Four-Dimensional-Printed Microrobots and Their Applications: A Review

Abstract

:1. Introduction

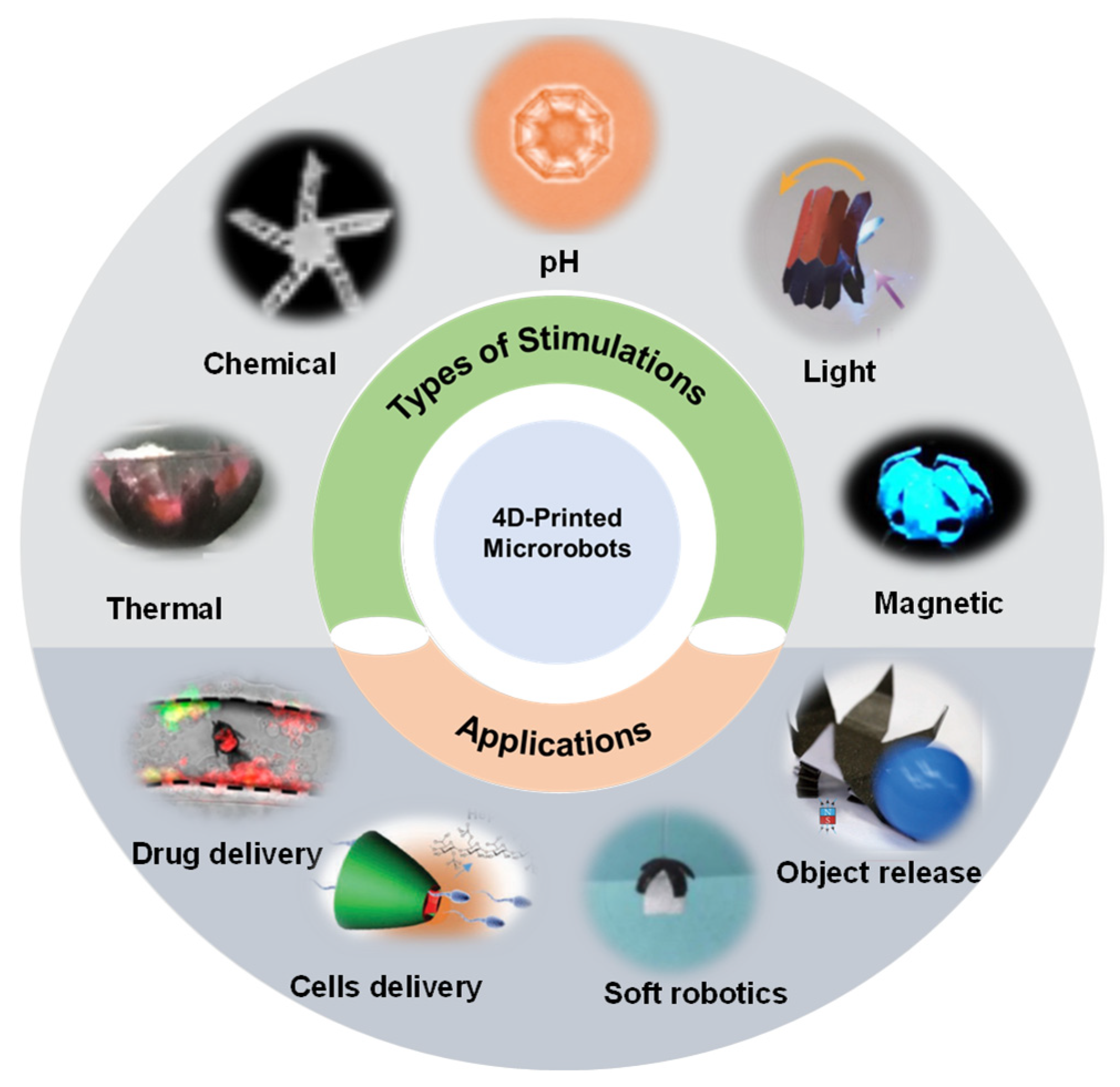

2. Reversible Shape Transformation Strategies for Microrobots

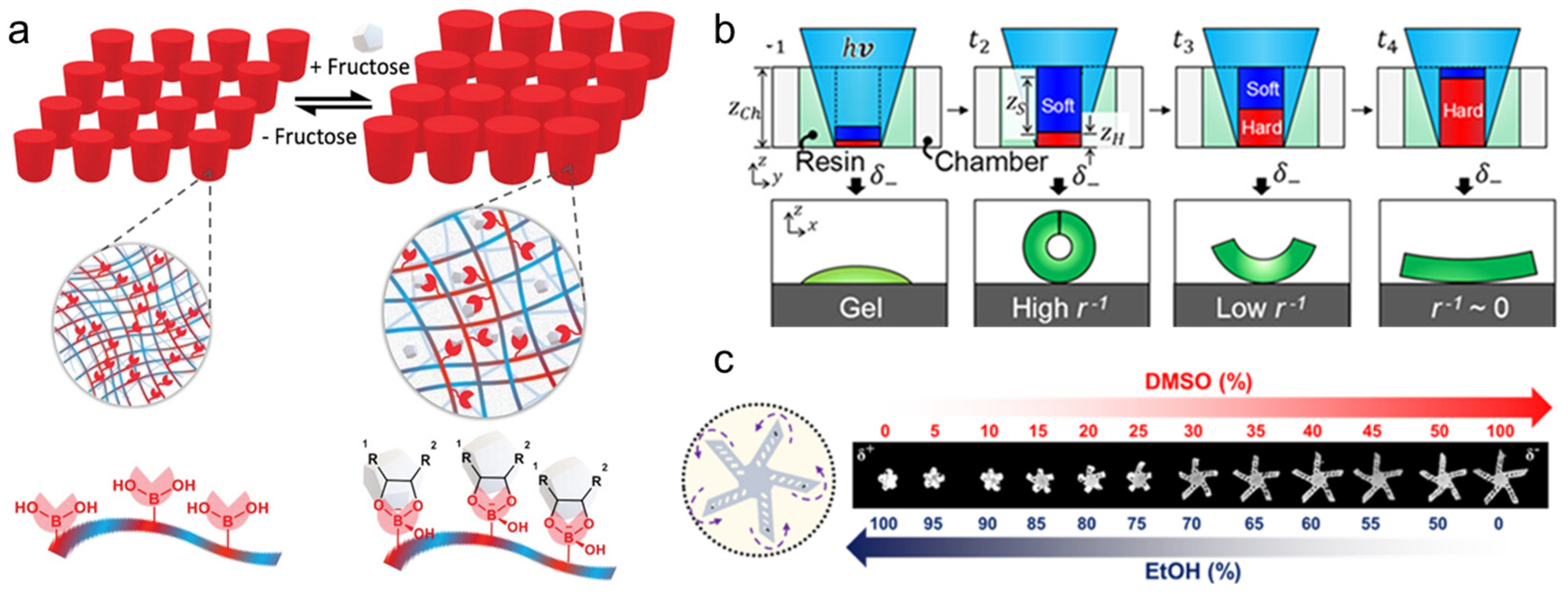

2.1. Single-Layer Material

2.2. Multilayer Material

3. Stimulations

3.1. Thermal

3.2. Chemical

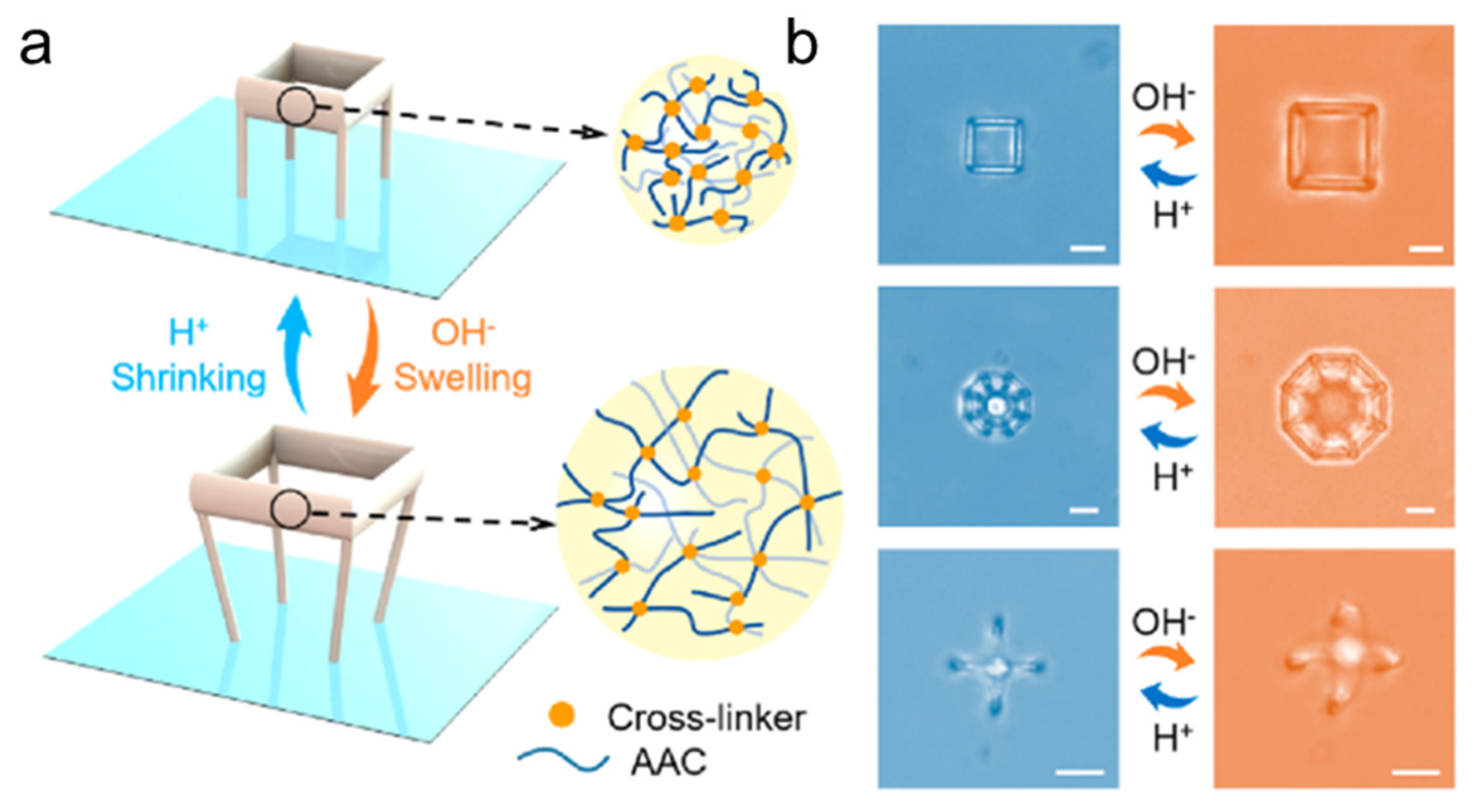

3.3. pH

3.4. Light

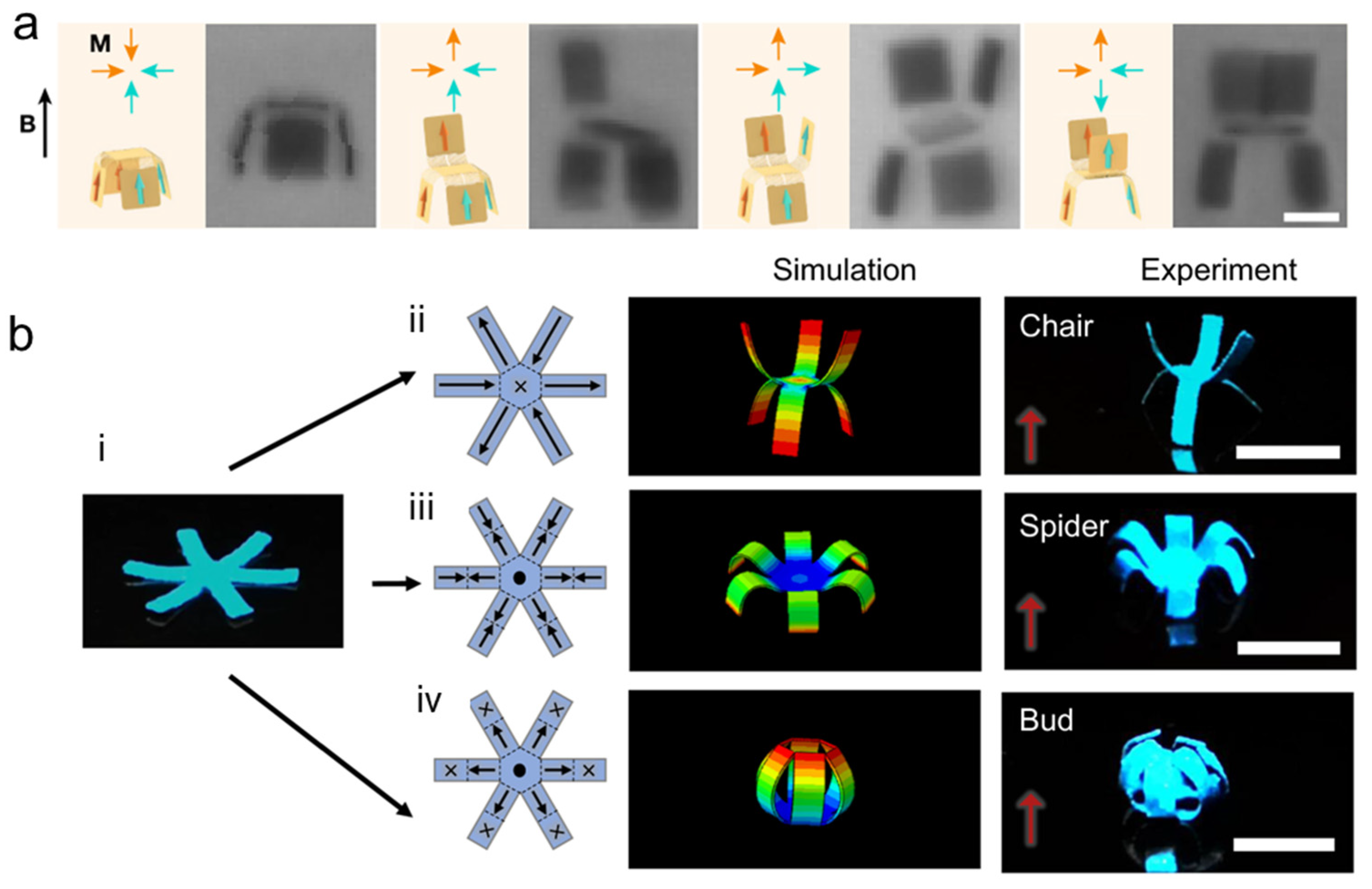

3.5. Magnetic

3.6. Hybrid

4. Applications

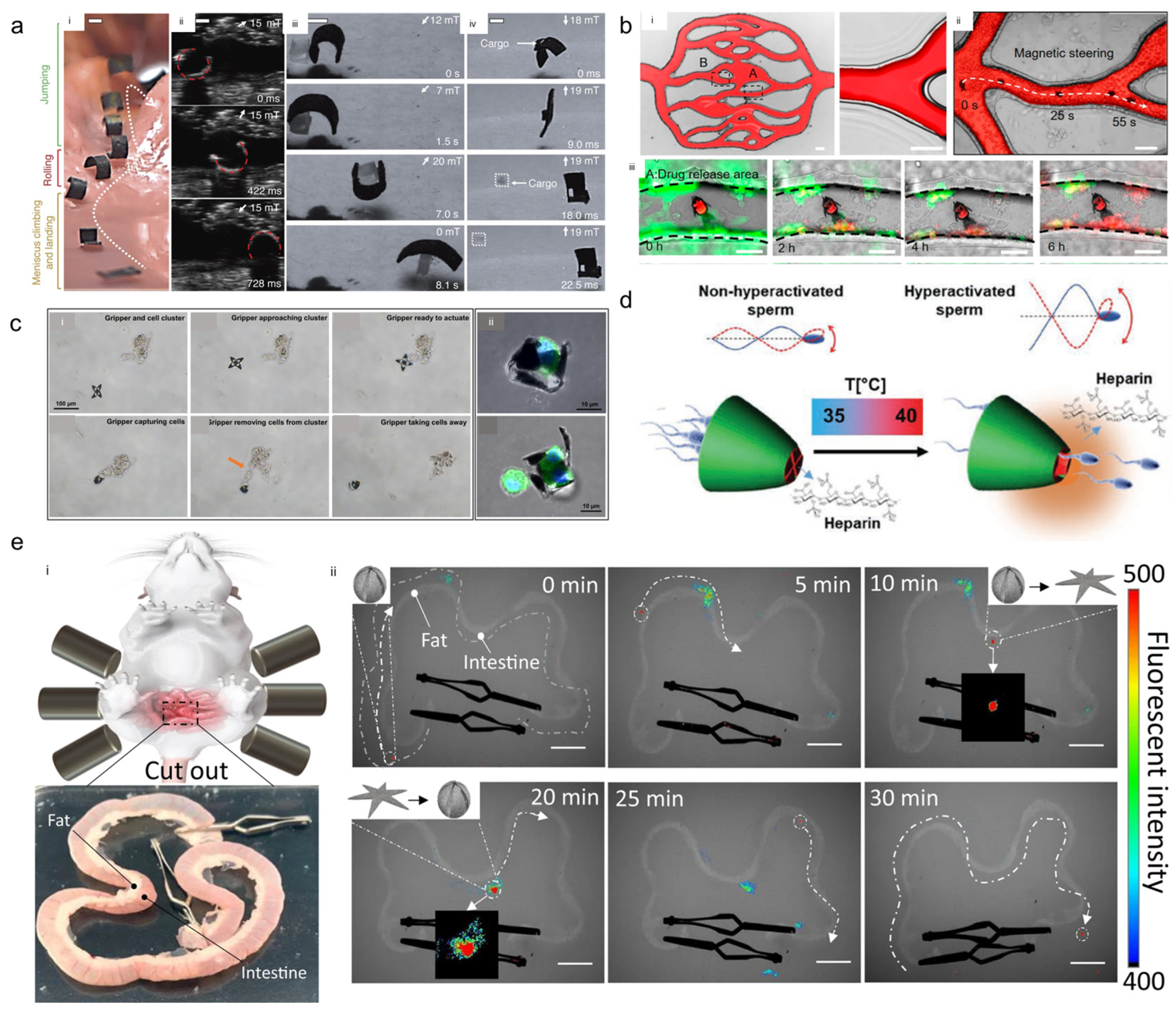

4.1. Medical Applications

4.1.1. Biopsy

4.1.2. Drug Delivery

4.1.3. Cells Delivery

4.1.4. Drug Treatment Evaluation

4.2. Nonmedical Applications

4.2.1. Soft Robotics

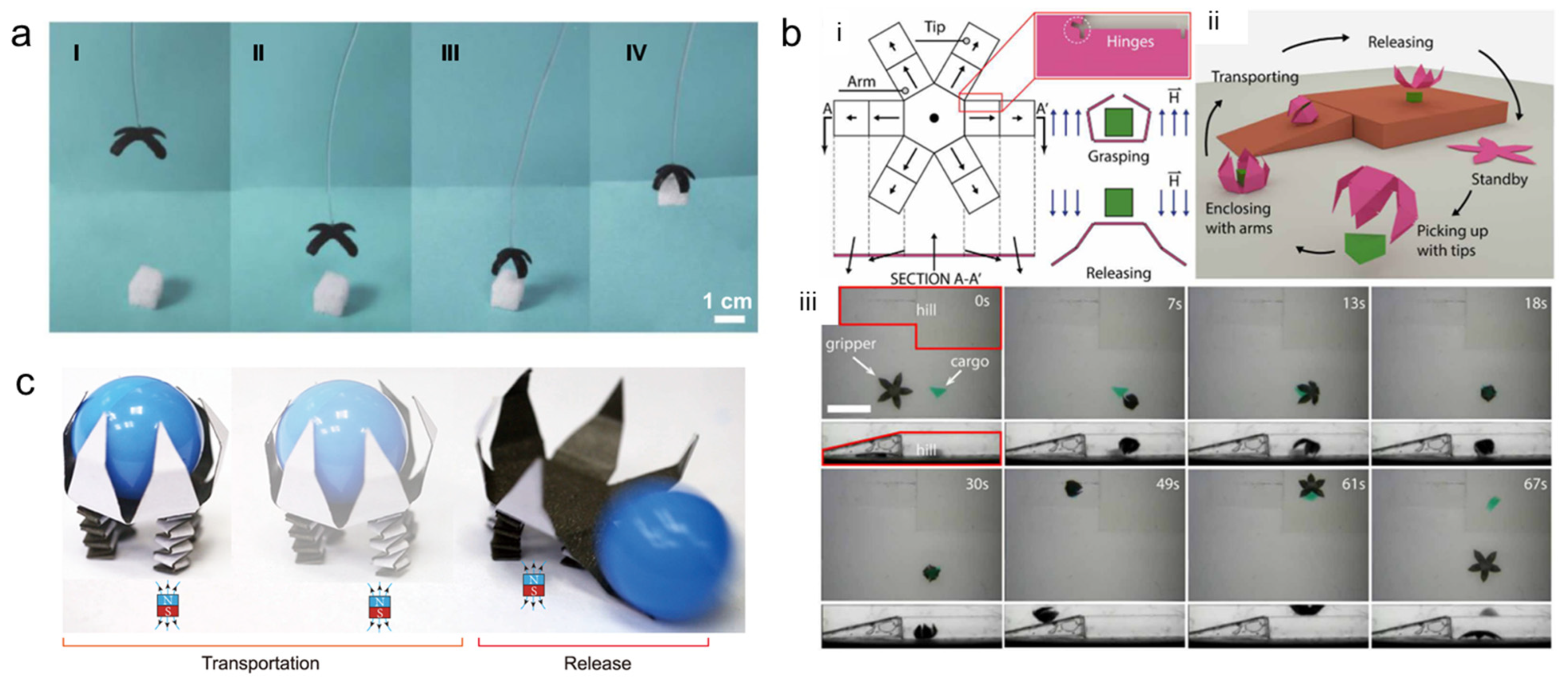

4.2.2. Cargo Delivery

5. Future Challenges and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sitti, M. Miniature Devices: Voyage of the Microrobots. Nature 2009, 458, 1121–1122. [Google Scholar] [CrossRef]

- Zhang, L.; Abbott, J.J.; Dong, L.; Kratochvil, B.E.; Bell, D.; Nelson, B.J. Artificial Bacterial Flagella: Fabrication and Magnetic Control. Appl. Phys. Lett. 2009, 94, 064107. [Google Scholar] [CrossRef] [Green Version]

- Vrba, J.; Maslen, C.; Maxova, J.; Duras, J.; Rehor, I.; Mares, J. An Automated Platform for Assembling Light-Powered Hydrogel Microrobots and Their Subsequent Chemical Binding [Formula Presented]. J. Comput. Sci. 2021, 55, 101446. [Google Scholar] [CrossRef]

- Luo, M.; Feng, Y.; Wang, T.; Guan, J. Micro-/Nanorobots at Work in Active Drug Delivery. Adv. Funct. Mater. 2018, 28, 1706100. [Google Scholar] [CrossRef]

- Dabbagh, S.R.; Sarabi, M.R.; Birtek, M.T.; Seyfi, S.; Sitti, M.; Tasoglu, S. 3D-Printed Microrobots from Design to Translation. Nat. Commun. 2022, 13, 5875. [Google Scholar] [CrossRef]

- Ceylan, H.; Giltinan, J.; Kozielski, K.; Sitti, M. Mobile Microrobots for Bioengineering Applications. Lab Chip 2017, 17, 1705–1724. [Google Scholar] [CrossRef] [Green Version]

- Palagi, S.; Fischer, P. Bioinspired Microrobots. Nat. Rev. Mater. 2018, 3, 113–124. [Google Scholar] [CrossRef]

- Nelson, B.J.; Kaliakatsos, I.K.; Abbott, J.J. Microrobots for Minimally Invasive Medicine. Annu. Rev. Biomed. Eng. 2010, 12, 55–85. [Google Scholar] [CrossRef] [Green Version]

- Zheng, S.; Hoang, M.C.; Nguyen, V.D.; Go, G.; Nan, M.; Darmawan, B.A.; Kim, S.; Im, S.; Lee, T.; Bang, D.; et al. Microrobot with Gyroid Surface and Gold Nanostar for High Drug Loading and Near-Infrared-Triggered Chemo-Photothermal Therapy. Pharmaceutics 2022, 14, 2393. [Google Scholar] [CrossRef]

- Go, G.; Yoo, A.; Nguyen, K.T.; Nan, M.; Darmawan, B.A.; Zheng, S.; Kang, B.; Kim, C.S.; Bang, D.; Lee, S.; et al. Multifunctional Microrobot with Real-Time Visualization and Magnetic Resonance Imaging for Chemoembolization Therapy of Liver Cancer. Sci. Adv. 2022, 8, eabq8545. [Google Scholar] [CrossRef]

- Kim, D.I.; Lee, H.; Kwon, S.H.; Sung, Y.J.; Song, W.K.; Park, S. Bilayer Hydrogel Sheet-Type Intraocular Microrobot for Drug Delivery and Magnetic Nanoparticles Retrieval. Adv. Healthc. Mater. 2020, 9, 2000118. [Google Scholar] [CrossRef]

- Cong, Z.; Tang, S.; Xie, L.; Yang, M.; Li, Y.; Lu, D.; Li, J.; Yang, Q.; Chen, Q.; Zhang, Z.; et al. Magnetic-Powered Janus Cell Robots Loaded with Oncolytic Adenovirus for Active and Targeted Virotherapy of Bladder Cancer. Adv. Mater. 2022, 34, 2201042. [Google Scholar] [CrossRef] [PubMed]

- Medina-Sánchez, M.; Schwarz, L.; Meyer, A.K.; Hebenstreit, F.; Schmidt, O.G. Cellular Cargo Delivery: Toward Assisted Fertilization by Sperm-Carrying Micromotors. Nano Lett. 2016, 16, 555–561. [Google Scholar] [CrossRef]

- Zhan, Z.; Chen, L.; Duan, H.; Chen, Y.; He, M.; Wang, Z. 3D Printed Ultra-Fast Photothermal Responsive Shape Memory Hydrogel for Microrobots. Int. J. Extrem. Manuf. 2022, 4, 015302. [Google Scholar] [CrossRef]

- Li, J.; Esteban-Fernández de Ávila, B.; Gao, W.; Zhang, L.; Wang, J. Micro/Nanorobots for Biomedicine: Delivery, Surgery, Sensing, and Detoxification. Sci. Robot. 2017, 2, eaam6431. [Google Scholar] [CrossRef]

- Bernasconi, R.; Carrara, E.; Hoop, M.; Mushtaq, F.; Chen, X.; Nelson, B.J.; Pané, S.; Credi, C.; Levi, M.; Magagnin, L. Magnetically Navigable 3D Printed Multifunctional Microdevices for Environmental Applications. Addit. Manuf. 2019, 28, 127–135. [Google Scholar] [CrossRef]

- Kong, L.; Ambrosi, A.; Nasir, M.Z.M.; Guan, J.; Pumera, M. Self-Propelled 3D-Printed “Aircraft Carrier” of Light-Powered Smart Micromachines for Large-Volume Nitroaromatic Explosives Removal. Adv. Funct. Mater. 2019, 29, 1903872. [Google Scholar] [CrossRef]

- Li, H.; Darmawan, B.A.; Go, G.; Kim, S.-J.; Nan, M.; Kang, B.; Kim, H.; Lee, S.B.; Bang, D.; Park, J.-O.; et al. Single-Layer 4D Printing System Using Focused Light: A Tool for Untethered Microrobot Applications. Chem. Mater. 2021, 33, 7703–7712. [Google Scholar] [CrossRef]

- Medina-Sánchez, M.; Magdanz, V.; Guix, M.; Fomin, V.M.; Schmidt, O.G. Swimming Microrobots: Soft, Reconfigurable, and Smart. Adv. Funct. Mater. 2018, 28, 1707228. [Google Scholar] [CrossRef]

- Hann, S.Y.; Cui, H.; Nowicki, M.; Zhang, L.G. 4D Printing Soft Robotics for Biomedical Applications. Addit. Manuf. 2020, 36, 101567. [Google Scholar] [CrossRef]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A.S.S. 4D Printing of Materials for the Future: Opportunities and Challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

- Dong, Y.; Wang, S.; Ke, Y.; Ding, L.; Zeng, X.; Magdassi, S.; Long, Y. 4D Printed Hydrogels: Fabrication, Materials, and Applications. Adv. Mater. Technol. 2020, 5, 2000034. [Google Scholar] [CrossRef]

- Falahati, M.; Ahmadvand, P.; Safaee, S.; Chang, Y.C.; Lyu, Z.; Chen, R.; Li, L.; Lin, Y. Smart Polymers and Nanocomposites for 3D and 4D Printing. Mater. Today 2020, 40, 215–245. [Google Scholar] [CrossRef]

- Mahmud, M.A.P.; Tat, T.; Xiao, X.; Adhikary, P.; Chen, J. Advances in 4D-printed Physiological Monitoring Sensors. Exploration 2021, 1, 20210033. [Google Scholar] [CrossRef]

- Tibbits, S. 4D Printing: Multi-Material Shape Change. Archit. Des. 2014, 84, 421–433. [Google Scholar] [CrossRef]

- Kirillova, A.; Ionov, L. Shape-Changing Polymers for Biomedical Applications. J. Mater. Chem. B 2019, 7, 1597–1624. [Google Scholar] [CrossRef] [PubMed]

- van Manen, T.; Janbaz, S.; Jansen, K.M.B.; Zadpoor, A.A. 4D Printing of Reconfigurable Metamaterials and Devices. Commun. Mater. 2021, 2, 56. [Google Scholar] [CrossRef]

- Kocak, G.; Tuncer, C.; Bütün, V. PH-Responsive Polymers. Polym. Chem. 2017, 8, 144–176. [Google Scholar] [CrossRef]

- Go, G.; Nguyen, V.D.; Jin, Z.; Park, J.O.; Park, S. A Thermo-Electromagnetically Actuated Microrobot for the Targeted Transport of Therapeutic Agents. Int. J. Control Autom. Syst. 2018, 16, 1341–1354. [Google Scholar] [CrossRef]

- Ko, H.; Ratri, M.C.; Kim, K.; Jung, Y.; Tae, G.; Shin, K. Formulation of Sugar/Hydrogel Inks for Rapid Thermal Response 4D Architectures with Sugar-Derived Macropores. Sci. Rep. 2020, 10, 7527. [Google Scholar] [CrossRef]

- Li, H.; Go, G.; Ko, S.Y.; Park, J.O.; Park, S. Magnetic Actuated PH-Responsive Hydrogel-Based Soft Micro-Robot for Targeted Drug Delivery. Smart Mater. Struct. 2016, 25, 27001. [Google Scholar] [CrossRef]

- Chen, Q.; Lin, W.; Wang, H.; Wang, J.; Zhang, L. PDEAEMA-Based PH-Sensitive Amphiphilic Pentablock Copolymers for Controlled Anticancer Drug Delivery. RSC Adv. 2016, 6, 68018–68027. [Google Scholar] [CrossRef]

- Darmawan, B.A.; Lee, S.B.; Nguyen, V.D.; Go, G.; Nguyen, K.T.; Lee, H.-S.; Nan, M.; Hong, A.; Kim, C.-S.; Li, H.; et al. Self-Folded Microrobot for Active Drug Delivery and Rapid Ultrasound-Triggered Drug Release. Sens. Actuators B Chem. 2020, 324, 128752. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Go, G.; Jin, Z.; Darmawan, B.A.; Yoo, A.; Kim, S.; Nan, M.; Lee, S.B.; Kang, B.; Kim, C.S.; et al. A Magnetically Guided Self-Rolled Microrobot for Targeted Drug Delivery, Real-Time X-Ray Imaging, and Microrobot Retrieval. Adv. Healthc. Mater. 2021, 10, 2001681. [Google Scholar] [CrossRef] [PubMed]

- He, C.; Zhang, M.; Devahastin, S. Investigation on Spontaneous Shape Change of 4D Printed Starch-Based Purees from Purple Sweet Potatoes As Induced by Microwave Dehydration. ACS Appl. Mater. Interfaces 2020, 12, 37896–37905. [Google Scholar] [CrossRef]

- Rösch, A.G.; Gall, A.; Aslan, S.; Hecht, M.; Franke, L.; Mallick, M.M.; Penth, L.; Bahro, D.; Friderich, D.; Lemmer, U. Fully Printed Origami Thermoelectric Generators for Energy-Harvesting. npj Flex. Electron. 2021, 5, 1. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, H.; Wang, Y.; Xu, C.; Esworthy, T.J.; Hann, S.Y.; Boehm, M.; Shen, Y.L.; Mei, D.; Zhang, L.G. 4D Printed Cardiac Construct with Aligned Myofibers and Adjustable Curvature for Myocardial Regeneration. ACS Appl. Mater. Interfaces 2021, 13, 12746–12758. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Liu, B.; Wang, C.; Xin, C.; Li, R.; Wang, D.; Xu, L.; Fan, S.; Zhang, J.; Zhang, C.; et al. Functional Shape-Morphing Microarchitectures Fabricated by Dynamic Holographically Shifted Femtosecond Multifoci. Nano Lett. 2022, 22, 5277–5286. [Google Scholar] [CrossRef]

- Vaezi, M.; Seitz, H.; Yang, S. A Review on 3D Micro-Additive Manufacturing Technologies. Int. J. Adv. Manuf. Technol. 2013, 67, 1721–1754. [Google Scholar] [CrossRef]

- Fusco, S.; Huang, H.W.; Peyer, K.E.; Peters, C.; Häberli, M.; Ulbers, A.; Spyrogianni, A.; Pellicer, E.; Sort, J.; Pratsinis, S.E.; et al. Shape-Switching Microrobots for Medical Applications: The Influence of Shape in Drug Delivery and Locomotion. ACS Appl. Mater. Interfaces 2015, 7, 6803–6811. [Google Scholar] [CrossRef]

- Malachowski, K.; Jamal, M.; Jin, Q.; Polat, B.; Morris, C.J.; Gracias, D.H. Self-Folding Single Cell Grippers. Nano Lett. 2014, 14, 4164–4170. [Google Scholar] [CrossRef] [Green Version]

- Breger, J.C.; Yoon, C.; Xiao, R.; Kwag, H.R.; Wang, M.O.; Fisher, J.P.; Nguyen, T.D.; Gracias, D.H. Self-Folding Thermo-Magnetically Responsive Soft Microgrippers. ACS Appl. Mater. Interfaces 2015, 7, 3398–3405. [Google Scholar] [CrossRef]

- Vannozzi, L.; Yasa, I.C.; Ceylan, H.; Menciassi, A.; Ricotti, L.; Sitti, M. Self-Folded Hydrogel Tubes for Implantable Muscular Tissue Scaffolds. Macromol. Biosci. 2018, 18, 1700377. [Google Scholar] [CrossRef]

- Qiu, T.; Lee, T.C.; Mark, A.G.; Morozov, K.I.; Münster, R.; Mierka, O.; Turek, S.; Leshansky, A.M.; Fischer, P. Swimming by Reciprocal Motion at Low Reynolds Number. Nat. Commun. 2014, 5, 5119. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, H.W.; Sakar, M.S.; Petruska, A.J.; Pané, S.; Nelson, B.J. Soft Micromachines with Programmable Motility and Morphology. Nat. Commun. 2016, 7, 12263. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, K.; Yoon, C.; Oh, S.H.; Pagaduan, J.V.; Gracias, D.H. Biodegradable Thermomagnetically Responsive Soft Untethered Grippers. ACS Appl. Mater. Interfaces 2019, 11, 151–159. [Google Scholar] [CrossRef]

- Su, J.W.; Tao, X.; Deng, H.; Zhang, C.; Jiang, S.; Lin, Y.; Lin, J. 4D Printing of a Self-Morphing Polymer Driven by a Swellable Guest Medium. Soft Matter 2018, 14, 765–772. [Google Scholar] [CrossRef] [PubMed]

- Ennis, A.; Nicdao, D.; Kolagatla, S.; Dowling, L.; Tskhe, Y.; Thompson, A.J.; Trimble, D.; Delaney, C.; Florea, L. Two-Photon Polymerization of Sugar Responsive 4D Microstructures. Adv. Funct. Mater. 2023, 2023, 2213947. [Google Scholar] [CrossRef]

- Xin, C.; Jin, D.; Hu, Y.; Yang, L.; Li, R.; Wang, L.; Ren, Z.; Wang, D.; Ji, S.; Hu, K.; et al. Environmentally Adaptive Shape-Morphing Microrobots for Localized Cancer Cell Treatment. ACS Nano 2021, 15, 18048–18059. [Google Scholar] [CrossRef] [PubMed]

- Darmawan, B.A.; Gong, D.; Park, H.; Jeong, S.; Go, G.; Kim, S.; Nguyen, K.T.; Zheng, S.; Nan, M.; Nguyen, V.D.; et al. Magnetically Controlled Reversible Shape-Morphing Microrobots with Real-Time X-ray Imaging for Stomach Cancer Applications. J. Mater. Chem. B 2022, 10, 4509–4518. [Google Scholar] [CrossRef]

- Xin, C.; Jin, D.; Li, R.; Wang, D.; Ren, Z.; Liu, B.; Chen, C.; Li, L.; Liu, S.; Xu, B.; et al. Rapid and Multimaterial 4D Printing of Shape-Morphing Micromachines for Narrow Micronetworks Traversing. Small 2022, 18, 2202272. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.W.; Kim, J.K.; Bozuyuk, U.; Dogan, N.O.; Khan, M.T.A.; Shiva, A.; Wild, A.M.; Sitti, M. Multifunctional 3D-Printed Pollen Grain-Inspired Hydrogel Microrobots for On-Demand Anchoring and Cargo Delivery. Adv. Mater. 2023, 35, 2209812. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Lu, H.C.; Lee, X.; Zeng, H.; Priimagi, A. Kirigami-Based Light-Induced Shape-Morphing and Locomotion. Adv. Mater. 2020, 32, 1906233. [Google Scholar] [CrossRef] [Green Version]

- Deng, C.; Liu, Y.; Fan, X.; Jiao, B.; Zhang, Z.; Zhang, M.; Chen, F.; Gao, H.; Deng, L.; Xiong, W. Femtosecond Laser 4D Printing of Light-Driven Intelligent Micromachines. Adv. Funct. Mater. 2023, 33, 2211473. [Google Scholar] [CrossRef]

- Zeng, H.; Wasylczyk, P.; Parmeggiani, C.; Martella, D.; Burresi, M.; Wiersma, D.S. Light-Fueled Microscopic Walkers. Adv. Mater. 2015, 27, 3883–3887. [Google Scholar] [CrossRef] [Green Version]

- Alapan, Y.; Karacakol, A.C.; Guzelhan, S.N.; Isik, I.; Sitti, M. Reprogrammable Shape Morphing of Magnetic Soft Machines. Sci. Adv. 2020, 6, eabc6414. [Google Scholar] [CrossRef]

- Soon, R.H.; Yin, Z.; Dogan, M.A.; Dogan, N.O.; Tiryaki, M.E.; Karacakol, A.C.; Aydin, A.; Esmaeili-Dokht, P.; Sitti, M. Pangolin-Inspired Untethered Magnetic Robot for on-Demand Biomedical Heating Applications. Nat. Commun. 2023, 14, 3320. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing Ferromagnetic Domains for Untethered Fast-Transorming Soft Materials. Nature 2018, 558 (Suppl. S1–S7), 274–279. [Google Scholar] [CrossRef]

- Yang, W.; Wang, X.; Wang, Z.; Yuan, Z.; Ge, Z.; Yu, H. A Multi-Stimulus-Responsive Bionic Fish Microrobot for Remote Intelligent Control Applications. Soft Matter 2022, 19, 913–920. [Google Scholar] [CrossRef]

- Choi, J.; Kwon, O.C.; Jo, W.; Lee, H.J.; Moon, M.W. 4D Printing Technology: A Review. 3D Print. Addit. Manuf. 2015, 2, 159–167. [Google Scholar] [CrossRef]

- Athinarayanarao, D.; Prod’hon, R.; Chamoret, D.; Qi, H.J.; Bodaghi, M.; André, J.C.; Demoly, F. Computational Design for 4D Printing of Topology Optimized Multi-Material Active Composites. npj Comput. Mater. 2023, 9, 1. [Google Scholar] [CrossRef]

- Naficy, S.; Gately, R.; Gorkin, R.; Xin, H.; Spinks, G.M. 4D Printing of Reversible Shape Morphing Hydrogel Structures. Macromol. Mater. Eng. 2017, 302, 1600212. [Google Scholar] [CrossRef]

- Spiegel, C.A.; Hippler, M.; Münchinger, A.; Bastmeyer, M.; Barner-Kowollik, C.; Wegener, M.; Blasco, E. 4D Printing at the Microscale. Adv. Funct. Mater. 2019, 30, 1907615. [Google Scholar] [CrossRef] [Green Version]

- Soto, F.; Karshalev, E.; Zhang, F.; Esteban Fernandez De Avila, B.; Nourhani, A.; Wang, J. Smart Materials for Microrobots. Chem. Rev. 2021, 122, 5365–5403. [Google Scholar] [CrossRef]

- Yan, X.; Wang, F.; Zheng, B.; Huang, F. Stimuli-Responsive Supramolecular Polymeric Materials. Chem. Soc. Rev. 2012, 41, 6042–6065. [Google Scholar] [CrossRef] [PubMed]

- Ionov, L. Hydrogel-Based Actuators: Possibilities and Limitations. Mater. Today 2014, 17, 494–503. [Google Scholar] [CrossRef]

- Geryak, R.; Tsukruk, V.V. Reconfigurable and Actuating Structures from Soft Materials. Soft Matter 2014, 10, 1246–1263. [Google Scholar] [CrossRef]

- Nishiguchi, A.; Zhang, H.; Schweizerhof, S.; Schulte, M.F.; Mourran, A.; Möller, M. 4D Printing of a Light-Driven Soft Actuator with Programmed Printing Density. ACS Appl. Mater. Interfaces 2020, 12, 12176–12185. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adam, G.; Benouhiba, A.; Rabenorosoa, K.; Clévy, C.; Cappelleri, D.J. 4D Printing: Enabling Technology for Microrobotics Applications. Adv. Intell. Syst. 2021, 3, 2000216. [Google Scholar] [CrossRef]

- Rivera-Tarazona, L.K.; Shukla, T.; Singh, K.A.; Gaharwar, A.K.; Campbell, Z.T.; Ware, T.H. 4D Printing of Engineered Living Materials. Adv. Funct. Mater. 2022, 32, 2106843. [Google Scholar] [CrossRef]

- Bian, Q.; Fu, L.; Li, H. Engineering Shape Memory and Morphing Protein Hydrogels Based on Protein Unfolding and Folding. Nat. Commun. 2022, 13, 137. [Google Scholar] [CrossRef] [PubMed]

- Peng, X.; Wang, H. Shape Changing Hydrogels and Their Applications as Soft Actuators. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 1314–1324. [Google Scholar] [CrossRef] [Green Version]

- Baker, A.B.; Bates, S.R.G.; Llewellyn-Jones, T.M.; Valori, L.P.B.; Dicker, M.P.M.; Trask, R.S. 4D Printing with Robust Thermoplastic Polyurethane Hydrogel-Elastomer Trilayers. Mater. Des. 2019, 163, 107544. [Google Scholar] [CrossRef]

- Chu, H.; Yang, W.; Sun, L.; Cai, S.; Yang, R.; Liang, W.; Yu, H.; Liu, L. 4D Printing: A Review on Recent Progresses. Micromachines 2020, 11, 796. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.; Ge, Z.; Wang, X.; Jiao, N.; Tung, S.; Liu, L. Multifunctional Thermo-Magnetically Actuated Hybrid Soft Millirobot Based on 4D Printing. Compos. Part B Eng. 2022, 228, 109451. [Google Scholar] [CrossRef]

- Lee, S.; Bang, D.; Park, J.O.; Choi, E. Programmed Shape-Morphing Material Using Single-Layer 4D Printing System. Micromachines 2022, 13, 243. [Google Scholar] [CrossRef]

- Zhang, Z.; Demir, K.G.; Gu, G.X. Developments in 4D-Printing: A Review on Current Smart Materials, Technologies, and Applications. Int. J. Smart Nano Mater. 2019, 10, 205–224. [Google Scholar] [CrossRef] [Green Version]

- Nojoomi, A.; Jeon, J.; Yum, K. 2D Material Programming for 3D Shaping. Nat. Commun. 2021, 12, 603. [Google Scholar] [CrossRef]

- Ji, Q.; Moughames, J.; Chen, X.; Fang, G.; Huaroto, J.J.; Laude, V.; Martínez, J.A.I.; Ulliac, G.; Clévy, C.; Lutz, P.; et al. 4D Thermomechanical Metamaterials for Soft Microrobotics. Commun. Mater. 2021, 2, 93. [Google Scholar] [CrossRef]

- Lui, Y.S.; Sow, W.T.; Tan, L.P.; Wu, Y.; Lai, Y.; Li, H. 4D Printing and Stimuli-Responsive Materials in Biomedical Aspects. Acta Biomater. 2019, 92, 19–36. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Zhao, W.; Yu, J.; Li, Y.; Zhao, C. Recent Development of PH-Responsive Polymers for Cancer Nanomedicine. Molecules 2019, 24, 4. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, B.; Dong, B.; Xin, C.; Chen, C.; Zhang, L.; Wang, D.; Hu, Y.; Li, J.; Zhang, L.; Wu, D.; et al. 4D Direct Laser Writing of Submerged Structural Colors at the Microscale. Small 2023, 19, 2204630. [Google Scholar] [CrossRef] [PubMed]

- Tan, L.; Davis, A.C.; Cappelleri, D.J. Smart Polymers for Microscale Machines. Adv. Funct. Mater. 2021, 31, 2007125. [Google Scholar] [CrossRef]

- Kim, J.; Kim, C.; Song, Y.S.; Jeong, S.G.; Kim, T.S.; Lee, C.S. Reversible Self-Bending Soft Hydrogel Microstructures with Mechanically Optimized Designs. Chem. Eng. J. 2017, 321, 384–393. [Google Scholar] [CrossRef]

- Ji, S.; Li, X.; Chen, Q.; Lv, P.; Duan, H. Enhanced Locomotion of Shape Morphing Microrobots by Surface Coating. Adv. Intell. Syst. 2021, 3, 2000270. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, Y.; Zheng, J.; Zhao, X.; Guo, H.; Qiu, Y.; Wang, X.; Liu, L.; Yu, H. A 4D-Printing Inverse Design Strategy for Micromachines with Customized Shape-Morphing. Small 2023, 2302656. [Google Scholar] [CrossRef]

- Guan, Z.; Wang, L.; Bae, J. Advances in 4D Printing of Liquid Crystalline Elastomers: Materials, Techniques, and Applications. Mater. Horiz. 2022, 9, 1825–1849. [Google Scholar] [CrossRef]

- Martella, D.; Nocentini, S.; Micheletti, F.; Wiersma, D.S.; Parmeggiani, C. Polarization-Dependent Deformation in Light Responsive Polymers Doped by Dichroic Dyes. Soft Matter 2019, 15, 1312–1318. [Google Scholar] [CrossRef]

- Cui, J.; Huang, T.Y.; Luo, Z.; Testa, P.; Gu, H.; Chen, X.Z.; Nelson, B.J.; Heyderman, L.J. Nanomagnetic Encoding of Shape-Morphing Micromachines. Nature 2019, 575, 164–168. [Google Scholar] [CrossRef]

- Yi, S.; Wang, L.; Chen, Z.; Wang, J.; Song, X.; Liu, P.; Zhang, Y.; Luo, Q.; Peng, L.; Wu, Z.; et al. High-Throughput Fabrication of Soft Magneto-Origami Machines. Nat. Commun. 2022, 13, 4177. [Google Scholar] [CrossRef] [PubMed]

- Xu, T.; Zhang, J.; Salehizadeh, M.; Onaizah, O.; Diller, E. Millimeter-Scale Flexible Robots with Programmable Three-Dimensional Magnetization and Motions. Sci. Robot. 2019, 4, eaav4494. [Google Scholar] [CrossRef]

- Deng, H.; Sattari, K.; Xie, Y.; Liao, P.; Yan, Z.; Lin, J. Laser Reprogramming Magnetic Anisotropy in Soft Composites for Reconfigurable 3D Shaping. Nat. Commun. 2020, 11, 6325. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhang, L. Magnetic Actuation Systems for Miniature Robots: A Review. Adv. Intell. Syst. 2020, 2, 2000082. [Google Scholar] [CrossRef]

- Kim, Y.; Parada, G.A.; Liu, S.; Zhao, X. Ferromagnetic Soft Continuum Robots. Sci. Robot. 2019, 4, eaax7329. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.W.; Ceylan, H.; Yasa, I.C.; Kilic, U.; Sitti, M. 3D-Printed Multi-Stimuli-Responsive Mobile Micromachines. ACS Appl. Mater. Interfaces 2021, 13, 12759–12766. [Google Scholar] [CrossRef]

- Nauber, R.; Goudu, S.R.; Goeckenjan, M.; Bornhäuser, M.; Ribeiro, C.; Medina-Sánchez, M. Medical Microrobots in Reproductive Medicine from the Bench to the Clinic. Nat. Commun. 2023, 14, 728. [Google Scholar] [CrossRef]

- Li, J.; Yu, J. Biodegradable Microrobots and Their Biomedical Applications: A Review. Nanomaterials 2023, 13, 1590. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, L.; Zhang, F.; Leng, J.; Liu, Y. Shape Memory Polymers and Their Composites in Biomedical Applications. Mater. Sci. Eng. C 2019, 97, 864–883. [Google Scholar] [CrossRef]

- Hoffman, A.S. Hydrogels for Biomedical Applications. Adv. Drug Deliv. Rev. 2012, 64, 18–23. [Google Scholar] [CrossRef]

- Hu, W.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-Scale Soft-Bodied Robot with Multimodal Locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef]

- Schmidt, C.K.; Medina-Sánchez, M.; Edmondson, R.J.; Schmidt, O.G. Engineering Microrobots for Targeted Cancer Therapies from a Medical Perspective. Nat. Commun. 2020, 11, 5618. [Google Scholar] [CrossRef] [PubMed]

- Jin, Q.; Yang, Y.; Jackson, J.A.; Yoon, C.; Gracias, D.H. Untethered Single Cell Grippers for Active Biopsy. Nano Lett. 2020, 20, 5383–5390. [Google Scholar] [CrossRef]

- Rajabasadi, F.; Moreno, S.; Fichna, K.; Aziz, A.; Appelhans, D.; Schmidt, O.G.; Medina-Sánchez, M. Multifunctional 4D-Printed Sperm-Hybrid Microcarriers for Assisted Reproduction. Adv. Mater. 2022, 34, 2204257. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Z.; Wang, H.; Dong, L.; Shi, Q.; Li, J.; Sun, T.; Huang, Q.; Fukuda, T. Ionic Shape-Morphing Microrobotic End-Effectors for Environmentally Adaptive Targeting, Releasing, and Sampling. Nat. Commun. 2021, 12, 411. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Lau, G.C.; Yuan, H.; Aggarwal, A.; Dominguez, V.L.; Liu, S.; Sai, H.; Palmer, L.C.; Sather, N.A.; Pearson, T.J.; et al. Fast and Programmable Locomotion of Hydrogel-Metal Hybrids under Light and Magnetic Fields. Sci. Robot. 2020, 5, eabb9822. [Google Scholar] [CrossRef] [PubMed]

- Sossou, G.; Demoly, F.; Belkebir, H.; Qi, H.J.; Gomes, S.; Montavon, G. Design for 4D Printing: Modeling and Computation of Smart Materials Distributions. Mater. Des. 2019, 181, 108074. [Google Scholar] [CrossRef]

- Zhou, W.; Qiao, Z.; Nazarzadeh Zare, E.; Huang, J.; Zheng, X.; Sun, X.; Shao, M.; Wang, H.; Wang, X.; Chen, D.; et al. 4D-Printed Dynamic Materials in Biomedical Applications: Chemistry, Challenges, and Their Future Perspectives in the Clinical Sector. J. Med. Chem. 2020, 63, 8003–8024. [Google Scholar] [CrossRef]

- Jin, Z.; Nguyen, K.T.; Go, G.; Kang, B.; Min, H.K.; Kim, S.J.; Kim, Y.; Li, H.; Kim, C.S.; Lee, S.; et al. Multifunctional Nanorobot System for Active Therapeutic Delivery and Synergistic Chemo-Photothermal Therapy. Nano Lett. 2019, 19, 8550–8564. [Google Scholar] [CrossRef]

- Jin, D.; Wang, Q.; Chan, K.F.; Xia, N.; Yang, H.; Wang, Q.; Yu, S.C.H.; Zhang, L. Swarming Self-Adhesive Microgels Enabled Aneurysm on-Demand Embolization in Physiological Blood Flow. Sci. Adv. 2023, 9, eadf9278. [Google Scholar] [CrossRef]

| Main Material | Fabrication | Layer | Geometry | Stimulation | Ref. |

|---|---|---|---|---|---|

| NIPAAM | UV | Multi | Gripper | Thermal | [42] |

| P(OEGMA- DSDMA) | UV | Multi | Gripper | Thermal | [46] |

| NIPAAM/PEGDA | UV | Multi | Helix | Thermal | [45] |

| SiO/SiO2 | UV | Multi | Gripper | Thermal | [41] |

| NIPAAM/PEGDA | UV | Multi | Gripper | Thermal | [29] |

| E-dent | UV | Single | Gripper | Chemical | [18] |

| SU-8 | 3D printing and UV | Single | Gripper | Chemical | [47] |

| Acrylamide | DLW | Single | Vase | Chemical | [48] |

| E-dent | UV | Single | Gripper | Chemical | [34] |

| NIPAAM/AAc | DLW | Single | Microfish | pH | [49] |

| AAc | DLW | Single | Microcage | pH | [38] |

| E-dent/pHEMA | UV | Multi | Gripper | pH | [50] |

| NIPAAM/AAc | DLW | Single | Trumpet | pH | [51] |

| pHEMA/PEGDA | UV | Multi | Gripper | pH | [31] |

| pNIPAAM/AAc | 3D printing | Multi | Pollen | pH | [52] |

| Liquid crystal polymer | Laser cutting | Single | Tube | Light | [53] |

| CNT/NIPAM | DLW | Single | Gripper | Light | [54] |

| Liquid crystal elastomers | DLW | Single | Cone | Light | [55] |

| CrO2/PDMS | Laser cutting | Single | Cube | Magnetic | [56] |

| Magnetic PDMS | Laser cutting | Multi | Rectangular | Magnetic | [57] |

| Silicon SE1700 | 3D printing | Single | Hexapedal | Magnetic | [58] |

| pNIPAM/CNT | UV | Single | Fish | Hybrid | [59] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darmawan, B.A.; Park, J.-O.; Go, G.; Choi, E. Four-Dimensional-Printed Microrobots and Their Applications: A Review. Micromachines 2023, 14, 1607. https://doi.org/10.3390/mi14081607

Darmawan BA, Park J-O, Go G, Choi E. Four-Dimensional-Printed Microrobots and Their Applications: A Review. Micromachines. 2023; 14(8):1607. https://doi.org/10.3390/mi14081607

Chicago/Turabian StyleDarmawan, Bobby Aditya, Jong-Oh Park, Gwangjun Go, and Eunpyo Choi. 2023. "Four-Dimensional-Printed Microrobots and Their Applications: A Review" Micromachines 14, no. 8: 1607. https://doi.org/10.3390/mi14081607

APA StyleDarmawan, B. A., Park, J.-O., Go, G., & Choi, E. (2023). Four-Dimensional-Printed Microrobots and Their Applications: A Review. Micromachines, 14(8), 1607. https://doi.org/10.3390/mi14081607