U-Shaped Tube Based Liquid–Solid Triboelectric Nanogenerator for Harvesting Unutilized Compressed Air Energy

Abstract

:1. Introduction

2. Materials and Methods

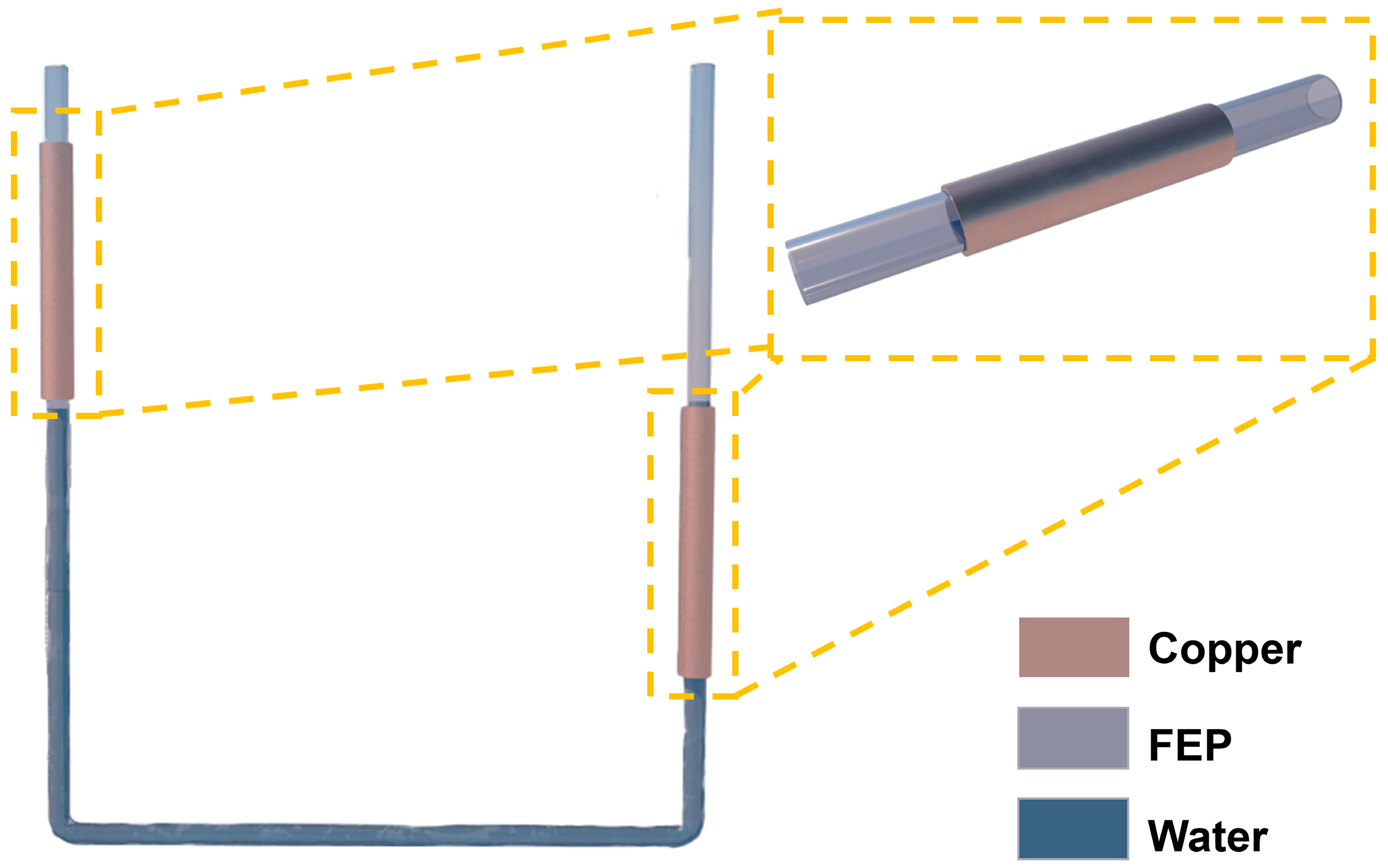

2.1. Fabrication of the UFC-TENG

2.2. Characterization and Measurement

3. Results and Discussion

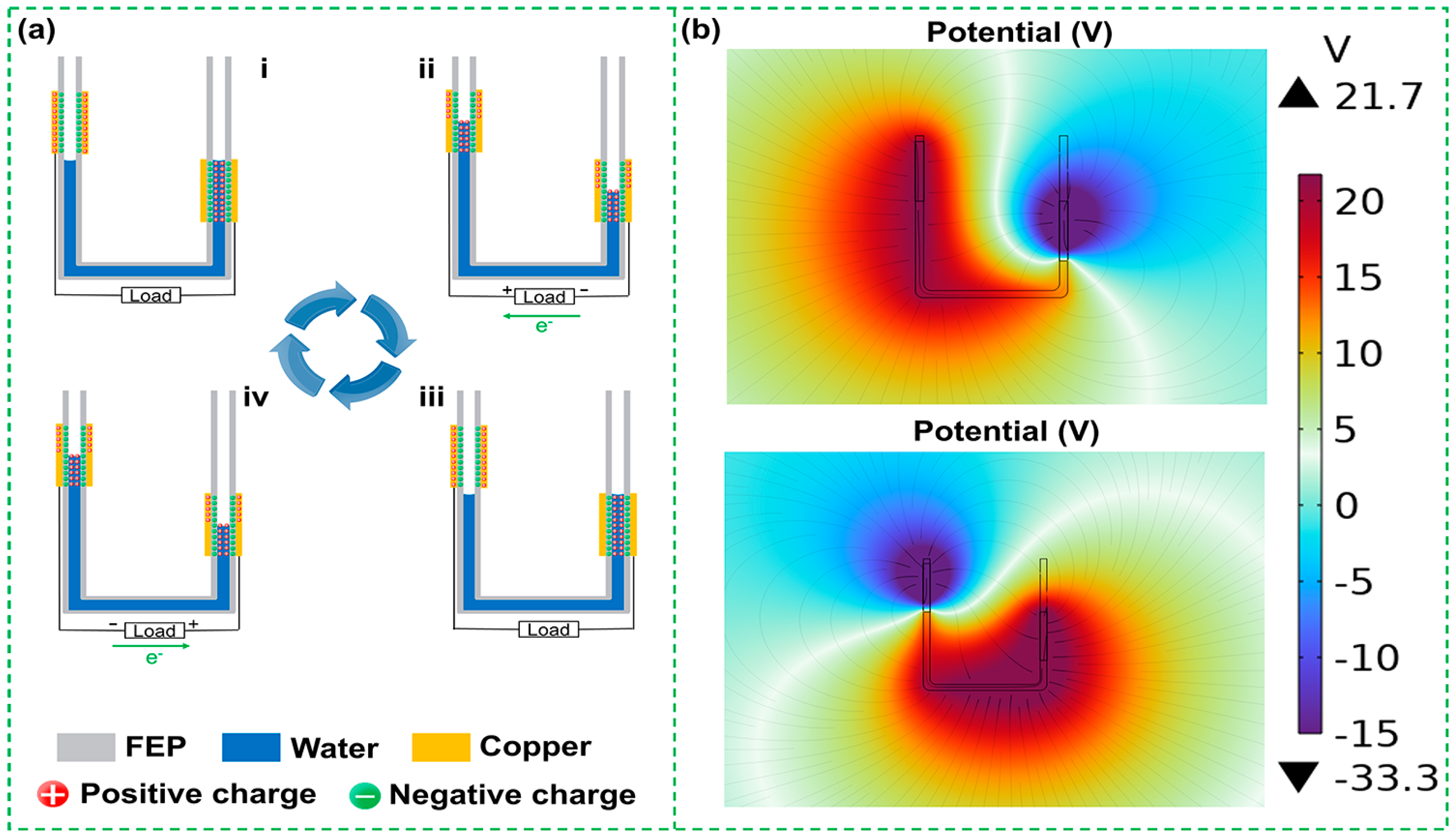

3.1. Structure Design and Working Principles of the UFC-TENG

3.2. Optimization of the UFC-TENG

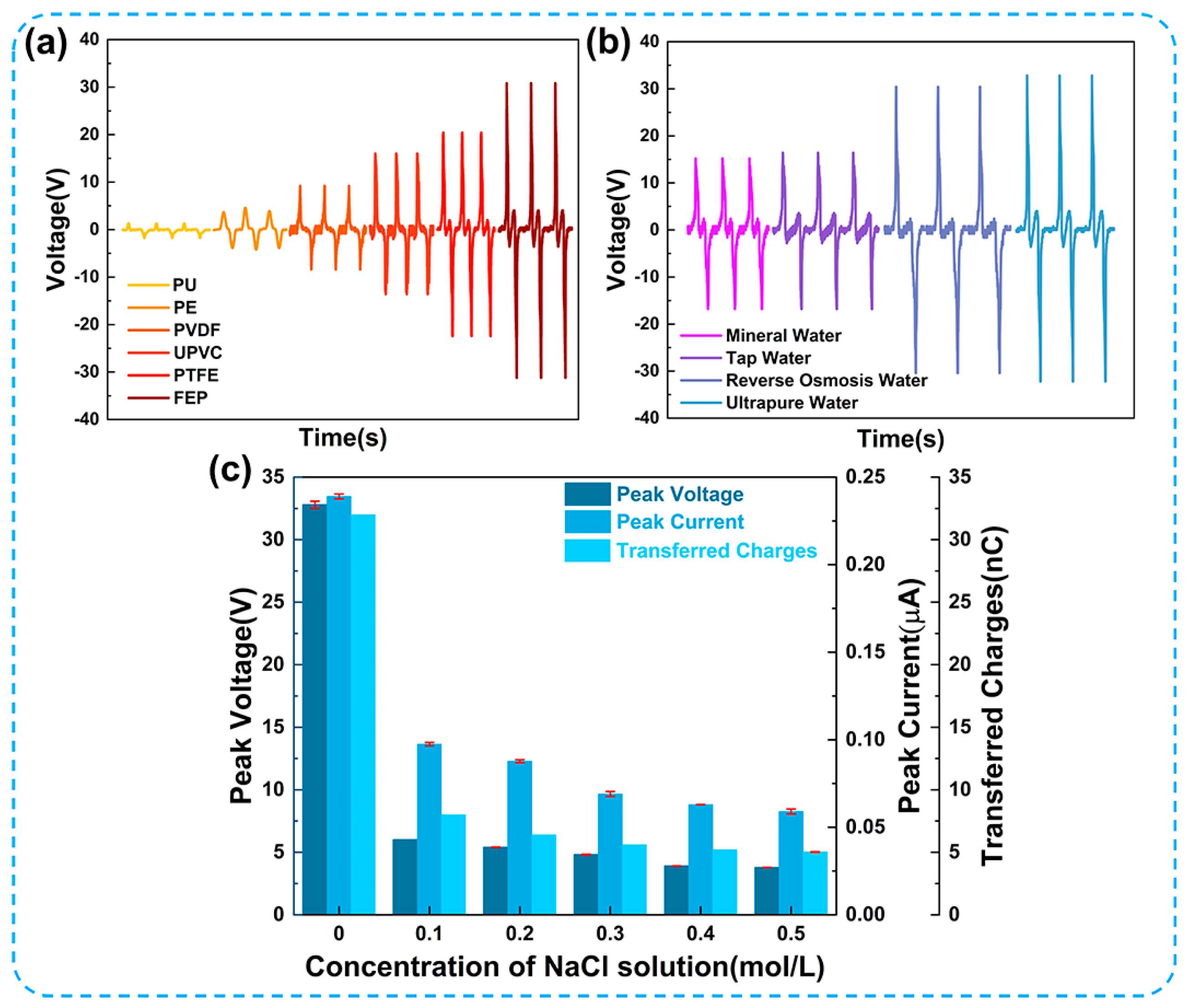

3.2.1. Influence of Tube Materials and Water Quality

3.2.2. Influence of Tube Structure Parameters

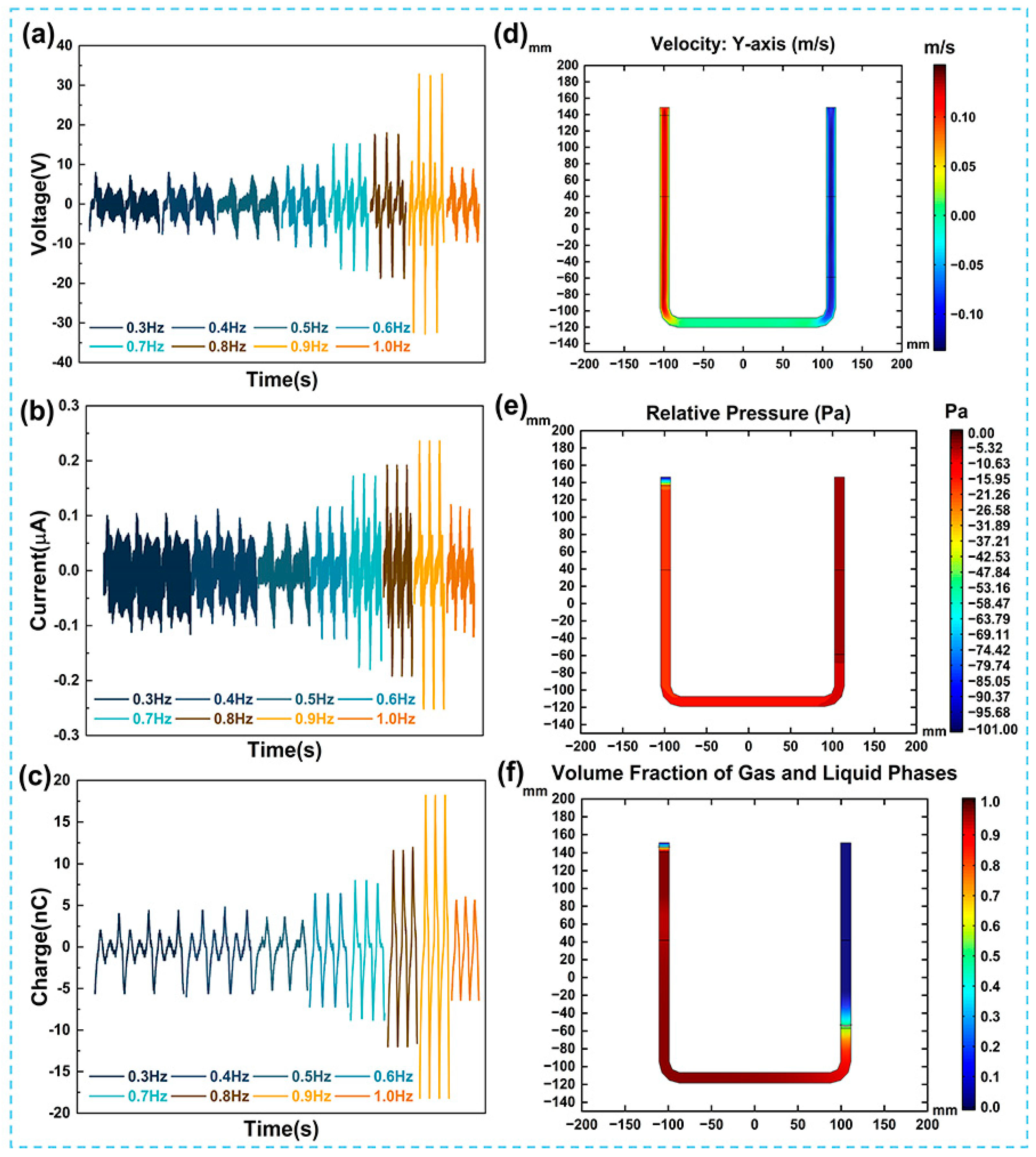

3.2.3. Influence of Liquid Flow Characteristics

3.2.4. Stability Testing

3.3. Applications of the UFC-TENG

- (1)

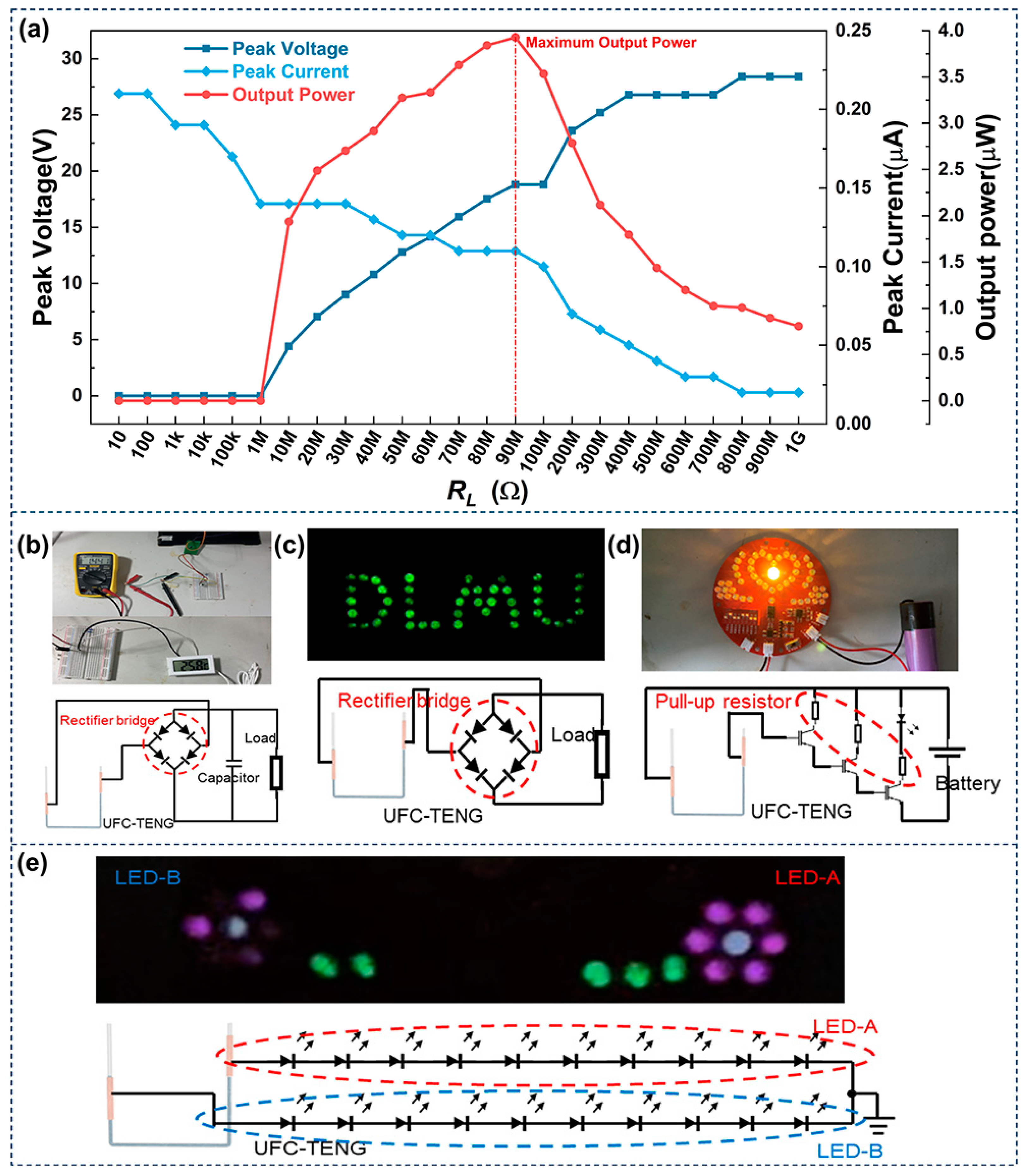

- The UFC-TENG can store electric energy in capacitors and use it to drive small electronic devices such as sensors. As shown in Figure 7b, the alternating current of the UFC-TENG is rectified by a full wave rectifier circuit and charged by a 100 μF capacitor. Subsequently, the connection between the UFC-TENG and the capacitor is disconnected, and the capacitor is connected to a temperature and humidity sensor. The capacitor can drive a simple temperature and humidity sensor.

- (2)

- The UFC-TENG can be used as a DC power supply to light up LEDs. LED lights are very common in our daily lives, serving various purposes such as creating atmospheres, decorating storefronts, and providing illumination. The UFC-TENG designed in this work can easily light up at least 40 LEDs after being rectified by a full wave rectifier circuit. The corresponding demonstration and circuit diagram are shown in Figure 7c and Video S1.

- (3)

- The UFC-TENG can be used as a signal collector and realize signal analysis and processing by connecting with other devices. Low-frequency signals can penetrate obstacles during the transmission process, demonstrating strong penetration ability and long transmission distances. The UFC-TENG can use an amplifier composed of transistors to acquire low-frequency signals. The corresponding circuit schematic diagram is illustrated in Figure 7d, and a detailed video demonstration is shown in Video S2. It can be seen from the demonstration that the UFC-TENG can transform the mechanical signals of liquid motion into weak electrical signals and be amplified through amplification circuits. As the alternating frequency of the liquid changes, the brightness flashing times of the small bulb are different. When the liquid is in its initial state and stops moving, the small bulb no longer lights up.

- (4)

- The UFC-TENG can be used as a self-powered sensor. With the rapid development of the Internet of Things, a huge number of sensors are distributed in every corner of the world. It is almost impossible to provide power for this amazing number of sensors with traditional batteries. Therefore, many scholars have dedicated themselves to the research of self-powered sensors. By connecting the UFC-TENG to the circuit shown in Figure 7e, when the liquid inside the UFC-TENG moves towards the right end, the current flows in the direction of the grounding end. At this time, the LED-A circuit is switched on, and the LEDs on this circuit light up. On the contrary, when the liquid inside the UFC-TENG moves towards the left end, the current flows in the direction of outflow from the ground end. At this time, the LED-B circuit is switched on, and the LEDs on this circuit light up. When the liquid alternately rises inside the UFC-TENG, the LEDs on the LED-A and LED-B circuits light up alternately. Therefore, observing the changes in the quantity and brightness of small light bulbs of LEDs can allow for the operation status of the equipment integrated with the UFC-TENG to be monitored.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, D.; Gao, Y.; Zhou, L.; Wang, J.; Wang, Z.L. Recent advances in high-performance triboelectric nanogenerators. Nano Res. 2023, 16, 11698–11717. [Google Scholar] [CrossRef]

- Jiang, D.; Lian, M.; Xu, M.; Sun, Q.; Xu, B.B.; Thabet, H.K.; El-Bahy, S.M.; Ibrahim, M.M.; Huang, M.; Guo, Z. Advances in triboelectric nanogenerator technology—Applications in self-powered sensors, Internet of things, biomedicine, and blue energy. Adv. Compos. Hybrid Mater. 2023, 6, 57. [Google Scholar] [CrossRef]

- Choi, D.; Lee, Y.; Lin, Z.-H.; Cho, S.; Kim, M.; Ao, C.K.; Soh, S.; Sohn, C.; Jeong, C.K.; Lee, J.; et al. Recent Advances in Triboelectric Nanogenerators: From Technological Progress to Commercial Applications. ACS Nano 2023, 17, 11087–11219. [Google Scholar] [CrossRef] [PubMed]

- Zhao, E.; Jiang, K.; Li, B.; Liu, X.; Zeng, F.; Chen, L.; Zhang, H.; Zhu, Z. Classification and utilization of waste electronic components based on triboelectric nanogenerator. Nanotechnology 2022, 33, 495401. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Jiang, T.; Xu, L. Toward the blue energy dream by triboelectric nanogenerator networks. Nano Energy 2017, 39, 9–23. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, G.; Bu, T.; Zhang, C. Effects of interfacial acid-base on the performance of contact-separation mode triboelectric nanogenerator. Mater. Today Energy 2021, 20, 100686. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, X.; Li, H.; Li, H.; Li, Z. Effect of humidity on tribological properties and electrification performance of sliding-mode triboelectric nanogenerator. Nano Energy 2020, 71, 104640. [Google Scholar] [CrossRef]

- Zhou, Q.; Lee, K.; Kim, K.N.; Park, J.G.; Pan, J.; Bae, J.; Baik, J.M.; Kim, T. High humidity- and contamination-resistant triboelectric nanogenerator with superhydrophobic interface. Nano Energy 2019, 57, 903–910. [Google Scholar] [CrossRef]

- Shen, J.; Li, Z.; Yu, J.; Ding, B. Humidity-resisting triboelectric nanogenerator for high performance biomechanical energy harvesting. Nano Energy 2017, 40, 282–288. [Google Scholar] [CrossRef]

- Luo, J.; Wang, Z.; Xu, L.; Wang, A.C.; Han, K.; Jiang, T.; Lai, Q.; Bai, Y.; Tang, W.; Fan, F.R.; et al. Flexible and durable wood-based triboelectric nanogenerators for self-powered sensing in athletic big data analytics. Nat. Commun. 2019, 10, 5147. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Zhao, Z.; Li, S.; Liu, Y.; Liu, L.; Gao, Y.; Wang, Z.L.; Wang, J. Simultaneously Enhancing Power Density and Durability of Sliding-Mode Triboelectric Nanogenerator via Interface Liquid Lubrication. Adv. Energy Mater. 2020, 10, 2022920. [Google Scholar] [CrossRef]

- Le, C.-D.; Vo, C.-P.; Vu, D.-L.; Nguyen, T.-H.; Ahn, K.K. Water electrification based triboelectric nanogenerator integrated harmonic oscillator for waste mechanical energy harvesting. Energy Convers. Manag. 2022, 251, 115014. [Google Scholar] [CrossRef]

- Yu, J.; Ma, T. Triboelectricity-based self-charging droplet capacitor for harvesting low-level ambient energy. Nano Energy 2020, 74, 104795. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Y.; Cai, H.; Yao, M.; Zhang, H.; Guo, L.; Lv, Z.; Li, M.; Lu, X.; Ren, C.; et al. A Single-Droplet Electricity Generator Achieves an Ultrahigh Output Over 100 V without Pre-Charging. Adv. Mater. 2021, 33, 2105761. [Google Scholar] [CrossRef] [PubMed]

- Luo, H.; Gu, G.; Shang, W.; Zhang, W.; Cui, P.; Zhang, B.; Guo, J.; Zheng, M.; Cheng, G.; Du, Z. Interactive-excited waterdrop triboelectric nanogenerator with ultrahigh charge density and instantaneous power. Nano Energy 2022, 97, 107158. [Google Scholar] [CrossRef]

- Xu, Q.; Shang, C.; Ma, H.; Hong, Q.; Li, C.; Ding, S.; Xue, L.; Sun, X.; Pan, Y.; Sugahara, T.; et al. A guided-liquid-based hybrid triboelectric nanogenerator for omnidirectional and high-performance ocean wave energy harvesting. Nano Energy 2023, 109, 108240. [Google Scholar] [CrossRef]

- Zhang, Q.; He, M.; Pan, X.; Huang, D.; Long, H.; Jia, M.; Zhao, Z.; Zhang, C.; Xu, M.; Li, S. High performance liquid-solid tubular triboelectric nanogenerator for scavenging water wave energy. Nano Energy 2022, 103, 107810. [Google Scholar] [CrossRef]

- Sun, X.; Shang, C.; Ma, H.; Li, C.; Xue, L.; Xu, Q.; Wei, Z.; Li, W.; Yalikun, Y.; Lai, Y.-C.; et al. A tube-shaped solid–liquid-interfaced triboelectric–electromagnetic hybrid nanogenerator for efficient ocean wave energy harvesting. Nano Energy 2022, 100, 107540. [Google Scholar] [CrossRef]

- Zhu, G.; Su, Y.; Bai, P.; Chen, J.; Jing, Q.; Yang, W.; Wang, Z.L. Harvesting water wave energy by asymmetric screening of electrostatic charges on a nanostructured hydrophobic thin-film surface. ACS Nano 2014, 8, 6031. [Google Scholar] [CrossRef]

- Zhou, Q.; Wang, B.; Gao, A.; Xu, W.; Zhou, K.; Pan, J.; Meng, G.; Pan, C.; Xia, F. Solution-Tube-Based Volume Effect Triboelectric Nanogenerator with Salt and pH Sensitivity. Adv. Funct. Mater. 2022, 32, 2209100. [Google Scholar] [CrossRef]

- Wu, H.; Wang, Z.; Zi, Y. Multi-Mode Water-Tube-Based Triboelectric Nanogenerator Designed for Low-Frequency Energy Harvesting with Ultrahigh Volumetric Charge Density. Adv. Energy Mater. 2021, 11, 2100038. [Google Scholar] [CrossRef]

- Cha, K.; Chung, J.; Heo, D.; Song, M.; Chung, S.-H.; Hwang, P.T.J.; Kim, D.; Koo, B.; Hong, J.; Lee, S. Lightweight mobile stick-type water-based triboelectric nanogenerator with amplified current for portable safety devices. Sci Technol. Adv. Mater. 2022, 23, 161–168. [Google Scholar] [CrossRef] [PubMed]

- Zhan, T.; Zou, H.; Zhang, H.; He, P.; Liu, Z.; Chen, J.; He, M.; Zhang, Y.; Wang, Z.L. Smart liquid-piston based triboelectric nanogenerator sensor for real-time monitoring of fluid status. Nano Energy 2023, 111, 108419. [Google Scholar] [CrossRef]

- Munirathinam, K.; Prasad, G.; Kim, D.S.; Park, J.; Lee, D.W. Liquid-Metal-Based Stretchable Triboelectric Nanogenerators for Flowing-Liquid-Based Energy Harvesting and Self-Powered Sensor Applications. Adv. Mater. Technol. 2023, 8, 2201902. [Google Scholar] [CrossRef]

- Wang, J.; Xia, K.; Liu, J.; Li, T.; Zhao, X.; Shu, B.; Li, H.; Guo, J.; Yu, M.; Tang, W.; et al. Self-powered silicon PIN photoelectric detection system based on triboelectric nanogenerator. Nano Energy 2020, 69, 104461. [Google Scholar] [CrossRef]

- Zhao, H.; Xu, M.; Shu, M.; An, J.; Ding, W.; Liu, X.; Wang, S.; Zhao, C.; Yu, H.; Wang, H.; et al. Underwater wireless communication via TENG-generated Maxwell’s displacement current. Nat. Commun. 2022, 13, 3325. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, B.; Yuan, W.; Yang, O.; Liu, Y.; He, L.; Zhao, Z.; Zhou, L.; Wang, J.; Wang, Z.L. Seawater-Based Triboelectric Nanogenerators for Marine Anticorrosion. ACS Appl. Mater. Inter. 2022, 14, 8605–8612. [Google Scholar] [CrossRef] [PubMed]

- Raisch, A.; Sawodny, O. Modeling and Analysis of Pneumatic Cushioning Systems Under Energy-Saving Measures. IEEE Trans. Autom. Sci. Eng. 2020, 17, 1388–1398. [Google Scholar] [CrossRef]

- Saidur, R.; Rahim, N.A.; Hasanuzzaman, M. A review on compressed-air energy use and energy savings. Renew. Sustain. Energy Rev. 2010, 14, 1135–1153. [Google Scholar] [CrossRef]

- Harris, P.; Nolan, S.; O’Donnell, G.E. Energy optimisation of pneumatic actuator systems in manufacturing. J. Clean. Prod. 2014, 72, 35–45. [Google Scholar] [CrossRef]

- Pan, L.; Wang, J.; Wang, P.; Gao, R.; Wang, Y.C.; Zhang, X.; Zou, J.J.; Wang, Z.L. Liquid-FEP-based U-tube triboelectric nanogenerator for harvesting water-wave energy. Nano Res. 2018, 11, 4062–4073. [Google Scholar] [CrossRef]

- Xu, W.; Yang, J.; Liu, S.; Meng, Y.; Feng, D.; Jia, L.; Liu, S.; Wang, B.; Li, X. An instantaneous discharging liquid-solid triboelectric nanogenerator (IDLS-TENG) with boosted peak power output. Nano Energy 2021, 86, 106093. [Google Scholar] [CrossRef]

- Guo, X.; Shao, J.; Willatzen, M.; Wang, X.; Wang, Z.L. Quantifying Output Power and Dynamic Charge Distribution in Sliding Mode Freestanding Triboelectric Nanogenerator. Adv. Phys. Res. 2022, 2, 2200039. [Google Scholar] [CrossRef]

- Chen, X.; LIU, Z.; WANG, Z. The process of interfacial electron transfer in liquid-solid contact and the two-step mechanism model of EDL structure. Sci. Sin. Technol. 2023, 53, 844–859. [Google Scholar] [CrossRef]

- Wang, N.; Liu, Y.; Ye, E.; Li, Z.; Wang, D. Contact Electrification Behaviors of Solid–Liquid Interface: Regulation, Mechanisms, and Applications. Adv. Energy Sustain. Res. 2023, 4, 2200186. [Google Scholar] [CrossRef]

- Burgo, T.A.L.; Galembeck, F.; Pollack, G.H. Where is water in the triboelectric series? J. Electrost. 2016, 80, 30–33. [Google Scholar] [CrossRef]

- Cai, C.; Luo, B.; Liu, Y.; Fu, Q.; Liu, T.; Wang, S.; Nie, S. Advanced triboelectric materials for liquid energy harvesting and emerging application. Mater. Today 2021, 52, 299–326. [Google Scholar] [CrossRef]

- Li, S.; Nie, J.; Shi, Y.; Tao, X.; Wang, F.; Tian, J.; Lin, S.; Chen, X.; Wang, Z.L. Contributions of Different Functional Groups to Contact Electrification of Polymers. Adv. Mater. 2020, 32, 2001307. [Google Scholar] [CrossRef]

- Chi, J.; Liu, C.; Che, L.; Li, D.; Fan, K.; Li, Q.; Yang, W.; Dong, L.; Wang, G.; Wang, Z.L. Harvesting Water-Evaporation-Induced Electricity Based on Liquid–Solid Triboelectric Nanogenerator. Adv. Sci. 2022, 9, 2201586. [Google Scholar] [CrossRef]

- Jiang, D.; Fan, Z.; Wang, H.; Xu, M.; Chen, G.; Song, Y.; Wang, Z.L. Triboelectric Nanogenerator Powered Electrowetting-on-Dielectric Actuator for Concealed Aquatic Microbots. ACS Nano 2020, 14, 15394–15402. [Google Scholar] [CrossRef]

- Munirathinam, K.; Kim, D.-S.; Shanmugasundaram, A.; Park, J.; Jeong, Y.-J.; Lee, D.-W. Flowing water-based tubular triboelectric nanogenerators for sustainable green energy harvesting. Nano Energy 2022, 102, 107675. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, Y.; Wang, D.; Zhou, F. Solid-liquid triboelectrification in smart U-tube for multifunctional sensors. Nano Energy 2017, 40, 95–106. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, X.; Liu, Z.; Dong, J.; Li, H.; Han, J.; Huang, J.; Chen, H. U-Shaped Tube Based Liquid–Solid Triboelectric Nanogenerator for Harvesting Unutilized Compressed Air Energy. Micromachines 2023, 14, 2057. https://doi.org/10.3390/mi14112057

Cai X, Liu Z, Dong J, Li H, Han J, Huang J, Chen H. U-Shaped Tube Based Liquid–Solid Triboelectric Nanogenerator for Harvesting Unutilized Compressed Air Energy. Micromachines. 2023; 14(11):2057. https://doi.org/10.3390/mi14112057

Chicago/Turabian StyleCai, Xuhang, Zhijian Liu, Jingming Dong, Haoji Li, Jiamu Han, Jiaming Huang, and Haotian Chen. 2023. "U-Shaped Tube Based Liquid–Solid Triboelectric Nanogenerator for Harvesting Unutilized Compressed Air Energy" Micromachines 14, no. 11: 2057. https://doi.org/10.3390/mi14112057

APA StyleCai, X., Liu, Z., Dong, J., Li, H., Han, J., Huang, J., & Chen, H. (2023). U-Shaped Tube Based Liquid–Solid Triboelectric Nanogenerator for Harvesting Unutilized Compressed Air Energy. Micromachines, 14(11), 2057. https://doi.org/10.3390/mi14112057