High-Performance Low-Voltage Transparent Metal-Semiconductor-Metal Ultraviolet Photodetectors Based on Ultrathin Gold Asymmetric Interdigitated Electrodes

Abstract

1. Introduction

2. Materials and Methods

2.1. Fabrication of Ultrathin Au Films

2.2. Fabrication of UV PDs

2.3. Characterization

3. Results and Discussion

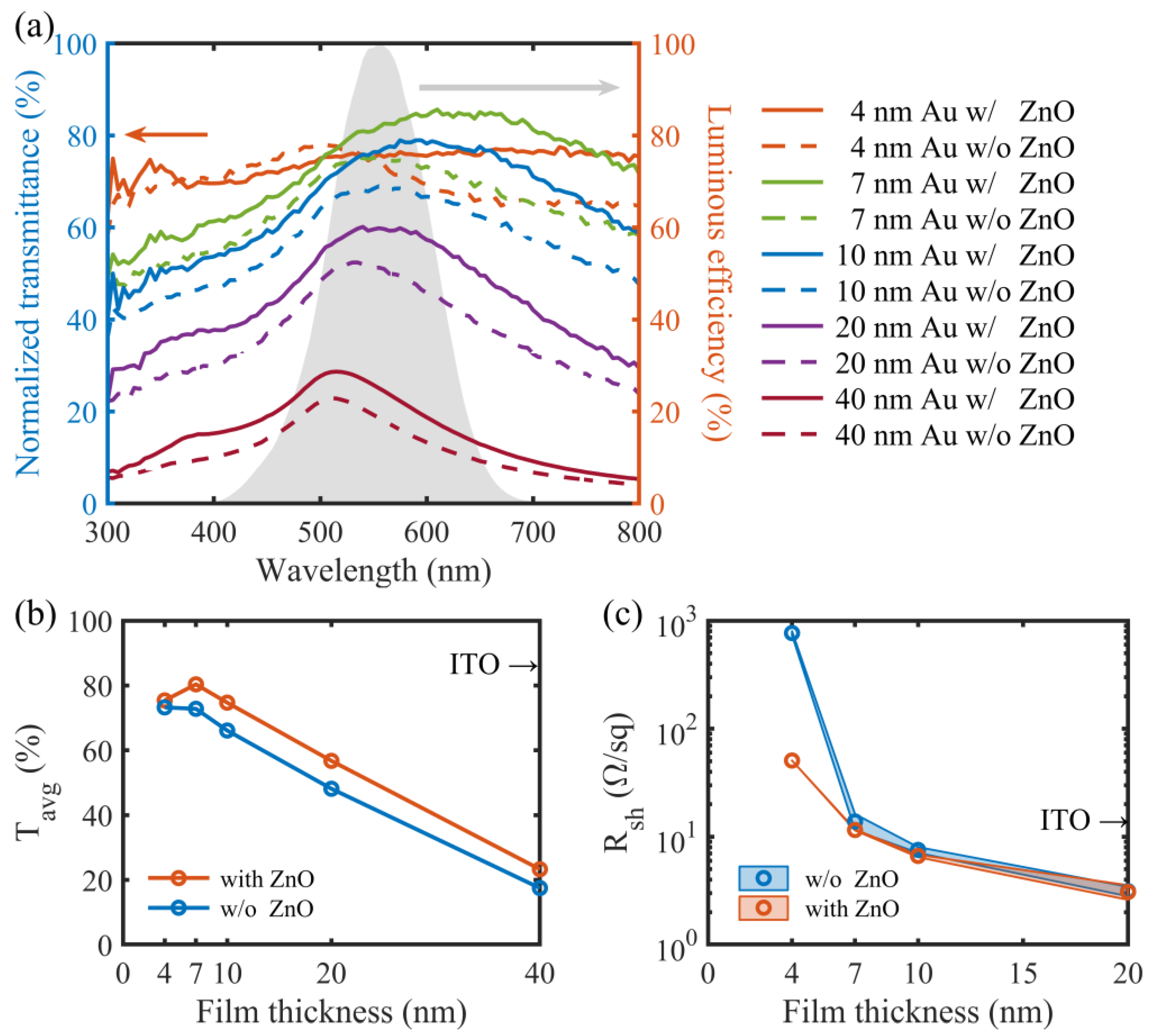

3.1. Continuous Sub-10 nm Thick Au Film with High Transparency and High Conductivity

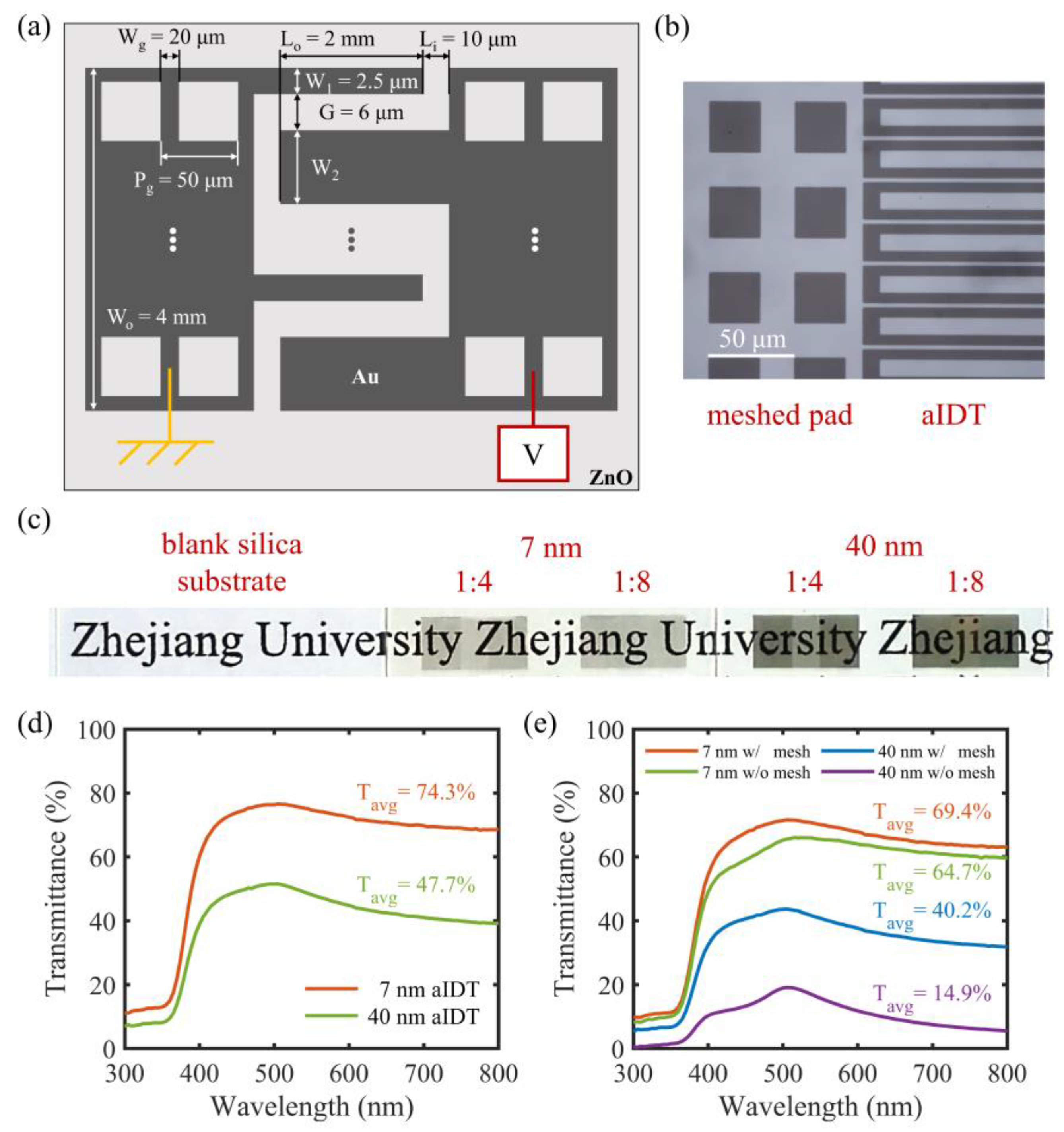

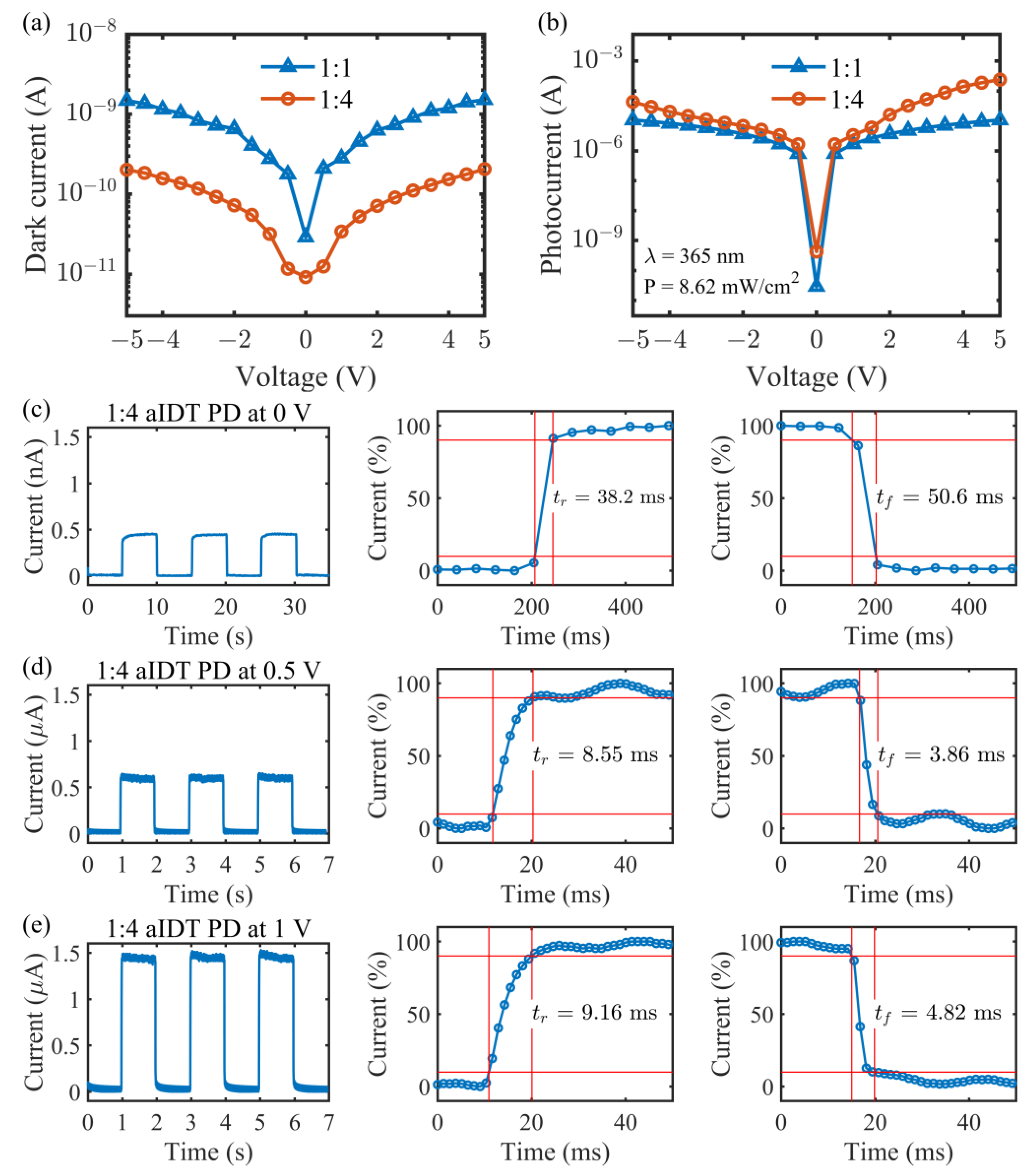

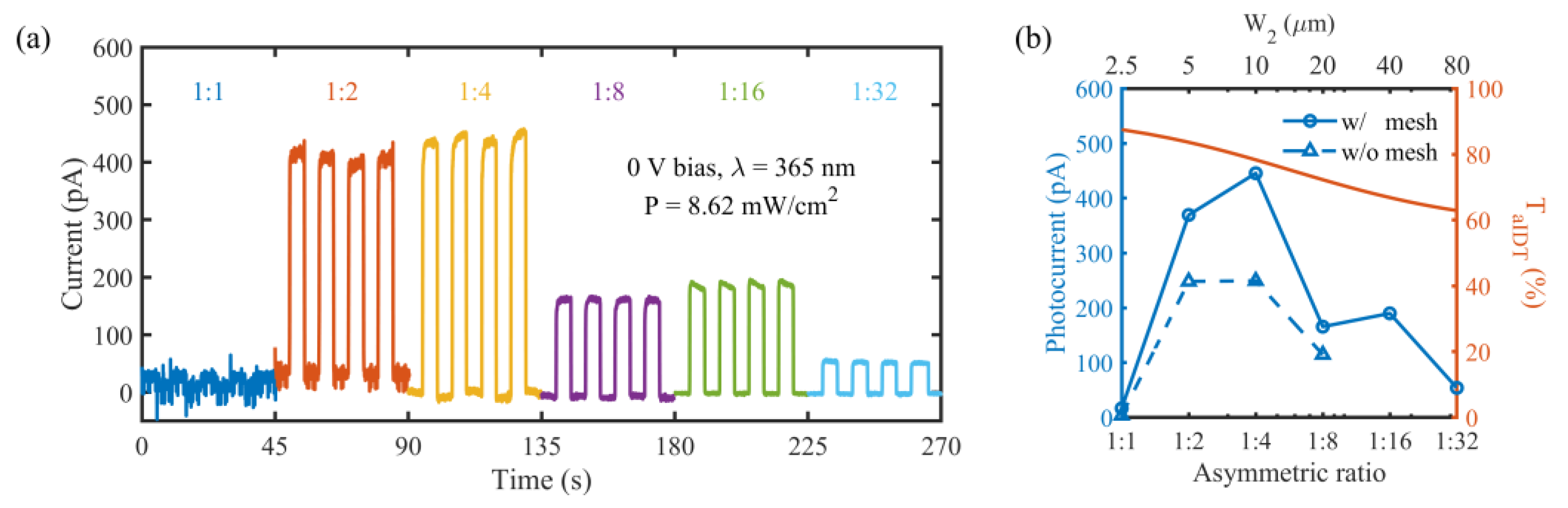

3.2. High-Performance, Low-Voltage, Transparent MSM UV PDs Based on Asymmetric Sub-10 nm Thick Au Interdigital Electrodes

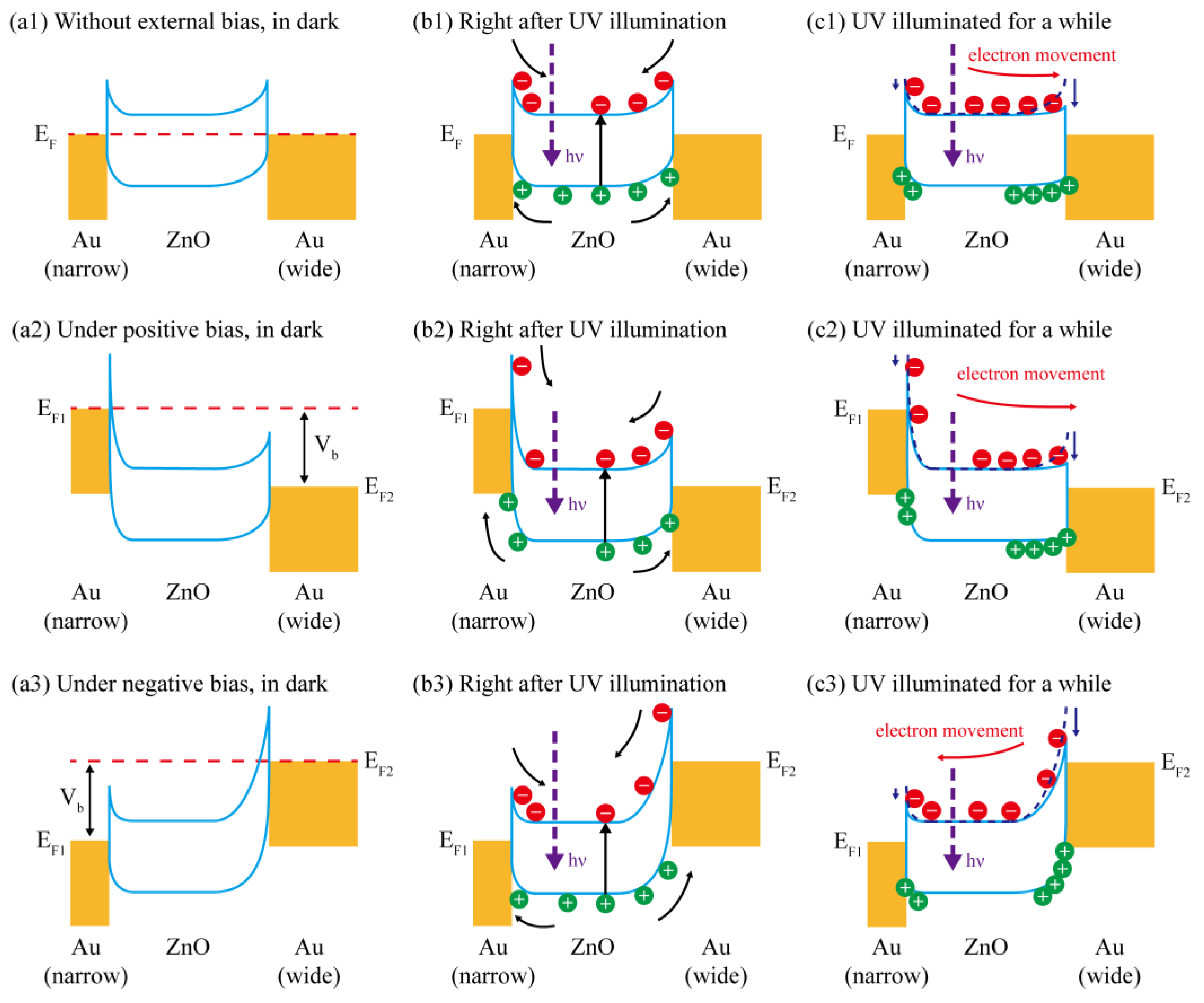

3.3. Working Mechanism of Transparent UV PD with aIDT Electrodes under Low Voltages

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Monroy, E.; Omnes, F.; Calle, F. Wide-bandgap semiconductor ultraviolet photodetectors. Semicond. Sci. Technol. 2003, 18, R33–R51. [Google Scholar] [CrossRef]

- Liu, K.; Sakurai, M.; Aono, M. ZnO-based ultraviolet photodetectors. Sensors 2010, 10, 8604–8634. [Google Scholar] [CrossRef] [PubMed]

- Fang, H.J.; Zheng, C.; Wu, L.L.; Li, Y.; Cai, J.; Hu, M.X.; Fang, X.S.; Ma, R.; Wang, Q.; Wang, H. Solution-Processed Self-Powered Transparent Ultraviolet Photodetectors with Ultrafast Response Speed for High-Performance Communication System. Adv. Funct. Mater. 2019, 29, 1809013. [Google Scholar] [CrossRef]

- Wu, L.L.; Fang, H.J.; Zheng, C.; Wang, Q.; Wang, H. A multifunctional smart window: Detecting ultraviolet radiation and regulating the spectrum automatically. J. Mater. Chem. C 2019, 7, 10446–10453. [Google Scholar] [CrossRef]

- Chen, H.Y.; Liu, K.W.; Hu, L.F.; Al-Ghamdi, A.A.; Fang, X.S. New concept ultraviolet photodetectors. Mater. Today 2015, 18, 493–502. [Google Scholar] [CrossRef]

- Peng, L.; Hu, L.; Fang, X. Low-dimensional nanostructure ultraviolet photodetectors. Adv. Mater. 2013, 25, 5321–5328. [Google Scholar] [CrossRef]

- Nasiri, N.; Jin, D.Y.; Tricoli, A. Nanoarchitechtonics of Visible-Blind Ultraviolet Photodetector Materials: Critical Features and Nano-Microfabrication. Adv. Opt. Mater. 2019, 7, 1800580. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Yang, W.; Liu, H.; Fang, X. 2D Perovskite Sr2Nb3O10 for High-Performance UV Photodetectors. Adv. Mater. 2020, 32, 1905443. [Google Scholar] [CrossRef]

- Jung, B.O.; Kim, D.C.; Kong, B.H.; Kim, D.W.; Cho, H.K. Fully transparent vertically aligned ZnO nanostructure-based ultraviolet photodetectors with high responsivity. Sens. Actuators B Chem. 2011, 160, 740–746. [Google Scholar] [CrossRef]

- Abbas, S.; Kumar, M.; Kim, J. All metal oxide-based transparent and flexible photodetector. Mater. Sci. Semicond. Process. 2018, 88, 86–92. [Google Scholar] [CrossRef]

- Patel, M.; Kim, J. Transparent NiO/ZnO heterojunction for ultra-performing zero-bias ultraviolet photodetector on plastic substrate. J. Alloys Compd. 2017, 729, 796–801. [Google Scholar] [CrossRef]

- Li, X.; Wang, X.; Luo, J.; Jiang, J.; Ding, K.; Ye, L.; Xiong, Y.; Pang, D.; Li, H.; Yu, P.; et al. Fully-transparent self-powered ultraviolet photodetector based on GaOx/ZnO heterojunction for solar-blind imaging. Mater. Today Commun. 2023, 35, 106118. [Google Scholar] [CrossRef]

- Patel, M.; Kim, H.S.; Kim, J. All Transparent Metal Oxide Ultraviolet Photodetector. Adv. Electron. Mater. 2015, 1, 1500232. [Google Scholar] [CrossRef]

- Abbas, S.; Kim, J. All-metal oxide transparent photodetector for broad responses. Sens. Actuators A Phys. 2020, 303, 111835. [Google Scholar] [CrossRef]

- Li, Y.; Li, Y.H.; Chen, J.; Sun, Z.P.; Li, Z.; Han, X.; Li, P.; Lin, X.J.; Liu, R.Q.; Ma, Y.W.; et al. Full-solution processed all-nanowire flexible and transparent ultraviolet photodetectors. J. Mater. Chem. C 2018, 6, 11666–11672. [Google Scholar] [CrossRef]

- Patel, D.B.; Patel, M.; Chauhan, K.R.; Kim, J.; Oh, M.S.; Kim, J.W. High-performing flexible and transparent photodetector by using silver nanowire-networks. Mater. Res. Bull. 2018, 97, 244–250. [Google Scholar] [CrossRef]

- Zheng, Z.; Gan, L.; Li, H.; Ma, Y.; Bando, Y.; Golberg, D.; Zhai, T. A Fully Transparent and Flexible Ultraviolet-Visible Photodetector Based on Controlled Electrospun ZnO-CdO Heterojunction Nanofiber Arrays. Adv. Funct. Mater. 2015, 25, 5885–5894. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, M.Q.; Song, X.H.; Yan, G.D.; Ding, Y.C.; Bai, J.B. High-performance ZnO/Ag Nanowire/ZnO composite film UV photodetectors with large area and low operating voltage. J. Mater. Chem. C 2014, 2, 4312–4319. [Google Scholar] [CrossRef]

- Hu, M.; Teng, F.; Chen, H.; Jiang, M.; Gu, Y.; Lu, H.; Hu, L.; Fang, X. Novel Ω-Shaped Core-Shell Photodetector with High Ultraviolet Selectivity and Enhanced Responsivity. Adv. Funct. Mater. 2017, 27, 1704477. [Google Scholar] [CrossRef]

- Bazargan, A.M.; Sharif, F.; Mazinani, S.; Naderi, N. High-performance transparent ultraviolet photodetector based on thermally reduced graphene oxide and ZnO thin films. J. Mater. Sci. Mater. Electron. 2017, 28, 11108–11113. [Google Scholar] [CrossRef]

- Ko, K.B.; Ryu, B.D.; Han, M.; Hong, C.H.; Dinh, D.A.; Cuong, T.V. Multidimensional graphene and ZnO-based heterostructure for flexible transparent ultraviolet photodetector. Appl. Surf. Sci. 2019, 481, 524–530. [Google Scholar] [CrossRef]

- Chen, C.H.; Chang, S.J.; Su, Y.K.; Chi, G.C.; Chi, J.Y.; Chang, C.A.; Sheu, J.K.; Chen, J.F. GaN metal-semiconductor-metal ultraviolet photodetectors with transparent indium-tin-oxide Schottky contacts. IEEE Photon. Technol. Lett. 2001, 13, 848–850. [Google Scholar] [CrossRef]

- He, X.; Yang, L.; He, S. Visible-blind and flexible metal-semiconductor-metal ultraviolet photodetectors based on sub-10-nm thick silver interdigital electrodes. Opt. Lett. 2021, 46, 4666–4669. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Li, Z.; Ni, F.; Ouyang, W.; Fang, X. Bio-inspired transparent MXene electrodes for flexible UV photodetectors. Mater. Horiz. 2020, 7, 1828–1833. [Google Scholar] [CrossRef]

- Long, Z.; Xu, X.; Yang, W.; Hu, M.; Shtansky, D.V.; Golberg, D.; Fang, X. Cross-Bar SnO2-NiO Nanofiber-Array-Based Transparent Photodetectors with High Detectivity. Adv. Electron. Mater. 2020, 6, 1901048. [Google Scholar] [CrossRef]

- Chen, H.Y.; Liu, K.W.; Chen, X.; Zhang, Z.Z.; Fan, M.M.; Jiang, M.M.; Xie, X.H.; Zhao, H.F.; Shen, D.Z. Realization of a self-powered ZnO MSM UV photodetector with high responsivity using an asymmetric pair of Au electrodes. J. Mater. Chem. C 2014, 2, 9689–9694. [Google Scholar] [CrossRef]

- Dong, L.; Yu, J.; Jia, R.; Hu, J.; Zhang, Y.; Sun, J. Self-powered MSM deep-ultraviolet β-Ga2O3 photodetector realized by an asymmetrical pair of Schottky contacts. Opt. Mater. Express 2019, 9, 1191–1199. [Google Scholar] [CrossRef]

- Zhang, C.; Ji, C.; Park, Y.B.; Guo, L.J. Thin-Metal-Film-Based Transparent Conductors: Material Preparation, Optical Design, and Device Applications. Adv. Opt. Mater. 2020, 9, 2001298. [Google Scholar] [CrossRef]

- Yun, J. Ultrathin Metal films for Transparent Electrodes of Flexible Optoelectronic Devices. Adv. Funct. Mater. 2017, 27, 1606641. [Google Scholar] [CrossRef]

- Xie, J.; Bi, Y.G.; Ye, M.; Rao, Z.G.; Shu, L.L.; Lin, P.; Zeng, X.R.; Ke, S.M. Epitaxial ultrathin Au films on transparent mica with oxide wetting layer applied to organic light-emitting devices. Appl. Phys. Lett. 2019, 114, 081902. [Google Scholar] [CrossRef]

- Lim, J.W.; Lee, Y.T.; Pandey, R.; Yoo, T.H.; Sang, B.I.; Ju, B.K.; Hwang, D.K.; Choi, W.K. Effect of geometric lattice design on optical/electrical properties of transparent silver grid for organic solar cells. Opt. Express 2014, 22, 26891–26899. [Google Scholar] [CrossRef] [PubMed]

- Bahramian, R.; Eshghi, H.; Moshaii, A. Influence of annealing temperature on morphological, optical and UV detection properties of ZnO nanowires grown by chemical bath deposition. Mater. Des. 2016, 107, 269–276. [Google Scholar] [CrossRef]

- Donolato, C. Approximate analytical solution to the space charge problem in nanosized Schottky diodes. J. Appl. Phys. 2004, 95, 2184–2186. [Google Scholar] [CrossRef]

- Zhang, Z.; Yates, J.T., Jr. Band bending in semiconductors: Chemical and physical consequences at surfaces and interfaces. Chem. Rev. 2012, 112, 5520–5551. [Google Scholar] [CrossRef]

- He, X.; Cao, Q.; Pan, J.; Yang, L.; He, S. Patterned few nanometer-thick silver films with high optical transparency and high electrical conductivity. RSC Adv. 2021, 11, 11481–11489. [Google Scholar] [CrossRef] [PubMed]

| PD Architecture | T a | Bias (V) | Id (A) | R (A/W) | D* (Jones) | tr/tf | Refs. |

|---|---|---|---|---|---|---|---|

| Ag NWs/TiO2/FTO, vertical | 70% (device) | 0 | ~1 n | 32.5 m | ~6 × 109 | 44 ns/1.85 µs | [3] |

| NiO/ZnO/ITO, vertical | 74.8% (device) | 0 | 1.8 p | 20 μ | 7.2 × 1011 | 41 µs/71 µs | [11] |

| Ag NWs/NiO/TiO2/FTO, vertical | 44.2% (0.4–1 μm; device) | 0 | ~57 μ | 136 m | 1.11 × 109 | 1.5 ms/1.7 ms | [14] |

| Ag NWs/ZnO NWs/Ag NWs, vertical | 75% (device) | 0.5 | 53.3 n | 4.16 | 1.59 × 1013 | 1.83 s/1.75 s | [15] |

| GaN MSM ITO IDT | — | 0.5 | 0.1 n | 0.9 | — | — | [22] |

| ZnO/CdO NFs b MSM Ti/Au w/o IDT | ~95% (active layer) | 0.5 | — | 1 | — | 3 s/3 s | [17] |

| AgxO/TiO2/ITO, vertical | 70% (device) | −1 | 0.65 m | 0.323 | 4.2 × 108 | 287 ms/361 ms | [10] |

| TiO2 MSM FTO IDT | ~80% (device) | 1 | 33.1 n | 67.15 m | 2.71 × 1012 | 1.71 s/3.17 s | [4] |

| ZnO:Ag NWs MSM Au w/o IDT | 75% (active layer) | 1 | 15.0 n | 2.4 | 6.8 × 1012 | 3.53 s/3.67 s | [18] |

| ZnO MSM 7 nm Au aIDT | 74.3% (weighted with V(λ); device) | 0 | 9.18 p | 0.636 μ | 1.05 × 108 | 38.2 ms/50.6 ms | This work |

| 0.5 | 12.5 p | 2.41 m | 3.41 × 1011 | 8.55 ms/3.86 ms | |||

| 1 | 34.1 p | 4.86 m | 4.15 × 1011 | 9.16 ms/4.82 ms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, J.; Yang, L.; He, S. High-Performance Low-Voltage Transparent Metal-Semiconductor-Metal Ultraviolet Photodetectors Based on Ultrathin Gold Asymmetric Interdigitated Electrodes. Micromachines 2023, 14, 1447. https://doi.org/10.3390/mi14071447

Huang J, Yang L, He S. High-Performance Low-Voltage Transparent Metal-Semiconductor-Metal Ultraviolet Photodetectors Based on Ultrathin Gold Asymmetric Interdigitated Electrodes. Micromachines. 2023; 14(7):1447. https://doi.org/10.3390/mi14071447

Chicago/Turabian StyleHuang, Jianfeng, Liu Yang, and Sailing He. 2023. "High-Performance Low-Voltage Transparent Metal-Semiconductor-Metal Ultraviolet Photodetectors Based on Ultrathin Gold Asymmetric Interdigitated Electrodes" Micromachines 14, no. 7: 1447. https://doi.org/10.3390/mi14071447

APA StyleHuang, J., Yang, L., & He, S. (2023). High-Performance Low-Voltage Transparent Metal-Semiconductor-Metal Ultraviolet Photodetectors Based on Ultrathin Gold Asymmetric Interdigitated Electrodes. Micromachines, 14(7), 1447. https://doi.org/10.3390/mi14071447