Fabrication of Microfluidic Tesla Valve Employing Femtosecond Bursts

Abstract

:1. Introduction

2. Materials and Methods

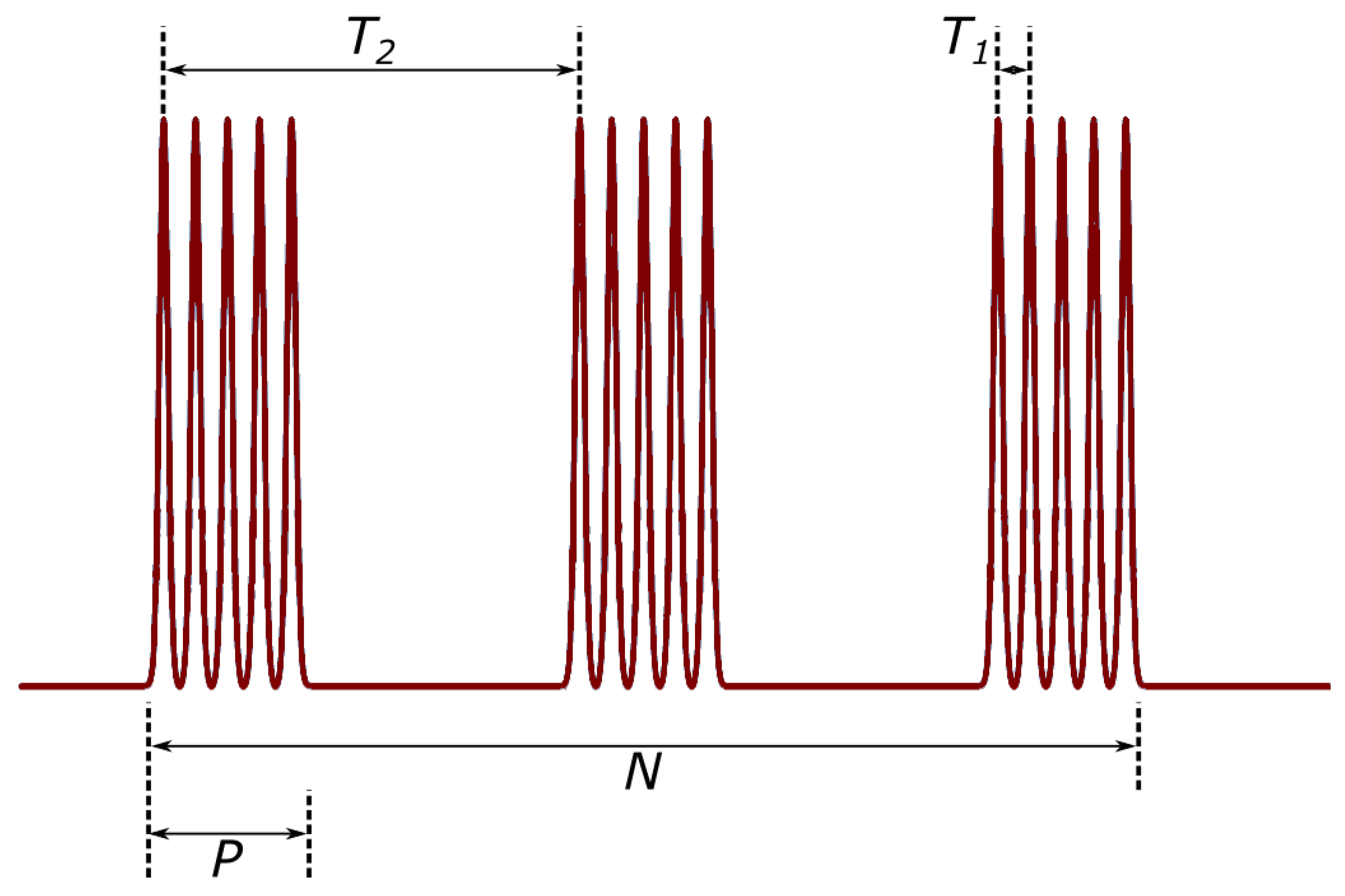

2.1. Experimental Setup

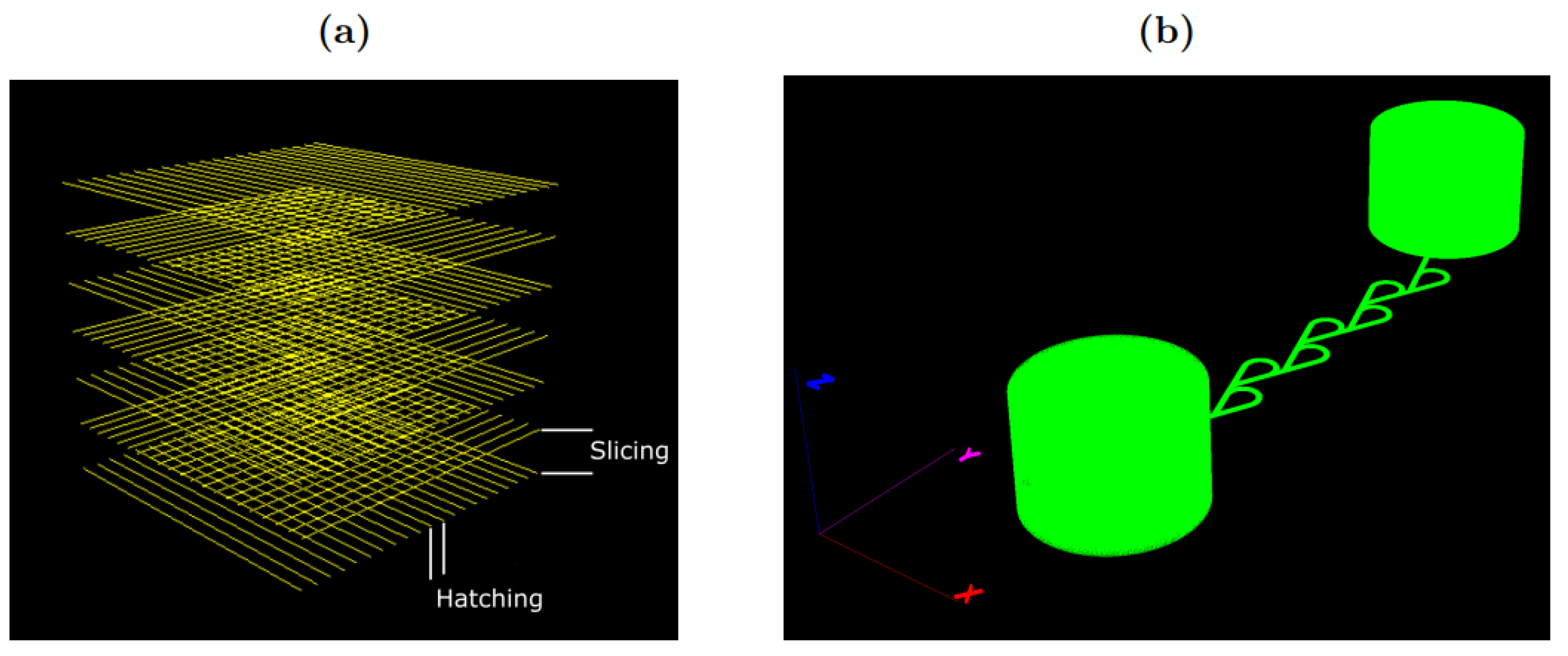

2.2. 3D Models

2.3. Sample Characterization

3. Results and Discussion

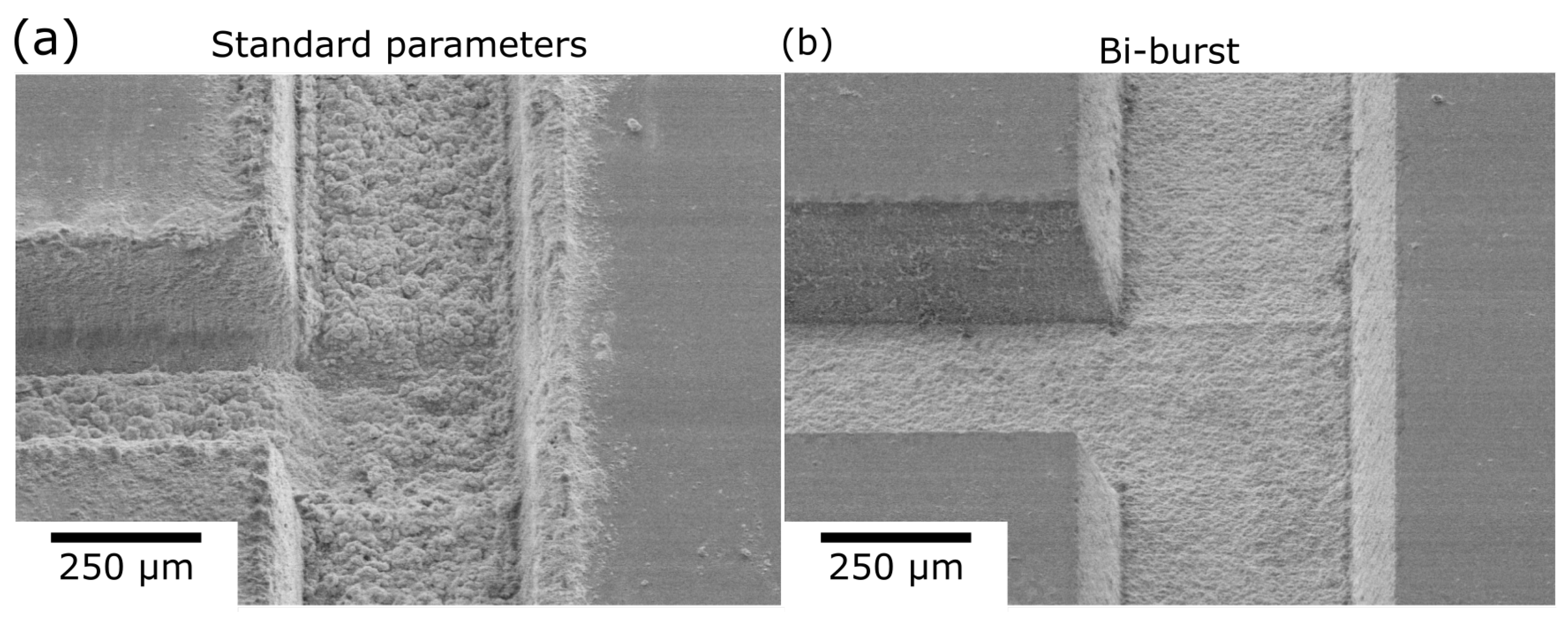

3.1. Fabrication of the Microchannel System

3.2. Sealing of Tesla Valve

3.3. Testing of the Tesla Valve

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gravesen, P.; Branebjerg, J.; Jensen, O.S. Microfluidics-a review. J. Micromech. Microeng. 1993, 3, 168–182. [Google Scholar] [CrossRef]

- Convery, N.; Gadegaard, N. 30 years of microfluidics. Micro Nano Eng. 2019, 2, 76–91. [Google Scholar] [CrossRef]

- Whitesides, G.M. The origins and the future of microfluidics. Nature 2006, 442, 368–373. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Lee, R.J.; Huang, X.; Li, Y.; Lv, B.; Wang, T.; Qi, Y.; Hao, F.; Lu, J.; Meng, Q.; et al. Single-step microfluidic synthesis of transferrin-conjugated lipid nanoparticles for siRNA delivery. Nanomed. Nanotechnol. Biol. Med. 2017, 13, 371–381. [Google Scholar] [CrossRef]

- Rackus, D.G.; Shamsi, M.H.; Wheeler, A.R. Electrochemistry, biosensors and microfluidics: A convergence of fields. Chem. Soc. Rev. 2015, 44, 5320–5340. [Google Scholar] [CrossRef]

- Landoulsi, A.; Leroy, J.; Dalmay, C.; Pothier, A.; Bessaudou, A.; Blondy, P. A Microfluidic Sensor Dedicated to Microwave Dielectric Spectroscopy of Liquids Medium and Flowing Colloidal Suspension. Procedia Eng. 2014, 87, 504–507. [Google Scholar] [CrossRef] [Green Version]

- Kurita, R.; Niwa, O. Microfluidic platforms for DNA methylation analysis. Lab Chip 2016, 16, 3631–3644. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, P.; Kwon, K.W.; Park, M.C.; Lee, S.H.; Kim, S.M.; Suh, K.Y. Soft Lithography for Microfluidics: A Review. Biochip J. 2008, 2, 1–11. [Google Scholar]

- Love, J.C.; Anderson, J.R.; Whitesides, G.M. Fabrication of Three-Dimensional Microfluidic Systems by Soft Lithography. MRS Bull. 2001, 26, 523–528. [Google Scholar] [CrossRef] [Green Version]

- Ho, C.M.B.; Ng, S.H.; Li, K.H.H.; Yoon, Y.J. 3D printed microfluidics for biological applications. Lab Chip 2015, 15, 3627–3637. [Google Scholar] [CrossRef]

- Bhattacharjee, N.; Urrios, A.; Kang, S.; Folch, A. The upcoming 3D-printing revolution in microfluidics. Lab Chip 2016, 16, 1720–1742. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.; Li, R.; Jin, Z.; Fan, Y.; Zhou, X.; Zhang, Y. Injection molding and characterization of PMMA-based microfluidic devices. Microsyst. Technol. 2019, 26, 1317–1324. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, Y.H.; Feng, L.; Felix, D.D.; Neil, J.; Antonio, R.M.P.; Rahman, M.; Yang, J.; Azizighannad, S.; Mitra, S.; et al. Communication—Electrochemical Impedance Signature of a Non-Planar, Interdigitated, Flow-Through, Porous, Carbon-Based Microelectrode. J. Electrochem. Soc. 2019, 166, B1669–B1672. [Google Scholar] [CrossRef]

- Arockiam, S.; Cheng, Y.H.; Armenante, P.M.; Basuray, S. Experimental determination and computational prediction of the mixing efficiency of a simple, continuous, serpentine-channel microdevice. Chem. Eng. Res. Des. 2021, 167, 303–317. [Google Scholar] [CrossRef]

- Butkutė, A.; Jonušauskas, L. 3D Manufacturing of Glass Microstructures Using Femtosecond Laser. Micromachines 2021, 12, 499. [Google Scholar] [CrossRef] [PubMed]

- Roth, G.L.; Esen, C.; Hellmann, R. Femtosecond laser direct generation of 3D-microfluidic channels inside bulk PMMA. Opt. Express 2017, 25, 18442–18450. [Google Scholar] [CrossRef]

- Vanagas, E. Glass cutting by femtosecond pulsed irradiation. J. Micro/Nanolithogr. MEMS MOEMS 2004, 3, 358. [Google Scholar] [CrossRef]

- Park, C.; Farson, D.F. Precise machining of disk shapes from thick metal substrates by femtosecond laser ablation. Int. J. Adv. Manuf. Technol. 2015, 83, 2049–2056. [Google Scholar] [CrossRef]

- Sun, Y.; Kwok, Y.C.; Nguyen, N.T. Low-pressure, high-temperature thermal bonding of polymeric microfluidic devices and their applications for electrophoretic separation. J. Micromech. Microeng. 2006, 16, 1681–1688. [Google Scholar] [CrossRef]

- Smyser, M.E.; Slipchenko, M.N.; Meyer, T.R.; Caswell, A.W.; Roy, S. Burst-mode laser architecture for the generation of high-peak-power MHz-rate femtosecond pulses. OSA Contin. 2019, 2, 3490–9498. [Google Scholar] [CrossRef]

- Förster, D.J.; Jäggi, B.; Michalowski, A.; Neuenschwander, B. Review on Experimental and Theoretical Investigations of Ultra-Short Pulsed Laser Ablation of Metals with Burst Pulses. Materials 2021, 14, 3331. [Google Scholar] [CrossRef] [PubMed]

- Žemaitis, A.; Gečys, P.; Barkauskas, M.; Račiukaitis, G.; Gedvilas, M. Highly-efficient laser ablation of copper by bursts of ultrashort tuneable (fs-ps) pulses. Sci. Rep. 2019, 9, 12280. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kažukauskas, E.; Butkus, S.; Tokarski, P.; Jukna, V.; Barkauskas, M.; Sirutkaitis, V. Micromachining of Transparent Biocompatible Polymers Applied in Medicine Using Bursts of Femtosecond Laser Pulses. Micromachines 2020, 11, 1093. [Google Scholar] [CrossRef]

- Tesla, N. Valvular Conduit. US1329559A, 3 February 1920. Available online: https://patents.google.com/patent/US1329559A/en (accessed on 9 June 2020).

- Jin, Z.; Xin Gao, Z.; Chen, M.; Yuan Qian, J. Parametric study on Tesla valve with reverse flow for hydrogen decompression. Int. J. Hydrogen Energy 2018, 43, 8888–8896. [Google Scholar] [CrossRef]

- García-Morales, N.G.; Morales-Cruzado, B.; Camacho-López, S.; Romero-Méndez, R.; Devia-Cruz, L.F.; Pérez-Gutiérrez, F.G. Numerical modeling of a micropump without mobile parts actuated by thermocavitation bubbles. Microsyst. Technol. 2020, 27, 801–812. [Google Scholar] [CrossRef]

- Jonušauskas, L.; Baravykas, T.; Andrijec, D.; Gadišauskas, T.; Purlys, V. Stitchless support-free 3D printing of free-form micromechanical structures with feature size on-demand. Sci. Rep. 2019, 9, 17533. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Winoto, S.H.; Low, H.T. Performance Simulations of Tesla Microfluidic Valves. In Proceedings of the First International Conference on Integration and Commercialization of Micro and Nanosystems, Parts A and B. ASMEDC, Sanya, China, 10–13 January 2007. [Google Scholar] [CrossRef]

- Jia, J.; Song, Q.; Liu, Z.; Wang, B. Effect of wall roughness on performance of microchannel applied in microfluidic device. Microsyst. Technol. 2018, 25, 2385–2397. [Google Scholar] [CrossRef]

- Butkutė, A.; Merkininkaitė, G.; Jurkšas, T.; Stančikas, J.; Baravykas, T.; Vargalis, R.; Tičkūnas, T.; Bachmann, J.; Šakirzanovas, S.; Sirutkaitis, V.; et al. Femtosecond Laser Assisted 3D Etching Using Inorganic-Organic Etchant. Materials 2022, 15, 2817. [Google Scholar] [CrossRef]

- Andrijec, D.; Andriukaitis, D.; Vargalis, R.; Baravykas, T.; Drevinskas, T.; Kornyšova, O.; Butkuė, A.; Kaškonienė, V.; Stankevičius, M.; Gricius, H.; et al. Hybrid additive-subtractive femtosecond 3D manufacturing of nanofilter-based microfluidic separator. Appl. Phys. A 2021, 127. [Google Scholar] [CrossRef]

- Wu, D.; Niu, L.G.; Wu, S.Z.; Xu, J.; Midorikawa, K.; Sugioka, K. Ship-in-a-bottle femtosecond laser integration of optofluidic microlens arrays with center-pass units enabling coupling-free parallel cell counting with a 100% success rate. Lab Chip 2015, 15, 1515–1523. [Google Scholar] [CrossRef]

- Amato, L.; Gu, Y.; Bellini, N.; Eaton, S.M.; Cerullo, G.; Osellame, R. Integrated three-dimensional filter separates nanoscale from microscale elements in a microfluidic chip. Lab Chip 2012, 12, 1135. [Google Scholar] [CrossRef] [PubMed]

- McDonald, J.C.; Duffy, D.C.; Anderson, J.R.; Chiu, D.T.; Wu, H.; Schueller, O.J.A.; Whitesides, G.M. Fabrication of microfluidic systems in poly(dimethylsiloxane). Electrophoresis 2000, 21, 27–40. [Google Scholar] [CrossRef]

- Cai, D.; Neyer, A. Cost-effective and reliable sealing method for PDMS (PolyDiMethylSiloxane)-based microfluidic devices with various substrates. Microfluid. Nanofluid. 2010, 9, 855–864. [Google Scholar] [CrossRef]

- Watanabe, W.; Onda, S.; Tamaki, T.; Itoh, K.; Nishii, J. Space-selective laser joining of dissimilar transparent materials using femtosecond laser pulses. Appl. Phys. Lett. 2006, 89, 021106. [Google Scholar] [CrossRef]

- Ozeki, Y.; Inoue, T.; Tamaki, T.; Yamaguchi, H.; Onda, S.; Watanabe, W.; Sano, T.; Nishiuchi, S.; Hirose, A.; Itoh, K. Direct Welding between Copper and Glass Substrates with Femtosecond Laser Pulses. Appl. Phys. Express 2008, 1, 082601. [Google Scholar] [CrossRef]

- Richter, S.; Nolte, S.; Tunnermann, A. Ultrashort pulse laser welding—A new approach for high-stability bonding of different glass. Phys. Procedia 2012, 39, 556–562. [Google Scholar] [CrossRef]

- Helie, D.; Begina, M.; Lacroix, F.; Vallee, R. Reinforced direct bonding of optical materials by femtosecond laser welding. Appl. Opt. 2012, 51, 2098–2106. [Google Scholar] [CrossRef]

- Kim, S.; Kim, J.; Joung, Y.H.; Choi, J.; Koo, C. Bonding Strength of a Glass Microfluidic Device Fabricated by Femtosecond Laser Micromachining and Direct Welding. Micromachines 2018, 9, 639. [Google Scholar] [CrossRef] [Green Version]

- Martynova, L.; Locascio, L.E.; Gaitan, M.; Kramer, G.W.; Christensen, R.G.; MacCrehan, W.A. Fabrication of Plastic Microfluid Channels by Imprinting Methods. Anal. Chem. 1997, 69, 4783–4789. [Google Scholar] [CrossRef]

- Schizas, C.; Melissinaki, V.; Gaidukeviciute, A.; Reinhardt, C.; Ohrt, C.; Dedoussis, V.; Chichkov, B.N.; Fotakis, C.; Farsari, M.; Karalekas, D. On the design and fabrication by two-photon polymerization of a readily assembled micro-valve. J. Adv. Manuf. Technol. 2009, 48, 435–441. [Google Scholar] [CrossRef]

| D | W | L | |||

|---|---|---|---|---|---|

| 2 | 150 µm | 75 µm | 400 µm | 45∘ | 20∘ |

| Conf. | P2N2 | P4N4 | P8N6 | P12N8 | P12N2 | P16N4 | P24N6 |

|---|---|---|---|---|---|---|---|

| RA (nm) | 428 | 730 | 926 | 1164 | 614 | 713 | 1219 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andriukaitis, D.; Vargalis, R.; Šerpytis, L.; Drevinskas, T.; Kornyšova, O.; Stankevičius, M.; Bimbiraitė-Survilienė, K.; Kaškonienė, V.; Maruškas, A.S.; Jonušauskas, L. Fabrication of Microfluidic Tesla Valve Employing Femtosecond Bursts. Micromachines 2022, 13, 1180. https://doi.org/10.3390/mi13081180

Andriukaitis D, Vargalis R, Šerpytis L, Drevinskas T, Kornyšova O, Stankevičius M, Bimbiraitė-Survilienė K, Kaškonienė V, Maruškas AS, Jonušauskas L. Fabrication of Microfluidic Tesla Valve Employing Femtosecond Bursts. Micromachines. 2022; 13(8):1180. https://doi.org/10.3390/mi13081180

Chicago/Turabian StyleAndriukaitis, Deividas, Rokas Vargalis, Lukas Šerpytis, Tomas Drevinskas, Olga Kornyšova, Mantas Stankevičius, Kristina Bimbiraitė-Survilienė, Vilma Kaškonienė, Audrius Sigitas Maruškas, and Linas Jonušauskas. 2022. "Fabrication of Microfluidic Tesla Valve Employing Femtosecond Bursts" Micromachines 13, no. 8: 1180. https://doi.org/10.3390/mi13081180

APA StyleAndriukaitis, D., Vargalis, R., Šerpytis, L., Drevinskas, T., Kornyšova, O., Stankevičius, M., Bimbiraitė-Survilienė, K., Kaškonienė, V., Maruškas, A. S., & Jonušauskas, L. (2022). Fabrication of Microfluidic Tesla Valve Employing Femtosecond Bursts. Micromachines, 13(8), 1180. https://doi.org/10.3390/mi13081180