Theoretical and Experimental Study of Friction Characteristics of Textured Journal Bearing

Abstract

1. Introduction

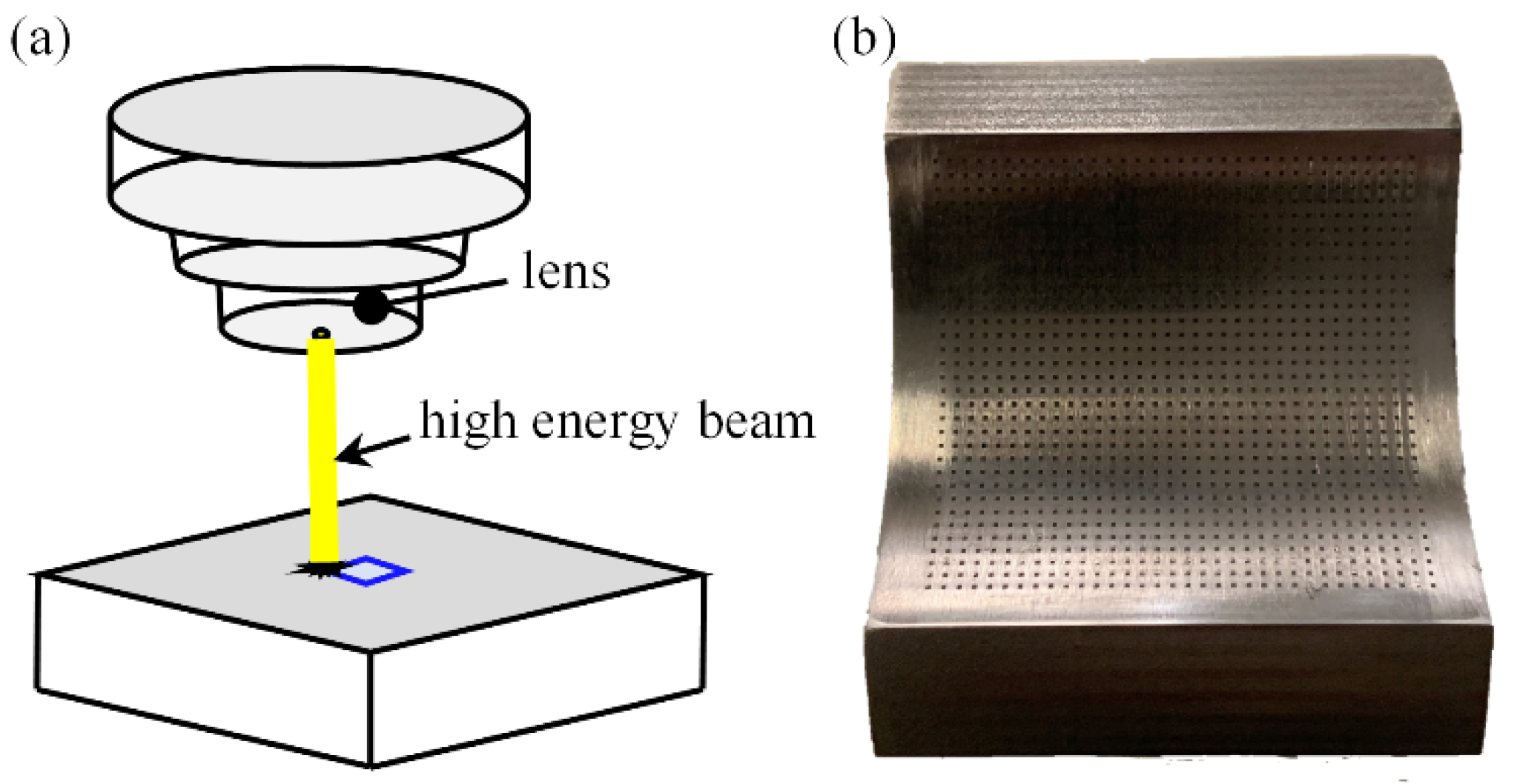

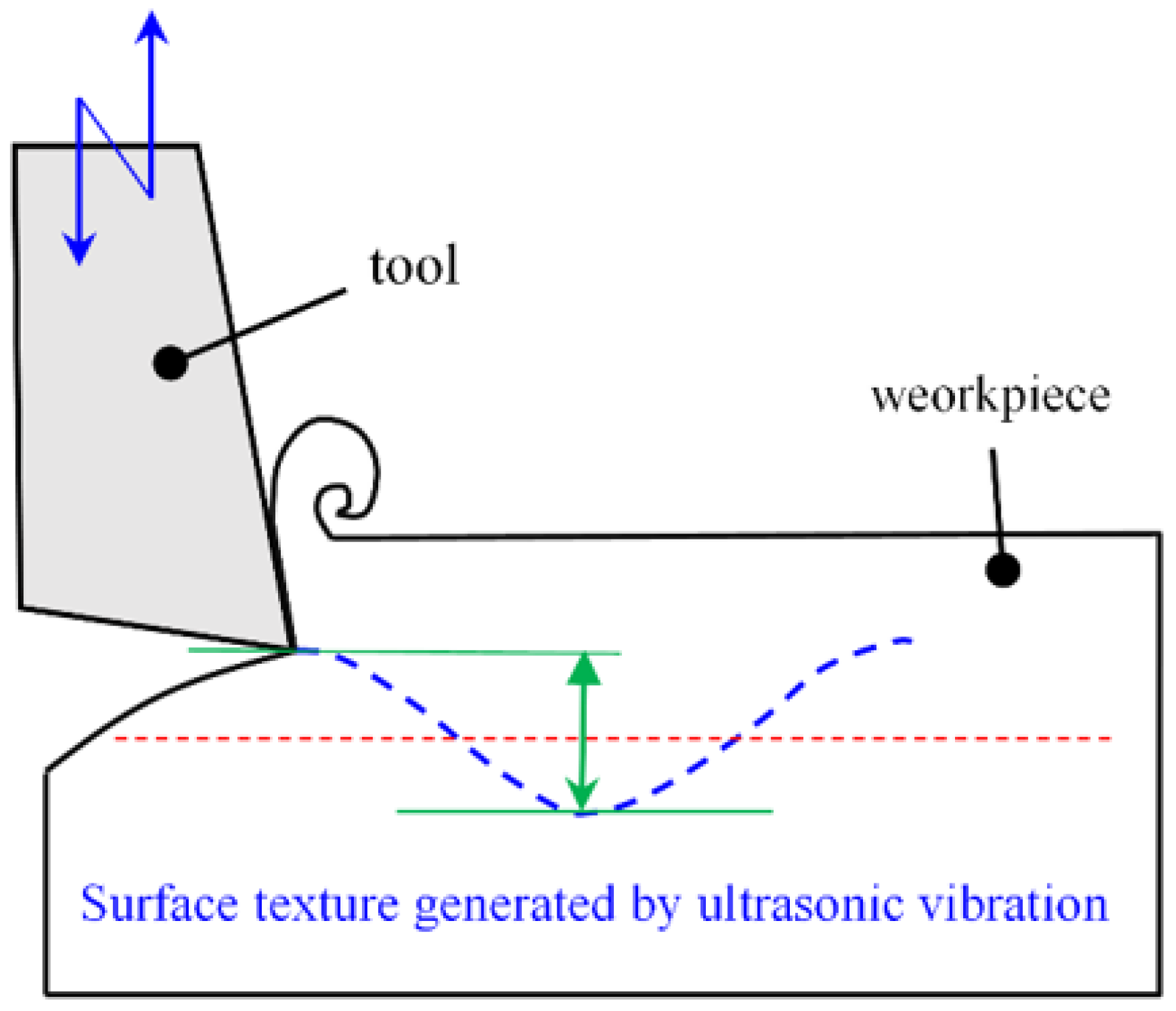

2. Theoretical Model and Experimental Method

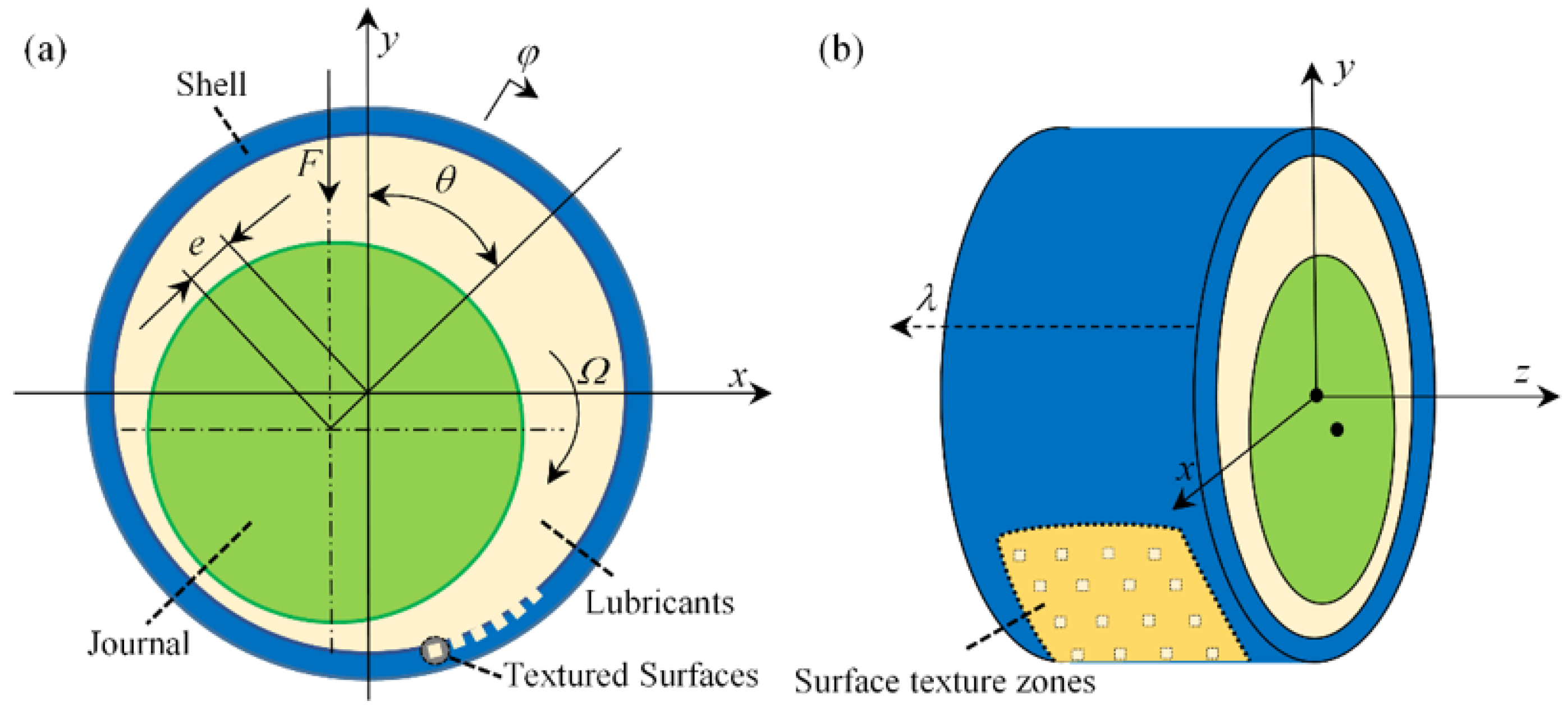

2.1. Theoretical Model

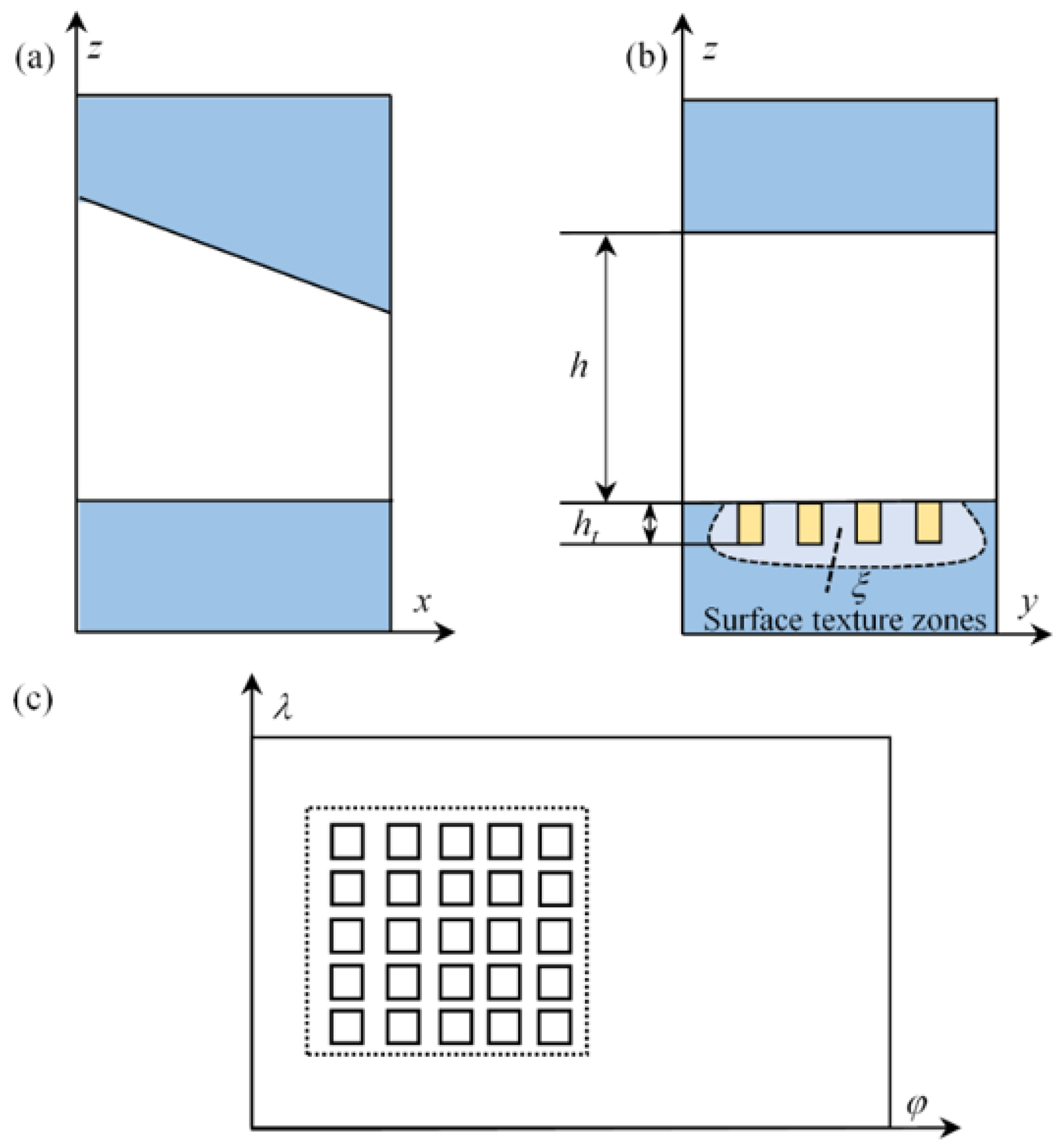

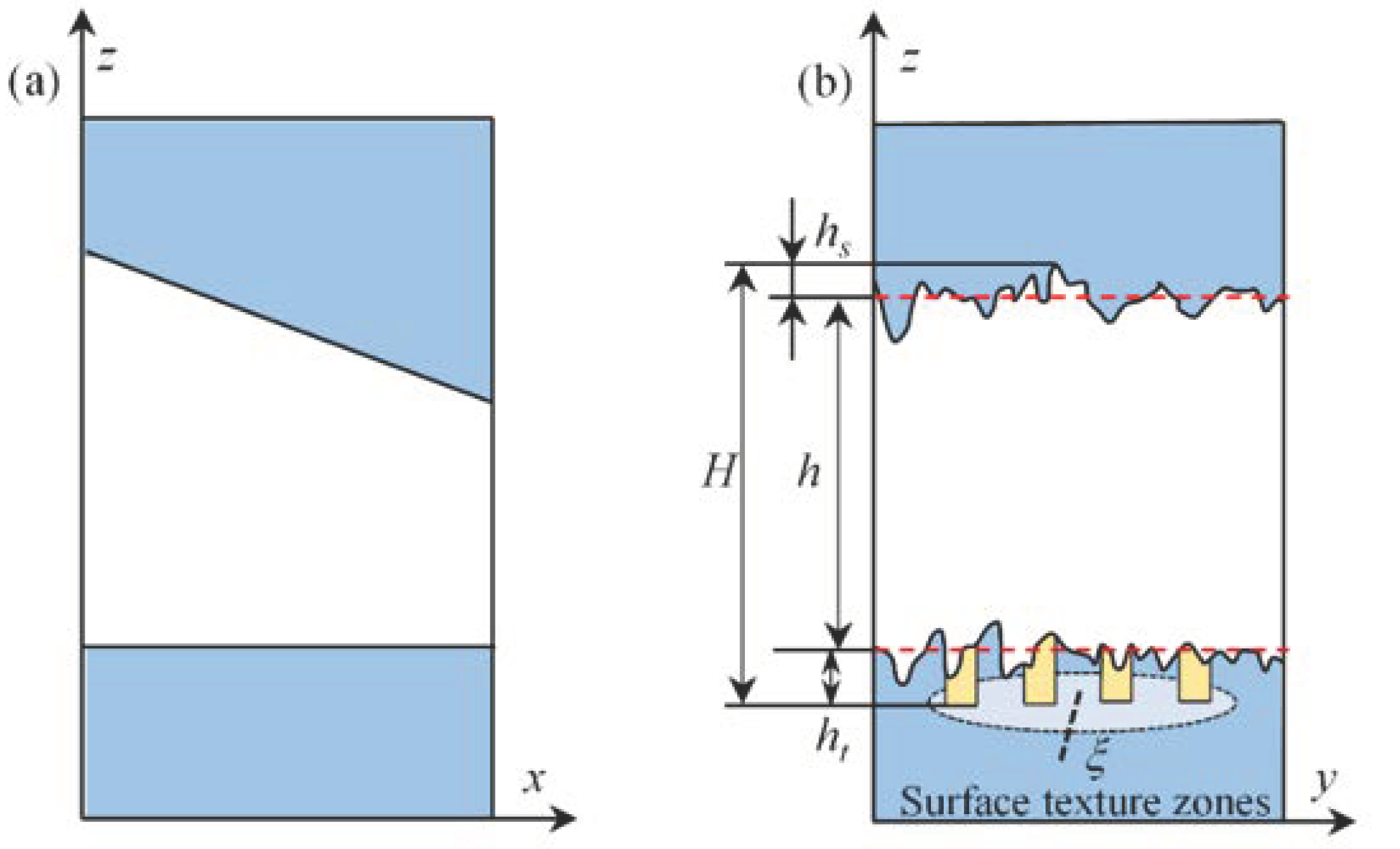

2.2. Mathematical Model

2.3. Tribological Characteristics

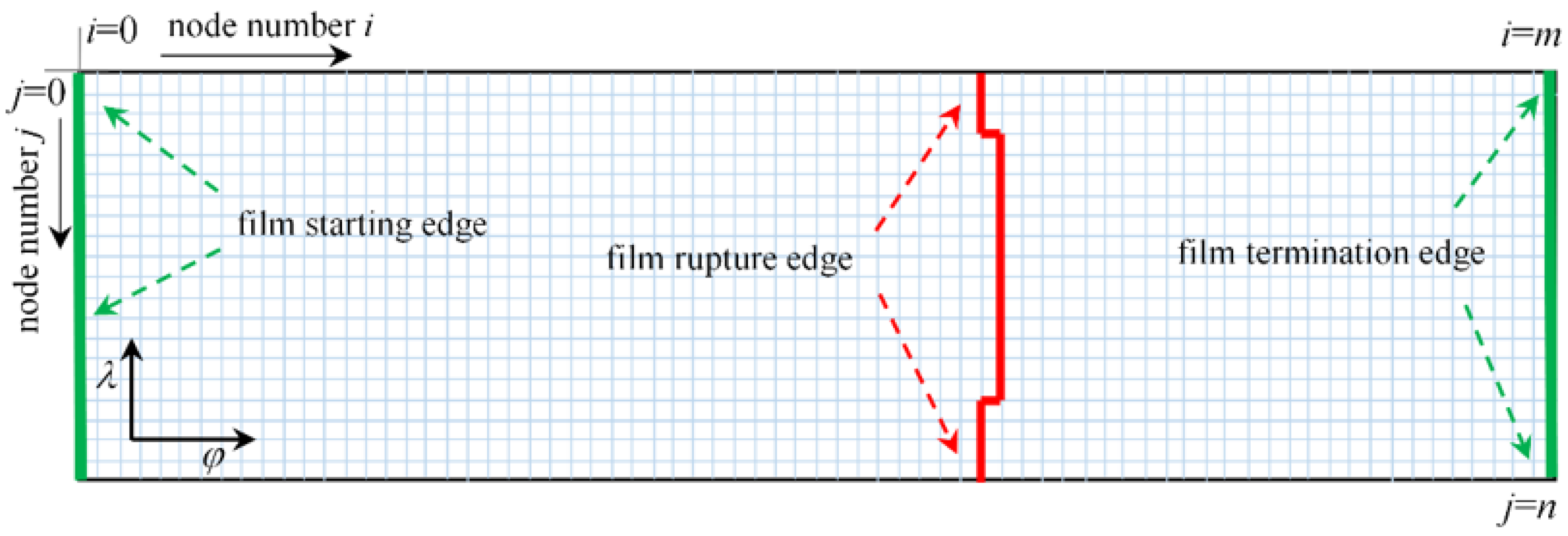

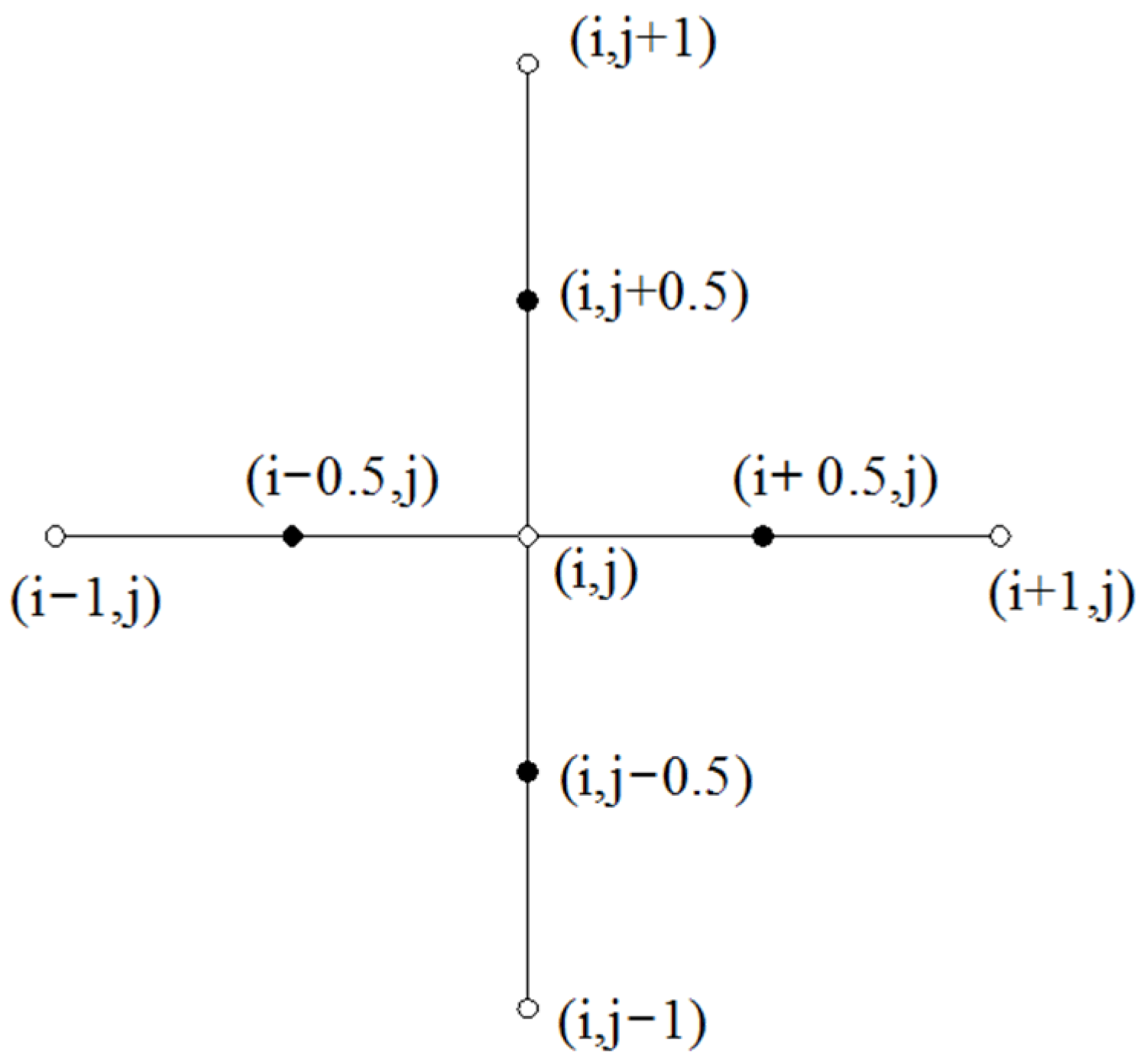

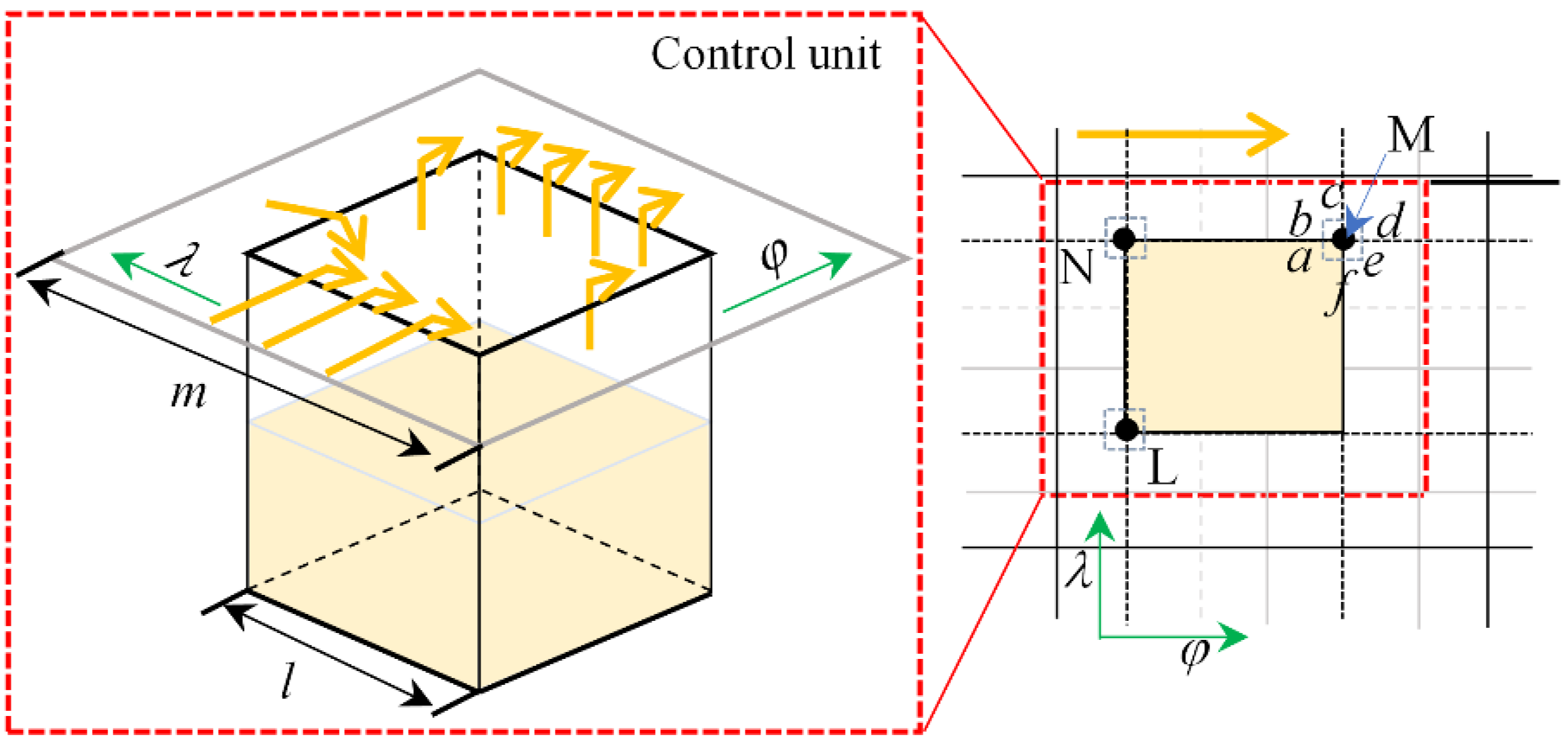

2.4. Film Discretization

2.5. Texture Boundary Film Thickness Variation Processing

3. Methods and Tests

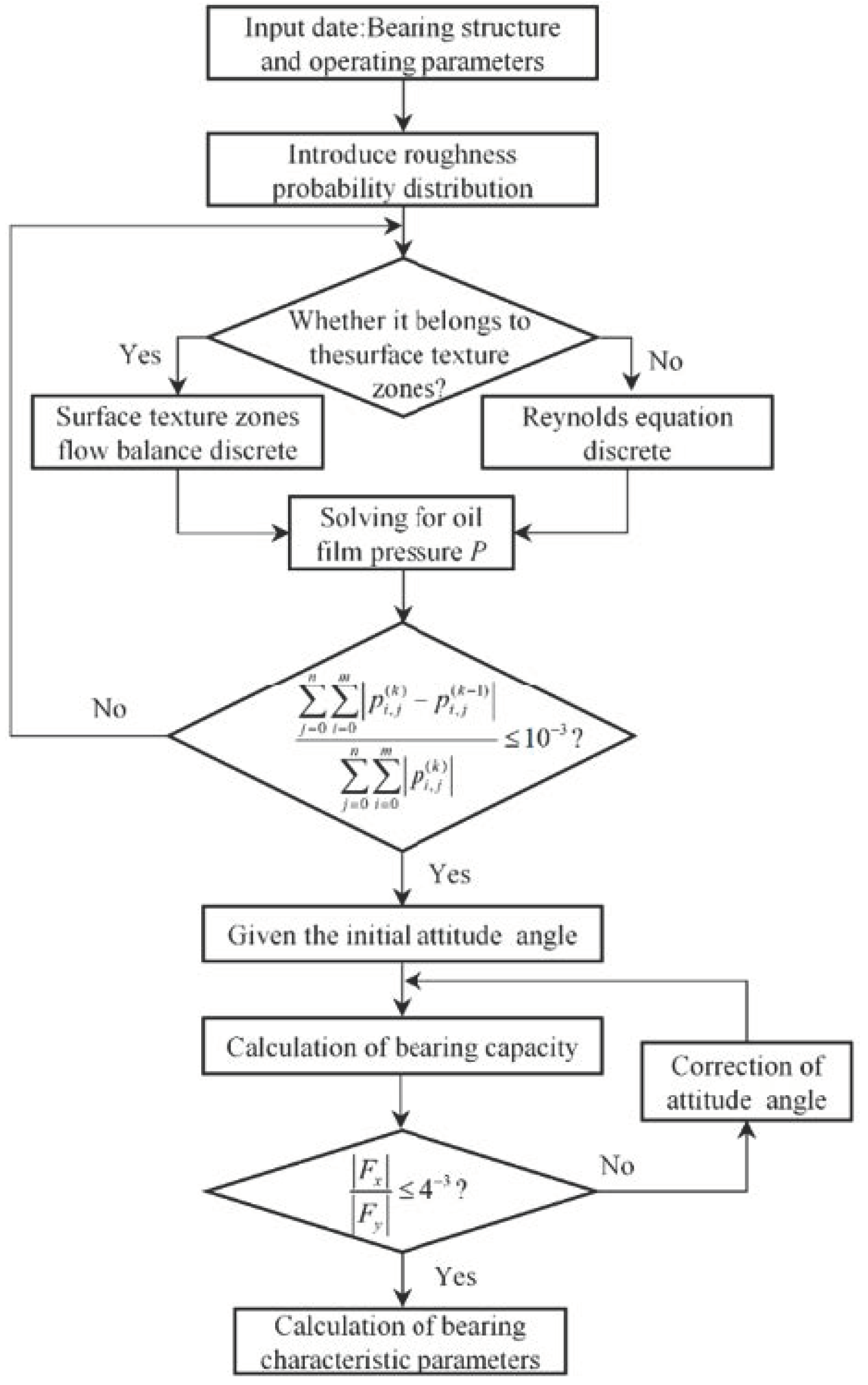

3.1. Solving Method

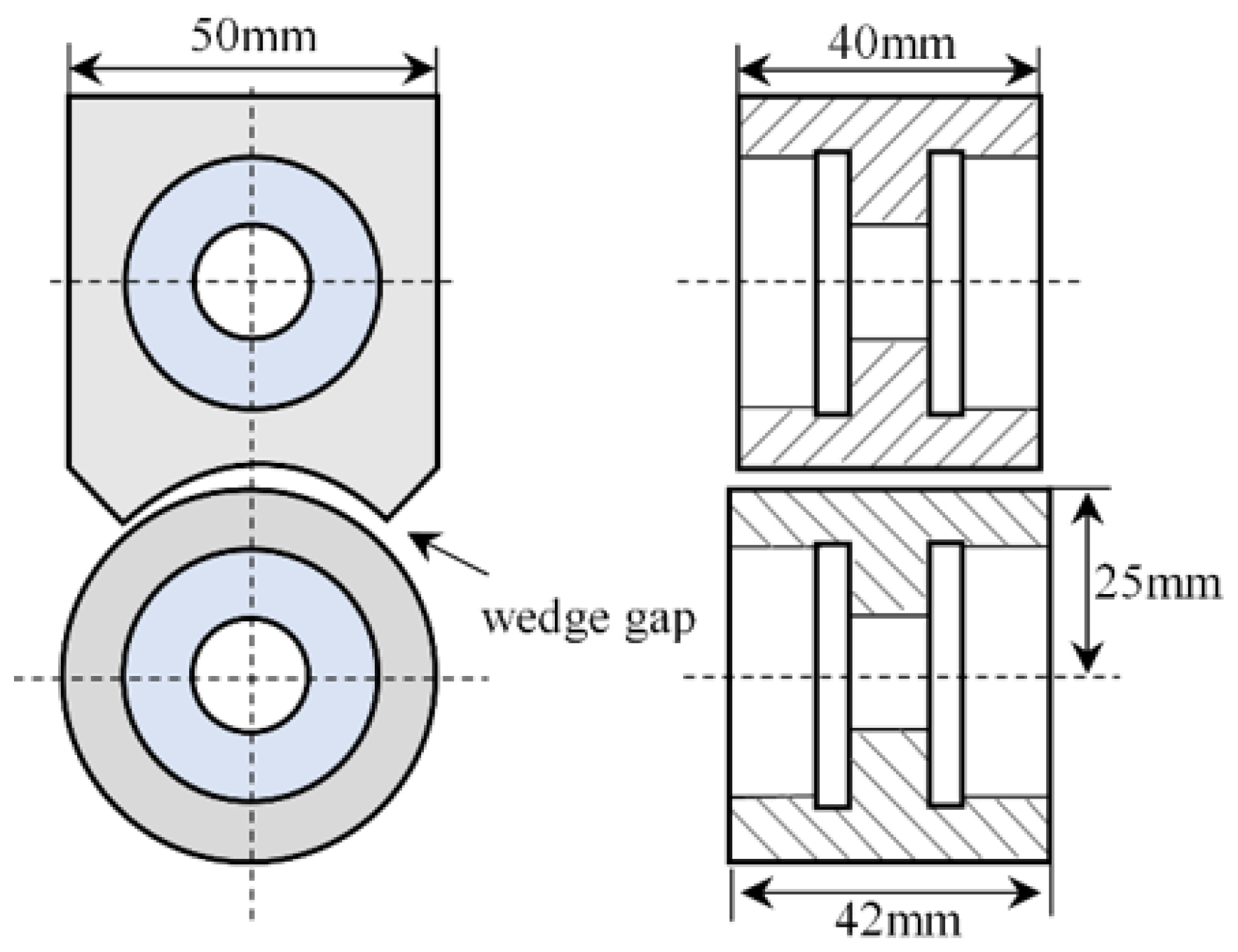

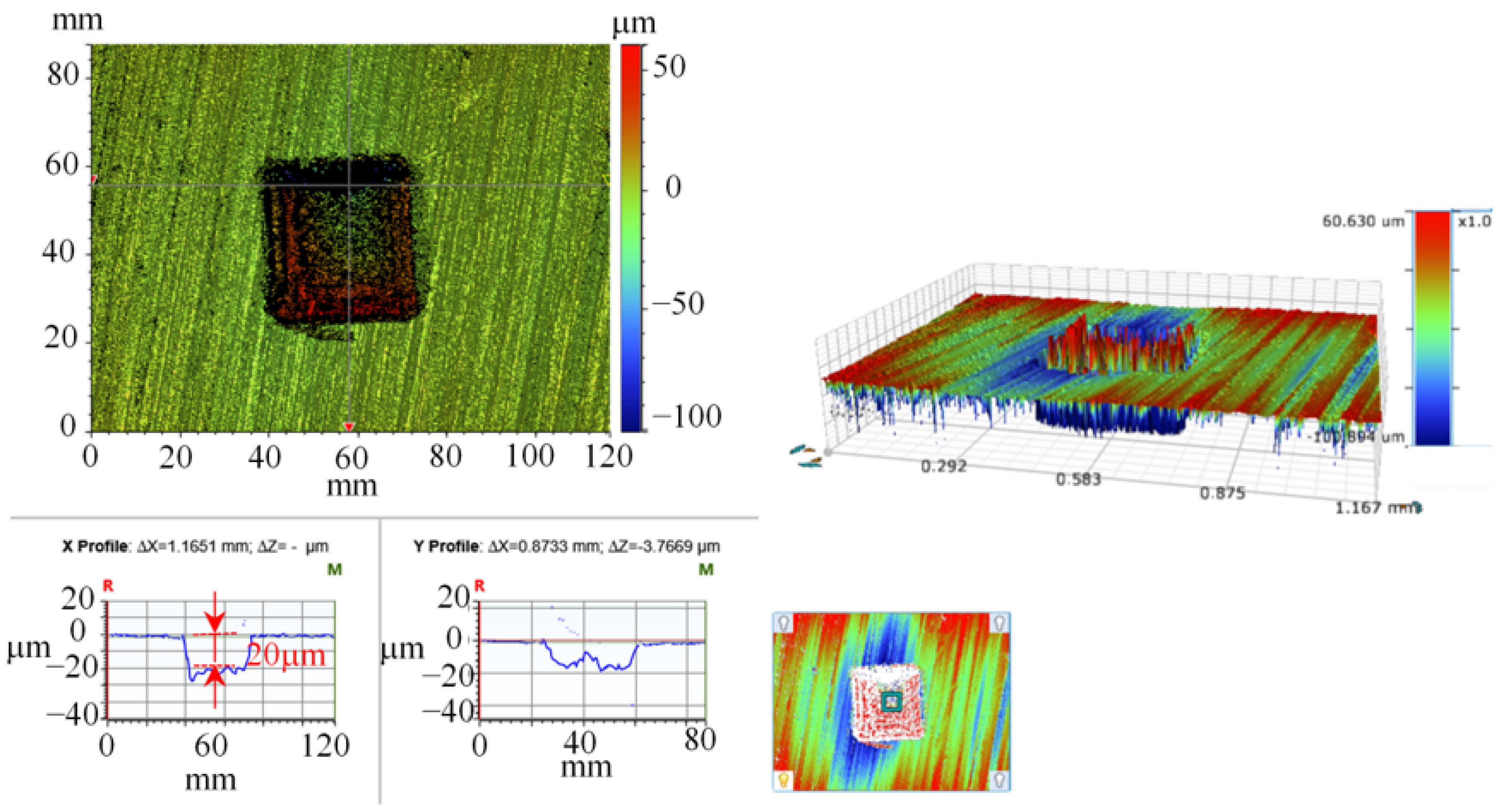

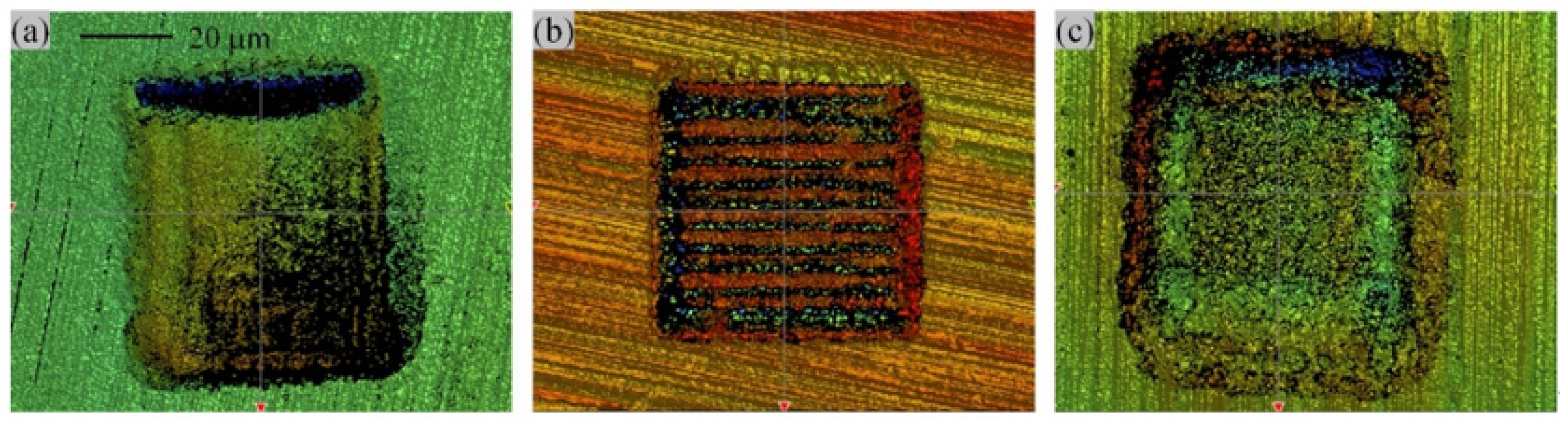

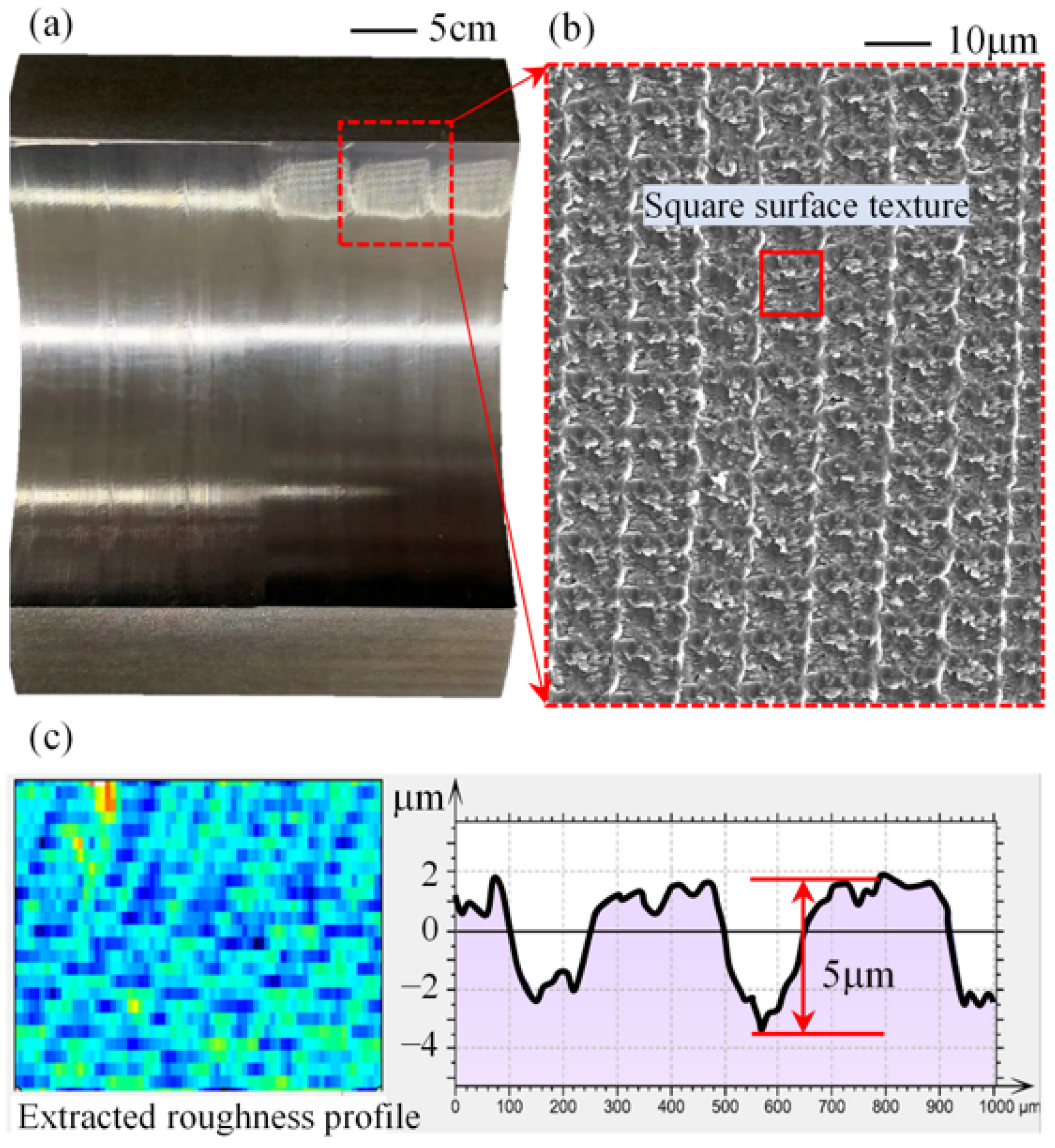

3.2. Bearing Preparation

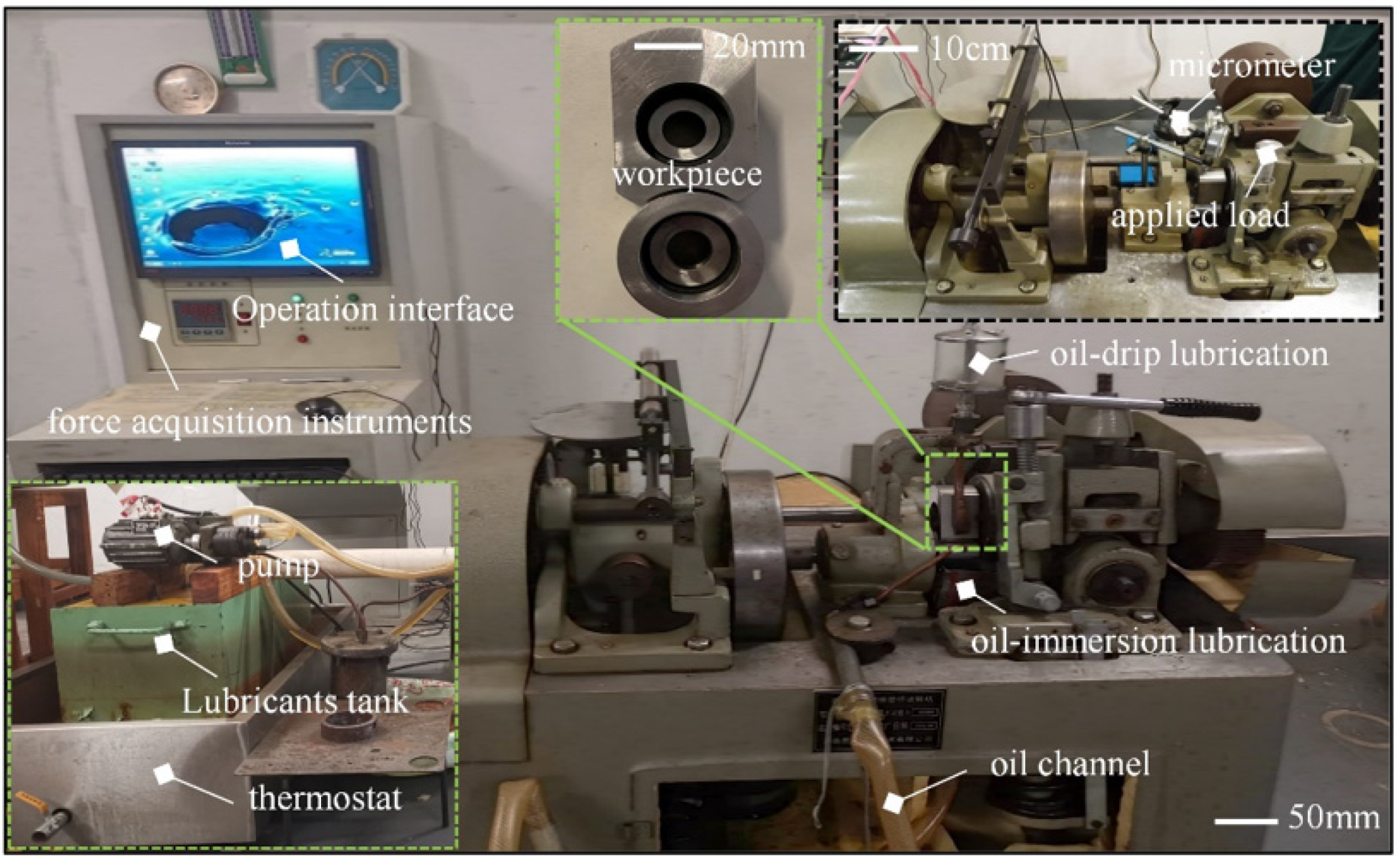

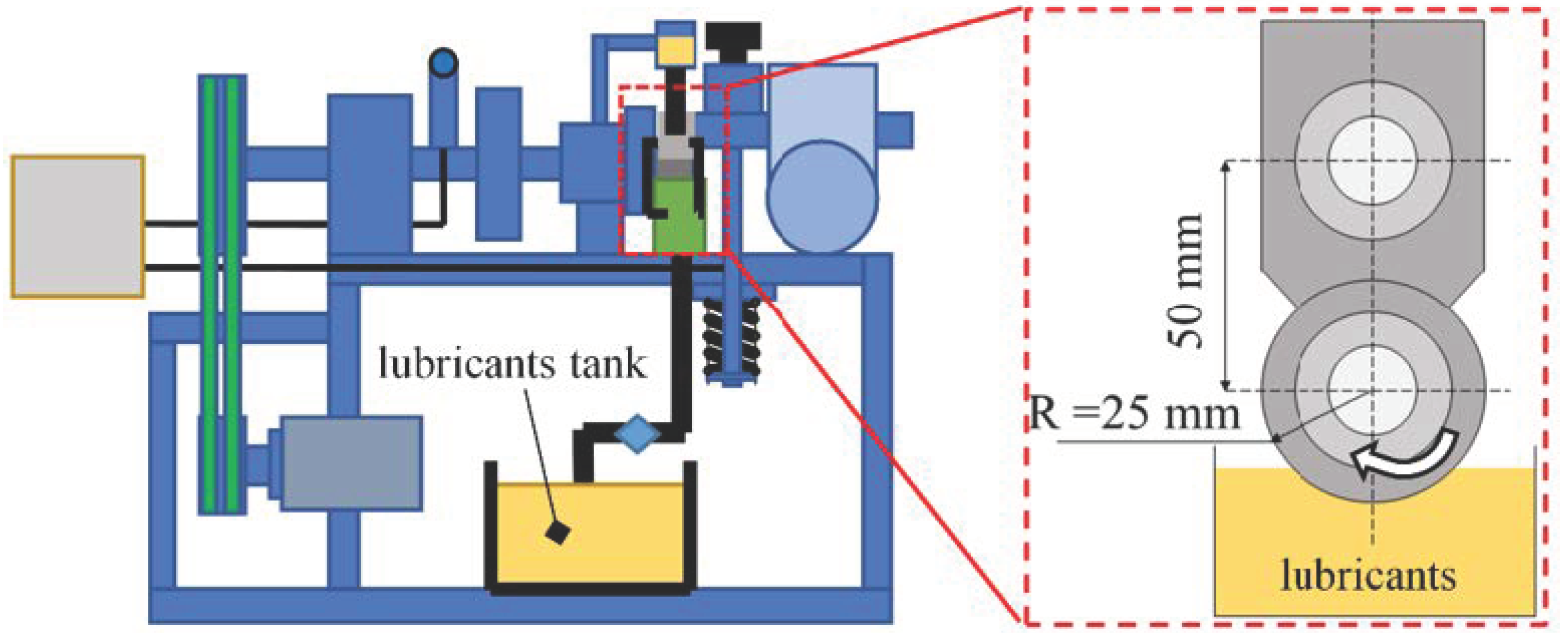

3.3. Frictional Wear Test

4. Analysis of Theoretical Results

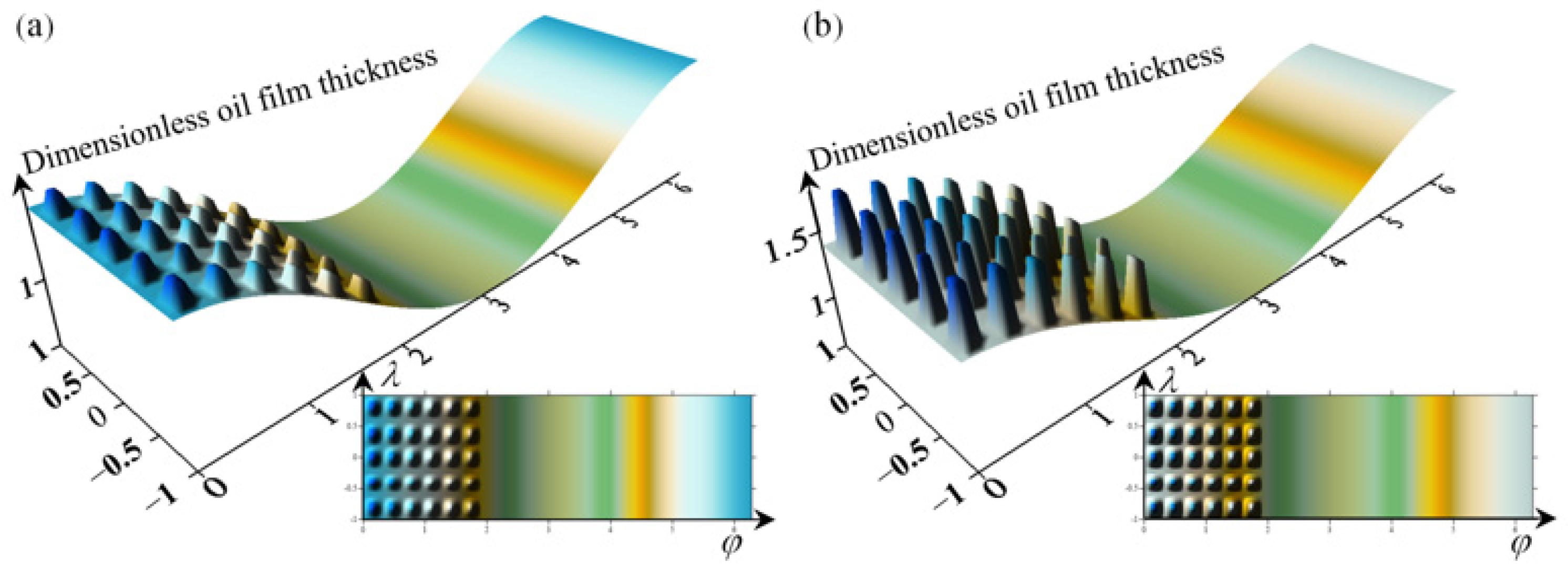

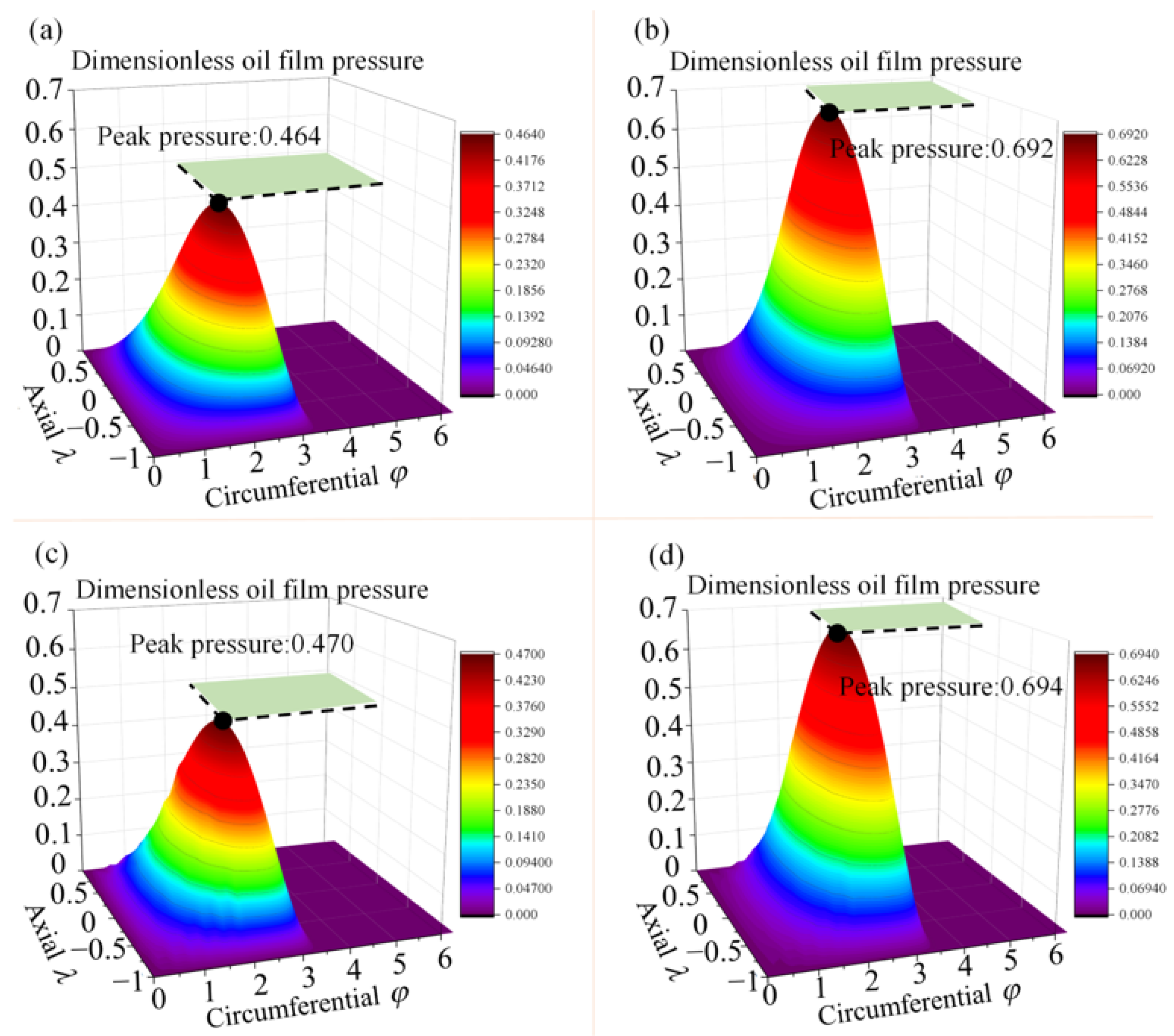

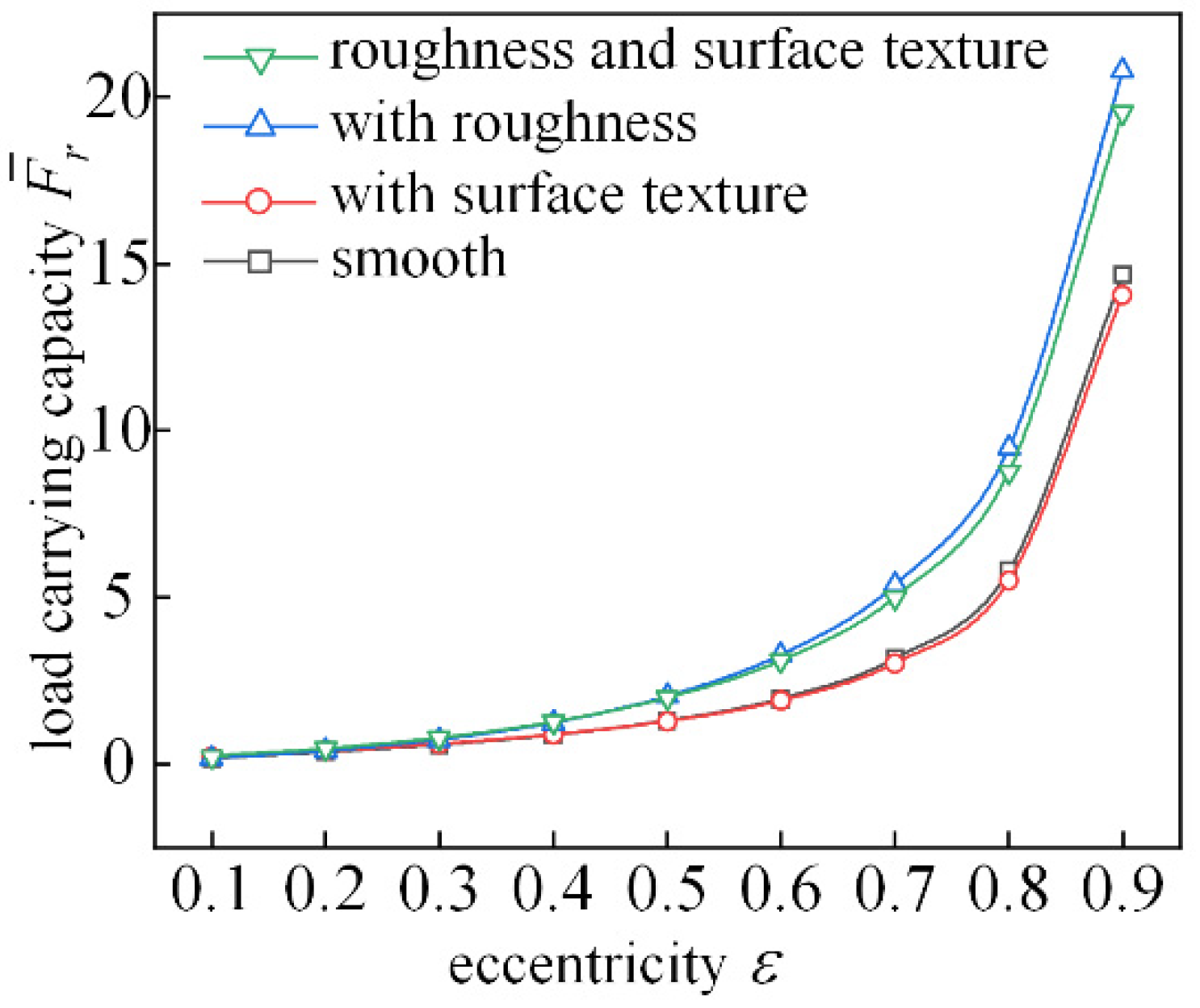

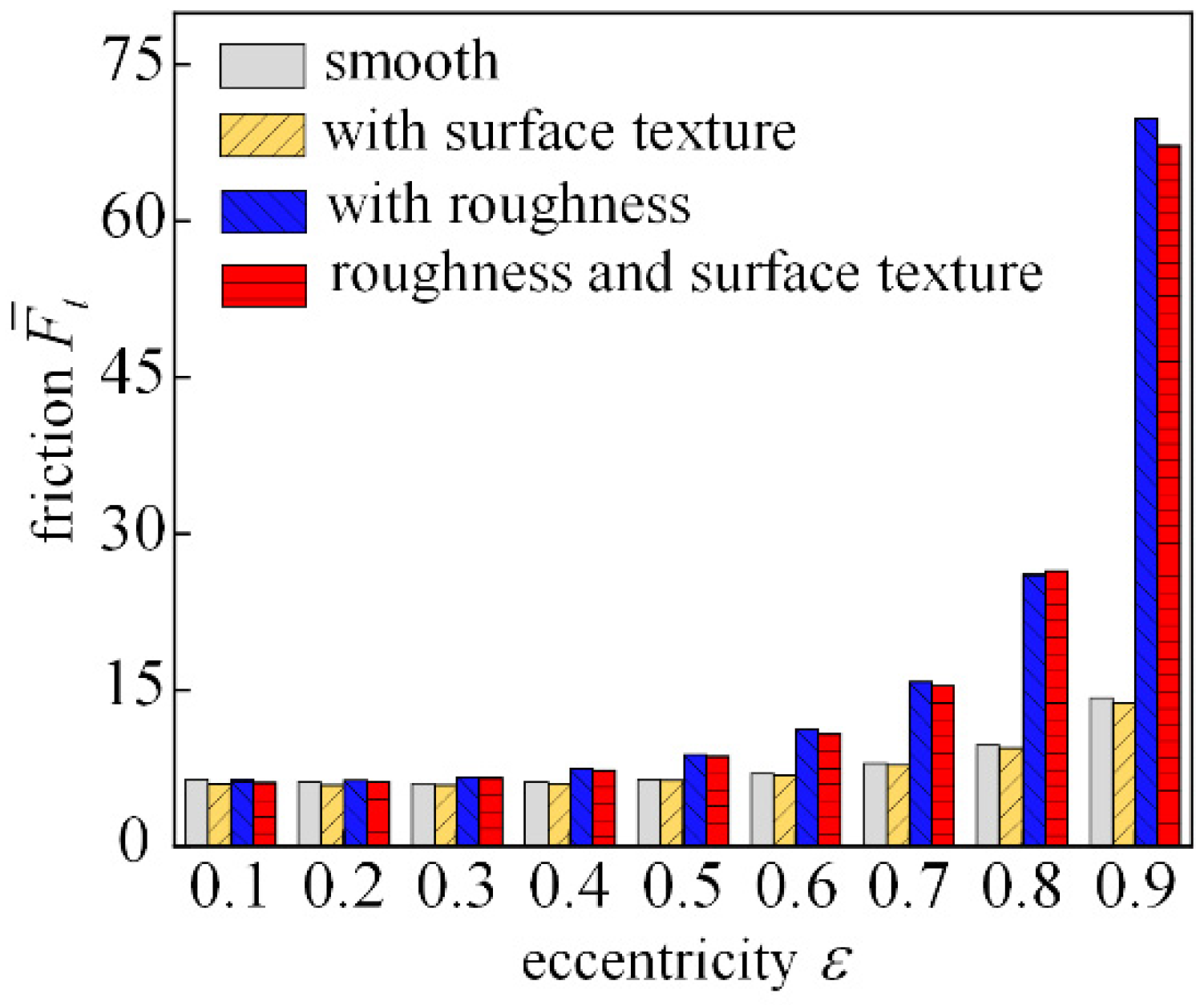

4.1. Textured Bearing Characteristics Considering Roughness

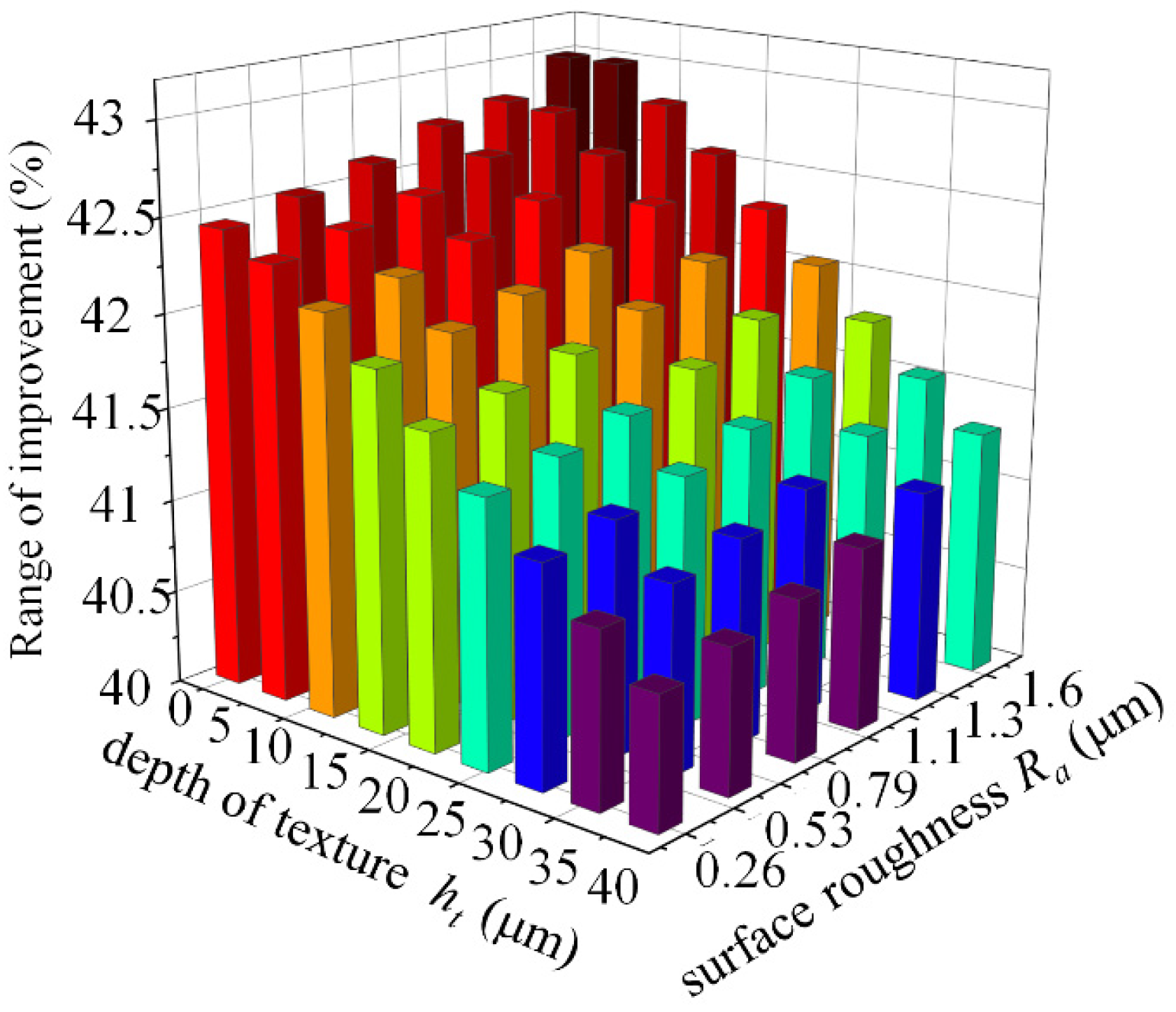

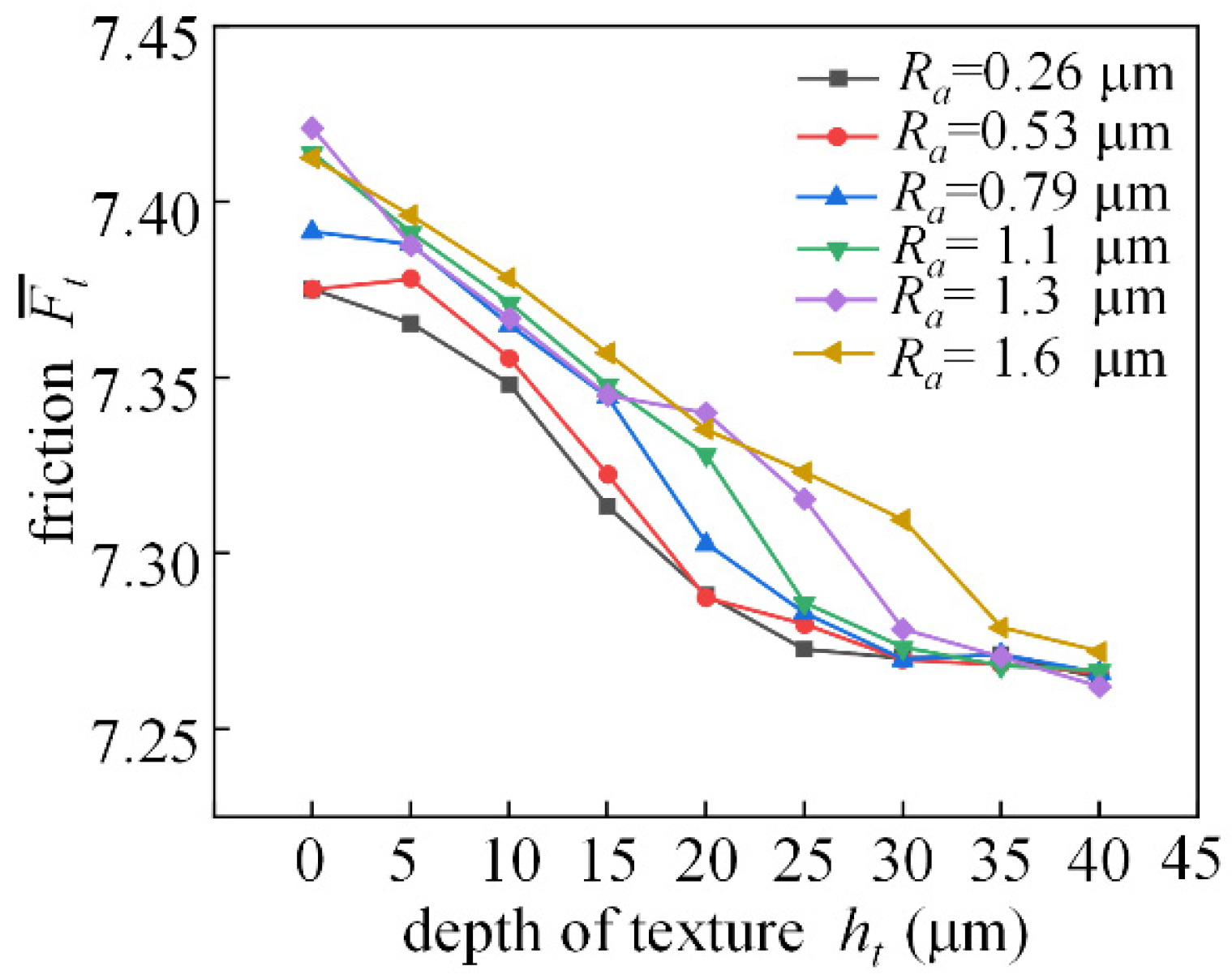

4.2. The Relationship between Texture Depth and Roughness

4.3. Analysis of Frictional Wear Test

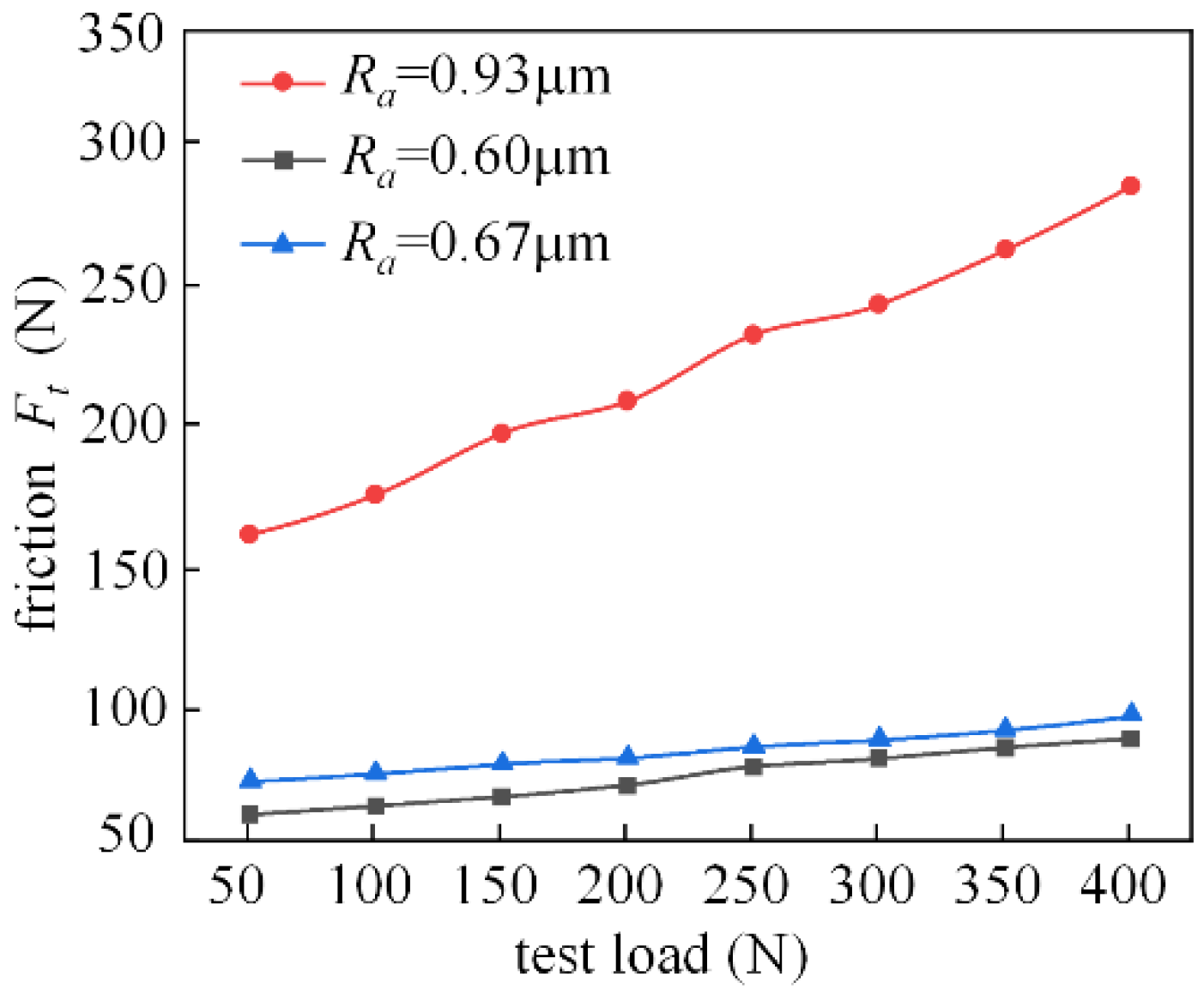

4.3.1. Working Condition of Spindle Speed 200 r/min

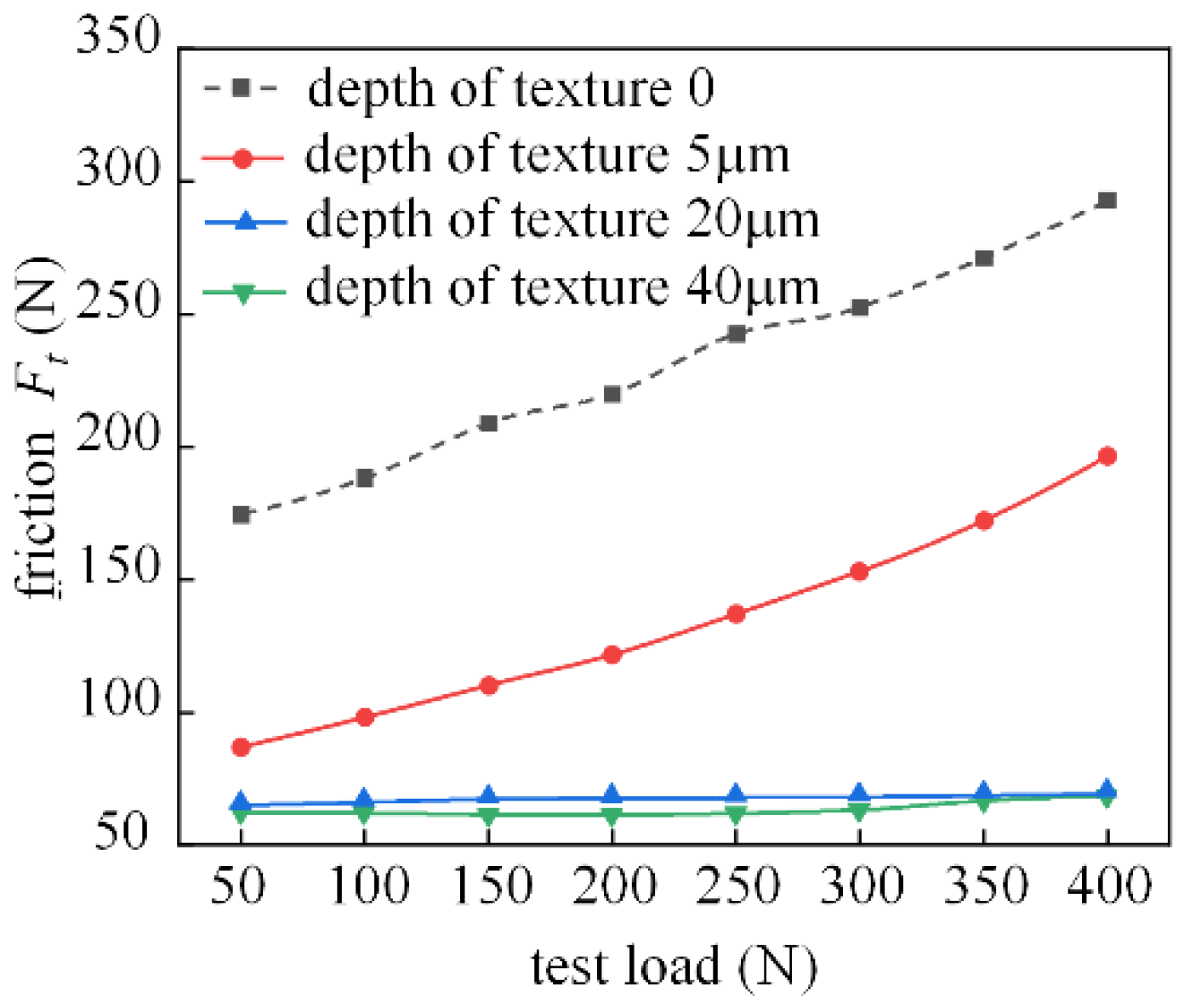

4.3.2. Working Condition of Spindle Speed 400 r/min

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Etsion, I. State of the Art in Laser Surface Texturing. J. Tribol. 2005, 127, 248–253. [Google Scholar] [CrossRef]

- Yu, H.; Huang, W.; Wang, X. Dimple patterns design for different circumstances. Lubr. Sci. 2013, 25, 67–78. [Google Scholar] [CrossRef]

- Yang, X.; Fu, Y.; Ji, J.; Chen, T.; Pan, C. Study on tribological properties of surface concave convex micro-texture on the mold steel. Ind. Lubr. Tribol. 2020, 72, 1167–1171. [Google Scholar] [CrossRef]

- Meng, Y.; Xu, J.; Jin, Z.; Jin, X.Z.; Prakash, B.; Hu, Y. A review of recent advances in tribology. Friction 2020, 8, 221–300. [Google Scholar] [CrossRef]

- Shinkarenko, A.; Kligerman, Y.; Etsion, I. The effect of surface texturing in softelasto-hydrodynamic lubrication. Tribol. Int. 2009, 42, 284–292. [Google Scholar] [CrossRef]

- He, B.; Chen, W.; Wang, Q.J. Surface Texture Effect on Friction of a Microtextured Poly(dimethylsiloxane) (PDMS). Tribol. Lett. 2008, 31, 187–197. [Google Scholar] [CrossRef]

- Ramesh, A.; Akram, W.; Mishra, S.P.; Cannon, A.H.; Polycarpou, A.A.; King, W.P. Friction characteristics of microtextured surfaces under mixed and hydrodynamic lubrication. Tribol. Int. 2013, 57, 170–176. [Google Scholar] [CrossRef]

- Hamilton, D.B.; Walowit, J.A.; Allen, C.M. A Theory of Lubrication by Microirregularities. J. Basic Eng. 1966, 88, 177–185. [Google Scholar] [CrossRef]

- Zhou, L.; Kato, K.; Umehara, N.; Miyake, Y. Friction and wear properties of hard coating materials on textured hard disk sliders. Wear 2000, 243, 133–139. [Google Scholar] [CrossRef]

- Yagi, K.; Matsunaka, W.; Sugimura, J. Impact of textured surfaces in starved hydrodynamic lubrication. Tribol. Int. 2020, 154, 106756. [Google Scholar] [CrossRef]

- Shinde, A.B.; Pawar, P.M. Multi-objective optimization of surface textured journal bearing by Taguchi based Grey relational analysis. Tribol. Int. 2017, 114, 349–357. [Google Scholar] [CrossRef]

- Su, B.; Huang, L.; Huang, W.; Wang, X. The load carrying capacity of textured sliding bearings with elastic deformation. Tribol. Int. 2017, 109, 86–96. [Google Scholar] [CrossRef]

- Krasnoperova, A.A.; Hector, S.; Pomerene, A.; Lamberti, A.; Wind, S.; Viswanathan, R.; Ito, H. Patterning of 100 nm Features Using X-ray Lithography. J. Photopolym. Sci. Technol. 1997, 10, 613–618. [Google Scholar] [CrossRef]

- Huff, M. Recent Advances in Reactive Ion Etching and Applications of High-Aspect-Ratio Microfabrication. Micromachines 2021, 12, 991. [Google Scholar] [CrossRef] [PubMed]

- Mekaru, H.; Goto, H.; Takahashi, M. Development of ultrasonic micro hot embossing technology. Microelectron. Eng. 2007, 84, 1282–1287. [Google Scholar] [CrossRef]

- Bhogal, S.S.; Sindhu, C.; Dhami, S.S.; Pabla, B.S. Minimization of Surface Roughness and Tool Vibration in CNC Milling Operation. J. Optim. 2015, 2015, 192030. [Google Scholar] [CrossRef]

- Kango, S.; Singh, D.; Sharma, R.K. Numerical investigation on the influence of surface texture on the performance of hydrodynamic journal bearing. Meccanica 2012, 47, 469–482. [Google Scholar] [CrossRef]

- Etsion, I. Modeling of surface texturing in hydrodynamic lubrication. Friction 2013, 1, 195–209. [Google Scholar] [CrossRef]

- Matele, S.; Pandey, K. Effect of surface texturing on the dynamic characteristics of hydrodynamic journal bearing comprising concepts of green tribology. J. Eng. Tribol. 2018, 232, 1365–1376. [Google Scholar] [CrossRef]

- Wang, L.; Guo, S.; Wei, Y.; Yuan, G.; Geng, H. Optimization research on the lubrication characteristics for friction pairs surface of journal bearings with micro texture. Meccanica 2019, 54, 1135–1148. [Google Scholar] [CrossRef]

- Quiñonez, A.F.; Morales-Espejel, G. Surface roughness effects in hydrodynamic bearings. Tribol. Int. 2016, 98, 212–219. [Google Scholar] [CrossRef]

- Li, S.; An, Q. Lubrication performance of planar thrust bearing with consideration of roughness of the surfaces. J. Eng. Tribol. 2019, 233, 1046–1058. [Google Scholar] [CrossRef]

- Zhang, S.; To, S.; Wang, S.; Zhu, Z. A review of surface roughness generation in ultra-precision machining. Int. J. Mach. Tools Manuf. 2015, 91, 76–95. [Google Scholar] [CrossRef]

- Shen, X.-H.; Zhang, J.; Xing, D.X.; Zhao, Y. A study of surface roughness variation in ultrasonic vibration-assisted milling. Int. J. Adv. Manuf. Technol. 2012, 58, 553–561. [Google Scholar] [CrossRef]

- Lu, H.; Zhu, L.; Yang, Z.; Yan, B.; Hao, Y.; Qin, S. Research on the generation mechanism and interference of surface texture in ultrasonic vibration assisted milling. Int. J. Mech. Sci. 2021, 208, 106681. [Google Scholar] [CrossRef]

- Christensen, H.; Tonder, K. The Hydrodynamic Lubrication of Rough Bearing Surfaces of Finite Width. J. Lubr. Technol. 1971, 93, 324–329. [Google Scholar] [CrossRef]

| Parameters | Symbol/Unit | Value |

|---|---|---|

| Length of bearing | l/mm | 40 |

| Radius of bearing | r/mm | 25 |

| Radius clearance | c/mm | 0.05 |

| Weight of rotor | M/kg | 100 |

| Eccentricity | ε | 0.1~0.9 |

| Lubricant density | ρ/kg·m−3 | 840.5 |

| Lubricant viscosity | μ/Pa·s | 0.04 |

| Texture area ratio | S | 0.36 |

| Dimensions of the texture | m/μm | 10 |

| Depth of texture | ht/μm | 0~40 |

| Value of roughness | Ra/μm | 0~1.6 |

| Test Piece Number | Value of Roughness (μm) | Depth of Texture (μm) |

|---|---|---|

| No.1 | 0.93 | - |

| No.2 | 0.6 | - |

| No.3 | 0.67 | - |

| No.4 | 0.51 | 5 |

| No.5 | 0.63 | 20 |

| No.6 | 0.47 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Bie, W.; Zhang, S.; Liu, T. Theoretical and Experimental Study of Friction Characteristics of Textured Journal Bearing. Micromachines 2023, 14, 577. https://doi.org/10.3390/mi14030577

Wang H, Bie W, Zhang S, Liu T. Theoretical and Experimental Study of Friction Characteristics of Textured Journal Bearing. Micromachines. 2023; 14(3):577. https://doi.org/10.3390/mi14030577

Chicago/Turabian StyleWang, Hongtao, Wenbo Bie, Shaolin Zhang, and Tengfei Liu. 2023. "Theoretical and Experimental Study of Friction Characteristics of Textured Journal Bearing" Micromachines 14, no. 3: 577. https://doi.org/10.3390/mi14030577

APA StyleWang, H., Bie, W., Zhang, S., & Liu, T. (2023). Theoretical and Experimental Study of Friction Characteristics of Textured Journal Bearing. Micromachines, 14(3), 577. https://doi.org/10.3390/mi14030577