An Exploratory Study of Laser Scribing Quality through Cross-Section Scribing Profiles

Abstract

:1. Introduction

2. Experimental Plan and Data Collection

2.1. Experimental Plan

- Experimental Setup:

- Laser Scribing Setup:

- Utilizes a femtosecond (fs) laser.

- Adjusts pulse energy using a half-wave plate and cube polarizer.

- Focuses pulse energy to a focal spot on the sample surface with a focusing lens.

- Sample Characteristics:

- Consists of a 300 nm thick aluminum film coated on silicon.

- Sample position controlled by an XYZ translation stage.

- Writing direction perpendicular to the beam propagation axis.

- Laser Scribing Process:

- Conducted on the Al-coated silicon sample.

- Variables Adjusted:

- Pulse energy (range: 12–360 μJ)

- Pulse duration (range: 0.184–10 ps)

- Pulse frequency (range: 250–200,000 Hz)

- Post-Scribing Analysis:

- Examination using a 3D optical profiler.

- Measure cross-sectional profiles for each scribe.

- Conducted at a minimum of three distinct locations.

2.2. Data Collection and Preprocessing

3. Cubic Spline Interpolation Approach

4. Scribing Quality Evaluation Using Cubic Spline Trajectory

4.1. Cubic Spline Fit of Laser Scribing Profiles

4.2. Area Ratio for Scribing Precision Measurement

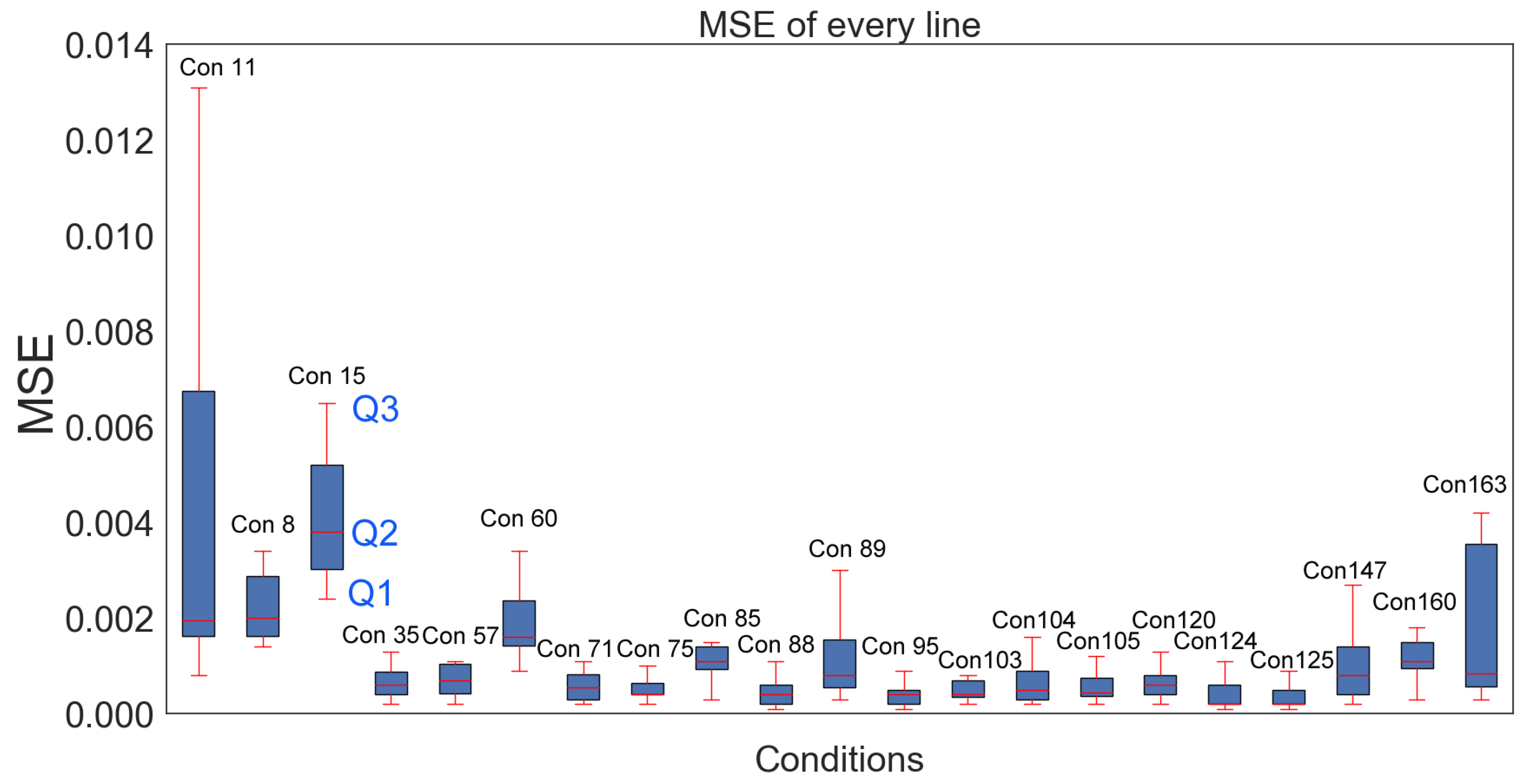

4.3. MSE for Scribing Consistency Measurement

4.4. Contour Plot Model for Exploring the Relationship between tp, E, RA, and MSE

5. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hung, C.-H.; Chang, F.-Y.; Chang, T.-L.; Chang, Y.-T.; Huang, K.-W.; Liang, P.-C. Micromachining NiTi tubes for use in medical devices by using a femtosecond laser. Opt. Lasers Eng. 2015, 66, 34–40. [Google Scholar] [CrossRef]

- Yang, W.; Zhao, W.; Li, Q.; Li, H.; Wang, Y.; Li, Y.; Wang, G. Fabrication of smart components by 3D printing and laser-scribing technologies. ACS Appl. Mater. Interfaces 2020, 12, 3928–3935. [Google Scholar] [CrossRef] [PubMed]

- Klepov, V.V.; De Siena, M.C.; Pandey, I.R.; Pan, L.; Bayikadi, K.S.; Butun, S.; Chung, D.Y.; Kanatzidis, M.G. Laser scribing for electrode patterning of perovskite spectrometer-grade CsPbBr3 gamma-ray detectors. ACS Appl. Mater. Interfaces 2023, 15, 16895–16901. [Google Scholar] [CrossRef]

- Kam, D.H.; Kim, J.; Mazumder, J. Near-IR nanosecond laser direct writing of multi-depth microchannel branching networks on silicon. J. Manuf. Process. 2018, 35, 99–106. [Google Scholar] [CrossRef]

- Bisheh, M.N.; Wang, X.; Chang, S.I.; Lei, S.; Ma, J. Image-based characterization of laser scribing quality using transfer learning. J. Intell. Manuf. 2022, 34, 2307–2319. [Google Scholar] [CrossRef]

- Mamun, M.A.A.; Cadusch, P.J.; Katkus, T.; Juodkazis, S.; Stoddart, P.R. Quantifying end-face quality of cleaved fibers: Femtosecond laser versus mechanical scribing. Opt. Laser Technol. 2021, 141, 107111. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, X.; Yan, K.; Zhu, H.; Wang, B.; Zou, B. Laser micro/nano-structuring pushes forward smart sensing: Opportunities and challenges. Adv. Funct. Mater. 2022, 33, 2211272. [Google Scholar] [CrossRef]

- Nejand, B.A.; Ritzer, D.B.; Hu, H.; Schackmar, F.; Moghadamzadeh, S.; Feeney, T.; Singh, R.; Laufer, F.; Schmager, R.; Azmi, R.; et al. Scalable two-terminal all-perovskite tandem solar modules with a 19.1% efficiency. Nat. Energy 2022, 7, 620–630. [Google Scholar] [CrossRef]

- Jeong, S.; Ham, S.S.; Choi, E.P.; Hwang, D.J.; Yu, H.; Kim, W.M.; Kim, G.Y.; Jeong, J.-H. Enhanced mechanical stability of CIGS solar module with Glass/Polyimide/Indium Tin oxide for potentially flexible applications. ACS Appl. Energy Mater. 2023, 6, 3745–3755. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Yu, B.; Tan, S.; Cui, Y.; Wu, H.; Luo, Y.; Shi, J.; Li, D.; Meng, Q. Efficient, stable formamidinium-cesium perovskite solar cells and minimodules enabled by crystallization regulation. Joule 2022, 6, 676–689. [Google Scholar] [CrossRef]

- Lu, G.; Sokol, D.W.; Zhang, Y.; Dulaney, J.L. Nanosecond pulsed laser-generated stress effect inducing macro-micro-nano structures and surface topography evolution. Appl. Mater. Today 2019, 15, 171–184. [Google Scholar] [CrossRef]

- Munoz-Garcia, C.; Canteli, D.; Lauzurica, S.; Morales, M.; Molpeceres, C.; Ros, E.; Ortega, P.; López-González, J.M.; Voz, C. Influence of wavelength and pulse duration on the selective laser ablation of WOx, VOx and MoOx thin films. Surf. Interfaces 2022, 28, 101613. [Google Scholar] [CrossRef]

- Kuk, S.; Wang, Z.; Yu, H.; Nam, C.Y.; Jeong, J.H.; Hwang, D. Nanosecond laser scribing for see-through CIGS thin film solar cells. Prog. Photovolt. Res. Appl. 2019, 28, 135–147. [Google Scholar] [CrossRef]

- Yang, B.; Wang, H.; Peng, S.; Cao, Q. Precision layered stealth dicing of SiC wafers by ultrafast lasers. Micromachines 2022, 13, 1011. [Google Scholar] [CrossRef]

- Zhao, L.; Liu, Z.; Chen, D.; Liu, F.; Yang, Z.; Li, X.; Yu, H.; Liu, H.; Zhou, W. Laser synthesis and microfabrication of micro/nanostructured materials toward energy conversion and storage. Nanomicro Lett. 2021, 13, 49. [Google Scholar] [CrossRef]

- Xiao, M.; Zheng, S.; Shen, D.; Duley, W.W.; Zhou, Y.N. Laser-induced joining of nanoscale materials: Processing, properties, and applications. Nano Today 2020, 35, 100959. [Google Scholar] [CrossRef]

- Suo, H.; Zhao, X.; Zhang, Z.; Guo, C. Ultra-sensitive optical nano-thermometer LaPO4: Yb3+/Nd3+ based on thermo-enhanced NIR-to-NIR emissions. Chem. Eng. J. 2020, 389, 124506. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, H. Characterization of the recasting-affected zone in the nickel-based superalloy upon single-pulse laser treatment. Mater. Sci. Eng. A 2021, 826, 141897. [Google Scholar] [CrossRef]

- Tangwarodomnukun, V.; Mekloy, S. Temperature field modeling and cut formation in laser micromachining of silicon in ice layer. J. Mater. Process. Technol. 2019, 271, 202–213. [Google Scholar] [CrossRef]

- Li, S.; Yuchi, G.; Zhang, X.; Shi, Z.; Duan, J.; Zhang, S.; Yang, Z.; Li, C.; Li, W.; Wen, D. Grinding behavior of biomimetic fractal-branched silicon carbide ceramic inspired from leaf-vein structure. Ceram. Int. 2022, 48, 18212–18223. [Google Scholar] [CrossRef]

- Rakocevic, L.; Schöpe, G.; Turan, B.; Genoe, J.; Aernouts, T.; Haas, S.; Gehlhaar, R.; Poortmans, J. Perovskite modules with 99% geometrical fill factor using point contact interconnections design. Prog. Photovolt. Res. Appl. 2020, 28, 1120–1127. [Google Scholar] [CrossRef]

- Schultz, C.; Fenske, M.; Dagar, J.; Zeiser, A.; Bartelt, A.; Schlatmann, R.; Unger, E.; Stegemann, B. Ablation mechanisms of nanosecond and picosecond laser scribing for metal halide perovskite module interconnection—An experimental and numerical analysis. Sol. Energy 2020, 198, 410–418. [Google Scholar] [CrossRef]

- Saetang, V.; Qi, H.; Smerchit, T.; Rujisamphan, N. Laser scribing of fluorine-doped tin oxide coated on glass substrate in air and water. Opt. Laser Technol. 2022, 153, 108280. [Google Scholar] [CrossRef]

- Fenske, M.; Schultz, C.; Dagar, J.; Kosasih, F.U.; Zeiser, A.; Junghans, C.; Bartelt, A.; Ducati, C.; Schlatmann, R.; Unger, E.; et al. Improved electrical performance of perovskite photovoltaic mini-modules through controlled PbI2 formation using nanosecond laser pulses for P3 patterning. Energy Technol. 2021, 9, 2000969. [Google Scholar] [CrossRef]

- Haas, S.; Gordijn, A.; Stiebig, H. High speed laser processing for monolithical series connection of silicon thin-film modules. Prog. Photovolt. Res. Appl. 2008, 16, 195–203. [Google Scholar] [CrossRef]

- Li, J.; Niu, J.; Wu, X.; Kong, Y.; Gao, J.; Zhu, J.; Li, Q.; Huang, L.; Wang, S.; Chi, Z.; et al. Effects of laser-scribed Mo groove shape on highly efficient Zn(O,S)-based Cu(In,Ga)Se2 solar modules. Sol. RRL 2020, 4, 1900510. [Google Scholar] [CrossRef]

- Gauthier, J.; Wu, Q.V.; Gooley, T.A. Cubic splines to model relationships between continuous variables and outcomes: A guide for clinicians. Bone Marrow Transplant. 2020, 55, 675–680. [Google Scholar] [CrossRef]

- Jalali, M.; Behnam, H.; Davoodi, F.; Shojaeifard, M. Temporal super-resolution of 2D/3D echocardiography using cubic B-spline interpolation. Biomed. Signal Process. Control 2020, 58, 101868. [Google Scholar] [CrossRef]

- Chang, S.I.; Yadama, S. Statistical process control for monitoring non-linear profiles using wavelet filtering and B-Spline approximation. Int. J. Prod. Res. 2008, 48, 1049–1068. [Google Scholar] [CrossRef]

- He, Y.; Li, H.; Wang, S.; Yao, X.J.N. Uncertainty analysis of wind power probability density forecasting based on cubic spline interpolation and support vector quantile regression. Neurocomputing 2021, 430, 121–137. [Google Scholar] [CrossRef]

- Cheduluri, G.; Bhardwaj, S.; Naik, G.R.; Hansigida, V.; Nali, A.R.; Acharyya, A. Low complex hardware architecture design methodology for cubic spline interpolation technique for assistive technologies. In Proceedings of the 2022 20th IEEE Interregional NEWCAS Conference (NEWCAS), Quebec City, QC, Canada, 19–22 June 2022; pp. 70–74. [Google Scholar]

- Peraman, R.; Bhadraya, K.; Reddy, Y.P. Analytical quality by design: A tool for regulatory flexibility and robust analytics. Int. J. Anal. Chem. 2015, 2015, 868727. [Google Scholar] [CrossRef] [PubMed]

- Balduzzi, S.; Rücker, G.; Schwarzer, G. How to perform a meta-analysis with R: A practical tutorial. BMJ Ment. Health 2019, 22, 153–160. [Google Scholar] [CrossRef] [PubMed]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Tusar, T.; Filipic, B. Visualization of Pareto Front Approximations in Evolutionary Multiobjective Optimization: A Critical Review and the Prosection Method. IEEE Trans. Evol. Comput. 2015, 19, 225–245. [Google Scholar] [CrossRef]

| Condition | E (µJ) | tp (ps) | fp (Hz) | MSE | RA |

|---|---|---|---|---|---|

| Con 8 | 240 | 10 | 500 | 0.00361 | 37.94 |

| Con 11 | 240 | 1 | 250 | 0.00638 | 44.61 |

| Con 15 | 360 | 2 | 250 | 0.00447 | 49.86 |

| Con 35 | 120 | 10 | 1000 | 0.00075 | 46.43 |

| Con 57 | 24 | 0.5 | 10,000 | 0.00107 | 42.06 |

| Con 60 | 24 | 10 | 10,000 | 0.00192 | 69.94 |

| Con 71 | 48 | 0.184 | 2000 | 0.00059 | 40.9 |

| Con 75 | 48 | 10 | 2000 | 0.00055 | 32.18 |

| Con 85 | 105 | 10 | 1000 | 0.00111 | 29.2 |

| Con 88 | 30 | 1 | 2000 | 0.00047 | 41.08 |

| Con 89 | 30 | 2 | 2000 | 0.00129 | 47.9 |

| Con 95 | 30 | 10 | 5000 | 0.00042 | 53.43 |

| Con 103 | 60 | 0.5 | 1000 | 0.00068 | 41.24 |

| Con 104 | 60 | 1 | 1000 | 0.00076 | 43.4 |

| Con 105 | 60 | 2 | 1000 | 0.00061 | 44.17 |

| Con 120 | 60 | 10 | 2000 | 0.00081 | 44 |

| Con 124 | 60 | 2 | 3000 | 0.00043 | 43.5 |

| Con 125 | 60 | 10 | 3000 | 0.00038 | 42.85 |

| Con 147 | 15 | 0.5 | 50,000 | 0.00107 | 11.66 |

| Con 160 | 10 | 10 | 100,000 | 0.00114 | 19.35 |

| Con 163 | 12 | 1 | 100,000 | 0.00184 | 10.95 |

| Variable | Coefficient (bi) | p-Value |

|---|---|---|

| Intercept | 51.454 | 0.000 |

| 4.017 | 0.309 | |

| −0.078 | 0.970 | |

| 9.500 | 0.018 |

| Variable | Coefficient (bi) | p-Value |

|---|---|---|

| Intercept | 64.3156 | 0.258 |

| 7.8994 | 0.900 | |

| 71.7138 | 0.300 | |

| 14.4419 | 0.817 | |

| 69.076 | 0.335 | |

| 2.3735 | 0.970 | |

| 77.5716 | 0.285 | |

| −0.5282 | 0.950 | |

| −10.109 | 0.264 | |

| −2.7738 | 0.752 | |

| 65.036 | 0.347 |

| Variable | Coefficient (bi) | p-Value |

|---|---|---|

| Intercept | 0.0035 | 0.000 |

| 0.0029 | 0.000 | |

| −0.0002 | 0.333 | |

| 0.0007 | 0.113 |

| Variable | Coefficient (bi) | p-Value |

|---|---|---|

| Intercept | −0.0128 | 0.069 |

| −0.0185 | 0.032 | |

| 0.0012 | 0.873 | |

| −0.0196 | 0.025 | |

| 0.0012 | 0.884 | |

| −0.0209 | 0.019 | |

| 0.0019 | 0.807 | |

| −0.0036 | 0.007 | |

| −0.0005 | 0.581 | |

| −0.0016 | 0.150 | |

| 0.0016 | 0.830 |

| Setting | tp (ps) | E (μJ) | fp (Hz) | RA | MSE |

|---|---|---|---|---|---|

| S1 | 5 | 31 | 10,000 | 65.64 | 4.9311 × 10−4 |

| S2 | 5 | 34 | 9705 | 65.45 | 2.1304 × 10−5 |

| S3 | 5 | 27 | 10,000 | 65.41 | 1.148 × 10−3 |

| S4 | 5 | 24 | 10,000 | 65.18 | 1.8 × 10−3 |

| S5 | 5 | 38 | 7833 | 62.56 | 4.5348 × 10−4 |

| S6 | 5 | 41 | 7636 | 62.39 | 7.94 × 10−5 |

| S7 | 7.5 | 24 | 10,000 | 70.25 | 1.6 × 10−3 |

| S8 | 7.5 | 27 | 9311 | 70.24 | 1.254 × 10−3 |

| S9 | 7.5 | 31 | 8720 | 70.21 | 9.21 × 10−4 |

| S10 | 7.5 | 34 | 8227 | 70.28 | 6.01 × 10−4 |

| S11 | 7.5 | 38 | 7735 | 70.01 | 3.23 × 10−4 |

| S12 | 7.5 | 41 | 7439 | 70.58 | 1.65 × 10−5 |

| S13 | 10 | 24 | 10,000 | 70.25 | 0.16 × 10−3 |

| S14 | 10 | 27 | 9311 | 70.24 | 0.1254 × 10−3 |

| S15 | 10 | 31 | 8720 | 70.21 | 0.9209 × 10−4 |

| S16 | 10 | 34 | 8326 | 70.78 | 5.675 × 10−4 |

| S17 | 10 | 38 | 7735 | 70.01 | 3.234 × 10−4 |

| S18 | 10 | 41 | 7439 | 70.58 | 1.6529 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, R.; Chang, S.; Lei, S. An Exploratory Study of Laser Scribing Quality through Cross-Section Scribing Profiles. Micromachines 2023, 14, 2020. https://doi.org/10.3390/mi14112020

Chen R, Chang S, Lei S. An Exploratory Study of Laser Scribing Quality through Cross-Section Scribing Profiles. Micromachines. 2023; 14(11):2020. https://doi.org/10.3390/mi14112020

Chicago/Turabian StyleChen, Ruqi, Shing Chang, and Shuting Lei. 2023. "An Exploratory Study of Laser Scribing Quality through Cross-Section Scribing Profiles" Micromachines 14, no. 11: 2020. https://doi.org/10.3390/mi14112020

APA StyleChen, R., Chang, S., & Lei, S. (2023). An Exploratory Study of Laser Scribing Quality through Cross-Section Scribing Profiles. Micromachines, 14(11), 2020. https://doi.org/10.3390/mi14112020