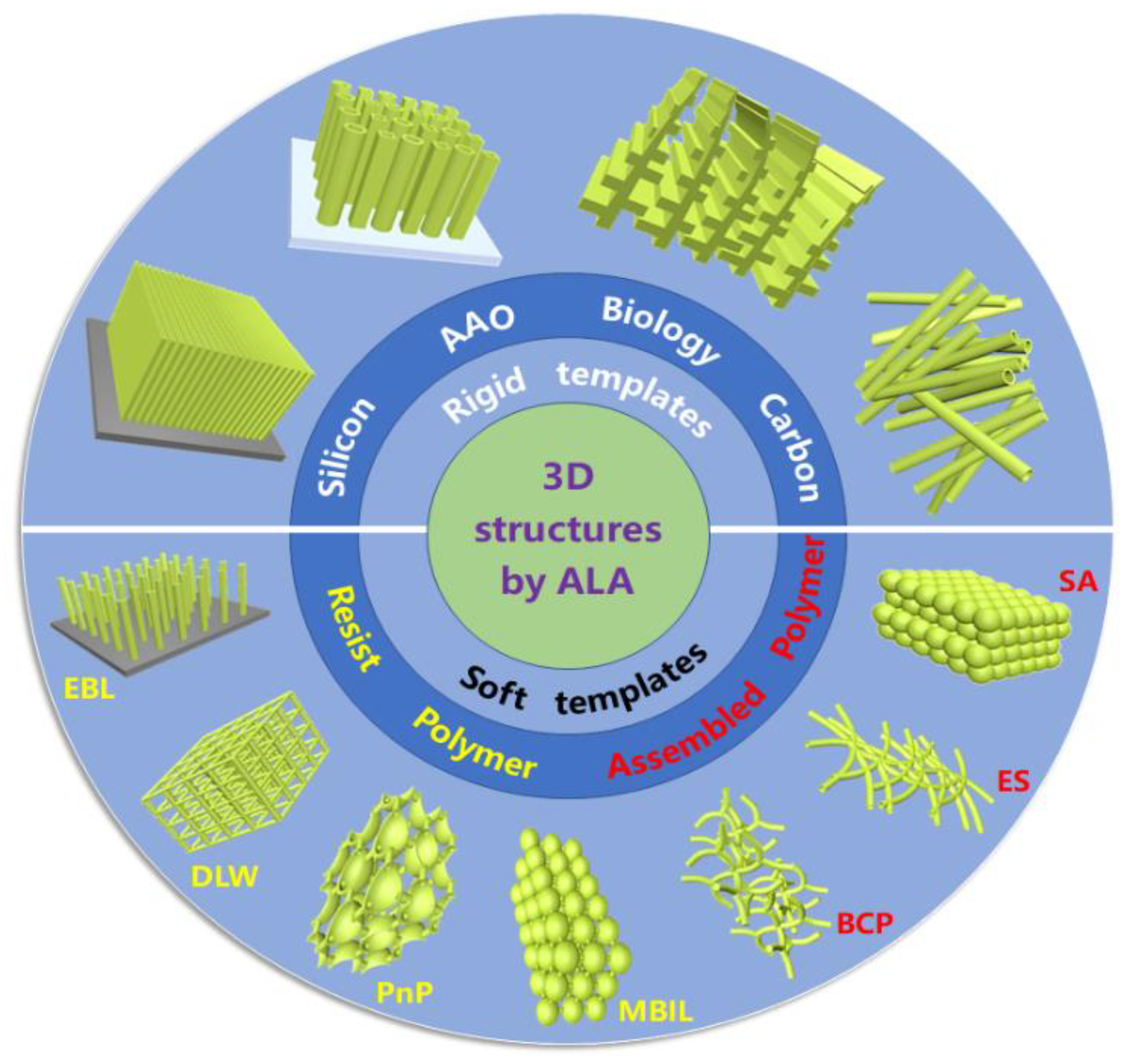

Atomic Layer Assembly Based on Sacrificial Templates for 3D Nanofabrication

Abstract

1. Introduction

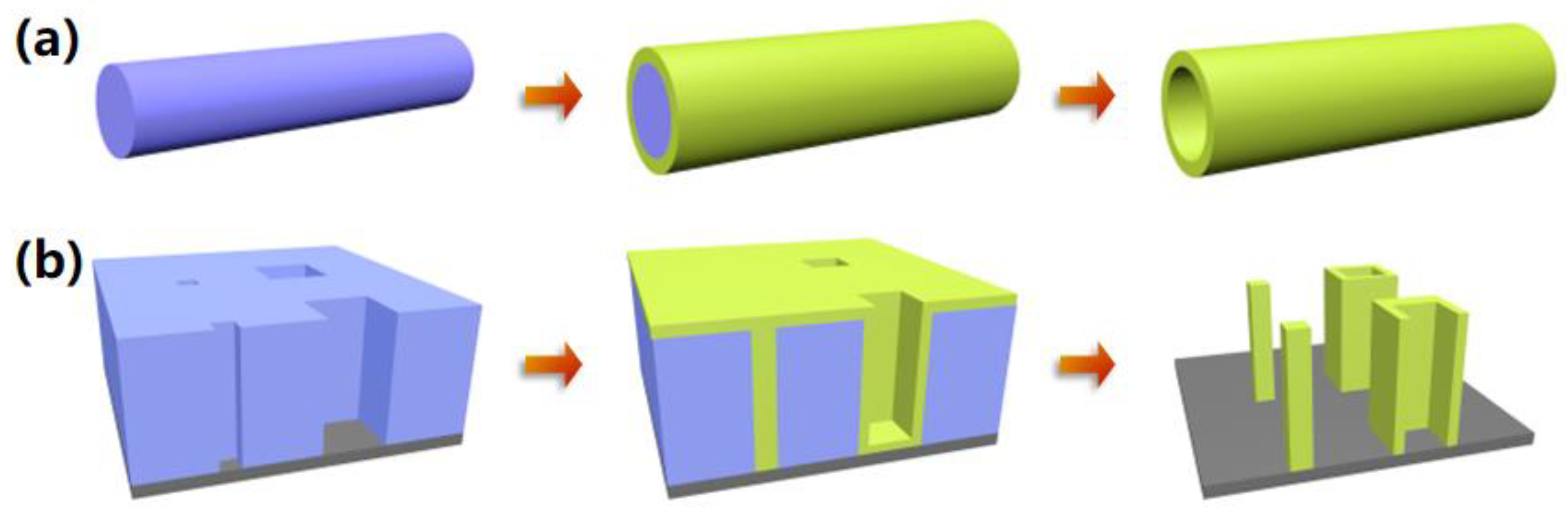

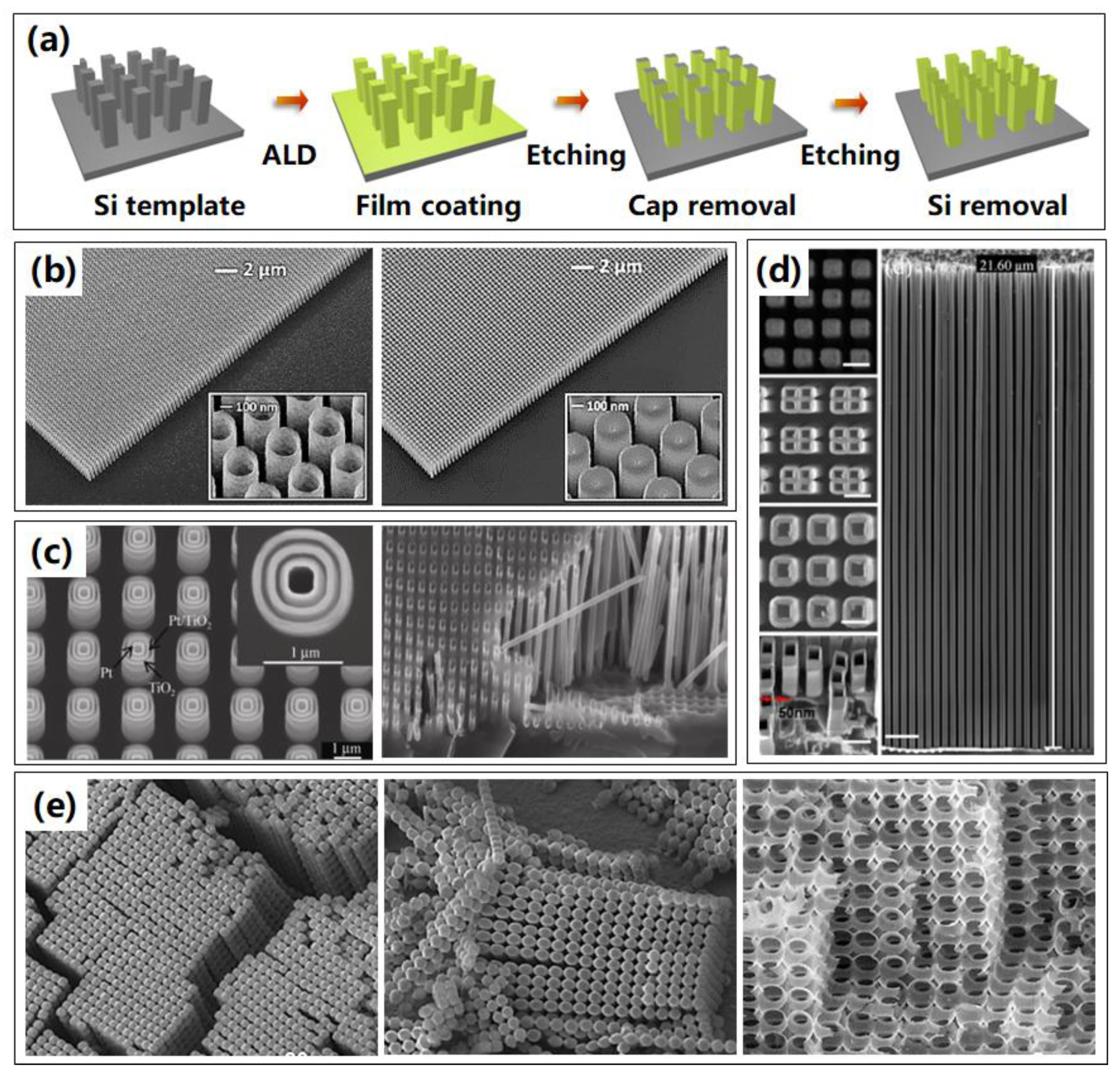

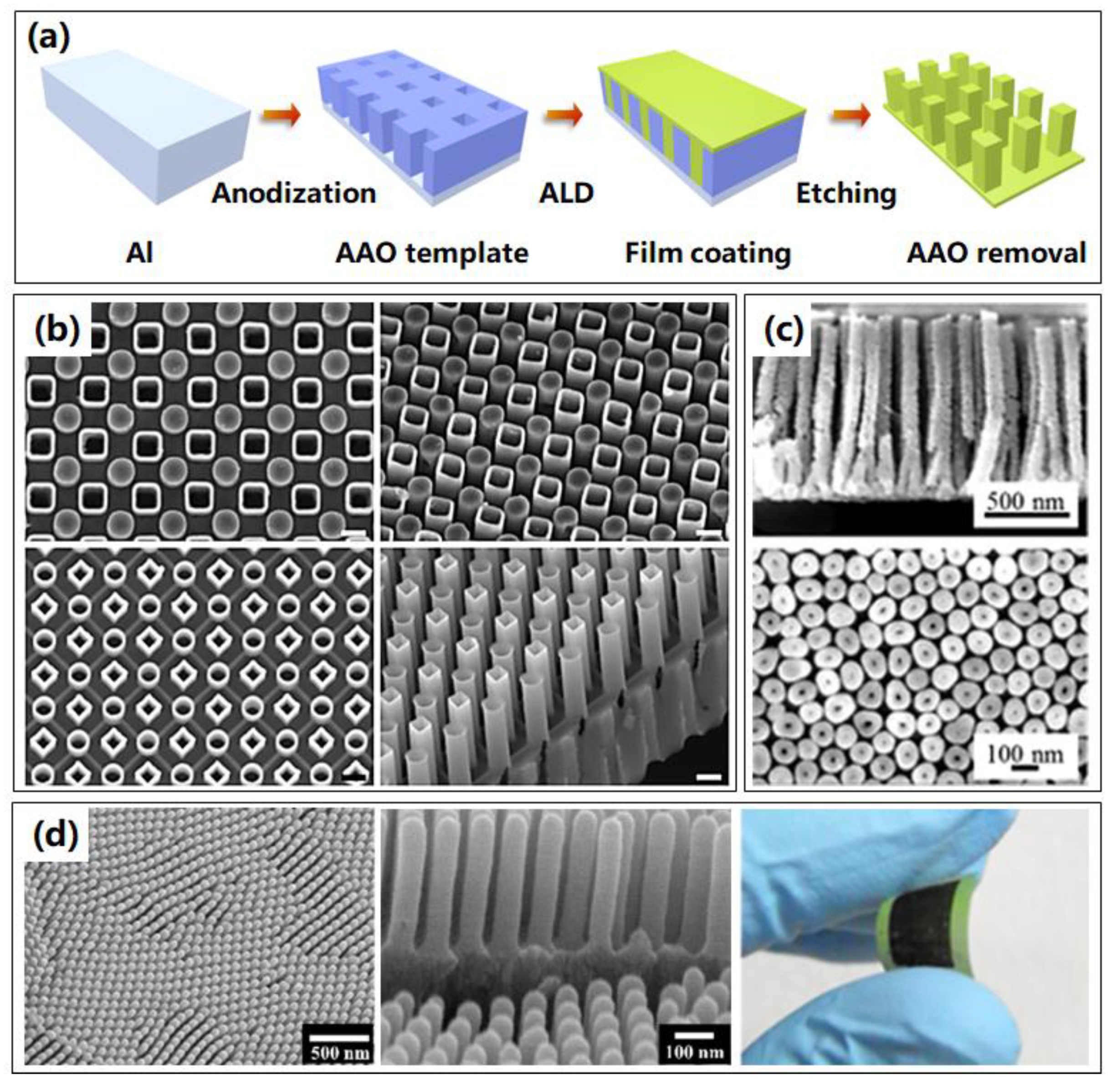

2. Rigid Templates for Fabricating 3D Nanostructures

2.1. Si Templates

2.2. AAO Templates

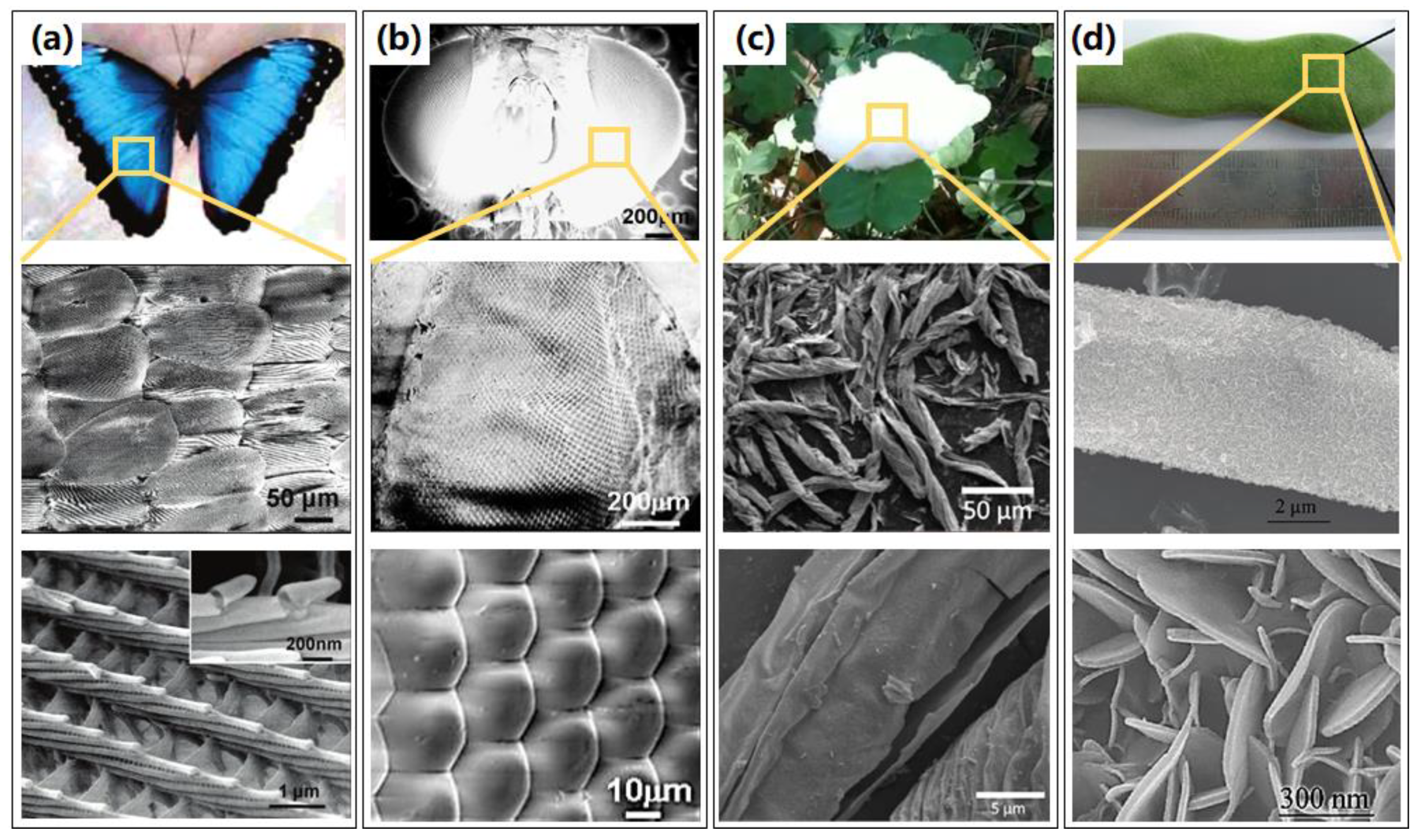

2.3. Biological Templates

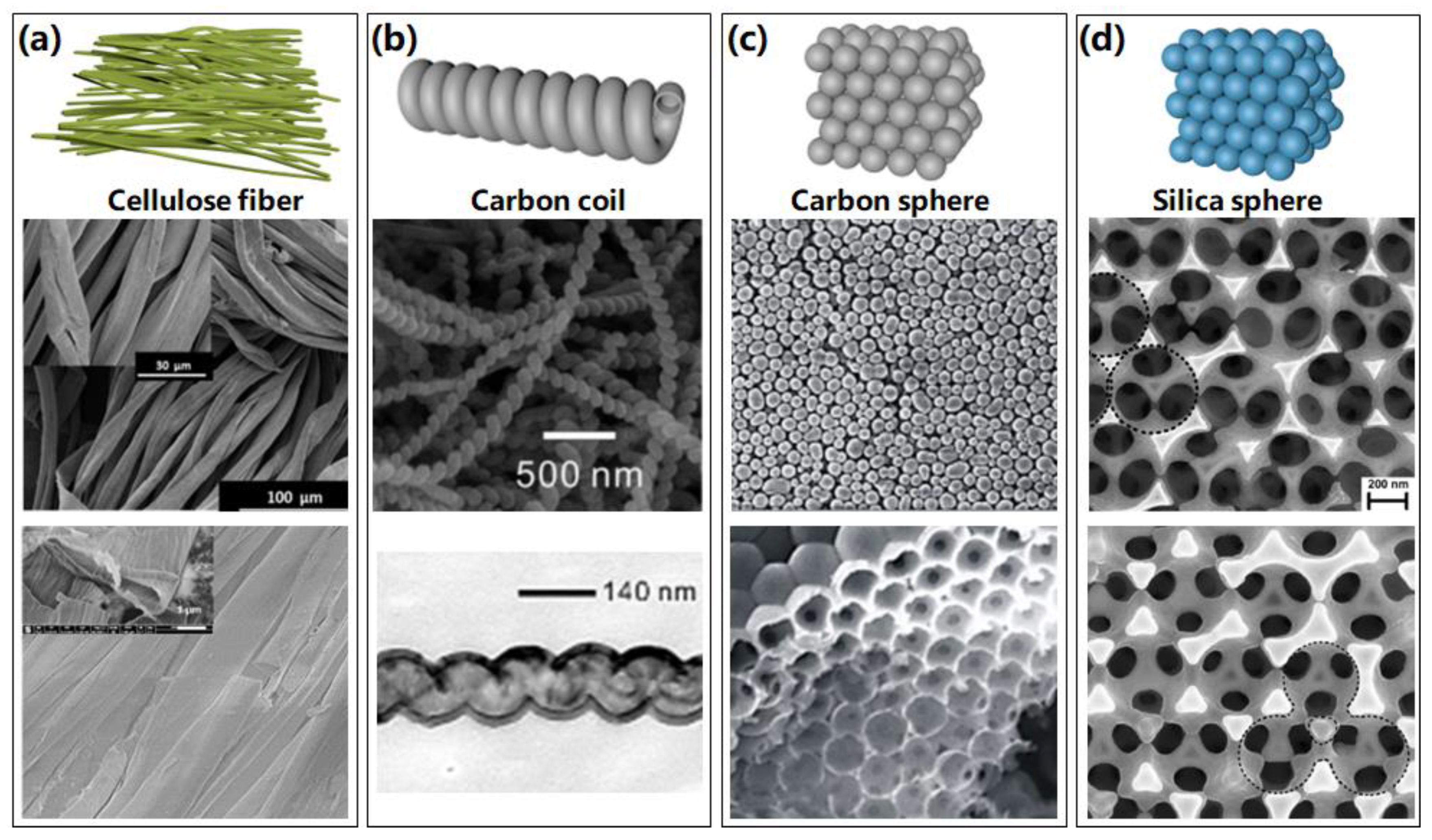

2.4. Other Rigid Templates

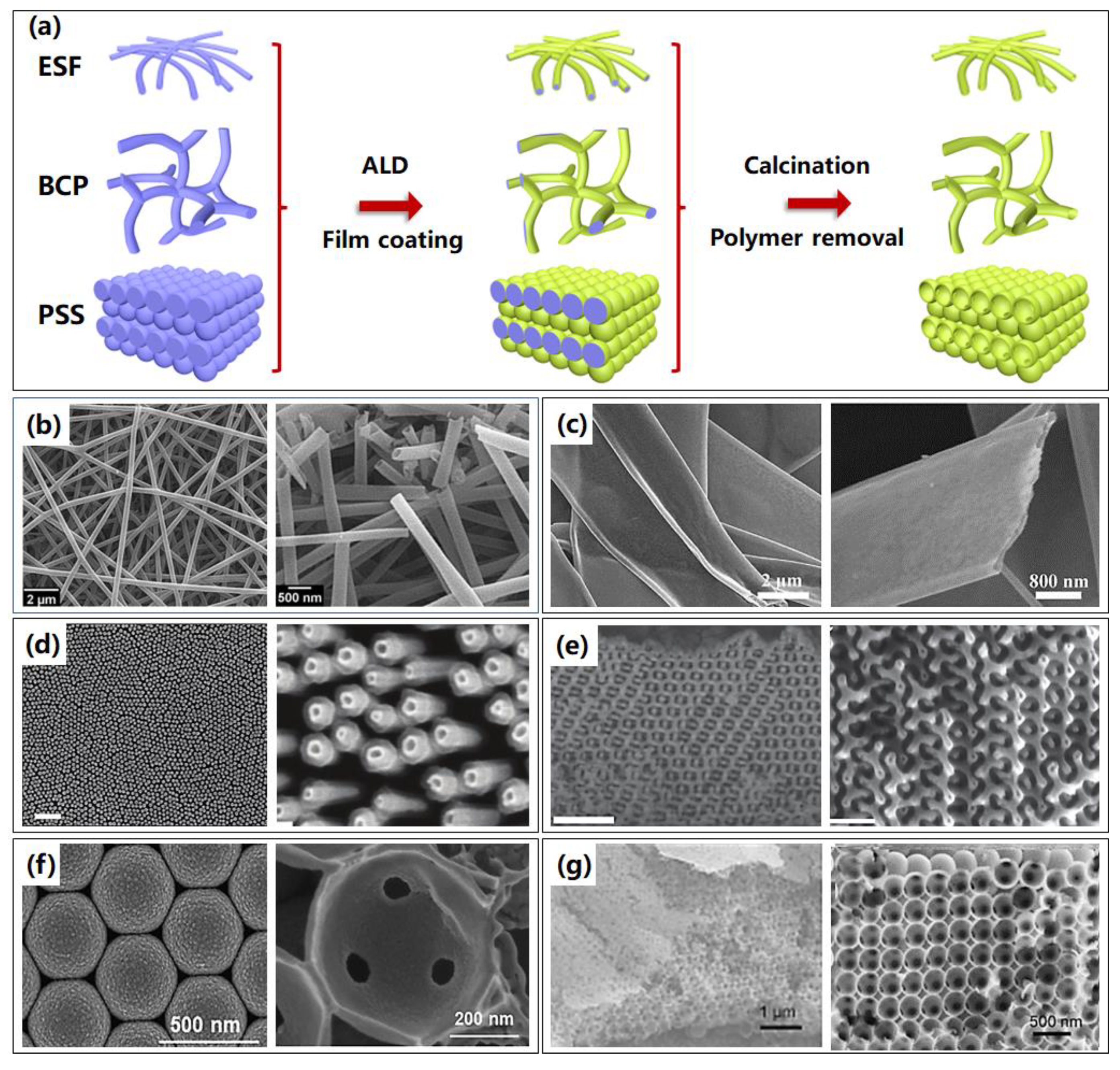

3. Soft Templates for Fabricating 3D Nanostructures

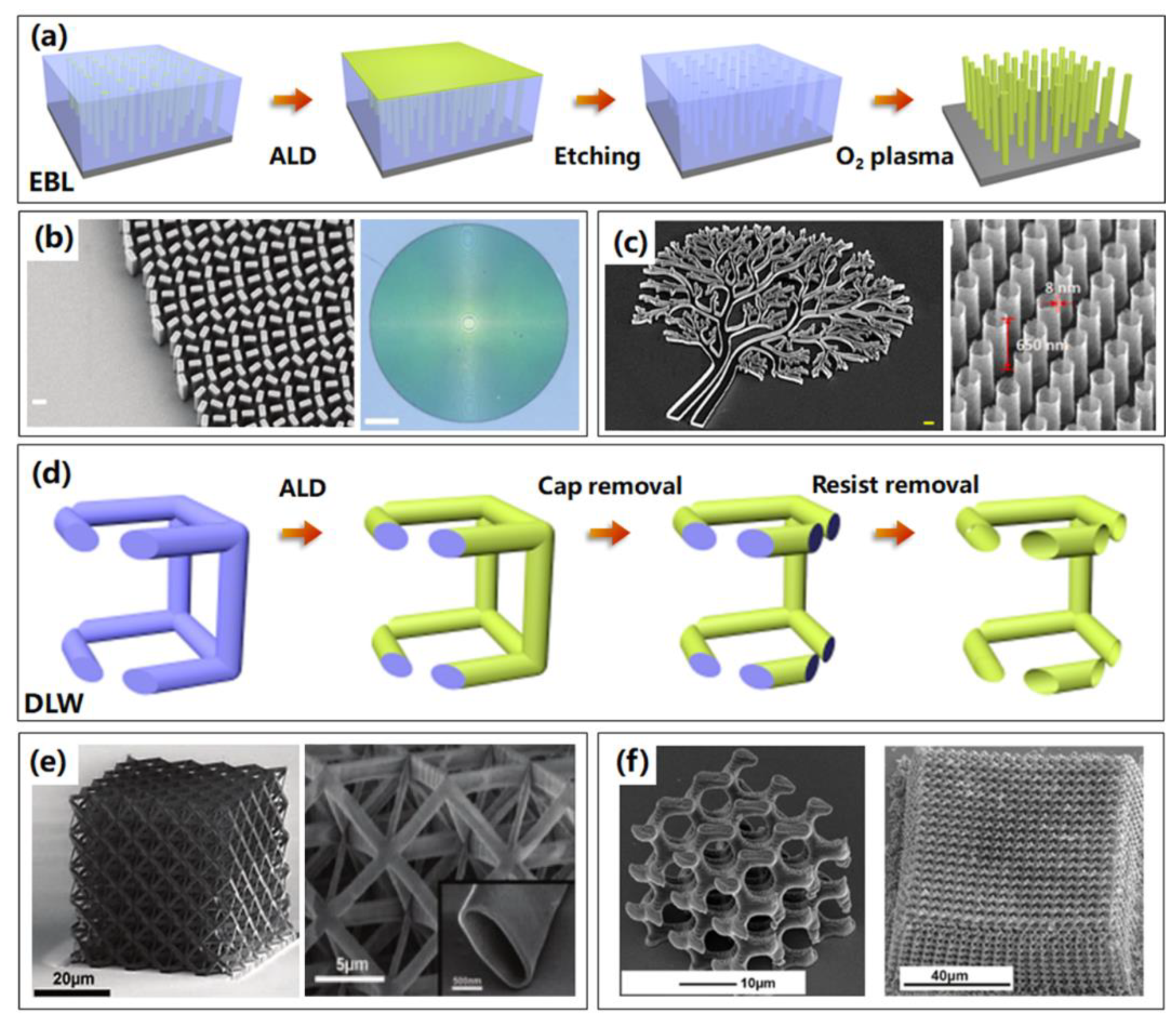

3.1. Resist Polymer Templates

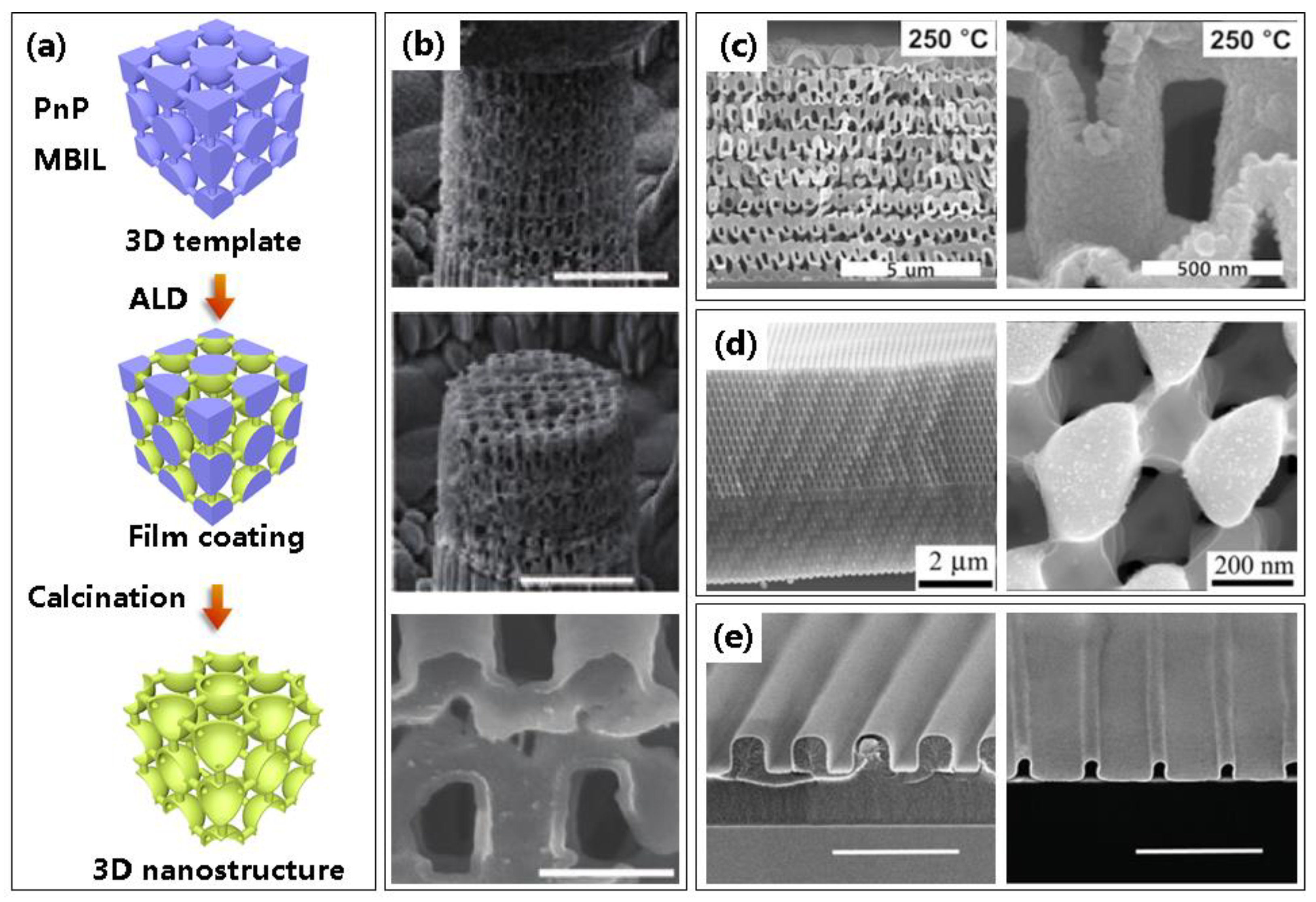

3.2. Assembled Polymer Templates

4. Comparison and Applications of 3D Nanostructures on Various Templates

4.1. Comparison of 3D Nanostructures on Various Templates

4.2. Applications of 3D Nanostructures on Various Templates

5. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cui, A.; Li, W.; Shen, T.H.; Yao, Y.; Fenton, J.C.; Peng, Y.; Liu, Z.; Zhang, J.; Gu, C. Thermally Induced Shape Modification of Free-standing Nanostructures for Advanced Functionalities. Sci. Rep. 2013, 3, 2429. [Google Scholar] [CrossRef] [PubMed]

- Clavijo, W.P.; Atkinson, G.M.; Castano, C.E.; Pestov, D. Novel low-temperature fabrication process for integrated high-aspect ratio zinc oxide nanowire sensors. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2016, 34, 022203. [Google Scholar] [CrossRef]

- Kelzenberg, M.D.; Boettcher, S.W.; Petykiewicz, J.A.; Turner-Evans, D.B.; Putnam, M.C.; Warren, E.L.; Spurgeon, J.M.; Briggs, R.M.; Lewis, N.S.; Atwater, H.A. Enhanced absorption and carrier collection in Si wire arrays for photovoltaic applications. Nat. Mater. 2010, 9, 239–244. [Google Scholar] [CrossRef] [PubMed]

- Tomioka, K.; Yoshimura, M.; Fukui, T. A III–V nanowire channel on silicon for high-performance vertical transistors. Nature 2012, 488, 189–192. [Google Scholar] [CrossRef]

- Kim, B.; Li, Y.; Jung, H.; Kim, J.Y.; Lee, D.-K.; Kim, B.; Son, H.J.; Kim, D.-H.; Ko, M.J. Enhanced interconnection of TiO2 nanoparticles using atomic layer deposition for flexible dye-sensitized solar cells with plastic substrates. Nano 2014, 9, 1440011. [Google Scholar] [CrossRef]

- Li, J.; Liu, W.; Wang, J.; Rozen, I.; He, S.; Chen, C.; Kim, H.G.; Lee, H.; Lee, H.; Kwon, S.; et al. Nanoconfined Atomic Layer Deposition of TiO2/Pt Nanotubes: Toward Ultrasmall Highly Efficient Catalytic Nanorockets. Adv. Funct. Mater. 2017, 27, 1700598. [Google Scholar] [CrossRef]

- Wu, W.; Wen, X.; Wang, Z.L. Taxel-Addressable Matrix of Vertical-Nanowire Piezotronic Transistors for Active and Adaptive Tactile Imaging. Science 2013, 340, 952–957. [Google Scholar] [CrossRef]

- Pan, C.; Dong, L.; Zhu, G.; Niu, S.; Yu, R.; Yang, Q.; Liu, Y.; Wang, Z.L. High-resolution electroluminescent imaging of pressure distribution using a piezoelectric nanowire LED array. Nat. Photon. 2013, 7, 752–758. [Google Scholar] [CrossRef]

- Banerjee, P.; Perez, I.; Henn-Lecordier, L.; Lee, S.B.; Rubloff, G. Nanotubular metal–insulator–metal capacitor arrays for energy storage. Nat. Nanotechnol. 2009, 4, 292–296. [Google Scholar] [CrossRef]

- Liu, C.; Gillette, E.; Chen, X.; Pearse, A.J.; Kozen, A.C.; Schroeder, M.; Gregorczyk, K.E.; Lee, S.B.; Rubloff, G.W. An all-in-one nanopore battery array. Nat. Nanotechnol. 2014, 9, 1031–1039. [Google Scholar] [CrossRef]

- Najiminaini, M.; Ertorer, E.; Kaminska, B.; Mittler, S.; Carson, J.J.L. Surface plasmon resonance sensing properties of a 3D nanostructure consisting of aligned nanohole and nanocone arrays. Analyst 2014, 139, 1876–1882. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Puurunen, R.L. Surface chemistry of atomic layer deposition: A case study for the trimethylaluminum/water process. J. Appl. Phys. 2005, 97, 121301. [Google Scholar] [CrossRef]

- Hämäläinen, J.; Ritala, M.; Leskelä, M. Atomic Layer Deposition of Noble Metals and Their Oxides. Chem. Mater. 2014, 26, 786–801. [Google Scholar] [CrossRef]

- Tripathi, T.S.; Karppinen, M. Atomic Layer Deposition of p-Type Semiconducting Thin Films: A Review. Adv. Mater. Interfaces 2017, 4, 1700300. [Google Scholar] [CrossRef]

- Miikkulainen, V.; Leskela, M.; Ritala, M.; Puurunen, R.L. Crystallinity of inorganic films grown by atomic layer deposition: Overview and general trends. J. Appl. Phys. 2013, 113, 021301. [Google Scholar] [CrossRef]

- Park, T.; Kim, H.; Leem, M.; Ahn, W.; Choi, S.; Kim, J.; Uh, J.; Kwon, K.; Jeong, S.-J.; Park, S.; et al. Atomic layer deposition of Al2O3 on MoS2, WS2, WSe2, and h-BN: Surface coverage and adsorption energy. RSC Adv. 2017, 7, 884–889. [Google Scholar] [CrossRef]

- Yuan, G.; Wang, N.; Huang, S.; Liu, J. A brief overview of atomic layer deposition and etching in the semiconductor processing. In Proceedings of the 17th International Conference on Electronic Packaging Technology (ICEPT), Wuhan, China, 16–19 August 2016; pp. 1365–1368. [Google Scholar] [CrossRef]

- Kim, D.H.; Lee, H.J.; Jeong, H.; Shong, B.; Kim, W.-H.; Park, T.J. Thermal Atomic Layer Deposition of Device-Quality SiO2 Thin Films under 100 °C Using an Aminodisilane Precursor. Chem. Mater. 2019, 31, 5502–5508. [Google Scholar] [CrossRef]

- Dominik, M.; Leśniewski, A.; Janczuk, M.; Niedziółka-Jönsson, J.; Hołdyński, M.; Wachnicki, Ł.; Godlewski, M.; Bock, W.J.; Śmietana, M. Titanium oxide thin films obtained with physical and chemical vapour deposition methods for optical biosensing purposes. Biosens. Bioelectron. 2017, 93, 102–109. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, B.; Brown, B. Atomic layer deposition of titanium oxide and nitride on vertically aligned carbon nanotubes for energy dense 3D microsupercapacitors. Appl. Surf. Sci. 2020, 521, 146349. [Google Scholar] [CrossRef]

- Sowa, M.J.; Ju, L.; Kozen, A.C.; Strandwitz, N.C.; Zeng, G.; Babuska, T.F.; Hsain, Z.; Krick, B.A. Plasma-enhanced atomic layer deposition of titanium vanadium nitride. J. Vac. Sci. Technol. A Vac. Surf. Film. 2018, 36, 06A103. [Google Scholar] [CrossRef]

- Meng, X.; Cao, Y.; Libera, J.A.; Elam, J.W. Atomic Layer Deposition of Aluminum Sulfide: Growth Mechanism and Electrochemical Evaluation in Lithium-Ion Batteries. Chem. Mater. 2017, 29, 9043–9052. [Google Scholar] [CrossRef]

- Peters, A.W.; Li, Z.; Farha, O.K.; Hupp, J.T. Atomically Precise Growth of Catalytically Active Cobalt Sulfide on Flat Surfaces and within a Metal–Organic Framework via Atomic Layer Deposition. ACS Nano 2015, 9, 8484–8490. [Google Scholar] [CrossRef] [PubMed]

- Kim, W.-H.; Shin, K.; Shong, B.; Godet, L.; Bent, S.F. Atomic Layer Deposition of Pt on the Surface Deactivated by Fluorocarbon Implantation: Investigation of the Growth Mechanism. Chem. Mater. 2020, 32, 9696–9703. [Google Scholar] [CrossRef]

- Weber, M.J.; Mackus, A.J.M.; Verheijen, M.A.; Longo, V.; Bol, A.A.; Kessels, W.M.M. Atomic Layer Deposition of High-Purity Palladium Films from Pd(hfac)2 and H2 and O2 Plasmas. J. Phys. Chem. C 2014, 118, 8702–8711. [Google Scholar] [CrossRef]

- Pereira, A.; Palma, J.L.; DeNardin, J.C.; Escrig, J. Temperature-dependent magnetic properties of Ni nanotubes synthesized by atomic layer deposition. Nanotechnology 2016, 27, 345709. [Google Scholar] [CrossRef][Green Version]

- Escrig, J.; Daub, M.; Landeros, P.; Nielsch, K.; Altbir, D. Angular dependence of coercivity in magnetic nanotubes. Nanotechnology 2007, 18, 445706. [Google Scholar] [CrossRef]

- Zhou, K.; Li, P.; Zhu, Y.; Ye, X.; Chen, H.; Yang, Y.; Dan, Y.; Yuan, Y.; Hou, H. Atomic Layer Deposition of ZnO on TiO2 Nanofibers for Boosted Photocatalytic Hydrogen Production. Catal. Lett. 2020, 151, 78–85. [Google Scholar] [CrossRef]

- Wei, Z.; Ruisheng, Y.; Guangzhou, G.; Yuancheng, F.; Xuyue, G.; Peng, L.; Quanhong, F.; Fuli, Z.; Changzhi, G.; Junjie, L. Titanium dioxide metasurface manipulating high-efficiency and broadband photonic spin Hall effect in visible regime. Nanophotonics 2020, 9, 4327–4335. [Google Scholar]

- Yun, S.; Kim, S.-J.; Youn, J.; Kim, H.; Ryu, J.; Bae, C.; No, K.; Hong, S. Flexible 3D Electrodes of Free-Standing TiN Nanotube Arrays Grown by Atomic Layer Deposition with a Ti Interlayer as an Adhesion Promoter. Nanomaterials 2020, 10, 409. [Google Scholar] [CrossRef]

- Huang, J.; Wang, X.; Wang, Z.L. Controlled Replication of Butterfly Wings for Achieving Tunable Photonic Properties. Nano Lett. 2006, 6, 2325–2331. [Google Scholar] [CrossRef]

- Shkondin, E.; Takayama, O.; Panah, M.E.A.; Liu, P.; Larsen, P.V.; Mar, M.D.; Jensen, F.; Lavrinenko, A.V. Large-scale high aspect ratio Al-doped ZnO nanopillars arrays as anisotropic metamaterials. Opt. Mater. Express 2017, 7, 1606–1627. [Google Scholar] [CrossRef]

- Tian, J.-L.; Wang, G.-G.; Zhang, H.-Y.; Han, J.-C. Nanopore diameter-dependent properties of thin three-dimensional ZnO layers deposited onto nanoporous silicon substrates. Ceram. Int. 2017, 43, 5173–5181. [Google Scholar] [CrossRef]

- Shkondin, E.; Takayama, O.; Lindhard, J.M.; Larsen, P.V.; Mar, M.D.; Jensen, F.; Lavrinenko, A.V. Fabrication of high aspect ratio TiO2 and Al2O3 nanogratings by atomic layer deposition. J. Vac. Sci. Technol. A Vac. Surf. Film. 2016, 34, 031605. [Google Scholar] [CrossRef]

- Gu, D.; Baumgart, H.; Tapily, K.; Shrestha, P.; Namkoong, G.; Ao, X.; Müller, F. Precise control of highly ordered arrays of nested semiconductor/metal nanotubes. Nano Res. 2010, 4, 164–170. [Google Scholar] [CrossRef]

- Li, H.; Xie, C. Fabrication of Ultra-High Aspect Ratio (>420:1) Al2O3 Nanotube Arraysby Sidewall TransferMetal Assistant Chemical Etching. Micromachines 2020, 11, 378. [Google Scholar] [CrossRef] [PubMed]

- Langner, A.; Knez, M.; Müller, F.; Gösele, U. TiO2 microstructures by inversion of macroporous silicon using atomic layer deposition. Appl. Phys. A 2008, 93, 399–403. [Google Scholar] [CrossRef][Green Version]

- Wen, L.; Wang, Z.; Mi, Y.; Xu, R.; Yu, S.-H.; Lei, Y. Designing Heterogeneous 1D Nanostructure Arrays Based on AAO Templates for Energy Applications. Small 2015, 11, 3408–3428. [Google Scholar] [CrossRef]

- Zhou, Z.; Nonnenmann, S.S. Progress in Nanoporous Templates: Beyond Anodic Aluminum Oxide and Towards Functional Complex Materials. Materials 2019, 12, 2535. [Google Scholar] [CrossRef]

- Wen, L.; Xu, R.; Mi, Y.; Lei, Y. Multiple nanostructures based on anodized aluminium oxide templates. Nat. Nanotechnol. 2017, 12, 244–250. [Google Scholar] [CrossRef]

- Huang, J.; Wang, X.; Wang, Z.L. Bio-inspired fabrication of antireflection nanostructures by replicating fly eyes. Nanotechnology 2007, 19, 025602. [Google Scholar] [CrossRef]

- Tian, R.; Feng, X.; Duan, H.; Zhang, P.; Li, H.; Liu, H.; Gao, L. Low-Weight 3D Al2 O3 Network as an Artificial Layer to Stabilize Lithium Deposition. ChemSusChem 2018, 11, 3243–3252. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wei, M.; Lu, J.; Wang, Z.L.; Duan, X. Biotemplated Hierarchical Nanostructure of Layered Double Hydroxides with Improved Photocatalysis Performance. ACS Nano 2009, 3, 4009–4016. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Xu, S.; Zhang, Y.; Wang, A.C.; Wang, M.H.; Xiu, Y.; Wong, C.P.; Wang, Z.L. Modifying the anti-wetting property of butterfly wings and water strider legs by atomic layer deposition coating: Surface materials versus geometry. Nanotechnology 2008, 19, 355708. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez, R.E.; Agarwal, S.P.; An, S.; Kazyak, E.; Das, D.; Shang, W.; Skye, R.; Deng, T.; Dasgupta, N.P. Biotemplated Morpho Butterfly Wings for Tunable Structurally Colored Photocatalysts. ACS Appl. Mater. Interfaces 2018, 10, 4614–4621. [Google Scholar] [CrossRef]

- Liu, F.; Liu, Y.; Huang, L.; Hu, X.; Dong, B.; Shi, W.; Xie, Y.; Ye, X. Replication of homologous optical and hydrophobic features by templating wings of butterflies Morpho menelaus. Opt. Commun. 2011, 284, 2376–2381. [Google Scholar] [CrossRef]

- Lidor-Shalev, O.; Pliatsikas, N.; Carmiel, Y.; Patsalas, P.; Mastai, Y. Chiral Metal-Oxide Nanofilms by Cellulose Template Using Atomic Layer Deposition Process. ACS Nano 2017, 11, 4753–4759. [Google Scholar] [CrossRef]

- Korhonen, J.T.; Hiekkataipale, P.; Malm, J.; Karppinen, M.; Ikkala, O.; Ras, R.H.A. Inorganic Hollow Nanotube Aerogels by Atomic Layer Deposition onto Native Nanocellulose Templates. ACS Nano 2011, 5, 1967–1974. [Google Scholar] [CrossRef]

- Qin, Y.; Kim, Y.; Zhang, L.; Lee, S.-M.; Bin Yang, R.; Pan, A.; Mathwig, K.; Alexe, M.; Gösele, U.; Knez, M. Preparation and Elastic Properties of Helical Nanotubes Obtained by Atomic Layer Deposition with Carbon Nanocoils as Templates. Small 2010, 6, 910–914. [Google Scholar] [CrossRef]

- Bakos, L.P.; Karajz, D.; Katona, A.; Hernadi, K.; Parditka, B.; Erdélyi, Z.; Lukács, I.; Hórvölgyi, Z.; Szitási, G.; Szilágyi, I.M. Carbon nanosphere templates for the preparation of inverse opal titania photonic crystals by atomic layer deposition. Appl. Surf. Sci. 2020, 504, 144443. [Google Scholar] [CrossRef]

- Graugnard, E.; King, J.S.; Gaillot, D.P.; Summers, C.J. Sacrificial-Layer Atomic Layer Deposition for Fabrication of Non-Close-Packed Inverse-Opal Photonic Crystals. Adv. Funct. Mater. 2006, 16, 1187–1196. [Google Scholar] [CrossRef]

- Deng, S.; Verbruggen, S.W.; He, Z.; Cott, D.J.; Vereecken, P.M.; Martens, J.A.; Bals, S.; Lenaerts, S.; Detavernier, C. Atomic layer deposition-based synthesis of photoactive TiO2 nanoparticle chains by using carbon nanotubes as sacrificial templates. RSC Adv. 2014, 4, 11648–11653. [Google Scholar] [CrossRef]

- Khorasaninejad, M.; Chen, W.T.; Devlin, R.C.; Oh, J.; Zhu, A.Y.; Capasso, F. Metalenses at visible wavelengths: Diffraction-limited focusing and subwavelength resolution imaging. Science 2016, 352, 1190–1194. [Google Scholar] [CrossRef] [PubMed]

- Geng, G.; Zhu, W.; Pan, R.; Zhang, Z.; Gu, C.; Li, J. Precise tailoring of multiple nanostructures based on atomic layer assembly via versatile soft-templates. Nano Today 2021, 38, 101145. [Google Scholar] [CrossRef]

- Kröger, N. Prescribing diatom morphology: Toward genetic engineering of biological nanomaterials. Curr. Opin. Chem. Biol. 2007, 11, 662–669. [Google Scholar] [CrossRef]

- Yang, W.; Chen, I.H.; Gludovatz, B.; Zimmermann, E.A.; Ritchie, R.O.; Meyers, M.A. Natural Flexible Dermal Armor. Adv. Mater. 2013, 25, 31–48. [Google Scholar] [CrossRef]

- Meza, L.R.; Das, S.; Greer, J.R. Strong, lightweight, and recoverable three-dimensional ceramic nanolattices. Science 2014, 345, 1322–1326. [Google Scholar] [CrossRef]

- Peng, S.; Zhang, R.; Chen, V.H.; Khabiboulline, E.T.; Braun, P.; Atwater, H.A. Three-Dimensional Single Gyroid Photonic Crystals with a Mid-Infrared Bandgap. ACS Photon. 2016, 3, 1131–1137. [Google Scholar] [CrossRef]

- Frölich, A.; Fischer, J.; Zebrowski, T.; Busch, K.; Wegener, M. Titania Woodpiles with Complete Three-Dimensional Photonic Bandgaps in the Visible. Adv. Mater. 2013, 25, 3588–3592. [Google Scholar] [CrossRef]

- Kawata, S.; Sun, H.; Tanaka, T.; Takada, K. Finer features for functional microdevices. Nature 2001, 412, 697–698. [Google Scholar] [CrossRef]

- Shi, Z.; Khorasaninejad, M.; Huang, Y.-W.; Roques-Carmes, C.; Zhu, A.Y.; Chen, W.T.; Sanjeev, V.; Ding, Z.-W.; Tamagnone, M.; Chaudhary, K.; et al. Single-Layer Metasurface with Controllable Multiwavelength Functions. Nano Lett. 2018, 18, 2420–2427. [Google Scholar] [CrossRef]

- Devlin, R.C.; Ambrosio, A.; Wintz, D.; Oscurato, S.L.; Zhu, A.Y.; Khorasaninejad, M.; Oh, J.; Maddalena, P.; Capasso, F. Spin-to-orbital angular momentum conversion in dielectric metasurfaces. Opt. Express 2017, 25, 377–393. [Google Scholar] [CrossRef] [PubMed]

- Khorasaninejad, M.; Chen, W.T.; Zhu, A.Y.; Oh, J.; Devlin, R.C.; Rousso, D.; Capasso, F. Multispectral Chiral Imaging with a Metalens. Nano Lett. 2016, 16, 4595–4600. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Lin, Q.; Xie, X.; Sun, Q.; Wang, Y.; Zhou, L.; Liu, L.; Yu, X.; Zhou, J.; Krauss, T.F.; et al. Ultrahigh Numerical Aperture Metalens at Visible Wavelengths. Nano Lett. 2018, 18, 4460–4466. [Google Scholar] [CrossRef] [PubMed]

- Devlin, R.C.; Khorasaninejad, M.; Chen, W.T.; Oh, J.; Capasso, F. Broadband high-efficiency dielectric metasurfaces for the visible spectrum. Proc. Natl. Acad. Sci. USA 2016, 113, 10473–10478. [Google Scholar] [CrossRef]

- Mueller, J.P.B.; Rubin, N.A.; Devlin, R.C.; Groever, B.; Capasso, F. Metasurface Polarization Optics: Independent Phase Control of Arbitrary Orthogonal States of Polarization. Phys. Rev. Lett. 2017, 118, 113901. [Google Scholar] [CrossRef]

- Wen, D.; Cadusch, J.J.; Meng, J.; Crozier, K.B. Multifunctional Dielectric Metasurfaces Consisting of Color Holograms Encoded into Color Printed Images. Adv. Funct. Mater. 2020, 30, 1906415. [Google Scholar] [CrossRef]

- Zhang, C.; Divitt, S.; Fan, Q.; Zhu, W.; Agrawal, A.; Lu, Y.; Xu, T.; Lezec, H.J. Low-loss metasurface optics down to the deep ultraviolet region. Light. Sci. Appl. 2020, 9, 1–10. [Google Scholar] [CrossRef]

- Ahn, C.; Park, J.; Kim, D.; Jeon, S. Monolithic 3D titania with ultrathin nanoshell structures for enhanced photocatalytic activity and recyclability. Nanoscale 2013, 5, 10384–10389. [Google Scholar] [CrossRef]

- Latimer, P.; Crouse, R.F. Talbot effect reinterpreted. Appl. Opt. 1992, 31, 80–89. [Google Scholar] [CrossRef]

- Park, J.; Wang, S.; Li, M.; Ahn, C.; Hyun, J.K.; Kim, D.S.; Kim, D.K.; Rogers, J.A.; Huang, Y.; Jeon, S. Three-dimensional nanonetworks for giant stretchability in dielectrics and conductors. Nat. Commun. 2012, 3, 916. [Google Scholar] [CrossRef]

- Na, Y.-E.; Shin, D.; Kim, K.; Ahn, C.; Jeon, S.; Jang, D. Emergence of New Density-Strength Scaling Law in 3D Hollow Ceramic Nanoarchitectures. Small 2018, 14, 1802239. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Yun, S.; Kim, K.; Kim, W.; Ryu, J.; Nam, H.G.; Han, S.M.; Jeon, S.; Hong, S. Breaking the elastic limit of piezoelectric ce-ramics using nanostructures: A case study using ZnO. Nano Energy 2020, 78, 105259. [Google Scholar] [CrossRef]

- King, J.S.; Graugnard, E.; Roche, O.M.; Sharp, D.N.; Scrimgeour, J.; Denning, R.G.; Turberfield, A.J.; Summers, C.J. Infiltration and Inversion of Holographically Defined Polymer Photonic Crystal Templates by Atomic Layer Deposition. Adv. Mater. 2006, 18, 1561–1565. [Google Scholar] [CrossRef]

- Min, J.-H.; Bagal, A.; Mundy, J.Z.; Oldham, C.J.; Wu, B.-I.; Parsons, G.N.; Chang, C.-H. Fabrication and design of metal nano-accordion structures using atomic layer deposition and interference lithography. Nanoscale 2016, 8, 4984–4990. [Google Scholar] [CrossRef]

- Stankevičius, E.; Daugnoraitė, E.; Račiukaitis, G. Mechanism of pillars formation using four-beam interference lithography. Opt. Lasers Eng. 2019, 116, 41–46. [Google Scholar] [CrossRef]

- Gedvilas, M.; Indrišiūnas, S.; Voisiat, B.; Stankevičius, E.; Selskis, A.; Račiukaitis, G. Nanoscale thermal diffusion during the laser interference ablation using femto-, pico-, and nanosecond pulses in silicon. Phys. Chem. Chem. Phys. 2018, 20, 12166–12174. [Google Scholar] [CrossRef]

- Stankevicius, E.; Balciunas, E.; Malinauskas, M.; Raciukaitis, G.; Baltriukiene, D.; Bukelskiene, V. Holographic lithography for biomedical applications. Proc. SPIE 2012, 8433, 843312. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, G.; Zhang, W.; Feng, Z.; Lin, L.; Zheng, Z. Low-cost micro-lens arrays fabricated by photosensitive sol–gel and multi-beam laser interference. Photon. Nanostructures Fundam. Appl. 2012, 10, 667–673. [Google Scholar] [CrossRef]

- Stankevicius, E.; Gedvilas, M.; Raciukaitis, G. Investigation of laser-induced polymerization using a smoothly varying intensity distribution. Appl. Phys. B 2015, 119, 525–532. [Google Scholar] [CrossRef]

- Yuan, L.; Herman, P.R. Laser Scanning Holographic Lithography for Flexible 3D Fabrication of Multi-Scale Integrated Nano-structures and Optical Biosensors. Sci. Rep. 2016, 6, 22294. [Google Scholar] [CrossRef]

- Stankevičius, E.; Garliauskas, M.; Raciukaitis, G. Bessel-like Beam Array Generation Using Round-tip Micro-structures and Their Use in the Material Treatment. J. Laser Micro Nanoeng. 2016, 11, 352–356. [Google Scholar]

- Haider, A.; Ozgit-Akgun, C.; Kayaci, F.; Okyay, A.K.; Uyar, T.; Biyikli, N. Fabrication of AlN/BN bishell hollow nanofibers by electrospinning and atomic layer deposition. APL Mater. 2014, 2, 096109. [Google Scholar] [CrossRef]

- Hou, H.; Liu, H.; Gao, F.; Shang, M.; Wang, L.; Xu, L.; Wong, W.-Y.; Yang, W. Packaging BiVO4 nanoparticles in ZnO microbelts for efficient photoelectrochemical hydrogen production. Electrochim. Acta 2018, 283, 497–508. [Google Scholar] [CrossRef]

- Kim, E.; Vaynzof, Y.; Sepe, A.; Guldin, S.; Scherer, M.R.J.; Cunha, P.; Roth, S.V.; Steiner, U. Gyroid-Structured 3D ZnO Networks Made by Atomic Layer Deposition. Adv. Funct. Mater. 2013, 24, 863–872. [Google Scholar] [CrossRef]

- Birnal, P.; Lucas, M.M.D.; Pochard, I.; Domenichini, B.; Imhoff, L. Photocatalytic properties of atomic layer deposited TiO2 inverse opals and planar films for the degradation of dyes. Appl. Surf. Sci. 2020, 512, 145693. [Google Scholar] [CrossRef]

- Li, X.; Puttaswamy, M.; Wang, Z.; Tan, C.K.; Grimsdale, A.C.; Kherani, N.P.; Tok, A.I.Y. A pressure tuned stop-flow atomic layer deposition process for MoS2 on high porous nanostructure and fabrication of TiO2/MoS2 core/shell inverse opal structure. Appl. Surf. Sci. 2017, 422, 536–543. [Google Scholar] [CrossRef]

- Boyadjiev, S.I.; Kéri, O.; Bárdos, P.; Firkala, T.; Gáber, F.; Nagy, Z.K.; Baji, Z.; Takács, M.; Szilágyi, I.M. TiO2/ZnO and ZnO/TiO2 core/shell nanofibers prepared by electrospinning and atomic layer deposition for photocatalysis and gas sensing. Appl. Surf. Sci. 2017, 424, 190–197. [Google Scholar] [CrossRef]

- Park, J.Y.; Choi, S.-W.; Lee, J.-W.; Lee, C.; Kim, S.S. Synthesis and Gas Sensing Properties of TiO2-ZnO Core-Shell Nanofibers. J. Am. Ceram. Soc. 2009, 92, 2551–2554. [Google Scholar] [CrossRef]

- Kim, W.-S.; Lee, B.-S.; Kim, D.-H.; Kim, H.-C.; Yu, W.-R.; Hong, S.-H. SnO2 nanotubes fabricated using electrospinning and atomic layer deposition and their gas sensing performance. Nanotechnology 2010, 21, 245605. [Google Scholar] [CrossRef]

- Choi, S.-W.; Park, J.Y.; Kim, S.S. Synthesis of SnO2–ZnO core-shell nanofibers via a novel two-step process and their gas sensing properties. Nanotechnology 2009, 20, 465603. [Google Scholar] [CrossRef]

- Katoch, A.; Kim, J.-H.; Kim, S.S. TiO2/ZnO Inner/Outer Double-Layer Hollow Fibers for Improved Detection of Reducing Gases. ACS Appl. Mater. Interfaces 2014, 6, 21494–21499. [Google Scholar] [CrossRef] [PubMed]

- Katoch, A.; Choi, S.-W.; Sun, G.-J.; Kim, H.W.; Kim, S.S. Mechanism and prominent enhancement of sensing ability to reducing gases in p/n core-shell nanofiber. Nanotechnology 2014, 25, 175501. [Google Scholar] [CrossRef] [PubMed]

- Katoch, A.; Choi, S.-W.; Kim, S.S. Effect of the wall thickness on the gas-sensing properties of ZnO hollow fibers. Nanotechnology 2014, 25, 455504. [Google Scholar] [CrossRef]

- Lee, B.-S.; Kim, W.-S.; Kim, D.-H.; Kim, H.-C.; Hong, S.-H.; Yu, W.-R. Fabrication of SnO2 nanotube microyarn and its gas sensing behavior. Smart Mater. Struct. 2011, 20, 105019. [Google Scholar] [CrossRef]

- Khalily, M.A.; Patil, B.; Yilmaz, E.; Uyar, T. Atomic layer deposition of Co3O4 nanocrystals on N-doped electrospun carbon nanofibers for oxygen reduction and oxygen evolution reactions. Nanoscale Adv. 2019, 1, 1224–1231. [Google Scholar] [CrossRef]

- Du, Q.; Wu, J.; Yang, H. Pt@Nb-TiO2 Catalyst Membranes Fabricated by Electrospinning and Atomic Layer Deposition. ACS Catal. 2014, 4, 144–151. [Google Scholar] [CrossRef]

- Kayaci, F.; Vempati, S.; Ozgit-Akgun, C.; Biyikli, N.; Uyar, T. Enhanced photocatalytic activity of homoassembled ZnO nanostructures on electrospun polymeric nanofibers: A combination of atomic layer deposition and hydrothermal growth. Appl. Catal. B Environ. 2014, 156, 173–183. [Google Scholar] [CrossRef]

- Donmez, I.; Kayaci, F.; Ozgit-Akgun, C.; Uyar, T.; Biyikli, N. Fabrication of hafnia hollow nanofibers by atomic layer deposition using electrospun nanofiber templates. J. Alloy. Compd. 2013, 559, 146–151. [Google Scholar] [CrossRef]

- Ozgit-Akgun, C.; Kayaci, F.; Vempati, S.; Haider, A.; Celebioglu, A.; Goldenberg, E.; Kizir, S.; Uyar, T.; Biyikli, N. Fabrication of flexible polymer–GaN core–shell nanofibers by the combination of electrospinning and hollow cathode plasma-assisted atomic layer deposition. J. Mater. Chem. C 2015, 3, 5199–5206. [Google Scholar] [CrossRef]

- Hu, M.; Teng, F.; Chen, H.; Jiang, M.; Gu, Y.; Lu, H.; Hu, L.; Fang, X. Novel Ω-Shaped Core-Shell Photodetector with High Ultraviolet Selectivity and Enhanced Responsivity. Adv. Funct. Mater. 2017, 27, 1704477. [Google Scholar] [CrossRef]

- Ku, S.J.; Jo, G.C.; Bak, C.H.; Kim, S.M.; Shin, Y.R.; Kim, K.H.; Kwon, S.H.; Kim, J.-B. Highly ordered freestanding titanium oxide nanotube arrays using Si-containing block copolymer lithography and atomic layer deposition. Nanotechnology 2013, 24, 85301. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.S.; Chang, J.B.; Verploegen, E.; Berggren, K.K.; Ross, C.A. A Path to Ultranarrow Patterns Using Self-Assembled Lithography. Nano Lett. 2010, 10, 1000–1005. [Google Scholar] [CrossRef] [PubMed]

- Jiao, J.; Wei, Y.; Chi, K.; Zhao, Z.; Duan, A.; Liu, J.; Jiang, G.; Wang, Y.; Wang, X.; Han, C.; et al. Platinum Nanoparticles Supported on TiO2 Photonic Crystals as Highly Active Photocatalyst for the Reduction of CO2 in the Presence of Water. Energy Technol. 2017, 5, 877–883. [Google Scholar] [CrossRef]

- Qi, D.; Lu, L.; Xi, Z.; Wang, L.; Zhang, J. Enhanced photocatalytic performance of TiO2 based on synergistic effect of Ti3+ self-doping and slow light effect. Appl. Catal. B Environ. 2014, 160, 621–628. [Google Scholar] [CrossRef]

- Lee, J.W.; Lee, J.; Kim, C.; Cho, C.-Y.; Moon, J.H. Facile fabrication of sub-100 nm mesoscale inverse opal films and their appli-cation in dye-sensitized solar cell electrodes. Sci. Rep. 2014, 4, 6804. [Google Scholar] [CrossRef]

- Kim, H.-N.; Moon, J.H. Enhanced Photovoltaic Properties of Nb2O5-Coated TiO2 3D Ordered Porous Electrodes in Dye-Sensitized Solar Cells. ACS Appl. Mater. Interfaces 2012, 4, 5821–5825. [Google Scholar] [CrossRef]

- Li, J.; Zheng, T. A comparison of chemical sensors based on the different ordered inverse opal films. Sens. Actuators B Chem. 2008, 131, 190–195. [Google Scholar] [CrossRef]

- Chiang, C.-C.; Tuyen, L.D.; Ren, C.-R.; Chau, L.-K.; Wu, C.Y.; Huang, P.-J.; Hsu, C.C. Fabrication of titania inverse opals by multi-cycle dip-infiltration for optical sensing. Photonics Nanostruct. 2016, 19, 48–54. [Google Scholar] [CrossRef]

- Li, X.; Wu, Y.; Shen, Y.; Sun, Y.; Yang, Y.; Xie, A. A novel bifunctional Ni-doped TiO2 inverse opal with enhanced SERS perfor-mance and excellent photocatalytic activity. Appl. Surf. Sci. 2018, 427, 739–744. [Google Scholar] [CrossRef]

- Qi, D.; Yan, X.; Wang, L.; Zhang, J. Plasmon-free SERS self-monitoring of catalysis reaction on Au nanoclusters/TiO2 photonic microarray. Chem. Commun. 2015, 51, 8813–8816. [Google Scholar] [CrossRef]

- Zhao, R.; Geng, G.; Wei, Q.; Liu, Y.; Zhou, H.; Zhang, X.; He, C.; Li, X.; Li, X.; Wang, Y.; et al. Controllable Polarization and Diffraction Modulated Multi-Functionality Based on Metasurface. Adv. Opt. Mater. 2022, 10, 2102596. [Google Scholar] [CrossRef]

- Wang, F.; Geng, G.; Wang, X.; Li, J.; Bai, Y.; Li, J.; Wen, Y.; Li, B.; Sun, J.; Zhou, J. Visible Achromatic Metalens Design Based on Artificial Neural Network. Adv. Opt. Mater. 2022, 10, 2101842. [Google Scholar] [CrossRef]

- Yao, Z.; Wang, C.; Li, Y.; Kim, N.-Y. AAO-assisted synthesis of highly ordered, large-scale TiO2 nanowire arrays via sputtering and atomic layer deposition. Nanoscale Res. Lett. 2015, 10, 166. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Liang, Y.-C.; Wang, C.-C.; Kei, C.-C.; Hsueh, Y.-C.; Cho, W.-H.; Perng, T.-P. Photocatalysis of Ag-Loaded TiO2 Nanotube Arrays Formed by Atomic Layer Deposition. J. Phys. Chem. C 2011, 115, 9498–9502. [Google Scholar] [CrossRef]

- Chang, W.-T.; Hsueh, Y.-C.; Huang, S.-H.; Liu, K.-I.; Kei, C.-C.; Perng, T.-P. Fabrication of Ag-loaded multi-walled TiO2 nanotube arrays and their photocatalytic activity. J. Mater. Chem. A 2013, 1, 1987–1991. [Google Scholar] [CrossRef]

- Al-Haddad, A.; Wang, Z.; Zhou, M.; Tarish, S.; Vellacheri, R.; Lei, Y. Constructing Well-Ordered CdTe/TiO2 Core/Shell Nanowire Arrays for Solar Energy Conversion. Small 2016, 12, 5538–5542. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, M.; Ren, W.; Ye, Z.-G. Well-ordered ZnO nanotube arrays and networks grown by atomic layer deposition. Appl. Surf. Sci. 2015, 340, 120–125. [Google Scholar] [CrossRef]

- Norek, M.; Zaleszczyk, W.; Łuka, G.; Budner, B.; Zasada, D. Tailoring UV emission from a regular array of ZnO nanotubes by the geometrical parameters of the array and Al2O3 coating. Ceram. Int. 2017, 43, 5693–5701. [Google Scholar] [CrossRef]

- Abdel-Fattah, T.M.; Gu, D.; Baumgart, H.; Namkoong, G. Optimizing the Release of ALD Grown ZnO Nanotubes from Anodic Aluminum Oxide Templates. ECS Trans. 2009, 25, 315–320. [Google Scholar] [CrossRef]

- Gu, D.; Baumgart, H.; Abdel-Fattah, T.M.; Namkoong, G. Synthesis of Nested Coaxial Multiple-Walled Nanotubes by Atomic Layer Deposition. ACS Nano 2010, 4, 753–758. [Google Scholar] [CrossRef]

- Gu, D.; Baumgart, H.; Namkoong, G.; Abdel-Fattah, T. Atomic Layer Deposition of ZrO2 and HfO2 Nanotubes by Template Replication. Electrochem. Solid State Lett. 2009, 12, K25. [Google Scholar] [CrossRef]

- Tian, L.; Soum-Glaude, A.; Volpi, F.; Salvo, L.; Berthomé, G.; Coindeau, S.; Mantoux, A.; Boichot, R.; Lay, S.; Brizé, V.; et al. Undoped TiO2 and nitrogen-doped TiO2 thin films deposited by atomic layer deposition on planar and architectured surfaces for photovoltaic applications. J. Vac. Sci. Technol. A Vac. Surf. Film. 2015, 33, 01A141. [Google Scholar] [CrossRef]

- Liu, L.; Karuturi, S.K.; Su, L.T.; Tok, A.I.Y. TiO2 inverse-opal electrode fabricated by atomic layer deposition for dye-sensitized solar cell applications. Energy Environ. Sci. 2011, 4, 209–215. [Google Scholar] [CrossRef]

- Singh, R.; Bapat, R.; Qin, L.; Feng, H.; Polshettiwar, V. Atomic Layer Deposited (ALD) TiO2 on Fibrous Nano-Silica (KCC-1) for Photocatalysis: Nanoparticle Formation and Size Quantization Effect. ACS Catal. 2016, 6, 2770–2784. [Google Scholar] [CrossRef]

- You, J.; Dou, L.; Yoshimura, K.; Kato, T.; Ohya, K.; Moriarty, T.; Emery, K.; Chen, C.-C.; Gao, J.; Li, G.; et al. A polymer tandem solar cell with 10.6% power conversion efficiency. Nat. Commun. 2013, 4, 1446. [Google Scholar] [CrossRef] [PubMed]

- Yip, C.T.; Huang, H.; Zhou, L.; Xie, K.; Wang, Y.; Feng, T.; Li, J.; Tam, W.Y. Direct and Seamless Coupling of TiO2 Nanotube Photonic Crystal to Dye-Sensitized Solar Cell: A Single-Step Approach. Adv. Mater. 2011, 23, 5624–5628. [Google Scholar] [CrossRef]

- Kim, H.J.; Jackson, D.H.K.; Lee, J.; Guan, Y.; Kuech, T.F.; Huber, G.W. Enhanced Activity and Stability of TiO2-Coated Cobalt/Carbon Catalysts for Electrochemical Water Oxidation. ACS Catal. 2015, 5, 3463–3469. [Google Scholar] [CrossRef]

- Sridharan, K.; Jang, E.; Park, Y.M.; Park, T.J. Superior Photostability and Photocatalytic Activity of ZnO Nanoparticles Coated with Ultrathin TiO2 Layers through Atomic-Layer Deposition. Chem. A Eur. J. 2015, 21, 19136–19141. [Google Scholar] [CrossRef]

- Kurttepeli, M.; Deng, S.; Verbruggen, S.W.; Guzzinati, G.; Cott, D.J.; Lenaerts, S.; Verbeeck, J.; Tendeloo, G.V.; Detavernier, C.; Bals, S. Synthesis and Characterization of Photoreactive TiO2–Carbon Nanosheet Composites. J. Phys. Chem. C 2014, 118, 21031–21037. [Google Scholar] [CrossRef]

- Park, S.-G.; Jeon, T.Y.; Jeon, H.C.; Yang, S.-M.; Kwon, J.-D.; Mun, C.-W.; Cho, B.; Kim, C.S.; Kim, D.-H. Fabrication of 3D ZnO hollow shell structures by prism holographic lithography and atomic layer deposition. J. Mater. Chem. C 2014, 2, 1957–1961. [Google Scholar] [CrossRef]

- Marichy, C.; Donato, N.; Latino, M.; Willinger, M.G.; Tessonnier, J.-P.; Neri, G.; Pinna, N. Gas sensing properties and p-type response of ALD TiO2 coated carbon nanotubes. Nanotechnology 2014, 26, 24004. [Google Scholar] [CrossRef] [PubMed]

- Baranowska-Korczyc, A.; Sobczak, K.; Dłużewski, P.; Reszka, A.; Kowalski, B.J.; Kłopotowski, Ł.; Elbaum, D.; Fronc, K. Facile synthesis of core/shell ZnO/ZnS nanofibers by electrospinning and gas-phase sulfidation for biosensor applications. Phys. Chem. Chem. Phys. 2015, 17, 24029–24037. [Google Scholar] [CrossRef] [PubMed]

- Purniawan, A.; Pandraud, G.; Moh, T.S.Y.; Marthen, A.; Vakalopoulos, K.A.; French, P.J.; Sarro, P.M. Fabrication and optical measurements of a TiO2-ALD evanescent waveguide sensor. Sens. Actuator A Phys. 2012, 188, 127–132. [Google Scholar] [CrossRef]

- Shkondin, O.T.E.; Panah, M.E.A.; Liu, P.; Larsen, P.V.; Mar, M.D.; Jensen, F.; Lavrinenko, A.V. High aspect ratio titanium nitride trench structures as plasmonic biosensor. Opt. Mater. Express 2017, 7, 4171–4182. [Google Scholar] [CrossRef]

- Jang, D.; Meza, L.; Greer, F.; Greer, J.R. Fabrication and deformation of three-dimensional hollow ceramic nanostructures. Nat. Mater. 2013, 12, 893–898. [Google Scholar] [CrossRef]

- Meza, L.R.; Greer, J.R. Mechanical characterization of hollow ceramic nanolattices. J. Mater. Sci. 2014, 49, 2496–2508. [Google Scholar] [CrossRef]

- Yoon, J.; Kim, S.; Kim, D.; Kim, I.-D.; Hong, S.; No, K. Fabrication of Highly Ordered and Well-Aligned PbTiO3/TiN Core-Shell Nanotube Arrays. Small 2015, 11, 3750–3754. [Google Scholar] [CrossRef]

- Park, J.; Kim, K.-I.; Kim, K.; Kim, D.-C.; Cho, D.; Lee, J.H.; Jeon, S. Rapid, High-Resolution 3D Interference Printing of Multilevel Ultralong Nanochannel Arrays for High-Throughput Nanofluidic Transport. Adv. Mater. 2015, 27, 8000–8006. [Google Scholar] [CrossRef]

- Yang, J.; Mi, H.; Luo, S.; Li, Y.; Zhang, P.; Deng, L.; Sun, L.; Ren, X. Atomic layer deposition of TiO2 on nitrogen-doped carbon nanofibers supported Ru nanoparticles for flexible Li-O2 battery: A combined DFT and experimental study. J. Power Sources 2017, 368, 88–96. [Google Scholar] [CrossRef]

- Vempati, S.; Ranjith, K.S.; Topuz, F.; Biyikli, N.; Uyar, T. Electrospinning Combined with Atomic Layer Deposition to Generate Applied Nanomaterials: A Review. ACS Appl. Nano Mater. 2020, 3, 6186–6209. [Google Scholar] [CrossRef]

| Template | Template Fabrication Technique | Template Elimination Technique | Obtained 3D Nanostructures | Controllability (a) | Cost | Productivity | Flexibility | Application (b) | |

|---|---|---|---|---|---|---|---|---|---|

| Rigid templates | Si | Etching (Dry, wet) | Etching (Dry, wet) | Nanotubes, Nanopillars | M | M | L | M | ●★◆ |

| AAO | Anodization | Wet etching | Nanotubes, Nanopillars | M | M | M | M | ●★◆ | |

| Biological structure | Native | Calcination | Replica of biological structures | L | L | H | L | ●◆▲ | |

| Carbon | CVD | Calcination | Nanotubes Nanospheres | L | L | M | L | ●▲ | |

| Electron resist | EBL | O2 plasma/Dissolution | Nanotubes, Nanopillars, Custom structures | H | H | L | H | ●★■◆▲ | |

| Soft templates | Photoresist | DLW/PnP/MBIL | O2 plasma | Nanotubes, Nanopillars, Custom structures | H | M | M | H | ●★■◆▲ |

| Fiber | ES | Calcination | Nanofibers | L | L | H | L | ★◆▲ | |

| BCP | SA | Calcination | 3D networks | M | L | H | M | ●★■◆▲ | |

| PS sphere | SA | Calcination | Inverse-opals | L | L | H | L | ●◆▲ | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, G.; Zhang, Z.; Li, C.; Pan, R.; Li, Y.; Yang, H.; Li, J. Atomic Layer Assembly Based on Sacrificial Templates for 3D Nanofabrication. Micromachines 2022, 13, 856. https://doi.org/10.3390/mi13060856

Geng G, Zhang Z, Li C, Pan R, Li Y, Yang H, Li J. Atomic Layer Assembly Based on Sacrificial Templates for 3D Nanofabrication. Micromachines. 2022; 13(6):856. https://doi.org/10.3390/mi13060856

Chicago/Turabian StyleGeng, Guangzhou, Zhongshan Zhang, Chensheng Li, Ruhao Pan, Yunlong Li, Haifang Yang, and Junjie Li. 2022. "Atomic Layer Assembly Based on Sacrificial Templates for 3D Nanofabrication" Micromachines 13, no. 6: 856. https://doi.org/10.3390/mi13060856

APA StyleGeng, G., Zhang, Z., Li, C., Pan, R., Li, Y., Yang, H., & Li, J. (2022). Atomic Layer Assembly Based on Sacrificial Templates for 3D Nanofabrication. Micromachines, 13(6), 856. https://doi.org/10.3390/mi13060856