Revealing the Mechanism of the Bias Temperature Instability Effect of p-GaN Gate HEMTs by Time-Dependent Gate Breakdown Stress and Fast Sweeping Characterization

Abstract

:1. Introduction

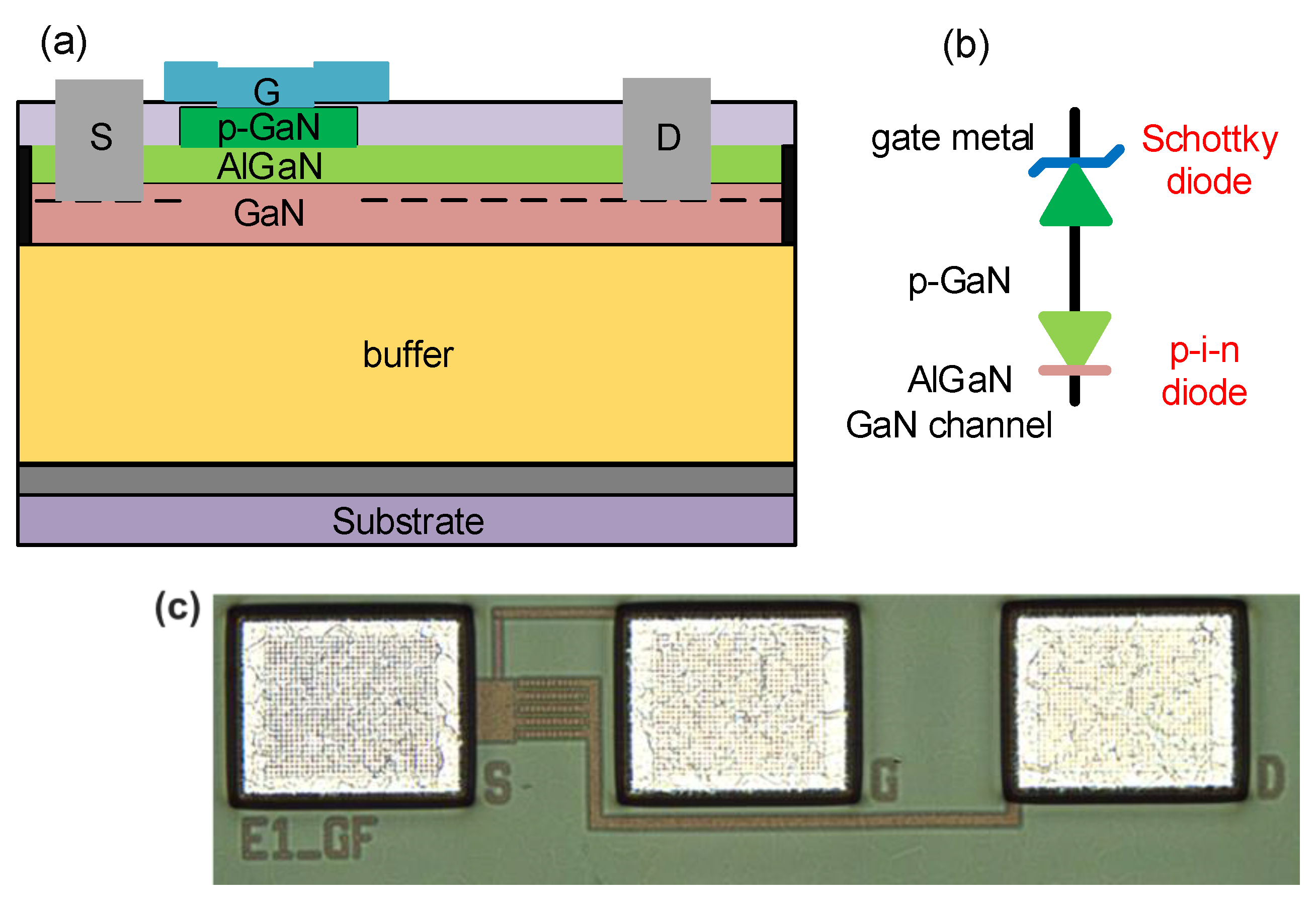

2. Devices and Characterization

2.1. Devices

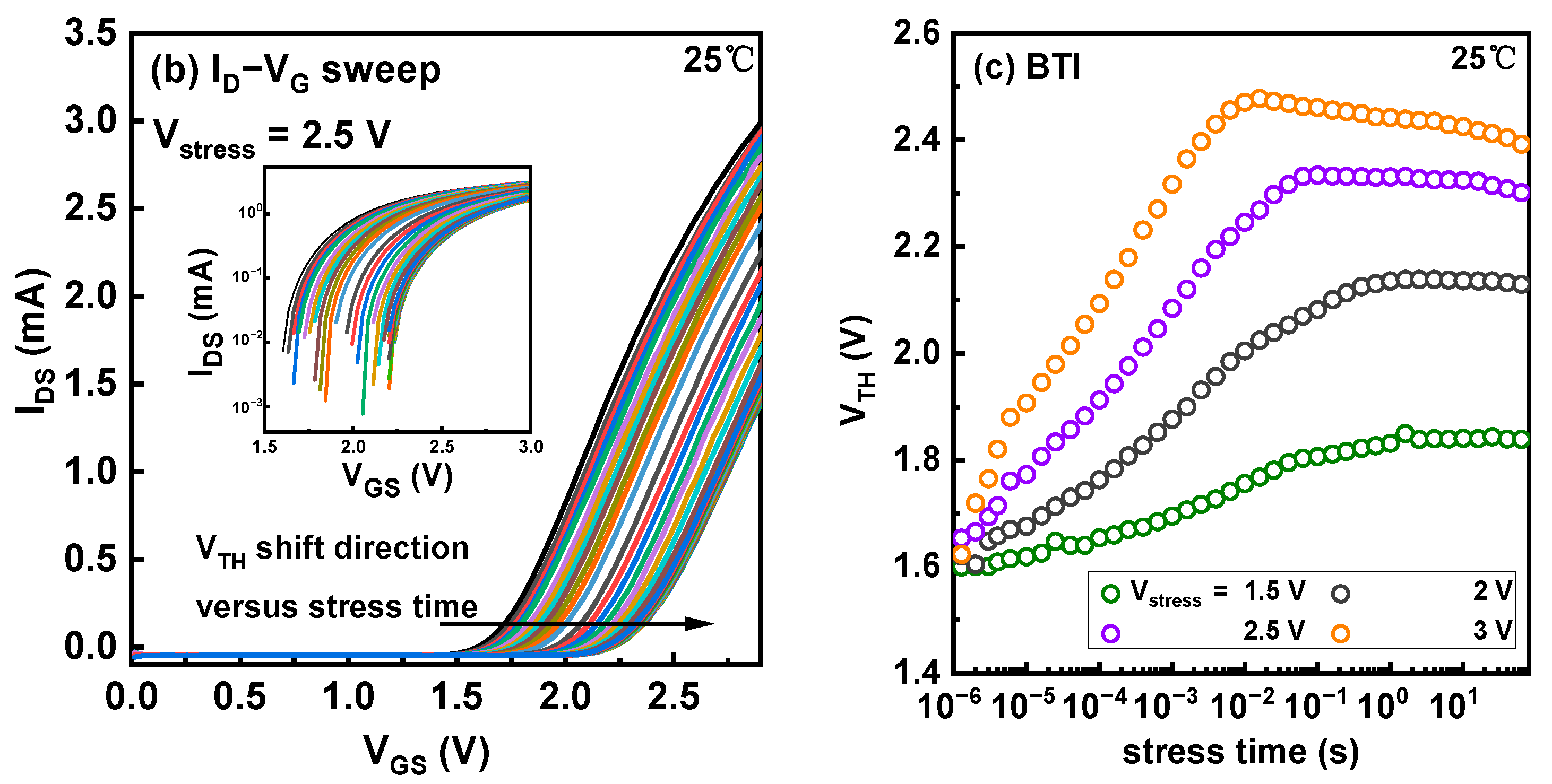

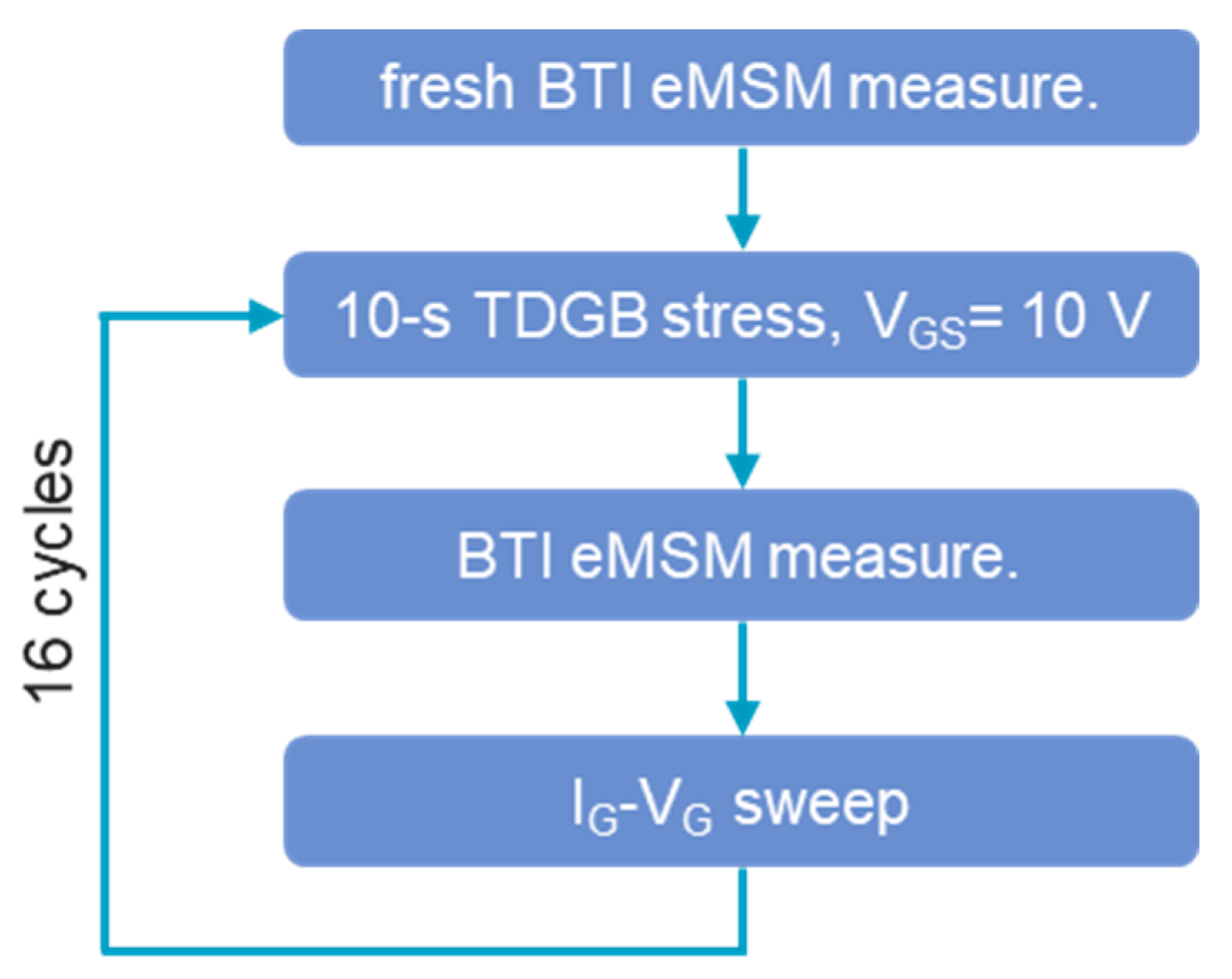

2.2. BTI Characterization

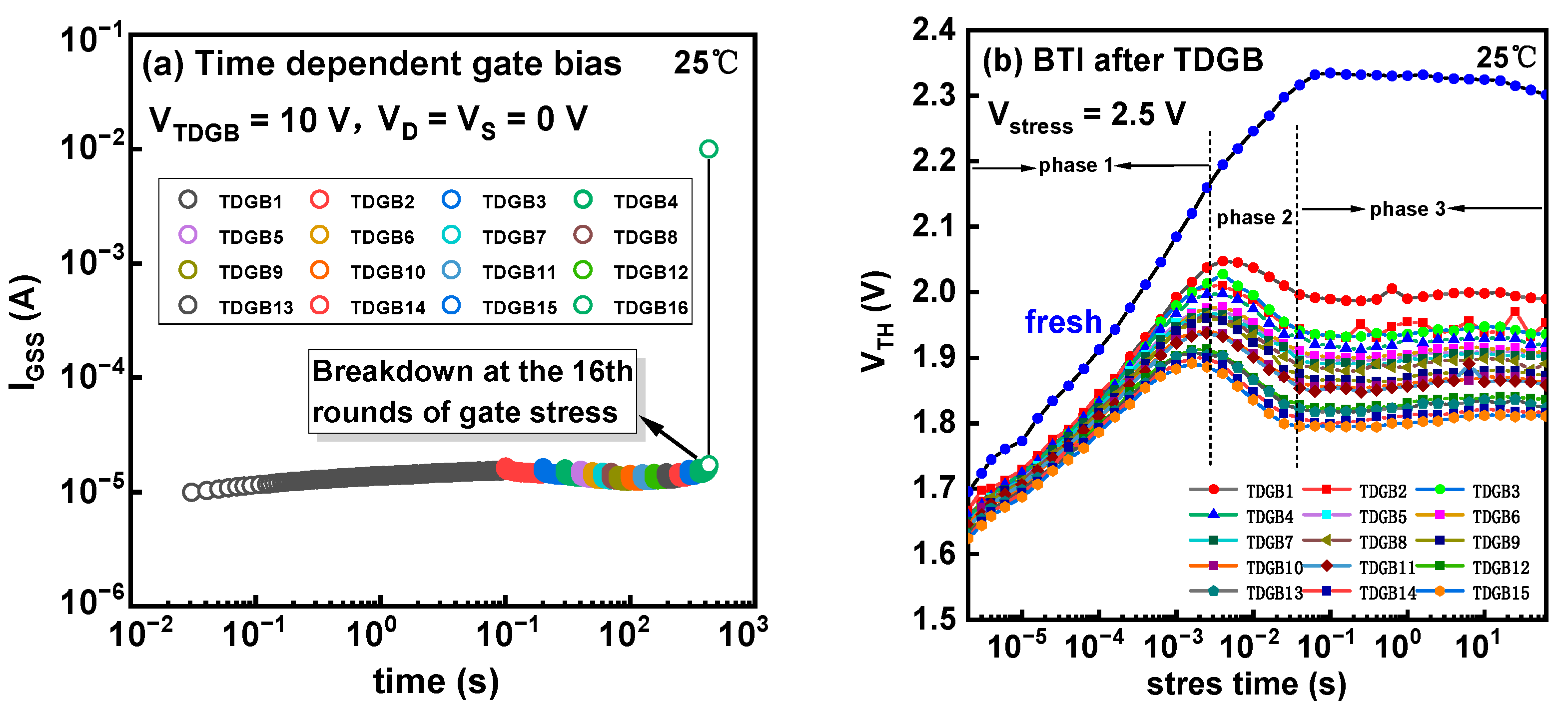

3. Results

3.1. BTI of the p-GaN Gate HEMTs

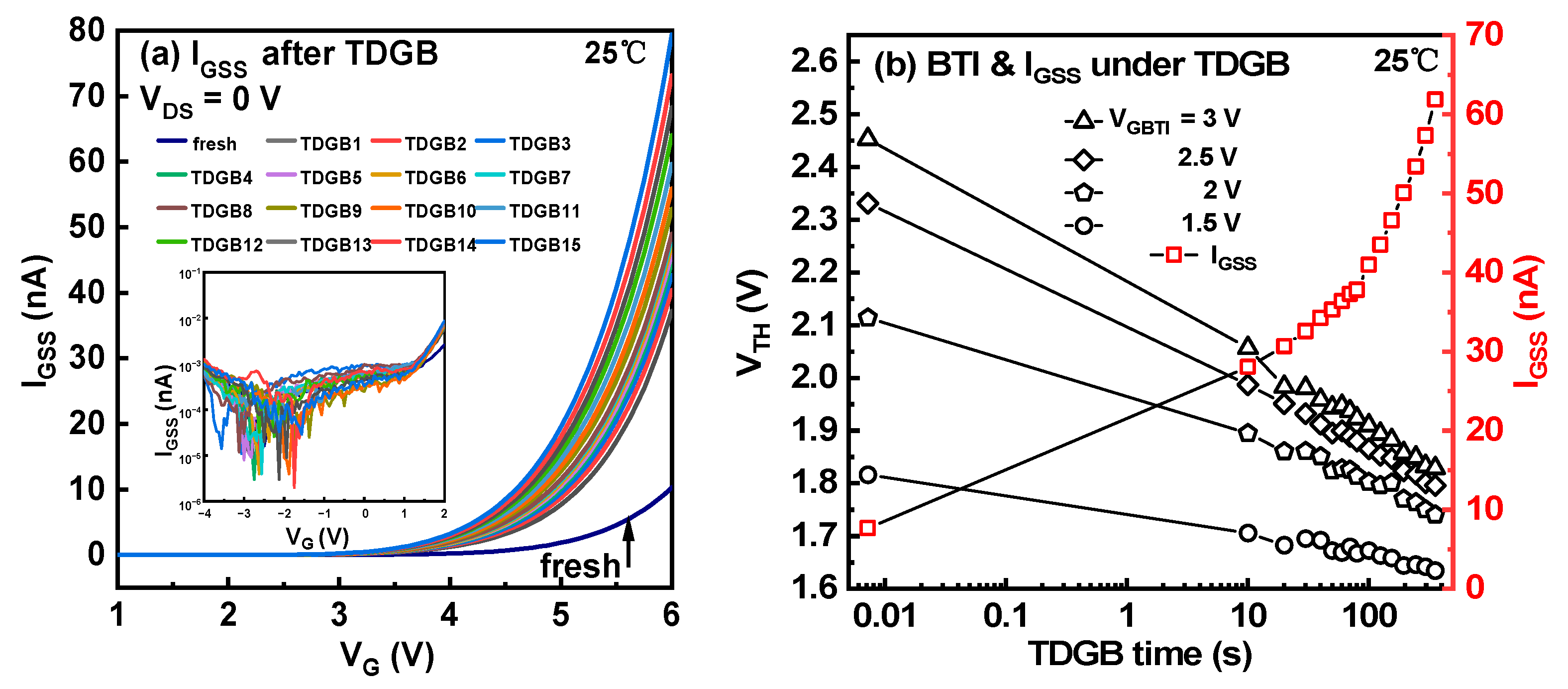

3.2. Suppressing the BTI Effect by TDGB Stress

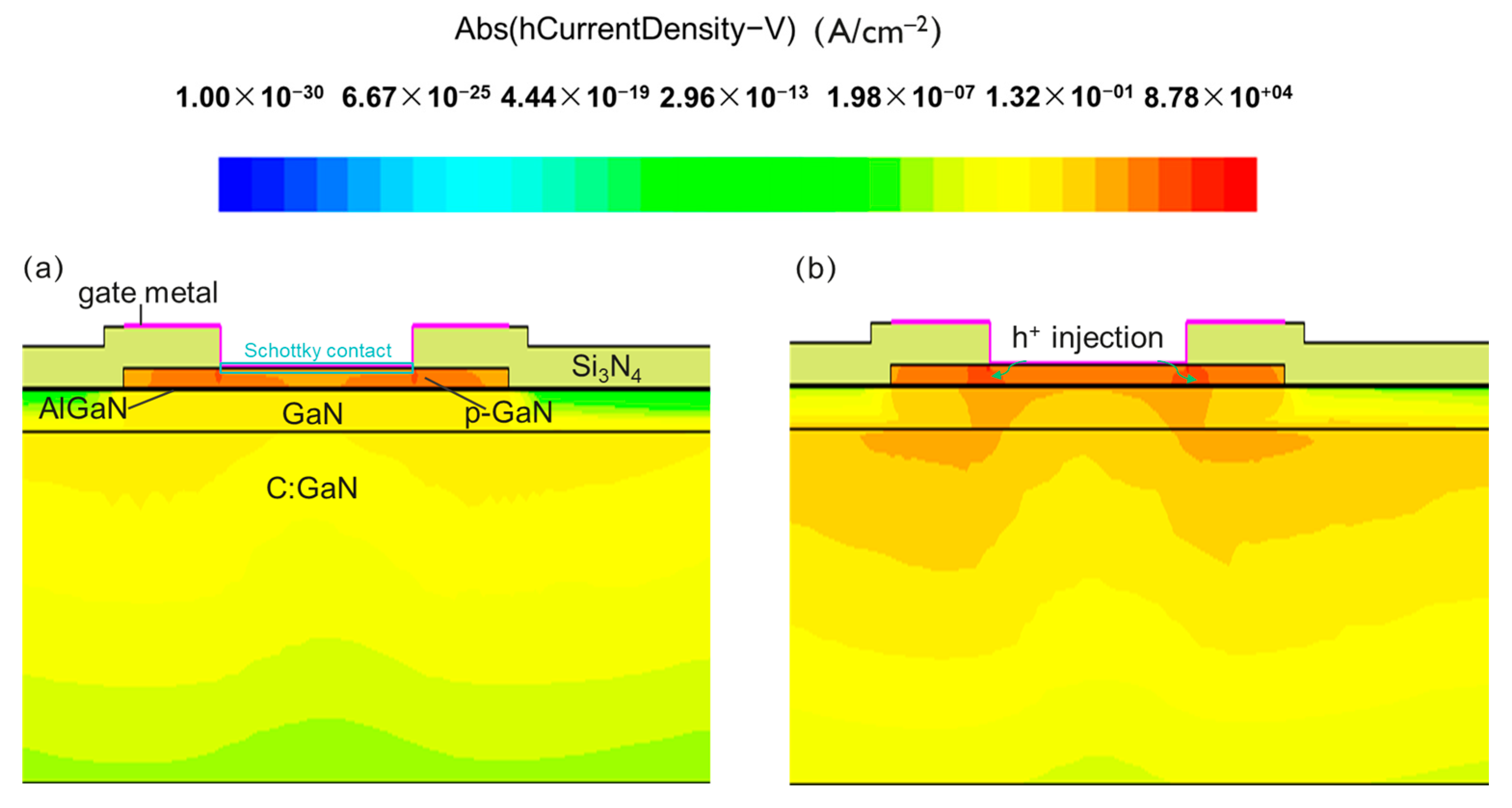

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Infineon. IGO60R070D1 Datasheet. 2018. Available online: https://www.infineon.com (accessed on 15 March 2023).

- GaN Systems. GS66502B Datasheet. 2017. Available online: http://www.gansystems.com (accessed on 15 March 2023).

- Efficient Power Conversion. EPC2019 Datasheet. 2019. Available online: https://epc-co.com/epc (accessed on 15 March 2023).

- Morita, T.; Tamura, S.; Anda, Y.; Ishida, M.; Uemoto, Y.; Ueda, T.; Tanaka, T.; Ueda, D. 99.3% efficiency of three-phase inverter for motor drive using GaN-based gate injection transistors. In Proceedings of the Twenty-Sixth Annual IEEE Applied Power Electronics Conference and Exposition (APEC), Fort Worth, TX, USA, 6–11 March 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 481–484. [Google Scholar]

- Uemoto, Y.; Hikita, M.; Ueno, H.; Matsuo, H.; Ishida, H.; Yanagihara, M.; Ueda, T.; Tanaka, T.; Ueda, D. Gate injection transistor (GIT)—A normally-off AlGaN/GaN power transistor using conductivity modulation. IEEE Trans. Electron Devices 2007, 54, 3393–3399. [Google Scholar] [CrossRef]

- Kaminski, N.; Hilt, O. SiC and GaN devices—Wide bandgap is not all the same. IET Circuits Devices Syst. 2014, 8, 227–236. [Google Scholar] [CrossRef]

- Zagni, N.; Cioni, M.; Castagna, M.E.; Moschetti, M.; Iucolano, F.; Verzellesi, G.; Chini, A. Symmetrical VTH/RON drifts due to negative/positive gate stress in p-GaN power HEMTs. In Proceedings of the IEEE 9th Workshop on Wide Bandgap Power Devices & Applications (WiPDA), Redondo Beach, CA, USA, 7–9 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 31–34. [Google Scholar]

- Wang, Y.; Wei, J.; Yang, S.; Lei, J.; Hua, M.; Chen, K.J. Characterization of dynamic IOFF in schottky-type p-GaN gate HEMTs. In Proceedings of the Energy Conversion Congress and Exposition, Montreal, QC, Canada, 20–24 September 2015; pp. 400–407. [Google Scholar]

- Elangovan, S.; Huang, C.-H.; Chen, C.-A.; Cheng, S.; Chang, E.Y. Bias Temperature Instability of GaN Cascode Power Switch. In Proceedings of the IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), Singapore, 20–23 July 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–5. [Google Scholar]

- Viey, A.G.; Vandendaele, W.; Jaud, M.-A.; Gerrer, L.; Garros, X.; Cluzel, J.; Martin, S.; Krakovinsky, A.; Biscarrat, J.; Gwoziecki, R.; et al. Carbon-related PBTI degradation mechanisms in GaN-on-Si E-Mode MOSc-HEMT. In Proceedings of the IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 9–13 December 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 23.6.1–23.6.4. [Google Scholar]

- Leurquin, C.; Vandendaele, W.; Viey, A.G.; Gwoziecki, R.; Escoffier, R.; Salot, R.; Despesse, G.; Iucolano, F.; Modica, R.; Constant, A. Novel high voltage bias temperature instabilities (HV-BTI) setup to monitor RON/VTH drift on GaN-on-Si E-mode MOSc-HEMTs under drain voltage. In Proceedings of the IEEE International Reliability Physics Symposium (IRPS), Dallas, TX, USA, 27–31 March 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 10B.3-1–10B.3-6. [Google Scholar]

- Guo, A.; del Alamo, J.A. Positive-bias temperature instability (PBTI) of GaN MOSFETs. In Proceedings of the IEEE International Reliability Physics Symposium, Monterey, CA, USA, 19–23 April 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 6C.5.1–6C.5.7. [Google Scholar]

- Cingu, D.; Li, X.; Bakeroot, B.; Amirifar, N.; Geens, K.; Jacobs, K.J.P.; Zhao, M.; You, S.; Groeseneken, G.; Decoutere, S. Reliability of P-GaN Gate HEMTs in Reverse Conduction. IEEE Trans. Electron Devices 2021, 68, 645–652. [Google Scholar] [CrossRef]

- Zhang, C.; Li, S.; Liu, S.; Wei, J.; Wu, W.; Sun, W. Electrical degradations of P-GaN HEMT under high off-state bias stress with negative gate voltage. In Proceedings of the IEEE 26th International Symposium on Physical and Failure Analysis of Integrated Circuits (IPFA), Hangzhou, China, 2–5 July 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Yang, S.; Huang, S.; Wei, J.; Zheng, Z.; Wang, Y.; He, J.; Chen, K.J. Identification of Trap States in P-GaN Layer of a p-GaN/AlGaN/GaN Power HEMT Structure by Deep-Level Transient Spectroscopy. IEEE Electron Device Lett. 2020, 41, 685–688. [Google Scholar] [CrossRef]

- Zhong, K.; Wei, J.; He, J.; Feng, S.; Wang, Y.; Yang, S.; Chen, K.J. IG- and VGS-Dependent Dynamic RON Characterization of Commercial High-Voltage p-GaN Gate Power HEMTs. IEEE Trans. Ind. Electron. 2022, 69, 8387–8395. [Google Scholar] [CrossRef]

- Hwang, I.; Kim, J.; Choi, H.S.; Choi, H.; Lee, J.; Kim, K.Y.; Park, J.-B.; Lee, J.C.; Ha, J.; Oh, J.; et al. P-GaN Gate HEMTs with Tungsten Gate Metal for High Threshold Voltage and Low Gate Current. IEEE Electron Device Lett. 2013, 34, 202–204. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Xie, R.; Liu, C.; Tang, G.; Chen, K.J. Maximizing the Performance of 650-V p-GaN Gate HEMTs: Dynamic RON Characterization and Circuit Design Considerations. IEEE Trans. Power Electron. 2017, 32, 5539–5549. [Google Scholar] [CrossRef]

- Wang, H.; Lin, Y.; Jiang, J.; Dong, D.; Ji, F.; Zhang, M.; Jiang, M.; Gan, W.; Li, H.; Wang, M.; et al. Investigation of Thermally Induced Threshold Voltage Shift in Normally-OFF p-GaN Gate HEMTs. IEEE Trans. Electron Devices 2022, 69, 2287–2292. [Google Scholar] [CrossRef]

- Sayadi, L.; Iannaccone, G.; Sicre, S.; Häberlen, O.; Curatola, G. Threshold voltage instability in p-GaN gate AlGaN/GaN HFETs. IEEE Trans. Electron Devices 2018, 65, 2454–2460. [Google Scholar] [CrossRef]

- Canato, E.; Masin, F.; Borga, M.; Zanoni, E.; Meneghini, M.; Meneghesso, G.; Stockman, A.; Banerjee, A.; Moens, P. μs-range evaluation of threshold voltage instabilities of GaN-on-Si HEMTs with p-GaN gate. In Proceedings of the IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 31 March–4 April 2019; pp. 1–6. [Google Scholar]

- Tang, X.; Liu, Y.; Wang, H.; Dong, D.; Yin, Y.; Lin, Y.; Li, H.; Chen, P.; Li, H.; Huang, Z.; et al. On the Physics Link between Time-Dependent Gate Breakdown and Electroluminescence in Schottky-Type p-GaN Gate HEMTs. In Proceedings of the IEEE 34th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Vancouver, BC, Canada, 22–25 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 57–60. [Google Scholar]

- Kaczer, B.; Grasser, T.; Roussel, P.; Martin-Martinez, J.; O’Connor, R.; O’Sullivan, B.; Groeseneken, G. Ubiquitous relaxation in BTI stressing—New evaluation and insights. In Proceedings of the IEEE International Reliability Physics Symposium, Phoenix, AZ, USA, 27 April–1 May 2008; pp. 20–27. [Google Scholar]

- Li, X.; Posthuma, N.; Bakeroot, B.; Liang, H.; You, S.; Wu, Z.; Zhao, M.; Groeseneken, G.; Decoutere, S. Investigating the Current Collapse Mechanisms of p-GaN Gate HEMTs by Different Passivation Dielectrics. IEEE Tran. Power Electron. 2021, 36, 4927–4930. [Google Scholar] [CrossRef]

- Li, X.; Bakeroot, B.; Wu, Z.; Amirifar, N.; You, S.; Posthuma, N.; Zhao, M.; Liang, H.; Groeseneken, G.; Decoutere, S. Observation of Dynamic V-TH of p-GaN Gate HEMTs by Fast Sweeping Characterization. IEEE Electron Device Lett. 2020, 41, 577–580. [Google Scholar] [CrossRef]

- Xu, H.; Zheng, Z.; Zhang, L.; Sun, J.; Yang, S.; He, J.; Wei, J.; Chen, K. Dynamic interplays of gate junctions in schottky-type p-GaN gate power HEMTs during switching operation. In Proceedings of the IEEE 34th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Vancouver, BC, Canada, 22–25 May 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 325–328. [Google Scholar]

- Stockman, A.; Canato, E.; Meneghini, M.; Meneghesso, G.; Moens, P.; Bakeroot, B. Threshold voltage instability mechanisms in p-GaN gate AlGaN/GaN HEMTs. In Proceedings of the 31st International Symposium on Power Semiconductor Devices and ICs (ISPSD), Shanghai, China, 19–23 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 287–290. [Google Scholar]

- Tang, X.; Li, B.K.; Moghadam, H.A.; Tanner, P.; Han, J.S.; Dimitrijev, S. Mechanism of Threshold Voltage Shift in p-GaN Gate AlGaN/GaN Transistors. IEEE Electron Device Lett. 2018, 39, 1145–1148. [Google Scholar] [CrossRef]

- Tanaka, K.; Morita, T.; Umeda, H.; Kaneko, S.; Kuroda, M.; Ikoshi, A.; Yamagiwa, H.; Okita, H.; Hikita, M.; Yanagihara, M.; et al. Suppression of current collapse by hole injection from drain in a normally-off GaN-based hybrid-drain-embedded gate injection transistor. Appl. Phys. Lett. 2015, 107, 163502. [Google Scholar] [CrossRef]

- He, J.B.; Tang, G.F.; Chen, K.J. V-TH Instability of p-GaN Gate HEMTs Under Static and Dynamic Gate Stress. IEEE Electron Device Lett. 2018, 39, 1576–1579. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, M.; Zhang, J.; Gao, R.; Wang, H.; Yang, W.; Yuan, J.; You, S.; Chang, J.; Liu, Z.; et al. Revealing the Mechanism of the Bias Temperature Instability Effect of p-GaN Gate HEMTs by Time-Dependent Gate Breakdown Stress and Fast Sweeping Characterization. Micromachines 2023, 14, 1042. https://doi.org/10.3390/mi14051042

Li X, Wang M, Zhang J, Gao R, Wang H, Yang W, Yuan J, You S, Chang J, Liu Z, et al. Revealing the Mechanism of the Bias Temperature Instability Effect of p-GaN Gate HEMTs by Time-Dependent Gate Breakdown Stress and Fast Sweeping Characterization. Micromachines. 2023; 14(5):1042. https://doi.org/10.3390/mi14051042

Chicago/Turabian StyleLi, Xiangdong, Meng Wang, Jincheng Zhang, Rui Gao, Hongyue Wang, Weitao Yang, Jiahui Yuan, Shuzhen You, Jingjing Chang, Zhihong Liu, and et al. 2023. "Revealing the Mechanism of the Bias Temperature Instability Effect of p-GaN Gate HEMTs by Time-Dependent Gate Breakdown Stress and Fast Sweeping Characterization" Micromachines 14, no. 5: 1042. https://doi.org/10.3390/mi14051042

APA StyleLi, X., Wang, M., Zhang, J., Gao, R., Wang, H., Yang, W., Yuan, J., You, S., Chang, J., Liu, Z., & Hao, Y. (2023). Revealing the Mechanism of the Bias Temperature Instability Effect of p-GaN Gate HEMTs by Time-Dependent Gate Breakdown Stress and Fast Sweeping Characterization. Micromachines, 14(5), 1042. https://doi.org/10.3390/mi14051042