Transition Routes of Electrokinetic Flow in a Divergent Microchannel with Bending Walls

Abstract

1. Introduction

2. Theory

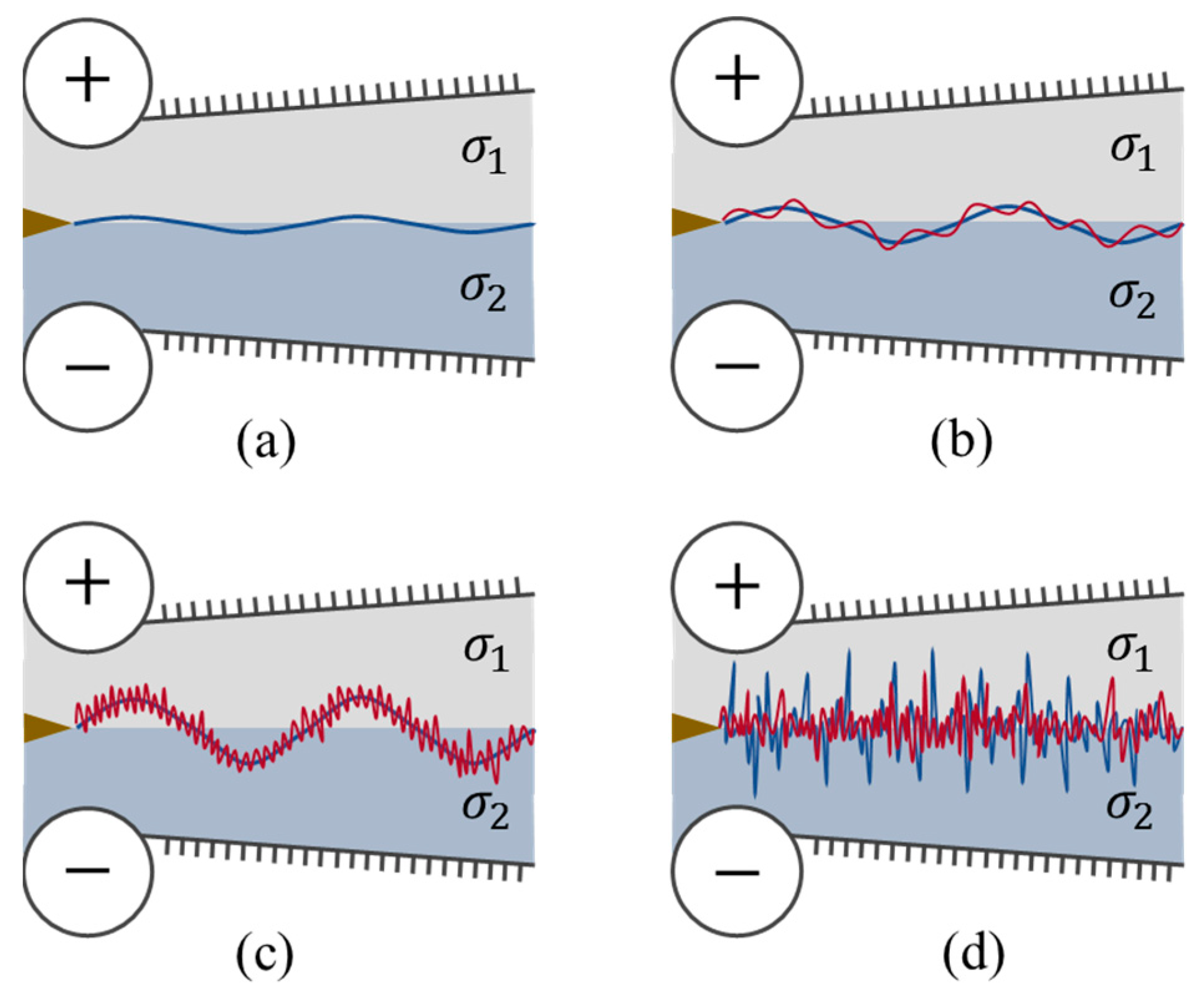

2.1. Physical Model of the EKI

2.2. Linear Response Regime

- (1)

- If , the direct coupling between the applied AC electric field and the fluctuations of flow structures is absent. The EK flow cannot immediately respond to the applied AC electric field and will exhibit perturbations at much lower frequencies. Thus, the terms to are negligible in the driving of , while and must be dominant, even though these are nonlinear forcing terms.

- (2)

- If , the applied AC electric field and the fluctuations of the flow structures have direct and strong coupling. Similar to a forced pendulum, share similar spectra as in a linear instability/receptivity model.

2.3. Nonlinear Response Regime

2.4. Fluctuations of the Fluorescent Dye Concentration

3. Experimental Setup

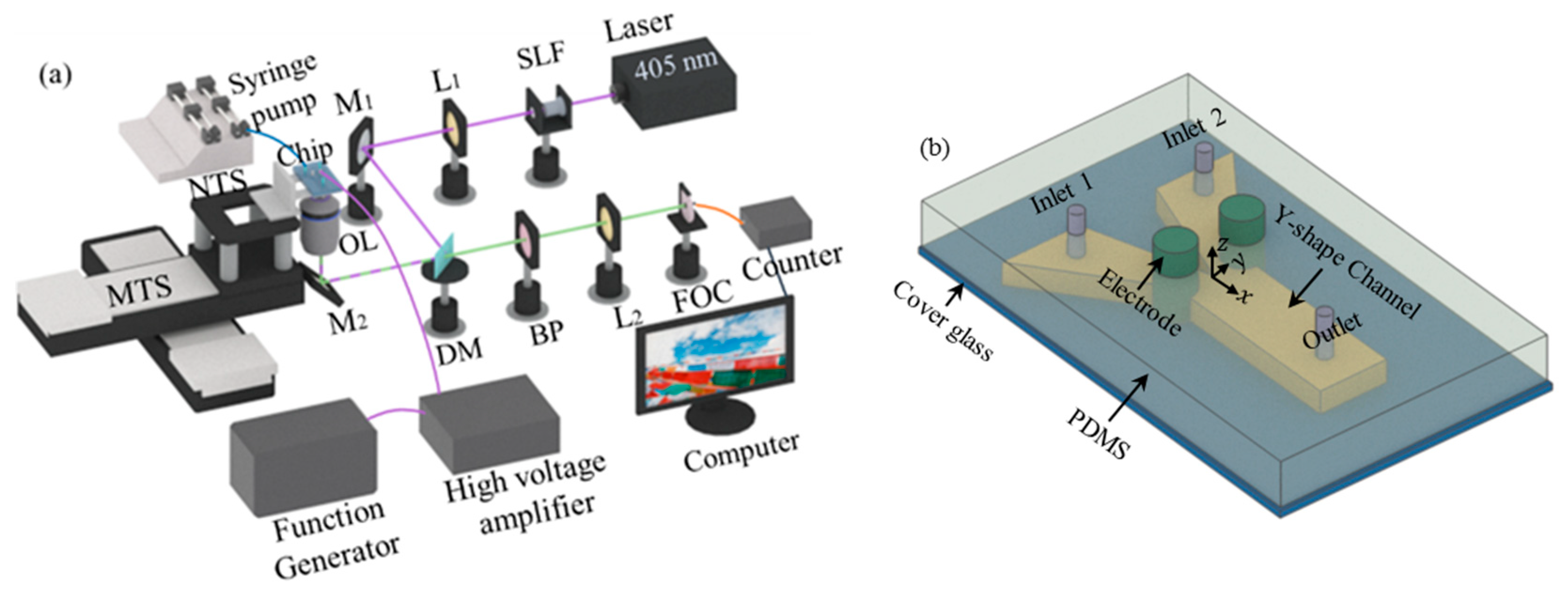

3.1. Optical System

3.2. Solution Preparation

3.3. Fabrication of the Micromixer Chip

3.4. Flow Visualization

3.5. EK Flow System

4. Experimental Results

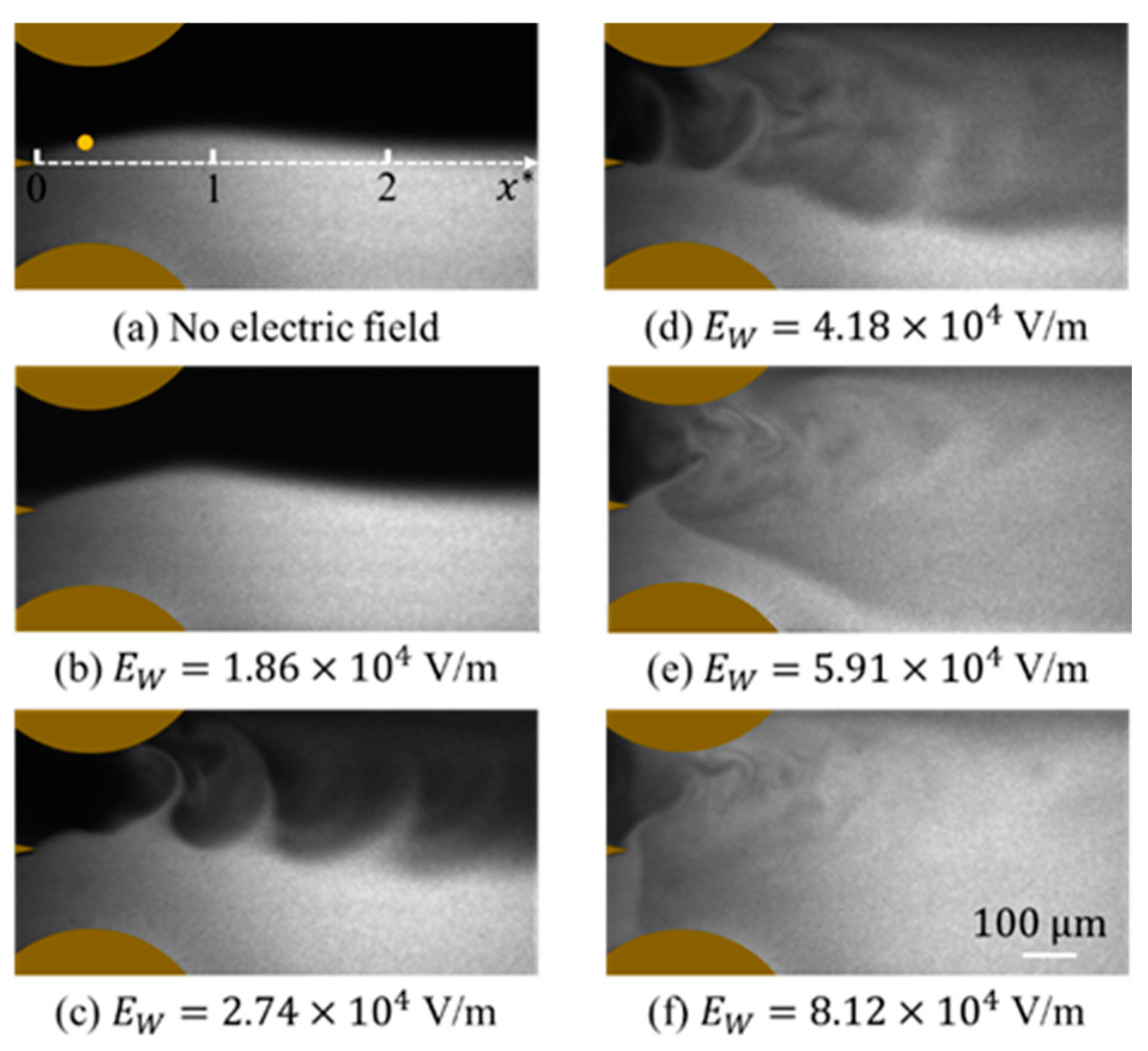

4.1. Flow Visualization

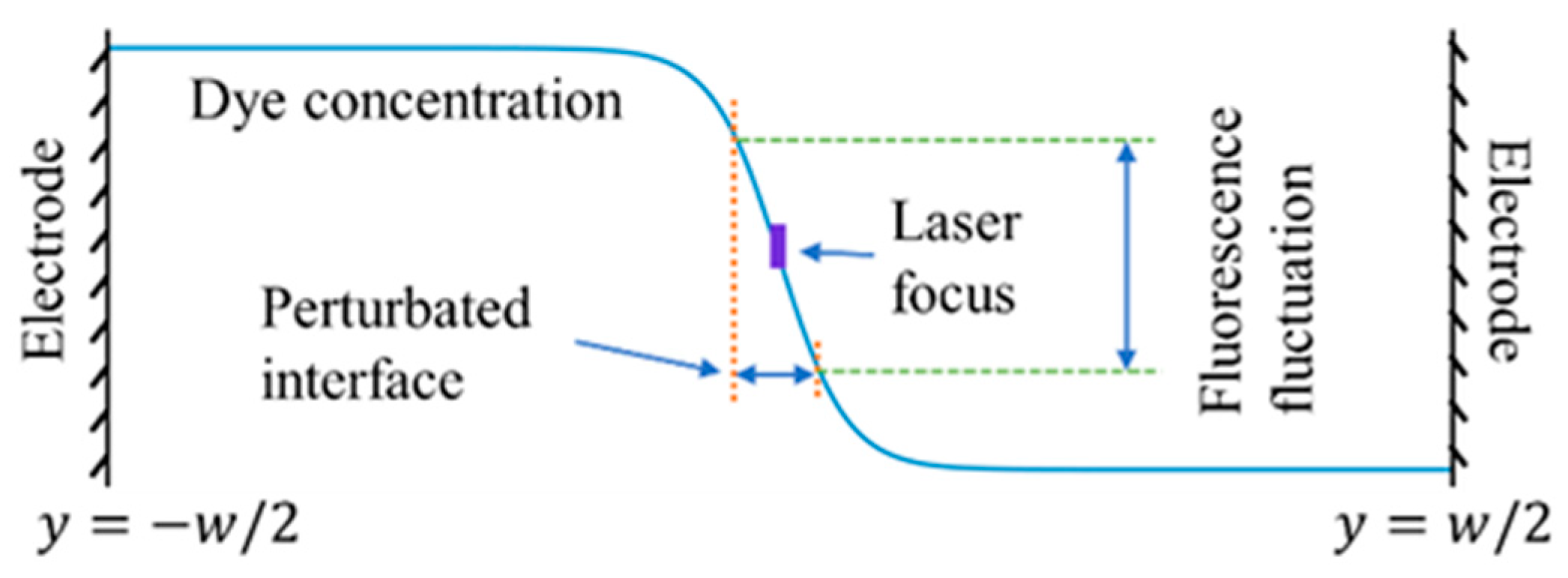

4.2. Single-Point LIF for Concentration Measurement

4.3. Time Series of Fluorescence Fluctuations

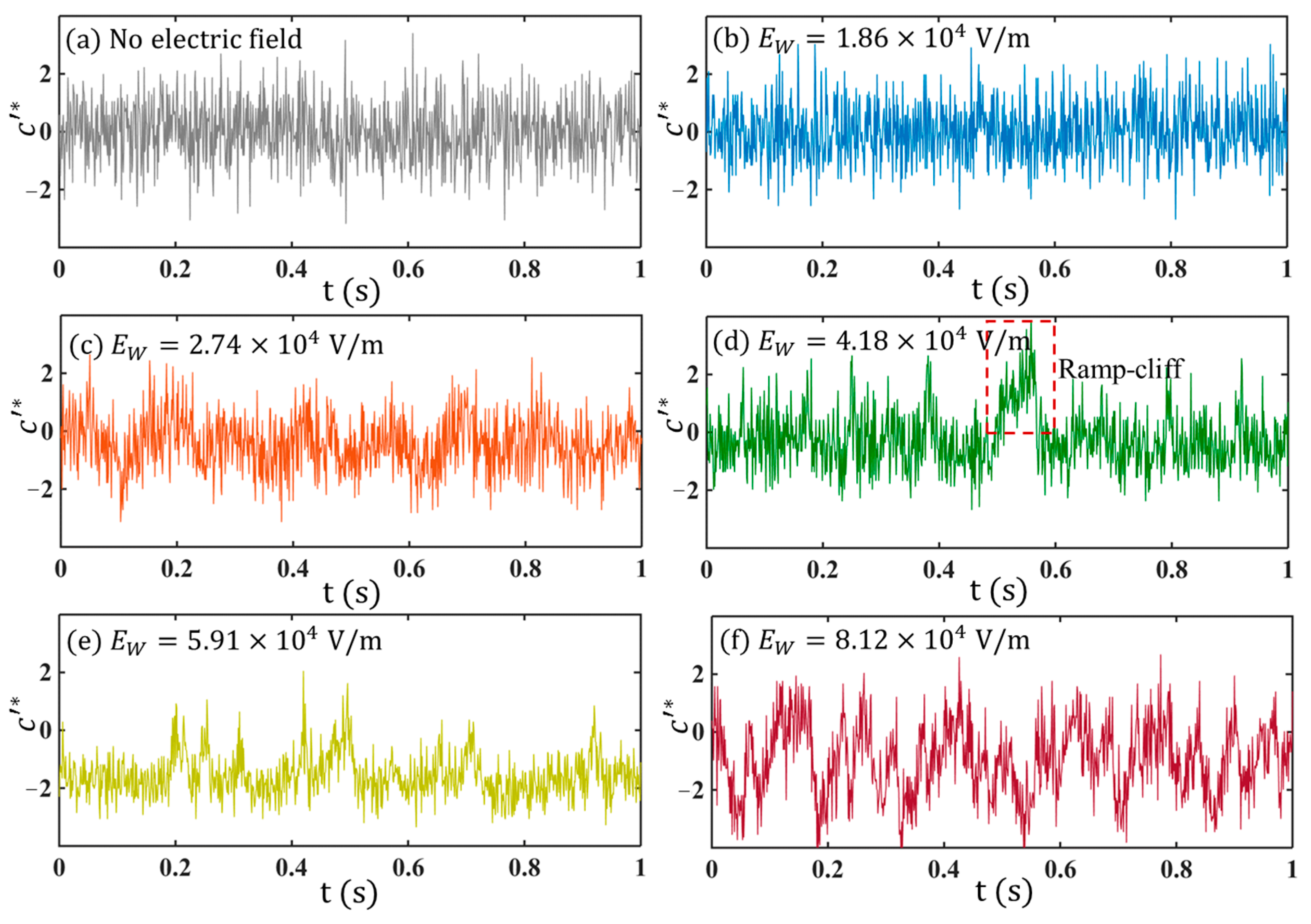

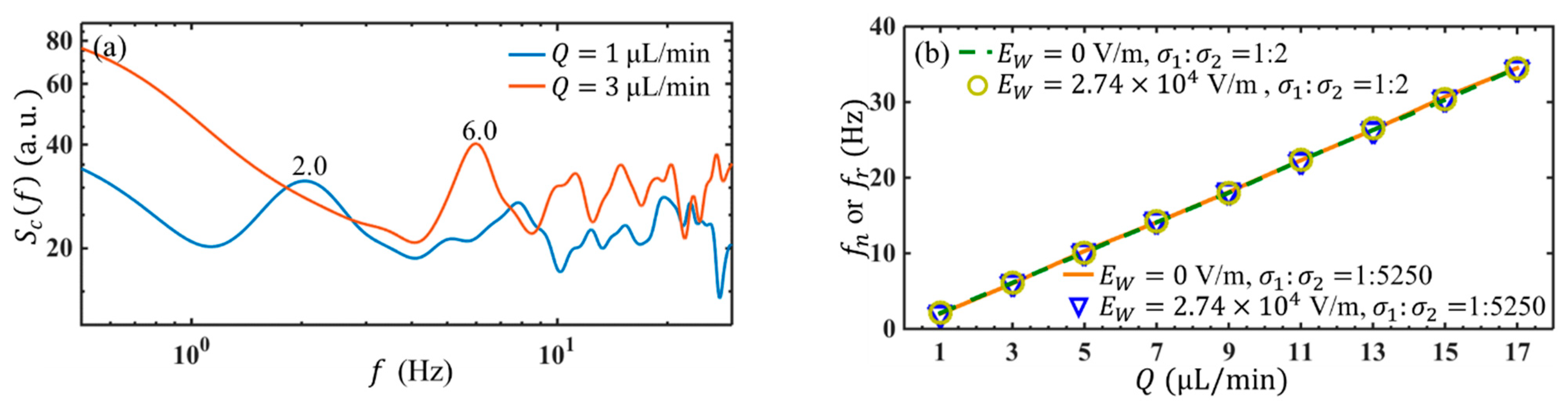

4.4. Neutral Frequency of Basic Flow Instability

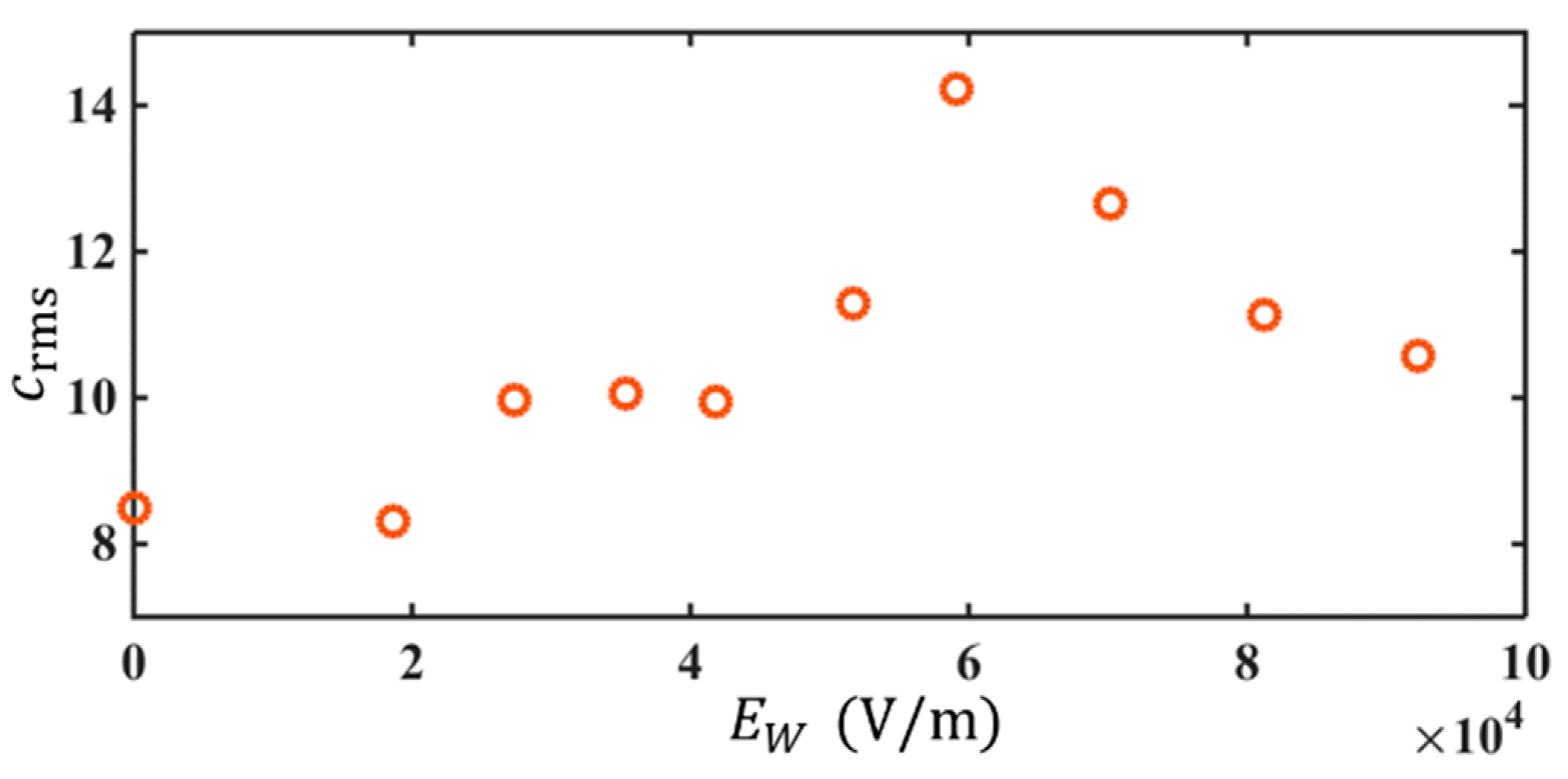

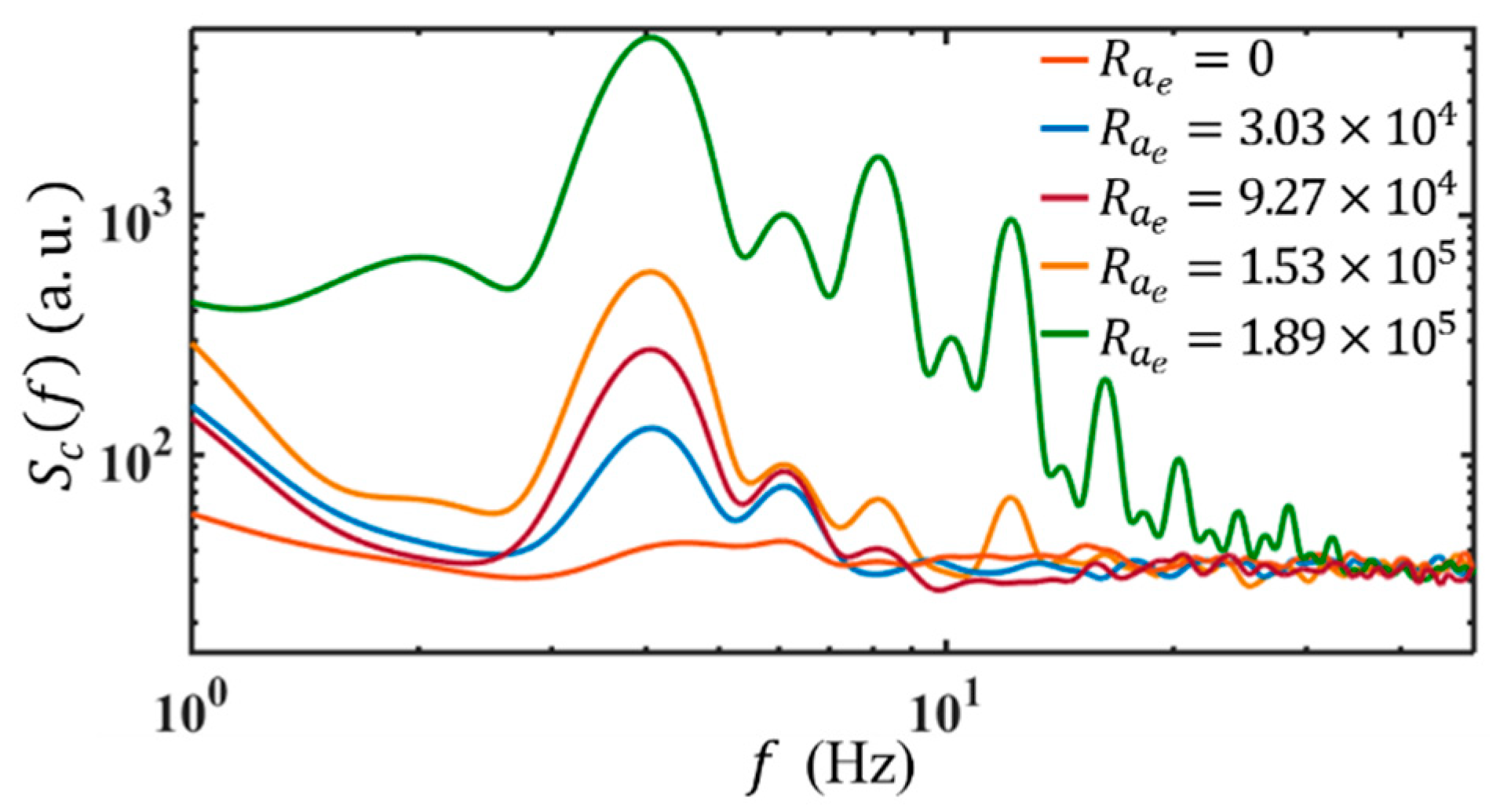

4.5. under Different

4.5.1. Initial Stage

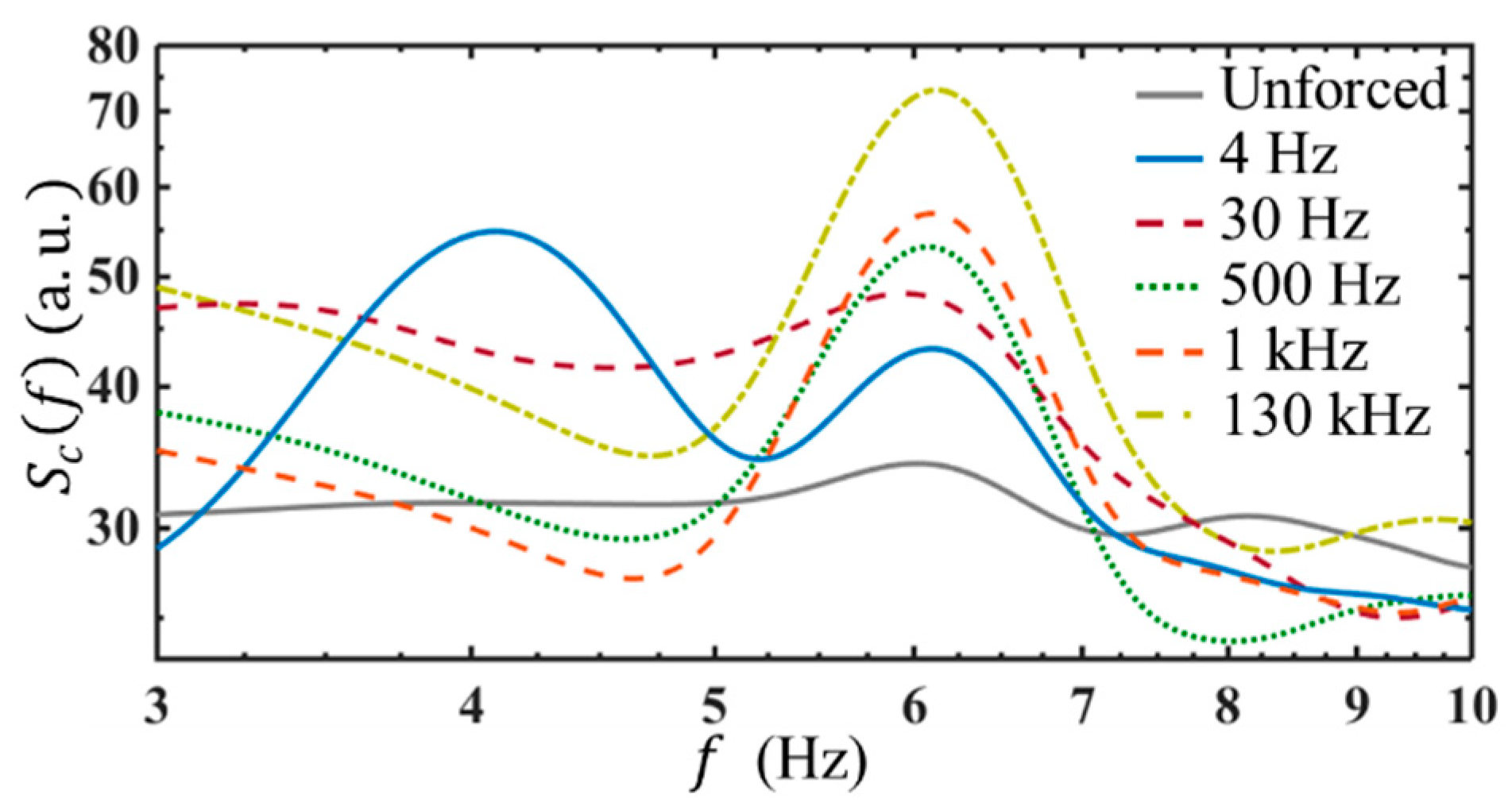

- (1)

- As shown in Figure 10, when the AC frequency is below 30 Hz, for instance, at Hz, there are two spectral peaks observed. One is at the neutral frequency, i.e., Hz, when 3 μL/min. The other is at the forcing frequency, i.e., 4 Hz. Since the applied AC voltage is only , the EK flow fluctuates linearly to the external electric field, forming a forced oscillation system. In this case, the peak of locates at , indicating the concentration fluctuation (which is also the fluctuation of electric conductivity) has . Since the peak of is also corresponding to the peak of velocity power spectra according to Equation (35), the flow is perturbed at the AC frequency as well. This observation is interesting since it can only be achieved in two cases. One is that still keeps unchanged at a low frequency. The other is really “tricky”, in that, , and , two of them have exactly inverse phases, but the same frequencies. Therefore, by the forcing terms to , and , it is also possible to have .

- (2)

- When the AC frequency is equal to or above 30 Hz, even though a larger electric field V/m has been applied, there is only a single peak observed at the neutral frequency (e.g., Hz). This indicates, on the one hand, when a high-frequency AC electric field was applied, the AC EK instability plays a part to generate flow disturbance indirectly, and relies on the instability of the basic flow. Furthermore, the experimental results also show that at the same AC voltage, the concentration fluctuation is the greatest and most unstable at kHz. This implies, on the other hand, the response of the basic flow to the AC electric field is not the same. The basic flow exhibits a higher receptivity at a higher AC frequency.

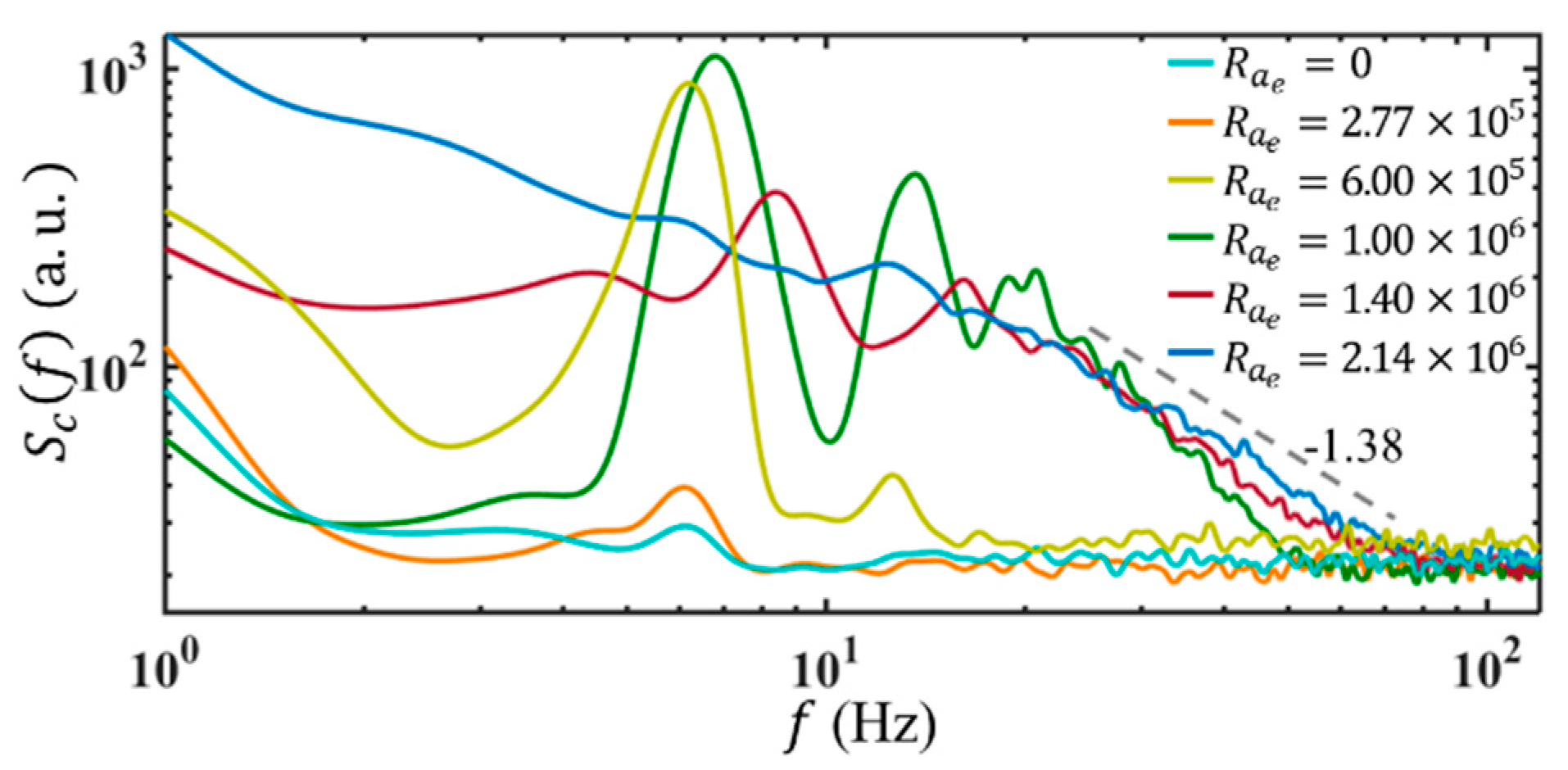

4.5.2. Evolution with Increasing Electric Rayleigh Number

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| fluorescent dye concentration | |

| concentration fluctuation | |

| root-mean-square of | |

| hydraulic diameter | |

| diffusivity of fluorescent dye | |

| effective diffusivity of | |

| nominal electric field | |

| electric body force density | |

| frequency | |

| AC frequency | |

| response frequency | |

| neutral frequency | |

| fluorescent intensity | |

| length of channel | |

| pressure fluctuation | |

| pressure | |

| mean value of | |

| flow rate | |

| electric Rayleigh number | |

| critical electric Rayleigh number where nonlinearity emerges | |

| velocity power spectrum | |

| concentration power spectrum, i.e., | |

| electric conductivity power spectrum | |

| mean values of | |

| mean flow velocity at the centerline | |

| bulk flow velocity | |

| velocity vector | |

| x-directional velocity component | |

| velocity fluctuation in the x direction | |

| mean values of | |

| peak-to-peak voltage | |

| velocity fluctuation in the y direction | |

| y-directional velocity component | |

| z-directional velocity component | |

| width of the interface | |

| width of channel | |

| x | streamwise position |

| y | spanwise position |

| z | vertical position |

| dimensionless frequency | |

| electric permittivity | |

| dynamic viscosity | |

| kinematic viscosity | |

| ρ | fluid density |

| charge density | |

| electric conductivity | |

| electric conductivity of water solution | |

| electric conductivity of fluorescent solution | |

| electric conductivity fluctuation | |

| mean value of | |

| angular frequency | |

| cut-off frequencies of | |

| cut-off frequencies of | |

| cut-off frequencies of electric field | |

| ¯ | ensemble average |

References

- Ohno, K.I.; Tachikawa, K.; Manz, A. Microfluidics: Applications for analytical purposes in chemistry and biochemistry. Electrophoresis 2008, 29, 4443–4453. [Google Scholar] [CrossRef]

- Mishra, A.; Kwon, J.S.; Thakur, R.; Wereley, S. Optoelectrical microfluidics as a promising tool in biology. Trends Biotechnol. 2014, 32, 414–421. [Google Scholar] [CrossRef]

- Psaltis, D.; Quake, S.R.; Yang, C. Developing optofluidic technology through the fusion of microfluidics and optics. Nature 2006, 442, 381–386. [Google Scholar] [CrossRef]

- Sorg, D.; Danowski, K.; Korenkova, V.; Rusnakova, V.; Küffner, R.; Zimmer, R.; Meyer, H.H.D.; Kliem, H. Microfluidic high-throughput RT-qPCR measurements of the immune response of primary bovine mammary epithelial cells cultured from milk to mastitis pathogens. Animal 2012, 7, 799–805. [Google Scholar] [CrossRef]

- Fujii, S.I.; Uematsu, M.; Abo, M.; Yoshimura, E.; Sato, K. Microbioassay system for an anti-cancer agent test using animal cells on a microfluidic gradient mixer. Anal. Sci. 2006, 22, 87–90. [Google Scholar] [CrossRef]

- Kamholz, A.E.; Yager, P. Theoretical analysis of molecular diffusion in pressure-driven laminar flow in microfluidic channels. Biophys. J. 2001, 80, 155–160. [Google Scholar] [CrossRef]

- Qian, L.; Winfree, E.; Bruck, J. Neural network computation with DNA strand displacement cascades. Nature 2011, 475, 368–372. [Google Scholar] [CrossRef]

- Kralj, J.G.; Sahoo, H.R.; Jensen, K.F. Integrated continuous microfluidic liquid–liquid extraction. Lab Chip 2007, 7, 256–263. [Google Scholar] [CrossRef]

- Ramos, A.; Morgan, H.; Green, N.G.; Castellanos, A. AC electrokinetics: A review of forces in microelectrode structures. J. Phys. D Appl. Phys. 1998, 31, 2338–2353. [Google Scholar] [CrossRef]

- Green, N.G.; Ramos, A.; Gonza’lez, A.; Morgan, H.; Castellanos, A. Fluid flow induced by nonuniform AC electric fields in electrolytes on microelectrodes. I. experimental measurements. Phys. Rev. E 2000, 61, 4011–4018. [Google Scholar] [CrossRef]

- González, A.; Ramos, A.; Green, N.G.; Castellanos, A.; Morgan, H. Fluid flow induced by nonuniform AC electric fields in electrolytes on microelectrodes. II. A linear double-Layer analysis. Phys. Rev. E 2000, 61, 4019–4028. [Google Scholar] [CrossRef] [PubMed]

- Green, N.G.; Ramos, A.; González, A.; Morgan, H.; Castellanos, A. Fluid flow induced by nonuniform AC electric fields in electrolytes on microelectrodes. III. observation of streamlines and numerical simulation. Phys. Rev. E 2002, 66, 026305. [Google Scholar] [CrossRef]

- Oddy, M.H.; Santiago, J.G.; Mikkelsen, J.C. Electrokinetic instability micromixing. Anal. Chem. 2001, 73, 5822–5832. [Google Scholar] [CrossRef] [PubMed]

- Lin, H.; Storey, B.D.; Oddy, M.; Chen, C.-H.; Santiago, J.G. Instability of electrokinetic microchannel flows with conductivity gradients. Phys. Fluids 2004, 16, 1922–1935. [Google Scholar] [CrossRef]

- Chen, C.H.; Lin, H.; Lele, S.K.; Santiago, J.G. Convective and absolute electrokinetic instability with conductivity gradients. J. Fluid Mech. 2005, 524, 263–303. [Google Scholar] [CrossRef]

- Posner, J.D.; Santiago, J.G. Convective instability of electrokinetic flows in a cross-shaped microchannel. J. Fluid Mech. 2006, 555, 1–42. [Google Scholar] [CrossRef]

- Luo, W.-J. Effect of ionic concentration on electrokinetic instability in a cross-shaped microchannel. Microfluid Nanofluid 2009, 6, 189–202. [Google Scholar] [CrossRef]

- Li, Q.; Delorme, Y.; Frankel, S.H. Parametric numerical study of electrokinetic instability in crossshaped microchannels. Microfluid Nanofluid 2016, 20, 29. [Google Scholar] [CrossRef]

- Dubey, K.; Gupta, A.; Bahga, S.S. Coherent structures in electrokinetic instability with orthogonal conductivity gradient and electric field. Phys. Fluids 2017, 29, 092007. [Google Scholar] [CrossRef]

- Posner, J.D.; Pérez, C.L.; Santiago, J.G. Electric fields yield chaos in microflows. Proc. Natl. Acad. Sci. USA 2012, 109, 14353–14356. [Google Scholar] [CrossRef]

- Wang, G.R.; Yang, F.; Zhao, W. There can be turbulence in microfluidics at low Reynolds number. Lab Chip 2014, 14, 1452–1458. [Google Scholar] [CrossRef]

- Wang, G.R.; Yang, F.; Zhao, W. Microelectrokinetic turbulence in microfluidics at low Reynolds number. Phys. Rev. E 2016, 93, 013106. [Google Scholar] [CrossRef]

- Wang, G.R.; Yang, F.; Zhao, W.; Chen, C.-P. On micro-electrokinetic scalar turbulence in microfluidics at a low Reynolds number. Lab Chip 2016, 16, 1030–1038. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Yang, F.; Wang, K.G.; Bai, J.T.; Wang, G.R. Rapid mixing by turbulent-like electrokinetic microflow. Chem. Eng. Sci. 2017, 165, 113–121. [Google Scholar] [CrossRef]

- Nan, K.; Shi, Y.; Zhao, T.; Tang, X.; Zhu, Y.Q.; Wang, K.G.; Bai, J.T.; Zhao, W. Mixing and flow transition in an optimized electrokinetic turbulent micromixer. Anal. Chem. 2022, 94, 12231–12239. [Google Scholar] [CrossRef] [PubMed]

- Baygents, J.C.; Baldessari, F. Electrohydrodynamic instability in a thin fluid layer with an electrical conductivity gradient. Phys. Fluids 1998, 10, 301–311. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, G.R. Scaling of velocity and scalar structure functions in AC electrokinetic turbulence. Phys. Rev. E 2017, 95, 023111. [Google Scholar] [CrossRef]

- Oks, D.; Mininni, P.D.; Marino, R.; Pouquet, A. Inverse cascades and resonant triads in rotating and stratified turbulence. Phys. Fluids 2017, 29, 111109. [Google Scholar] [CrossRef]

- Henderson, D.; Hammack, J.L. Experiments on ripple instabilities. Part 1. resonant triads. J. Fluid Mech. 1987, 184, 15–41. [Google Scholar] [CrossRef]

- Kartashova, E.; L’vov, V.; Nazarenko, S.; Procaccia, I. Towards a Theory of Discrete and Mesoscopic Wave Turbulence; Technical Report, RISC Report Series; University of Linz: Linz, Austria, 2010. [Google Scholar]

- Hu, Z.Y.; Zhao, W.X.; Chen, Y.; Zhang, C.; Feng, X.Q.; Jing, G.Y.; Wang, K.G.; Bai, J.T.; Wang, G.R.; Zhao, W. Onset of nonlinear electroosmotic flow under AC electric field. Anal. Chem. 2022, 94, 17913–17921. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Kuang, C.F.; Zhao, W.; Wang, G. AC electrokinetic fast mixing in non-parallel microchannels. Chem. Eng. Commun. 2017, 204, 190–197. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, F.; Khan, J.; Reifsnider, K.; Wang, G.R. Measurement of velocity fluctuations in microfluidics with simultaneously ultrahigh spatial and temporal resolution. Exp. Fluids 2016, 57, 11. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, X.; Yang, F.; Wang, K.G.; Bai, J.T.; Qiao, R.; Wang, G.R. Study of oscillating electroosmotic flows with high temporal and spatial resolution. Anal. Chem. 2018, 90, 1652–1659. [Google Scholar] [CrossRef]

- Hu, Z.Y.; Zhao, T.Y.; Zhao, W.; Yang, F.; Wang, H.X.; Wang, K.G.; Bai, J.T.; Wang, G.R. Transition from periodic to chaotic AC electroosmotic flows near electric double layer. AlChE J. 2021, 67, e17148. [Google Scholar] [CrossRef]

- Buaria, D.; Clay, M.P.; Sreenivasan, K.R.; Yeung, P.K. Small-scale isotropy and ramp-cliff structures in scalar turbulence. Phys. Reivew Lett. 2021, 126, 034504. [Google Scholar] [CrossRef]

- Zaman, K.B.M.Q.; Bar-Sever, A.; Mangalam, S.M. Effect of acoustic excitation on the flow over a low-Re airfoil. J. Fluid Mech. 1987, 182, 127–148. [Google Scholar] [CrossRef]

- Wang, L.Q.; Xu, M.T. Property of period-doubling bifurcations. Chaos Solitons Fractals 2005, 24, 527–532. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, D.L.; Liu, A.J.; Luo, K.; Wu, J.; Yi, H.L. Full bifurcation scenarios and pattern formation of laminar electroconvection in a cavity. Phys. Fluids 2022, 34, 103612. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Y.; Zeng, M.; Bai, H.; Meng, S.; Zhang, C.; Feng, X.; Zhang, C.; Wang, K.; Zhao, W. Transition Routes of Electrokinetic Flow in a Divergent Microchannel with Bending Walls. Micromachines 2023, 14, 474. https://doi.org/10.3390/mi14020474

Shi Y, Zeng M, Bai H, Meng S, Zhang C, Feng X, Zhang C, Wang K, Zhao W. Transition Routes of Electrokinetic Flow in a Divergent Microchannel with Bending Walls. Micromachines. 2023; 14(2):474. https://doi.org/10.3390/mi14020474

Chicago/Turabian StyleShi, Yanxia, Ming Zeng, Haoxin Bai, Shuangshuang Meng, Chen Zhang, Xiaoqiang Feng, Ce Zhang, Kaige Wang, and Wei Zhao. 2023. "Transition Routes of Electrokinetic Flow in a Divergent Microchannel with Bending Walls" Micromachines 14, no. 2: 474. https://doi.org/10.3390/mi14020474

APA StyleShi, Y., Zeng, M., Bai, H., Meng, S., Zhang, C., Feng, X., Zhang, C., Wang, K., & Zhao, W. (2023). Transition Routes of Electrokinetic Flow in a Divergent Microchannel with Bending Walls. Micromachines, 14(2), 474. https://doi.org/10.3390/mi14020474