High-Power Femtosecond Laser Processing of SiC Ceramics with Optimized Material Removal Rate

Abstract

:1. Introduction

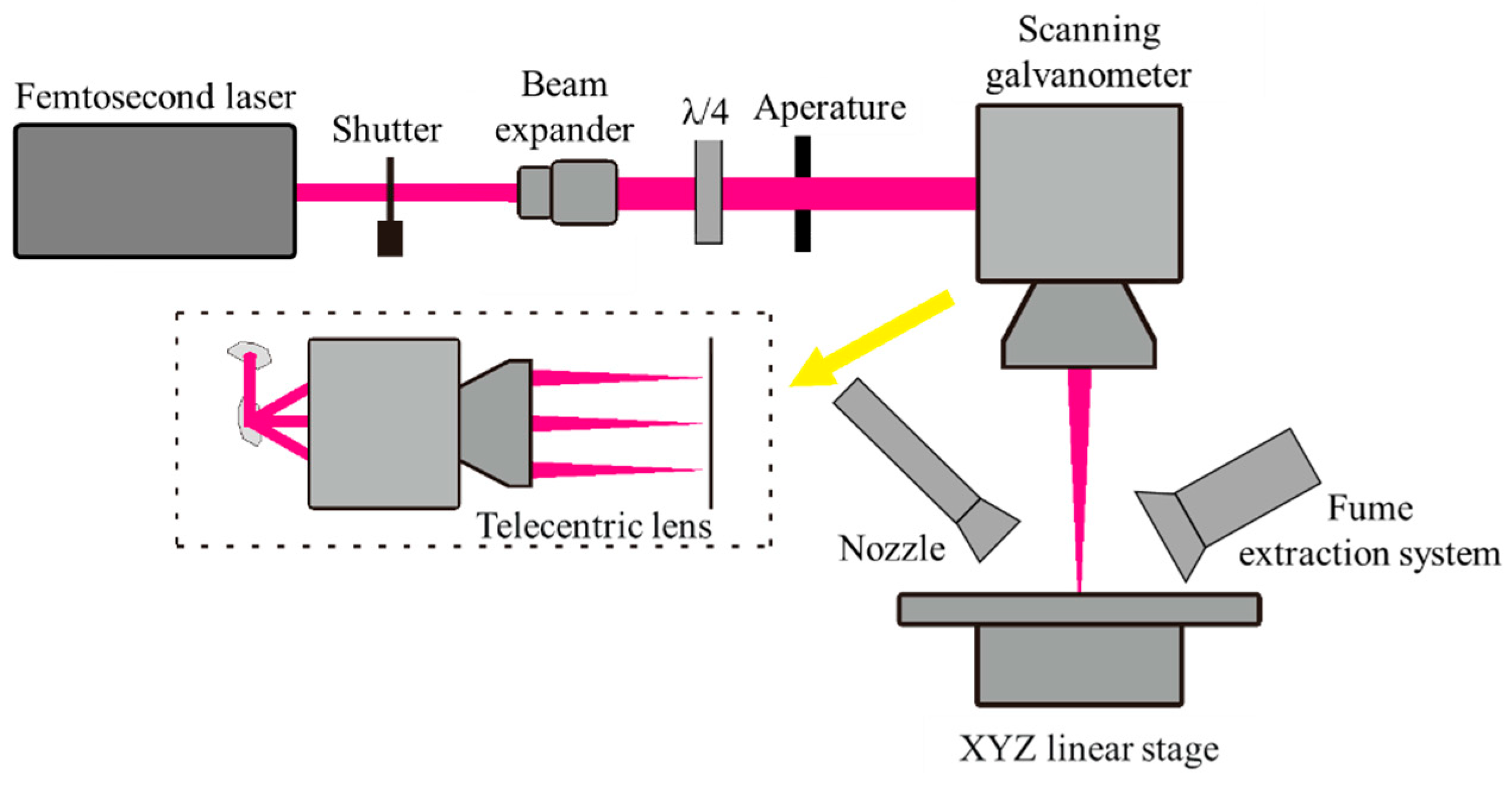

2. Experimental Setup and Methodology

3. Results and Discussions

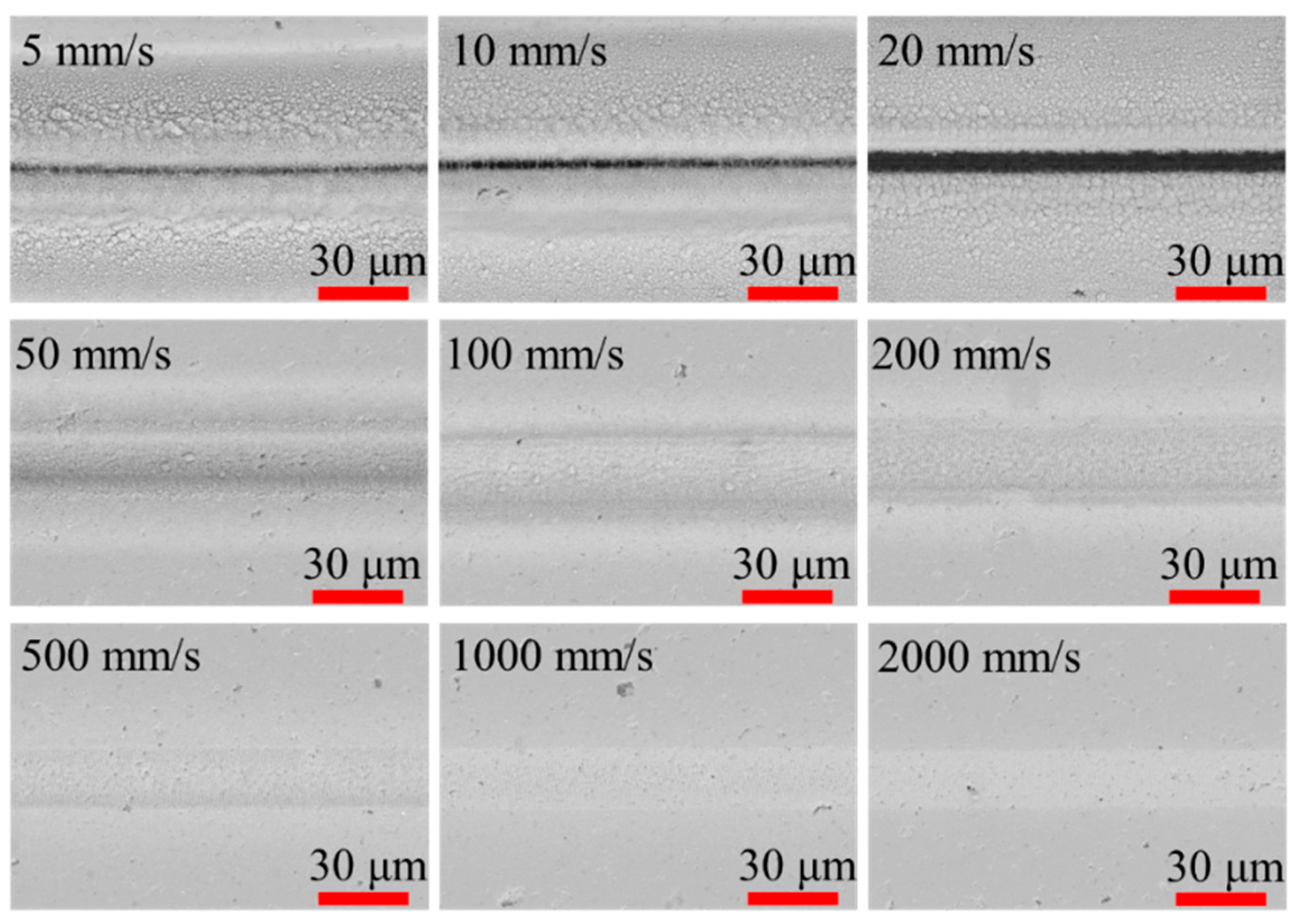

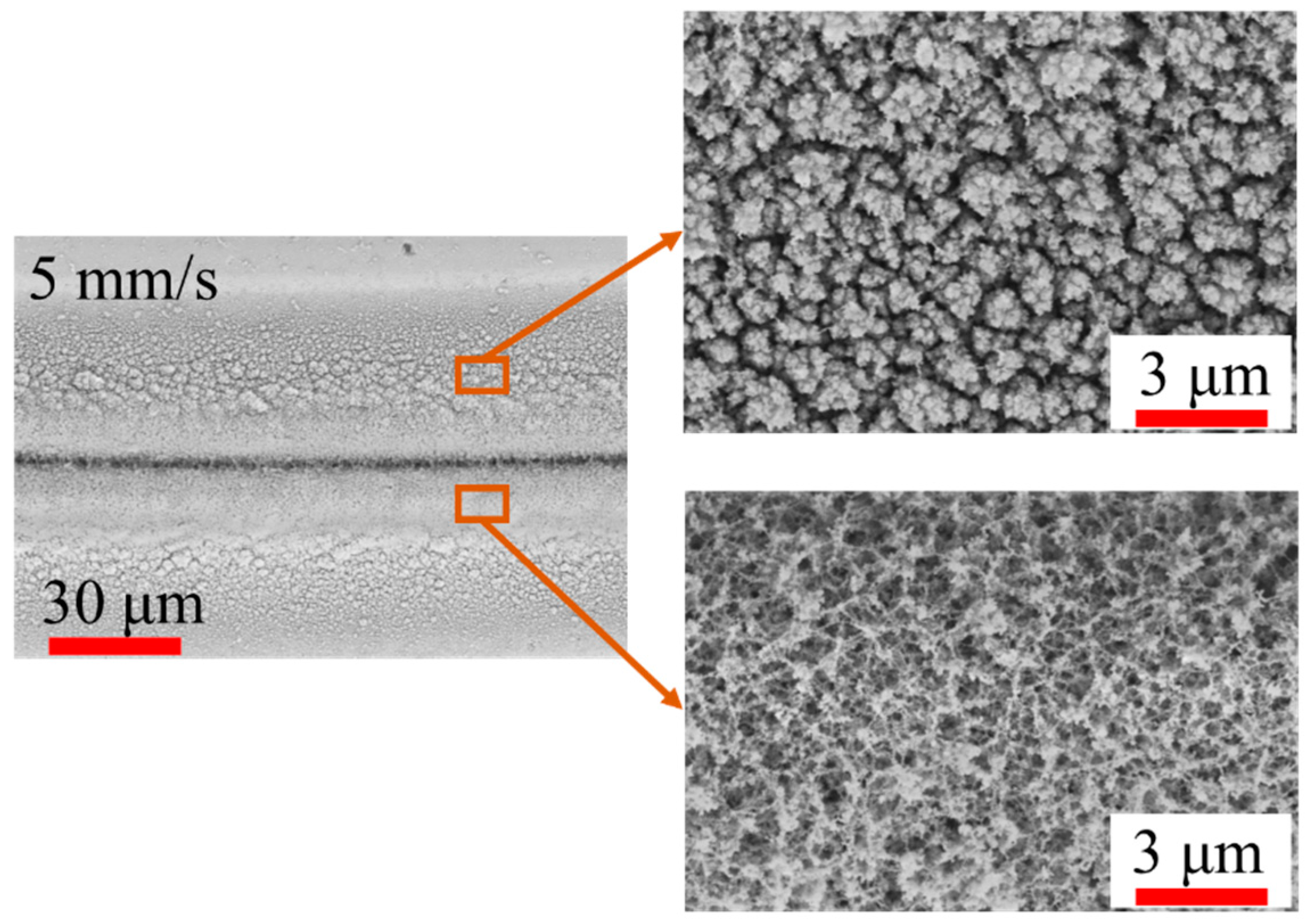

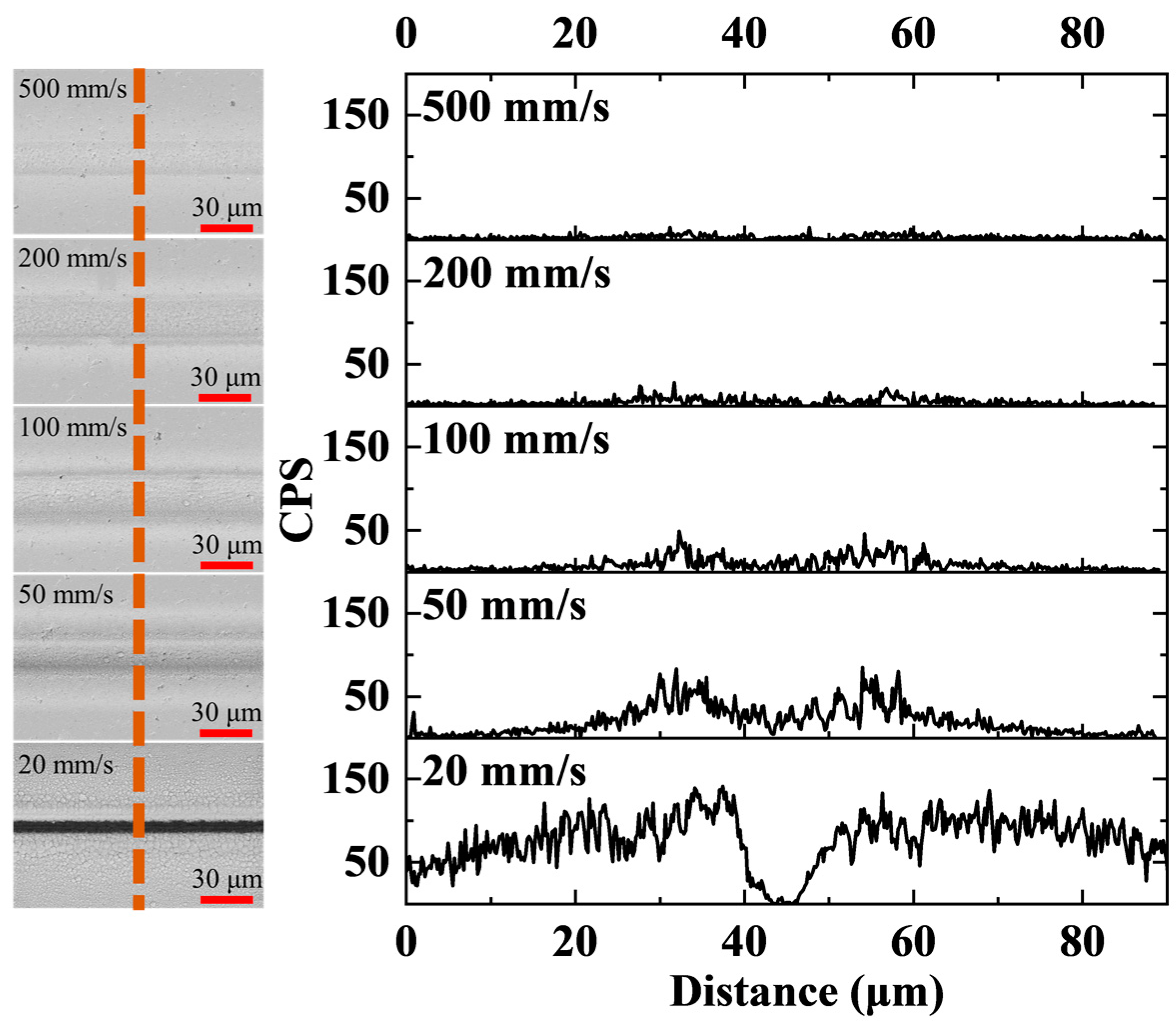

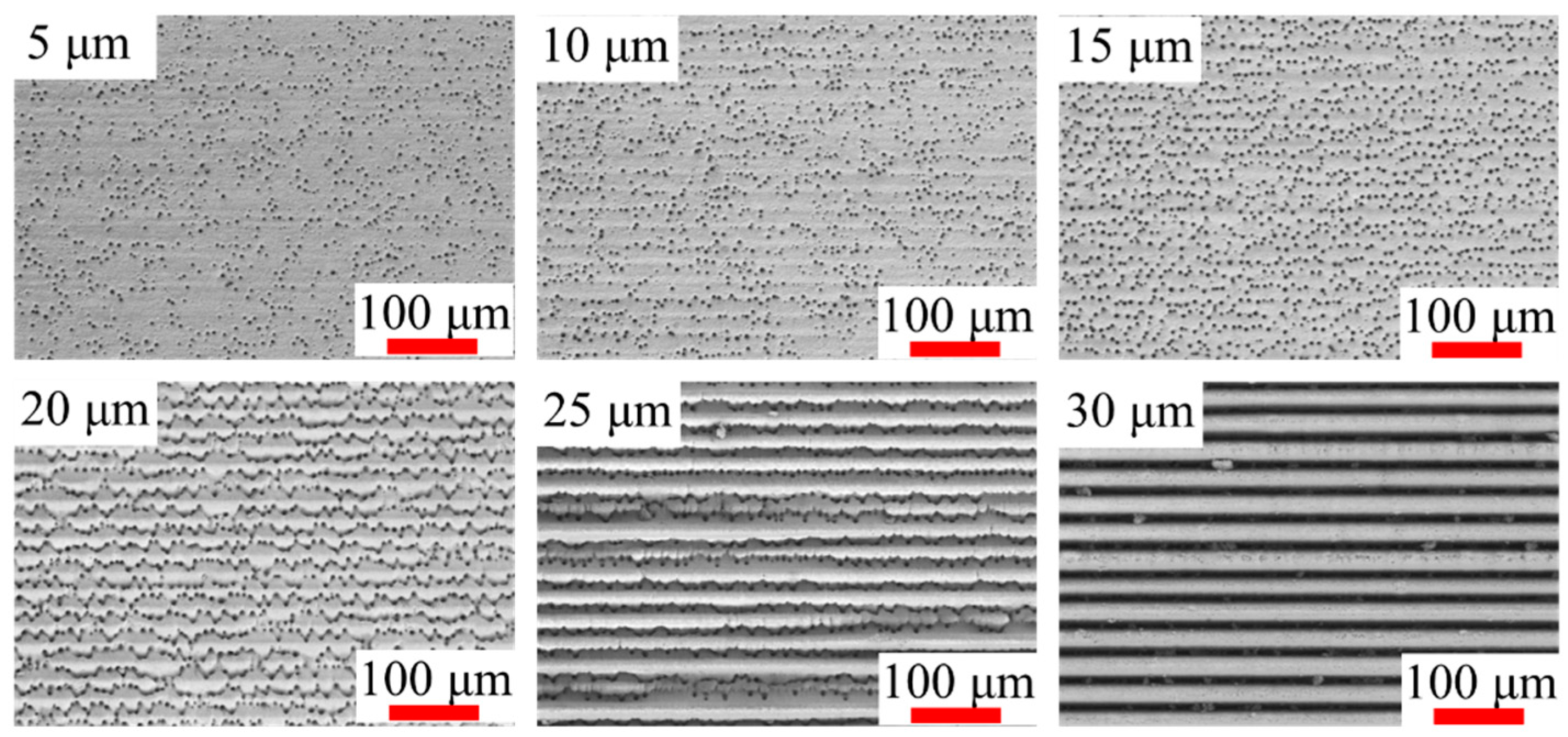

3.1. Morphological Analysis of the Grooves Processed by Femtosecond Laser

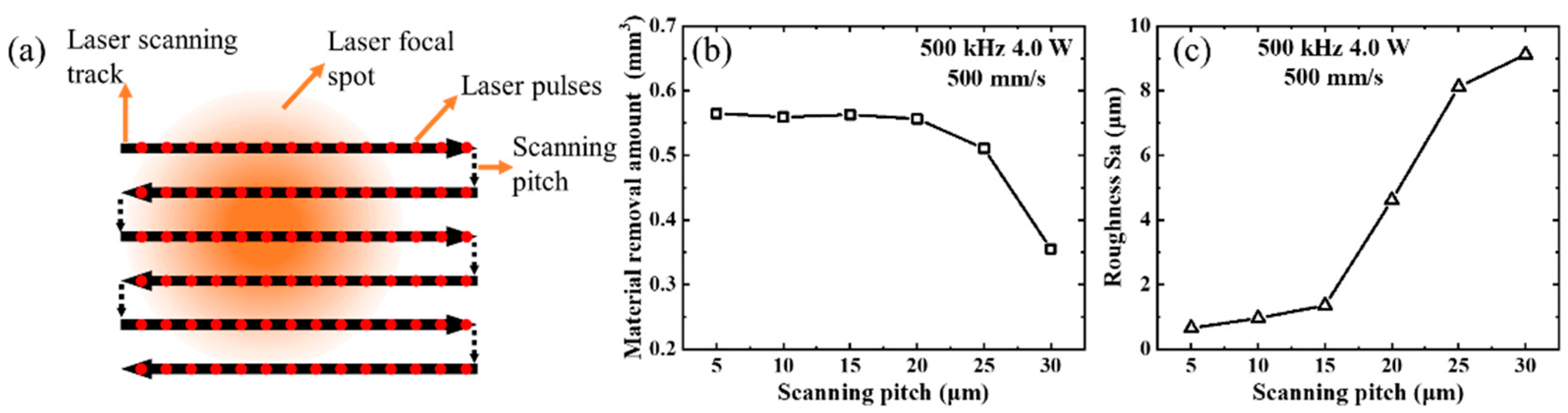

3.2. Influence of the Laser Scanning Pitch on Material Removal Rate and Roughness

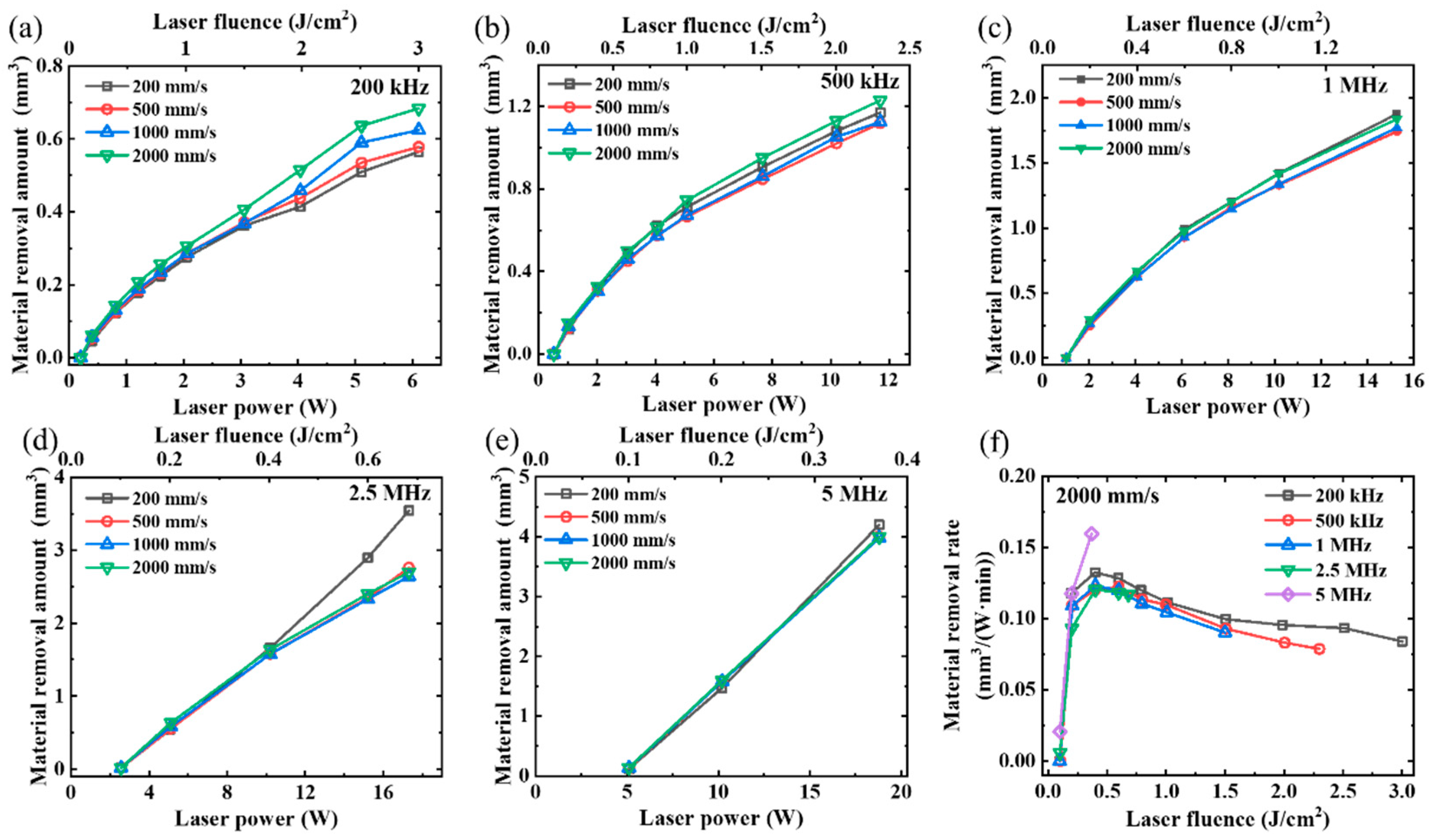

3.3. Influence of Laser Scanning Speed and Power on Material Removal Rate and Roughness

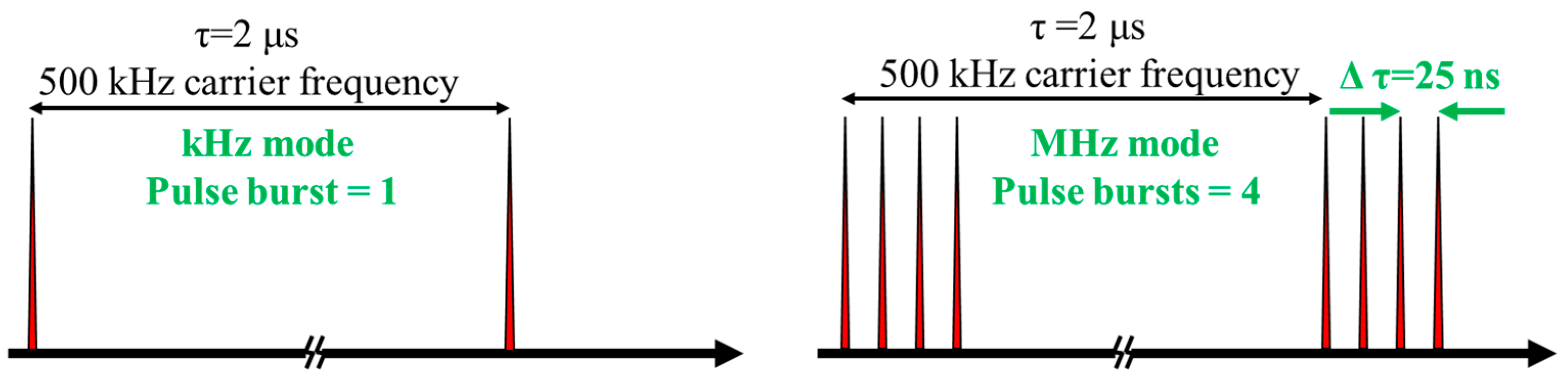

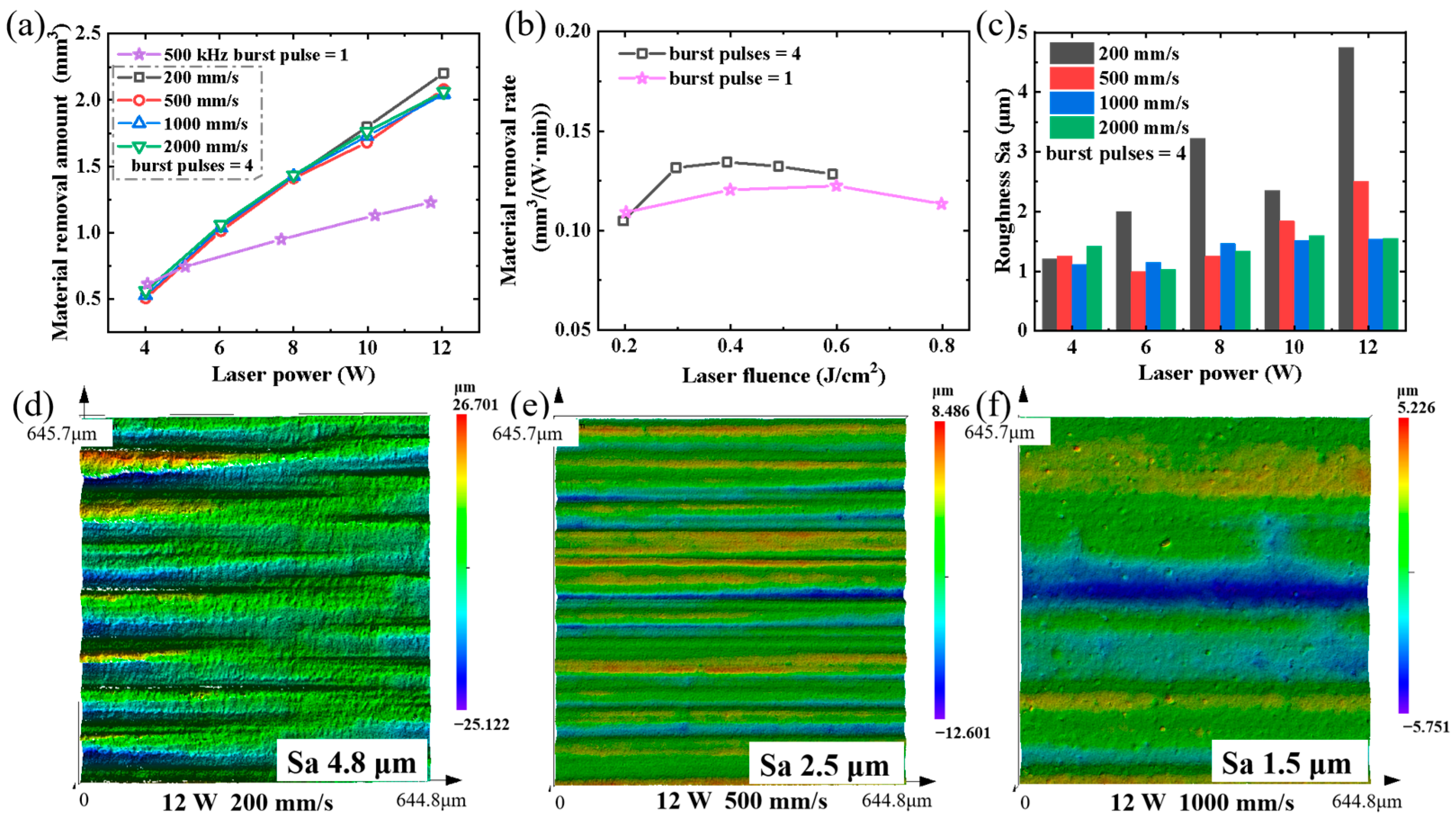

3.4. Influence of the Laser Burst Mode on Material Removal Rate

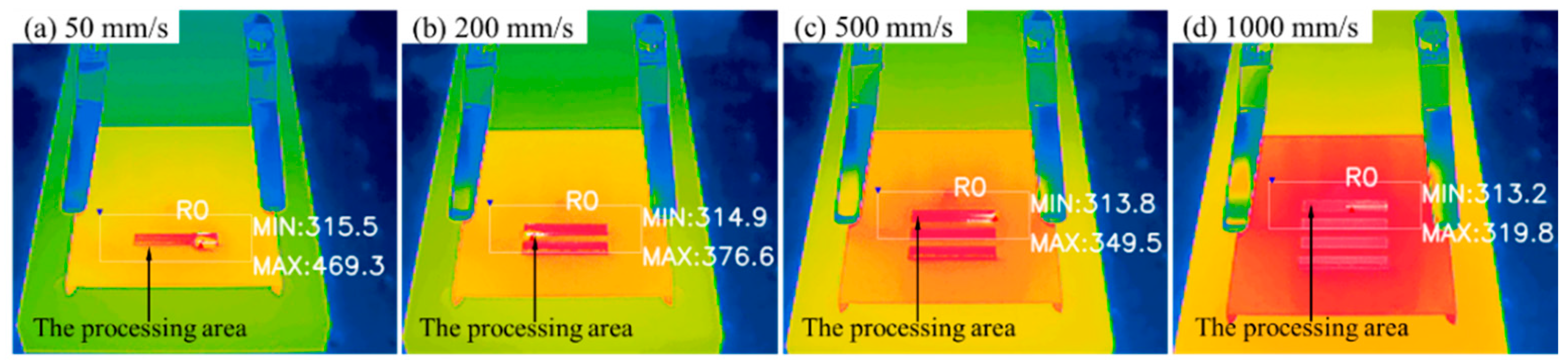

3.5. Thermal Infrared Images of the Processing Areas

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Gao, X.; Zhang, Z.; Cheng, L.; Ma, H.P.; Yang, W. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. J. Eur. Ceram. Soc. 2021, 41, 4671–4688. [Google Scholar] [CrossRef]

- Raju, K.; Yoon, D.H. Sintering additives for SiC based on the reactivity: A review. Ceram. Int. 2016, 42, 17947–17962. [Google Scholar] [CrossRef]

- Katoh, Y.; Snead, L.L. Silicon carbide and its composites for nuclear applications–Historical overview. J. Nucl. Mater. 2019, 526, 151849. [Google Scholar] [CrossRef]

- Masuda, H.; Ohta, Y.; Kitayama, M. Additive manufacturing of SiC ceramics with complicated shapes using the FDM type 3D-printer. J. Mater. Sci. Chem. Eng. 2019, 7, 90735. [Google Scholar] [CrossRef]

- Grossin, D.; Montón, A.; Navarrete-Segado, P.; Özmen, E.; Urruth, G.; Maury, F.; Maury, D.; Frances, C.; Tourbin, M.; Lenormand, P. A review of additive manufacturing of ceramics by powder bed selective laser processing (sintering/melting): Calcium phosphate, silicon carbide, zirconia, alumina, and their composites. Open Ceram. 2021, 5, 100073. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, K.; Xu, T.; Zeng, T.; Cheng, S. The fabrication and mechanical properties of SiC/SiC composites prepared by SLS combined with PIP. Ceram. Int. 2018, 44, 20992–20999. [Google Scholar] [CrossRef]

- Zhang, L.; Ren, C.; Ji, C.; Wang, Z.; Chen, G. Effect of fiber orientations on surface grinding process of unidirectional C/SiC composites. Appl. Surf. Sci. 2016, 366, 424–431. [Google Scholar] [CrossRef]

- Feng, P.; Wang, J.; Zhang, J.; Zheng, J. Drilling induced tearing defects in rotary ultrasonic machining of C/SiC composites. Ceram. Int. 2017, 43, 791–799. [Google Scholar] [CrossRef]

- Phillips, K.C.; Gandhi, H.H.; Mazur, E.; Sundaram, S.K. Ultrafast laser processing of materials: A review. Adv. Opt. Photonics 2015, 7, 684–712. [Google Scholar] [CrossRef]

- An, Q.; Chen, J.; Ming, W.; Chen, M. Machining of SiC ceramic matrix composites: A review. Chin. J. Aeronaut. 2020, 34, 540–567. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast lasers—Reliable tools for advanced materials processing. Light Sci. Appl. 2014, 3, 149. [Google Scholar] [CrossRef]

- Rethfeld, B.; Sokolowski-Tinten, K.; Von Der Linde, D.; Anisimov, S.I. Timescales in the response of materials to femtosecond laser excitation. Appl. Phys. A. 2004, 79, 767–769. [Google Scholar] [CrossRef]

- Wang, X.; Yu, H.; Li, P.; Zhang, Y.; Wen, Y.; Qiu, Y.; Liu, Z.; Li, Y.; Liu, L. Femtosecond laser-based processing methods and their applications in optical device manufacturing: A review. Opt. Laser Technol. 2021, 135, 10668. [Google Scholar] [CrossRef]

- Liu, H.; Lin, W.; Hong, M. Hybrid laser precision engineering of transparent hard materials: Challenges, solutions and applications. Light Sci. Appl. 2021, 10, 162. [Google Scholar] [CrossRef] [PubMed]

- Audouard, E.; Bonamis, G.; Hönninger, C.; Mottay, E. GHz femtosecond processing with agile high-power laser: High power and flexible fs lasers in GHz burst mode open new horizons for femtosecond laser processing. Adv. Opt. Technol. 2021, 10, 263–275. [Google Scholar] [CrossRef]

- Lopez, J.; Mishchik, K.; Mincuzzi, G.; Audouard, E.; Mottay, E.; Kling, R. Efficient metal processing using high average power ultrafast laser. J. Laser Micro/Nanoeng. 2017, 12, 296–303. [Google Scholar]

- Kirsch, D.; Chen, S.; Sidharthan, R.; Chen, Y.; Yoo, S.; Chernysheva, M. Short-wave IR ultrafast fiber laser systems: Current challenges and prospective applications. J. Appl. Phys. 2020, 128, 180906. [Google Scholar] [CrossRef]

- Zhai, Z.; Wei, C.; Zhang, Y.; Cui, Y.; Zeng, Q. Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser. Appl. Surf. Sci. 2020, 502, 144131. [Google Scholar] [CrossRef]

- Zhang, J.; Geng, F.; Liu, Z.; Zhang, Q.; Xu, Q.; Li, Y. High-speed processing of silicon carbide ceramic by high repetition frequency femtosecond laser. SPIE 2021, 12057, 732–738. [Google Scholar]

- Gopal, P.M.; Kavimani, V.; Gupta, K.; Marinkovic, D. Laser-Based Manufacturing of Ceramics: A Review. Micromachines 2023, 14, 1564. [Google Scholar] [CrossRef]

- Narazaki, A.; Takada, H.; Yoshitomi, D.; Torizuka, K.; Kobayashi, Y. Study on nonthermal–thermal processing boundary in drilling of ceramics using ultrashort pulse laser system with variable parameters over a wide range. Appl. Phys. A 2020, 126, 252. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, X.; Chen, T.; Ma, G.; Zhang, W.; Huang, L. Influence of Pulse Energy and Defocus Amount on the Mechanism and Surface Characteristics of Femtosecond Laser Polishing of SiC Ceramics. Micromachines 2022, 13, 1118. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Fang, X.; Liu, F.; Guo, X.; Maeda, R.; Jiang, Z. High speed and low roughness micromachining of silicon carbide by plasma etching aided femtosecond laser processing. Ceram. Int. 2020, 46, 17896–17902. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, B.; Wang, J.; Wang, Y.; Sheng, L.; Jiao, J.; Yao, J.; Huang, Y.; Zhang, W. Effects of incidence angle and optimization in femtosecond laser polishing of C/SiC composites. Ceram. Int. 2022, 48, 32290–33230. [Google Scholar] [CrossRef]

- Wang, L.; Zhao, Y.; Yang, Y.; Zhang, M.; Zhao, Y. Experimental Investigation on Ablation of 4H-SiC by Infrared Femtosecond Laser. Micromachines 2022, 13, 1291. [Google Scholar] [CrossRef]

- De Zanet, A.; Casalegno, V.; Salvo, M. Laser surface texturing of ceramics and ceramic composite materials-A review. Ceram. Int. 2021, 47, 7307–7320. [Google Scholar] [CrossRef]

- Bauer, F.; Michalowski, A.; Kiedrowski, T.; Nolte, S. Heat accumulation in ultra-short pulsed scanning laser ablation of metals. Opt. Express 2015, 23, 1035–1043. [Google Scholar] [CrossRef] [PubMed]

- Žemaitis, A.; Gaidys, M.; Brikas, M.; Gečys, P.; Račiukaitis, G.; Gedvilas, M. Advanced laser scanning for highly-efficient ablation and ultrafast surface structuring: Experiment and model. Sci. Rep. 2018, 8, 17376. [Google Scholar] [CrossRef]

- Martan, J.; Prokešová, L.; Moskal, D.; Ferreira de Faria, B.C.; Honner, M.; Lang, V. Heat accumulation temperature measurement in ultrashort pulse laser micromachining. Int. J. Heat Mass Transf. 2021, 168, 120866. [Google Scholar] [CrossRef]

- Balage, P.; Guilberteau, T.; Lafargue, M.; Bonamis, G.; Hönninger, C.; Lopez, J.; Manek-Hönninger, I. Bessel Beam Dielectrics Cutting with Femtosecond Laser in GHz-Burst Mode. Micromachines 2023, 14, 1650. [Google Scholar] [CrossRef]

- Lopez, J.; Niane, S.; Bonamis, G.; Balage, P.; Audouard, E.; Hönninger, C.; Mottay, E.; Manek-Hönninger, I. Percussion drilling in glasses and process dynamics with femtosecond laser GHz-bursts. Opt. Express 2022, 30, 12533–12544. [Google Scholar] [CrossRef] [PubMed]

- Colombo, P.; Demir, A.G.; Norgia, M.; Previtali, B. Self-mixing interferometry as a diagnostics tool for plasma characteristics in laser microdrilling. Opt. Lasers Eng. 2017, 92, 17–28. [Google Scholar] [CrossRef]

- Taylor, L.L.; Qiao, J.; Qiao, J. Optimization of femtosecond laser processing of silicon via numerical modeling. Opt. Mater. Express 2016, 6, 2745–2758. [Google Scholar] [CrossRef]

- Butkus, S.; Jukna, V.; Paipulas, D.; Barkauskas, M.; Sirutkaitis, V. Micromachining of Invar foils with GHz, MHz and kHz femtosecond burst modes. Micromachines 2020, 11, 733. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Value |

|---|---|

| Laser wavelength | 1030 ± 5 nm |

| Pulse energy (max) | 40 μJ |

| Pulse width (FWHM) | 470 fs |

| Repetition frequency | 50/100/200/300/500/800 kHz, 1/1.2/2.5/5 MHz |

| Power (max) | 20 W |

| Laser mode | TEM00 (M2 < 1.3) |

| Parameters | Value |

|---|---|

| Sample roughness (Sa) | 0.1 μm |

| Sample side length | 50 mm |

| Sample thickness | 4 mm |

| Focal length | 100 mm |

| Focal spot | 36 μm |

| Laser scanning speed | 1–2000 mm/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Liu, Z.; Zhang, Y.; Geng, F.; Wang, S.; Fan, F.; Zhang, Q.; Xu, Q. High-Power Femtosecond Laser Processing of SiC Ceramics with Optimized Material Removal Rate. Micromachines 2023, 14, 1960. https://doi.org/10.3390/mi14101960

Zhang J, Liu Z, Zhang Y, Geng F, Wang S, Fan F, Zhang Q, Xu Q. High-Power Femtosecond Laser Processing of SiC Ceramics with Optimized Material Removal Rate. Micromachines. 2023; 14(10):1960. https://doi.org/10.3390/mi14101960

Chicago/Turabian StyleZhang, Jian, Zhichao Liu, Yuanhang Zhang, Feng Geng, Shengfei Wang, Fei Fan, Qinghua Zhang, and Qiao Xu. 2023. "High-Power Femtosecond Laser Processing of SiC Ceramics with Optimized Material Removal Rate" Micromachines 14, no. 10: 1960. https://doi.org/10.3390/mi14101960

APA StyleZhang, J., Liu, Z., Zhang, Y., Geng, F., Wang, S., Fan, F., Zhang, Q., & Xu, Q. (2023). High-Power Femtosecond Laser Processing of SiC Ceramics with Optimized Material Removal Rate. Micromachines, 14(10), 1960. https://doi.org/10.3390/mi14101960