Spiral Chiral Metamaterial Structure Shape for Optical Activity Improvements

Abstract

1. Introduction

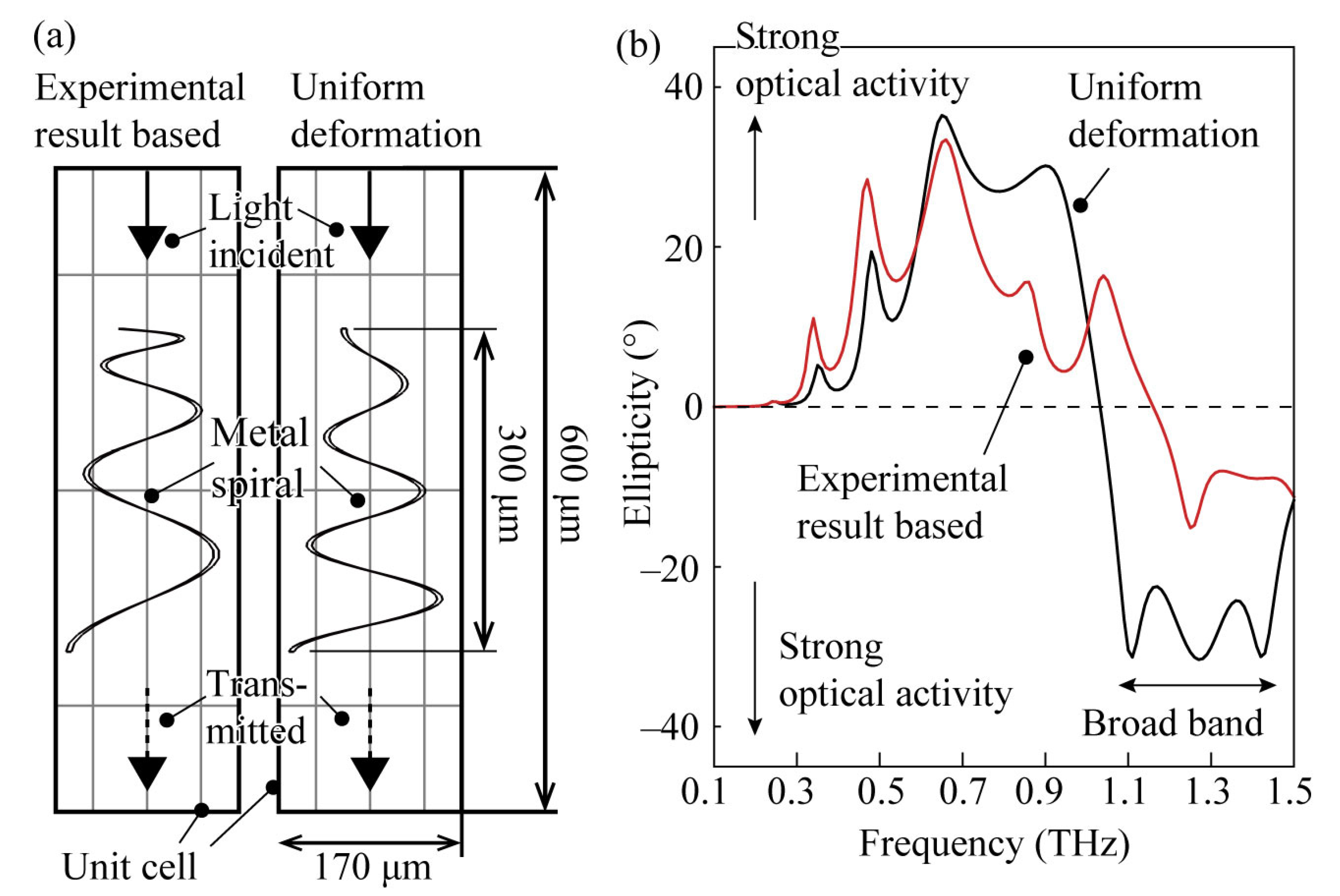

2. Materials and Methods

2.1. Numerical Analysis

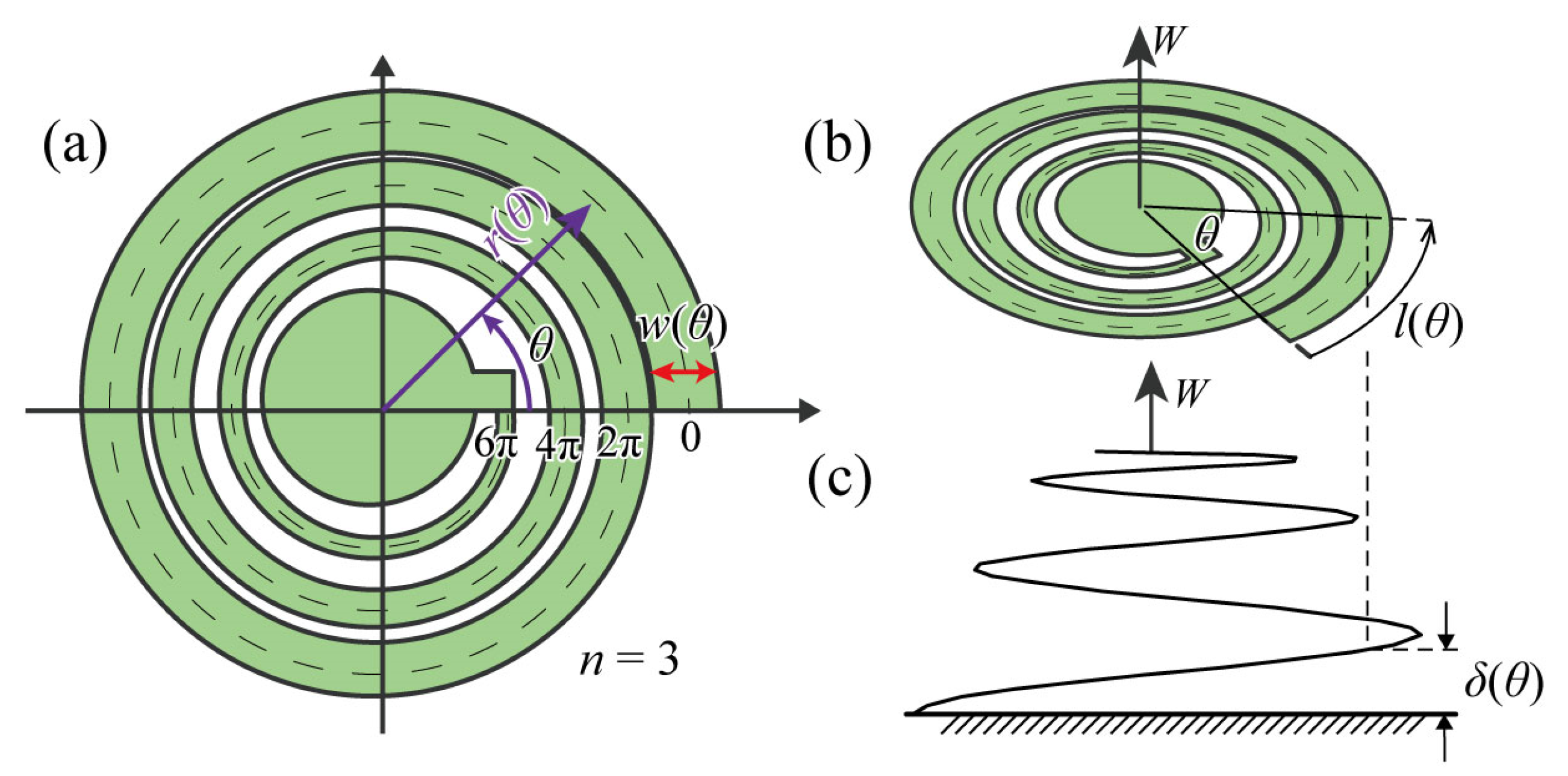

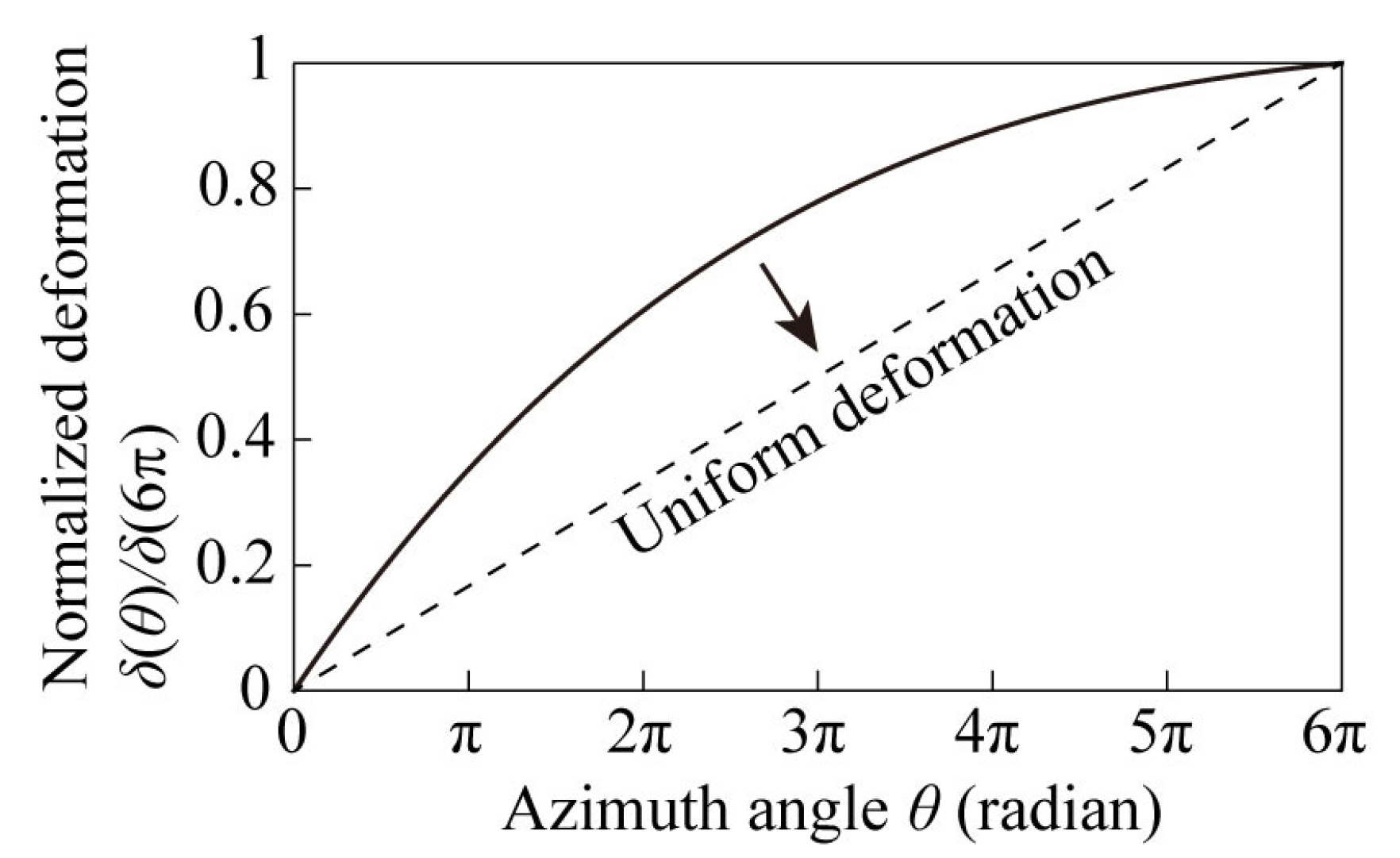

2.2. Deformation Theory of the Spiral Structure

2.3. Design of the Spiral Structure

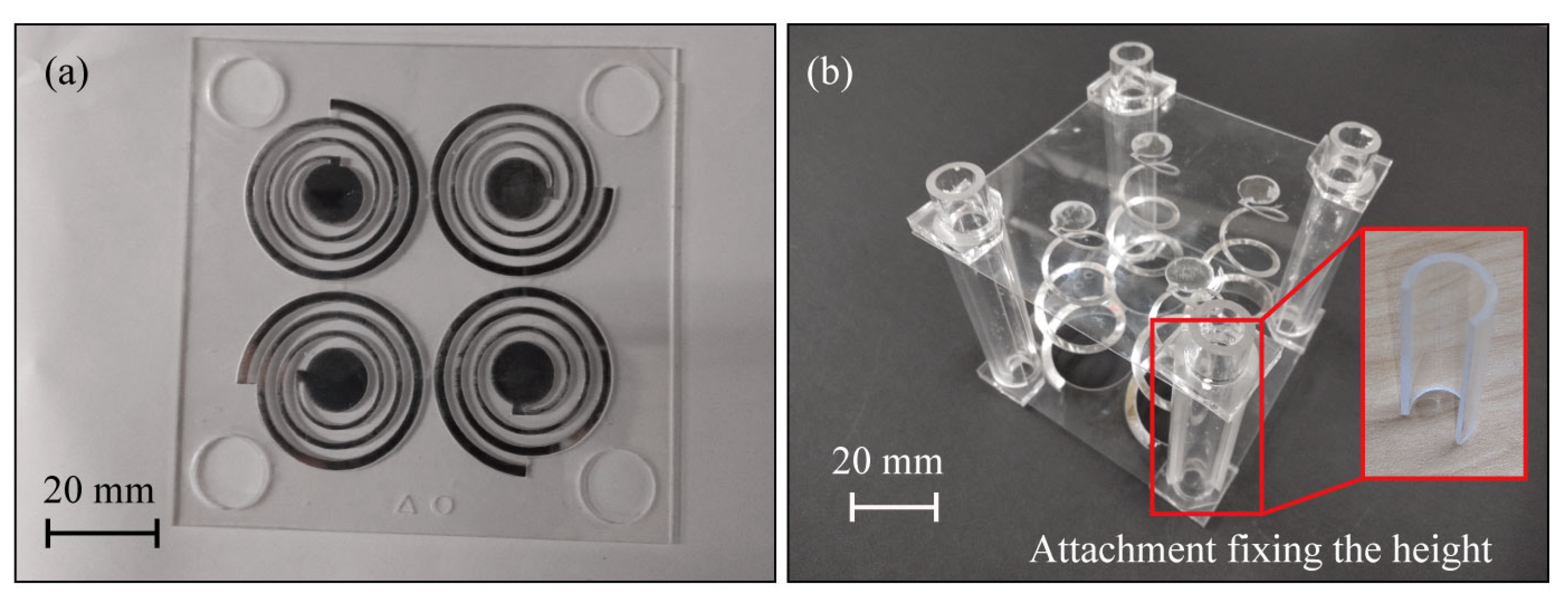

2.4. Fabrication

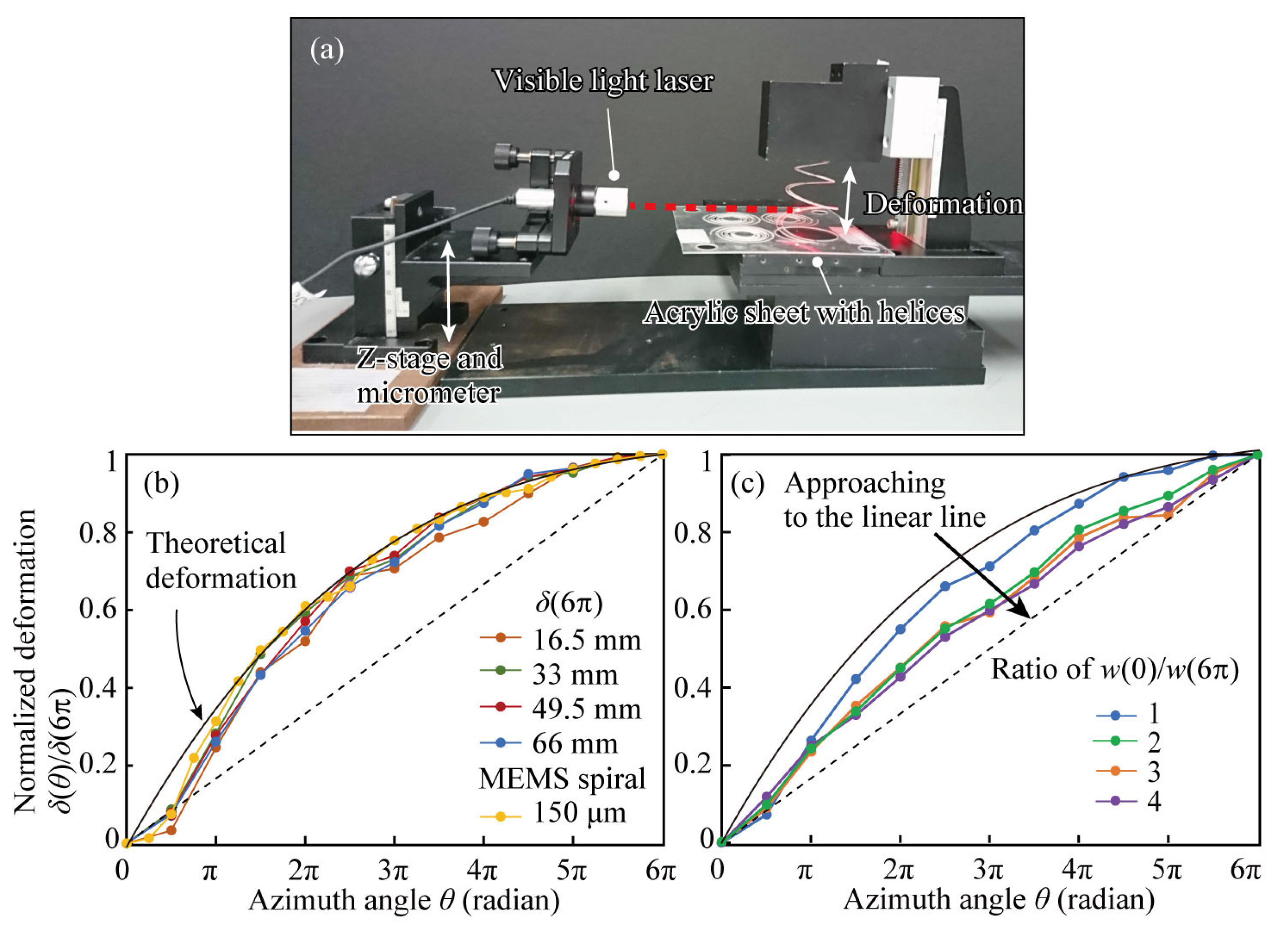

2.5. Deformation Measurement

3. Results

3.1. Optical Measurement

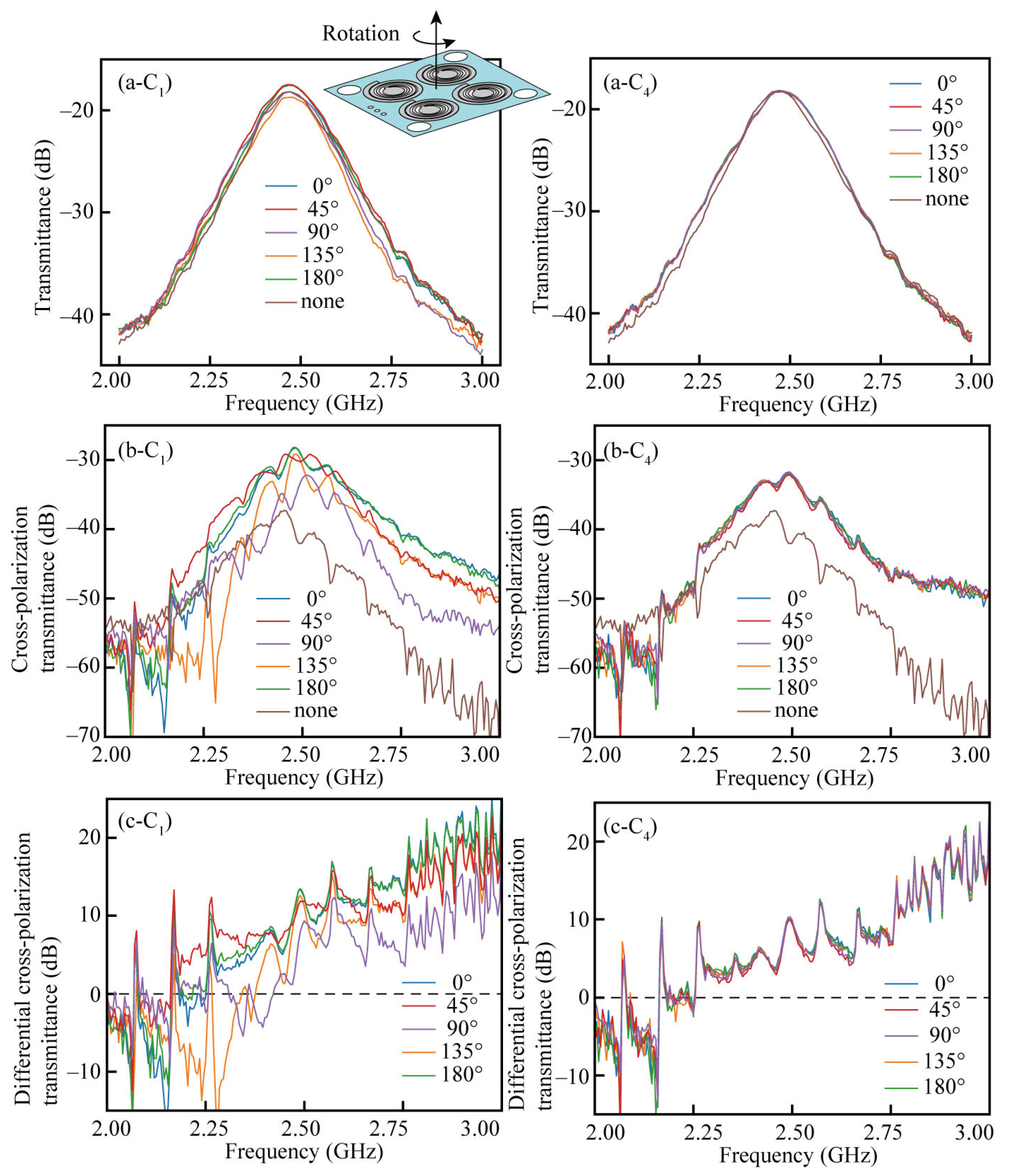

3.2. Verification of Linear Birefringence in the C1 and C4 Structures

3.3. Optical Response Change by Deformation

3.4. Effect of the Beam Width

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pendry, J.B.; Holden, A.J.; Robbins, D.J.; Stewart, W.J. Magnetism from Conductors and Enhanced Nonlinear Phenomena. IEEE Trans. Microw. Theory Tech. 1999, 47, 2075–2084. [Google Scholar] [CrossRef]

- Pendry, J.B.; Holden, A.J.; Robbins, D.J.; Stewart, W.J. Low Frequency Plasmons in Thin-Wire Structures. J. Phys. Condens. Matter 1998, 10, 4785–4809. [Google Scholar] [CrossRef]

- Pendry, J.B.; Holden, A.J.; Stewart, W.J.; Youngs, I. Extremely Low Frequency Plasmons in Metallic Mesostructures. Phys. Rev. Lett. 1996, 76, 4773–4776. [Google Scholar] [CrossRef] [PubMed]

- Fleischman, D.; Sweatlock, L.A.; Murakami, H.; Atwater, H. Hyper-Selective Plasmonic Color Filters. Opt. Express 2017, 25, 27386. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Wu, Y.K.; Luo, X.; Guo, L.J. Plasmonic Nanoresonators for High-Resolution Colour Filtering and Spectral Imaging. Nat. Commun. 2010, 1, 59. [Google Scholar] [CrossRef] [PubMed]

- Tittl, A.; Michel, A.K.U.; Schaferling, M.; Yin, X.H.; Gholipour, B.; Cui, L.; Wuttig, M.; Taubner, T.; Neubrech, F.; Giessen, H. A Switchable Mid-Infrared Plasmonic Perfect Absorber with Multispectral Thermal Imaging Capability. Adv. Mater. 2015, 27, 4597–4603. [Google Scholar] [CrossRef]

- Miao, Z.; Wu, Q.; Li, X.; He, Q.; Ding, K.; An, Z.; Zhang, Y.; Zhou, L. Widely Tunable Terahertz Phase Modulation with Gate-Controlled Graphene Metasurfaces. Phys. Rev. X 2015, 5, 041027. [Google Scholar] [CrossRef]

- Morea, M.; Zang, K.; Kamins, T.I.; Brongersma, M.L.; Harris, J.S. Electrically Tunable, CMOS-Compatible Metamaterial Based on Semiconductor Nanopillars. ACS Photonics 2018, 5, 4702–4709. [Google Scholar] [CrossRef]

- Yangjian, Z.; Chuhuan, F.; Qi, L.; Xin, S.; Hongbin, Y. Dynamic Reflection Phase Modulation in Terahertz Metamaterial. IEEE Photonics J. 2019, 11, 4601212. [Google Scholar] [CrossRef]

- Park, J.; Kang, J.H.; Kim, S.J.; Liu, X.; Brongersma, M.L. Dynamic Reflection Phase and Polarization Control in Metasurfaces. Nano Lett. 2017, 17, 407–413. [Google Scholar] [CrossRef]

- Plum, E.; Liu, X.X.; Fedotov, V.A.; Chen, Y.; Tsai, D.P.; Zheludev, N.I. Metamaterials: Optical Activity without Chirality. Phys. Rev. Lett. 2009, 102, 113902. [Google Scholar] [CrossRef]

- Kenanakis, G.; Zhao, R.; Katsarakis, N.; Kafesaki, M.; Soukoulis, C.M.; Economou, E.N. Optically Controllable THz Chiral Metamaterials. Opt. Express 2014, 22, 12149–12159. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Park, Y.-S.; Li, J.; Lu, X.; Zhang, W.; Zhang, X. Negative Refractive Index in Chiral Metamaterials. Phys. Rev. Lett. 2009, 102, 023901. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Zhou, J.; Koschny, T.; Soukoulis, C.M. Nonplanar Chiral Metamaterials with Negative Index. Appl. Phys. Lett. 2009, 94, 151112. [Google Scholar] [CrossRef]

- Decker, M.; Klein, M.W.; Wegener, M.; Linden, S. Circular Dichroism of Planar Chiral Magnetic Metamaterials. Opt. Lett. 2007, 32, 856–858. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Zeng, B.Q.; Zhong, S. A Double-Layer Chiral Metamaterial with Negative Index. J. Electromagn. Waves. Appl. 2010, 24, 983–992. [Google Scholar] [CrossRef]

- Zhou, J.; Chowdhury, D.R.; Zhao, R.; Azad, A.K.; Chen, H.T.; Soukoulis, C.M.; Taylor, A.J.; O’Hara, J.F. Terahertz Chiral Metamaterials with Giant and Dynamically Tunable Optical Activity. Phys. Rev. B Condens. Matter. Mater. Phys. 2012, 86, 035448. [Google Scholar] [CrossRef]

- Kan, T.; Isozaki, A.; Kanda, N.; Nemoto, N.; Konishi, K.; Takahashi, H.; Kuwata-Gonokami, M.; Matsumoto, K.; Shimoyama, I. Enantiomeric Switching of Chiral Metamaterial for Terahertz Polarization Modulation Employing Vertically Deformable MEMS Spirals. Nat. Commun. 2015, 6, 8422. [Google Scholar] [CrossRef]

- Barron, L.D. Molecular Light Scattering and Optical Activity; Cambridge University Press: Cambridge, UK, 2004. [Google Scholar] [CrossRef]

- Kuwata-Gonokami, M.; Saito, N.; Ino, Y.; Kauranen, M.; Jefimovs, K.; Vallius, T.; Turunen, J.; Svirko, Y. Giant Optical Activity in Quasi-Two-Dimensional Planar Nanostructures. Phys. Rev. Lett. 2005, 95, 227401. [Google Scholar] [CrossRef]

- Kanda, N.; Konishi, K.; Kuwata-Gonokami, M. Dynamics of Photo-Induced Terahertz Optical Activity in Metal Chiral Gratings. Opt. Lett. 2012, 37, 3510–3512. [Google Scholar] [CrossRef]

- Kanda, N.; Konishi, K.; Kuwata-Gonokami, M. Light-Induced Terahertz Optical Activity. Opt. Lett. 2009, 34, 3000–3002. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, J.; Park, Y.S.; Rho, J.; Singh, R.; Nam, S.; Azad, A.K.; Chen, H.T.; Yin, X.; Taylor, A.J.; et al. Photoinduced Handedness Switching in Terahertz Chiral Metamolecules. Nat. Commun. 2012, 3, 942. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.T.; Oh, S.S.; Kim, H.D.; Park, H.S.; Hess, O.; Min, B.; Zhang, S. Electrical Access to Critical Coupling of Circularly Polarized Waves in Graphene Chiral Metamaterials. Sci. Adv. 2017, 3, e1701377. [Google Scholar] [CrossRef] [PubMed]

- Choi, W.J.; Cheng, G.; Huang, Z.; Zhang, S.; Norris, T.B.; Kotov, N.A. Terahertz Circular Dichroism Spectroscopy of Biomaterials Enabled by Kirigami Polarization Modulators. Nat. Mater. 2019, 18, 820–826. [Google Scholar] [CrossRef] [PubMed]

- Kan, T.; Isozaki, A.; Kanda, N.; Nemoto, N.; Konishi, K.; Kuwata-Gonokami, M.; Matsumoto, K.; Shimoyama, I. Spiral Metamaterial for Active Tuning of Optical Activity. Appl. Phys. Lett. 2013, 102, 221906. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maruyama, K.; Mizuna, M.; Kosuge, T.; Takeda, Y.; Iwase, E.; Kan, T. Spiral Chiral Metamaterial Structure Shape for Optical Activity Improvements. Micromachines 2023, 14, 1156. https://doi.org/10.3390/mi14061156

Maruyama K, Mizuna M, Kosuge T, Takeda Y, Iwase E, Kan T. Spiral Chiral Metamaterial Structure Shape for Optical Activity Improvements. Micromachines. 2023; 14(6):1156. https://doi.org/10.3390/mi14061156

Chicago/Turabian StyleMaruyama, Kohei, Miyako Mizuna, Takuya Kosuge, Yuki Takeda, Eiji Iwase, and Tetsuo Kan. 2023. "Spiral Chiral Metamaterial Structure Shape for Optical Activity Improvements" Micromachines 14, no. 6: 1156. https://doi.org/10.3390/mi14061156

APA StyleMaruyama, K., Mizuna, M., Kosuge, T., Takeda, Y., Iwase, E., & Kan, T. (2023). Spiral Chiral Metamaterial Structure Shape for Optical Activity Improvements. Micromachines, 14(6), 1156. https://doi.org/10.3390/mi14061156