Towards Broadband High-Frequency Vibration Attenuation Using Notched Cross-Shaped Metamaterial

Abstract

:1. Introduction

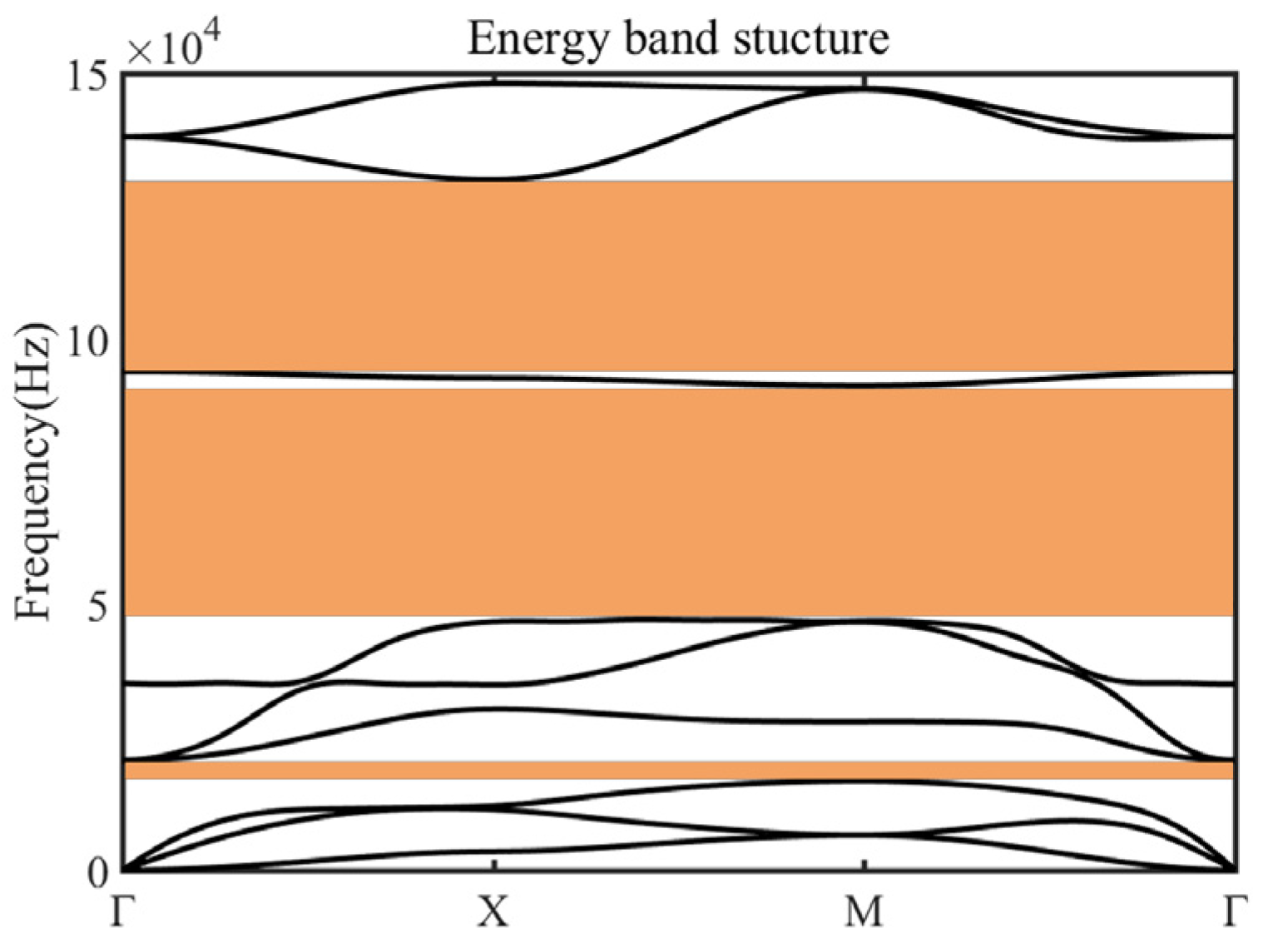

2. Design and Simulations

3. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Krause, M.; Dackermann, U. Elastic wave modes for the assessment of structural timber: Ultrasonic echo for building elements and guided waves for poleand pile structures. J. Civ. Struct. Health Monit. 2015, 5, 221–249. [Google Scholar] [CrossRef]

- Han, J.H.; Youn, S.H.; Jeong, H.K. Enhanced shock and vibration isolator for the attenuation of low-frequency vibration and high-frequency pyroshock loads. In Proceedings of the Third International Conference on Smart Materials and Nanotechnology in Engineering, Shenzhen, China, 11–13 November 2011; SPIE: Bellingham, WA, USA, 2012; Volume 8409, pp. 288–295. [Google Scholar]

- Farhat, M.; Guenneau, S.; Enoch, S. Negative refraction, surface modes, and superlensing effect via homogenization near resonances for a finite array of split-ring resonators. Phys. Rev. E 2009, 80, 046309. [Google Scholar] [CrossRef] [PubMed]

- Cummer, S.; Popa, B.; Schurig, D.; Smith, D.; Pendry, J.; Rahm, M.; Starr, A. Scattering theory derivation of a 3D acoustic cloaking shell. Phys. Rev. Lett 2008, 100, 024301. [Google Scholar] [CrossRef] [PubMed]

- Tian, Z.; Shen, C.; Li, J.; Reit, E.; Gu, Y.; Fu, H.; Cummer, S.; Huang, T. Programmable acoustic metasurfaces. Adv. Funct. Mater 2019, 29, 1808489. [Google Scholar] [CrossRef]

- Lang, B.; Yuan, B.; Cheng, J.-C. Acoustic diode: Rectification of acoustic energy flux in one-dimensional systems. Phys. Rev. Lett 2009, 103, 104301. [Google Scholar]

- Bilal, O.; Foehr, A.; Daraio, C. Bistable metamaterial for switching and cascading elastic vibrations. Proc. Natl. Acad. Sci. USA 2017, 114, 4603–4606. [Google Scholar] [CrossRef]

- Attarzadeh, M.; Callanan, J.; Nouh, M. Experimental observation of nonreciprocal waves in a resonant metamaterial beam. Phys. Rev. Appl. 2020, 13, 021001. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, X.; Mao, Y.; Zhu, Y.; Yang, Z.; Chan, C.; Sheng, P. Locally resonant sonic materials. Science 2000, 289, 1734–1736. [Google Scholar] [CrossRef]

- Wu, T.T.; Huang, Z.G.; Tsai, T.C.; Wu, T.C. Evidence of complete band gap and resonances in a plate with periodic stubbed surface. Appl. Phys. Lett. 2008, 93, 111902. [Google Scholar] [CrossRef]

- Wu, T.C.; Wu, T.T.; Hsu, J.C. Waveguiding and frequency selection of Lamb waves in a plate with a periodic stubbed surface. Phys. Rev. B 2009, 79, 104306. [Google Scholar] [CrossRef]

- Pennec, Y.; Djafari-Rouhani, B.; Larabi, H.; Vasseur, J.O.; Hladky-Hennion, A.C. Low-Frequency gaps in a phononic crystal constituted of cylindrical dots deposited on a thin homogeneous plate. Phys. Rev. B 2008, 78, 104105. [Google Scholar] [CrossRef]

- Pennec, Y.; Djafari-Rouhani, B.; Larabi, H.; Akjouj, A.; Gillet, J.N.; Vasseur, J.O.; Thabet, G. Phonon transport and waveguiding in a phononic crystal made up of cylindrical dots on a thin homogeneous plate. Phys. Rev. B 2009, 80, 144302. [Google Scholar] [CrossRef]

- Liu, X.N.; Hu, G.K.; Huang, G.L.; Sun, C.T. An elastic metamaterial with simultaneously negative mass density and bulk modulus. Appl. Phys. Lett. 2011, 98, 251790. [Google Scholar] [CrossRef]

- Oudich, M.; Senesi, M.; Assouar, M.B.; Ruzenne, M.; Sun, J.H.; Vincent, B.; Hou, Z.; Wu, T.T. Experimental evidence of locally resonant sonic band gap in two-dimensional phononic stubbed plates. Phys. Rev. B 2011, 84, 165136. [Google Scholar] [CrossRef]

- Pourabolghasem, R.; Khelif, A.; Mohammadi, S.; Eftekhar, A.A.; Adib, A. Physics of band-gap formation and its evolution in the pillar-based phononic crystal structures. J. Appl. Phys. 2014, 116, 013514. [Google Scholar] [CrossRef]

- Assouar, M.B.; Sun, J.H.; Lin, F.S.; Hsu, J.C. Hybrid phononic crystal plates for lowering and widening acoustic band gaps. Ultrasonics 2014, 54, 2159–2164. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, T.; Wang, X.; Xi, Y.; Liang, Q. Enlargement of locally resonant sonic band gap by using composite plate-type acoustic metamaterial. Phys. Lett. A 2015, 379, 412–416. [Google Scholar] [CrossRef]

- Assouar, M.B.; Oudich, M. Enlargement of a locally resonant sonic band gap by using double-sides stubbed phononic plates. Appl. Phys. Lett. 2012, 100, 123506. [Google Scholar] [CrossRef]

- Ma, C.; Guo, J.; Liu, Y. Extending and lowing band gaps in one-dimensional phononic crystal strip with pillars and holes. J. Phys. Chem. Solids 2015, 87, 95–103. [Google Scholar] [CrossRef]

- Shu, F.; Liu, Y.; Wu, J. Band gap in tubular pillar phononic crystal plate. Ultrasonics 2016, 71, 172–176. [Google Scholar] [CrossRef]

- Wen, J.; Yu, D.; Wang, G. The directional propagation characteristics of elastic wave in two-dimensional thin plate phononic crystals. Phys. Lett. A 2007, 364, 323–328. [Google Scholar] [CrossRef]

- Xiao, Y.; Wen, J.; Wen, X. Longitudinal wave band gaps in metamaterial-based elastic rods containing multi-degree-of-freedom resonators. New J. Phys. 2012, 14, 033042. [Google Scholar] [CrossRef]

- Peng, H.; Pai, P.F. Design of multi-stopband metamaterial plates for absorption of broadband elastic waves and vibration. Health Monit. Struct. Biol. Syst. 2015, 9438, 227–245. [Google Scholar]

- Yan, L.; Shi, D.; He, D.; Wang, L.; Zhao, K. Band gap characteristics of two-dimensional functionally graded periodic grid structures with local resonators. Mech. Adv. Mater. Struct. 2022. [Google Scholar] [CrossRef]

- Zouari, S.; Brocail, J.; Genevaux, J.M. Flexural wave band gaps in metamaterial plates: A numerical and experimental study from infinite to finite models. J. Sound Vib. 2018, 435, 246–263. [Google Scholar] [CrossRef]

- Zi, H.; Li, Y.G. Low-Frequency broadband vibration attenuation of sandwich plate-type metastructures with periodic thin-wall tube cores. J. Low Freq. Noise Vib. Act. Control. 2022, 41, 330–339. [Google Scholar] [CrossRef]

- Xia, B.; Jiang, Z.; Tong, L.; Zheng, S.; Man, X. Topological bound states in elastic phononic plates induced by disclinations. Acta Mech. Sin. 2022, 38, 521459. [Google Scholar] [CrossRef]

- Krushynska, A.O.; Amendola, A.; Bosia, F.; Daraio, C.; Pugno, N.M.; Fraternali, F. Accordion-like metamaterials with tunable ultra-wide low-frequency band gaps. New J. Phys. 2018, 20, 073051. [Google Scholar] [CrossRef]

- Xiao, Y.; Mace, B.R.; Wen, J.; Wen, X. Formation and coupling of band gaps in a locally resonant elastic system comprising a string with attached resonators. Phys. Lett. Appl. 2011, 375, 1485–1491. [Google Scholar] [CrossRef]

- Peng, H.; Frank Pai, P.; Deng, H. Acoustic multi-stopband metamaterial plates design for broadband elastic wave absorption and vibration suppression. Int. J. Mech. Sci. 2015, 103, 104–114. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Y.; Liu, Y.; Lv, L.; Peng, F.; Wang, L. Extending and lowering band gaps by multilayered locally resonant phononic crystals. Appl. Acoust. 2018, 133, 97–106. [Google Scholar] [CrossRef]

- Barnhart, M.V.; Xu, X.; Chen, Y.; Zhang, S.; Song, J.; Huang, G. Experimental demonstration of a dissipative multi-resonator metamaterial for broadband elastic wave attenuation. J. Sound Vib. 2019, 438, 1–12. [Google Scholar] [CrossRef]

- Naify, C.J.; Chang, C.-M.; McKnight, G.; Nutt, S. Transmission loss of membrane-type acoustic metamaterials with coaxial ring masses. J. Appl. Phys. 2011, 110, 124903. [Google Scholar] [CrossRef]

- Stein, A.; Nouh, M.; Singh, T. Widening, transition and coalescence of local resonance band gaps in multi-resonator acoustic metamaterials: From unit cells to finite chains. J. Sound Vib. 2022, 523, 116716. [Google Scholar] [CrossRef]

- Tian, Y.; Wu, J.H.; Li, H.; Gu, C.; Yang, Z.; Zhao, Z.; Lu, K. Elastic wave propagation in the elastic metamaterials containing parallel multi-resonators. J. Phys. D Appl. Phys. 2019, 52, 395301. [Google Scholar] [CrossRef]

- Xiao, Y.; Wen, J.; Wen, X. Broadband locally resonant beams containing multiple periodic arrays of attached resonators. Appl. Phys. Lett. 2012, 376, 1384–1390. [Google Scholar] [CrossRef]

- Xiao, Y.; Wen, J.; Wen, X. Sound transmission loss of metamaterial-based thin plates with multiple subwavelength arrays of attached resonators. J. Sound Vib. 2012, 331, 5408–5423. [Google Scholar] [CrossRef]

- Meng, Z.; Wang, L.; Li, Z.; Wang, J. A theoretical framework for joining multiple locally resonant bandgaps of metamaterials towards a super-wide bandgap. Compos. Struct. 2023, 304, 116348. [Google Scholar] [CrossRef]

- Lu, K.; Zhou, G.; Gao, N. Flexural vibration bandgaps of the multiple local resonance elastic metamaterial plates with irregular resonators. Appl. Acoust. 2020, 159, 107115. [Google Scholar] [CrossRef]

- Williams, E.G.; Roux, P.; Rupin, M.; Kuperman, W.A. Theory of multiresonant metamaterials for A0 lamb waves. Phys. Rev. B 2015, 91, 104307. [Google Scholar] [CrossRef]

- Lim, C.W.; Reddy, J.N. Built-Up structural steel sections as seismic metamaterials for surface wave attenuation with low frequency wide bandgap in layered soil medium. Eng. Struct. 2019, 188, 440–451. [Google Scholar]

- Xiong, Y.; Wen, S.; Li, F.; Zhang, C. Enhancement of the band-gap characteristics of hierarchical periodic elastic metamaterial beams. Waves Random Complex Media 2022, 32, 1862–1878. [Google Scholar] [CrossRef]

- Yan, G.W.; Yao, S.; Li, Y.L. Propagation of elastic waves in metamaterial plates with various lattices for low-frequency vibration attenuation. J. Sound Vib. 2022, 536, 117140. [Google Scholar] [CrossRef]

- Hofstadter, D.R. Energy levels and wave functions of Bloch electrons in rational and irrational magnetic fields. Phys. Rev. B 1976, 14, 2239. [Google Scholar] [CrossRef]

- Xiong, Y.H.; Xu, A.D.; Wen, S.R.; Li, F.M.; Hosseini, S.M. Optimization of vibration band-gap characteristics of a periodic elastic metamaterial plate. Mech. Adv. Mater. Struct. 2022. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Zhao, R.; Shi, Y. Towards Broadband High-Frequency Vibration Attenuation Using Notched Cross-Shaped Metamaterial. Micromachines 2023, 14, 414. https://doi.org/10.3390/mi14020414

Guo J, Zhao R, Shi Y. Towards Broadband High-Frequency Vibration Attenuation Using Notched Cross-Shaped Metamaterial. Micromachines. 2023; 14(2):414. https://doi.org/10.3390/mi14020414

Chicago/Turabian StyleGuo, Jin, Rui Zhao, and Yunbo Shi. 2023. "Towards Broadband High-Frequency Vibration Attenuation Using Notched Cross-Shaped Metamaterial" Micromachines 14, no. 2: 414. https://doi.org/10.3390/mi14020414

APA StyleGuo, J., Zhao, R., & Shi, Y. (2023). Towards Broadband High-Frequency Vibration Attenuation Using Notched Cross-Shaped Metamaterial. Micromachines, 14(2), 414. https://doi.org/10.3390/mi14020414