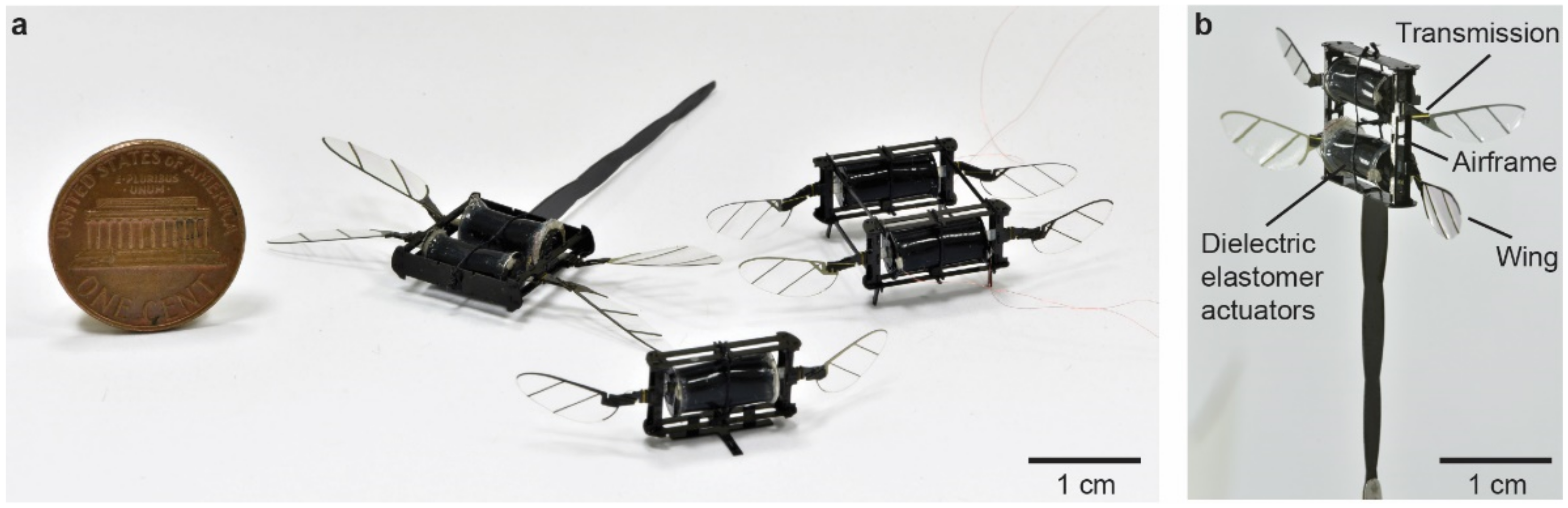

Design, Characterization, and Liftoff of an Insect-Scale Soft Robotic Dragonfly Powered by Dielectric Elastomer Actuators

Abstract

:1. Introduction

2. Materials and Methods

2.1. Design of the Soft Robotic Dragonfly

2.2. Experimental Setup

2.2.1. Static Flapping-Wing Experiments

2.2.2. Liftoff Experiments and Lift Force Measurement

3. Results

3.1. Calibration for Liftoff Tests

3.2. Influence of Relative Phase on Lift Force Production and Wing Kinematics

3.3. Influence of Driving Frequency on Lift Force Production and Stroke Amplitudes

3.4. Influence of Voltage Amplitude on Lift Force Production and Stroke Amplitudes

4. Discussion

Stroke Amplitudes, Lift Production, and Wing Pitch

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Dickerson, A.K.; Shankles, P.G.; Madhavan, N.M.; Hu, D.L. Mosquitoes survive raindrop collisions by virtue of their low mass. Proc. Natl. Acad. Sci. USA 2012, 109, 9822–9827. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, P.; Sane, S.P.; Mongeau, J.-M.; Zhao, J.; Cheng, B. Flies land upside down on a ceiling using rapid visually mediated rotational maneuvers. Sci. Adv. 2019, 5, eaax1877. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Z.J. Dissecting insect flight. Annu. Rev. Fluid Mech. 2005, 37, 183–210. [Google Scholar] [CrossRef] [Green Version]

- Wood, R.J.; Steltz, E.; Fearing, R. Optimal energy density piezoelectric bending actuators. Sens. Actuators A Phys. 2005, 119, 476–488. [Google Scholar] [CrossRef]

- Wood, R.J.; Avadhanula, S.; Sahai, R.; Steltz, E.; Fearing, R.S. Microrobot design using fiber reinforced composites. J. Mech. Des. 2008, 130, 052304. [Google Scholar] [CrossRef] [Green Version]

- Ma, K.Y.; Chirarattananon, P.; Fuller, S.B.; Wood, R.J. Controlled flight of a biologically inspired, insect-scale robot. Science 2013, 340, 603–607. [Google Scholar] [CrossRef] [Green Version]

- Helbling, E.F.; Fuller, S.B.; Wood, R.J. Altitude estimation and control of an insect-scale robot with an onboard proximity sensor. In Robotics Research; Springer: Berlin/Heidelberg, Germany, 2018; pp. 57–69. [Google Scholar]

- Graule, M.; Chirarattananon, P.; Fuller, S.; Jafferis, N.; Ma, K.; Spenko, M.; Kornbluh, R.; Wood, R. Perching and takeoff of a robotic insect on overhangs using switchable electrostatic adhesion. Science 2016, 352, 978–982. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Wang, H.; Helbling, E.F.; Jafferis, N.T.; Zufferey, R.; Ong, A.; Ma, K.; Gravish, N.; Chirarattananon, P.; Kovac, M.; et al. A biologically inspired, flapping-wing, hybrid aerial-aquatic microrobot. Sci. Robot. 2017, 2, eaao5619. [Google Scholar] [CrossRef] [Green Version]

- Jafferis, N.T.; Helbling, E.F.; Karpelson, M.; Wood, R.J. Untethered flight of an insect-sized flapping-wing microscale aerial vehicle. Nature 2019, 570, 491–495. [Google Scholar] [CrossRef]

- Zou, Y.; Zhang, W.; Zhang, Z. Liftoff of an electromagnetically driven insect-inspired flapping-wing robot. IEEE Trans. Robot. 2016, 32, 1285–1289. [Google Scholar] [CrossRef]

- Drew, D.S.; Lambert, N.O.; Schindler, C.B.; Pister, K.S. Toward controlled flight of the ionocraft: A flying microrobot using electrohydrodynamic thrust with onboard sensing and no moving parts. IEEE Robot. Autom. Lett. 2018, 3, 2807–2813. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, S.; Ren, Z.; Chirarattananon, P. Collision Resilient Insect-Scale Soft-Actuated Aerial Robots with High Agility. IEEE Trans. Robot. 2021, 37, 1752–1764. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, H.; Mao, J.; Chirarattananon, P.; Helbling, E.F.; Hyun, N.-S.P.; Clarke, D.R.; Wood, R.J. Controlled flight of a microrobot powered by soft artificial muscles. Nature 2019, 575, 324–329. [Google Scholar] [CrossRef]

- Ren, Z.; Kim, S.; Ji, X.; Zhu, W.; Niroui, F.; Kong, J.; Chen, Y. A High-Lift Micro-Aerial-Robot Powered by Low-Voltage and Long-Endurance Dielectric Elastomer Actuators. Adv. Mater. 2022, 34, 2106757. [Google Scholar] [CrossRef]

- Wang, Z.J.; Russell, D. Effect of forewing and hindwing interactions on aerodynamic forces and power in hovering dragonfly flight. Phys. Rev. Lett. 2007, 99, 148101. [Google Scholar] [CrossRef] [Green Version]

- Alexander, D.E. Unusual phase relationships between the forewings and hindwings in flying dragonflies. J. Exp. Biol. 1984, 109, 379–383. [Google Scholar] [CrossRef]

- Rüppell, G. Kinematic analysis of symmetrical flight manoeuvres of Odonata. J. Exp. Biol. 1989, 144, 13–42. [Google Scholar] [CrossRef]

- Wakeling, J.; Ellington, C. Dragonfly flight. II. Velocities, accelerations and kinematics of flapping flight. J. Exp. Biol. 1997, 200, 557–582. [Google Scholar] [CrossRef]

- Wang, Z.J.; Melfi, J., Jr.; Leonardo, A. Recovery mechanisms in the dragonfly righting reflex. Science 2022, 376, 754–758. [Google Scholar] [CrossRef]

- Hu, Y.; Ru, W.; Liu, Q.; Wang, Z. Design and Aerodynamic Analysis of Dragonfly-like Flapping Wing Micro Air Vehicle. J. Bionic Eng. 2022, 19, 343–354. [Google Scholar] [CrossRef]

- TechJect Inc. Robot Dragonfly-Micro Aerial Vehicle. Available online: https://www.indiegogo.com/projects/robot-dragonfly-micro-aerial-vehicle#/ (accessed on 16 June 2022).

- Gravish, N.; Peters, J.M.; Combes, S.A.; Wood, R.J. Collective flow enhancement by tandem flapping wings. Phys. Rev. Lett. 2015, 115, 188101. [Google Scholar] [CrossRef] [Green Version]

- Usherwood, J.R.; Lehmann, F.O. Phasing of dragonfly wings can improve aerodynamic efficiency by removing swirl. J. R. Soc. Interface 2008, 5, 1303–1307. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Gravish, N.; Desbiens, A.L.; Malka, R.; Wood, R.J. Experimental and computational studies of the aerodynamic performance of a flapping and passively rotating insect wing. J. Fluid Mech. 2016, 791, 1–33. [Google Scholar] [CrossRef] [Green Version]

- Shah, R.A.; Asghar, Z.; Ali, N. Mathematical modeling related to bacterial gliding mechanism at low Reynolds number with Ellis Slime. Eur. Phys. J. Plus 2022, 137, 600. [Google Scholar] [CrossRef]

- Asghar, Z.; Ali, N.; Waqas, M.; Nazeer, M.; Khan, W.A. Locomotion of an efficient biomechanical sperm through viscoelastic medium. Biomech. Model. Mechanobiol. 2020, 19, 2271–2284. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Y.; Arase, C.; Ren, Z.; Chirarattananon, P. Design, Characterization, and Liftoff of an Insect-Scale Soft Robotic Dragonfly Powered by Dielectric Elastomer Actuators. Micromachines 2022, 13, 1136. https://doi.org/10.3390/mi13071136

Chen Y, Arase C, Ren Z, Chirarattananon P. Design, Characterization, and Liftoff of an Insect-Scale Soft Robotic Dragonfly Powered by Dielectric Elastomer Actuators. Micromachines. 2022; 13(7):1136. https://doi.org/10.3390/mi13071136

Chicago/Turabian StyleChen, Yufeng, Cathleen Arase, Zhijian Ren, and Pakpong Chirarattananon. 2022. "Design, Characterization, and Liftoff of an Insect-Scale Soft Robotic Dragonfly Powered by Dielectric Elastomer Actuators" Micromachines 13, no. 7: 1136. https://doi.org/10.3390/mi13071136

_Chen.png)