Experimental Study on the Roundness of Deep Holes in 7075 Aluminum Alloy Parts by Two-Dimensional Ultrasonic Elliptical Vibration Boring

Abstract

:1. Introduction

2. Analysis of Kinematics Characteristics of Deep Hole Boring

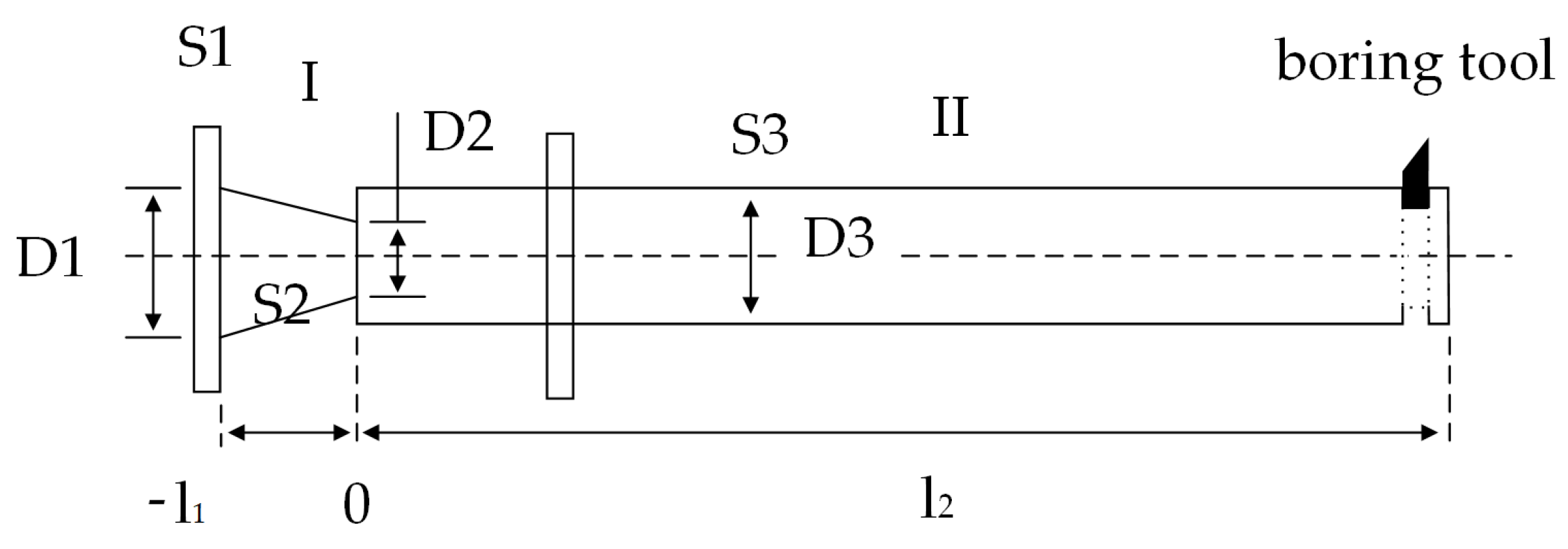

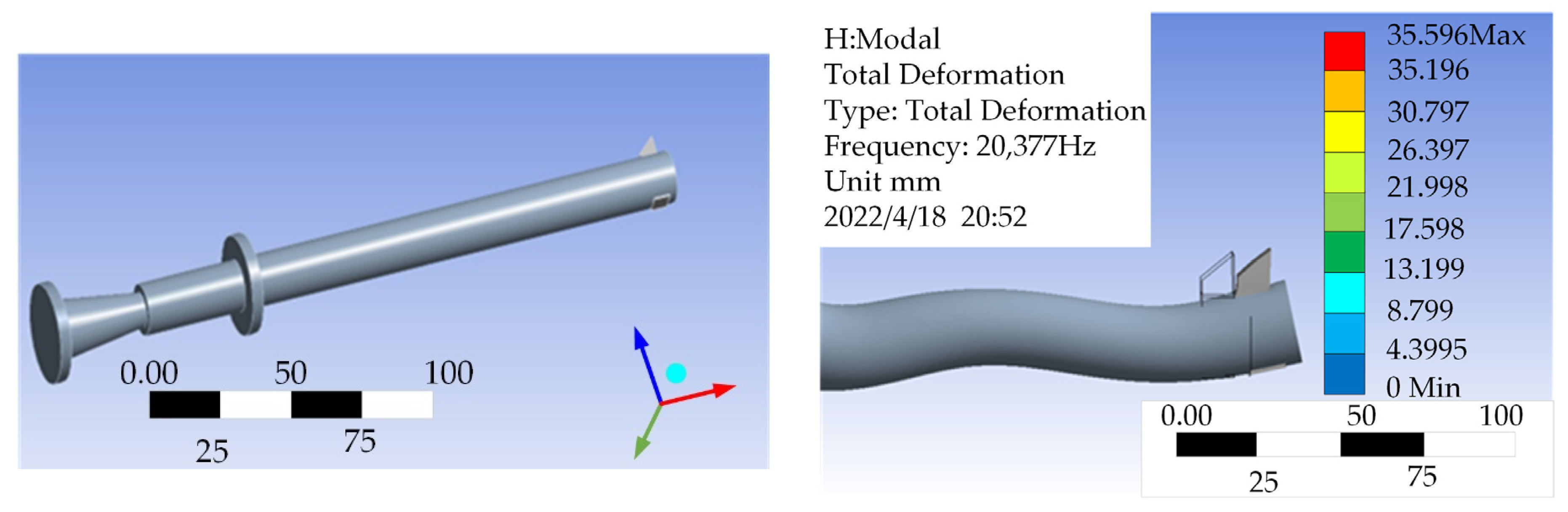

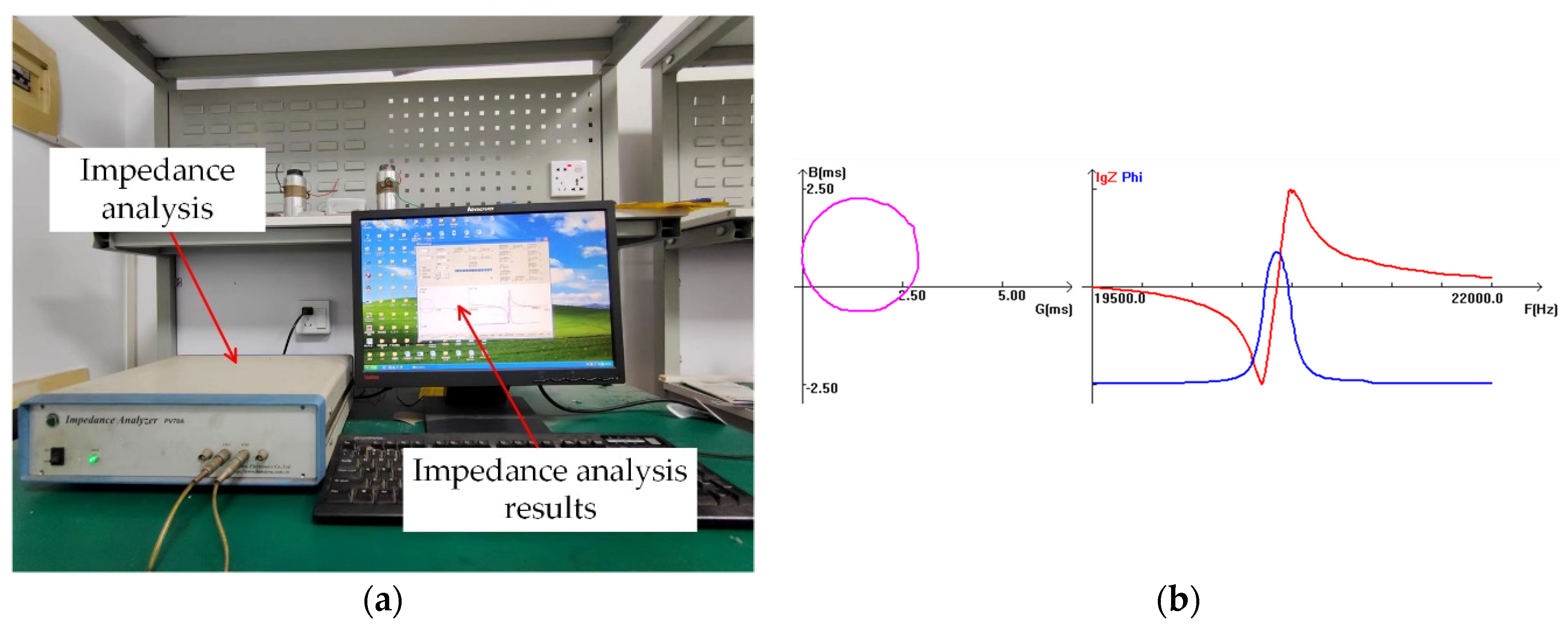

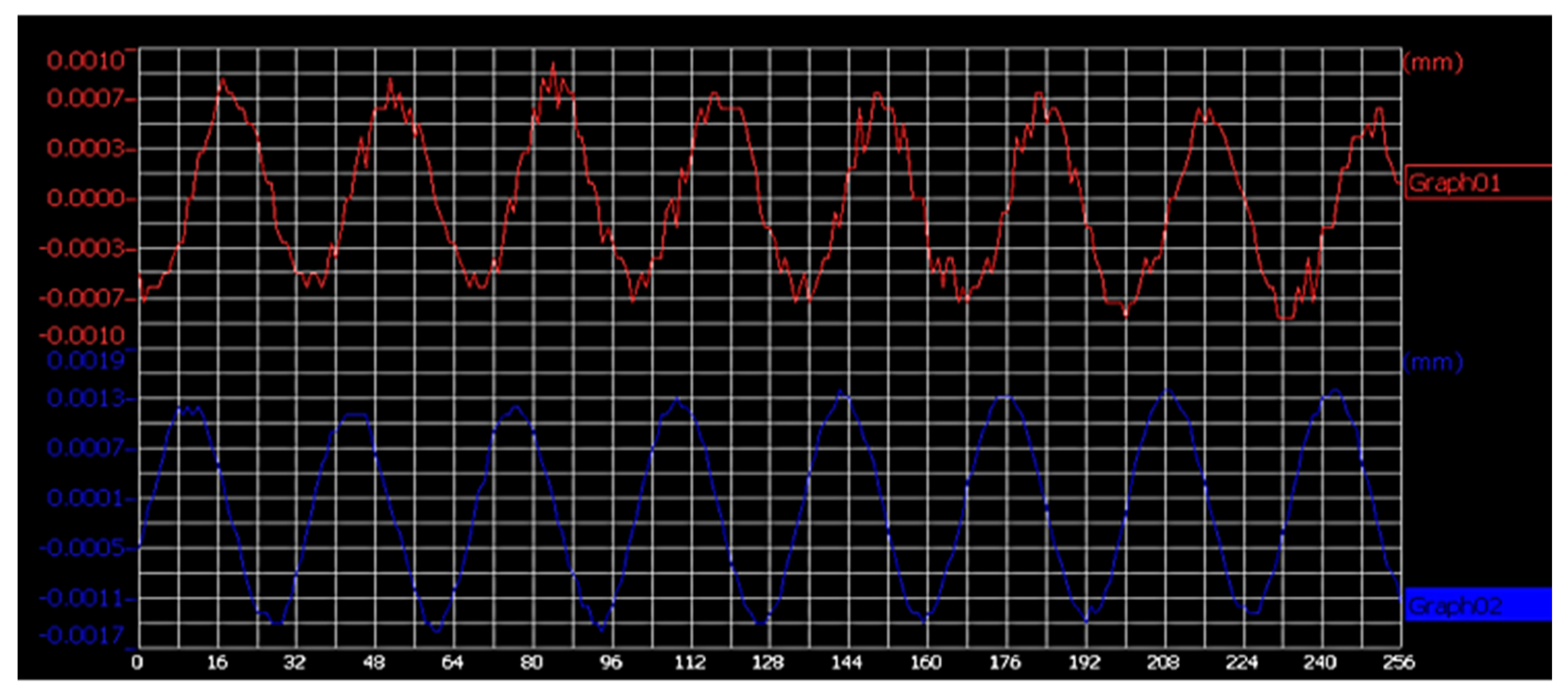

2.1. Design and Analysis Testing of Two-Dimensional Ultrasonic Vibration Boring Tool

2.2. Kinematics Model of Ultrasonic Elliptical Vibration Turning

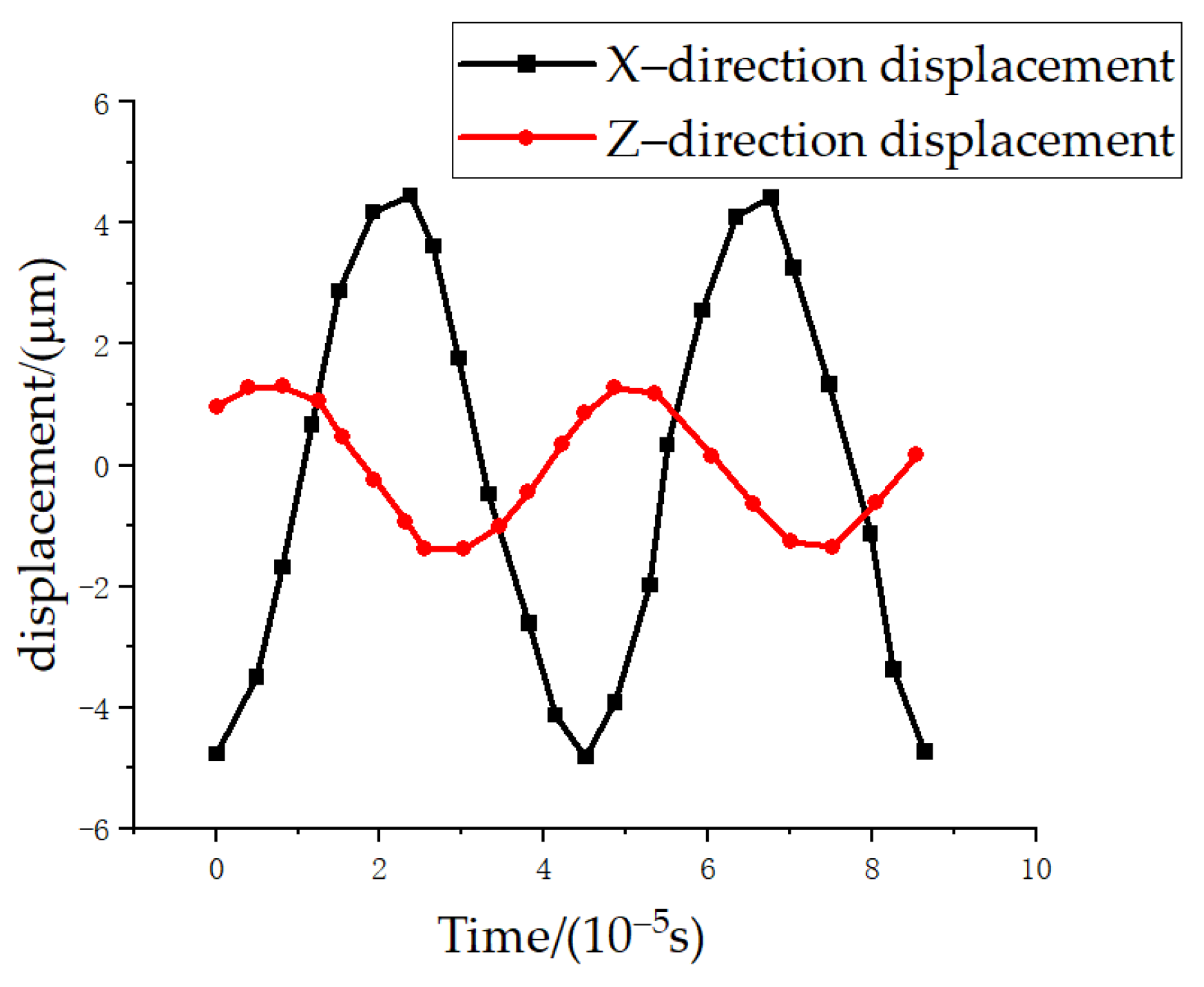

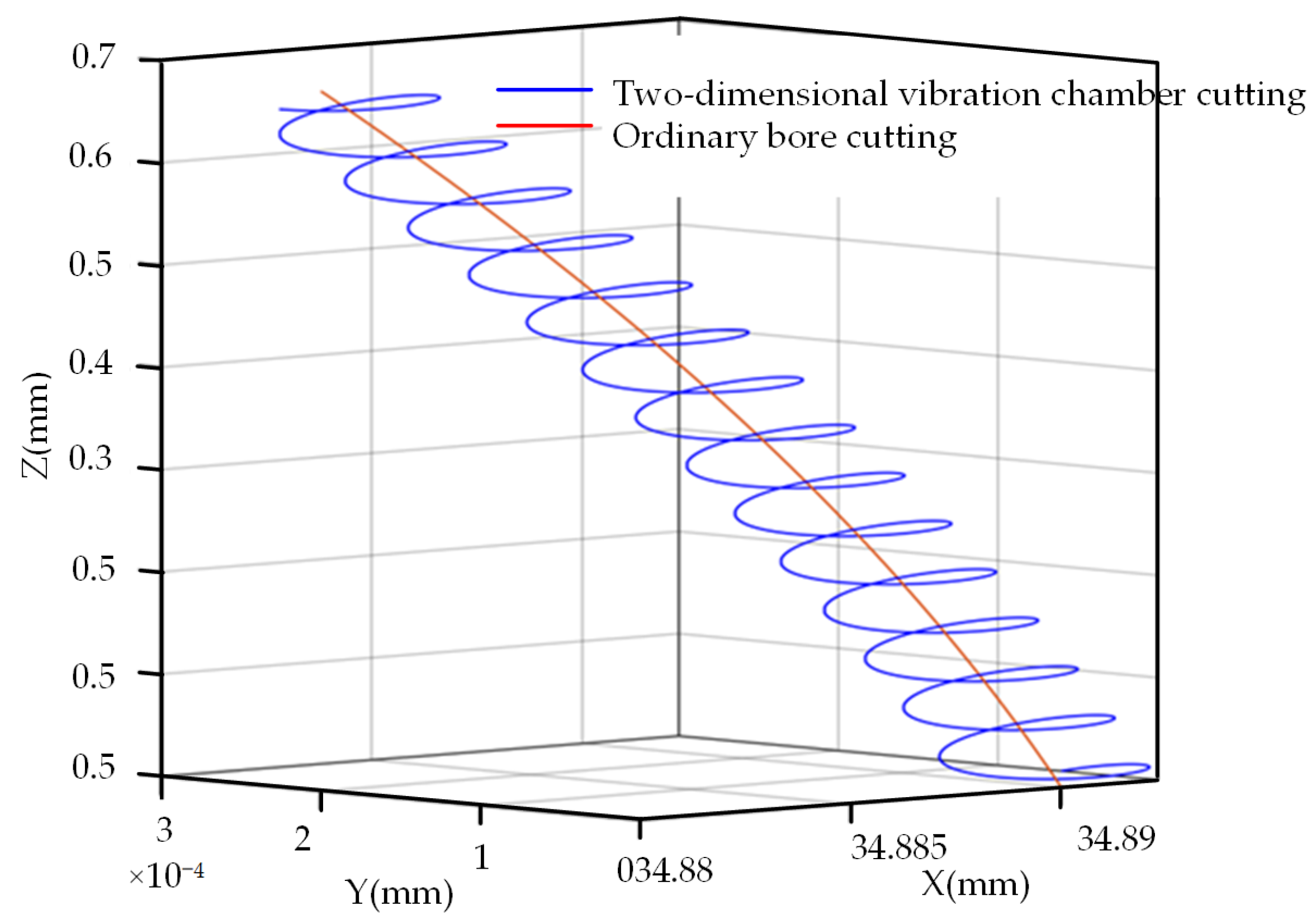

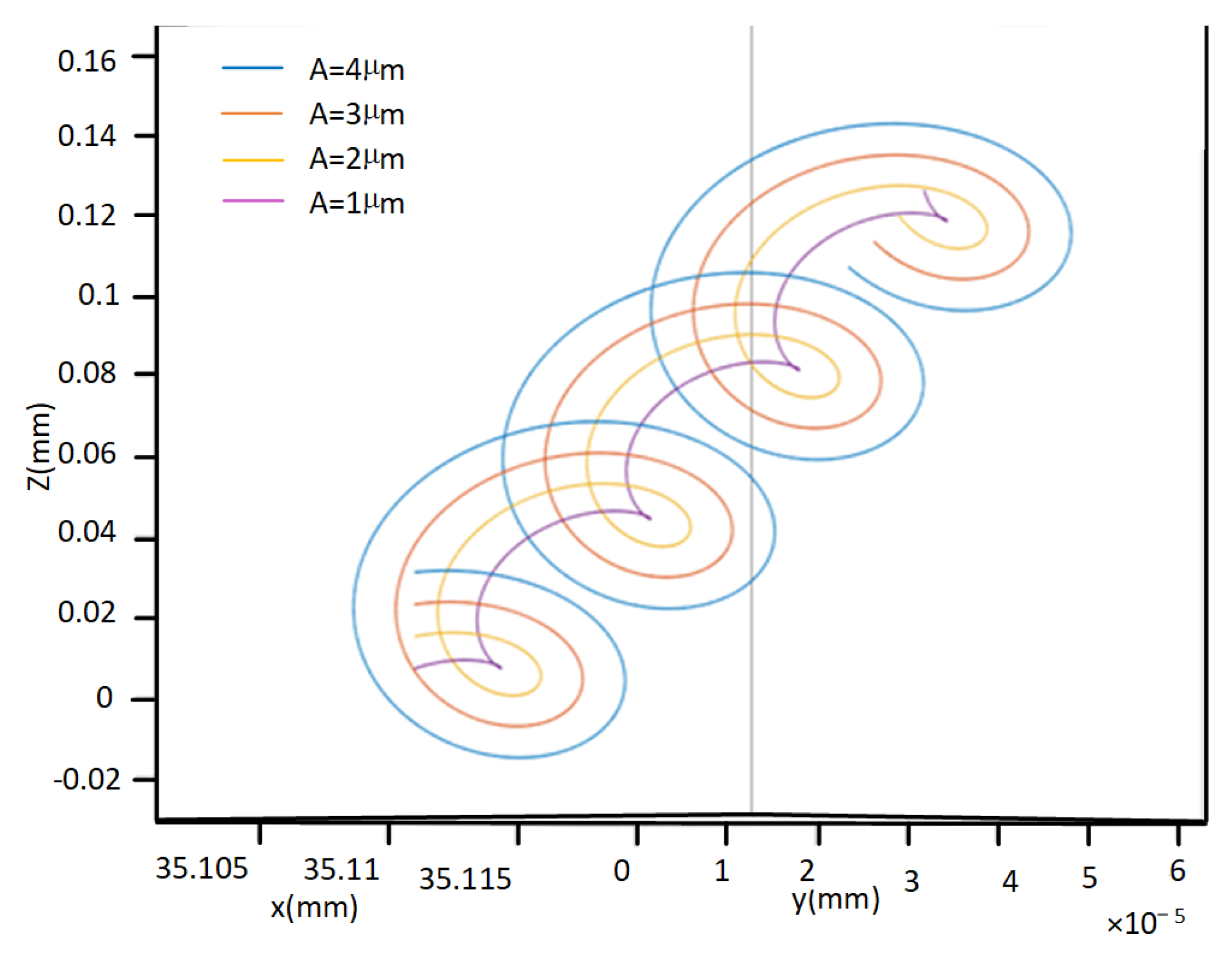

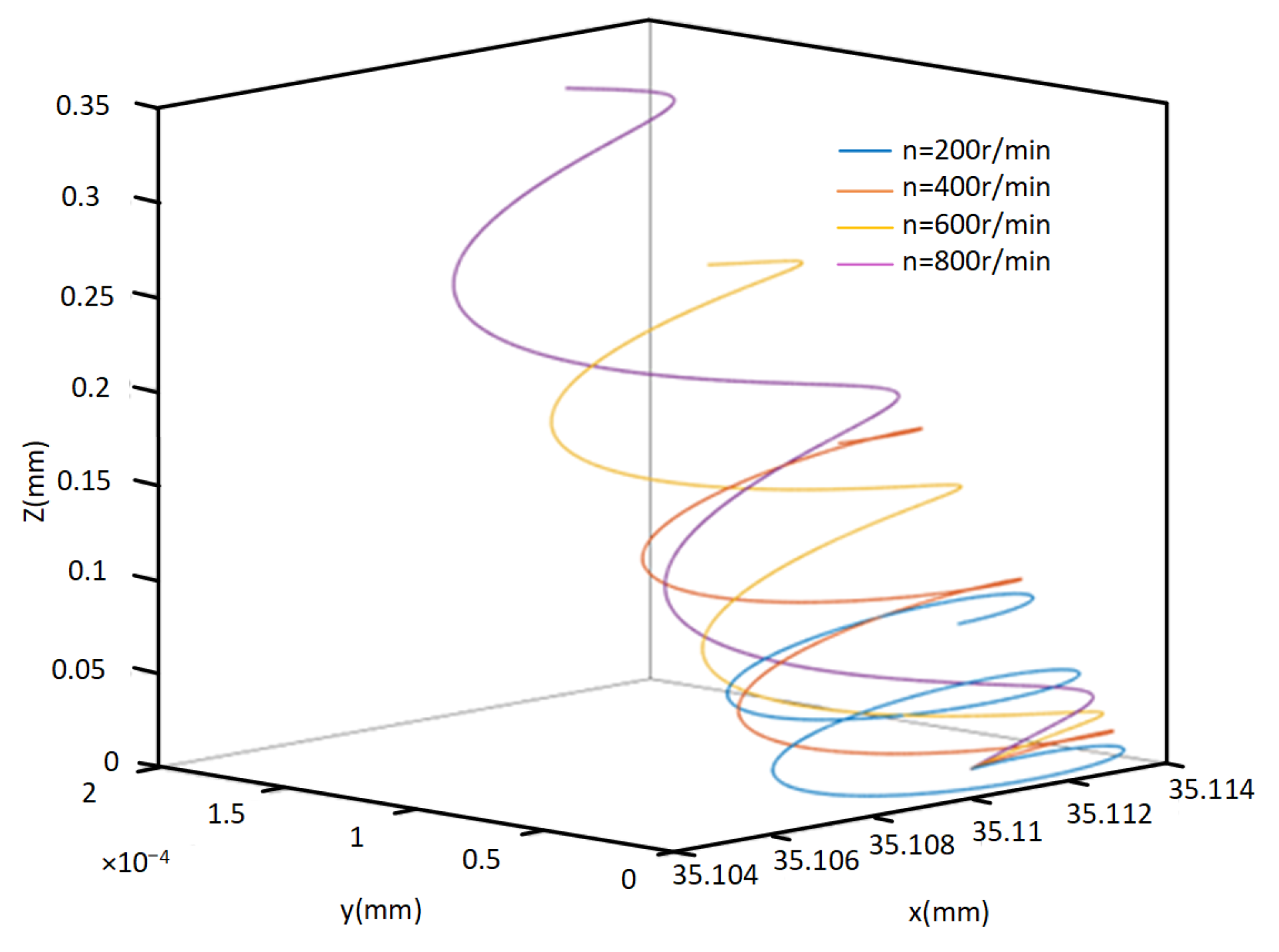

2.3. Simulation of Cutting Edge Motion Trajectory

- 1.

- The Effect of Ultrasonic Amplitude on Cutting Edge Trajectory

- 2.

- The Influence of Rotational Speed on Cutting Edge Trajectory

- 3.

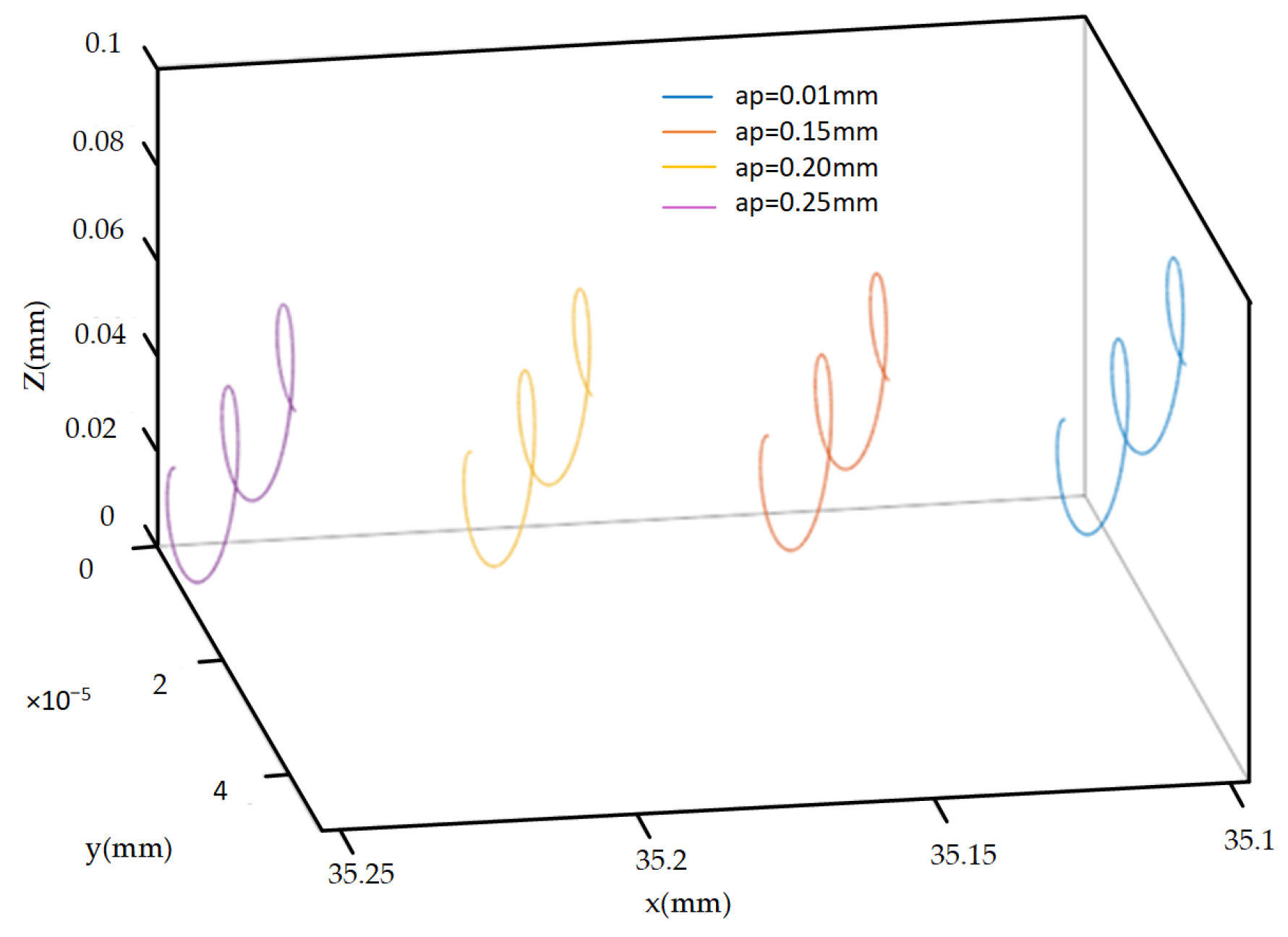

- The Influence of Cutting Depth on Cutting Edge Trajectory

- 4.

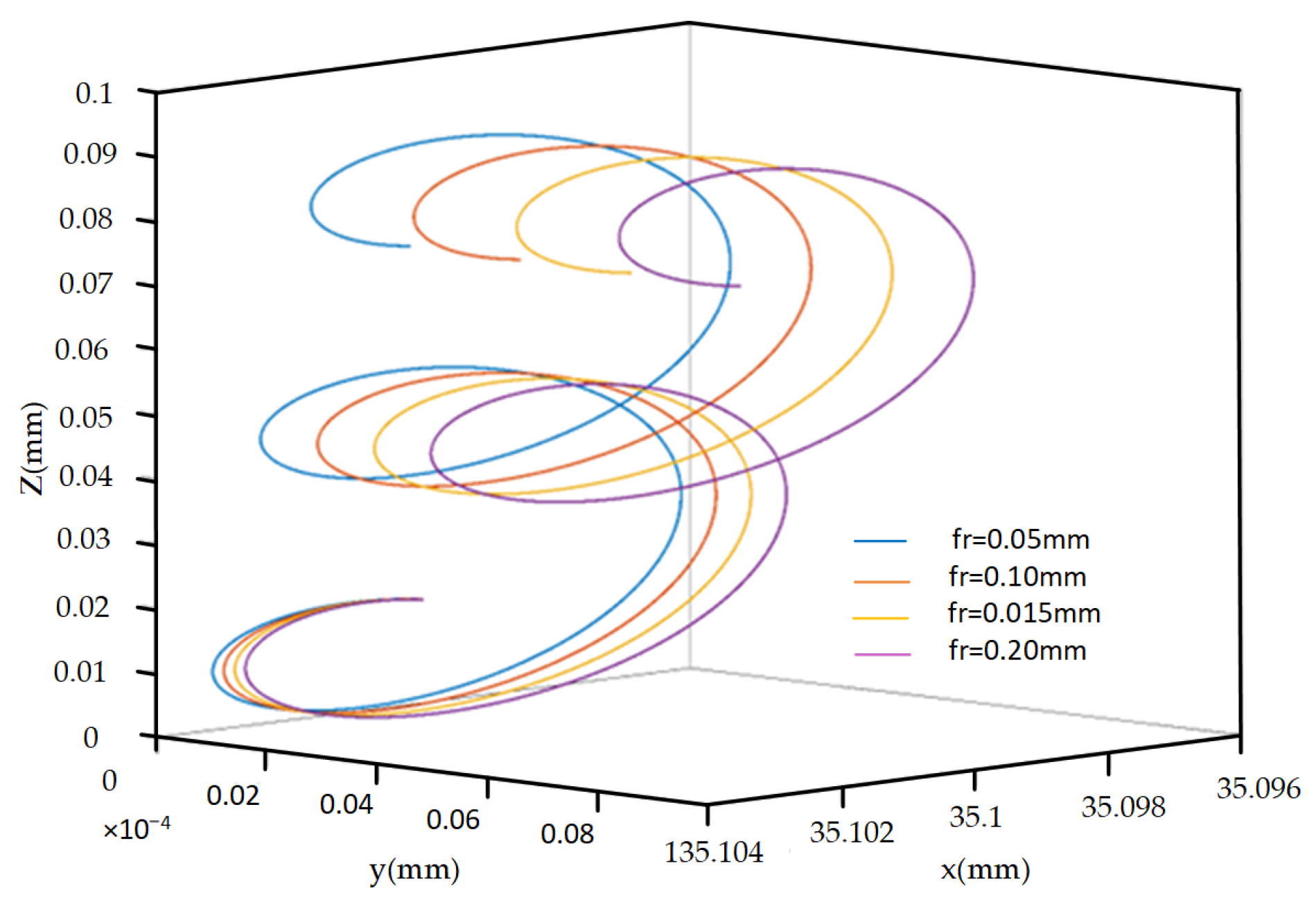

- The Influence of Feed Rate on Cutting Edge Trajectory

3. Design of Experiments and Method

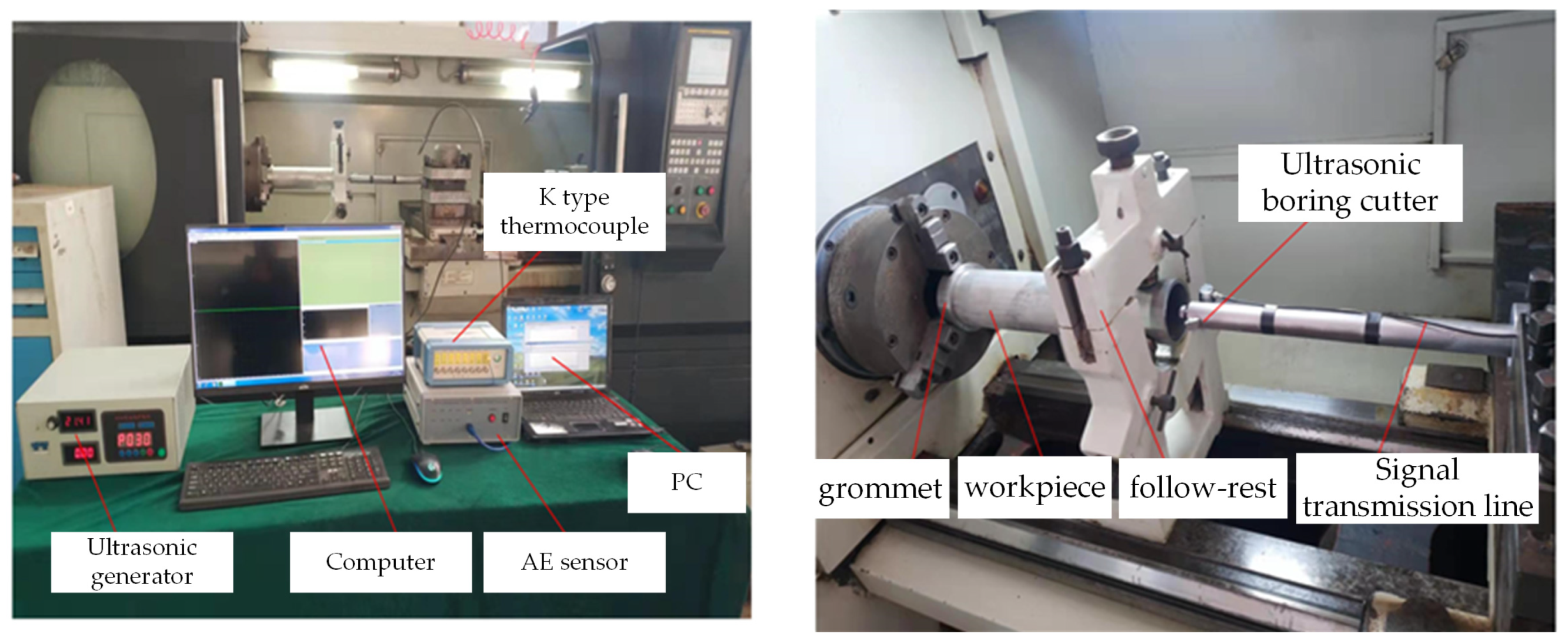

3.1. Construction of Experimental Platform

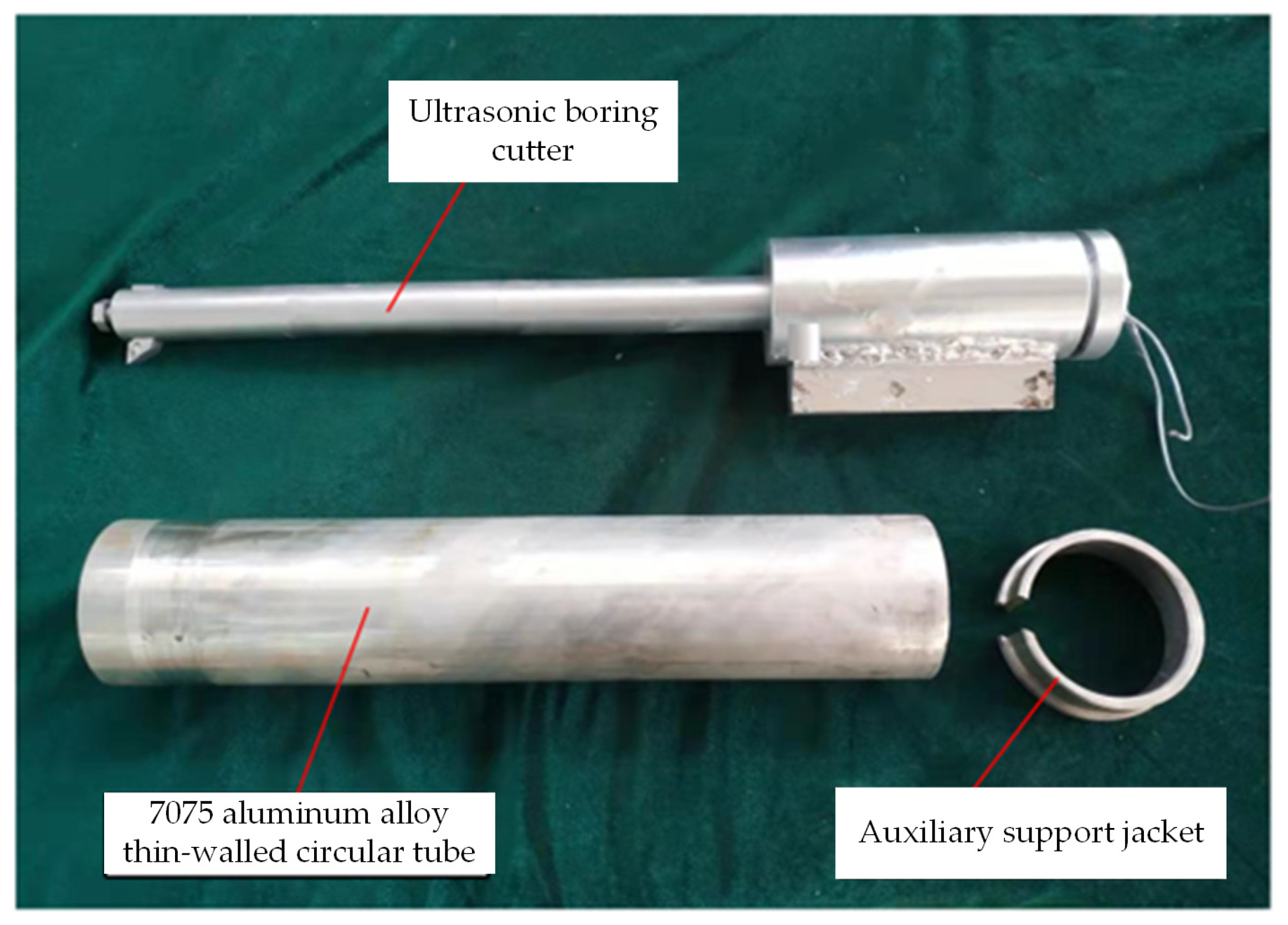

3.2. Test Materials

3.3. Design of Experimental Plan

3.4. Test Result Detection

4. Experimental Results and Analysis

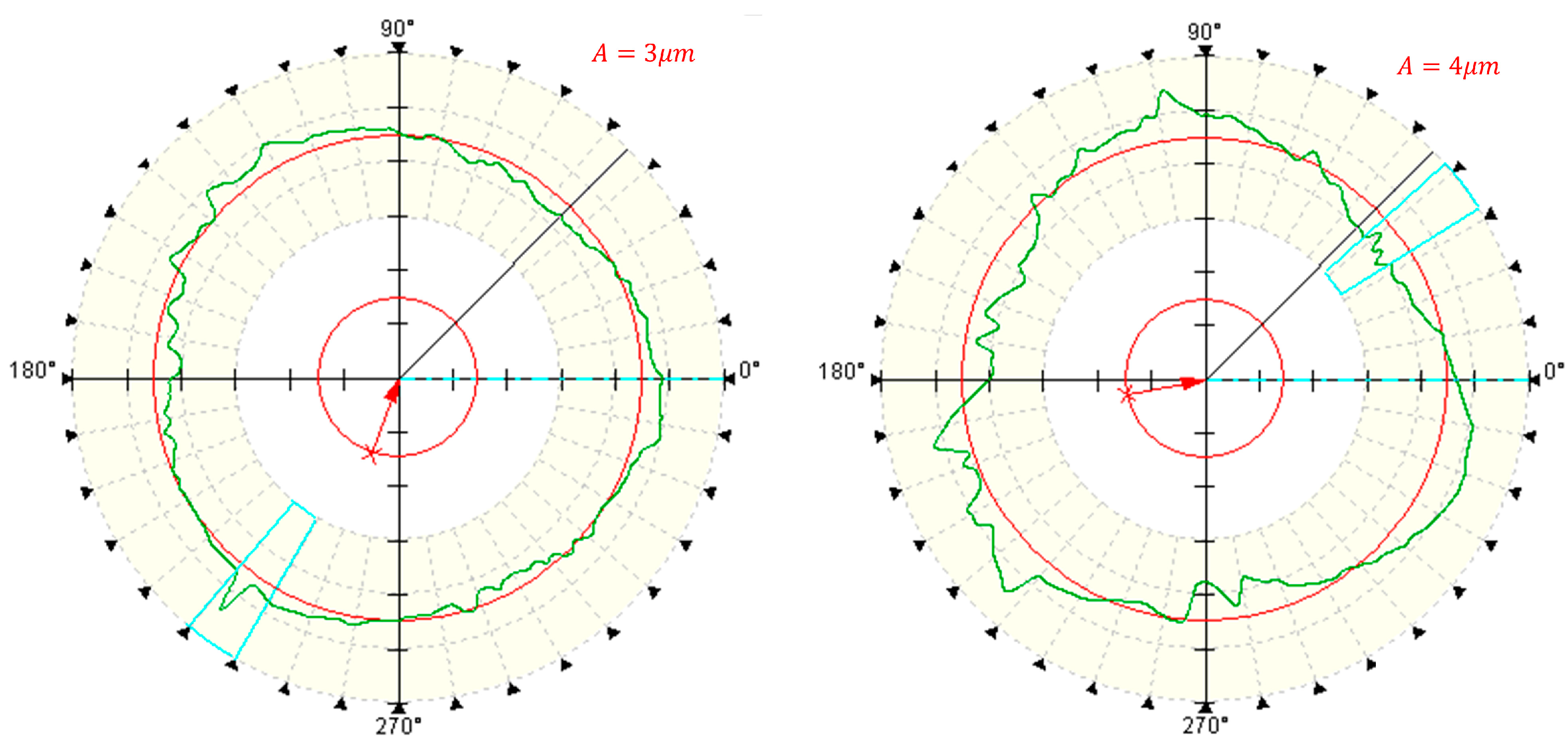

4.1. Analysis of Roundness Single-Factor Test Results

- 1.

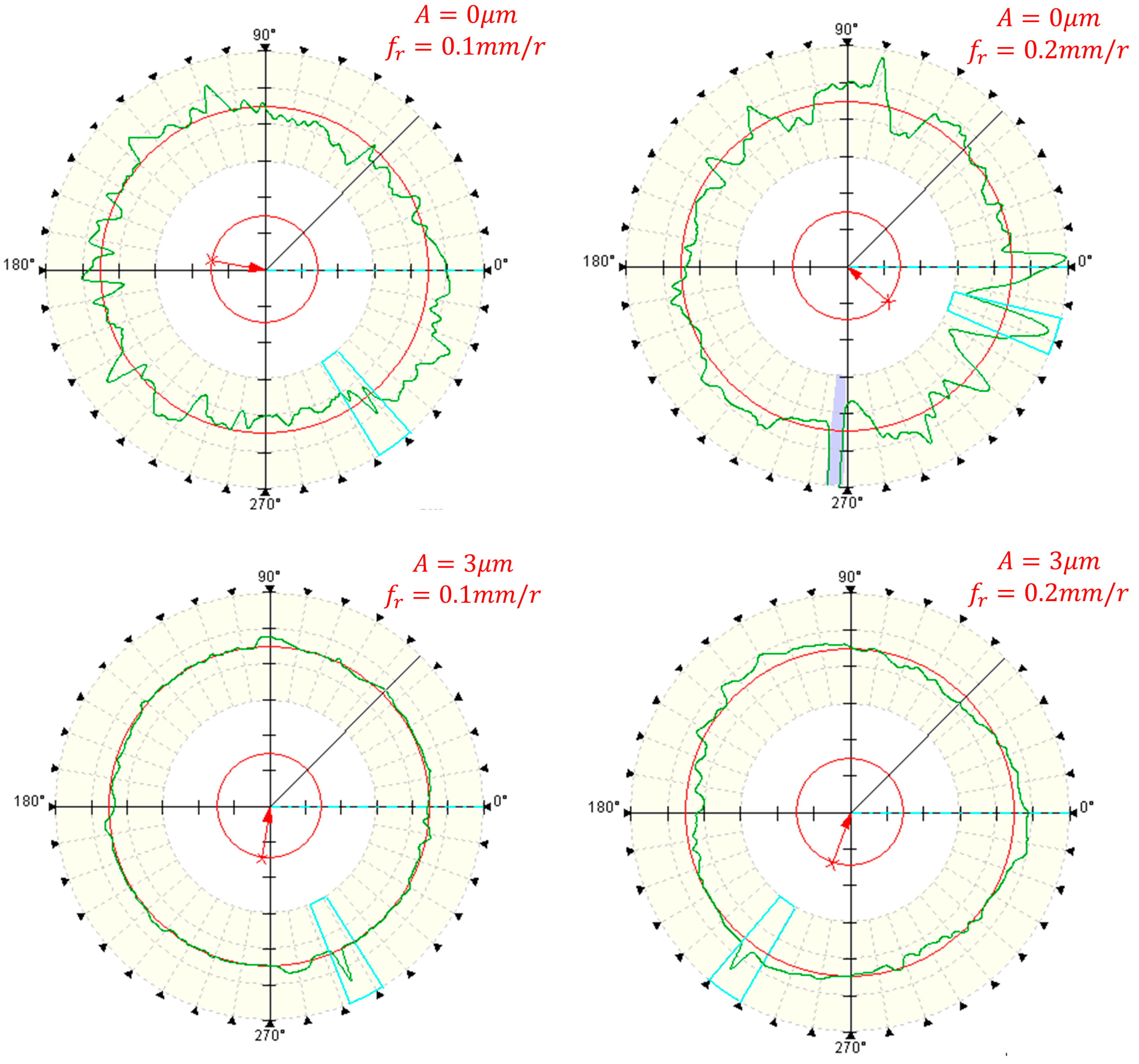

- The influence of Feed Rate on Roundness

- 2.

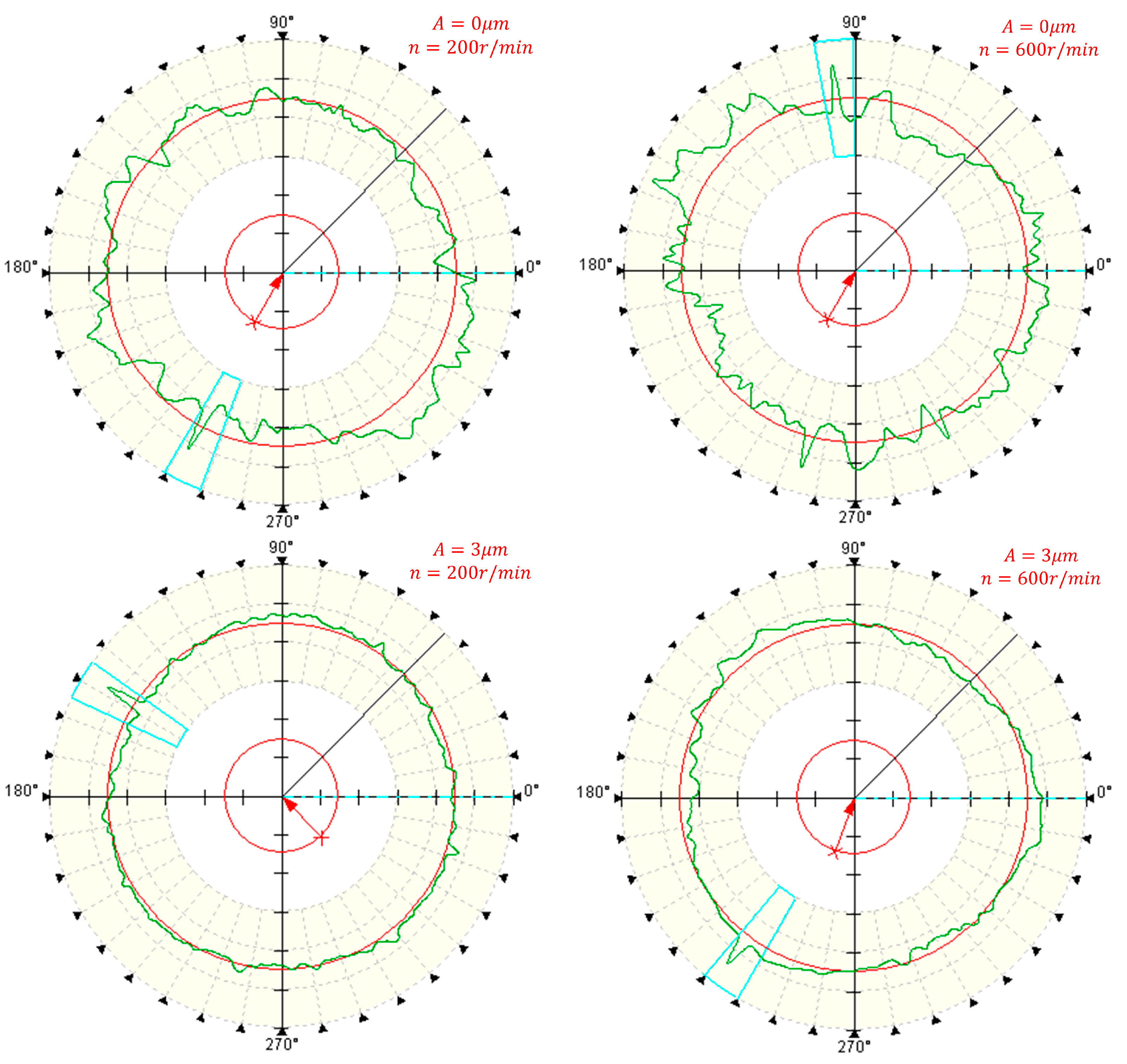

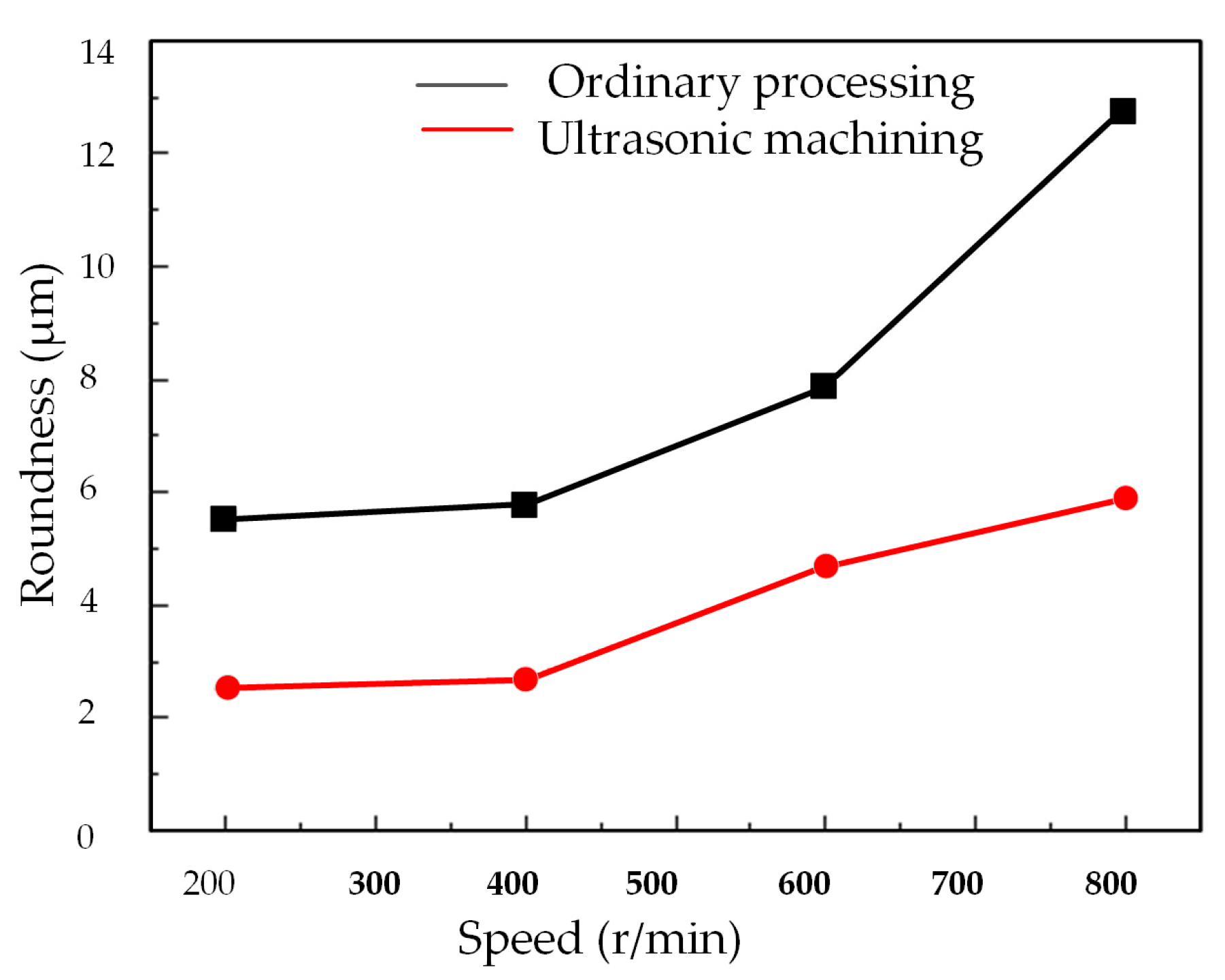

- The Effect of Rotational Speed on Roundness

- 3.

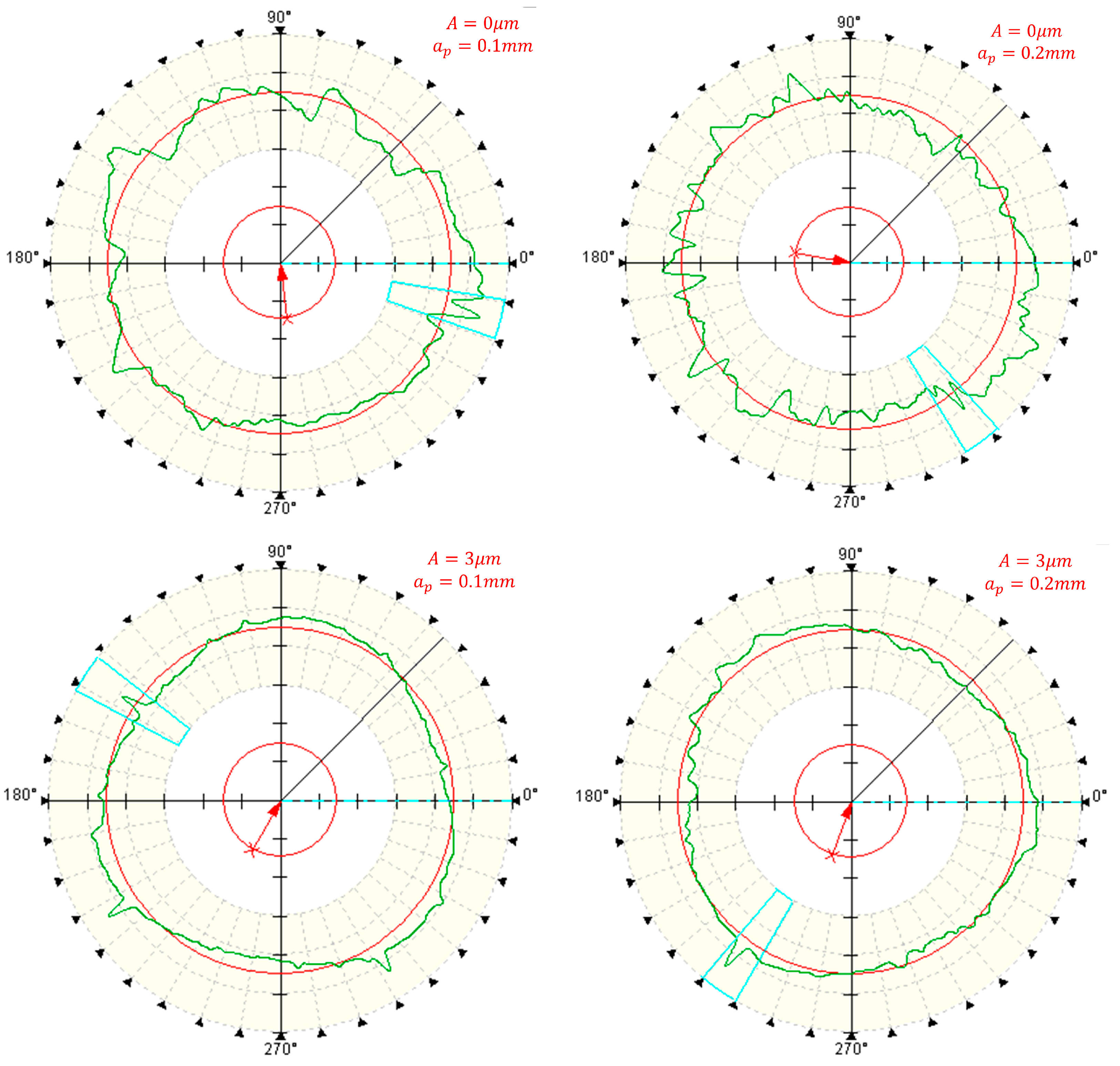

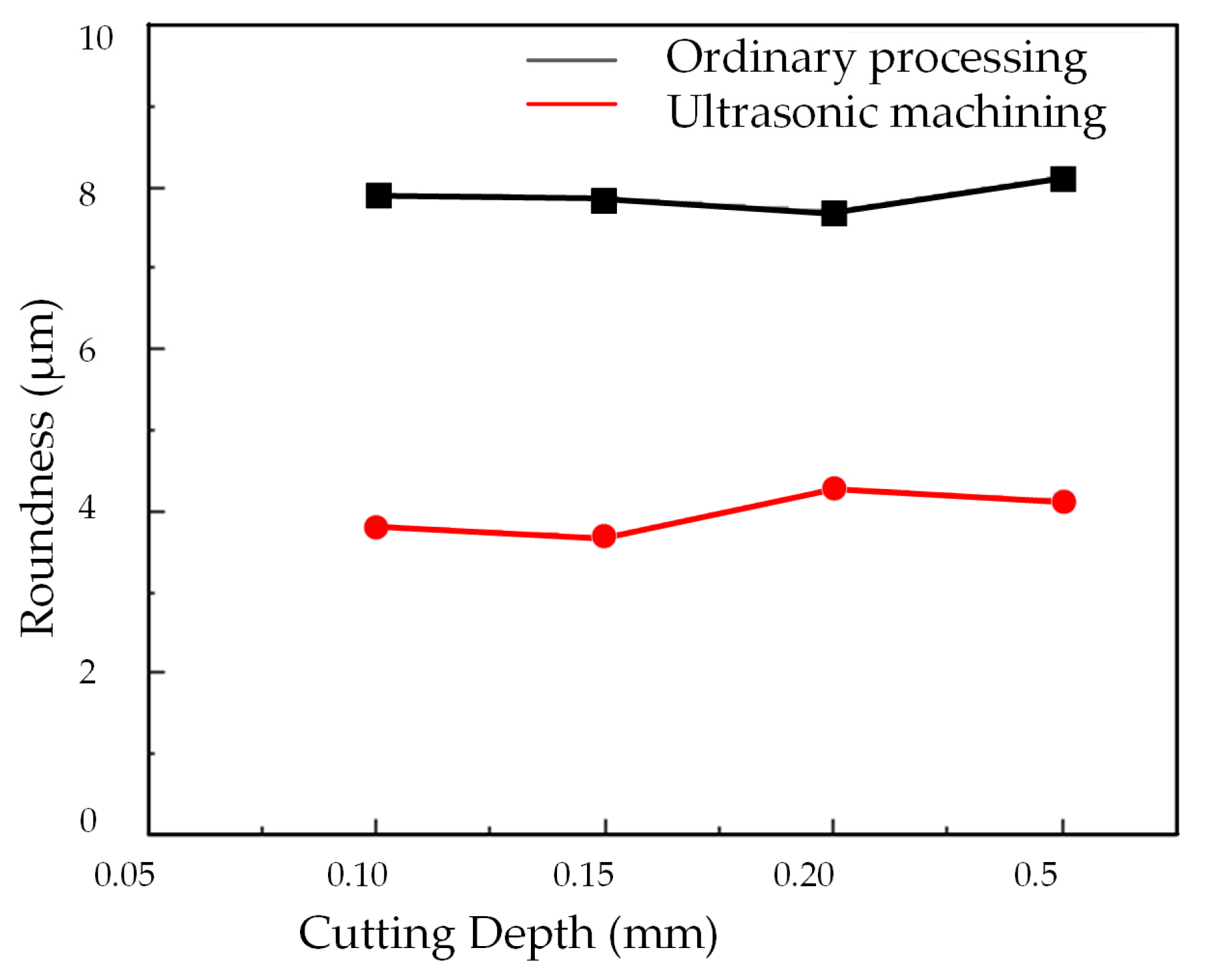

- The Influence of Cutting Depth on Roundness

- 4.

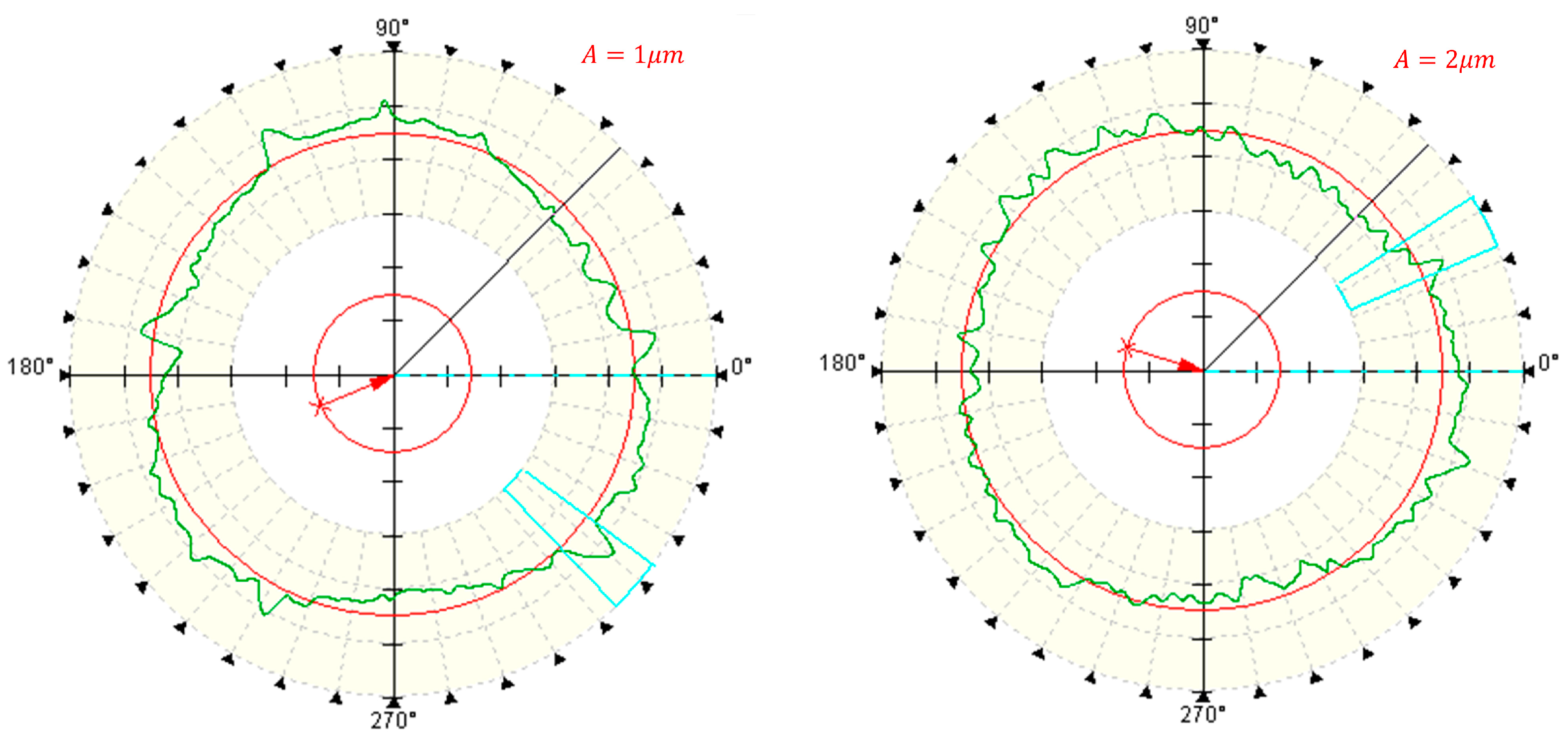

- The Effect of Ultrasonic Amplitude on Roundness

4.2. Analysis of Roundness Orthogonal Test Results

5. Conclusions

- This approach begins with the design of a two-dimensional ultrasonic vibration boring tool featuring a single-excitation asymmetric structure. Subsequently, a model describing the motion trajectory of the cutting edge in two-dimensional ultrasonic elliptical vibration deep hole boring is developed, and a simulation analysis is conducted to explore the cutting edge’s behavior under various machining parameters. Through theoretical analysis and simulation analysis, the correctness and effectiveness of a two-dimensional ultrasonic vibration boring device with single-excitation asymmetric structure are proved.

- The simulation results show that when the amplitude is , the rotary cutting phenomenon is obvious, and the group SR< is satisfied. Under the condition of 1, the higher speed can improve the machining efficiency and ensure the two-dimensional ultrasonic vibration boring effect. The cutting depth has no obvious influence on the tool trajectory, and the feed rate only produces displacement change in the X direction.

- An experimental platform for two-dimensional ultrasonic elliptical vibration deep hole boring was meticulously constructed. Both single-factor and orthogonal experimental plans were meticulously devised, and the ensuing experimental outcomes were meticulously measured and comprehensively analyzed.

- The experimental results found that, firstly, as the feed rate escalates, the roundness of the deep hole surface experiences an increase. Secondly, an increase in spindle speed corresponds to an augmentation in the roundness of the deep hole surface. Notably, when the speed remains below 400 r/min, alterations in speed do not lead to significant changes in roundness. However, when the speed surpasses 400 r/min, there is a noticeable elevation in the roundness value of the deep hole surface. Thirdly, as the ultrasonic amplitude grows, the roundness of the deep holes exhibits an initial decrease followed by an increase. This suggests that larger amplitudes tend to decrease the roundness of deep holes. Lastly, the impact of cutting depth on the roundness of the deep hole surface is relatively insignificant. As the cutting depth continues to rise, there is a marginal increase in the roundness of the deep hole surface.

- A comparative analysis was conducted between the results of ultrasonic boring and conventional boring experiments. The analysis revealed that the first processing method enhances the quality of deep hole machining, with a maximum roundness reduction of 54.1% and an average reduction of 50.4%. This underscores the significant impact of two-dimensional ultrasonic vibration boring on reducing the roundness value of deep hole machining. Based on the comprehensive orthogonal experimental findings, the optimal combination of processing parameters is as follows:

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Zhu, L.; Zhang, G.; Ni, C.; Lin, B. Review of ultrasonic vibration-assisted machining in advanced materials. Int. J. Mach. Tools Manuf. 2020, 156, 103594. [Google Scholar] [CrossRef]

- Han, X.; Zhang, D.; Song, G. Review on current situation and development trend for ultrasonic vibration cutting technology. Mater. Today Proc. 2020, 22, 444–455. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, D.; Singh, I.; Rath, D. An insight into ultrasonic vibration assisted conventional manufacturing processes: A comprehensive review. Adv. Mech. Eng. 2022, 14, 16878132221107812. [Google Scholar] [CrossRef]

- Duan, Z.; Li, C.; Ding, W.; Zhang, Y.; Yang, M.; Gao, T.; Cao, H.; Xu, X.; Wang, D.; Mao, C.; et al. Milling force model for aviation aluminum alloy: Academic insight and perspective analysis. Chin. J. Mech. Eng. 2021, 34, 18. [Google Scholar] [CrossRef]

- Wang, X.; Gao, X.; Zhang, Z.; Cheng, L.; Ma, H.; Yang, W. Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: A focused review. J. Eur. Ceram. Soc. 2021, 41, 4671–4688. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, B.; Zhang, S. The advancement of 7xxx series aluminum alloys for aircraft structures: A review. Metals 2021, 11, 718. [Google Scholar] [CrossRef]

- Liu, H.; Zheng, J.; Guo, Y.; Zhu, L. Residual stresses in high-speed two-dimensional ultrasonic rolling 7050 aluminum alloy with thermal-mechanical coupling. Int. J. Mech. Sci. 2020, 186, 105824. [Google Scholar] [CrossRef]

- Gao, J.; Song, Q.; Liu, Z. Chatter detection and stability region acquisition in thin-walled workpiece milling based on CMWT. Int. J. Adv. Manuf. Technol. 2018, 98, 699–713. [Google Scholar] [CrossRef]

- Kumabe, J.; Park, S. New development of vibration cutting technology. Airborne Missile 1987, 11, 53–57+64. [Google Scholar] [CrossRef]

- Zhang, X.; Kumar, A.S.; Rahman, M.; Liu, K. Modeling of the effect of tool edge radius on surface generation in elliptical vibration cutting. Int. J. Adv. Manuf. Technol. 2013, 65, 35–42. [Google Scholar] [CrossRef]

- Zhang, C.; Ehmann, K.; Li, Y. Analysis of cutting forces in the ultrasonic elliptical vibration-assisted micro-groove turning process. Int. J. Adv. Manuf. Technol. 2015, 78, 139–152. [Google Scholar] [CrossRef]

- He, Y.; Zou, P.; Zhu, W.L.; Ehmann, K.F. Ultrasonic elliptical vibration cutting of hard materials: Simulation and experimental study. Int. J. Adv. Manuf. Technol. 2017, 91, 363–374. [Google Scholar] [CrossRef]

- Xu, Y.; Wan, Z.; Zou, P.; Huang, W.; Zhang, G. Experimental study on cutting force in ultrasonic vibration-assisted turning of 304 austenitic stainless steel. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 494–513. [Google Scholar] [CrossRef]

- Deswal, N.; Kant, R. Experimental investigation on magnesium AZ31B alloy during ultrasonic vibration assisted turning process. Mater. Manuf. Process. 2022, 37, 1708–1714. [Google Scholar] [CrossRef]

- Li, B.; Xiang, D.; Peng, P.; Li, Y.; Liu, G.; Gao, G.; Zhao, B. Experimental and FEM study of surface formation and deformation mechanism of SiCp/Al composites in laser-ultrasonic vibration assisted turning. Ceram. Int. 2023, 49, 13510–13519. [Google Scholar] [CrossRef]

- Veiga, F.; Val, A.G.D.; Penalva, M.L.; Pereira, O.; Suárez, A.; López de Lacalle Marcaide, L.N. Predicted torque model in low-frequency-assisted boring (lfab) operations. Metals 2021, 11, 1009. [Google Scholar] [CrossRef]

- Zou, F.; Dang, J.; An, Q.; Chen, M. Mechanism and feasibility study of low frequency vibration assisted drilling of a newly developed cfrp/al co-cured material. J. Manuf. Process. 2021, 68, 115–127. [Google Scholar] [CrossRef]

- Lacalle, L.N.L.D.; Val, A.G.D.; Penalva, M.; Veiga, F.; Suárez, A. Evaluation on advantages of low frequency assisted drilling (lfad) aluminium alloy al7075. Int. J. Mechatron. Manuf. Syst. 2020, 13, 230. [Google Scholar]

- Luo, H.; Wang, Y.; Zhang, P. Effect of cutting and vibration parameters on the cutting performance of 7075-T651 aluminum alloy by ultrasonic vibration. Int. J. Adv. Manuf. Technol. 2020, 107, 371–384. [Google Scholar] [CrossRef]

- Tong, J.; Zhao, J.; Chen, P.; Zhao, B. Effect of ultrasonic elliptical vibration turning on the microscopic morphology of aluminum alloy surface. Int. J. Adv. Manuf. Technol. 2020, 106, 1397–1407. [Google Scholar] [CrossRef]

- Puga, H.; Grilo, J.; Carneiro, V.H. Ultrasonic assisted turning of Al alloys: Influence of material processing to improve surface roughness. Surfaces 2019, 2, 326–335. [Google Scholar] [CrossRef]

- Liu, X.; Hu, X.; Zhang, J.; Wu, D. Study on the fabrication of micro-textured end face in one-dimensional ultrasonic vibration–assisted turning. Int. J. Adv. Manuf. Technol. 2019, 105, 2599–2613. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Li, L.; Huang, W. Theoretical and Simulation Analysis on Fabrication of Micro-Textured Surface under Intermittent Cutting Condition by One-Dimensional Ultrasonic Vibration-Assisted Turning. Machines 2022, 10, 166. [Google Scholar] [CrossRef]

- Kim, G.D.; Loh, B.G. Machining of micro-channels and pyramid patterns using elliptical vibration cutting. Int. J. Adv. Manuf. Technol. 2010, 49, 961–968. [Google Scholar] [CrossRef]

- Zhou, M.; Hu, L. Development of an innovative device for ultrasonic elliptical vibration cutting. Ultrasonics 2015, 60, 76–81. [Google Scholar] [CrossRef]

- Yang, J.; Feng, P.; Zhang, J.; Wang, J. Design optimization of ultrasonic vibration cutting tool to generate well-decoupled elliptical trajectory. Int. J. Adv. Manuf. Technol. 2022, 119, 7199–7214. [Google Scholar] [CrossRef]

- Yin, S.; Dong, Z.; Bao, Y.; Kang, R.; Du, W.; Pan, Y.; Jin, Z. Development and optimization of ultrasonic elliptical vibration cutting device based on single excitation. J. Manuf. Sci. Eng. 2021, 143, 081005. [Google Scholar] [CrossRef]

- Nestler, A.; Schubert, A. Surface properties in ultrasonic vibration assisted turning of particle reinforced aluminium matrix composites. Procedia CIRP 2014, 13, 125–130. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.K.; Bertolini, R.; Krolczyk, G.M.; Khanna, N. Sustainable cooling strategies to reduce tool wear, power consumption and surface roughness during ultrasonic assisted turning of Ti-6Al-4V. Tribol. Int. 2022, 169, 107494. [Google Scholar] [CrossRef]

- Teimouri, R.; Amini, S.; Mohagheghian, N. Experimental study and empirical analysis on effect of ultrasonic vibration during rotary turning of aluminum 7075 aerospace alloy. J. Manuf. Process. 2017, 26, 1–12. [Google Scholar] [CrossRef]

- Dong, G.; Wang, L.; Li, C.; Yu, Y. Investigation on ultrasonic elliptical vibration boring of deep holes with large depth–diameter ratio for high-strength steel 18Cr2Ni4WA. Int. J. Adv. Manuf. Technol. 2020, 108, 1527–1539. [Google Scholar] [CrossRef]

- Sui, H.; Zhang, L.; Wang, S.; Gu, Z. Theoretical and experimental investigation into the machining performance in axial ultrasonic vibration-assisted cutting of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2021, 116, 449–472. [Google Scholar] [CrossRef]

- Sui, H.; Zhang, L.; Wang, S.; Gu, Z. Feasibility study on machining extra-large aspect ratio aviation deep-hole Ti6Al4V part with axial ultrasonic vibration-assisted boring. Int. J. Adv. Manuf. Technol. 2021, 118, 3995–4017. [Google Scholar] [CrossRef]

- Lu, D.; Shi, Y.; Zhao, P. Theoretical and experimental investigations of ultrasonic vibration–assisted boring for titanium alloy. Int. J. Adv. Manuf. Technol. 2022, 121, 2169–2179. [Google Scholar] [CrossRef]

- Ngo, Q.H.; Chu, N.H.; Nguyen, V.D. A study on design of vibratory apparatus and experimental validation on hard boring with ultrasonic-assisted cutting. Int. J. Adv. Eng. Res. Appl. 2018, 3, 383–396. [Google Scholar]

| Group Number | Spindle Speed n (r/min) | Cutting Depth ap (mm) | Feed Speed vf (mm/r) | Ultrasonic Amplitude A (μm) |

|---|---|---|---|---|

| 1 | 200 | 0.15 | 0.1 | 3 |

| 400 | ||||

| 600 | ||||

| 800 | ||||

| 2 | 600 | 0.1 | 0.1 | 3 |

| 0.15 | ||||

| 0.2 | ||||

| 0.25 | ||||

| 3 | 600 | 0.15 | 0.05 | 3 |

| 0.1 | ||||

| 0.15 | ||||

| 0.2 | ||||

| 4 | 600 | 0.15 | 0.1 | 1 |

| 2 | ||||

| 3 | ||||

| 4 |

| Equipment and Material Names | Parameter |

|---|---|

| CNC lathe | CK6140 |

| Ultrasonic generator | Resonant frequency 20 kHz |

| Laser displacement sensor | LK-G10 |

| Material | Anterior Angle/(°) | Relief Angle/(°) | Nose Radius/mm | Nose Angle/(°) | Lead Angle/(°) | Blade Inclination Angle/(°) |

|---|---|---|---|---|---|---|

| hard metal | 0 | 7 | 0.4 | 55 | 62.5 | 0 |

| Level | fr (mm/r) | n (r/min) | ap (mm) | |

|---|---|---|---|---|

| 1 | 0.05 | 200 | 0.1 | 1 |

| 2 | 0.1 | 400 | 0.15 | 2 |

| 3 | 0.15 | 600 | 0.2 | 3 |

| 4 | 0.2 | 800 | 0.25 | 4 |

| NO. | fr (mm/r) | n (r/min) | ap (mm) | |

|---|---|---|---|---|

| E-1 | 0.05 | 400 | 0.15 | 3 |

| E-2 | 0.1 | 400 | 0.15 | 3 |

| E-3 | 0.15 | 400 | 0.15 | 3 |

| E-4 | 0.2 | 400 | 0.15 | 3 |

| F-1 | 0.1 | 200 | 0.15 | 3 |

| F-2 | 0.1 | 400 | 0.15 | 3 |

| F-3 | 0.1 | 600 | 0.15 | 3 |

| F-4 | 0.1 | 800 | 0.15 | 3 |

| G-1 | 0.1 | 400 | 0.1 | 3 |

| G-2 | 0.1 | 400 | 0.15 | 3 |

| G-3 | 0.1 | 400 | 0.2 | 3 |

| G-4 | 0.1 | 400 | 0.25 | 3 |

| H-1 | 0.1 | 400 | 0.15 | 1 |

| H-2 | 0.1 | 400 | 0.15 | 2 |

| H-3 | 0.1 | 400 | 0.15 | 3 |

| H-4 | 0.1 | 400 | 0.15 | 4 |

| Test Number | fr (mm/r) | n (r/min) | ap (mm) | ||

|---|---|---|---|---|---|

| A-1 | 0.05 | 200 | 1 | 0.1 | 4.705 |

| A-2 | 0.05 | 400 | 2 | 0.15 | 6.415 |

| A-3 | 0.05 | 600 | 3 | 0.2 | 3.88 |

| A-4 | 0.05 | 800 | 4 | 0.25 | 4.905 |

| B-1 | 0.1 | 200 | 2 | 0.2 | 3.675 |

| B-2 | 0.1 | 400 | 1 | 0.25 | 3.06 |

| B-3 | 0.1 | 600 | 3 | 0.1 | 1.91 |

| B-4 | 0.1 | 800 | 4 | 0.15 | 2.9 |

| C-1 | 0.15 | 200 | 3 | 0.25 | 3.58 |

| C-2 | 0.15 | 400 | 4 | 0.2 | 2.535 |

| C-3 | 0.15 | 600 | 1 | 0.15 | 3.765 |

| C-4 | 0.15 | 800 | 2 | 0.1 | 4.67 |

| D-1 | 0.2 | 200 | 4 | 0.15 | 3.51 |

| D-2 | 0.2 | 400 | 3 | 0.1 | 3.275 |

| D-3 | 0.2 | 600 | 2 | 0.25 | 3.905 |

| D-4 | 0.2 | 800 | 1 | 0.2 | 4.62 |

| Level | Feed Rate | Speed | Amplitude | Cutting Depth |

|---|---|---|---|---|

| K1 | 4.9763 | 3.8675 | 4.0375 | 3.64 |

| K2 | 2.8863 | 3.8213 | 4.6663 | 4.1475 |

| K3 | 3.6375 | 3.365 | 3.4088 | 3.6775 |

| K4 | 3.8275 | 4.2738 | 3.215 | 3.8625 |

| Range R | 2.09 | 0.9088 | 1.4513 | 0.5075 |

| Factor | Sum of Squares of Deviations | Freedom | Mean Square Error | F Compare | Contribution Rate | Significance |

|---|---|---|---|---|---|---|

| fr | 8.966406 | 3 | 2.988802 | 11.182062 | 56.69% | 0.004892 |

| n | 1.658431 | 3 | 0.552810 | 2.068240 | 10.49% | 0.226598 |

| A | 5.192131 | 3 | 1.730710 | 6.475140 | 32.83% | 0.068421 |

| ap | 0.644819 | 3 | 0.214940 | 0.804158 | 0.656485 | |

| Error column | 0.801856 | 3 | 0.267285 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.; Tong, J.; Liu, Z.; Ye, Y.; Zhai, H.; Tao, H. Experimental Study on the Roundness of Deep Holes in 7075 Aluminum Alloy Parts by Two-Dimensional Ultrasonic Elliptical Vibration Boring. Micromachines 2023, 14, 2185. https://doi.org/10.3390/mi14122185

Yang S, Tong J, Liu Z, Ye Y, Zhai H, Tao H. Experimental Study on the Roundness of Deep Holes in 7075 Aluminum Alloy Parts by Two-Dimensional Ultrasonic Elliptical Vibration Boring. Micromachines. 2023; 14(12):2185. https://doi.org/10.3390/mi14122185

Chicago/Turabian StyleYang, Shuaikun, Jinglin Tong, Ziqiang Liu, Yanqiu Ye, Haojie Zhai, and Hongqing Tao. 2023. "Experimental Study on the Roundness of Deep Holes in 7075 Aluminum Alloy Parts by Two-Dimensional Ultrasonic Elliptical Vibration Boring" Micromachines 14, no. 12: 2185. https://doi.org/10.3390/mi14122185

APA StyleYang, S., Tong, J., Liu, Z., Ye, Y., Zhai, H., & Tao, H. (2023). Experimental Study on the Roundness of Deep Holes in 7075 Aluminum Alloy Parts by Two-Dimensional Ultrasonic Elliptical Vibration Boring. Micromachines, 14(12), 2185. https://doi.org/10.3390/mi14122185