Mechanism Analysis of Discharge Energy in the Electrostatic-Field-Induced Electrolyte Jet Micro-EDM

Abstract

:1. Introduction

2. Materials and Methods

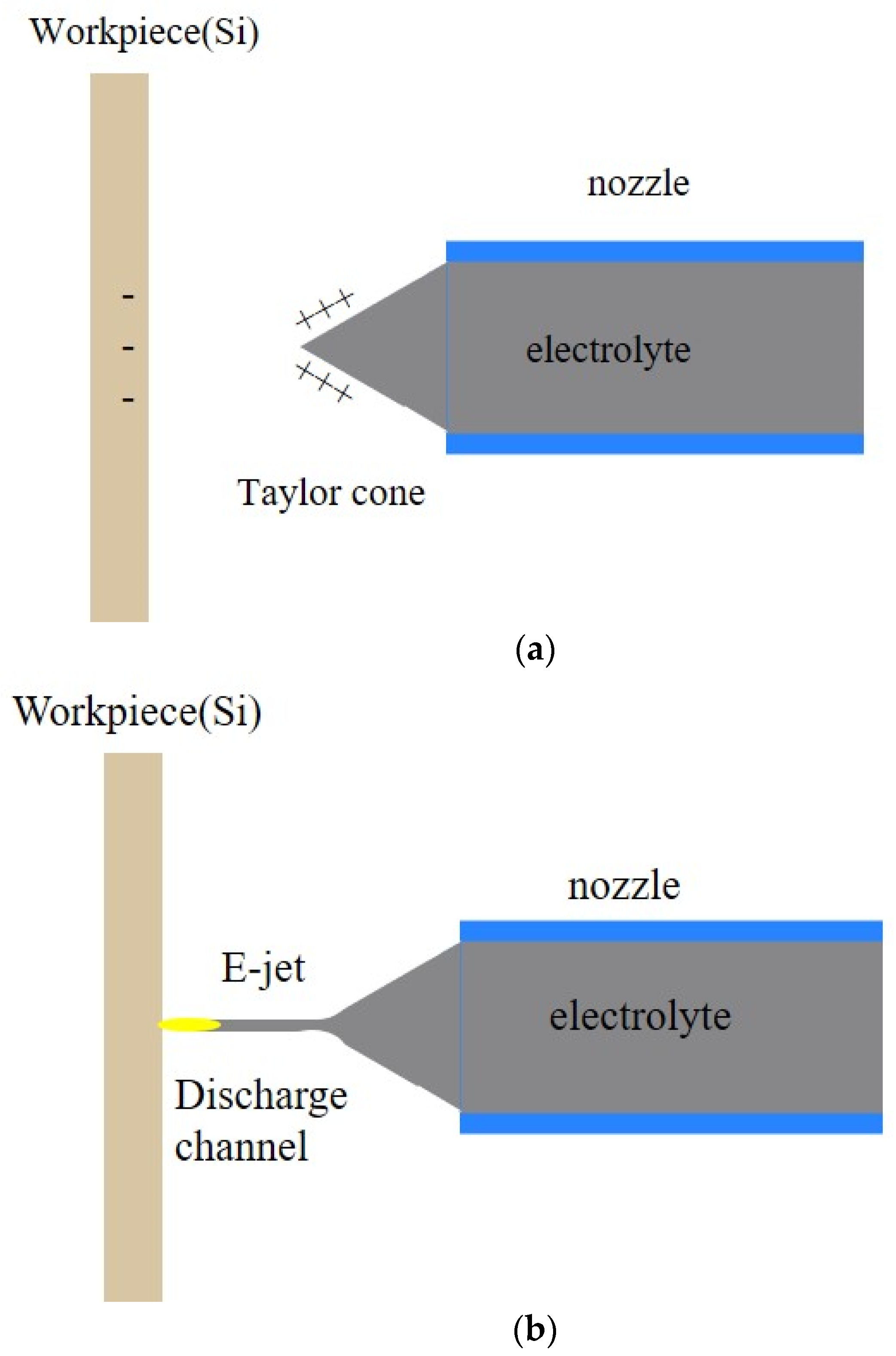

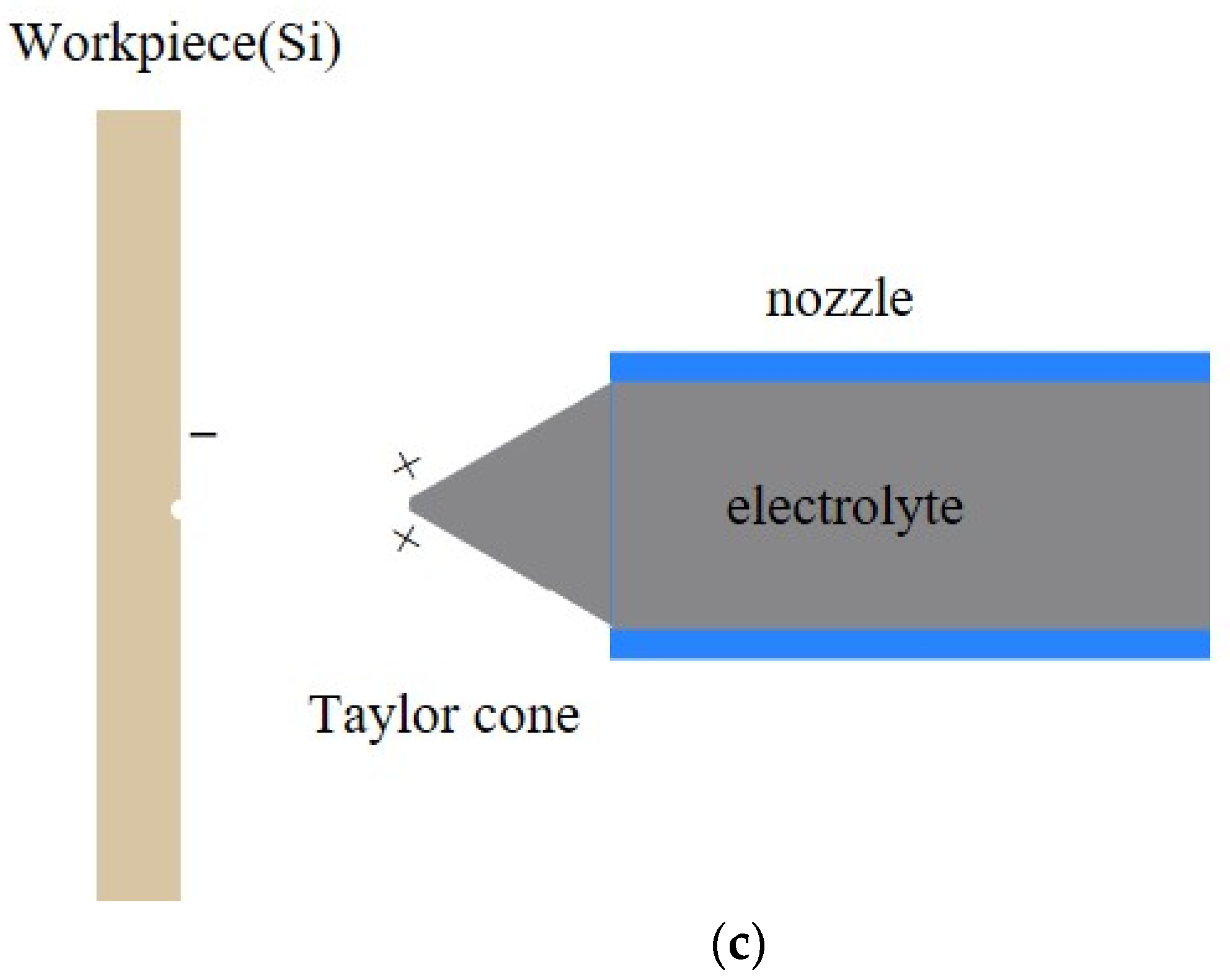

2.1. The Principle of E-Jet EDM

2.2. The Analysis of the Equivalent Circuit of the E-Jet EDM

3. Experimental Methods

3.1. Experimental Platform Setup

3.2. Experimental Design

4. Signal Acquisition and Analyses

4.1. Gap Voltage and Current Signals

- (a)

- Voltage and current sampling experimental result

- (b)

- The discussion of the voltage and current signals

4.2. Discharge Frequency Acquisition and Analyses

- (a)

- Discharge Frequency Experimental Results

- (b)

- The discussion of the discharge frequency

4.3. Discharge Energy Experimental Results and Analyses

- (a)

- Discharge energy experimental results

- (b)

- Discharge energy experimental analyses

4.4. The Machining Experiments

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, S.K.; Mali, H.S.; Unune, D.R.; Abdul-Rani, A.M.; Wojciechowski, S. Material independent effectiveness of workpiece vibration in μ-EDM drilling. J. Mater. Res. Technol. 2022, 18, 531–546. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Shen, Y.; Li, Z.; Ji, R.; Cai, B. A novel method of determining energy distribution and plasma diameter of EDM. Int. J. Heat Mass Transf. 2014, 75, 425–432. [Google Scholar] [CrossRef]

- Kunieda, M.; Lauwers, B.; Rajurkar, K.P.; Schumacher, B.M. Advancing EDM through fundamental insight into the process. CIRP Ann.-Manuf. Technol. 2005, 54, 64–87. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Q.; Zhang, M.; Yang, F. Study on the discharge characteristics of single-pulse discharge in micro-EDM. Micromachines 2020, 11, 55–67. [Google Scholar] [CrossRef]

- Chu, X.; Feng, W.; Wang, C.; Hong, Y. Analysis of mechanism based on two types of pulse generators in micro-EDM using single pulse discharge. Int. J. Adv. Manuf. Technol. 2017, 89, 3217–3230. [Google Scholar] [CrossRef]

- Hou, S.; Bai, J. Experimental investigation on electrode wear of array holes machining in micro-EDM. Procedia CIRP 2020, 95, 527–532. [Google Scholar] [CrossRef]

- Petersen, T.; Ahmed, S.; Kunieda, M.; Klink, A. Observation of EDM plasma behavior influenced by parasitic working gap capacitance. Procedia CIRP 2020, 95, 189–194. [Google Scholar] [CrossRef]

- Benedict, G.F. Nontraditional Manufacturing Processes; Routledge: Abingdon-on-Thames, UK, 2017. [Google Scholar]

- Davim, J.P. (Ed.) Traditional Machining Processes: Research Advances; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Zhang, M.; Mao, X.; Wang, A.; Huo, M.; Wang, S. Design of Synchronous EDM Power Supply for Multi-hole Synchronous Machining. New Technol. New Process 2019, 12, 35–38. [Google Scholar]

- Muthuramalingam, T.; Mohan, B. A study on improving machining characteristics of electrical discharge machining with modified transistor pulse generator. Int. J. Manuf. Technol. Manag. 2013, 27, 101–111. [Google Scholar] [CrossRef]

- Yan, M.T.; Lin, T.C. Development of a Pulse Generator for Rough Cutting of Oil-based Micro Wire-EDM. Procedia CIRP 2016, 42, 709–714. [Google Scholar] [CrossRef]

- Yan, M.T.; Cheng, Y.C.; Luo, S.Y. Improvement of wire electrical discharge machining characteristics in machining boron-doped polycrystalline diamond using a novel iso-pulse generator. Int. J. Precis. Eng. Manuf. 2019, 20, 159–166. [Google Scholar] [CrossRef]

- Coteaţǎ, M.; Floca, A.; Dodun, O.; Ionescu, N.; Nagîţ, G.; SlǍtineanu, L. Pulse Generator for Obtaining Surfaces of Small Dimensions by Electrical Discharge Machining. Procedia CIRP 2016, 42, 715–720. [Google Scholar] [CrossRef]

- Abbas, N.M.; Kunieda, M. Increasing discharge energy of micro-EDM with electrostatic induction feeding method through resonance in circuit. Precis. Eng. 2016, 45, 118–125. [Google Scholar] [CrossRef]

- Abbas, N.M.; Kunieda, M. Improving Discharge Energy in Micro-EDM with Electrostatic Induction Feeding by Controlled Pulse Train Method. Int. J. Electr. Mach. 2017, 20, 45–51. [Google Scholar] [CrossRef]

- Zhang, Y.; Han, N.; Kang, X.; Zhao, W.; Xu, K. Experimental study of an electrostatic field–induced electrolyte jet electrical discharge machining process. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1752–1759. [Google Scholar]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, M.K.; Go, D.B.; Chang, H.C. Electrospray cone-jet breakup and droplet production for electrolyte solutions. EPL (Europhys. Lett.) 2012, 99, 64003. [Google Scholar] [CrossRef]

- Zhou, Y.; Hajjar, J.J. A circuit model of electrostatic discharge generators for ESD and EMC SPICE simulation. In Proceedings of the 2014 IEEE International Conference on Electron Devices and Solid-State Circuits, Chengdu, China, 18–20 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–2. [Google Scholar]

- Kuwahata, Y.; Takehara, H.; Ichiki, T. Comprehensive study on electrospray deposition in the single Taylor cone–jet mode by changing the spatial electric potential using a ring-shaped ternary electrode. AIP Adv. 2020, 10, 045107. [Google Scholar] [CrossRef]

- Fan, Y.; Bai, J.; Li, Q.; Li, C.; Cao, Y.; Li, Z. Research on maintaining voltage of spark discharge in EDM. Procedia CIRP 2016, 42, 28–33. [Google Scholar] [CrossRef]

- Gundersen, M.A.; Schaefer, G. (Eds.) Physics and Applications of Pseudosparks; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Wei, W.; Gu, Z.; Wang, S.; Zhang, Y.; Lei, K.; Kase, K. Numerical simulation of the cone–jet formation and current generation in electrostatic spray—Modeling as regards space charged droplet effect. J. Micromech. Microeng. 2012, 23, 015004. [Google Scholar] [CrossRef]

- Borra, J.P.; Ehouarn, P.; Boulaud, D. Electrohydrodynamic atomisation of water stabilised by glow discharge—Operating range and droplet properties. J. Aerosol Sci. 2004, 35, 1313–1332. [Google Scholar] [CrossRef]

- Dos Santos, A.P.; Diehl, A.; Levin, Y. Surface tensions, surface potentials, and the Hofmeister series of electrolyte solutions. Langmuir 2010, 26, 10778–10783. [Google Scholar] [CrossRef] [PubMed]

- Abbas, N.M.; Solomon, D.G.; Bahari, M.F. A review on current research trends in electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2016, 47, 1214–1228. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, V.; Kumar, J. Investigation of machining parameters and surface integrity in wire electric discharge machining of pure titanium. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 972–992. [Google Scholar] [CrossRef]

- Faraji, S.; Sadri, B.; Vajdi Hokmabad, B.; Jadidoleslam, N.; Esmaeilzadeh, E. Experimental study on the role of electrical conductivity in pulsating modes of electrospraying. Exp. Therm. Fluid Sci. 2017, 81, 327–335. [Google Scholar] [CrossRef]

- Chodisetti, S.P.; Malik, V.K.; Kumar, B.V.M. Development of spark plasma sintered conductive SiC–TiB2 composites for electrical discharge machining applications. Int. J. Appl. Ceram. Technol. 2022, 19, 1367–1378. [Google Scholar] [CrossRef]

- Jaworek, A.; Krupa, A. Classification of the modes of EHD spraying. J. Aerosol Sci. 1999, 30, 873–893. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Yang, X.; Gao, Q.; Wang, J.; Zhao, W. Mechanism Analysis of Discharge Energy in the Electrostatic-Field-Induced Electrolyte Jet Micro-EDM. Micromachines 2023, 14, 1919. https://doi.org/10.3390/mi14101919

Zhang Y, Yang X, Gao Q, Wang J, Zhao W. Mechanism Analysis of Discharge Energy in the Electrostatic-Field-Induced Electrolyte Jet Micro-EDM. Micromachines. 2023; 14(10):1919. https://doi.org/10.3390/mi14101919

Chicago/Turabian StyleZhang, Yaou, Xiangjun Yang, Qiang Gao, Jian Wang, and Wansheng Zhao. 2023. "Mechanism Analysis of Discharge Energy in the Electrostatic-Field-Induced Electrolyte Jet Micro-EDM" Micromachines 14, no. 10: 1919. https://doi.org/10.3390/mi14101919

APA StyleZhang, Y., Yang, X., Gao, Q., Wang, J., & Zhao, W. (2023). Mechanism Analysis of Discharge Energy in the Electrostatic-Field-Induced Electrolyte Jet Micro-EDM. Micromachines, 14(10), 1919. https://doi.org/10.3390/mi14101919