Fabrication of High Precision Silicon Spherical Microlens Arrays by Hot Embossing Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Equipment

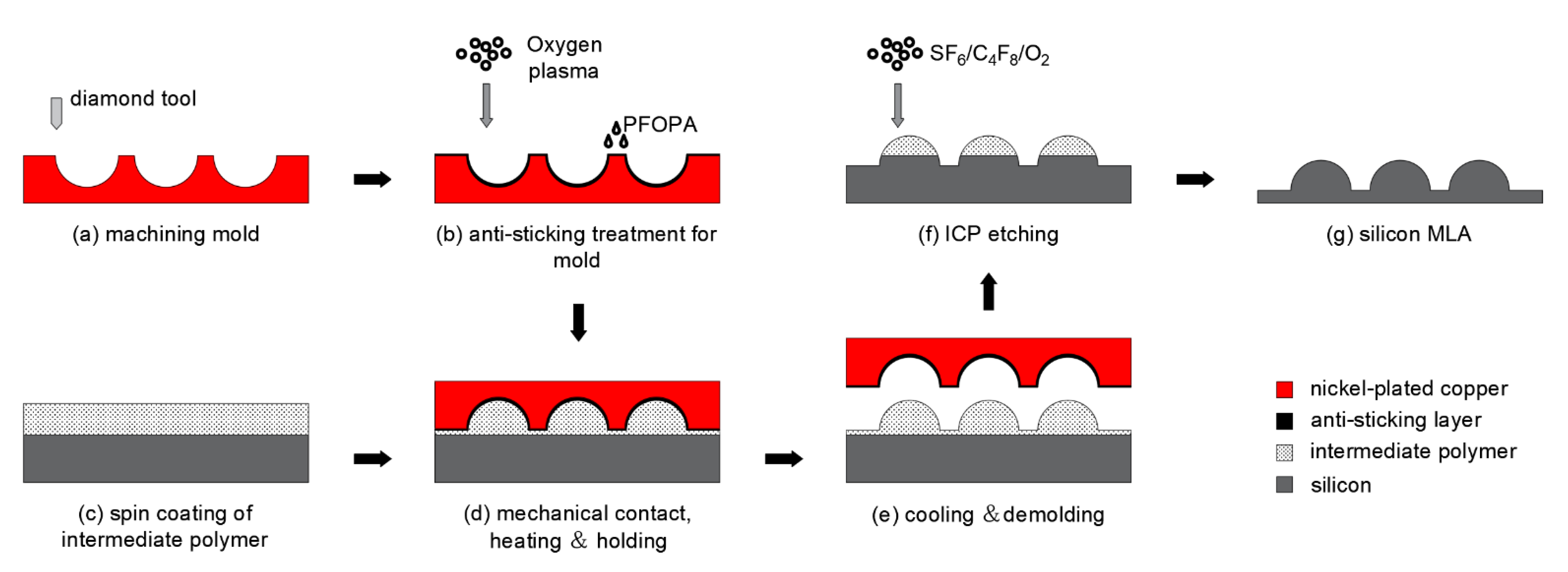

2.3. Methods

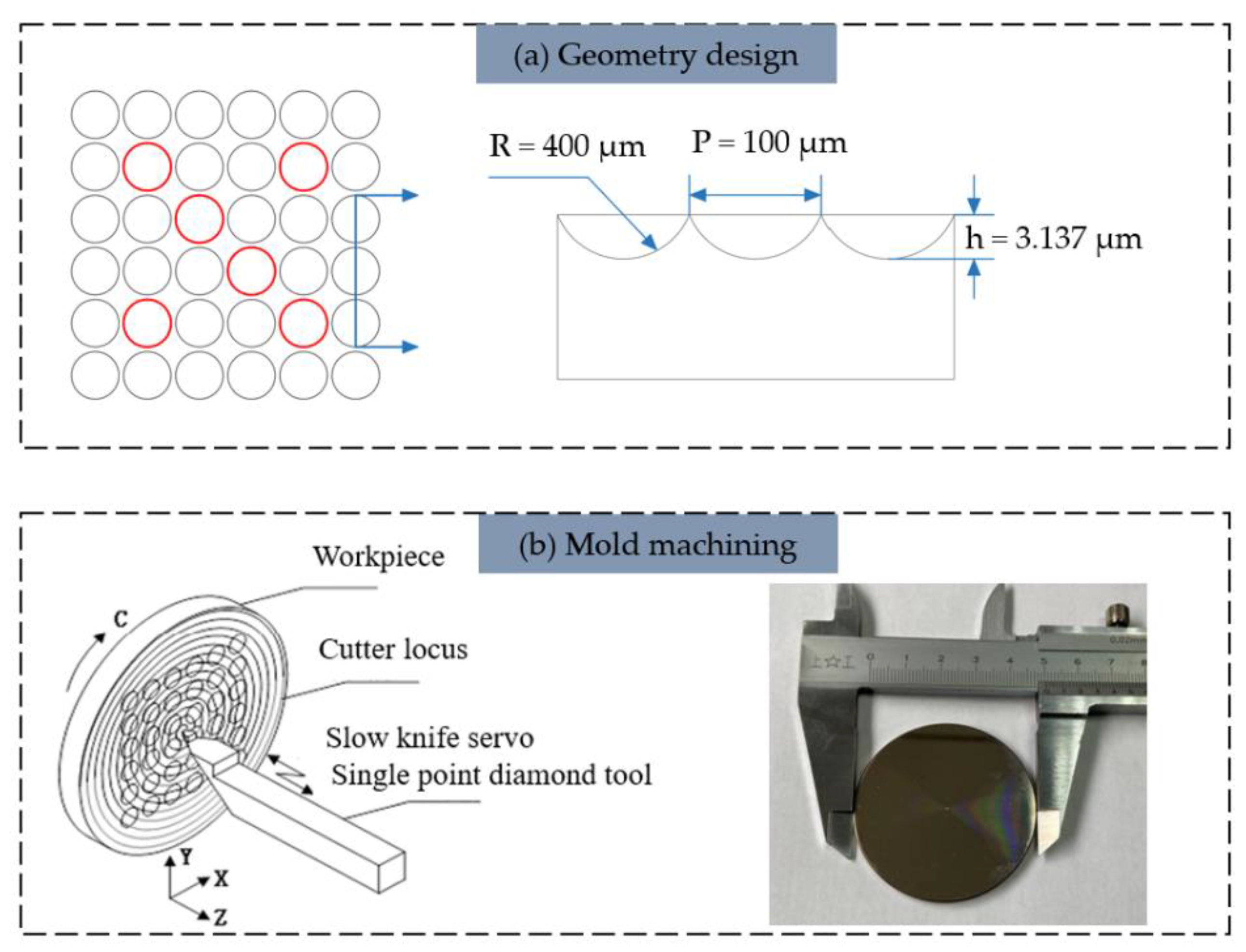

2.3.1. Single-Point Diamond Turning Method for Making Mold of MLA

2.3.2. Anti-Sticking Treatment of Nickel Mold

2.3.3. Orthogonal Experiment of Hot Embossing Process

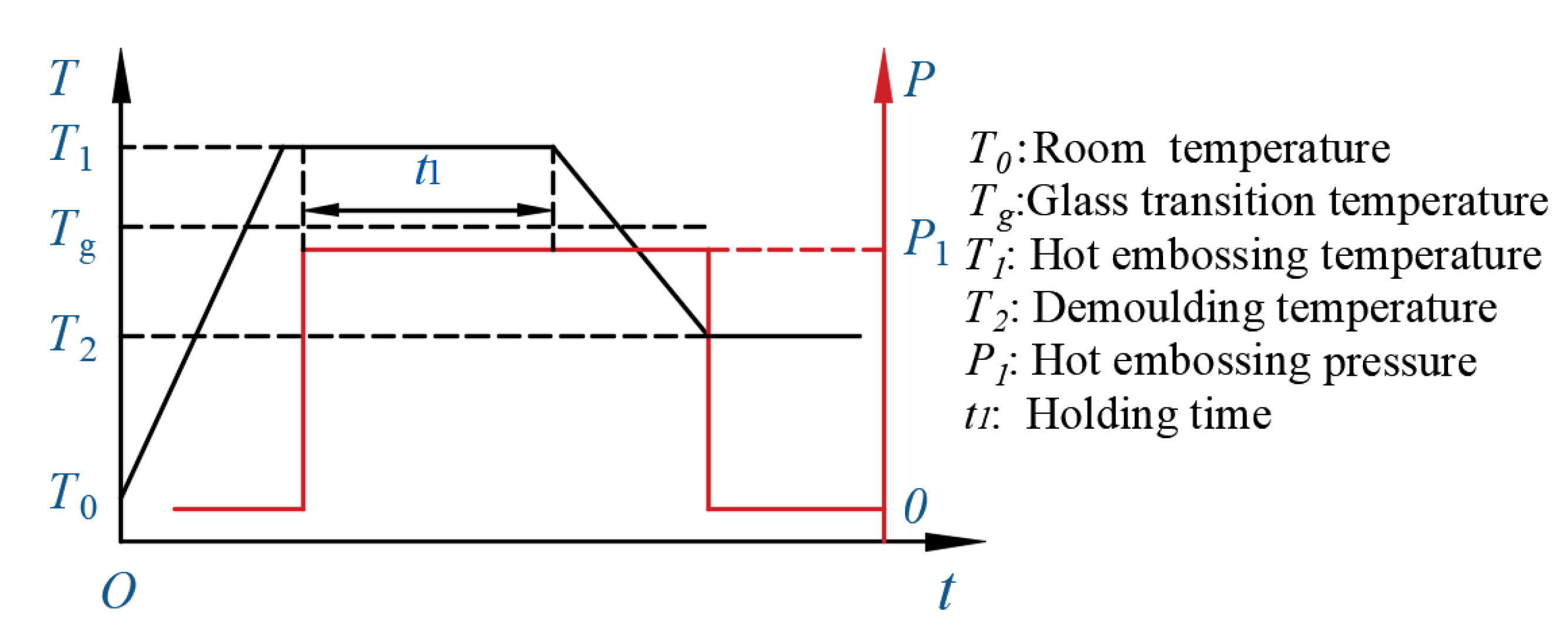

2.3.4. ICP Etching Experiment

2.4. Characterization

3. Results and Discussions

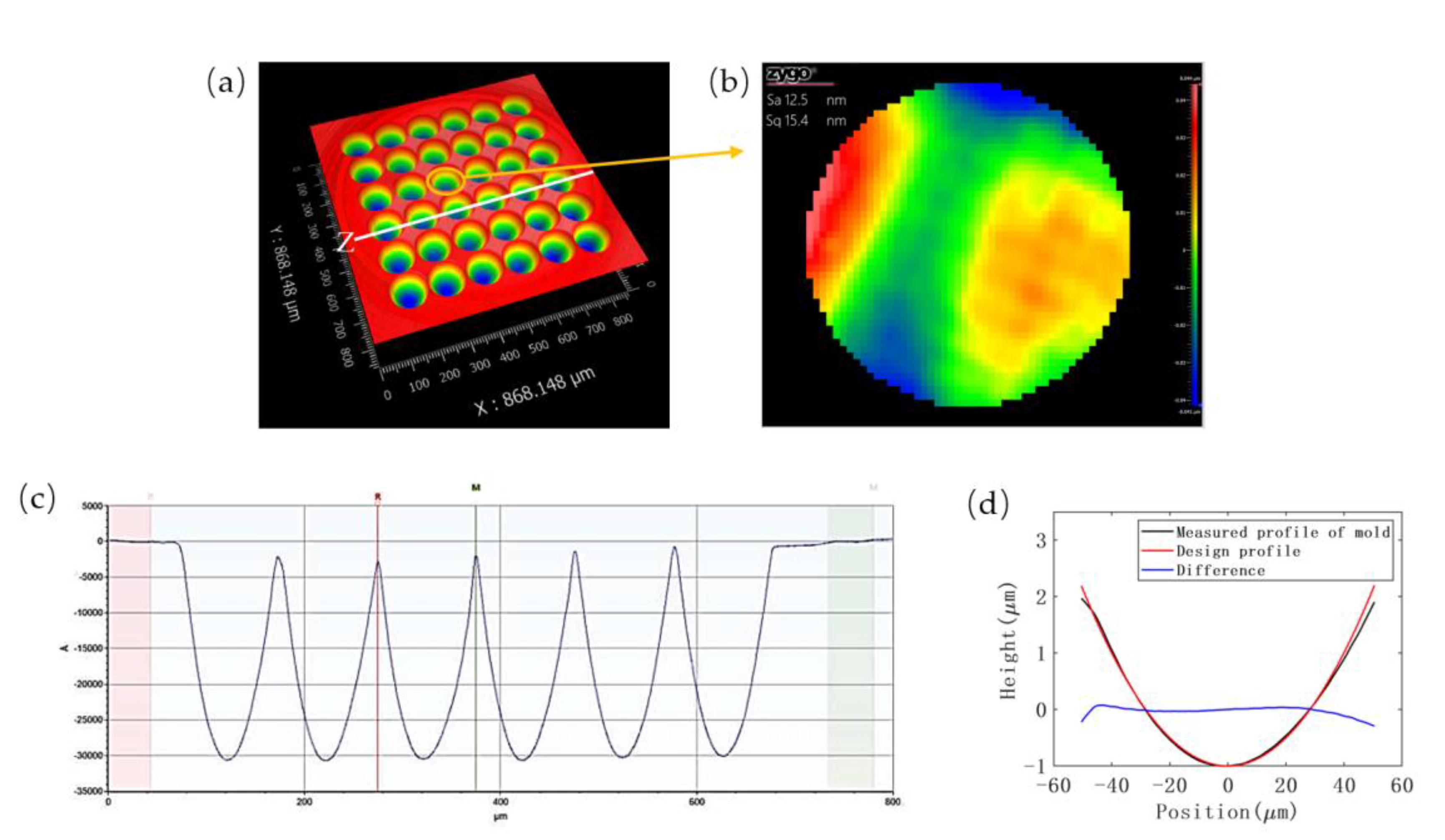

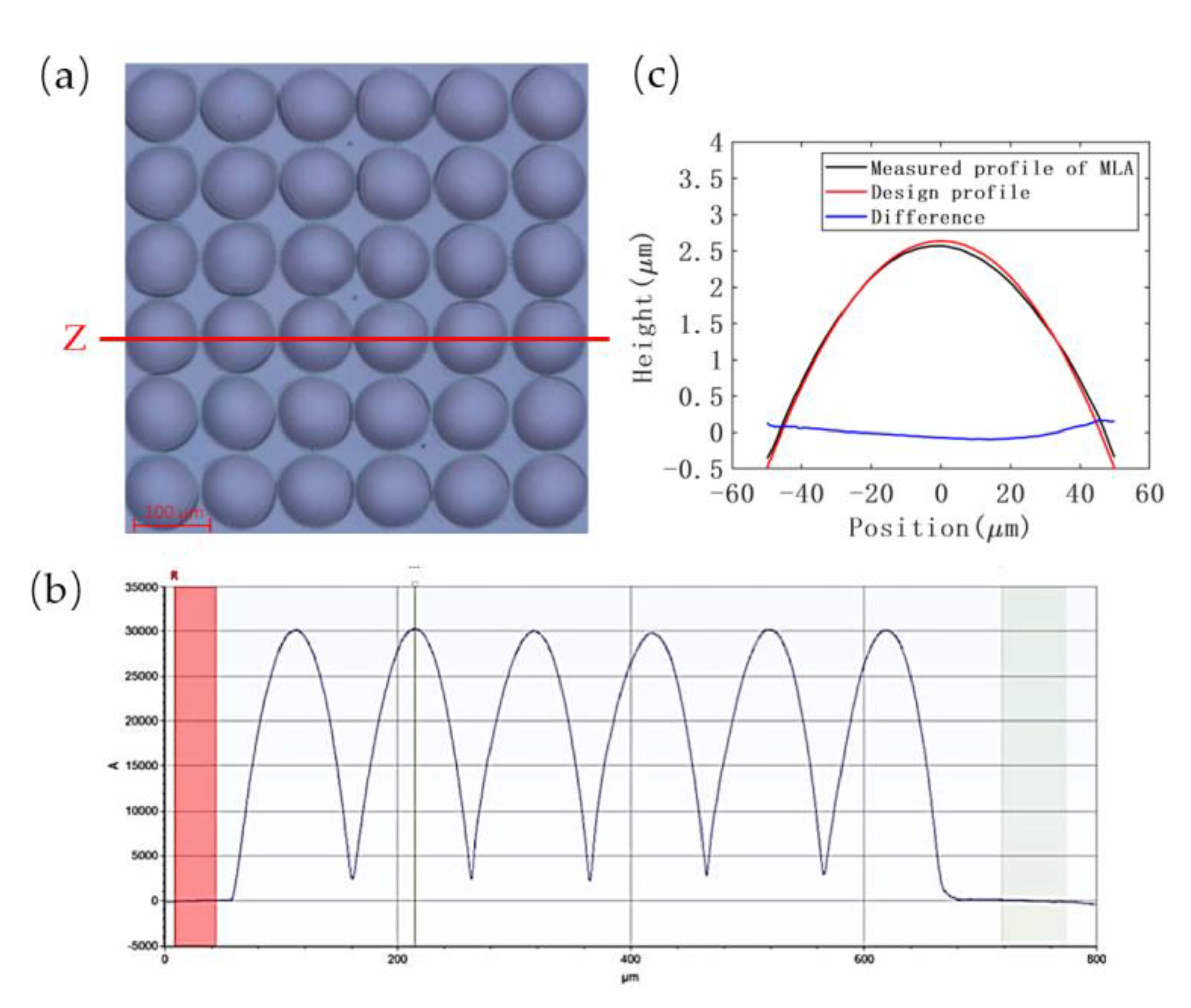

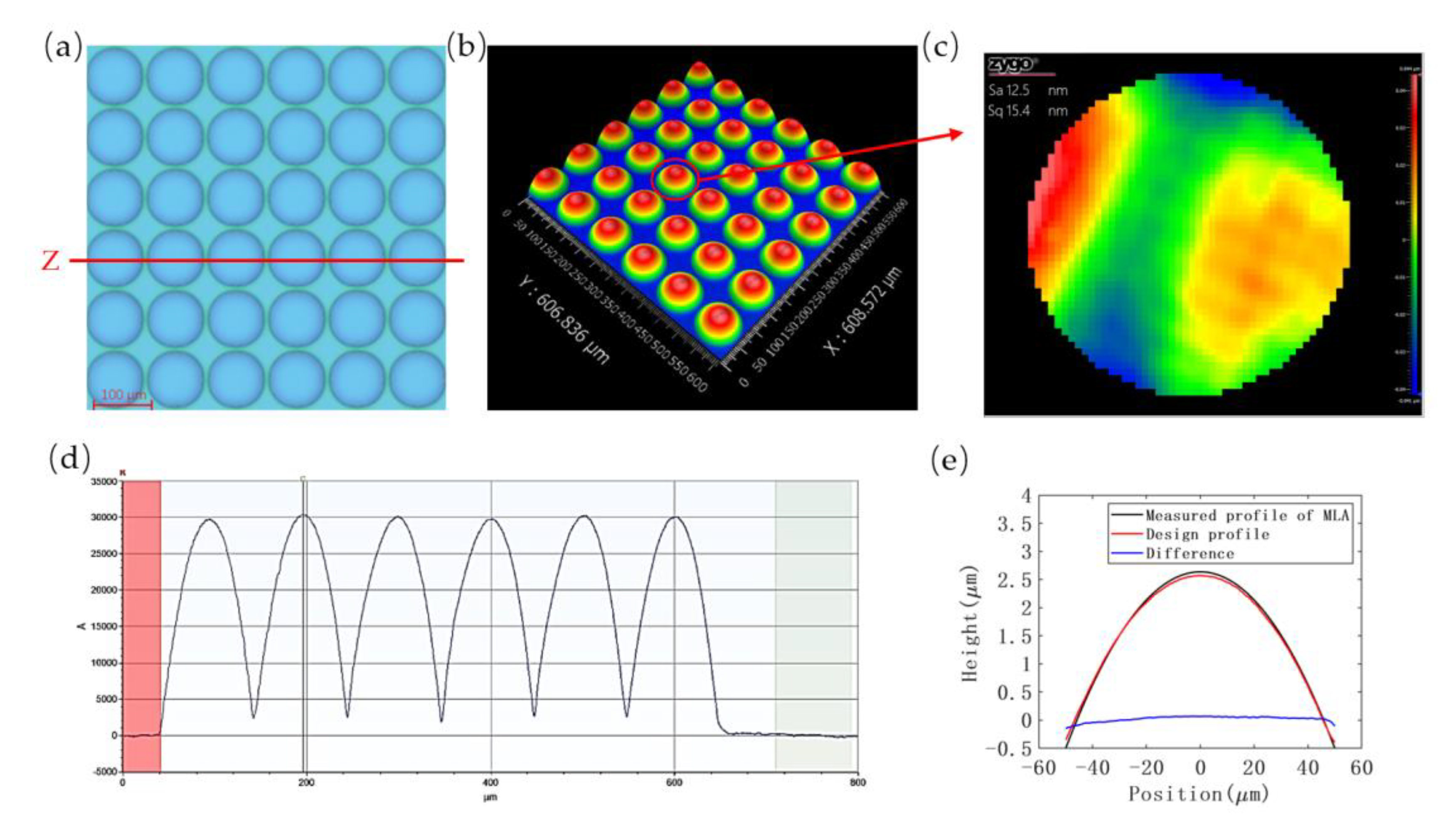

3.1. Inspection Results of Hot Embossing Mold

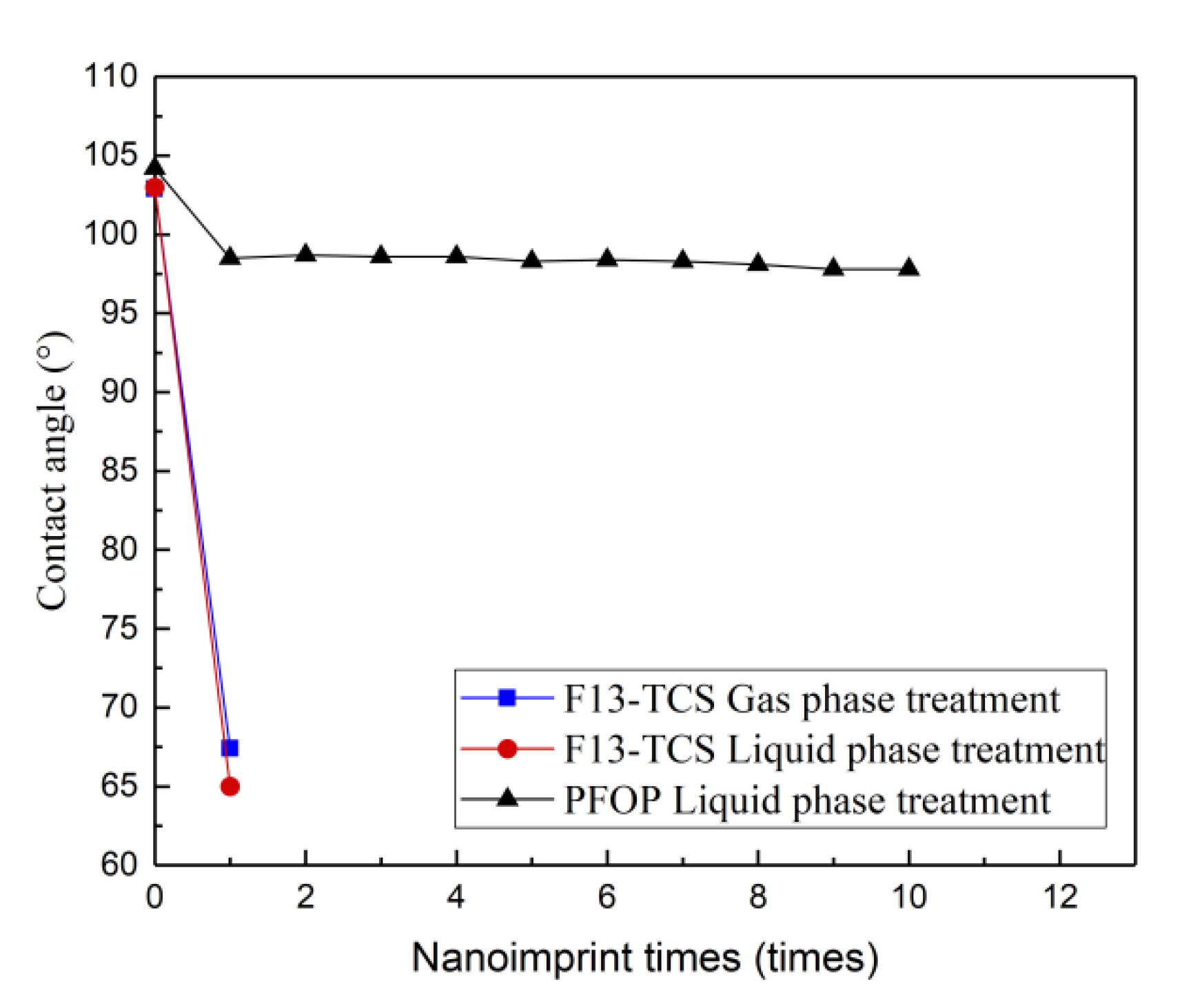

3.2. Effect of Anti-Sticking Treatment of Nickel Mold

3.3. Results and Analysis of Hot Embossing Experiments

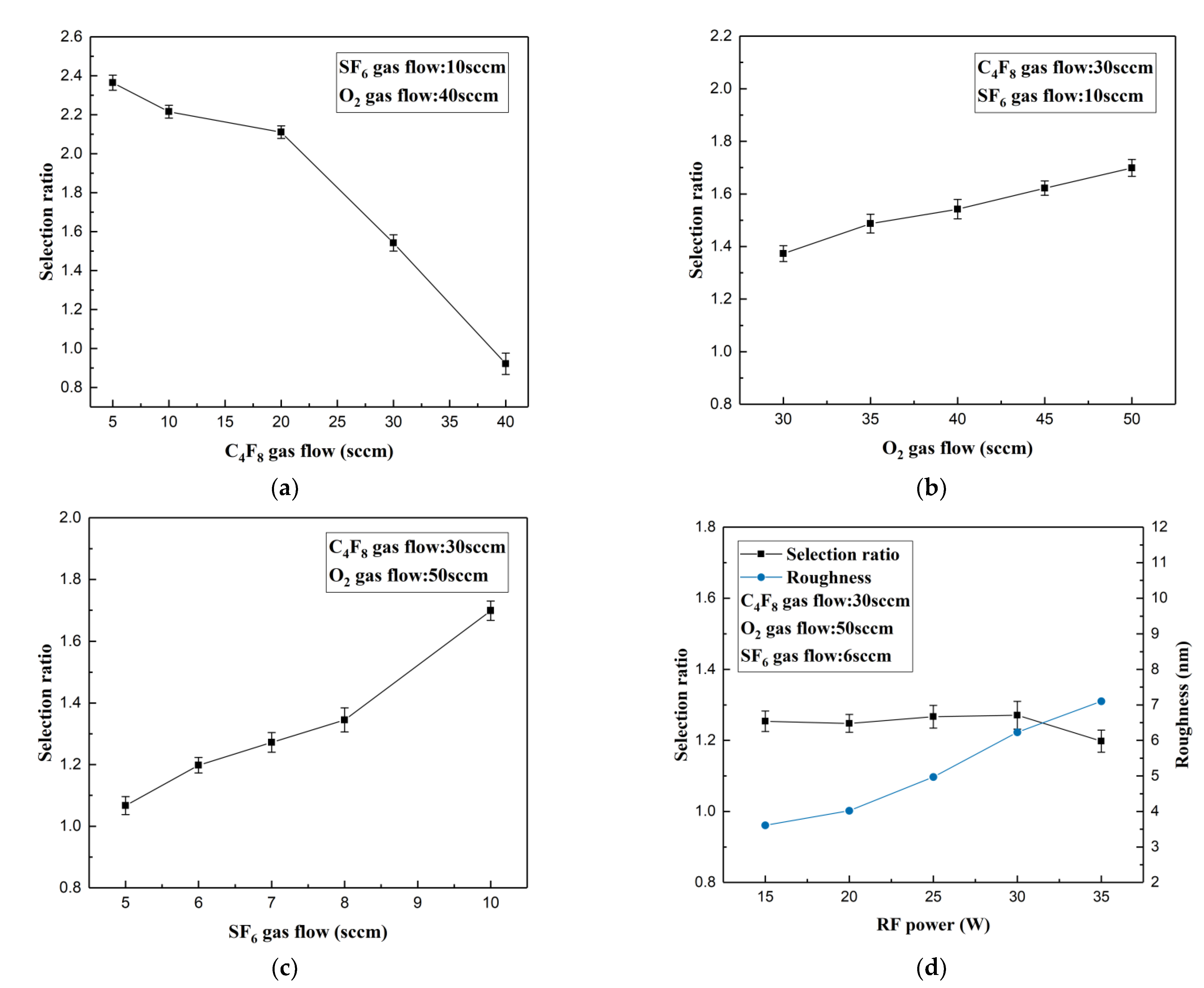

3.4. Results and Analysis of ICP Etching Experiment

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, X.Q.; Yu, L.; Yang, S.N.; Chen, Q.D.; Wang, L.; Juodkazis, S.; Sun, H.B. Optical Nanofabrication of Concave Microlens Arrays. Laser Photon. Rev. 2019, 13, 1800272. [Google Scholar] [CrossRef]

- Qu, Y.; Kim, J.; Coburn, C.; Forrest, S.R. Efficient, Nonintrusive Outcoupling in Organic Light Emitting Devices Using Embedded Microlens Arrays. ACS Photonics 2018, 5, 2453–2458. [Google Scholar] [CrossRef]

- Petsch, S.; Schuhladen, S.; Dreesen, L.; Zappe, H. The engineered eyeball, a tunable imaging system using soft-matter micro-optics. Light Sci. Appl. 2016, 5, e16068. [Google Scholar] [CrossRef] [Green Version]

- Lee, G.J.; Yoo, Y.J.; Song, Y.M. Recent advances in imaging systems and photonic nanostructures inspired by insect eye geometry. Appl. Spectrosc. Rev. 2018, 53, 112–128. [Google Scholar] [CrossRef]

- Wu, D.; Xu, J.; Niu, L.G.; Wu, S.Z.; Midorikawa, K.; Sugioka, K. In-channel integration of designable microoptical devices using flat scaffold-supported femtosecond-laser microfabrication for coupling-free optofluidic cell counting. Light Sci. Appl. 2015, 4, 228. [Google Scholar] [CrossRef] [Green Version]

- Sieler, M.; Schreiber, P.; Dannberg, P.; Bräuer, A. Design and realization of an ultra-slim array projector. In Proceedings of the 17th Microopics Conference (MOC), Sendai, Japan, 30 October–2 November 2011; IEEE: New York, NY, USA, 2011. [Google Scholar]

- Kim, S.M.; Kim, H.; Kang, S. Development of an ultraviolet imprinting process for integrating a microlens array onto an image sensor. Opt. Lett. 2006, 31, 2710–2712. [Google Scholar] [CrossRef]

- Urey, H.; Powell, K.D. Microlens-array-based exit-pupil expander for full-color displays. Appl. Opt. 2005, 44, 4930–4936. [Google Scholar] [CrossRef]

- Yu, W.; Yuan, X.; Ngo, N.; Que, W.; Cheong, W.; Koudriachov, V. Single-step fabrication of continuous surface relief micro-optical elements in hybrid sol-gel glass by laser direct writing. Opt Express 2002, 10, 443–448. [Google Scholar] [CrossRef]

- Fu, Y.; Bryan, N.K. Semiconductor microlenses fabricated by one-step focused ion beam direct writing. IEEE Trans. Semicond. Manuf. 2002, 15, 229–231. [Google Scholar] [CrossRef]

- Gissibl, T.; Thiele, S.; Herkommer, A.; Giessen, H. Two-photon direct laser writing of ultracompact multi-lens objectives. Nat. Photonics 2016, 10, 554–560. [Google Scholar] [CrossRef]

- Waits, C.M.; Morgan, B.; Kastantin, M.; Ghodssi, R. Microfabrication of 3D silicon MEMS structures using gray-scale lithography and deep reactive ion etching. Sens. Actuator A-Phys. 2004, 119, 245–253. [Google Scholar] [CrossRef]

- Waits, C.M.; Ghodssi, R.; Ervin, M.H.; Dubey, M. MEMS-based gray-scale lithography. Semicond. Device Res. Symp. ISDRS—Proc. 2001, 182, 182–185. [Google Scholar] [CrossRef]

- Totsu, K.; Esashi, M. Gray-scale photolithography using maskless exposure system. J. Vac. Sci. Technol. B 2005, 23, 1487–1490. [Google Scholar] [CrossRef]

- Chung, C.K.; Hong, Y.Z. Fabrication and analysis of the reflowed microlens arrays using JSR THB-130 N photoresist with different heat treatments. Microsyst. Technol. 2007, 13, 523–530. [Google Scholar] [CrossRef]

- Grigaliūnas, V.; Lazauskas, A.; Jucius, D.; Viržonis, D.; Abakevičienė, B.; Smetona, S.; Tamulevičius, S. Microlens fabrication by 3D electron beam lithography combined with thermal reflow technique. Microelectron. Eng. 2016, 164, 23–29. [Google Scholar] [CrossRef]

- Kim, Y.K.; Ju, J.H.; Kim, S.M. Replication of a glass microlens array using a vitreous carbon mold. Opt. Express 2018, 26, 14936–14944. [Google Scholar] [CrossRef]

- Chang, C.Y.; Yu, C.H. A basic experimental study of ultrasonic assisted hot embossing process for rapid fabrication of microlens arrays. J. Micromech. Microeng. 2015, 25, 025010. [Google Scholar] [CrossRef]

- Chang, C.Y.; Yang, S.Y.; Huang, L.S.; Chang, J.H. Fabrication of plastic microlens array using gas-assisted micro-hot-embossing with a silicon mold. Infrared Phys. Technol. 2006, 48, 163–173. [Google Scholar] [CrossRef]

- Schulz, H.; Wissen, M.; Bogdanski, N.; Scheer, H.C.; Mattes, K.; Friedrich, C. Choice of the molecular weight of an imprint polymer for hot embossing lithography. Microelectron. Eng. 2005, 78, 625–632. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Imprint of sub-25 nm vias and trenches in polymers. Appl. Phys. Lett. 1995, 67, 3114–3116. [Google Scholar] [CrossRef] [Green Version]

- Asif, M.H.; Graczyk, M.; Heidari, B.; Maximov, I. Comparison of UV-curable materials for high-resolution polymer nanoimprint stamps. Micro Nano Eng. 2022, 14, 100118. [Google Scholar] [CrossRef]

- Graczyk, M.; Cattoni, A.; Rösner, B.; Seniutinas, G.; Löfstrand, A.; Kvennefors, A.; Maximov, I. Nanoimprint stamps with ultra-high resolution: Optimal fabrication techniques. Microelectron. Eng. 2018, 190, 73–78. [Google Scholar] [CrossRef]

- Jia, Z.; Choi, J.; Park, S. Selection of UV-resins for nanostructured molds for thermal-NIL. Nanotechnology 2018, 29, 365302. [Google Scholar] [CrossRef]

- Hua, F.; Sun, Y.; Gaur, A.; Meitl, M.A.; Bilhaut, L.; Rotkina, L.; Shim, A. Polymer imprint lithography with molecular-scale resolution. Nano Lett. 2004, 4, 2467–2471. [Google Scholar] [CrossRef]

- Hua, J.G.; Ren, H.; Jia, A.; Tian, Z.N.; Wang, L.; Juodkazis, S.; Chen, Q.; Sun, H.B. Convex silica microlens arrays via femtosecond laser writing. Opt. Lett. 2020, 45, 636–639. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Yang, Q.; Chen, F.; Meng, X.; Bian, H.; Yong, J.; Chan, C.; Hou, X. Fabrication of large-area concave microlens array on silicon by femtosecond laser micromachining. Opt. Lett. 2015, 40, 1928–1931. [Google Scholar] [CrossRef] [Green Version]

- Mukaida, M.; Yan, J. Fabrication of hexagonal microlens arrays on single-crystal silicon using the tool-servo driven segment turning method. Micromachines 2017, 8, 323. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Li, K.; Gong, F. Fabrication and Optical Characterization of Polymeric Aspherical Microlens Array Using Hot Embossing Technology. Appl. Sci. 2021, 11, 882. [Google Scholar] [CrossRef]

- Zhang, G.; Dai, Y.; Lai, Z. A novel force-based two-dimensional tool centre error identification method in single-point diamond turning. Precis. Eng. 2021, 70, 92–109. [Google Scholar] [CrossRef]

- Yang, Z.H.; Chiu, C.Y.; Yang, J.T.; Yeh, J.A. Investigation and application of an ultrahydrophobic hybrid-structured surface with anti-sticking character. J. Micromech. Microeng. 2009, 19, 085022. [Google Scholar] [CrossRef]

- Keil, M.; Beck, M.; Ling, T.G.I.; Graczyk, M.; Montelius, L.; Heidari, B. Development and characterization of silane antisticking layers on nickel-based stamps designed for nanoimprint lithography. J. Vac. Sci. Technol. B 2005, 23, 575–584. [Google Scholar] [CrossRef]

- Padeste, C.; Bellini, S.; Siewert, D.; Schift, H. Anti-sticking layers for nickel-based nanoreplication tools. Microelectron. Eng. 2014, 123, 23–27. [Google Scholar] [CrossRef]

- Sökmen, Ü.; Balke, M.; Stranz, A.; Fündling, S.; Peiner, E.; Wehmann, H.H.; Waag, A. ICP cryogenic dry etching for shallow and deep etching in silicon. In Smart Sensors, Actuators, and MEMS IV; SPIE Europe Microtechnologies for the New Millennium: Dresden, Germany, 2009. [Google Scholar] [CrossRef]

- Duanmu, Q.; Zhang, A.; Wang, G.; Gao, Y.; Li, Y.; Jiang, D.; Tian, J. Silicon microhole array prepared by ICP. In MEMS/MOEMS Technologies and Applications II, Photonics Asia, Beijing, China, 8–11 November 2004; Ma, Z.C., Jin, G.F., Chen, X.Y., Eds.; SPIE: Bellingham, WA, USA, 2004. [Google Scholar] [CrossRef]

- Henry, M.D. ICP Etching of Silicon for Micro and Nanoscale Devices; Order No. 3597138; California Institute of Technology: Pasadena, CA, USA, 2010. [Google Scholar]

- Gawalt, E.S.; Avaltroni, M.J.; Koch, N.; Schwartz, J. Self-assembly and bonding of alkanephosphonic acids on the native oxide surface of titanium. Langmuir 2001, 17, 5736–5738. [Google Scholar] [CrossRef]

- Keil, M.; Beck, M.; Frennesson, G.; Theander, E.; Bolmsjö, E.; Montelius, L.; Heidari, B. Process development and characterization of antisticking layers on nickel-based stamps designed for nanoimprint lithography. J. Vac. Sci. Technol. B 2004, 22, 3283–3287. [Google Scholar] [CrossRef]

- Lee, M.J.; Cho, S.U.; Lee, S.M.; Kim, C.S.; Jeong, M.Y. Enhanced uniformity and durability of antisticking layer in imprinting stamps. Appl. Surf. Sci. 2012, 17, 6545–6549. [Google Scholar] [CrossRef]

| Cutting Conditions | Value |

|---|---|

| Workpiece material | Nickel–phosphorus alloy |

| Tool rake angle | 0° |

| Tool relief angle | 15° |

| Tool nose radius | 0.1 mm |

| Depth of cut | from 2 to 5 μm |

| X-axis interpolation increments per revolution | 0.001 mm |

| C-axis interpolation arc length increment | 0.001 mm |

| Interpolation time interval | 2 ms |

| Level | A: Embossing Temperature (T1)/°C | B: Embossing Pressure (P1)/bar | C: Embossing Time (t1)/s |

|---|---|---|---|

| 1 | 140 | 20 | 180 |

| 2 | 160 | 26 | 240 |

| 3 | 180 | 32 | 300 |

| Number | Experimental Factors | Replication Effect | ||

|---|---|---|---|---|

| Embossing Temperature (T1)/°C | Embossing Pressure (P1)/bar | Embossing Time (t1)/s | ||

| 1 | 140 | 20 | 180 | 85.8% |

| 2 | 140 | 26 | 240 | 89.6% |

| 3 | 140 | 32 | 300 | 91.6% |

| 4 | 160 | 20 | 240 | 93.5% |

| 5 | 160 | 26 | 300 | 94.4% |

| 6 | 160 | 32 | 180 | 97.8% |

| 7 | 180 | 20 | 300 | 95.2% |

| 8 | 180 | 26 | 180 | 97.3% |

| 9 | 180 | 32 | 240 | 98.0% |

| M1 | 89.0% | 91.5% | 93.7% | |

| M2 | 95.2% | 93.8% | 93.7% | |

| M3 | 96.8% | 95.8% | 93.7% | |

| R | 0.239 | 0.132 | 0.002 | |

| Number | Chamber Pressure (mTorr) | ICP Power (W) | RF Power (W) | Gas Flow (Sccm) | Selectivity | ||

|---|---|---|---|---|---|---|---|

| C4F8 | SF6 | O2 | |||||

| 1 | 10 | 800 | 35 | 30 | 10 | 40 | 1.542:1 |

| 2 | 10 | 800 | 35 | 30 | 10 | 50 | 1.699:1 |

| 3 | 10 | 800 | 35 | 30 | 10 | 45 | 1.622:1 |

| 4 | 10 | 800 | 35 | 30 | 6 | 50 | 1.198:1 |

| 5 | 10 | 800 | 35 | 20 | 10 | 40 | 2.111:1 |

| 6 | 10 | 800 | 35 | 10 | 10 | 40 | 2.216:1 |

| 7 | 10 | 800 | 35 | 30 | 6 | 50 | 1.207:1 |

| 8 | 10 | 800 | 35 | 30 | 5 | 50 | 1.067:1 |

| 9 | 10 | 800 | 35 | 30 | 7 | 50 | 1.272:1 |

| 10 | 10 | 800 | 35 | 40 | 10 | 40 | 0.922:1 |

| 11 | 10 | 800 | 35 | 5 | 10 | 40 | 2.365:1 |

| 12 | 10 | 800 | 35 | 30 | 10 | 35 | 1.487:1 |

| 13 | 10 | 800 | 35 | 30 | 10 | 30 | 1.373:1 |

| 14 | 10 | 800 | 35 | 30 | 8 | 50 | 1.345:1 |

| 15 | 10 | 800 | 30 | 30 | 6 | 50 | 1.271:1 |

| 16 | 10 | 800 | 25 | 30 | 6 | 50 | 1.267:1 |

| 17 | 10 | 800 | 20 | 30 | 6 | 50 | 1.248:1 |

| 18 | 10 | 800 | 15 | 30 | 6 | 50 | 1.254:1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Tang, J.; Shen, L.; Lan, J.; Shen, Z.; Xiao, J.; Chen, X.; Zhang, J.; Wu, Y.; Xu, J.; et al. Fabrication of High Precision Silicon Spherical Microlens Arrays by Hot Embossing Process. Micromachines 2022, 13, 899. https://doi.org/10.3390/mi13060899

Sun Q, Tang J, Shen L, Lan J, Shen Z, Xiao J, Chen X, Zhang J, Wu Y, Xu J, et al. Fabrication of High Precision Silicon Spherical Microlens Arrays by Hot Embossing Process. Micromachines. 2022; 13(6):899. https://doi.org/10.3390/mi13060899

Chicago/Turabian StyleSun, Quanquan, Jiaxuan Tang, Lifeng Shen, Jie Lan, Zhenfeng Shen, Junfeng Xiao, Xiao Chen, Jianguo Zhang, Yu Wu, Jianfeng Xu, and et al. 2022. "Fabrication of High Precision Silicon Spherical Microlens Arrays by Hot Embossing Process" Micromachines 13, no. 6: 899. https://doi.org/10.3390/mi13060899

APA StyleSun, Q., Tang, J., Shen, L., Lan, J., Shen, Z., Xiao, J., Chen, X., Zhang, J., Wu, Y., Xu, J., & Wang, X. (2022). Fabrication of High Precision Silicon Spherical Microlens Arrays by Hot Embossing Process. Micromachines, 13(6), 899. https://doi.org/10.3390/mi13060899