Wafer-Scale Fabrication of Ultra-High Aspect Ratio, Microscale Silicon Structures with Smooth Sidewalls Using Metal Assisted Chemical Etching

Abstract

1. Introduction

2. Materials and Methods

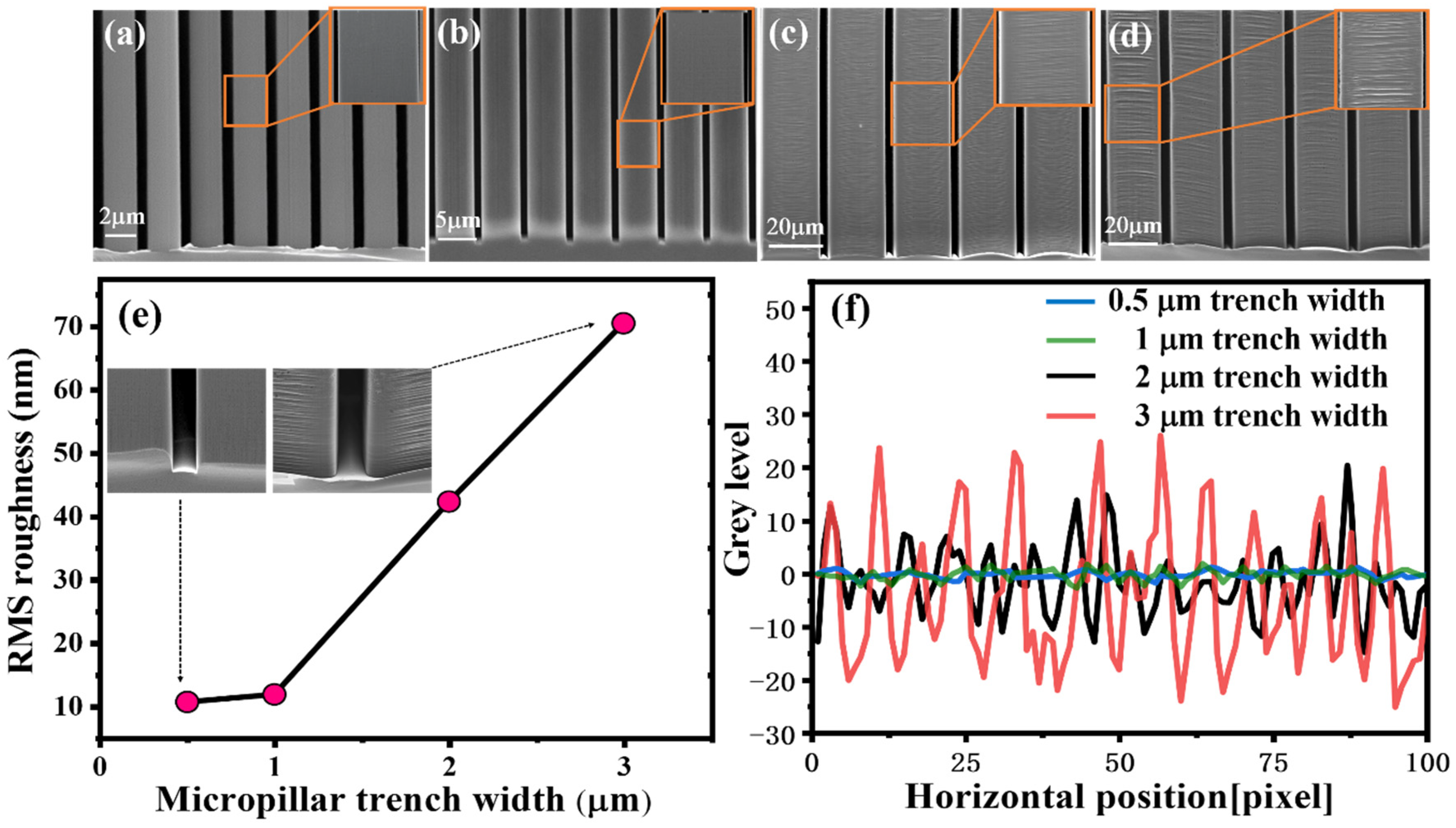

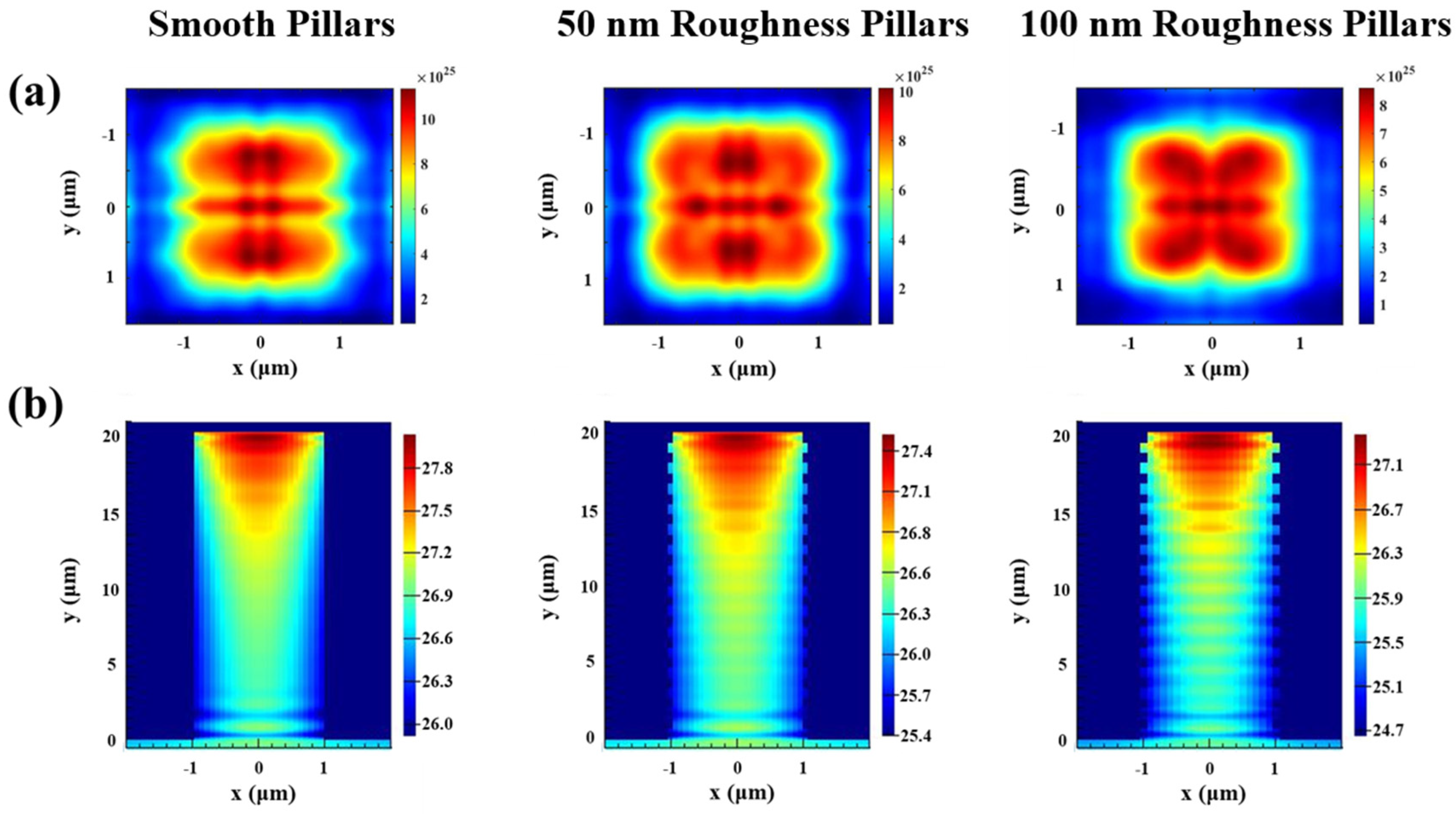

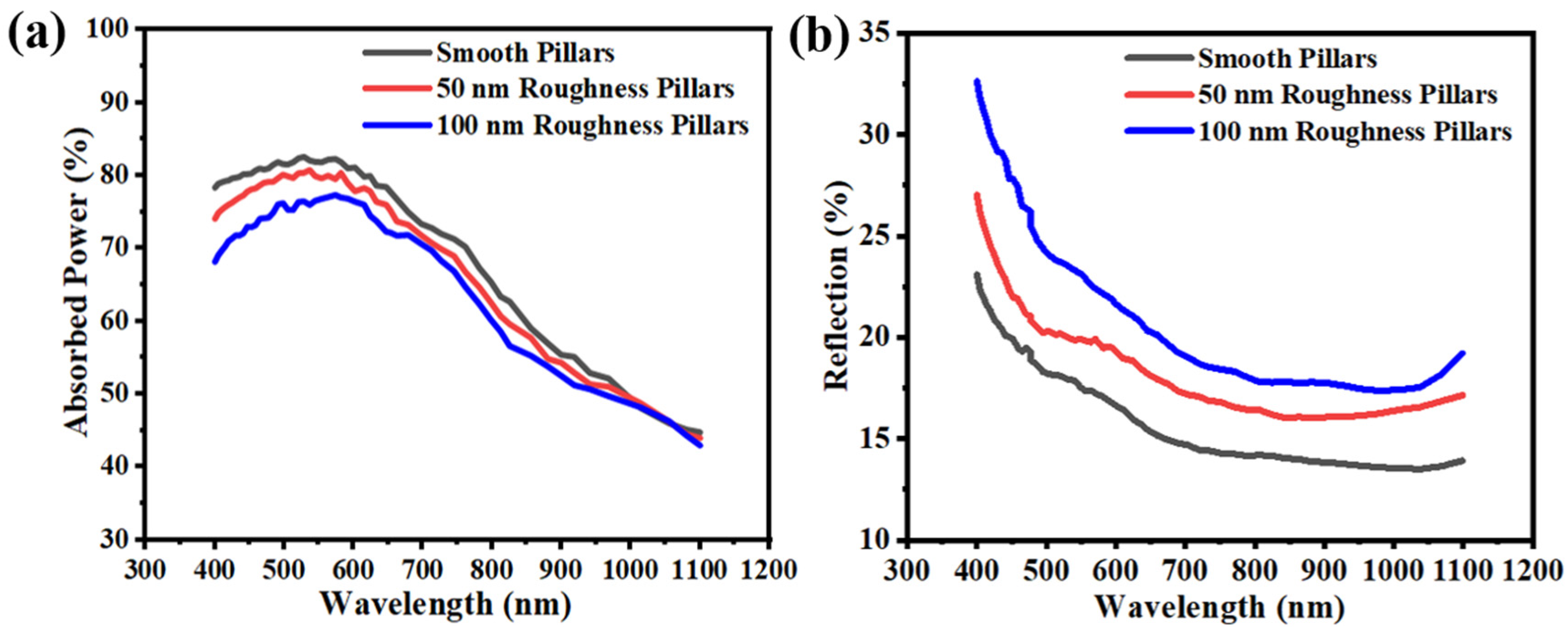

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lai, X.; Halpert, J.E.; Wang, D. Recent advances in micro-/nano-structured hollow spheres for energy applications: From simple to complex systems. Energy Environ. Sci. 2012, 5, 5604–5618. [Google Scholar] [CrossRef]

- Wang, W.; Li, P.F.; Xie, R.; Ju, X.J.; Liu, Z.; Chu, L.Y. Designable Micro-/Nano-Structured Smart Polymeric Materials. Adv. Mater. 2021, 34, 2107877. [Google Scholar] [CrossRef]

- Lima, A.C.; Mano, J.F. Micro/nano-structured superhydrophobic surfaces in the biomedical field: Part II: Applications overview. Nanomedicine 2015, 10, 271–297. [Google Scholar] [CrossRef]

- Malek, C.K.; Saile, V. Applications of LIGA technology to precision manufacturing of high-aspect-ratio micro-components and-systems: A review. Microelectron. J. 2004, 35, 131–143. [Google Scholar] [CrossRef]

- Milos, F.; Tullii, G.; Gobbo, F.; Lodola, F.; Galeotti, F.; Verpelli, C.; Mayer, D.; Maybeck, V.; Offenhäusser, A.; Antognazza, M.R. High aspect ratio and light-sensitive micropillars based on a semiconducting polymer optically regulate neuronal growth. ACS Appl. Mater. Interfaces 2021, 13, 23438–23451. [Google Scholar] [CrossRef]

- Trifonov, T.; Marsal, L.; Rodríguez, A.; Pallarès, J.; Alcubilla, R. Fabrication of two-and three-dimensional photonic crystals by electrochemical etching of silicon. Phys. Status Solidi C 2005, 2, 3104–3107. [Google Scholar] [CrossRef]

- Baytemir, G.; Ciftpinar, E.H.; Turan, R. Enhanced metal assisted etching method for high aspect ratio microstructures: Applications in silicon micropillar array solar cells. Sol. Energy 2019, 194, 148–155. [Google Scholar] [CrossRef]

- Morganti, D.; Leonardi, A.A.; Lo Faro, M.J.; Leonardi, G.; Salvato, G.; Fazio, B.; Musumeci, P.; Livreri, P.; Conoci, S.; Neri, G. Ultrathin silicon nanowires for optical and electrical nitrogen dioxide detection. Nanomaterials 2021, 11, 1767. [Google Scholar] [CrossRef]

- Jia, Y.; Wang, J.; Yosinski, S.; Xu, Y.; Reed, M.A. A Fast and Label-Free Potentiometric Method for Direct Detection of Glutamine with Silicon Nanowire Biosensors. Biosensors 2022, 12, 368. [Google Scholar] [CrossRef]

- Lin, H.; Wu, F.; Gao, P.; Shen, W. Shape-Controlled Silicon Microwire Arrays from Au–Ag-Catalyzed Metal-Assisted Chemical Etching for Radial Junction Solar Cells. ACS Appl. Energy Mater. 2019, 2, 5871–5876. [Google Scholar] [CrossRef]

- Wu, F.; Lin, H.; Yang, Z.; Liao, M.; Wang, Z.; Li, Z.; Gao, P.; Ye, J.; Shen, W. Suppression of surface and Auger recombination by formation and control of radial junction in silicon microwire solar cells. Nano Energy 2019, 58, 817–824. [Google Scholar] [CrossRef]

- Um, H.-D.; Lee, K.; Hwang, I.; Park, J.; Choi, D.; Kim, N.; Kim, H.; Seo, K. Progress in silicon microwire solar cells. J. Mater. Chem. A 2020, 8, 5395–5420. [Google Scholar] [CrossRef]

- Xi, Y.; Zhang, W.; Fan, Z.; Ma, Q.; Wang, S.; Ma, D.; Jiang, Z.; Li, H.; Zhang, Y. A facile synthesis of silicon nanowires/micropillars structure using lithography and metal-assisted chemical etching method. J. Solid State Chem. 2018, 258, 181–190. [Google Scholar] [CrossRef]

- Zheng, D.; Choi, C.-H.; Zhao, X.; Sun, G. Facile fabrication of sponge-like porous micropillar arrays via an electrochemical process. Nanoscale 2020, 12, 10565–10572. [Google Scholar] [CrossRef]

- Chang, B.; Jensen, F.; Hübner, J.; Jansen, H. DREM2: A facile fabrication strategy for freestanding three dimensional silicon micro-and nanostructures by a modified Bosch etch process. J. Micromech. Microeng. 2018, 28, 105012. [Google Scholar] [CrossRef]

- He, Y.; Jiang, C.; Yin, H.; Chen, J.; Yuan, W. Superhydrophobic silicon surfaces with micro–nano hierarchical structures via deep reactive ion etching and galvanic etching. J. Colloid Interface Sci. 2011, 364, 219–229. [Google Scholar] [CrossRef]

- Laermer, F.; Urban, A. MEMS at Bosch–Si plasma etch success story, history, applications, and products. Plasma Process. Polym. 2019, 16, 1800207. [Google Scholar] [CrossRef]

- Alessandri, A.; D’Ercoli, F.; Petruzza, P.; Sciutti, A. Deep Silicon Etch. In Silicon Sensors and Actuators; Springer: Berlin/Heidelberg, Germany, 2022; pp. 133–167. [Google Scholar]

- Oehrlein, G.S. Dry etching damage of silicon: A review. Mater. Sci. Eng. B 1989, 4, 441–450. [Google Scholar] [CrossRef]

- Pal, P.; Swarnalatha, V.; Rao, A.V.N.; Pandey, A.K.; Tanaka, H.; Sato, K. High speed silicon wet anisotropic etching for applications in bulk micromachining: A review. Micro Nano Syst. Lett. 2021, 9, 1–59. [Google Scholar] [CrossRef]

- Sreejith, K.; Sharma, A.K.; Basu, P.K.; Kottantharayil, A. Etching methods for texturing industrial multi-crystalline silicon wafers: A comprehensive review. Sol. Energy Mater. Sol. Cells 2022, 238, 111531. [Google Scholar] [CrossRef]

- Finnegan, P.S.; Hollowell, A.E.; Arrington, C.L.; Dagel, A.L. High aspect ratio anisotropic silicon etching for X-ray phase contrast imaging grating fabrication. Mater. Sci. Semicond. Process. 2019, 92, 80–85. [Google Scholar] [CrossRef]

- Li, X.; Bohn, P. Metal-assisted chemical etching in HF/H2O2 produces porous silicon. Appl. Phys. Lett. 2000, 77, 2572–2574. [Google Scholar] [CrossRef]

- Huang, Z.; Geyer, N.; Werner, P.; De Boor, J.; Gösele, U. Metal-assisted chemical etching of silicon: A review: In memory of Prof. Ulrich Gösele. Adv. Mater. 2011, 23, 285–308. [Google Scholar] [CrossRef]

- Romano, L.; Kagias, M.; Vila-Comamala, J.; Jefimovs, K.; Tseng, L.-T.; Guzenko, V.A.; Stampanoni, M. Metal assisted chemical etching of silicon in the gas phase: A nanofabrication platform for X-ray optics. Nanoscale Horiz. 2020, 5, 869–879. [Google Scholar] [CrossRef] [PubMed]

- Huo, C.; Wang, J.; Fu, H.; Li, X.; Yang, Y.; Wang, H.; Mateen, A.; Farid, G.; Peng, K.Q. Metal-Assisted Chemical Etching of Silicon in Oxidizing HF Solutions: Origin, Mechanism, Development, and Black Silicon Solar Cell Application. Adv. Funct. Mater. 2020, 30, 2005744. [Google Scholar] [CrossRef]

- Van Minh, N.; Van Hieu, D.; Van Tuan, P.; Dung, N.D.; Hoang, C.M. Characteristics of silicon nano-pillars fabricated by nano-sphere lithography and metal assisted chemical etching. Mater. Sci. Semicond. Process. 2022, 142, 106483. [Google Scholar] [CrossRef]

- Kim, M.; Huang, H.-C.; Kim, J.D.; Chabak, K.D.; Kalapala, A.R.K.; Zhou, W.; Li, X. Nanoscale groove textured β-Ga2O3 by room temperature inverse metal-assisted chemical etching and photodiodes with enhanced responsivity. Appl. Phys. Lett. 2018, 113, 222104. [Google Scholar] [CrossRef]

- Sun, Y.; Tang, Y.; Zhang, S.; Yuan, W.; Tang, H. A review on fabrication and pool boiling enhancement of three-dimensional complex structures. Renew. Sustain. Energy Rev. 2022, 162, 112437. [Google Scholar] [CrossRef]

- Romano, L.; Vila-Comamala, J.; Jefimovs, K.; Stampanoni, M. High-Aspect-Ratio Grating Microfabrication by Platinum-Assisted Chemical Etching and Gold Electroplating. Adv. Eng. Mater. 2020, 22, 2000258. [Google Scholar] [CrossRef]

- Xiao, J.; Zhao, J.; Liu, G.; Cole, M.T.; Zhou, S.; Chen, K.; Liu, X.; Li, Z.; Li, C.; Dai, Q. Stable field emission from vertically oriented SiC nanoarrays. Nanomaterials 2021, 11, 3025. [Google Scholar] [CrossRef]

- Liu, H.-C.; Lin, Y.-H.; Hsu, W. Sidewall roughness control in advanced silicon etch process. Microsyst. Technol. 2003, 10, 29–34. [Google Scholar] [CrossRef]

- Fu, J.; Li, J.; Yu, J.; Liu, R.; Li, J.; Wang, W.; Wang, W.; Chen, D. Improving sidewall roughness by combined RIE-Bosch process. Mater. Sci. Semicond. Process. 2018, 83, 186–191. [Google Scholar] [CrossRef]

- Kong, L.; Dasgupta, B.; Ren, Y.; Mohseni, P.K.; Hong, M.; Li, X.; Chim, W.K.; Chiam, S.Y. Evidences for redox reaction driven charge transfer and mass transport in metal-assisted chemical etching of silicon. Sci. Rep. 2016, 6, 1–13. [Google Scholar] [CrossRef]

- Santizo, I.E.; Garzón, I.L. Geometrical model for the growth mechanism of si nanopores. Silicon 2022, 14, 4317–4323. [Google Scholar] [CrossRef]

- Wang, J.; Hu, Y.; Zhao, H.; Fu, H.; Wang, Y.; Huo, C.; Peng, K.Q. Oxidant Concentration Modulated Metal/Silicon Interface Electrical Field Mediates Metal-Assisted Chemical Etching of Silicon. Adv. Mater. Interfaces 2018, 5, 1801132. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, Y.; Yao, C.; Niu, J.; Xie, C.; Li, H. Facile and stable fabrication of wafer-scale, ultra-black c-silicon with 3D nano/micro hybrid structures for solar cells. Nanoscale Adv. 2022, 5, 142–152. [Google Scholar] [CrossRef]

- Yao, C.; Zhao, Y.; Zhang, X.; Li, H.; Xie, C. Design and fabrication of wafer-scale highly uniform silicon nanowire arrays by metal-assisted chemical etching for antireflection films. Results Phys. 2021, 31, 105018. [Google Scholar] [CrossRef]

- Wagner, J. Heavily doped silicon studied by luminescence and selective absorption. Solid-State Electron. 1985, 28, 25–30. [Google Scholar] [CrossRef]

- Su, Y.; Zhang, Y.; Qiu, C.; Guo, X.; Sun, L. Silicon photonic platform for passive waveguide devices: Materials, fabrication, and applications. Adv. Mater. Technol. 2020, 5, 1901153. [Google Scholar] [CrossRef]

- Choi, D.; Yoon, H.; Kim, K.-H.; Um, H.-D.; Seo, K. ITO-free carrier-selective contact for crystalline silicon solar cells. J. Mater. Chem. A 2019, 7, 2192–2199. [Google Scholar] [CrossRef]

- Kim, N.; Choi, D.; Kim, H.; Um, H.-D.; Seo, K. Silicon Microwire Arrays with Nanoscale Spacing for Radial Junction c-Si Solar Cells with an Efficiency of 20.5%. ACS Nano 2021, 15, 14756–14765. [Google Scholar] [CrossRef] [PubMed]

- Luckhaus, S.; Modica, L. The Gibbs-Thompson relation within the gradient theory of phase transitions. Arch. Ration. Mech. Anal. 1989, 107, 71–83. [Google Scholar] [CrossRef]

- Sparacin, D.K.; Spector, S.J.; Kimerling, L.C. Silicon waveguide sidewall smoothing by wet chemical oxidation. J. Light. Technol. 2005, 23, 2455–2461. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Yao, C.; Niu, J.; Li, H.; Xie, C. Wafer-Scale Fabrication of Ultra-High Aspect Ratio, Microscale Silicon Structures with Smooth Sidewalls Using Metal Assisted Chemical Etching. Micromachines 2023, 14, 179. https://doi.org/10.3390/mi14010179

Zhang X, Yao C, Niu J, Li H, Xie C. Wafer-Scale Fabrication of Ultra-High Aspect Ratio, Microscale Silicon Structures with Smooth Sidewalls Using Metal Assisted Chemical Etching. Micromachines. 2023; 14(1):179. https://doi.org/10.3390/mi14010179

Chicago/Turabian StyleZhang, Xiaomeng, Chuhao Yao, Jiebin Niu, Hailiang Li, and Changqing Xie. 2023. "Wafer-Scale Fabrication of Ultra-High Aspect Ratio, Microscale Silicon Structures with Smooth Sidewalls Using Metal Assisted Chemical Etching" Micromachines 14, no. 1: 179. https://doi.org/10.3390/mi14010179

APA StyleZhang, X., Yao, C., Niu, J., Li, H., & Xie, C. (2023). Wafer-Scale Fabrication of Ultra-High Aspect Ratio, Microscale Silicon Structures with Smooth Sidewalls Using Metal Assisted Chemical Etching. Micromachines, 14(1), 179. https://doi.org/10.3390/mi14010179