Superelastic NiTi Functional Components by High-Precision Laser Powder Bed Fusion Process: The Critical Roles of Energy Density and Minimal Feature Size

Abstract

1. Introduction

2. Materials and Methods

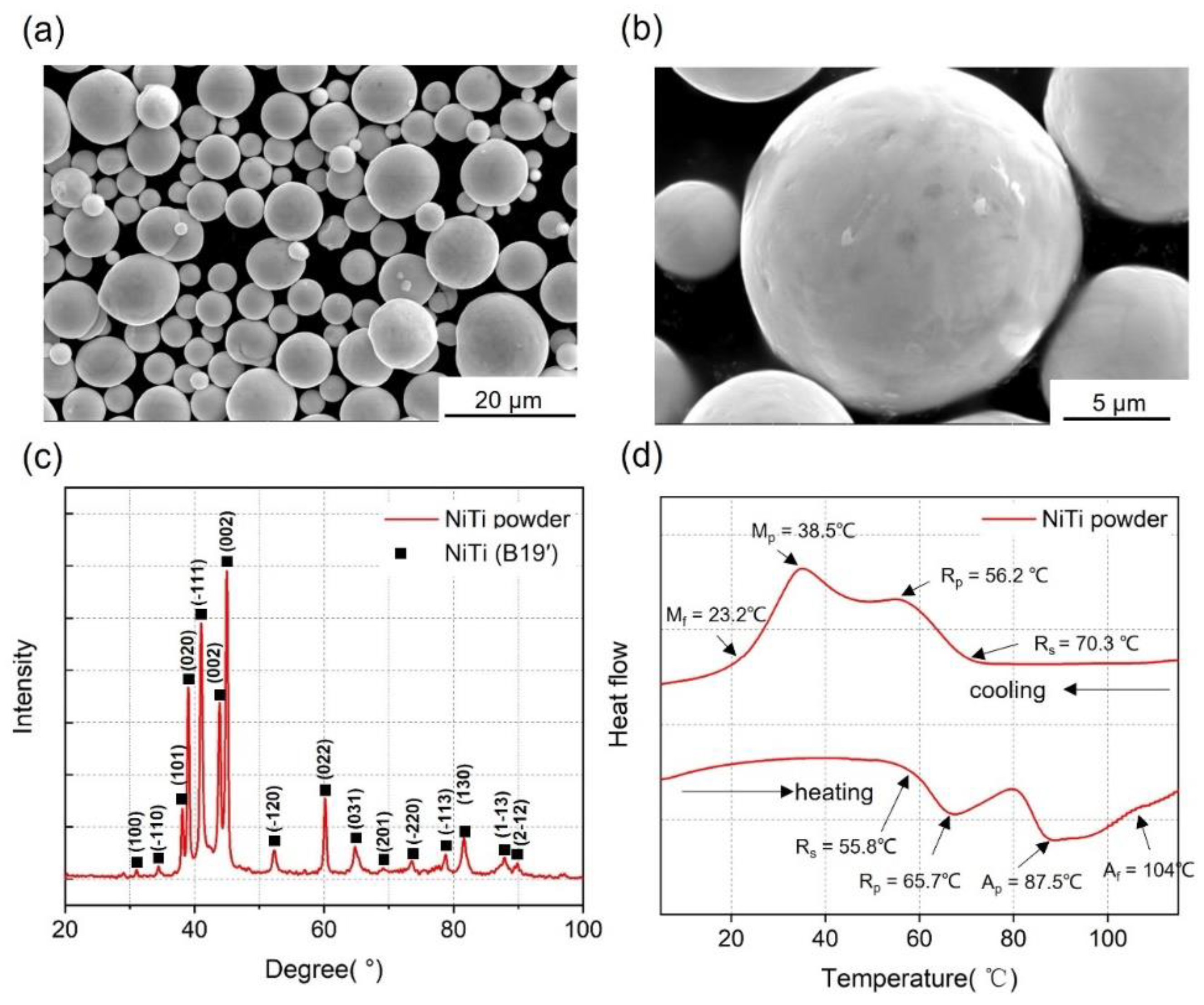

2.1. Materials and Processes

2.2. Characterization

2.3. Geometric Modeling of Component Structures

3. Results and Discussion

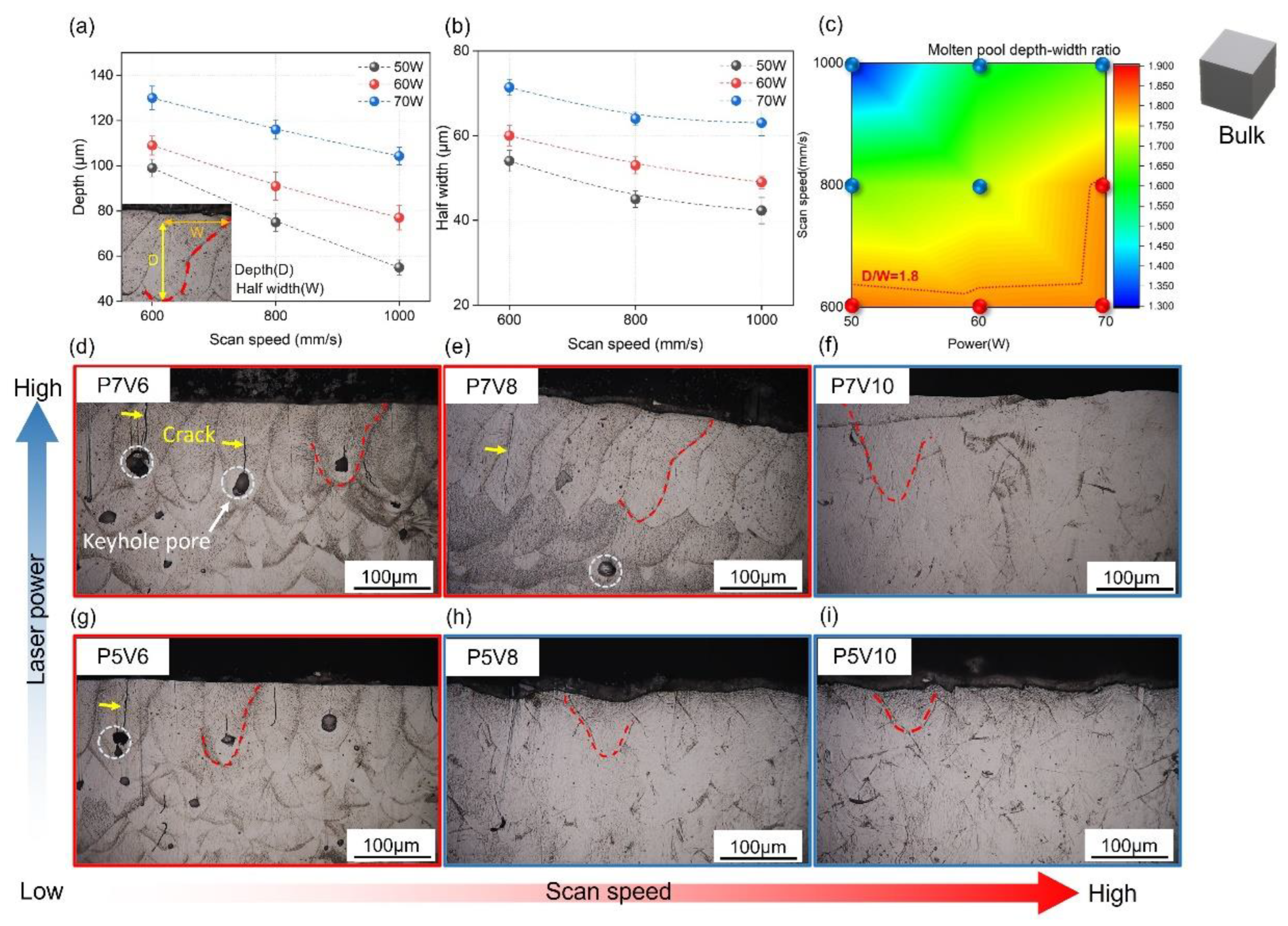

3.1. Effect of Process Parameters on Thin-Wall Structure Fabrication

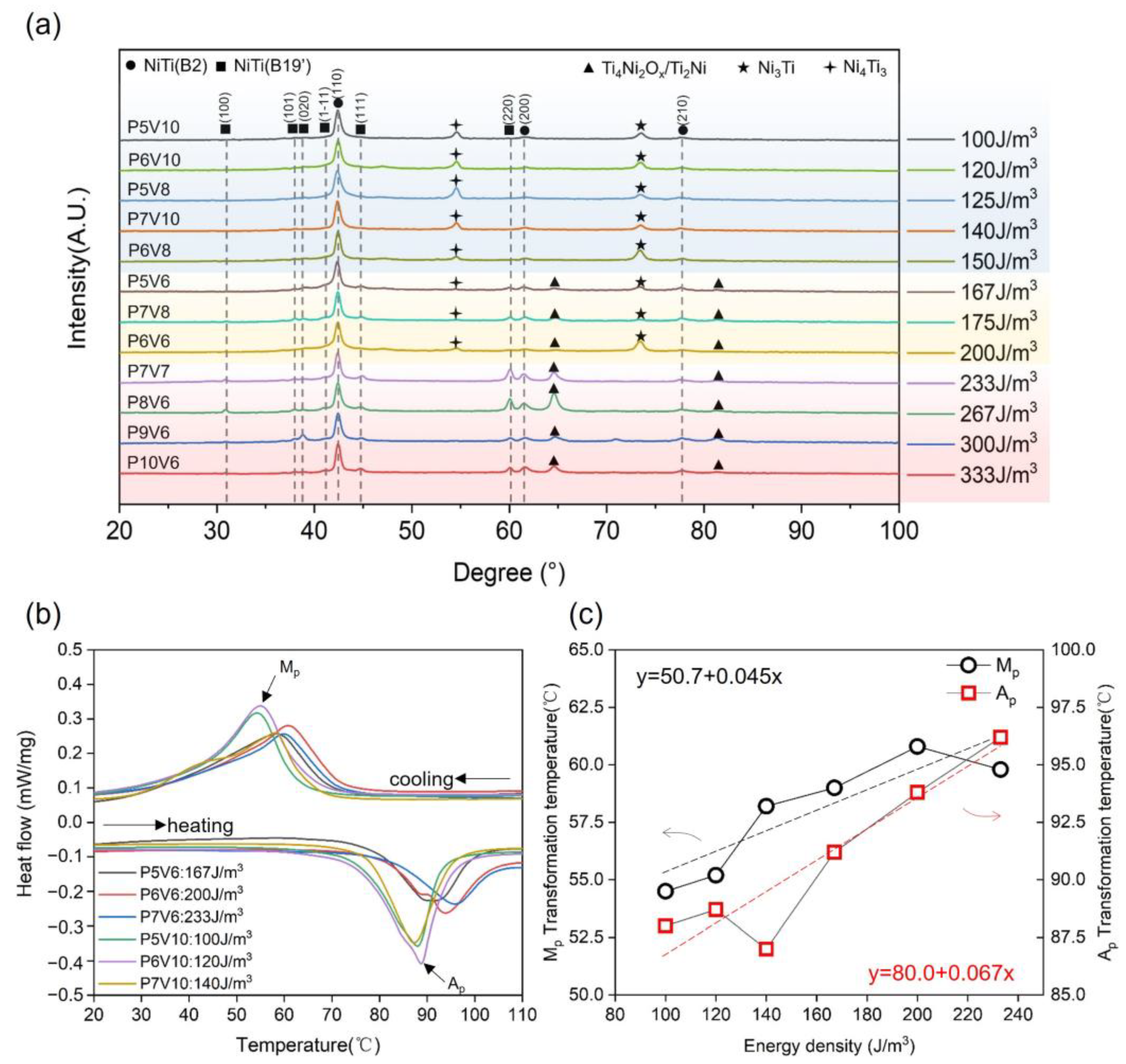

3.2. Effect of Process Parameters on Bulk Fabrication

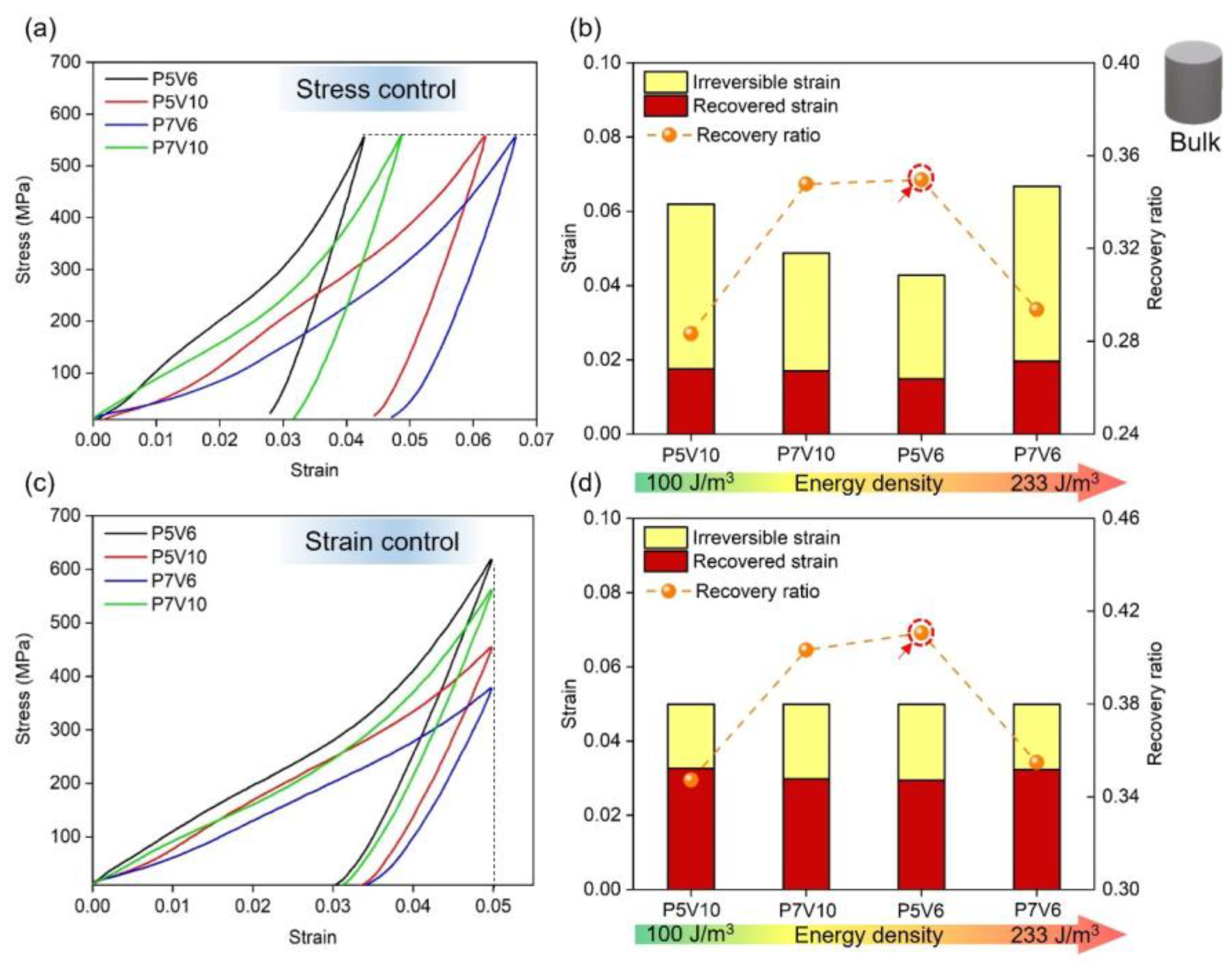

3.3. Superelastic Property of NiTi

3.3.1. Effect of Process Parameters on Bulk Samples

3.3.2. Effect of Process Parameters on TPMS Samples

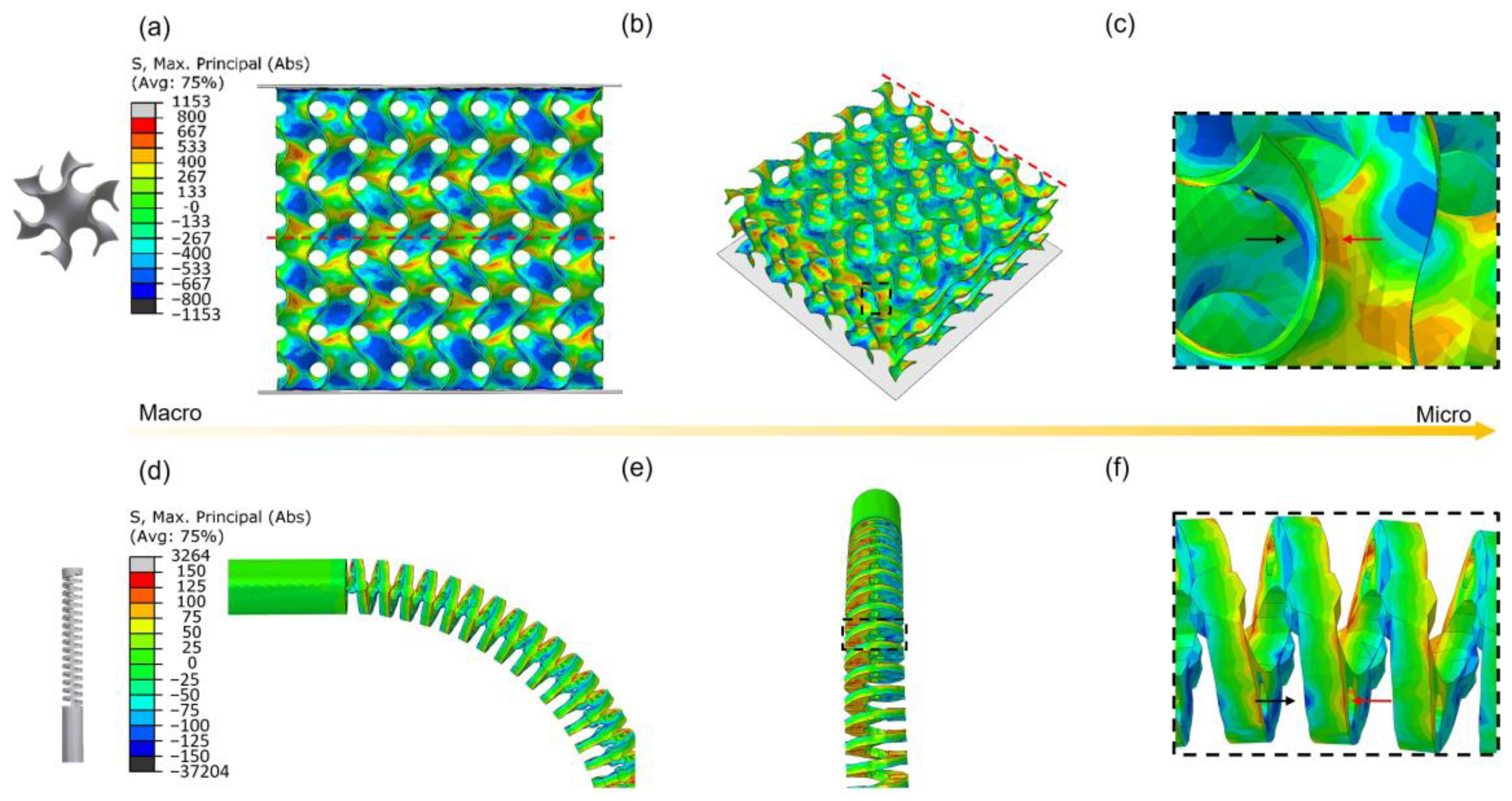

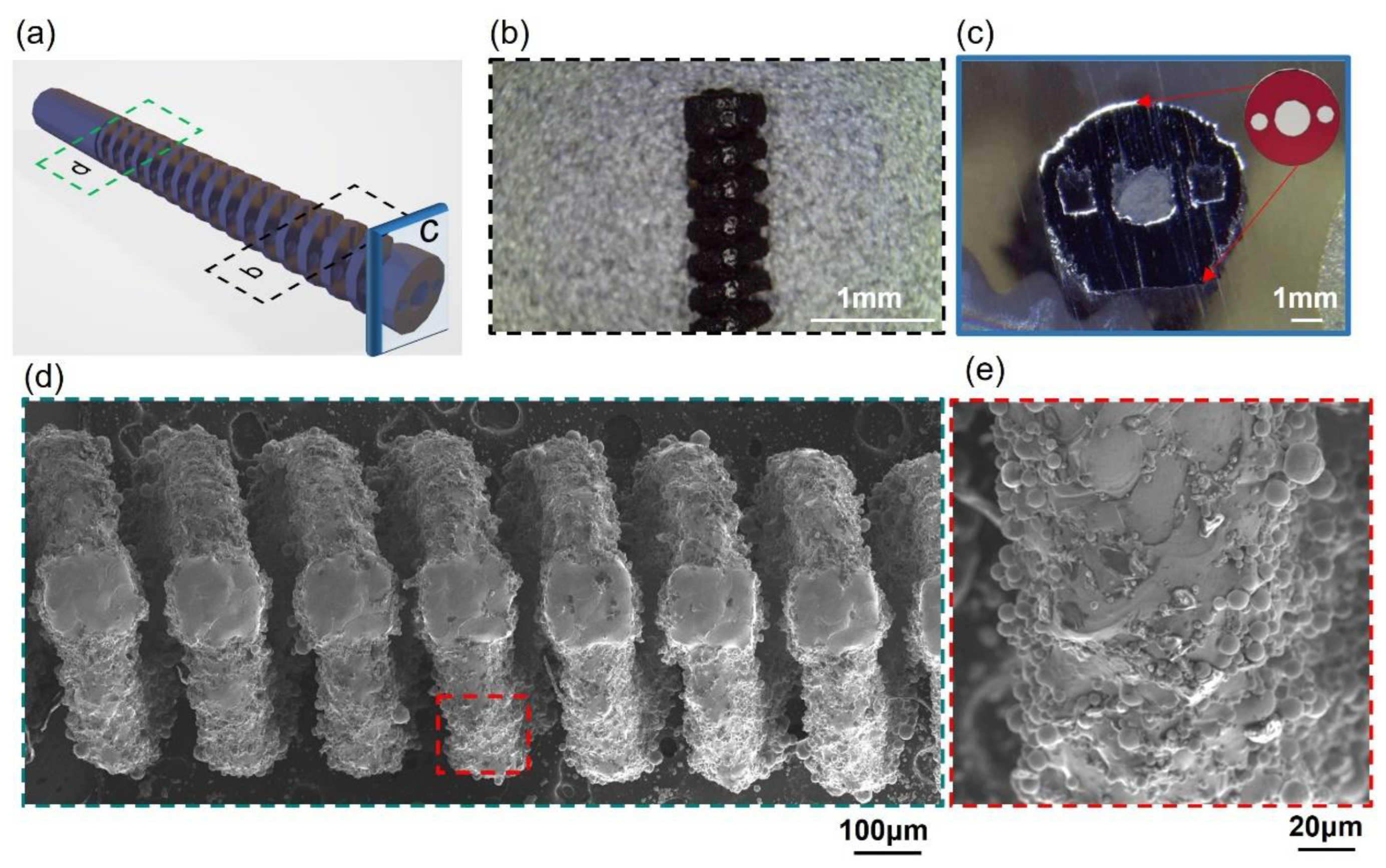

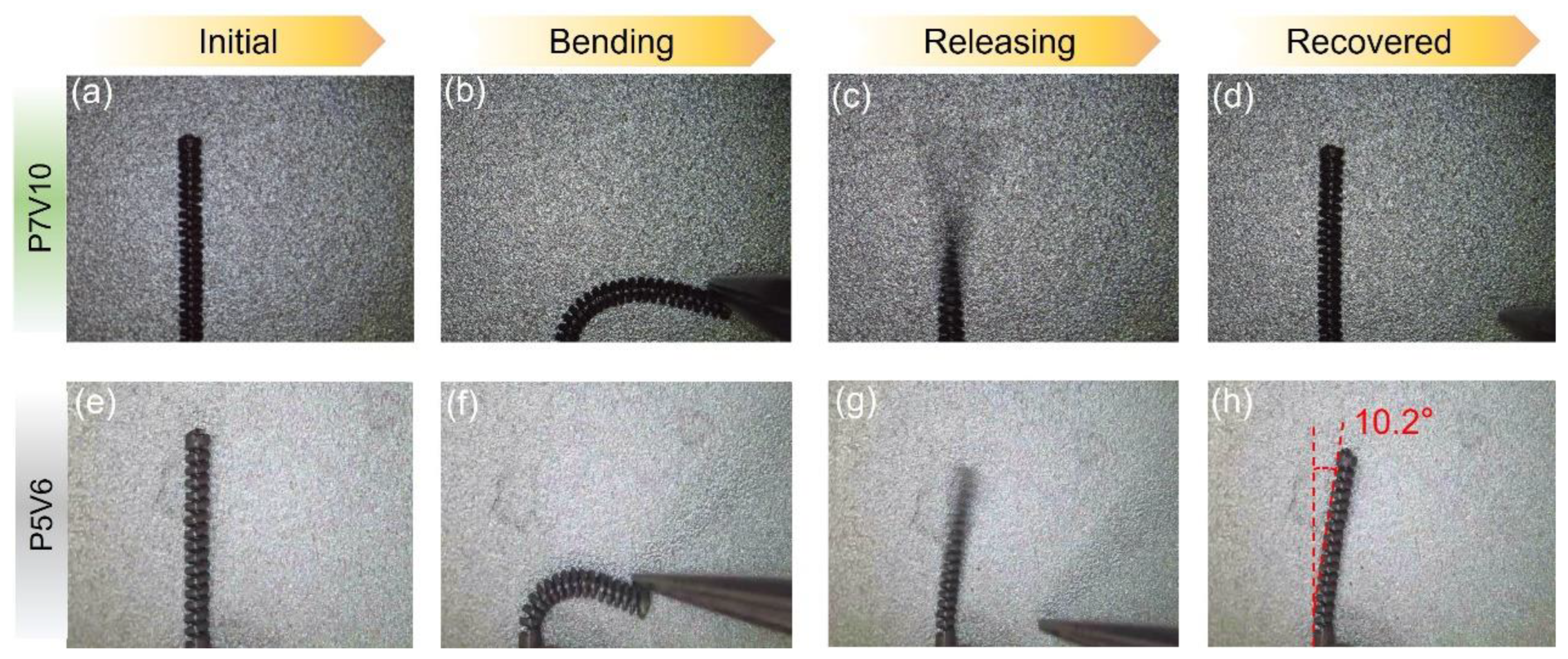

3.4. Superelastic Performance of Robot Cannula Tips: A Case Study

4. Conclusions

- (1)

- Thin-walled structures were fabricated using parameters that yielded different LEDs. The LED had a significant influence on the wall thickness. The thinnest single track of 62 μm was achieved with a laser power of 50 W and a scan speed of 1000 mm/s.

- (2)

- Bulk components with an RD higher than 99.5% could be printed with a VED lower than 160 J/mm3. Pores and cracks were observed in the microstructure when the D/W ratio of the molten pools was larger than 1.8. The precipitated phase changed from Ni4Ti3 and Ni3Ti to Ti4Ni2Ox/Ti2Ni with the increase in VED, which also caused an increase in the TTs.

- (3)

- Cylinders by VED of 140~167 J/m3 had better shape recovery properties than other parameters (100 J/m3 or 233 J/m3) due to a good controlling of VED for the balance of Ni4Ti3 segregation and Ni evaporation.

- (4)

- When the wall thickness of the G-TPMS lattice is smaller than 130 μm, the optimal VED for superelasticity is changed from 167 J/m3 to 140 J/m3 owing to the lower cooling rate of thinner walls.

- (5)

- The robotic cannula tips with a 120 μm strut diameter fabricated with 140 J/m3 VED exhibited excellent superelasticity properties thanks to the tailored phase compositions. It reveals the coupling effects of parameters, microstructure and feature size in LPBF, and proposes a new approach to processing high-performance intricate NiTi components.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Otsuka, K.; Ren, X. Physical metallurgy of Ti–Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Chau, E.T.F.; Friend, C.M.; Allen, D.M.; Hora, J.; Webster, J.R. A technical and economic appraisal of shape memory alloys for aerospace applications. Mater. Sci. Eng. A 2006, 438–440, 589–592. [Google Scholar] [CrossRef]

- Zhang, B.; Chen, J.; Coddet, C. Microstructure and Transformation Behavior of in-situ Shape Memory Alloys by Selective Laser Melting Ti–Ni Mixed Powder. J. Mater. Sci. Technol. 2013, 29, 863–867. [Google Scholar] [CrossRef]

- Mohd Jani, J.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Des. 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Sandoval, L.; Haskins, J.B.; Lawson, J.W. Stability, structure, and suppression of the martensitic transition temperature by B19′ compound twins in NiTi: Ab initio and classical simulations. Acta Mater. 2018, 154, 182–189. [Google Scholar] [CrossRef]

- Krause, D.; Thomas, B.; Leinenbach, C.; Eifler, D.; Minay, E.J.; Boccaccini, A.R. The electrophoretic deposition of Bioglass® particles on stainless steel and Nitinol substrates. Surf. Coat. Technol. 2006, 200, 4835–4845. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Van Humbeeck, J.; Kruth, J.-P. Laser additive manufacturing of bulk and porous shape-memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Guo, W.; Kato, H. Development of a high-damping NiTi shape-memory-alloy-based composite. Mater. Lett. 2015, 158, 1–4. [Google Scholar] [CrossRef]

- Ma, C.; Wu, M.; Dai, D.; Xia, M. Stress-induced heterogeneous transformation and recoverable behavior of laser powder bed fused Ni-rich Ni50.6Ti49.4 alloys without post treatment. J. Alloys Compd. 2022, 905, 164212. [Google Scholar] [CrossRef]

- Elahinia, M.; Shayesteh Moghaddam, N.; Amerinatanzi, A.; Saedi, S.; Toker, G.P.; Karaca, H.; Bigelow, G.S.; Benafan, O. Additive manufacturing of NiTiHf high temperature shape memory alloy. Scr. Mater. 2018, 145, 90–94. [Google Scholar] [CrossRef]

- Hou, H.; Simsek, E.; Ma, T.; Johnson, N.S.; Qian, S.; Cissé, C.; Stasak, D.; Al Hasan, N.; Zhou, L.; Hwang, Y.; et al. Fatigue-resistant high-performance elastocaloric materials made by additive manufacturing. Science 2019, 366, 1116–1121. [Google Scholar] [CrossRef] [PubMed]

- Speirs, M.; Van Hooreweder, B.; Van Humbeeck, J.; Kruth, J.P. Fatigue behaviour of NiTi shape memory alloy scaffolds produced by SLM, a unit cell design comparison. J. Mech. Behav. Biomed. Mater. 2017, 70, 53–59. [Google Scholar] [CrossRef] [PubMed]

- Dadbakhsh, S.; Speirs, M.; Kruth, J.-P.; Van Humbeeck, J. Influence of SLM on shape memory and compression behaviour of NiTi scaffolds. CIRP Ann. 2015, 64, 209–212. [Google Scholar] [CrossRef]

- Elahinia, M.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Guo, W.; Feng, B.; Yang, Y.; Ren, Y.; Liu, Y.; Yang, H.; Yang, Q.; Cui, L.; Tong, X.; Hao, S. Effect of laser scanning speed on the microstructure, phase transformation and mechanical property of NiTi alloys fabricated by LPBF. Mater. Des. 2022, 215, 110460. [Google Scholar] [CrossRef]

- Saedi, S.; Shayesteh Moghaddam, N.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 144, 552–560. [Google Scholar] [CrossRef]

- Qu, S.; Ding, J.; Fu, J.; Fu, M.; Zhang, B.; Song, X. High-precision laser powder bed fusion processing of pure copper. Addit. Manuf. 2021, 48, 102417. [Google Scholar] [CrossRef]

- Shi, G.; Li, L.; Yu, Z.; Liu, R.; Sha, P.; Xu, Z.; Guo, Y.; Xi, R.; Liu, J.; Xin, R.; et al. The interaction effect of process parameters on the phase transformation behavior and tensile properties in additive manufacturing of Ni-rich NiTi alloy. J. Manuf. Process. 2022, 77, 539–550. [Google Scholar] [CrossRef]

- Chen, W.; Yang, Q.; Huang, S.; Huang, S.; Kruzic, J.J.; Li, X. Laser power modulated microstructure evolution, phase transformation and mechanical properties in NiTi fabricated by laser powder bed fusion. J. Alloys Compd. 2021, 861, 157959. [Google Scholar] [CrossRef]

- Ye, D.; Li, S.F.; Misra, R.D.K.; Zheng, R.; Yang, Y.F. Ni-loss compensation and thermomechanical property recovery of 3D printed NiTi alloys by pre-coating Ni on NiTi powder. Addit. Manuf. 2021, 47, 102344. [Google Scholar] [CrossRef]

- Khanlari, K.; Shi, Q.; Li, K.; Hu, K.; Cao, P.; Liu, X. Effects of printing volumetric energy densities and post-processing treatments on the microstructural properties, phase transformation temperatures and hardness of near-equiatomic NiTinol parts fabricated by a laser powder bed fusion technique. Intermetallics 2021, 131, 107088. [Google Scholar] [CrossRef]

- Guo, F.; Guo, Y.; Kong, X.; Xiong, Z.; Hao, S. The Effect of Wall Thickness and Scanning Speed on the Martensitic Transformation and Tensile Properties of Selective Laser Melted NiTi Thin-Wall Structures. Metals 2022, 12, 519. [Google Scholar] [CrossRef]

- Fu, J.; Hu, Z.; Song, X.; Zhai, W.; Long, Y.; Li, H.; Fu, M. Micro selective laser melting of NiTi shape memory alloy: Defects, microstructures and thermal/mechanical properties. Opt. Laser Technol. 2020, 131, 106374. [Google Scholar] [CrossRef]

- Qu, S.; Ding, J.; Song, X. Achieving Triply Periodic Minimal Surface Thin-Walled Structures by Micro Laser Powder Bed Fusion Process. Micromachines 2021, 12, 705. [Google Scholar] [CrossRef]

- Fu, J.; Qu, S.; Ding, J.; Song, X.; Fu, M.W. Comparison of the microstructure, mechanical properties and distortion of stainless steel 316 L fabricated by micro and conventional laser powder bed fusion. Addit. Manuf. 2021, 44, 102067. [Google Scholar] [CrossRef]

- Saedi, S.; Turabi, A.S.; Andani, M.T.; Moghaddam, N.S.; Elahinia, M.; Karaca, H.E. Texture, aging, and superelasticity of selective laser melting fabricated Ni-rich NiTi alloys. Mater. Sci. Eng. A 2017, 686, 1–10. [Google Scholar] [CrossRef]

- Yu, Z.; Xu, Z.; Guo, Y.; Sha, P.; Liu, R.; Xin, R.; Li, L.; Chen, L.; Wang, X.; Zhang, Z.; et al. Analysis of microstructure, mechanical properties, wear characteristics and corrosion behavior of SLM-NiTi under different process parameters. J. Manuf. Process. 2022, 75, 637–650. [Google Scholar] [CrossRef]

- Feng, B.; Wang, C.; Zhang, Q.; Ren, Y.; Cui, L.; Yang, Q.; Hao, S. Effect of laser hatch spacing on the pore defects, phase transformation and properties of selective laser melting fabricated NiTi shape memory alloys. Mater. Sci. Eng. A 2022, 840, 142965. [Google Scholar] [CrossRef]

- Xiong, Z.; Li, H.; Yang, H.; Yang, Y.; Liu, Y.; Cui, L.; Li, X.; Masseling, L.; Shen, L.; Hao, S. Micro laser powder bed fusion of NiTi alloys with superior mechanical property and shape recovery function. Addit. Manuf. 2022, 57, 102960. [Google Scholar] [CrossRef]

- Ding, J.; Qu, S.; Zhang, L.; Wang, M.Y.; Song, X. Geometric deviation and compensation for thin-walled shell lattice structures fabricated by high precision laser powder bed fusion. Addit. Manuf. 2022, 58, 103061. [Google Scholar] [CrossRef]

- Yan, J.; Chen, J.; Chen, J.; Yan, W.; Ding, Q.; Yan, K.; Du, J.; Lam, C.P.; Wong, G.K.C.; Cheng, S.S. A Continuum Robotic Cannula with Tip Following Capability and Distal Dexterity for Intracerebral Hemorrhage Evacuation. IEEE Trans. Biomed. Eng. 2022, 69, 2958–2969. [Google Scholar] [CrossRef] [PubMed]

- Nespoli, A.; Biffi, C.A.; Previtali, B.; Villa, E.; Tuissi, A. Laser and Surface Processes of NiTi Shape Memory Elements for Micro-actuation. Metall. Mater. Trans. A 2014, 45, 2242–2249. [Google Scholar] [CrossRef]

- AbuZaiter, A.; Hikmat, O.F.; Nafea, M.; Ali, M.S.M. Design and fabrication of a novel XYθz monolithic micro-positioning stage driven by NiTi shape-memory-alloy actuators. Smart. Mater. Struct. 2016, 25, 105004. [Google Scholar] [CrossRef]

- Chun, Y.J.; Levi, D.S.; Mohanchandra, K.P.; Fishbein, M.C.; Carman, G.P. Novel micro-patterning processes for thin film NiTi vascular devices. Smart. Mater. Struct. 2010, 19, 105021. [Google Scholar] [CrossRef]

- Safdel, A.; Zarei-Hanzaki, A.; Abedi, H.R.; Pourbabak, S.; Schryvers, D.; Basu, R. Asymmetrical superelastic behavior of thermomechanically processed semi-equiatomic NiTi alloy in tensile and compressive modes of deformation. J. Alloys Compd. 2021, 878, 160443. [Google Scholar] [CrossRef]

- Gall, K.; Sehitoglu, H. The role of texture in tension–compression asymmetry in polycrystalline NiTi. Int. J. Plast. 1999, 15, 69–92. [Google Scholar] [CrossRef]

- Al-Ketan, O.; Rowshan, R.; Abu Al-Rub, R.K. Topology-mechanical property relationship of 3D printed strut, skeletal, and sheet based periodic metallic cellular materials. Addit. Manuf. 2018, 19, 167–183. [Google Scholar] [CrossRef]

- Fu, J.; Ding, J.; Qu, S.; Zhang, L.; Wang, M.Y.; Fu, M.W.; Song, X. Improved light-weighting potential of SS316L triply periodic minimal surface shell lattices by micro laser powder bed fusion. Mater. Des. 2022, 222, 111018. [Google Scholar] [CrossRef]

- Simard, J.M.; Thakor, N.V.; Fukuda, T.; Hogan, N.; Carmena, J.M.; Arkin, R. Plenary lectures: Problems in neurosurgery—A rich environment for engineer. In Proceedings of the 2012 4th IEEE RAS & EMBS International Conference on Biomedical Robotics and Biomechatronics (BioRob), Rome, Italy, 24–27 June 2012; pp. l–lv. [Google Scholar]

- Guo, X.; Ding, J.; Li, X.; Qu, S.; Song, X.; Fuh, J.Y.H.; Lu, W.F.; Zhai, W. Enhancement in the mechanical behaviour of a Schwarz Primitive periodic minimal surface lattice structure design. Int. J. Mech. Sci. 2022, 216, 106977. [Google Scholar] [CrossRef]

- Yin, H.; Zheng, X.; Wen, G.; Zhang, C.; Wu, Z. Design optimization of a novel bio-inspired 3D porous structure for crashworthiness. Compos. Struct. 2021, 255, 112897. [Google Scholar] [CrossRef]

- Ding, J.; Zou, Q.; Qu, S.; Bartolo, P.; Song, X.; Wang, C.C.L. STL-free design and manufacturing paradigm for high-precision powder bed fusion. CIRP Ann. 2021, 70, 167–170. [Google Scholar] [CrossRef]

- Wan, X.; Feng, Y.; Lin, X.; Tan, H. Large superelastic recovery and elastocaloric effect in as-deposited additive manufactured Ni50.8Ti49.2 alloy. Appl. Phys. Lett. 2019, 114, 221903. [Google Scholar] [CrossRef]

- Zhao, C.; Parab, N.D.; Li, X.; Fezzaa, K.; Tan, W.; Rollett, A.D.; Sun, T. Critical instability at moving keyhole tip generates porosity in laser melting. Science 2020, 370, 1080–1086. [Google Scholar] [CrossRef]

- Huang, Y.; Fleming, T.G.; Clark, S.J.; Marussi, S.; Fezzaa, K.; Thiyagalingam, J.; Leung, C.L.A.; Lee, P.D. Keyhole fluctuation and pore formation mechanisms during laser powder bed fusion additive manufacturing. Nat. Commun. 2022, 13, 1170. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, H.; Yin, J.; Li, Y.; Nie, Z.; Li, X.; You, D.; Guan, K.; Duan, W.; Cao, L.; et al. A Review of Spatter in Laser Powder Bed Fusion Additive Manufacturing: In Situ Detection, Generation, Effects, and Countermeasures. Micromachines 2022, 13, 1366. [Google Scholar] [CrossRef] [PubMed]

- Michael, A.; Zhou, Y.N.; Yavuz, M.; Khan, M.I. Modelling the alloy element composition change in NiTi achieved through laser induced vaporization. Mater. Chem. Phys. 2019, 231, 87–94. [Google Scholar] [CrossRef]

- Shi, G.; Li, L.; Yu, Z.; Sha, P.; Cao, Q.; Xu, Z.; Liu, Y.; Guo, Y.; Si, J.; Liu, J. Effect of crystallographic anisotropy on phase transformation and tribological properties of Ni-rich NiTi shape memory alloy fabricated by LPBF. Opt. Laser Technol. 2023, 157, 108731. [Google Scholar] [CrossRef]

- Ma, J.; Franco, B.; Tapia, G.; Karayagiz, K.; Johnson, L.; Liu, J.; Arroyave, R.; Karaman, I.; Elwany, A. Spatial Control of Functional Response in 4D-Printed Active Metallic Structures. Sci. Rep. 2017, 7, 46707. [Google Scholar] [CrossRef]

| Property | Size | D10 | D50 | D90 |

|---|---|---|---|---|

| Value | 5–25 μm | 10.0 μm | 19.8 μm | 28.5 μm |

| Element | Ni | C | O | N | Fe | H | Ti |

|---|---|---|---|---|---|---|---|

| Value/wt% | 55.2 | 0.01 | 0.07 | 0.002 | 0.01 | 0.001 | Balance |

| Sample Name | Laser Power (W) | Scan Speed (mm/s) | Linear Energy Density (J/m) |

|---|---|---|---|

| L50 | 50 | 1000 | 50 |

| L60 | 60 | 1000 | 60 |

| L63 | 50 | 800 | 63 |

| L70 | 70 | 1000 | 70 |

| L75 | 60 | 800 | 75 |

| L83 | 50 | 600 | 83 |

| L88 | 70 | 800 | 88 |

| L100 | 60 | 600 | 100 |

| L117 | 70 | 600 | 117 |

| Sample Name | Laser Power (W) | Scan Speed (mm/s) | Volumetric Energy Density (J/m3) |

|---|---|---|---|

| P5V6 | 50 | 1000 | 100 |

| P6V6 | 60 | 1000 | 120 |

| P7V6 | 50 | 800 | 125 |

| P8V6 | 70 | 1000 | 140 |

| P9V6 | 60 | 800 | 150 |

| P10V6 | 50 | 600 | 167 |

| P5V8 | 70 | 800 | 175 |

| P6V8 | 60 | 600 | 200 |

| P7V8 | 70 | 600 | 233 |

| P5V10 | 80 | 600 | 267 |

| P6V10 | 90 | 600 | 300 |

| P7V10 | 100 | 600 | 333 |

| Sample Name | Cell Size (mm) | Thickness (μm) | RD (%) |

|---|---|---|---|

| G10 | 2 | 65 | 10 |

| G20 | 2 | 130 | 20 |

| G40 | 2 | 260 | 40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, S.; Wang, L.; Ding, J.; Fu, J.; Gao, S.; Ma, Q.; Liu, H.; Fu, M.; Lu, Y.; Song, X. Superelastic NiTi Functional Components by High-Precision Laser Powder Bed Fusion Process: The Critical Roles of Energy Density and Minimal Feature Size. Micromachines 2023, 14, 1436. https://doi.org/10.3390/mi14071436

Qu S, Wang L, Ding J, Fu J, Gao S, Ma Q, Liu H, Fu M, Lu Y, Song X. Superelastic NiTi Functional Components by High-Precision Laser Powder Bed Fusion Process: The Critical Roles of Energy Density and Minimal Feature Size. Micromachines. 2023; 14(7):1436. https://doi.org/10.3390/mi14071436

Chicago/Turabian StyleQu, Shuo, Liqiang Wang, Junhao Ding, Jin Fu, Shiming Gao, Qingping Ma, Hui Liu, Mingwang Fu, Yang Lu, and Xu Song. 2023. "Superelastic NiTi Functional Components by High-Precision Laser Powder Bed Fusion Process: The Critical Roles of Energy Density and Minimal Feature Size" Micromachines 14, no. 7: 1436. https://doi.org/10.3390/mi14071436

APA StyleQu, S., Wang, L., Ding, J., Fu, J., Gao, S., Ma, Q., Liu, H., Fu, M., Lu, Y., & Song, X. (2023). Superelastic NiTi Functional Components by High-Precision Laser Powder Bed Fusion Process: The Critical Roles of Energy Density and Minimal Feature Size. Micromachines, 14(7), 1436. https://doi.org/10.3390/mi14071436