Mechanism Analysis and Multi-Scale Protection Design of GaN HEMT Induced by High-Power Electromagnetic Pulse

Abstract

:1. Introduction

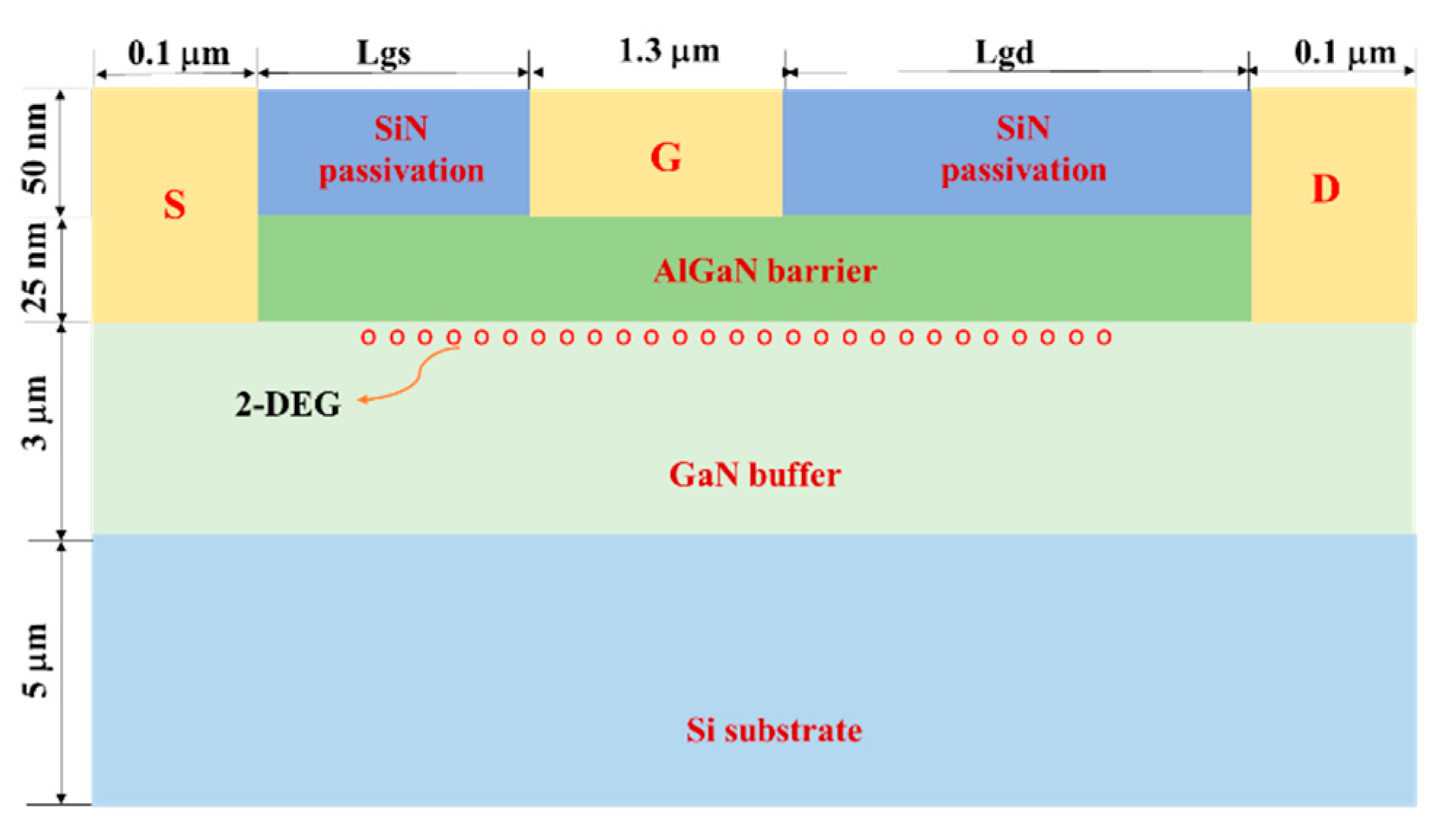

2. Simulation Model

2.1. Structure Model

2.2. Numerical Model

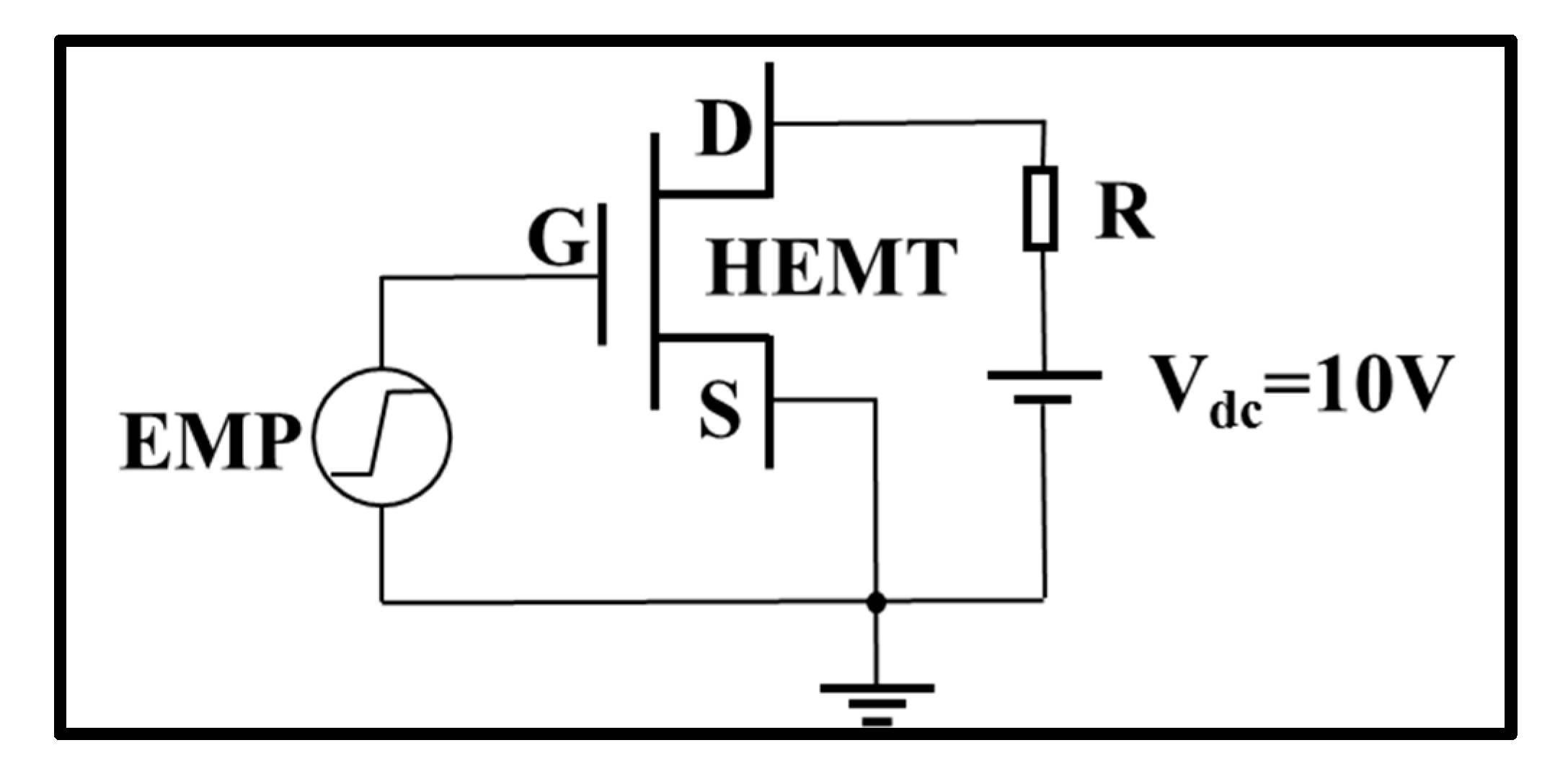

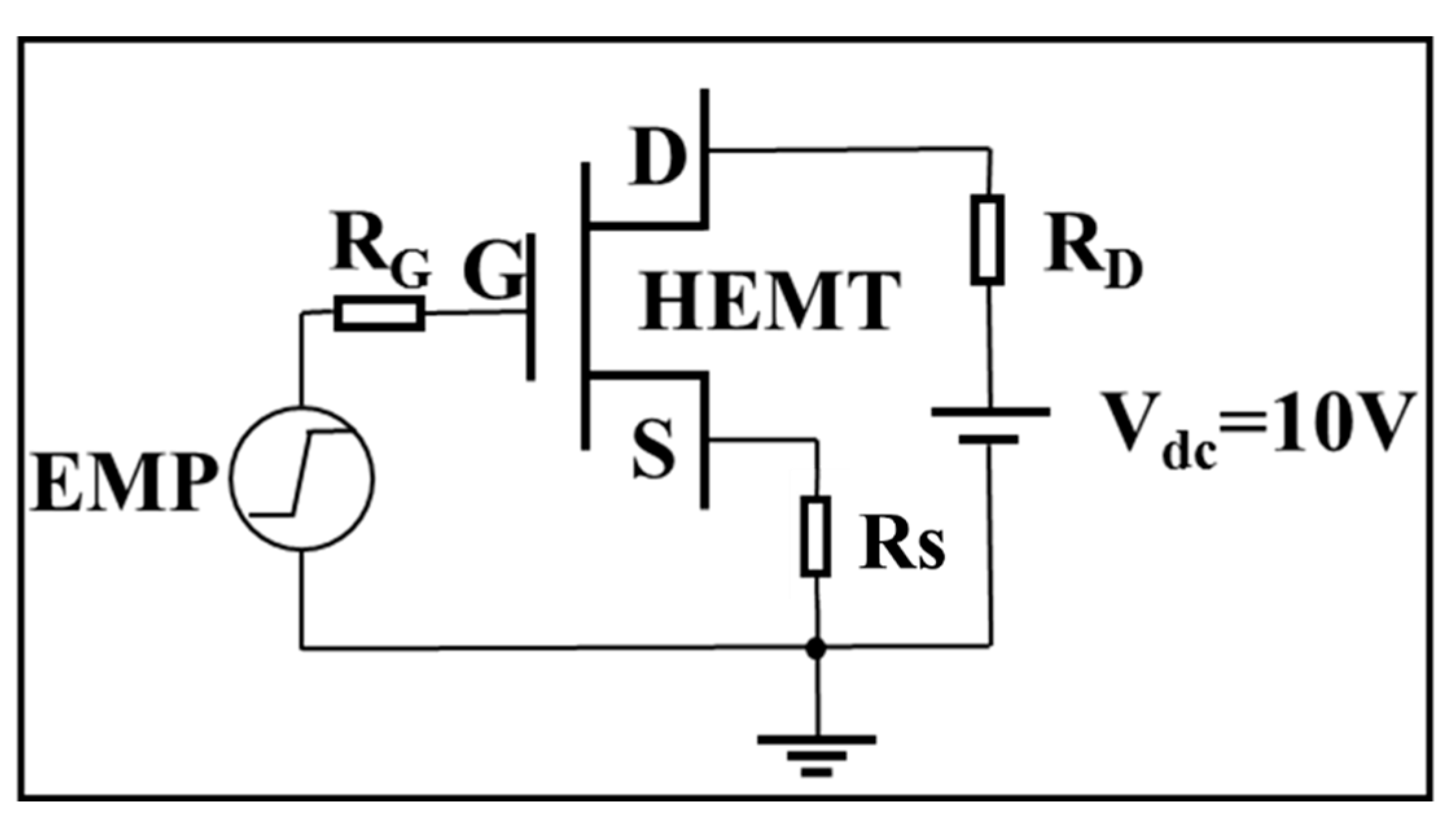

2.3. Circuit Model

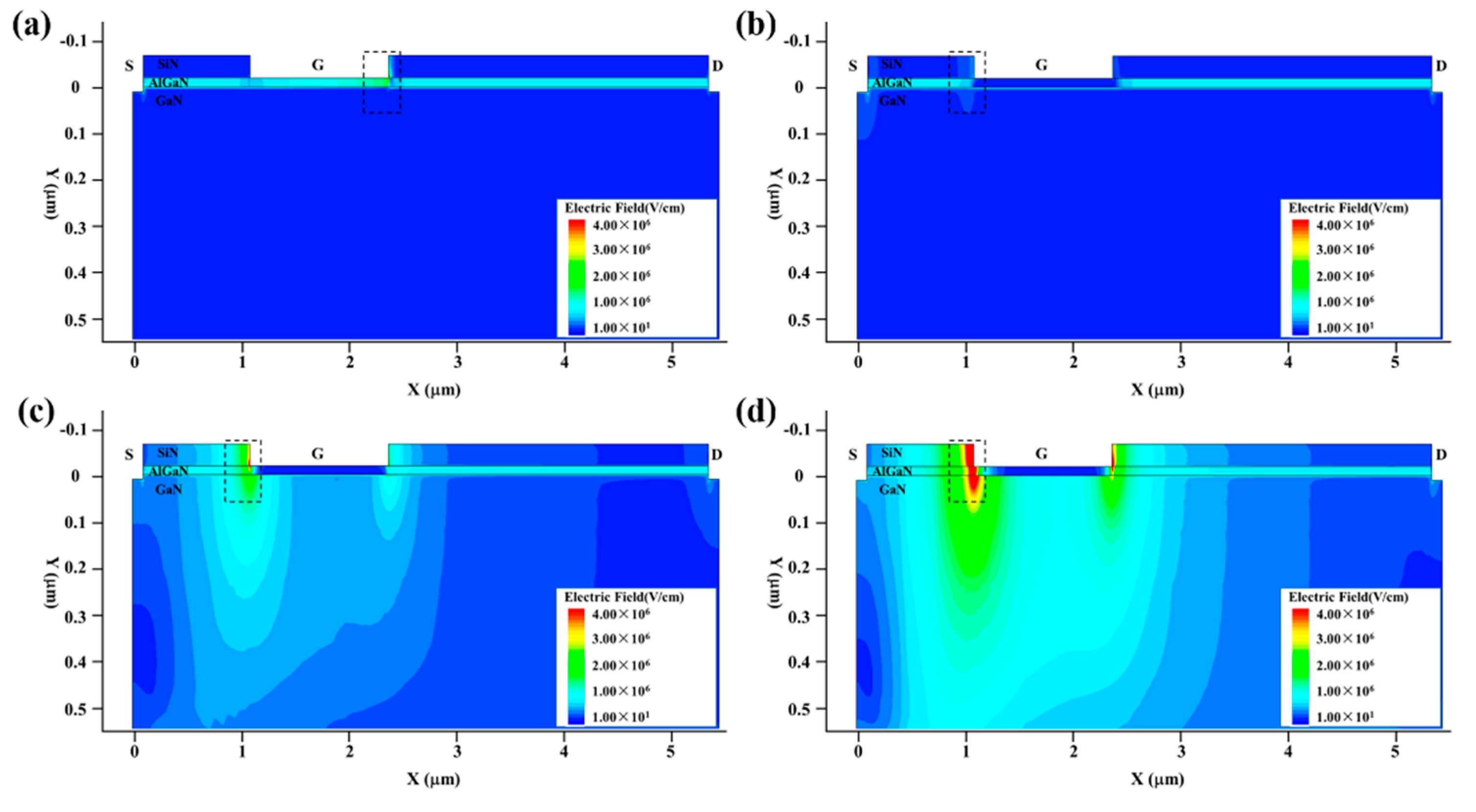

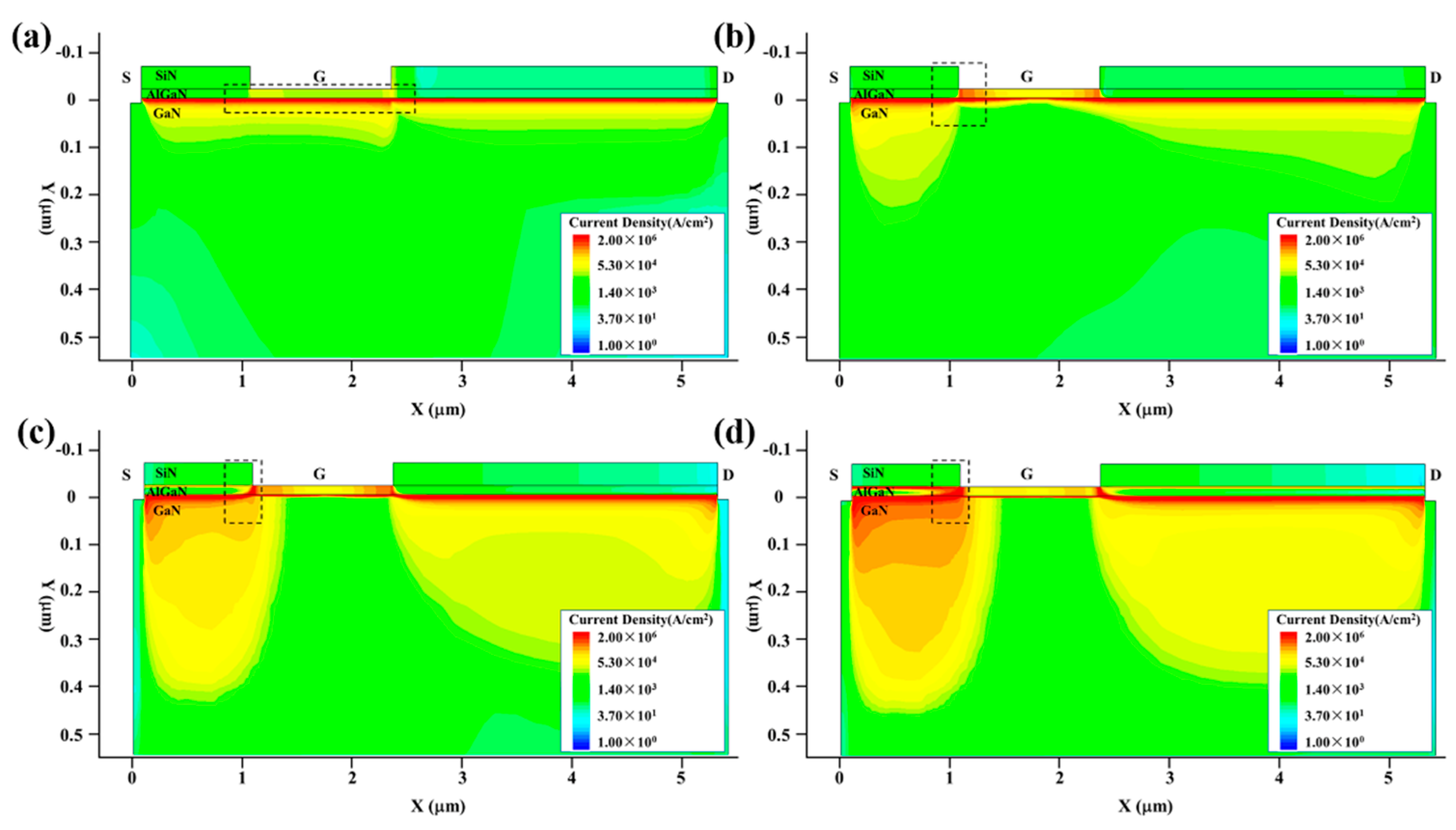

3. Results and Discussion

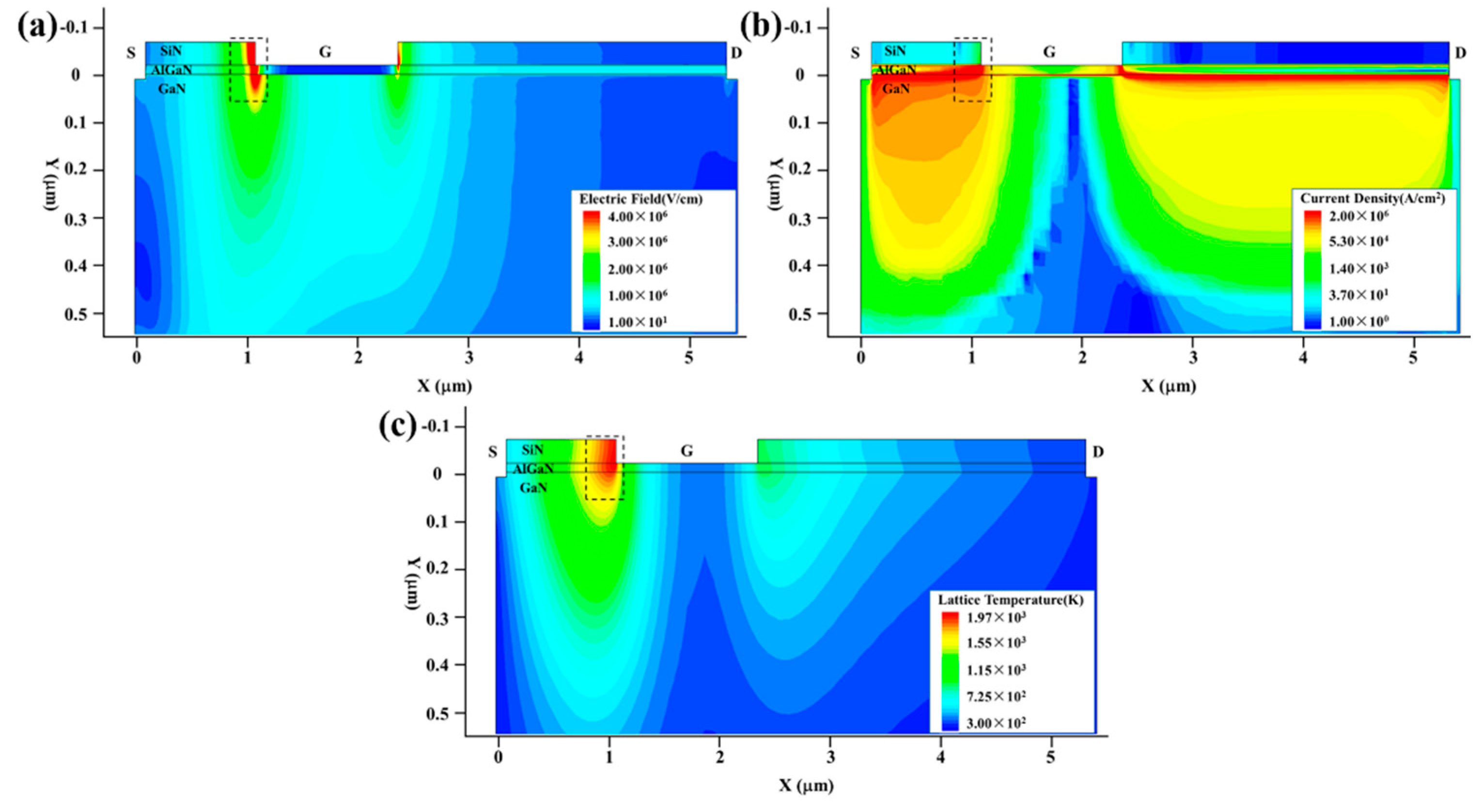

3.1. The Damage Effect and Mechanism Analysis

3.2. Multi-Scale Protection Design

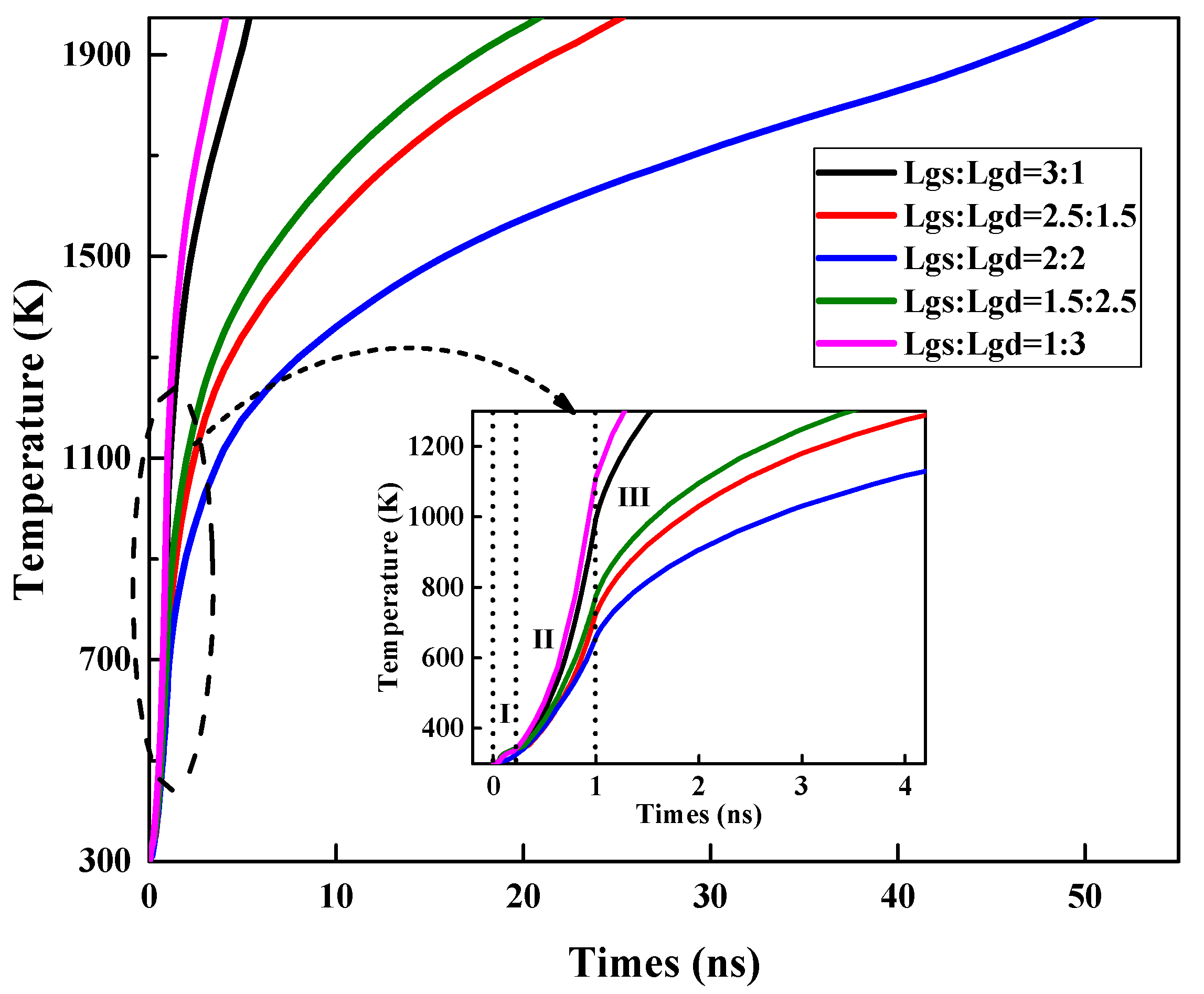

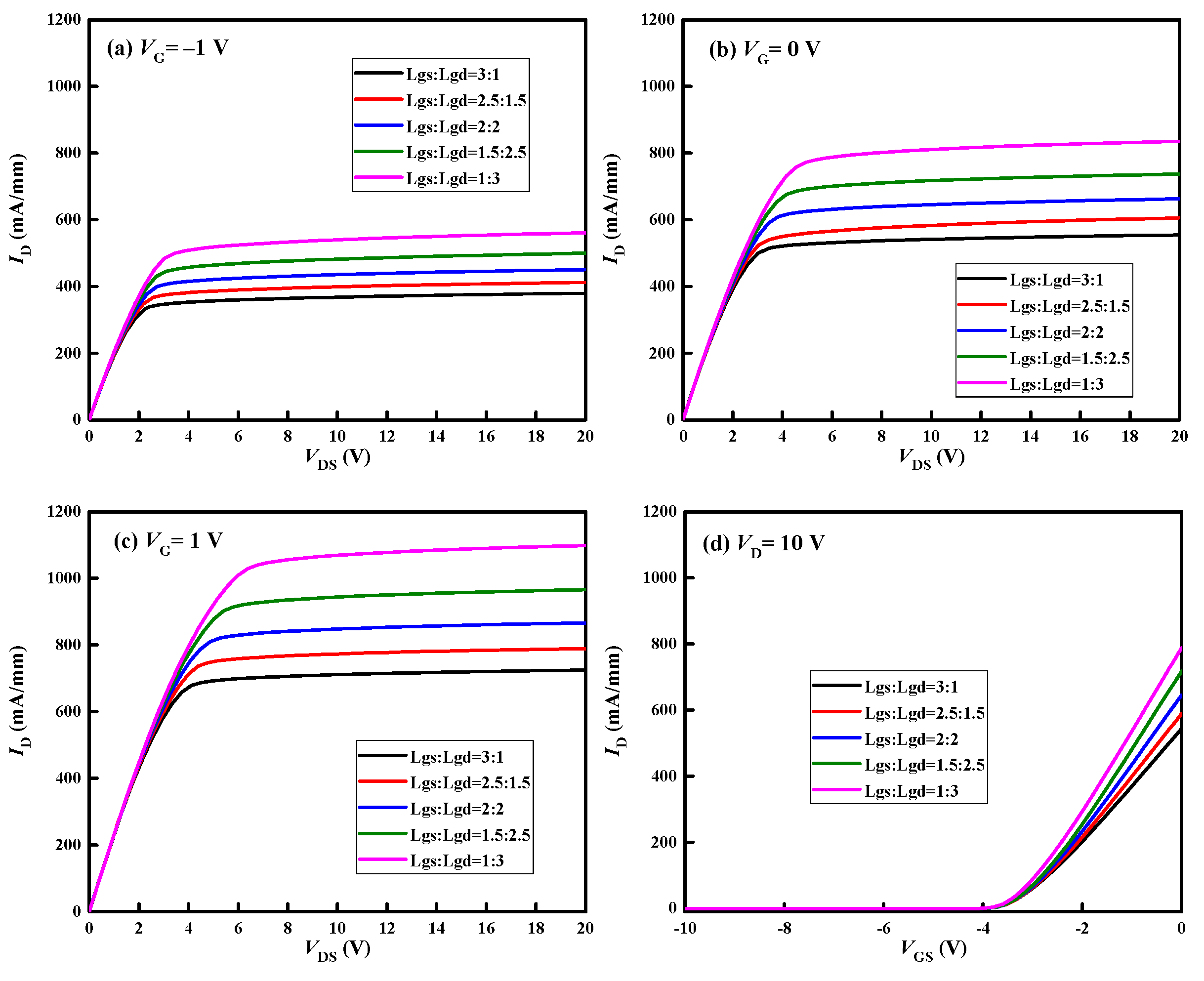

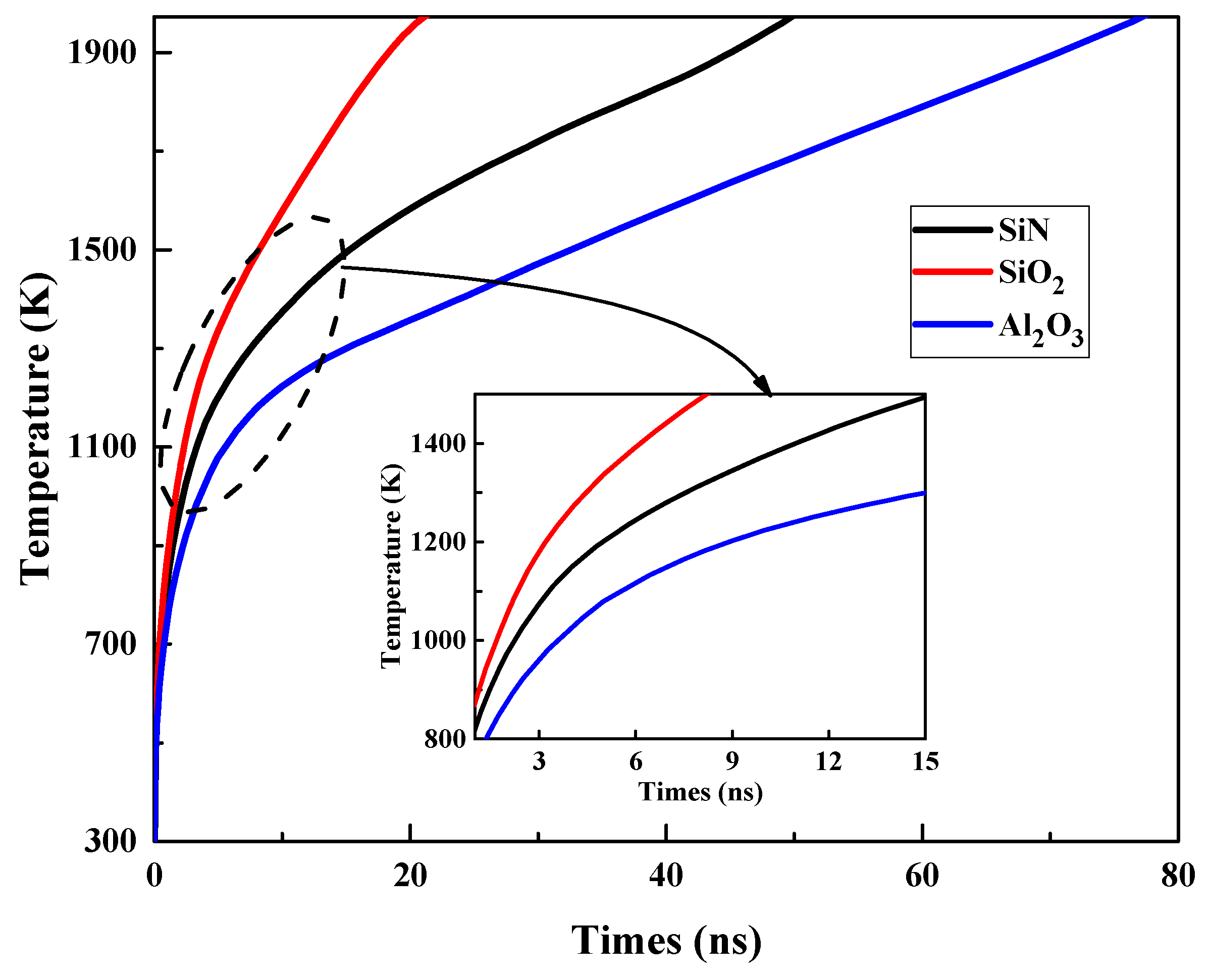

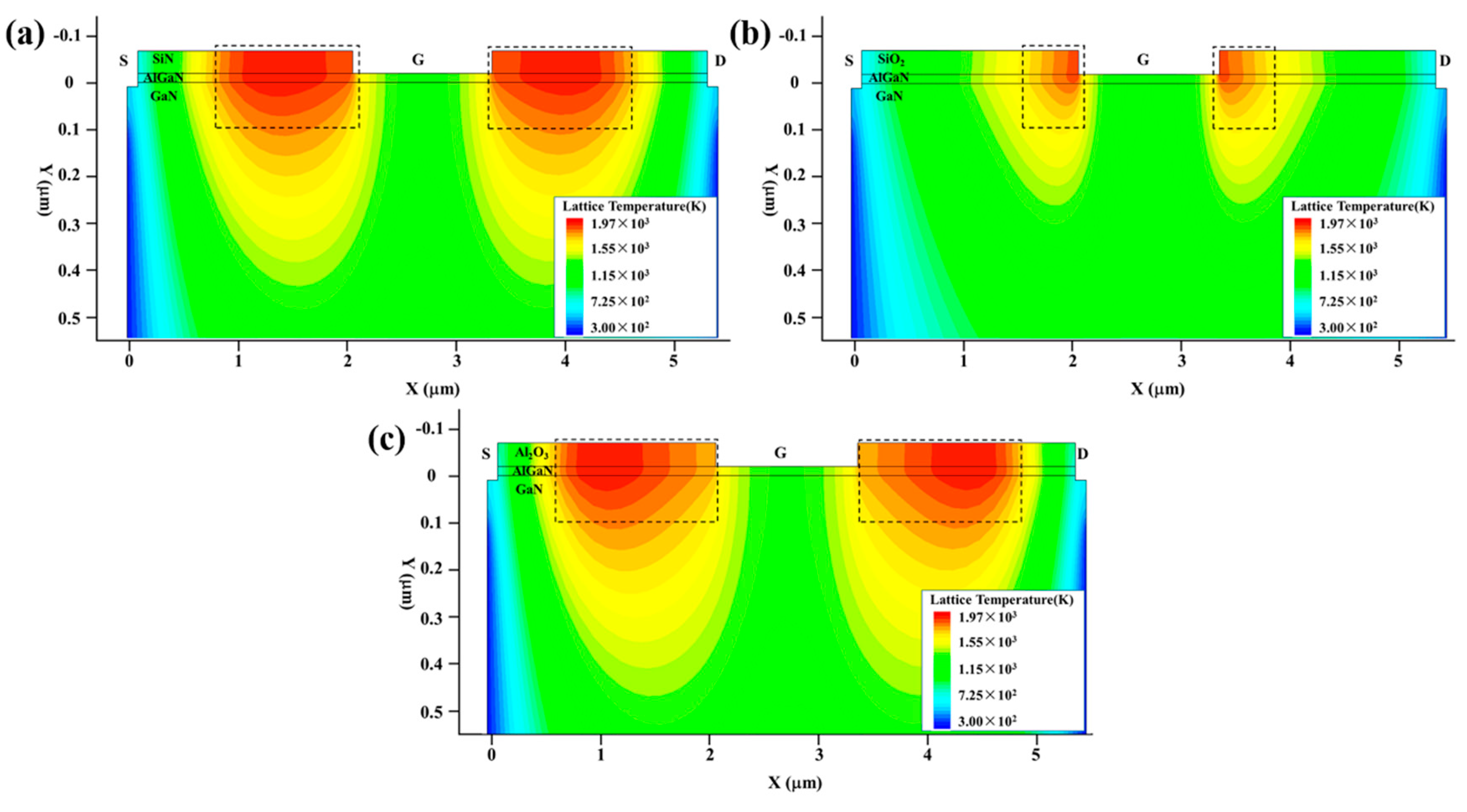

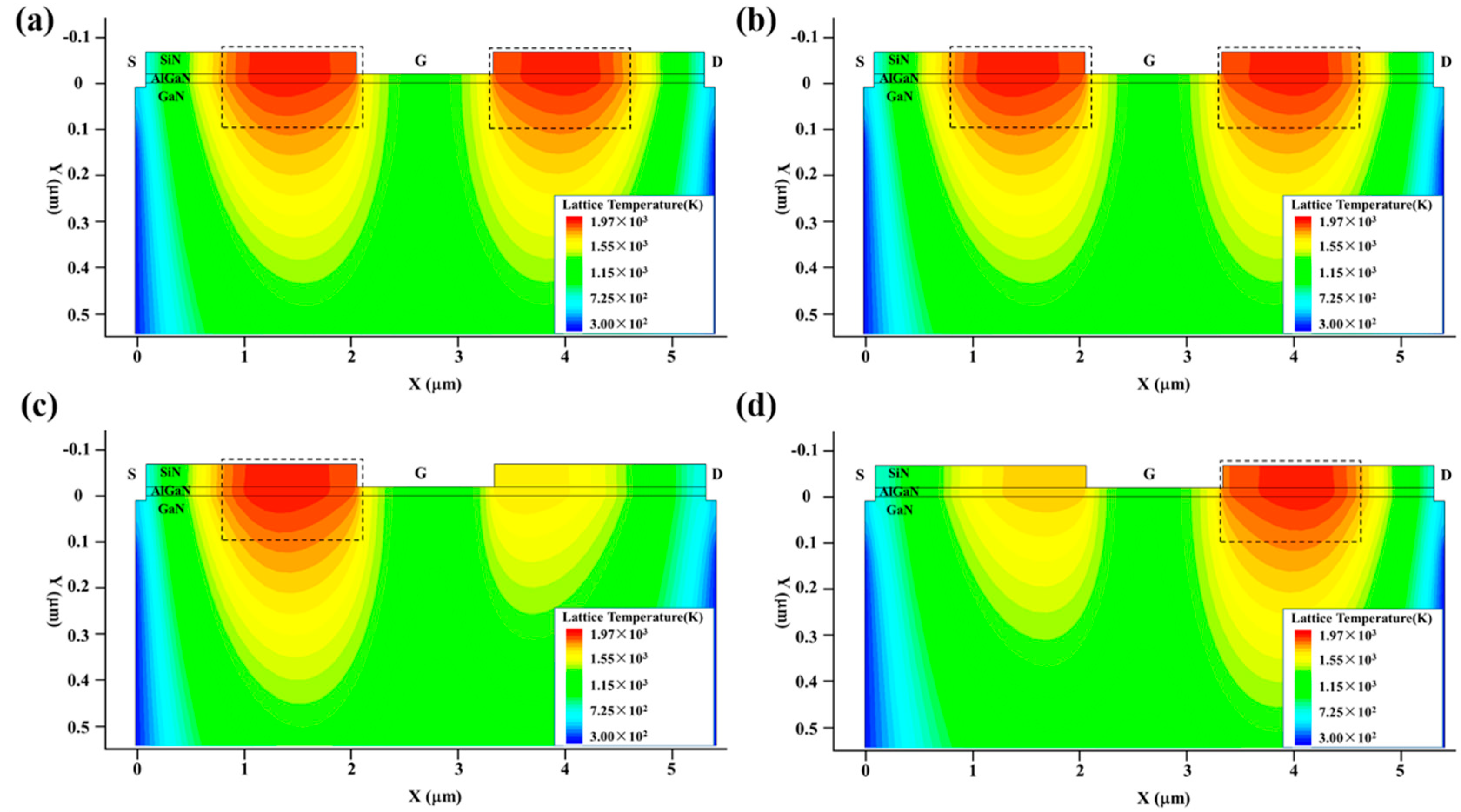

3.2.1. The Device Structure Optimization Design

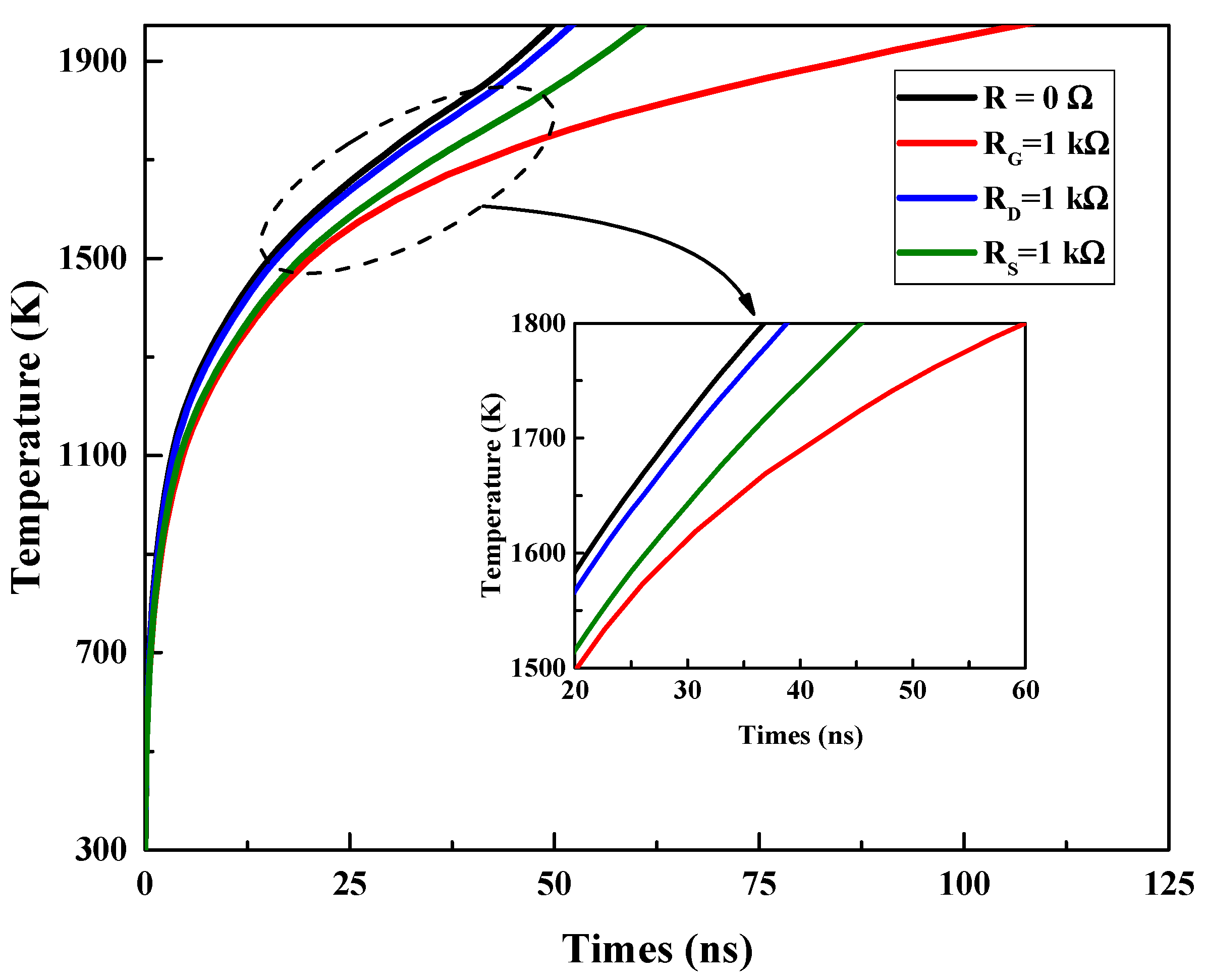

3.2.2. The External Circuit Optimization Design

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, R.; Guo, H.; Hou, Q.; Lei, J.; Wang, J.; Xue, J.; Liu, B.; Chen, D.; Lu, H.; Zhang, R.; et al. Evaluation on Temperature-Dependent Transient VT Instability in p-GaN Gate HEMTs under Negative Gate Stress by Fast Sweeping Characterization. Micromachines 2022, 13, 1096. [Google Scholar] [CrossRef] [PubMed]

- Chow, T.P.; Tyagi, R. Wide bandgap compound semiconductors for superior high-voltage power devices. In Proceedings of the 5th International Symposium on Power Semiconductor Devices and ICs, Monterey, CA, USA, 18–20 May 1993; pp. 84–88. [Google Scholar]

- Chung, J.W.; Hoke, W.E.; Chumbes, E.M.; Palacios, T. AlGaN/GaN HEMT With 300-GHz fmax. IEEE Electron Device Lett. 2010, 31, 195–197. [Google Scholar] [CrossRef]

- Mishra, U.K.; Parikh, P.; Yi-Feng, W. AlGaN/GaN HEMTs—An overview of device operation and applications. Proc. IEEE 2002, 90, 1022–1031. [Google Scholar] [CrossRef] [Green Version]

- Yi-Feng, W.; Kapolnek, D.; Ibbetson, J.P.; Parikh, P.; Keller, B.P.; Mishra, U.K. Very-high power density AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2001, 48, 586–590. [Google Scholar] [CrossRef]

- Ambacher, O.; Christian, B.; Yassine, M.; Baeumler, M.; Leone, S.; Quay, R. Polarization induced interface and electron sheet charges of pseudomorphic ScAlN/GaN, GaAlN/GaN, InAlN/GaN, and InAlN/InN heterostructures. J. Appl. Phys. 2021, 129, 204501. [Google Scholar] [CrossRef]

- Nguyen, H.Q.; Nguyen, T.; Tanner, P.; Nguyen, T.K.; Foisal, A.R.M.; Fastier-Wooller, J.; Nguyen, T.H.; Phan, H.P.; Nguyen, N.T.; Dao, D.V. Piezotronic effect in a normally off p-GaN/AlGaN/GaN HEMT toward highly sensitive pressure sensor. Appl. Phys. Lett. 2021, 118, 242104. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, L.; Liu, Y.; Wang, H. Reduction in RF Loss Based on AlGaN Back-Barrier Structure Changes. Micromachines 2022, 13, 830. [Google Scholar] [CrossRef]

- Li, X.; Du, Z.; Li, M. Efficient Reciprocity-Based Hybrid Approach for Analyzing Radiated Susceptibility Responses of Multilayer PCBs. IEEE Trans. Electromagn. Compat. 2017, 59, 952–961. [Google Scholar] [CrossRef]

- Nitsch, D.; Camp, M.; Sabath, F.; Haseborg, J.L.T.; Garbe, H. Susceptibility of some electronic equipment to HPEM threats. IEEE Trans. Electromagn. Compat. 2004, 46, 380–389. [Google Scholar] [CrossRef]

- Hoad, R.; Carter, N.J.; Herke, D.; Watkins, S.P. Trends in EM susceptibility of IT equipment. IEEE Trans. Electromagn. Compat. 2004, 46, 390–395. [Google Scholar] [CrossRef]

- Li, F.; Changchun, C.; Han, W.; Lei, W.; Qishuai, L.; Qi, A.; Yintang, Y. Study on high power microwave nonlinear effects and degradation characteristics of C-band low noise amplifier. Microelectron. Reliab. 2022, 128, 114427. [Google Scholar] [CrossRef]

- Liu, L.; Du, Z. Influence of Microwave Pulse Power on The Burnout Effect of The AlGaN/GaN HEMT in a LNA. In Proceedings of the 2019 IEEE 6th International Symposium on Electromagnetic Compatibility (ISEMC), Nanjing, China, 1–4 November 2019; pp. 1–5. [Google Scholar]

- Li, H.; Chai, C.-C.; Liu, Y.-Q.; Wu, H.; Yang, Y.-T. Damage effects and mechanism of the silicon NPN monolithic composite transistor induced by high-power microwaves. Chin. Phys. B 2018, 27, 088502. [Google Scholar] [CrossRef]

- Chai, C.-C.; Xi, X.-W.; Ren, X.-R.; Yang, Y.-T.; Ma, Z.-Y. The damage effect and mechanism of the bipolar transistor induced by the intense electromagnetic pulse. Acta Phys. Sin. 2010, 59, 8118–8124. [Google Scholar] [CrossRef]

- Zhang, Y.-H.; Chai, C.-C.; Liu, Y.; Yang, Y.-T.; Shi, C.-L.; Fan, Q.-Y.; Liu, Y.-Q. Modeling and understanding of the thermal failure induced by high power microwave in CMOS inverter. Chin. Phys. B 2017, 26, 058502. [Google Scholar] [CrossRef]

- Liu, Y.; Chai, C.; Fan, Q.; Shi, C.; Xi, X.; Yu, X.; Yang, Y. Ku band damage characteristics of GaAs pHEMT induced by a front-door coupling microwave pulse. Microelectron. Reliab. 2016, 66, 32–37. [Google Scholar] [CrossRef]

- Kim, K.; Iliadis, A.A. Impact of Microwave Interference on Dynamic Operation and Power Dissipation of CMOS Inverters. IEEE Trans. Electromagn. Compat. 2007, 49, 329–338. [Google Scholar] [CrossRef]

- Chahine, I.; Kadi, M.; Gaboriaud, E.; Louis, A.; Mazari, B. Characterization and Modeling of the Susceptibility of Integrated Circuits to Conducted Electromagnetic Disturbances Up to 1 GHz. IEEE Trans. Electromagn. Compat. 2008, 50, 285–293. [Google Scholar] [CrossRef]

- Ma, Z.-Y.; Chai, C.-C.; Ren, X.-R.; Yang, Y.-T.; Chen, B.; Song, K.; Zhao, Y.-B. Microwave damage susceptibility trend of a bipolar transistor as a function of frequency. Chin. Phys. B 2012, 21, 098502. [Google Scholar] [CrossRef]

- Yu, X.; Chai, C.; Liu, Y.; Yang, Y. Modeling and understanding of the frequency dependent HPM upset susceptibility of the CMOS inverter. China Inf. Sci. 2015, 58, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Qin, Y.; Chai, C.; Li, F.; Liang, Q.; Wu, H.; Yang, Y. Study of Self-Heating and High-Power Microwave Effects for Enhancement-Mode p-Gate GaN HEMT. Micromachines 2022, 13, 106. [Google Scholar] [CrossRef]

- Tang, Z.; Huang, S.; Tang, X.; Li, B.; Chen, K.J. Influence of AlN Passivation on Dynamic ON-Resistance and Electric Field Distribution in High-Voltage AlGaN/GaN-on-Si HEMTs. IEEE Trans. Electron Devices 2014, 61, 2785–2792. [Google Scholar] [CrossRef]

- Lebon, G.; Machrafi, H.; Grmela, M.; Dubois, C. An extended thermodynamic model of transient heat conduction at sub-continuum scales. Proc. R. Soc. A Math. Phys. Eng. Sci. 2011, 467, 3241–3256. [Google Scholar] [CrossRef] [Green Version]

- Tyagi, M.S.; Van Overstraeten, R. Minority carrier recombination in heavily-doped silicon. Solid-State Electron. 1983, 26, 577–597. [Google Scholar] [CrossRef]

- Goebel, H.; Hoffmann, K. Full dynamic power diode model including temperature behavior for use in circuit simulators. In Proceedings of the 4th International Symposium on Power Semiconductor Devices and ICs, Tokyo, Japan, 19–21 May 1992; pp. 130–135. [Google Scholar]

- Ambacher, O.; Foutz, B.; Smart, J.; Shealy, J.R.; Weimann, N.G.; Chu, K.; Murphy, M.; Sierakowski, A.J.; Schaff, W.J.; Eastman, L.F.; et al. Two dimensional electron gases induced by spontaneous and piezoelectric polarization in undoped and doped AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 87, 334–344. [Google Scholar] [CrossRef]

- Ambacher, O.; Smart, J.; Shealy, J.R.; Weimann, N.G.; Chu, K.; Murphy, M.; Schaff, W.J.; Eastman, L.F.; Dimitrov, R.; Wittmer, L.; et al. Two-dimensional electron gases induced by spontaneous and piezoelectric polarization charges in N- and Ga-face AlGaN/GaN heterostructures. J. Appl. Phys. 1999, 85, 3222–3233. [Google Scholar] [CrossRef] [Green Version]

- Xi, X.-W.; Chai, C.-C.; Liu, Y.; Yang, Y.-T.; Fan, Q.-Y. Influence of the external condition on the damage process of the GaAs pseudomorphic high electron mobility transistor induced by the electromagnetic pulse. Acta Phys. Sin. 2017, 66, 078401. [Google Scholar]

- Robertson, J. High dielectric constant oxides. Eur. Phys. J. Appl. Phys. 2004, 28, 265–291. [Google Scholar] [CrossRef] [Green Version]

- Natarajan, R.; Parthasarathy, E.; Murugapandiyan, P. Influence of high-k passivation layer on gate field plate AlGaN/GaN/AlGaN double heterojunction HEMT. Silicon 2022. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Chai, C.; Zhao, T.; Li, F.; Qin, Y.; Yang, Y. Mechanism Analysis and Multi-Scale Protection Design of GaN HEMT Induced by High-Power Electromagnetic Pulse. Micromachines 2022, 13, 1288. https://doi.org/10.3390/mi13081288

Wang L, Chai C, Zhao T, Li F, Qin Y, Yang Y. Mechanism Analysis and Multi-Scale Protection Design of GaN HEMT Induced by High-Power Electromagnetic Pulse. Micromachines. 2022; 13(8):1288. https://doi.org/10.3390/mi13081288

Chicago/Turabian StyleWang, Lei, Changchun Chai, Tianlong Zhao, Fuxing Li, Yingshuo Qin, and Yintang Yang. 2022. "Mechanism Analysis and Multi-Scale Protection Design of GaN HEMT Induced by High-Power Electromagnetic Pulse" Micromachines 13, no. 8: 1288. https://doi.org/10.3390/mi13081288

APA StyleWang, L., Chai, C., Zhao, T., Li, F., Qin, Y., & Yang, Y. (2022). Mechanism Analysis and Multi-Scale Protection Design of GaN HEMT Induced by High-Power Electromagnetic Pulse. Micromachines, 13(8), 1288. https://doi.org/10.3390/mi13081288