Copper Wire Bonding: A Review

Abstract

:1. Introduction

- (1)

- High electrical and thermal conductivity.

- (2)

- It maintains high strength even at elevated levels of elongation.

- (3)

- Good arc stability.

- (4)

- Reduced formation of intermetallic compounds during the bonding process.

- (5)

- Formation of a favorable ball shape during bonding when protected by inert gas.

2. Types of Cu-Bonding Wire

2.1. Bare Cu Wire

2.2. Coated Cu Wire

2.3. Insulated Cu Wire

2.4. Cu Alloy Wire

3. FAB Morphology

4. Bonding Reliability

4.1. Influence of IMCs on the Reliability of Cu Wire Bonding

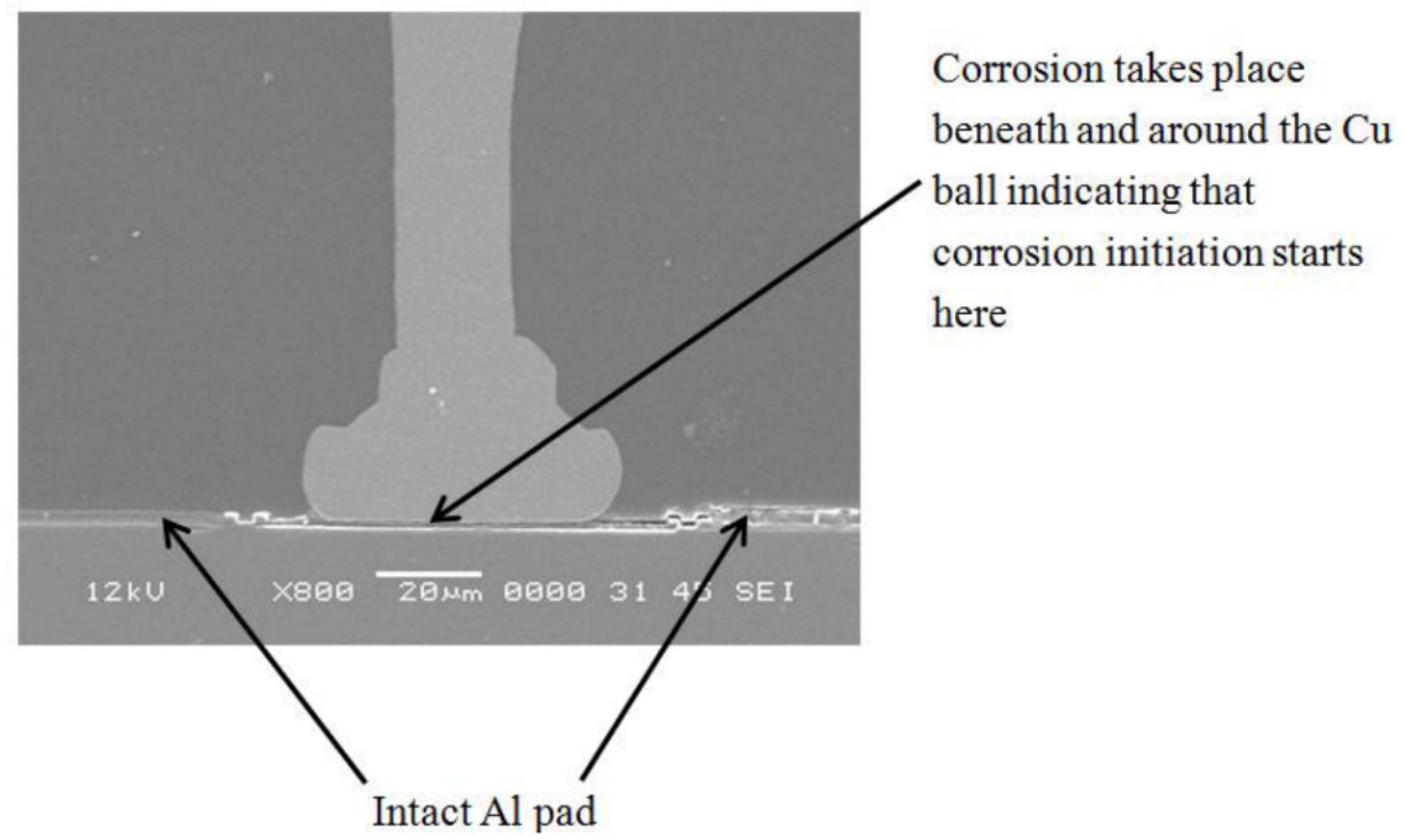

4.2. Influence of Corrosion on the Reliability of Cu Wire Bonding

- (1)

- Formation and stability of bond interface: corrosion may lead to the formation of IMCs at the bond interface, affecting the stability of the bond. Some IMCs formed during corrosion may enhance bond strength and reliability, whereas others can cause interface embrittlement and delamination, thereby reducing bond reliability;

- (2)

- Material loss and weakening: corrosion can cause material loss and weakening, resulting in thinning of the bond area or the formation of voids, which can impact bond strength and reliability;

- (3)

- Electrical and thermal properties of the interface: corrosion can alter the electrical and thermal properties of the bond interface, affecting the electrical and thermal performance of the device and, in turn, its reliability;

- (4)

- Accumulation of corrosion products: the accumulation of corrosion products can lead to local stress concentration in the bond area, increasing the risk of bond failure.

4.2.1. Effect of Halogen Ion on Corrosion of Cu Wire

4.2.2. Measures to Reduce and Prevent Interface Corrosion

5. Application of Simulation in Cu Wire Bonding

- (1)

- Cost-effectiveness: by using simulation techniques, virtual testing and optimization can be performed during the design phase, avoiding the costs associated with actual manufacturing and testing. This helps reduce material waste, production cycles, and overall costs;

- (2)

- Performance prediction: the performance of wire bonding can be predicted and evaluated in a simulated environment. By simulating the wire bonding process and stress distribution, potential failure points can be identified, and the reliability and durability of the wire can be predicted;

- (3)

- Design optimization: simulation tools allow for the optimization of wire bonding designs. By altering parameters such as wire dimensions, geometric shapes, and welding parameters, the impact of different design options on wire performance can be assessed, enabling the selection of the best design to enhance wire bonding performance;

- (4)

- Reduction in experiments: simulation techniques can reduce reliance on physical experiments. By simulating different scenarios and operating conditions, various hypotheses and solutions can be quickly tested in a virtual environment, reducing the number of experiments required and saving time.

6. Summary and Prospect

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Luo, J.J. Mainstream Bonded Copper Wire Semiconductor Packaging Technology for Microelectronic Packaging. Pract. Electron. 2022, 30, 98–100. [Google Scholar]

- Chen, G.Y.; Feng, J.; Yu, Y.J.; Dai, Y.; Lv, D. Study on the Difference of Intermetalic Compounds between Cu-Al and Au-Al of Plastic Encapsulated Microelectronics in Repeated Hygrothermal. Electron. Qual. 2022, 1, 50–53. [Google Scholar]

- Lu, K.; Ren, C.L.; Gao, N.Y.; Ding, R.Z. The Process and Reliability Researches of Copper Wire Bonding. Electron. Packag. 2010, 10, 1–6. [Google Scholar]

- Wu, J.D.; Luo, H.W. The Developments and Challenges of Cu Bonding Wire. Electron. Prod. Reliab. Environ. Test. 2008, 26, 39–42. [Google Scholar]

- Srikanth, N.; Murali, S.; Wong, Y.; Vath, C.J. Critical study of thermosonic copper ball bonding. Thin Solid Film. 2004, 462–463, 339–345. [Google Scholar] [CrossRef]

- Zhong, Z.W. Overview of wire bonding using copper wire or insulated wire. Microelectron. Reliab. 2011, 51, 4–12. [Google Scholar] [CrossRef]

- Bi, X.D. Application of Copper Wire Bonding Technology in Semiconductor Packaging Industry. Electron. Packag. 2010, 10, 1–4. [Google Scholar]

- Rezvani, A.; Shan, A.; Mayer, M.; Zhou, Y.; Moon, J.T. Role of impact ultrasound on bond strength and Al pad splash in Cu wire bonding. Microelectron. Reliab. 2013, 53, 1002–1008. [Google Scholar] [CrossRef]

- Chylak, B.; Ling, J.; Clauberg, H.; Thieme, T. Next Generation Nickel-Based Bond Pads Enable Copper Wire Bonding. ECS Trans. 2009, 18, 777–785. [Google Scholar] [CrossRef]

- Qin, I.W.; Chylak, B.; Clauberg, H.; Shah, A.; Foley, J. Ball Bond Process Optimization with Cu and Pd-Coated Cu Wire. ECS Trans. 2012, 44, 891–901. [Google Scholar] [CrossRef]

- Shah, A.; Mayer, M.; Zhou, Y.; Hong, S.J.; Moon, J.T. Reduction of underpad stress in thermosonic copper ball bonding. In Proceedings of the 2008 58th Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 27–30 May 2008; IEEE: Piscataway, NJ, USA. [Google Scholar]

- Singh, G.; Haseeb, A.S.M.A. Influence of laser power on bonding strength for low purity copper wire bonding technology. Microelectron. Eng. 2019, 211, 1–4. [Google Scholar] [CrossRef]

- Czerny, B.; Khatibi, G. Cyclic robustness of heavy wire bonds: Al, AlMg, Cu and CucorAl. Microelectron. Reliab. 2018, 88–90, 745–751. [Google Scholar] [CrossRef]

- Uno, T. Bond reliability under humid environment for coated copper wire and bare copper wire. Microelectron. Reliab. 2011, 51, 148–156. [Google Scholar] [CrossRef]

- Kaimori, S.; Nonaka, T.; Mizoguchi, A. The Development of Cu Bonding Wire with Oxidation-Resistant Metal Coating. IEEE Trans. Adv. Packag. 2006, 29, 227–231. [Google Scholar] [CrossRef]

- Cao, J.; Fan, J.L.; Xue, T.L. lnvestigation of copper coating Pd wire properties and bonding quality. Mater. Sci. Technol. 2014, 22, 48–53. [Google Scholar]

- Mitsubishi Electric Corporation. A Bonding Wire with a Core Material and a Coating Material Covering the Surface of the Core Material. JP2014232762A, 11 December 2014.

- Cheng, P.; Li, M.; Zheng, D.F. A Very Fine Palladium Plated Copper Bonding Wire and Its Production Method. CN104716118B, 15 December 2017. [Google Scholar]

- Lv, X.Y.; Ju, Q.K.; Shi, R.L. A Manufacturing Method for Palladium Plated Bonded Copper Wire. CN103219245B, 25 November 2015. [Google Scholar]

- Chang, C.Y.; Hung, F.Y.; Lui, T.S. Mechanical and Electrical Properties of Palladium-Coated Copper Wires with Flash Gold. J. Electron. Mater. 2017, 46, 4384–4391. [Google Scholar] [CrossRef]

- Uno, T. Enhancing bondability with coated copper bonding wire. Microelectron. Reliab. 2011, 51, 88–96. [Google Scholar] [CrossRef]

- Lin, Y.W.; Wang, R.Y.; Ke, W.B.; Wang, I.S.; Chiu, Y.T.; Lu, K.C.; Lin, K.L.; Lai, Y.S. The Pd distribution and Cu flow pattern of the Pd-plated Cu wire bond and their effect on the nanoindentation. Mater. Sci. Eng. A. 2012, 543, 152–157. [Google Scholar] [CrossRef]

- Lim, A.B.Y.; Boothroyd, C.B.; Yaum, O.; Chylak, B.; Gan, C.L.; Chen, Z. Interfacial evolution and bond reliability in thermosonic Pd coated Cu wire bonding on aluminum metallization: Effect of palladium distribution. Microelectron. Reliab. 2016, 63, 214–223. [Google Scholar] [CrossRef]

- Gan, C.L.; Hashim, U. Reliability Assessment and Activation Energy Study of Au and Pd-Coated Cu Wires Post High Temperature Aging in Nanoscale Semiconductor Packaging. J. Electron. Packag. 2013, 135, 210101–210107. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Yu, Y.; Zang, H.L. Research on investigation and evaluation of the environment condition of the electroplating industrial park and the surrounding groundwater. China Qual. Certif. 2022, 12, 53–55. [Google Scholar]

- Liao, M.L. Development Trend of Electroplating Wastewater Treatment. Resour. Econ. Environ. 2022, 70–73. [Google Scholar] [CrossRef]

- Ma, R.N.; Yu, G.B. Harm and Treatment of Electroplating Wastewater Pollutants. Leather Manuf. Environ. Technol. 2023, 4, 136–138. [Google Scholar]

- Yang, S.F.; Zhang, Q.; Zhang, Q.; Yue, S.P.; Wang, M.X.; Ge, Y.C.; Yang, G.X.; Dong, B.J.; Wang, Y.L.; Lu, P.L.; et al. Research Progress on Resource Utilization of Electroplating Sludge and Preparation of Ceramsite. Shandong Chem. Ind. 2023, 52, 86–88. [Google Scholar]

- Cao, J.; Fan, J.L.; Gao, W.B. Investigation of copper direct coating Pd technology and bonding properties. Mater. Sci. Technol. 2015, 23, 110–114. [Google Scholar]

- Chen, X. Comparative study on bonding between palladium plated copper wire and bare copper wire in IC packaging. Silicon Val. 2014, 7, 152–153. [Google Scholar]

- Kang, F.F.; Yang, G.X.; Kong, J.W.; Dao, P.; Wu, Y.J.; Zhang, K.H. The Development Trend of Palladium-plated Bonding Copper Wire. Mater. Rep. 2011, 25, 104–107. [Google Scholar]

- Leong, H.Y.; Yap, B.K.; Khan, N.; Ibrahim, M.R.; Tan, L.C.; Faiz, M. Characterisation of insulated Cu wire ball bonding. Mater. Res. Innov. 2014, 18, S6–S269. [Google Scholar] [CrossRef]

- Lykova, M.; Panchenko, I.; Künzelmann, U.; Johanna, R.; Geidel, M.; Wolf, J.; Lang, K.D. Characterisation of Cu/Cu bonding using self-assembled monolayer. Solder. Surf. Mt. Technol. 2018, 30, 106–111. [Google Scholar] [CrossRef]

- Lykova, M.; Langer, E.; Hinrichs, K.; Panchenko, I.; Künzelmann, U.; Wolf, M.J.; Lang, K.D. Characterization of self-assembled monolayers for Cu Cu bonding technology. Microelectron. Eng. 2018, 202, 19–24. [Google Scholar] [CrossRef]

- Whelan, C.M.; Kinsella, M.; Ho, H.M.; Maex, K. Corrosion Inhibition by Thiol-Derived SAMs for Enhanced Wire Bonding on Cu Surfaces. J. Electrochem. Soc. 2004, 151, B33. [Google Scholar] [CrossRef]

- Leong, H.; Yap, B.; Khan, N.; Ibrahim, M.R.; Tan, L.C. Insulated Cu wire free air ball characterization. Microelectron. Reliab. 2014, 54, 1567–1574. [Google Scholar] [CrossRef]

- Zhang, G. Bonding Copper Wire Technology for Semiconductor Packaging. New Technol. New Prod. China 2021, 70–72. [Google Scholar] [CrossRef]

- Fang, Y.B.; Zheng, Z.F.; Zheng, K.D. A Bonded Copper Wire and Its Preparation Method. CN1949492[P], 18 April 2007. [Google Scholar]

- Yu, J.M.; Deng, C.; Li, S.Y.; Yang, Z.X.; Mao, Y. The Development of Copper Bonding Wire from the Patent Literature. Yunnan Metall. 2013, 42, 51–55. [Google Scholar]

- Zhao, J.R.; Chen, Y.J.; Hung, F.Y. A Technology for Bonding Cu Wires with Cu Pads: Structure and Electrical Fatigue Mechanism of Fine Micro-alloyed Cu Wires. J. Electron. Mater. 2023, 52, 4169–4178. [Google Scholar] [CrossRef]

- Zhao, J.R.; Lin, Y.C.; Hung, F.Y. Microstructure, Tensile Mechanical Properties and Electrical Fatigue Mechanism of a Microalloyed Copper Wire. J. Electron. Mater. 2022, 51, 5857–5868. [Google Scholar] [CrossRef]

- Hsu, S.T.; Hung, F.Y.; Wu, B.D. Study of tensile properties, electrothermal characteristics and packaging reliability on Cu–Pt–Au–Pd fine micro-alloyed wire. J. Mater. Sci. Mater. Electron. 2023, 34, 1130. [Google Scholar] [CrossRef]

- Eto, M.; Araki, N.; Yamada, T.; Sugiyama, M.; Fujimoto, S. Microstructural characterization of alloyed palladium coated copper wire under high temperature. Microelectron. Reliab. 2021, 120, 114125. [Google Scholar] [CrossRef]

- Ho, H.M.; Tan, Y.C.; Tan, W.C.; Goh, H.M.; Toh, B.H.; Tan, J.; Zhong, Z.W. Investigation of Factors Affecting Bonded Ball Hardness on Copper Wire Bonding. Equip. Electron. Prod. Manuf. 2009, 38, 10–18. [Google Scholar]

- Lim, A.B.Y.; Chang, A.C.K.; Lee, C.X.; Yauw, O.; Chylak, B.; Chen, Z. Palladium-Coated and Bare Copper Wire Study for Ultra-Fine Pitch Wire Bonding. ECS Trans. 2013, 52, 717–730. [Google Scholar] [CrossRef]

- Du, Y.H.; Liu, Z.Q.; Ji, H.; Li, M.; Wen, M. The mechanism of Pd distribution in the process of FAB formation during Pd-coated Cu wire bonding. J. Mater. Sci. Mater. Electron. 2018, 29, 13774–13781. [Google Scholar] [CrossRef]

- Du, Y.; Wen, M.; Ji, H.; Li, M.; Liu, Z.Q. Effects of Pd addition on the interfacial reactions between Cu and Al during ultrasonic welding. J. Mater. Sci. Mater. Electron. 2019, 30, 12840–12850. [Google Scholar] [CrossRef]

- Manoharan, S.; Patel, C.; Hunter, S.; McCluskey, P. Mechanism of wire bond shear testing. Microelectron. Reliab. 2018, 88–90, 738–744. [Google Scholar] [CrossRef]

- Gu, L.Q.; Chen, Q.; Li, J.J.; Zhou, J.W.; Du, M.H.; Myungkee, C. Comparison of Ag Wire and Cu Wire in Memory Package. ECS Trans. 2013, 52, 747–751. [Google Scholar]

- Tan, Y.Y.; Sim, K.S. Effect of Cu and PdCu wire bonding on bond pad splash. Electron. Lett. 2014, 50, 1095–1096. [Google Scholar] [CrossRef]

- Gan, C.L.; Classe, F.C.; Chan, B.L.; Hashim, U. Evolution and investigation of copper and gold ball bonds in extended reliability stressing. Gold Bull. 2014, 47, 141–151. [Google Scholar] [CrossRef]

- Du, Y.; Gao, L.Y.; Yu, D.; Liu, Z.Q. Comparison and mechanism of electromigration reliability between Cu wire and Au wire bonding in molding state. J. Mater. Sci. Mater. Electron. 2020, 31, 2967–2975. [Google Scholar] [CrossRef]

- Qin, W.; Anderson, T.; Chang, G. Mechanism to improve the reliability of copper wire bonding with palladium-coating of the wire. Microelectron. Reliab. 2019, 99, 239–244. [Google Scholar] [CrossRef]

- Chen, K.J.; Hung, F.Y.; Chang, C.Y. A Study of the Sulfidation Behavior on Palladium-Coated Copper Wire with a Flash-Gold Layer (PCA) after Wire Bonding. Electronics 2019, 8, 792. [Google Scholar] [CrossRef]

- Gan, C.L.; Classe, F.C.; Chan, B.L.; Hashim, U. Effects of Bonding Wires and Epoxy Molding Compound on Gold and Copper Ball Bonds Intermetallic Growth Kinetics in Electronic Packaging. J. Electron. Mater. 2014, 43, 1017–1025. [Google Scholar] [CrossRef]

- Xu, H.; Liu, C.; Silberschmidt, V.V.; Pramana, S.S.; White, T.J.; Chen, Z.; Acoff, V.L. Behavior of aluminum oxide, intermetallics and voids in Cu–Al wire bonds. Acta Mater. 2011, 59, 5661–5673. [Google Scholar] [CrossRef]

- Hang, C.J.; Wang, C.Q.; Mayer, M.; Tian, Y.H.; Zhou, Y.; Wang, H.H. Growth behavior of Cu/Al intermetallic compounds and cracks in copper ball bonds during isothermal aging. Microelectron. Reliab. 2008, 48, 416–424. [Google Scholar] [CrossRef]

- Tan, Y.Y.; Yang, Q.L.; Sim, K.S.; Sun, L.T.; Wu, X. Cu–Al intermetallic compound investigation using ex-situ post annealing and in-situ annealing. Microelectron. Reliab. 2015, 55, 2316–2323. [Google Scholar] [CrossRef]

- Ming, X.; Fan, K. Temperature and Stress effects on IMC Behavior of Thin Film Cu-Al System in Wire Bond. ECS Trans. 2011, 34, 529–534. [Google Scholar] [CrossRef]

- Kim, H.G.; Kim, S.M.; Lee, J.Y.; Choi, M.R.; Choe, S.H.; Kim, K.H.; Ryu, J.S.; Kim, S.; Han, S.Z.; Kim, W.Y.; et al. Microstructural evaluation of interfacial intermetallic compounds in Cu wire bonding with Al and Au pads. Acta Mater. 2014, 64, 356–366. [Google Scholar] [CrossRef]

- Liu, C.P.; Chang, S.J.; Liu, Y.F.; Chen, W.S. Cu-Al interfacial formation and kinetic growth behavior during HTS reliability test. J. Mater. Process. Technol. 2019, 267, 90–102. [Google Scholar] [CrossRef]

- Anand, T.J.S.; Yau, C.K.; Leong, Y.S.; Keat, L.W.; Ting, H.M. Microstructural and mechanical analysis of Cu and Au interconnect on various bond pads. Curr. Appl. Phys. 2013, 13, 1674–1683. [Google Scholar] [CrossRef]

- Park, H.W.; Lee, S.J.; Cho, D.C.; Lee, S.H.; Kim, J.K.; Lee, J.H.; Jung, S.K.; Nam, H.S.; Hsu, P.; Low, S.; et al. Behavior of Au and Pd and the effects of these metals on IMCs in Pd-Au-coated copper wire. Microelectron. Reliab. 2018, 91, 283–290. [Google Scholar] [CrossRef]

- Xu, H.; Qin, I.; Clauberg, H.; Chylak, B.; Acoff, V.L. Behavior of palladium and its impact on intermetallic growth in palladium-coated Cu wire bonding. Acta Mater. 2013, 61, 79–88. [Google Scholar] [CrossRef]

- Lim, A.B.Y.; Long, X.; Shen, L.; Chen, X.; Ramanujan, R.V.; Gan, C.L.; Chen, Z. Effect of palladium on the mechanical properties of Cu–Al intermetallic compounds. J. Alloys Compd. 2015, 628, 107–112. [Google Scholar] [CrossRef]

- Zeng, Y.; Bai, K.; Jin, H. Thermodynamic study on the corrosion mechanism of copper wire bonding. Microelectron. Reliab. 2013, 53, 985–1001. [Google Scholar] [CrossRef]

- Takeda, T.; Seki, H.; Itoh, S.; Zenbutsu, S.I. Study of EMC for Cu bonding wire application. ECS Trans. 2011, 34, 825. [Google Scholar] [CrossRef]

- Gan, C.L.; Ng, E.K.; Chan, B.L.; Hashim, U.; Classe, F.C. Technical Barriers and Development of Cu Wirebonding in Nanoelectronics Device Packaging. J. Nanomater. 2012, 2012, 173025. [Google Scholar] [CrossRef]

- Van Soestbergen, M.; Mavinkurve, A.; Zaal, J.J.M.; O’Halloran, G.M.; Rongen, R.T.H.; Farrugia, M.L. Crevice Corrosion of Ball Bond Intermetallics of Cu and Ag Wire. In Proceedings of the 2016 IEEE 66th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 31 May–3 June 2016; IEEE: Piscataway, NJ, USA. [Google Scholar]

- Goh, C.; Chong, W.; Lee, T.; Breach, C. Corrosion Study and Intermetallics Formation in Gold and Copper Wire Bonding in Microelectronics Packaging. Crystals 2013, 3, 391–404. [Google Scholar] [CrossRef]

- Wu, Y.; Subramanian, K.N.; Barton, S.C.; Lee, A. Electrochemical studies of Pd-doped Cu and Pd-doped Cu-Al intermetallics for understanding corrosion behavior in wire-bonding packages. Microelectron. Reliab. 2017, 78, 355–361. [Google Scholar] [CrossRef]

- Wu, Y.; Lee, A. Effects of Temperature and Pd Concentration on the Corrosion Behavior of Pd-Doped Cu and Cu9Al4 at the Cu–Al Ball-Bond Interface. IEEE Trans. Compon. Packag. Manuf. Technol. 2020, 10, 1611–1616. [Google Scholar] [CrossRef]

- Mokhtari, O.; Nishikawa, H. Effect of surface potential distribution on corrosion behavior of Cu/Al interface in Cu wire bonding applications. Microelectron. Reliab. 2020, 113, 113942. [Google Scholar] [CrossRef]

- Liu, C.P.; Chang, S.J.; Liu, Y.F.; Su, J. Corrosion-induced degradation and its mechanism study of Cu–Al interface for Cu-wire bonding under HAST conditions. J. Alloys Compd. 2020, 825, 154046. [Google Scholar] [CrossRef]

- Yu, C.F.; Chan, C.M.; Chan, L.C.; Hsieh, K.C. Cu wire bond microstructure analysis and failure mechanism. Microelectron. Reliab. 2011, 51, 119–124. [Google Scholar] [CrossRef]

- Lim, A.B.; Neo, W.J.; Yauw, O.; Chylak, B.; Gan, C.L.; Chen, Z. Evaluation of the corrosion performance of Cu–Al intermetallic compounds and the effect of Pd addition. Microelectron. Reliab. 2016, 56, 155–161. [Google Scholar] [CrossRef]

- Ross, N.; Asokan, M.; Kumar, G.I.A.; Caperton, J.; Alptekin, J.; Salunke, A.S.; Chyan, O.M. Mechanistic study of copper wire-bonding failures on packaging devices in acidic chloride environments. Microelectron. Reliab. 2020, 113, 113917. [Google Scholar] [CrossRef]

- Wu, Y.; Barton, S.C.; Lee, A. Galvanic corrosion behavior at the Cu-Al ball bond interface: Influence of Pd addition and chloride concentration. Microelectron. Reliab. 2019, 92, 79–86. [Google Scholar] [CrossRef]

- Eto, M.; Araki, N.; Yamada, T.; Klengel, R.; Petzold, M.; Sugiyama, M.; Fujimoto, S. Effects of alloying elements in high reliability copper wire bond material for high temperature applications. Microelectron. Reliab. 2020, 114, 113819. [Google Scholar] [CrossRef]

- Eto, M.; Araki, N.; Yamada, T.; Sugiyama, M.; Fujimoto, S. Influence of post-bonding heating process on the long-term reliability of Cu/Al contact. Microelectron. Reliab. 2021, 118, 114058. [Google Scholar] [CrossRef]

- Hamid, K.A.; Badarisman, A.H.; Jalar, A.; Bakar, M.A. Effects of electrolyte towards copper wire metallurgical interconnection in semiconductor. J. Phys. Conf. Ser. 2022, 2169, 12013. [Google Scholar] [CrossRef]

- Hsu, H.C.; Lee, G.; Feng, W.R.; Kuo, C.H. An Investigation on Mechanical Behavior on Pt-Coated Copper Wire from a Nanoscale Perspective. ECS Trans. 2012, 44, 907–919. [Google Scholar] [CrossRef]

- Che, F.X.; Wai, L.C.; Chai, T.C. Failure Mode and Mechanism Analysis for Cu Wire Bond on Cu/Low-k Chip by Wire Pull Test and Finite-Element Analysis. IEEE Trans. Device Mat Reliab. 2018, 18, 163–172. [Google Scholar] [CrossRef]

- Hook, M.D.; Hunter, S.; Mayer, M. Deriving lifetime predictions for wire bonds at high temperatures. Microelectron. Reliab. 2018, 88–90, 1124–1129. [Google Scholar] [CrossRef]

- Mazloum-Nejadari, A.; Khatibi, G.; Czerny, B.; Lederer, M.; Nicolics, J.; Weiss, L. Reliability of Cu wire bonds in microelectronic packages. Microelectron. Reliab. 2017, 74, 147–154. [Google Scholar] [CrossRef]

- Gu, B.; Shen, S.; Li, H. Mechanism of microweld formation and breakage during Cu–Cu wire bonding investigated by molecular dynamics simulation. Chin. Phys. B 2022, 31, 16101–16495. [Google Scholar] [CrossRef]

- Long, Y.; He, B.; Cui, W.; Ji, Y.; Zhuang, X.; Twiefel, J. Investigations on the mechanism of microweld changes during ultrasonic wire bonding by molecular dynamics simulation. Mater. Des. 2020, 192, 108718. [Google Scholar] [CrossRef]

| Material | Electrical Conductivity (Ω·m) | Thermal Conductivity (W/(m·K)) | Tensile Strength (MPa) | Corrosion Resistance | Price |

|---|---|---|---|---|---|

| Cu wire | 0.0017–0.0018 | 401–429 | 200–250 | Moderate | Moderate |

| Al wire | 0.028–0.036 | 205–230 | 70–400 | Moderate | Low |

| Au wire | 0.024–0.028 | 310–318 | 100–400 | Good | High |

| Ag wire | 0.015–0.020 | 419–429 | 100–400 | Excellent | High |

| Cu Wire | Pd-Coated Cu | Bare Cu (No Coating) |

|---|---|---|

| Breaking load (mN) | 112 | 107 |

| Elongation (%) | 11.8 | 12.1 |

| Vickers hardness of wire | 55 | 54 |

| Electrical resistivity (10−8 Ω m) | 1.9 | 1.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, H.; Chang, A.; Fan, J.; Cao, J.; An, B.; Xia, J.; Yao, J.; Cui, X.; Zhang, Y. Copper Wire Bonding: A Review. Micromachines 2023, 14, 1612. https://doi.org/10.3390/mi14081612

Zhou H, Chang A, Fan J, Cao J, An B, Xia J, Yao J, Cui X, Zhang Y. Copper Wire Bonding: A Review. Micromachines. 2023; 14(8):1612. https://doi.org/10.3390/mi14081612

Chicago/Turabian StyleZhou, Hongliang, Andong Chang, Junling Fan, Jun Cao, Bin An, Jie Xia, Jingguang Yao, Xiaobin Cui, and Yingchong Zhang. 2023. "Copper Wire Bonding: A Review" Micromachines 14, no. 8: 1612. https://doi.org/10.3390/mi14081612

APA StyleZhou, H., Chang, A., Fan, J., Cao, J., An, B., Xia, J., Yao, J., Cui, X., & Zhang, Y. (2023). Copper Wire Bonding: A Review. Micromachines, 14(8), 1612. https://doi.org/10.3390/mi14081612