Analysis of the Influence of the Motion State of Ultra-Thin Sapphire Based on Layer-Stacked Clamping (LSC)

Abstract

1. Introduction

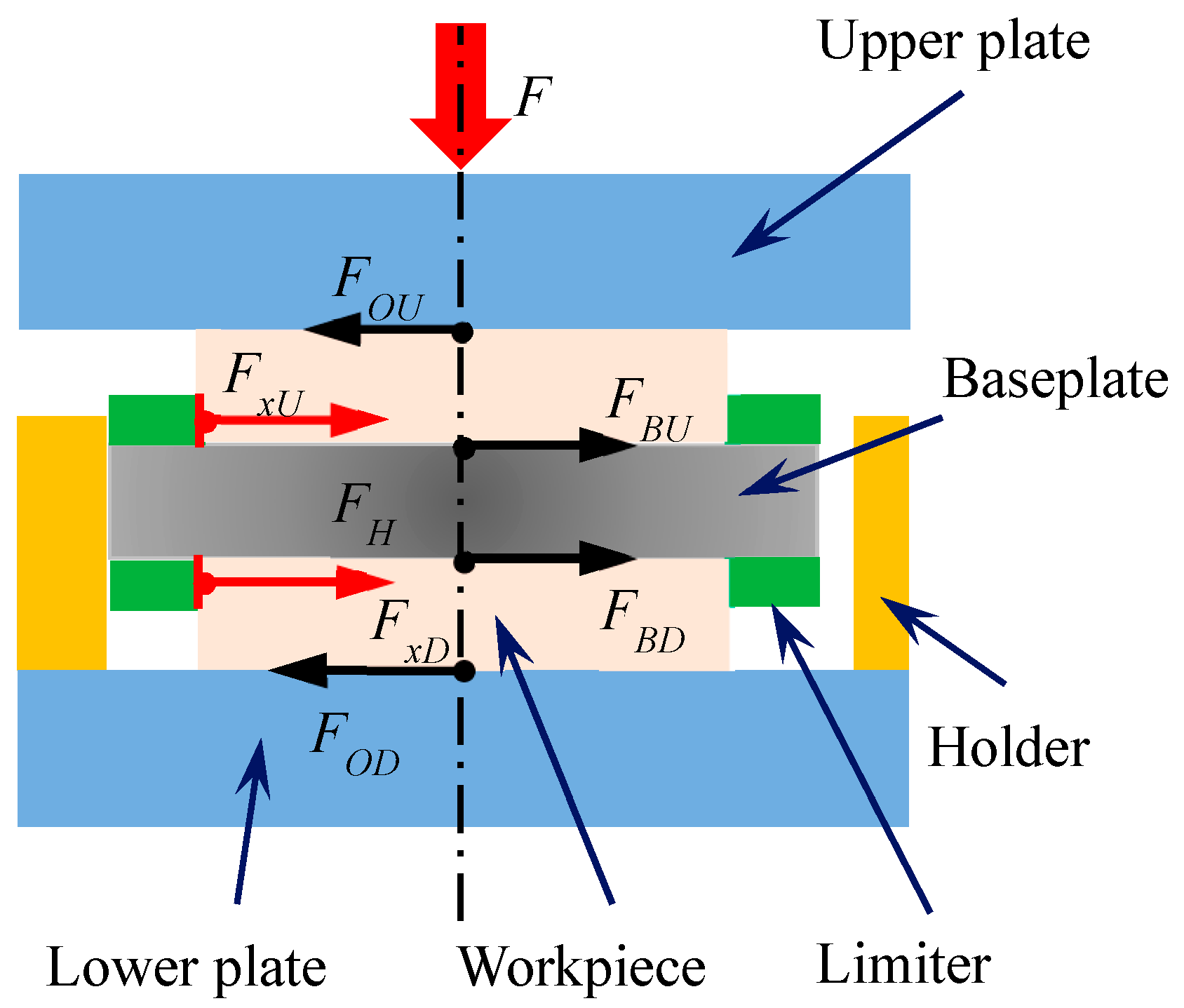

2. Motion Model of Workpiece

3. Analysis and Discussion of Workpiece Motion State

4. Experimental Research and Discussion

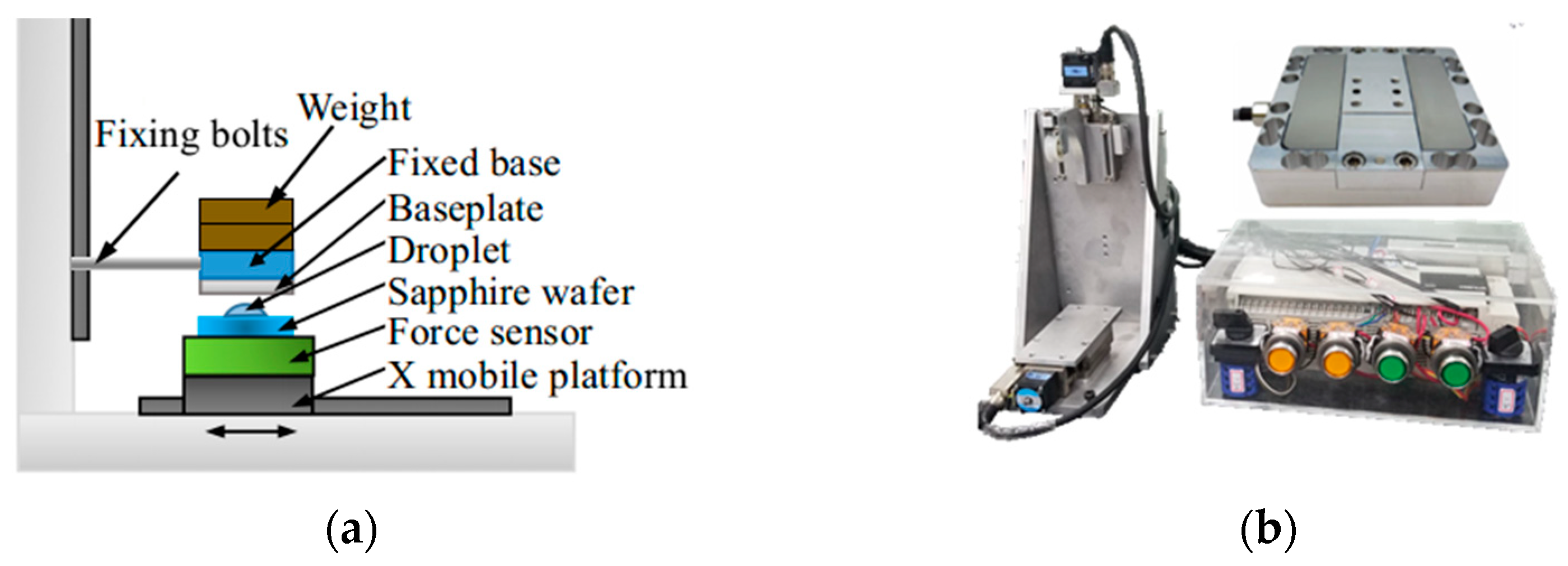

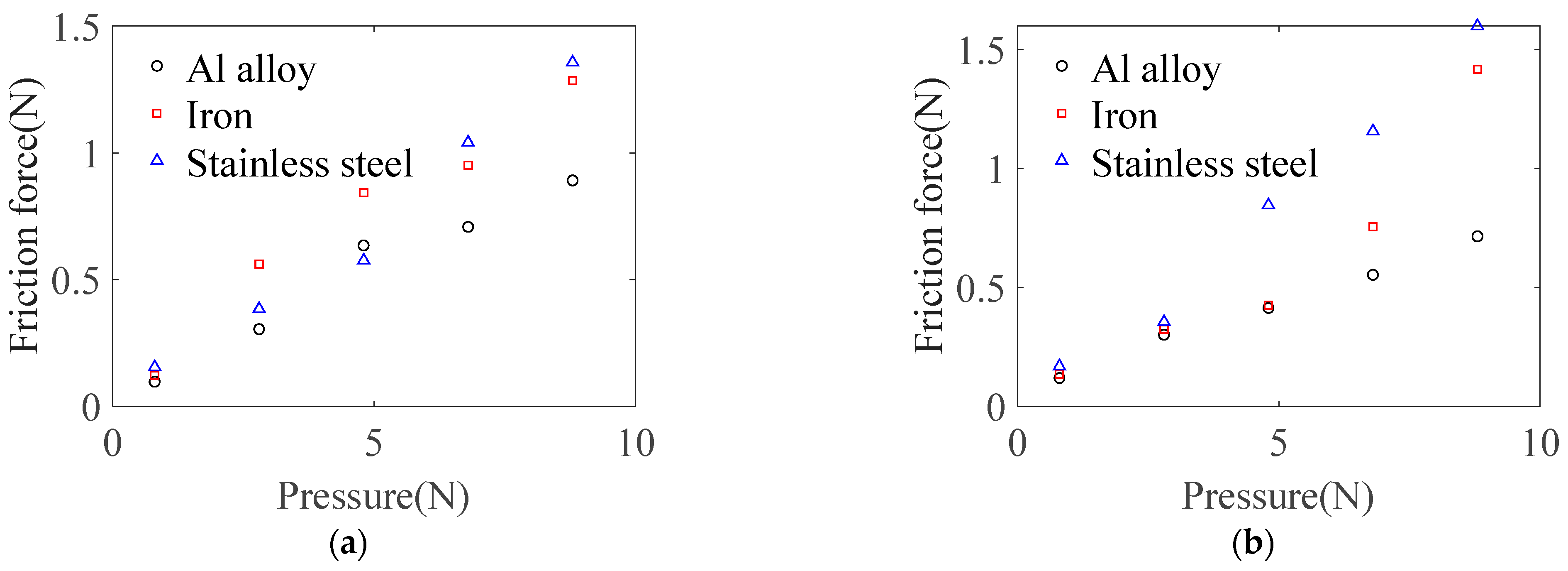

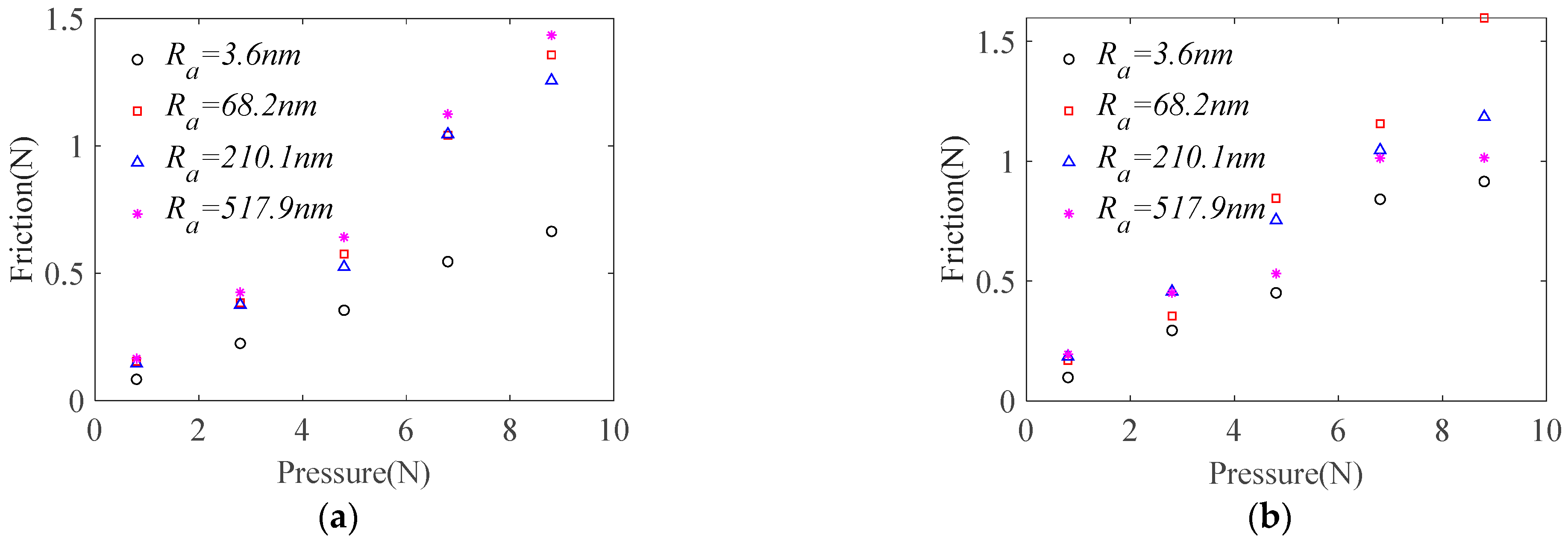

4.1. Tangential Force Analysis of Base Plate

4.2. Materials of Base Plate and Limiter

4.3. Experimental of Limiter Clamping Thickness

5. Conclusions

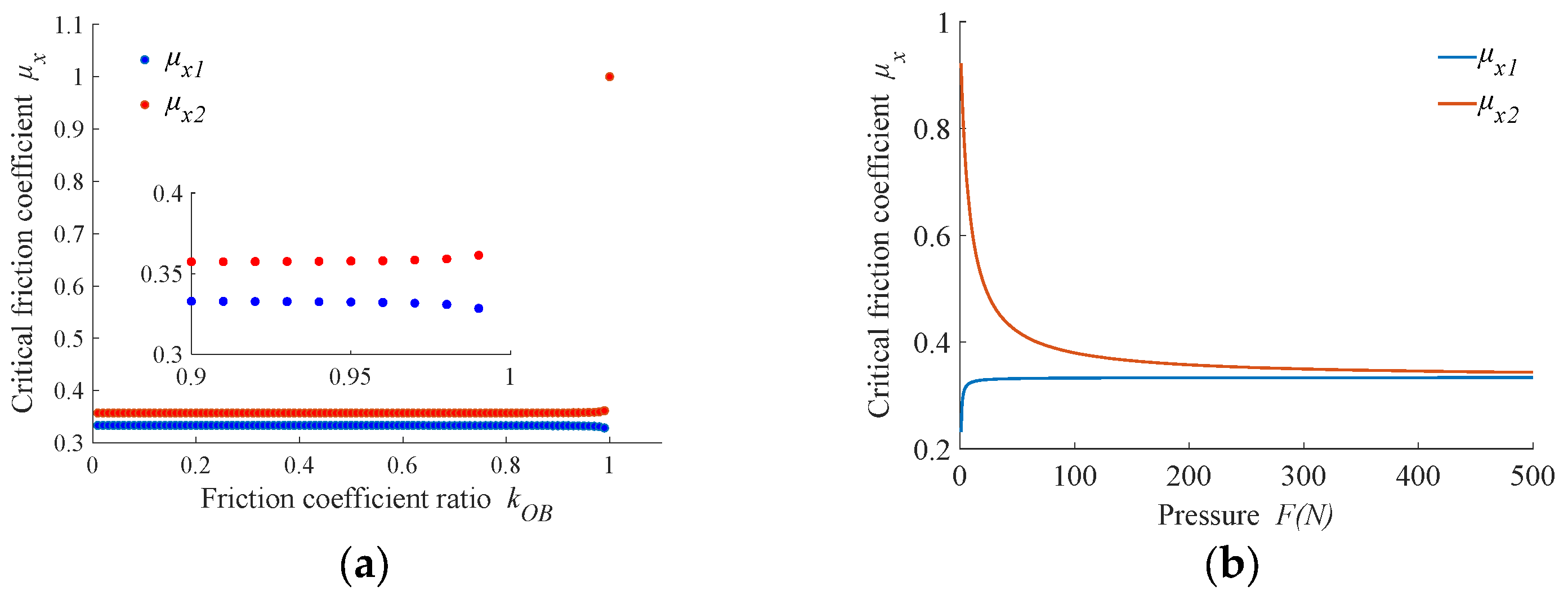

- The motion state of the workpiece in the LSC fixture is mainly affected by the friction coefficient ratio kOB and the friction coefficient between the workpiece and the limiter. When kOB < 1 and friction coefficient μx ≤ 0.33, the workpiece is driven by the polishing plate to rotate, and the motion state of the workpiece is independent of the motion state of the base plate and limiter.

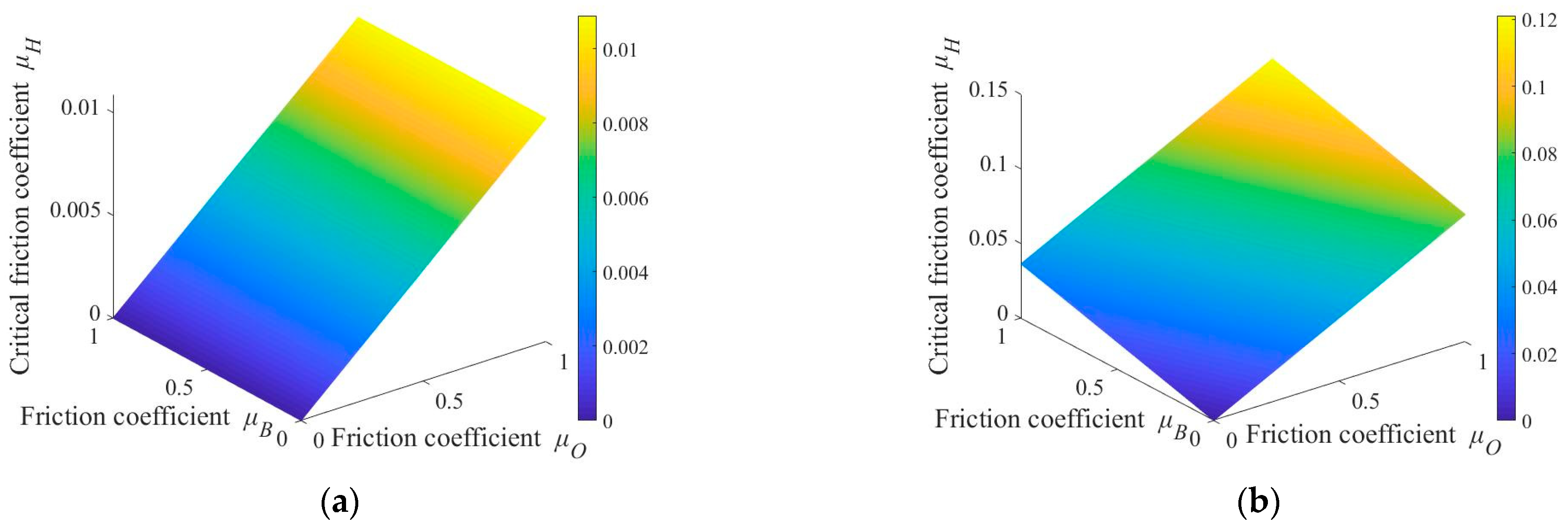

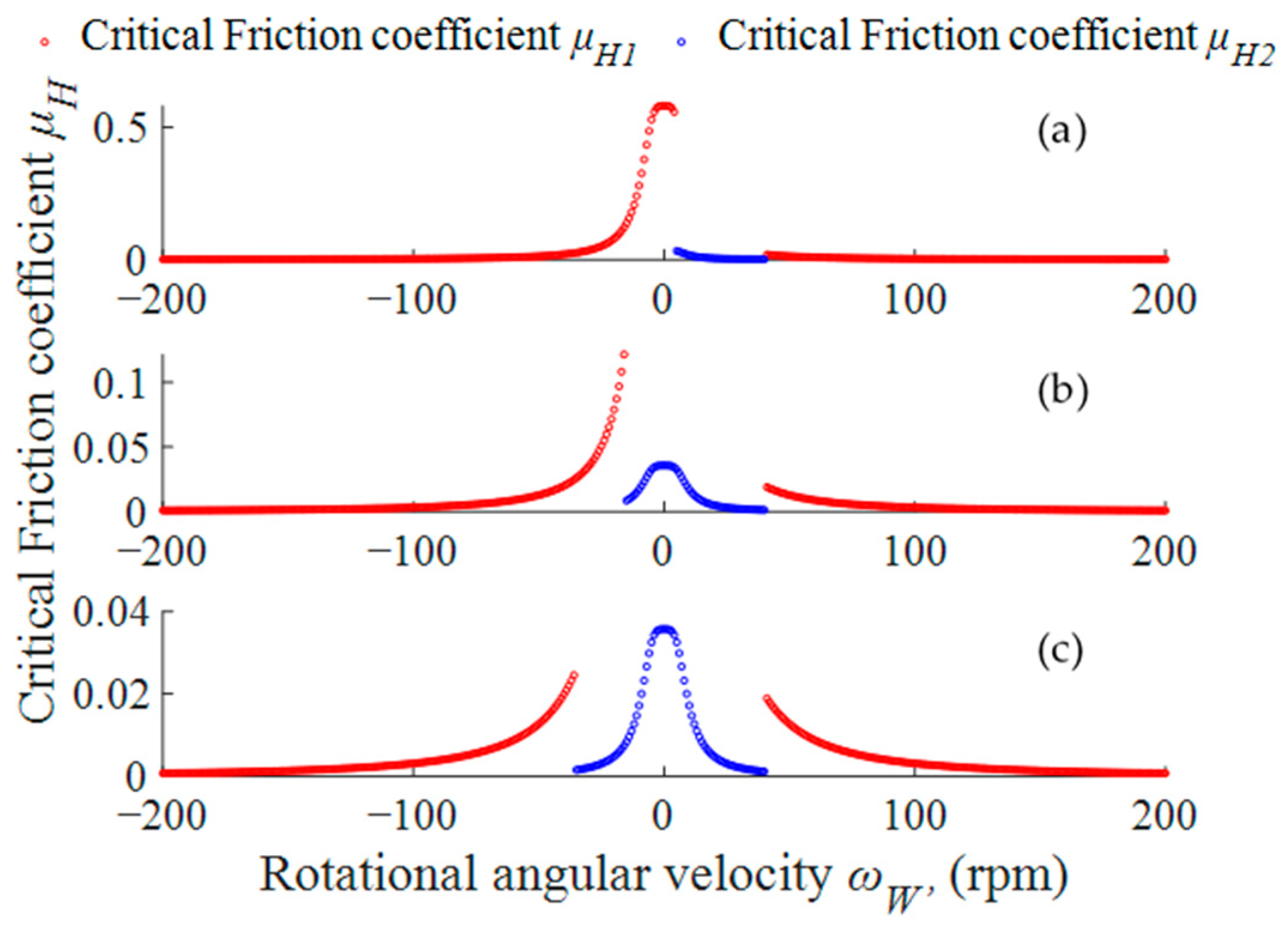

- When the speed of the upper and lower polishing plates is greater than 15 rpm and directions are opposite, the motion of the base plate is always driven by the holder.

- Sliding friction experiments show that as surface roughness of the base plate increases, due to the adhesion of water film, the friction force between the workpiece and base plate first increases then decreases. Stainless steel is the preferred material for the base plate.

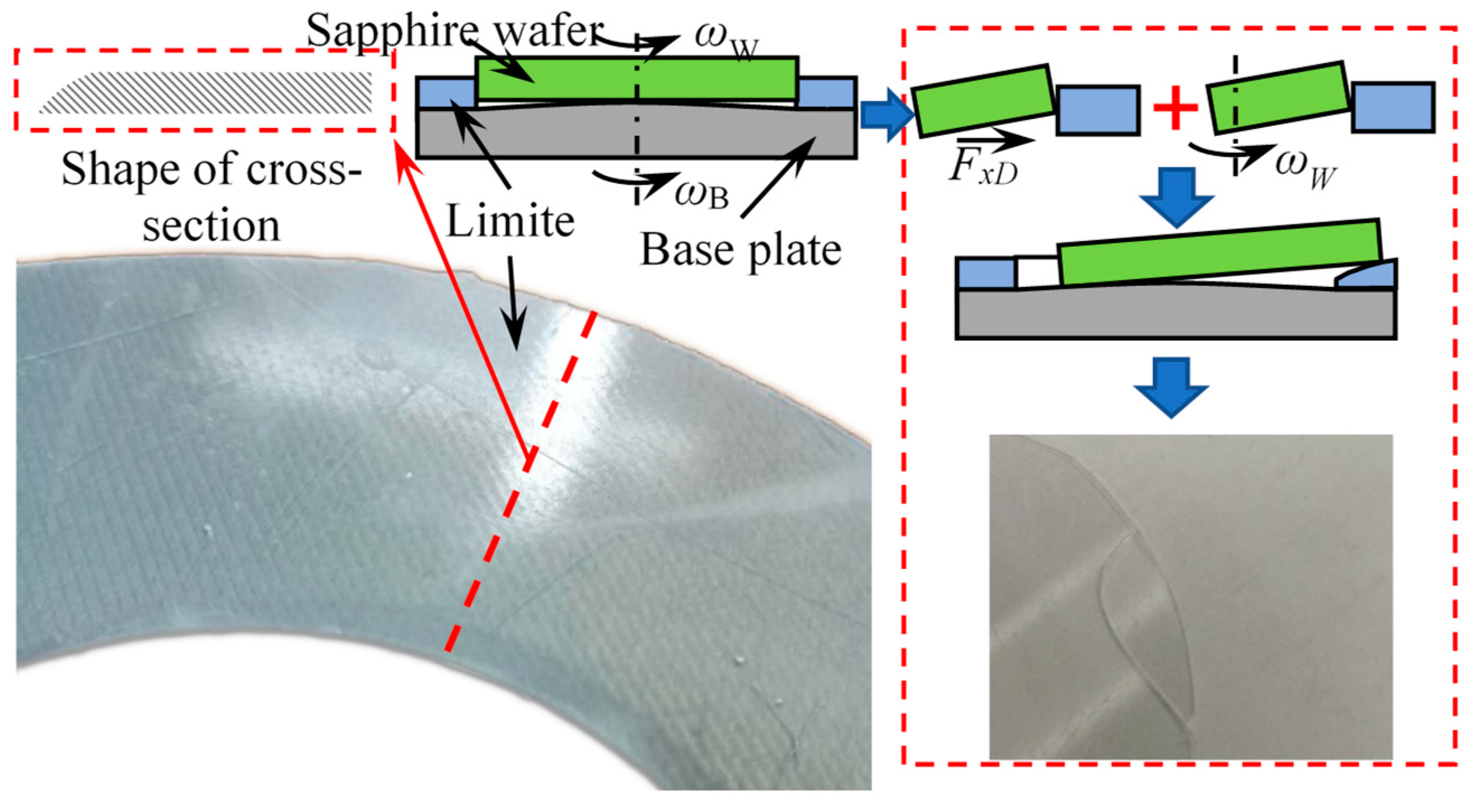

- Based on material mechanics, the material for limiter was selected as fiberglass board. The failure form of the limiter was determined through experiments. It manifested as being subjected to rotating cutting action of sapphire wafer, causing the limiter to form an inclined surface and the workpiece to slip and break.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, T.; Lei, H. Nd3+-doped colloidal SiO2 composite abrasives: Synthesis and the effects on chemical mechanical polishing (CMP) performances of sapphire wafers. Appl. Surf. Sci. 2017, 413, 16–26. [Google Scholar] [CrossRef]

- Xu, L.; Zou, C.; Shi, X.; Pan, G.; Luo, G.; Zhou, Y. Fe-Nx/C assisted chemical–mechanical polishing for improving the removal rate of sapphire. Appl. Surf. Sci. 2015, 343, 115–120. [Google Scholar] [CrossRef]

- Akselrod, M.S.; Bruni, F.J. Modern trends in crystal growth and new applications of sapphire. J. Cryst. Growth 2012, 360, 134–145. [Google Scholar] [CrossRef]

- He, D.; Zhao, Y.; Daemen, L.; Qian, J.; Shen, T.; Zerda, T. Boron suboxide: As hard as cubic boron nitride. Appl. Phys. Lett. 2002, 81, 643–645. [Google Scholar] [CrossRef]

- Katyba, G.; Zaytsev, K.; Dolganova, I.; Shikunova, I.; Chernomyrdin, N.; Yurchenko, S.; Komandin, G.; Reshetov, I.; Nesvizhevsky, V.; Kurlov, V. Sapphire shaped crystals for waveguiding, sensing and exposure applications. Prog. Cryst. Growth Charact. Mater. 2018, 64, 133–151. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Z.; Ge, J.; Zhuo, R.; Wan, L. Material Removal Rate Prediction for Sapphire Double-Sided CMP Based on RSM-SVM. ECS J. Solid State Sci. Technol. 2022, 11, 084002. [Google Scholar] [CrossRef]

- Wang, L.; Hu, Z.; Fang, C.; Yu, Y.; Xu, X. Study on the double-sided grinding of sapphire substrates with the trajectory method. Precis. Eng. 2018, 51, 308–318. [Google Scholar] [CrossRef]

- Wang, L.; Hu, Z.; Yu, Y.; Xu, X. Evaluation of double-sided planetary grinding using diamond wheels for sapphire substrates. Crystals 2018, 8, 262. [Google Scholar] [CrossRef]

- Lai, Z.; Hu, Z.; Fang, C.; Xiao, Z.; Hsieh, P.; Chen, M. Study on the wear characteristics of a lapping wheel in double-sided lapping based on the trajectory distribution. IEEE Trans. Semicond. Manuf. 2019, 32, 352–358. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, J.; Li, L. Trajectory uniformity of the double-sided mechanical polishing of SiC single crystal substrate. Mater. Sci. Semicond. Process. 2020, 107, 104814. [Google Scholar] [CrossRef]

- Yang, L.; Guo, X.; Kang, R.; Zhu, X.; Jia, Y. Effect of kinematic parameters considering workpiece rotation on surface quality in YAG double-sided planetary lapping with the trajectory method. Int. J. Adv. Manuf. Technol. 2022, 123, 2679–2690. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, G.; Ren, L.; Li, Y. Modeling and simulation method of trajectory in double-side autonomous grinding considering the dynamic friction coefficient. Int. J. Adv. Manuf. Technol. 2023, 124, 1199–1216. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Z.; Hu, Y. Effects of polishing parameters on surface quality in sapphire double-sided CMP. Ceram. Int. 2020, 46, 13356–13364. [Google Scholar] [CrossRef]

- Satake, U.; Enomoto, T. Polishing pad design for uniform removal distributions in double-sided polishing. CIRP Ann. 2023, 13, JAMDSM0020. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Sano, T.; Furumoto, T.; Hosokawa, A. Development an identification method of friction coefficient between wafer and carrier in double-sided lapping. Precis. Eng. 2019, 56, 364–369. [Google Scholar] [CrossRef]

- Hashimoto, Y.; Ozaki, R.; Furumoto, T.; Hosokawa, A. A calculation method for workpiece profile variation during double-sided lapping by considering workpiece elastic deformation. Precis. Eng. 2022, 73, 457–469. [Google Scholar] [CrossRef]

- Hirose, K.; Enomoto, T. Achievement of High Flatness of Large Diameter Silicon Wafer in Double-Sided Polishing: Optimization of Polishing Conditions Considering Relative Motion Direction. In Proceedings of the International Manufacturing Science and Engineering Conference, Online, 20 September 2009; pp. 671–676. [Google Scholar]

- Satake, U.; Enomoto, T.; Fujii, K.; Hirose, K. Optimization method for double-sided polishing process based on kinematical analysis. Procedia. Cirp. 2016, 41, 870–874. [Google Scholar] [CrossRef]

- Li, C.; Hu, Y.; Zhang, F.; Geng, Y.; Meng, B. Molecular dynamics simulation of laser assisted grinding of GaN crystals. Int. J. Mech. Sci. 2023, 239, 107856. [Google Scholar] [CrossRef]

- Li, C.; Piao, Y.; Meng, B.; Hu, Y.; Li, L.; Zhang, F. Phase transition and plastic deformation mechanisms induced by self-rotating grinding of GaN single crystals. Int. J. Mach. Tools Manuf. 2022, 172, 103827. [Google Scholar] [CrossRef]

- Ci, H.; Chang, H.; Wang, R.; Wei, T.; Wang, Y.; Chen, Z.; Sun, Y.; Dou, Z.; Liu, Z.; Li, J. Enhancement of heat dissipation in ultraviolet light-emitting diodes by a vertically oriented graphene nanowall buffer layer. Adv. Mater. 2019, 31, 1901624. [Google Scholar] [CrossRef]

- Ma, Y.; Luo, X. Enhancing opto-thermal performances of the reflective phosphor-converted laser diode by stacking a sapphire substrate for double-sided phosphor cooling. Int. J. Heat Mass Transf. 2019, 143, 118600. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, S. Study on sapphire removal for thin-film LEDs fabrication using CMP and dry etching. Appl. Surf. Sci. 2009, 255, 9469–9473. [Google Scholar] [CrossRef]

- Yan, J.; Yuan, J.; Jiang, Y.; Zhu, H.; Choi, H.W.; Wang, Y. A vertical AlGaN DUV light-emitting diode fabricated by wafer bonding and sapphire thinning technology. Appl. Phys. Express 2022, 15, 032003. [Google Scholar] [CrossRef]

- Chen, Z.; Cao, L.; Yuan, J.; Lyu, B.; Hang, W.; Wang, J. The Mechanism of Layer Stacked Clamping (LSC) for Polishing Ultra-Thin Sapphire Wafer. Micromachines 2020, 11, 759. [Google Scholar] [CrossRef] [PubMed]

| Parameters | Value | |

|---|---|---|

| Pressure (N) | 0.8, 2.8, 4.8, 6.8, 8.8 | |

| Movement speed of X-axis (mm/s) | 0.1 | |

| Material of base plate | Stainless steel, Aluminum alloy, Cast iron | |

| Roughness of base plate (nm) | Stainless steel | 3.6, 68.2, 210.1, 517.9 |

| Aluminum alloy | 60.2 | |

| Cast iron | 63.8 | |

| Parameters | Value |

|---|---|

| Height difference of base plate (μm) | 10 |

| Quality of base plate (kg) | 2.1 |

| Weights (N) | 6.86 |

| Number of weights | 1–15 |

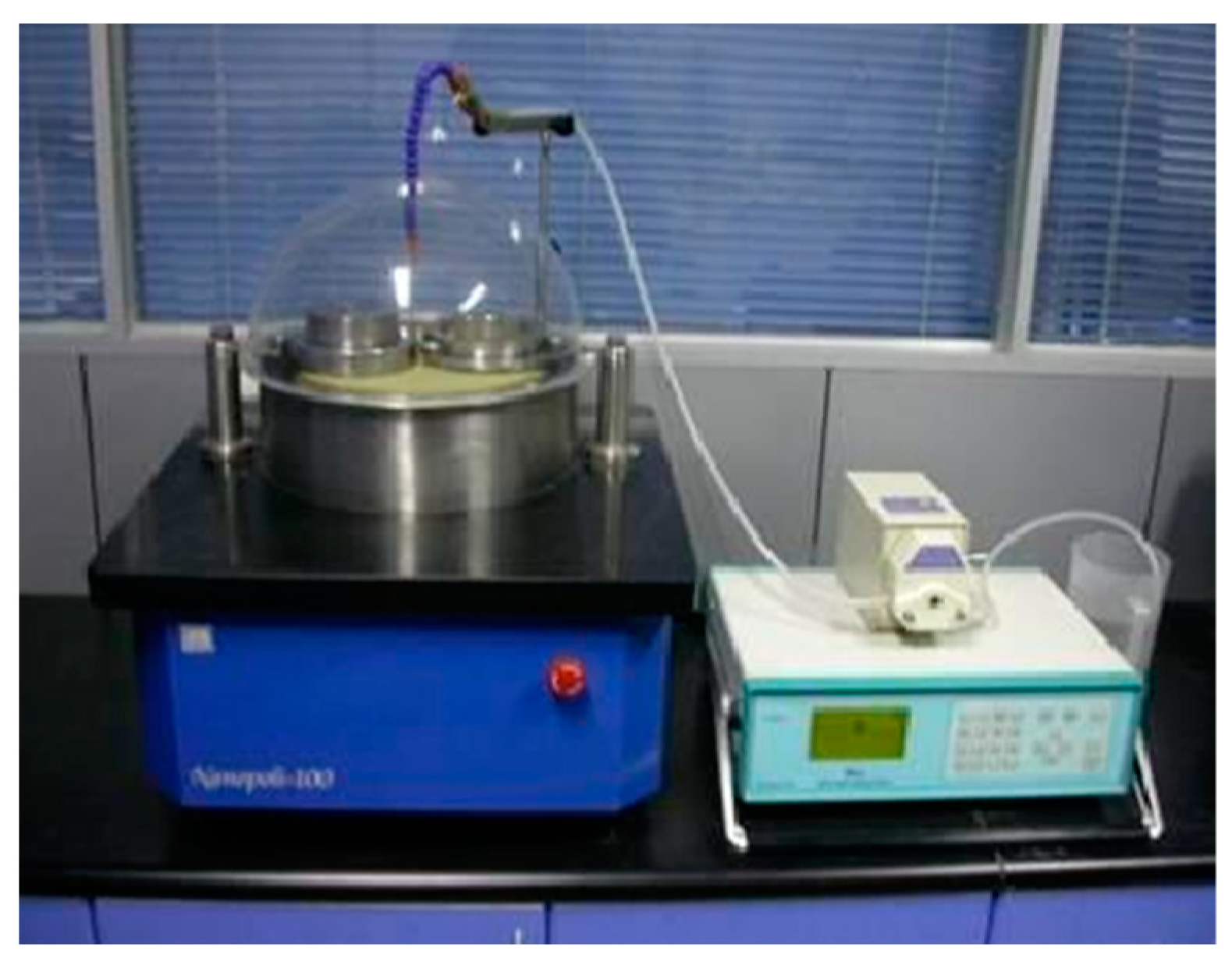

| Flow rate of polishing slurry (L/h) | 1500 |

| Limiter Thickness (mm) | Damaged Pressure (N) |

|---|---|

| 0.082 | 48.02 |

| 0.104 | 68.6 |

| 0.119 | 96.04 |

| 0.151 | Undamaged |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Han, S.; Feng, M.; Zhang, X. Analysis of the Influence of the Motion State of Ultra-Thin Sapphire Based on Layer-Stacked Clamping (LSC). Micromachines 2023, 14, 1124. https://doi.org/10.3390/mi14061124

Chen Z, Han S, Feng M, Zhang X. Analysis of the Influence of the Motion State of Ultra-Thin Sapphire Based on Layer-Stacked Clamping (LSC). Micromachines. 2023; 14(6):1124. https://doi.org/10.3390/mi14061124

Chicago/Turabian StyleChen, Zhixiang, Shunkai Han, Ming Feng, and Xianglei Zhang. 2023. "Analysis of the Influence of the Motion State of Ultra-Thin Sapphire Based on Layer-Stacked Clamping (LSC)" Micromachines 14, no. 6: 1124. https://doi.org/10.3390/mi14061124

APA StyleChen, Z., Han, S., Feng, M., & Zhang, X. (2023). Analysis of the Influence of the Motion State of Ultra-Thin Sapphire Based on Layer-Stacked Clamping (LSC). Micromachines, 14(6), 1124. https://doi.org/10.3390/mi14061124