Experimental Study on Carbon Fiber-Reinforced Polymer Groove Machining by High-Power Water-Jet-Guided Laser

Abstract

:1. Introduction

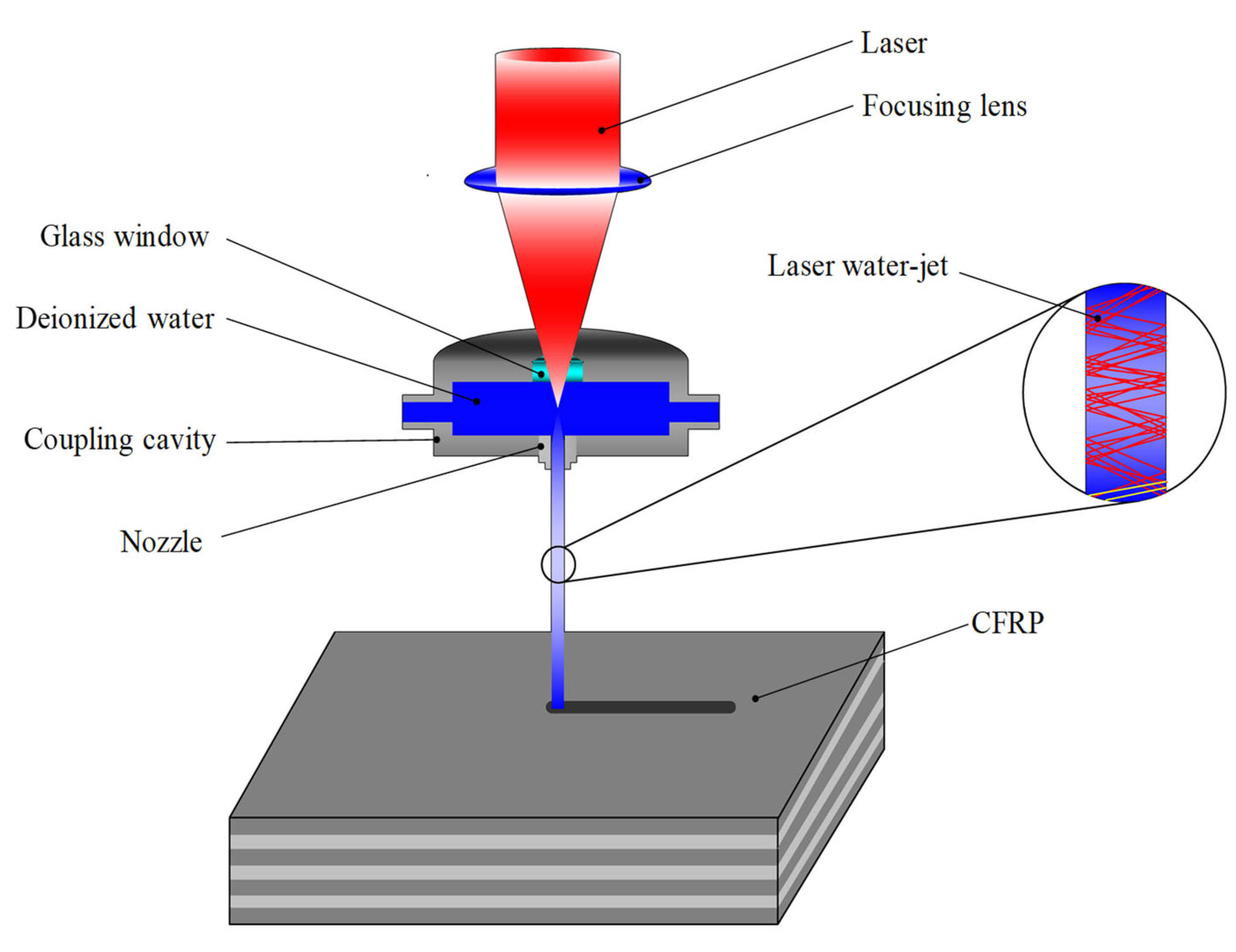

2. Experimental Principle

3. Experiment Setup

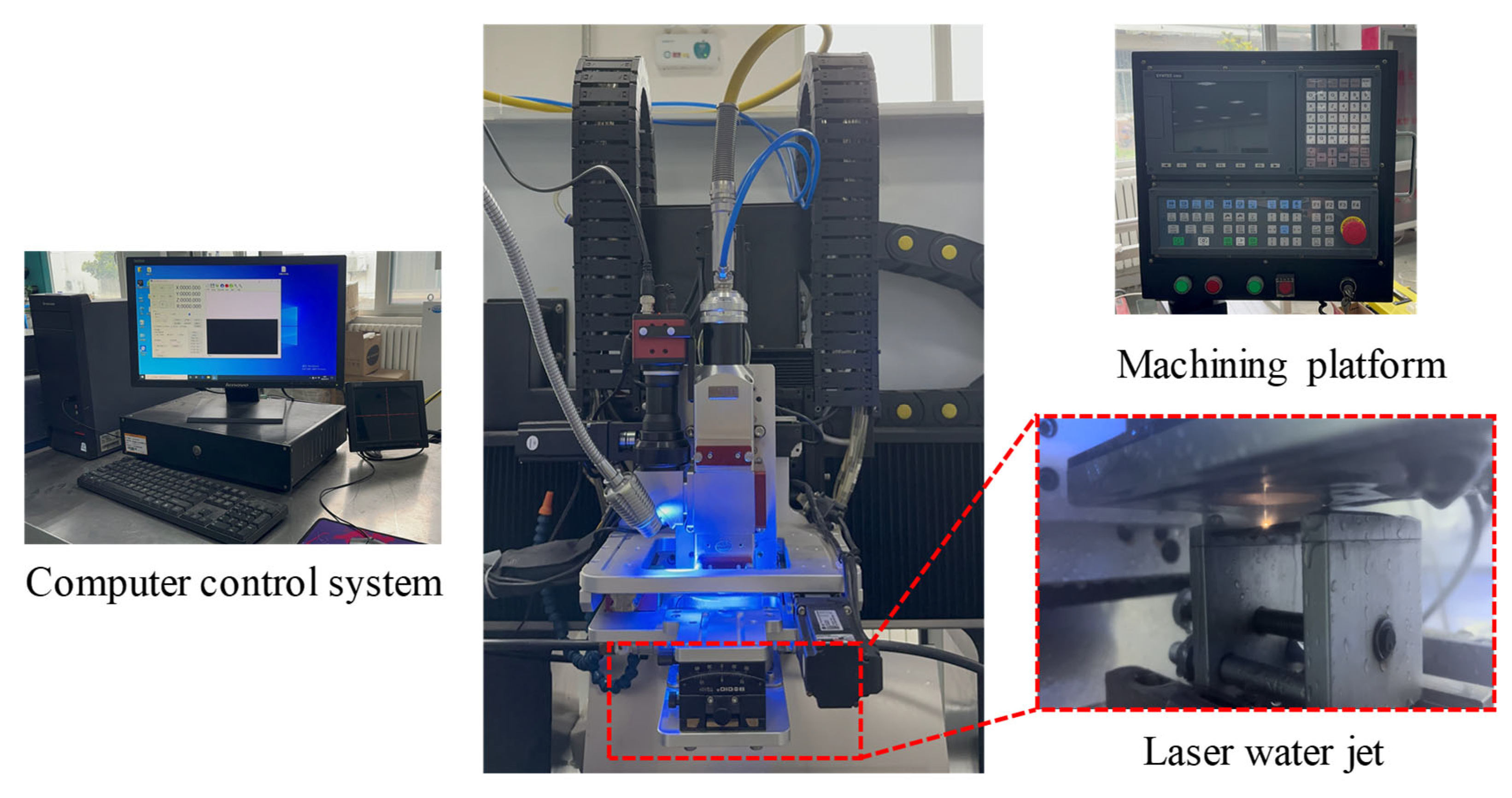

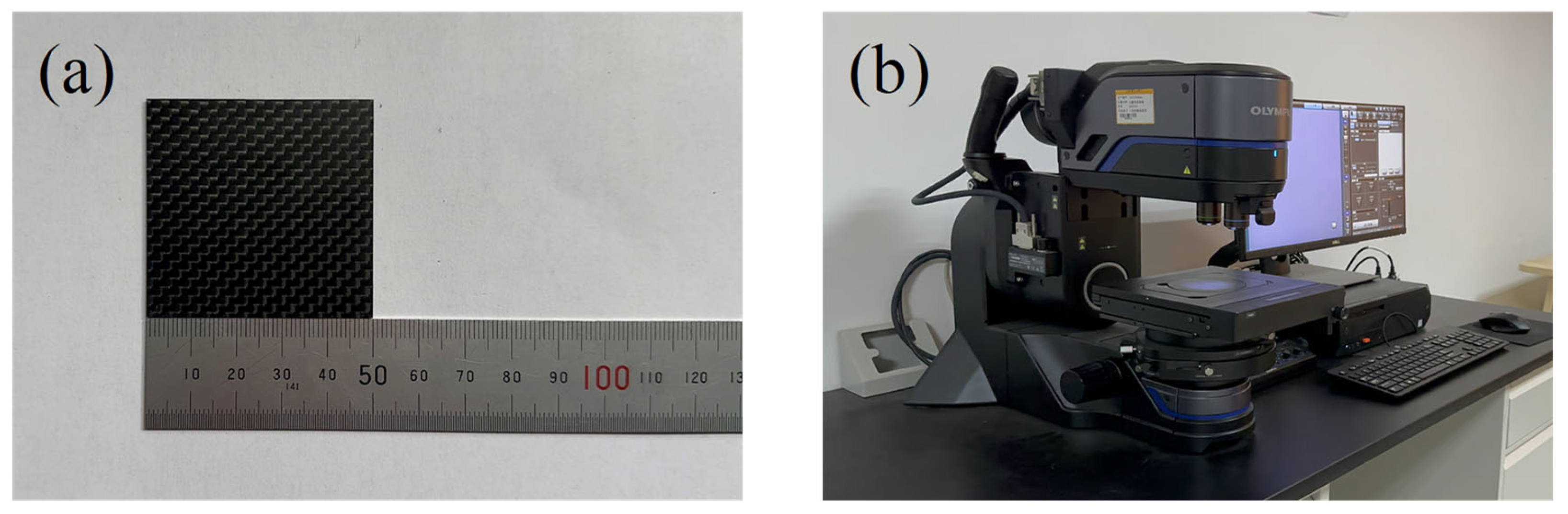

3.1. Experiment Equipment

3.2. Experimental Design

4. Single-Factor Experiment Design and Result Analysis

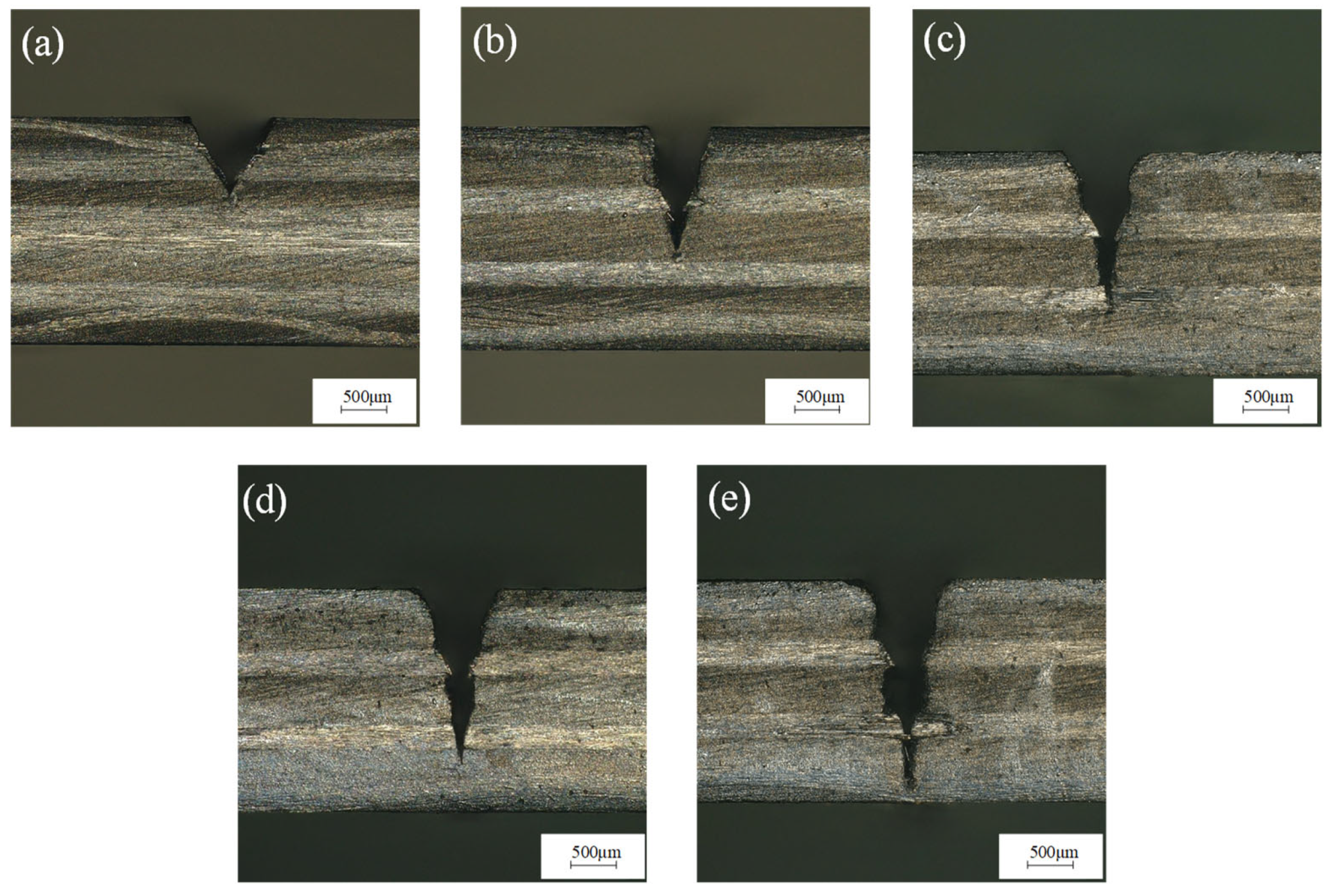

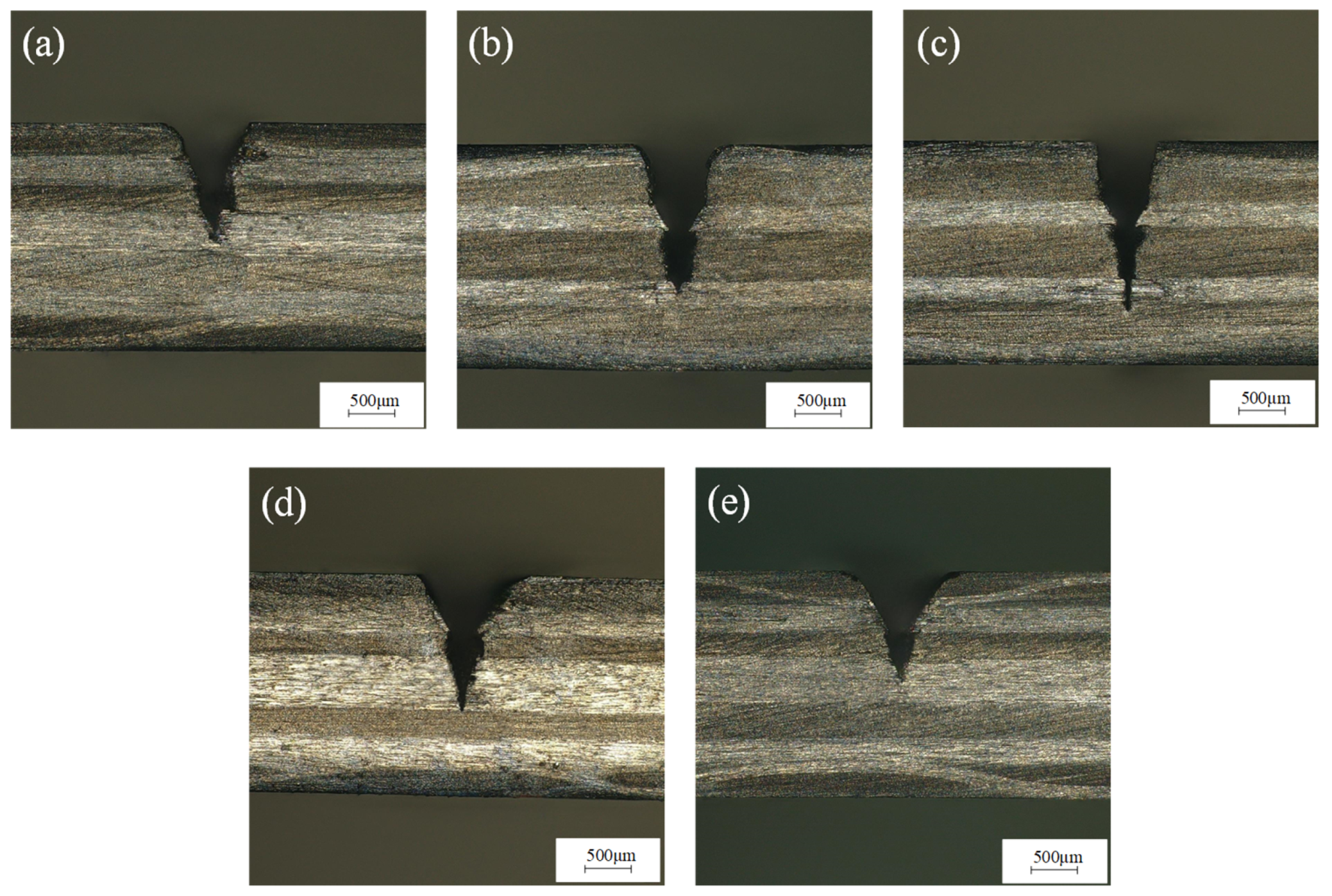

4.1. Influence of High Laser Power on Cutting Quality

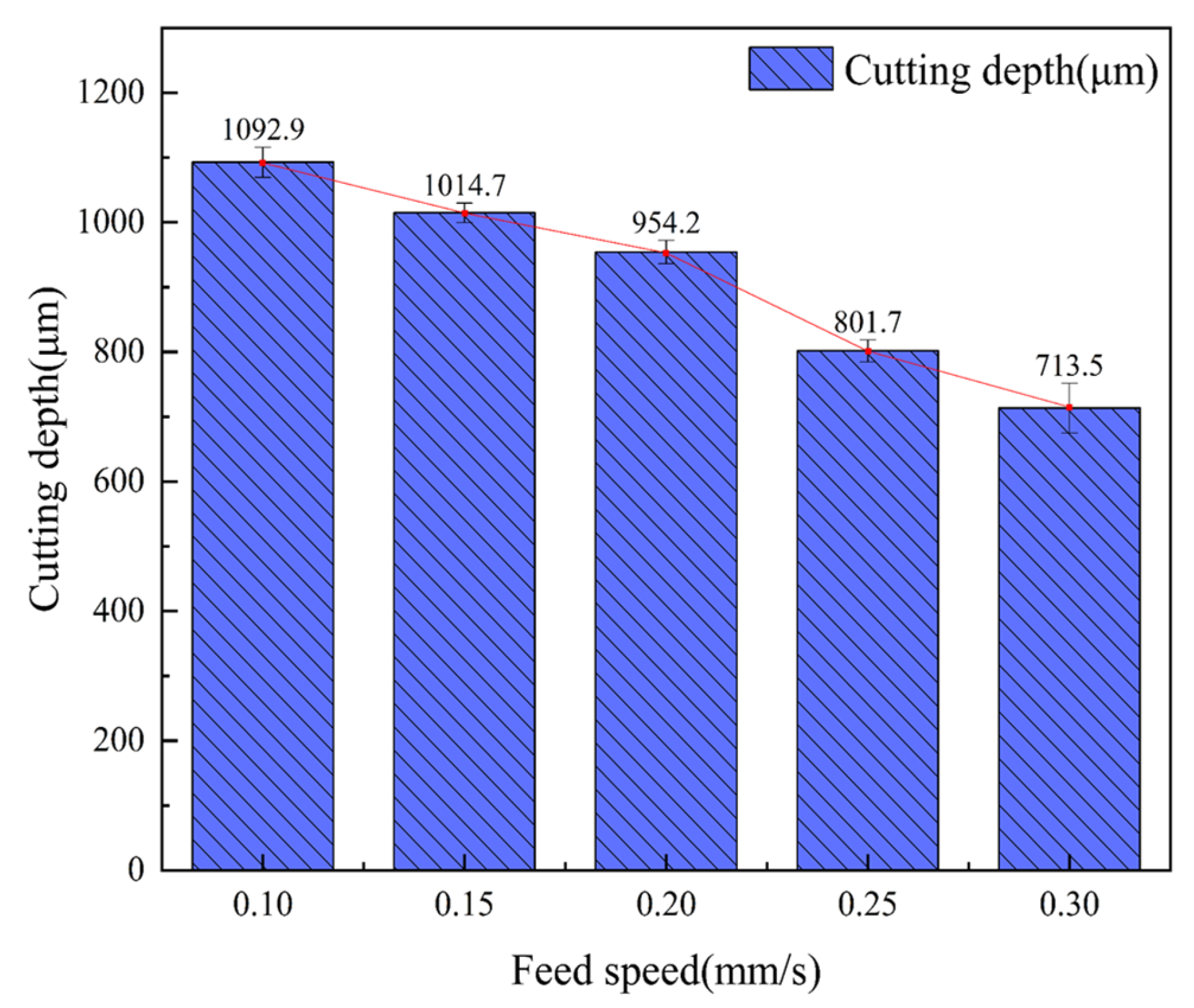

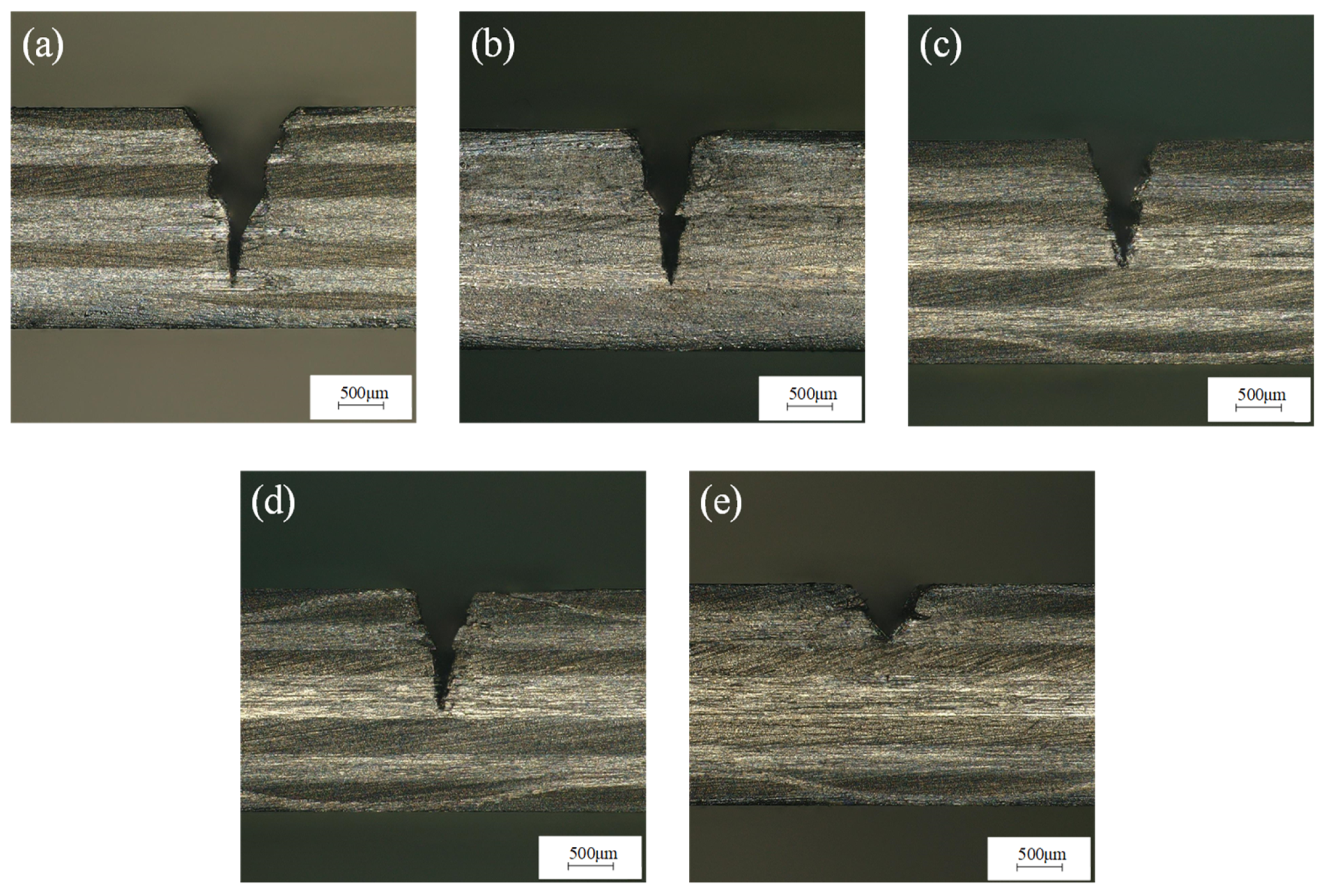

4.2. The Influence of Feed Speed on Cutting Quality

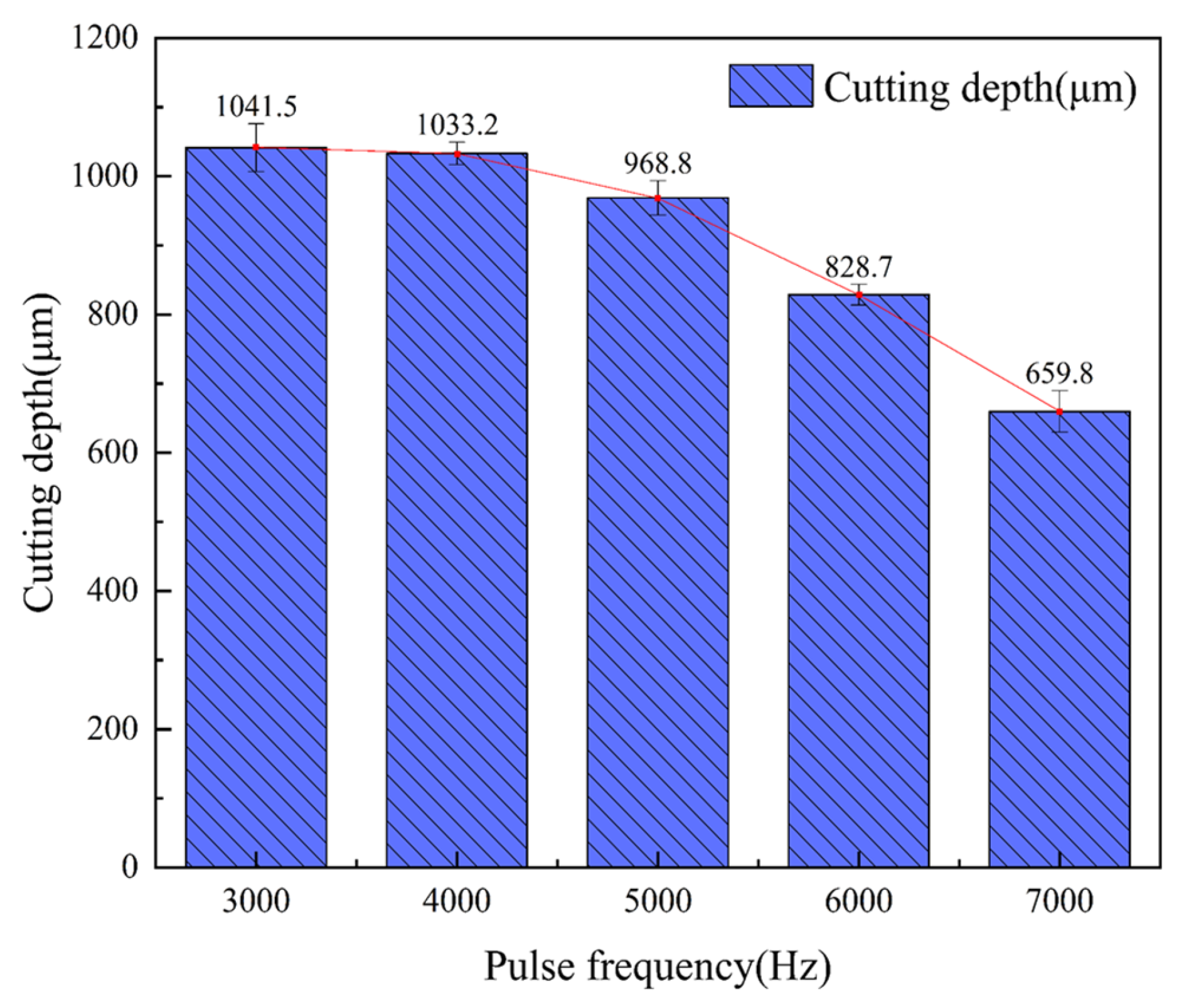

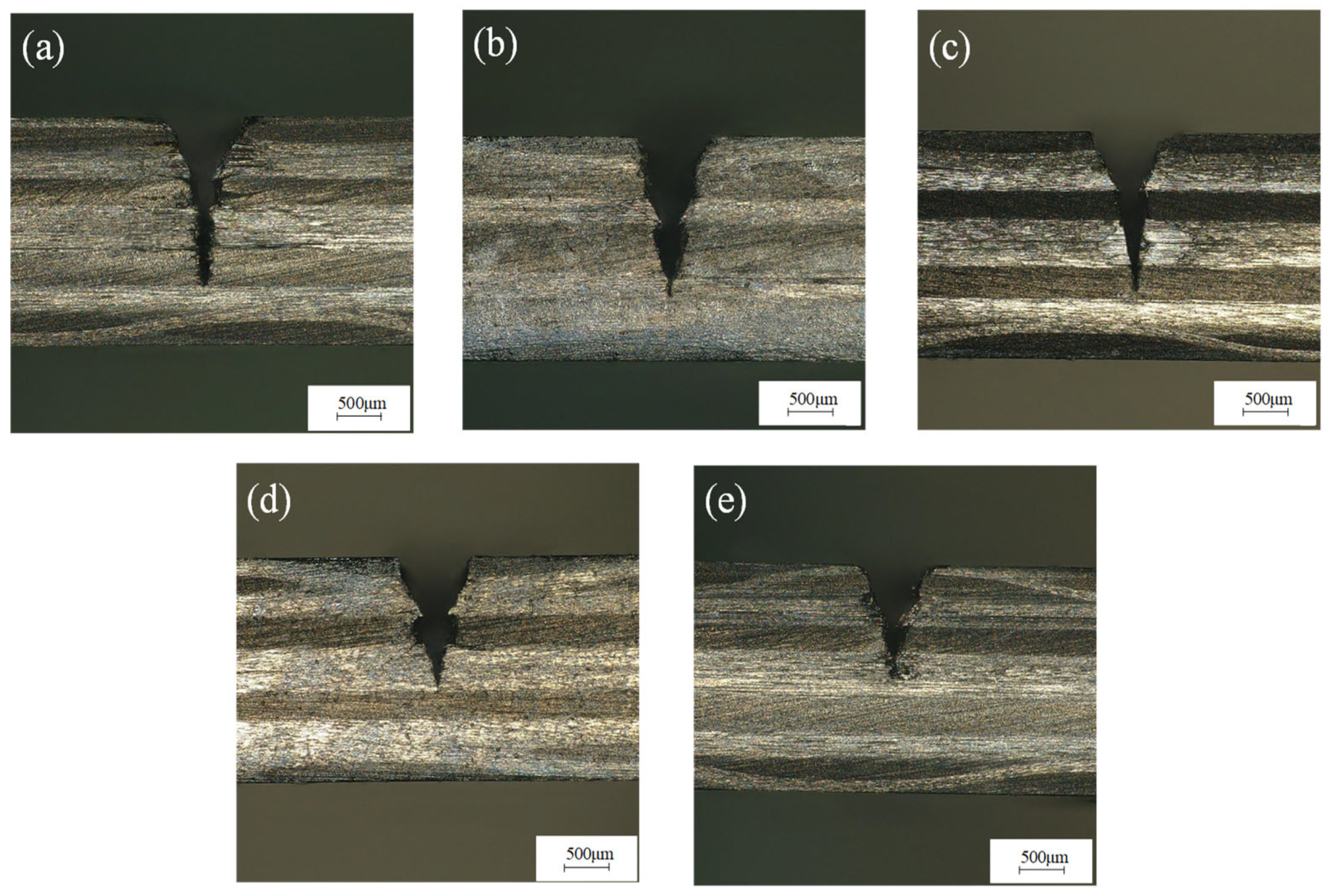

4.3. Influence of Laser Pulse Frequency on Cutting Quality

4.4. Influence of Water Pressure on Cutting Quality

5. Analysis of Response Surface Experimental Results

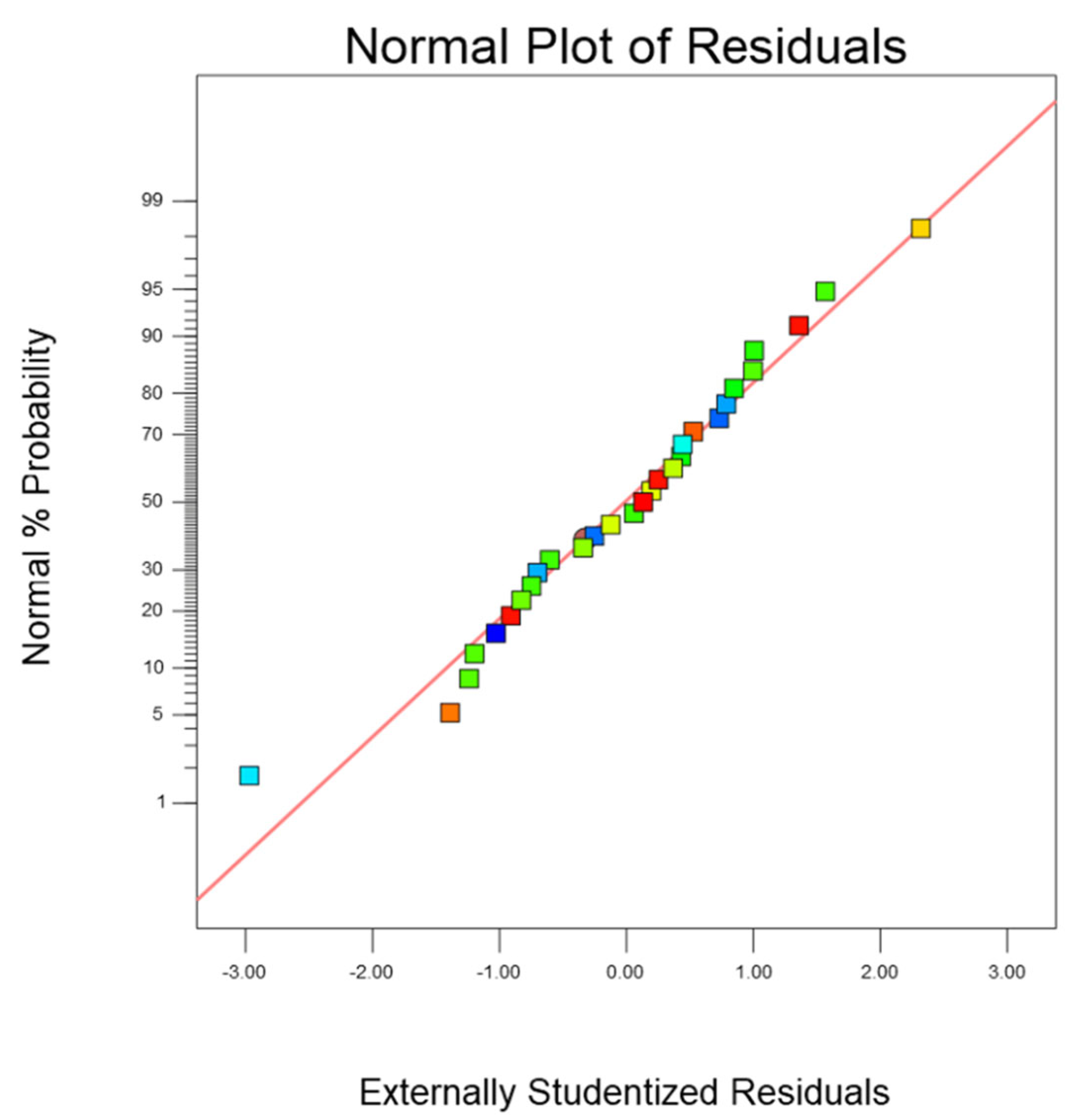

5.1. Regression Model and Variance Analysis

5.2. Response Surface Analysis of Process Parameters

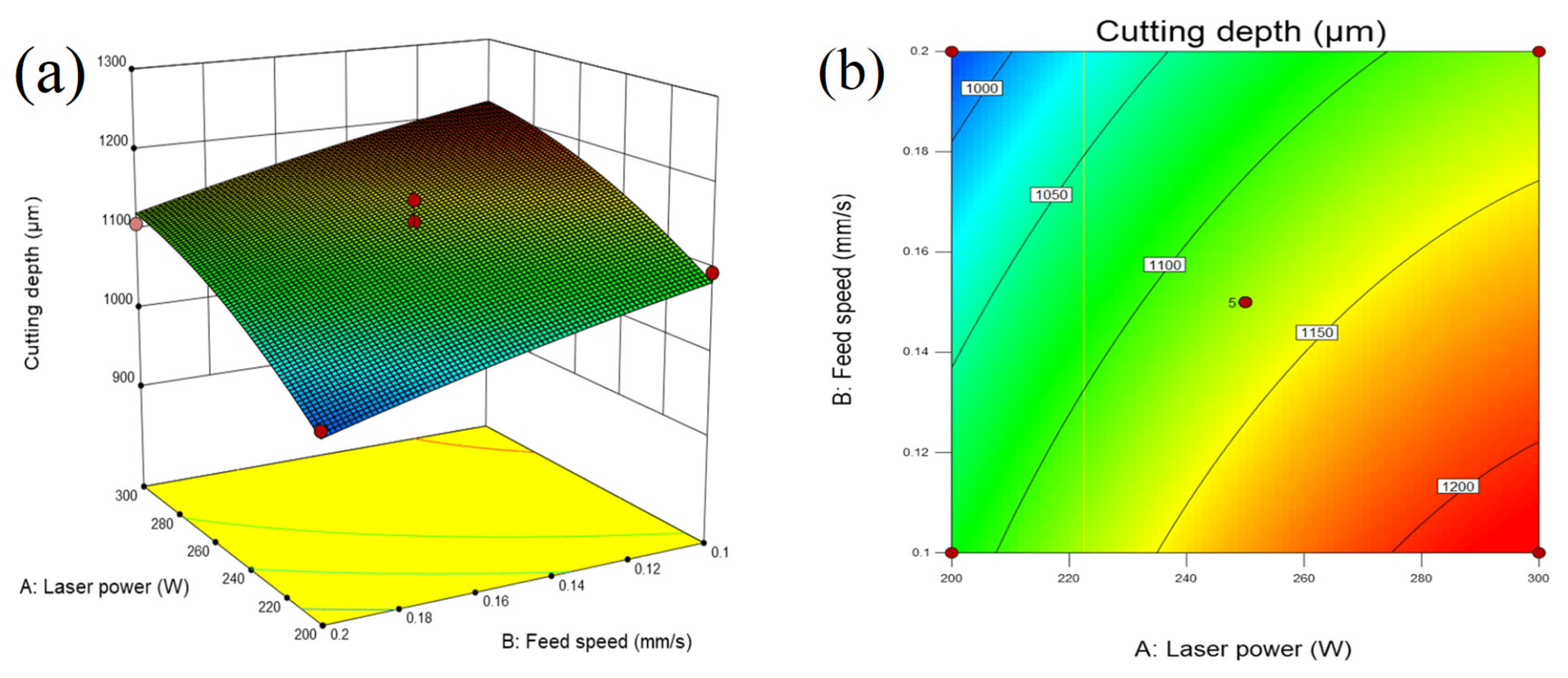

5.2.1. Response Surface Analysis of Laser Power and Feed Speed

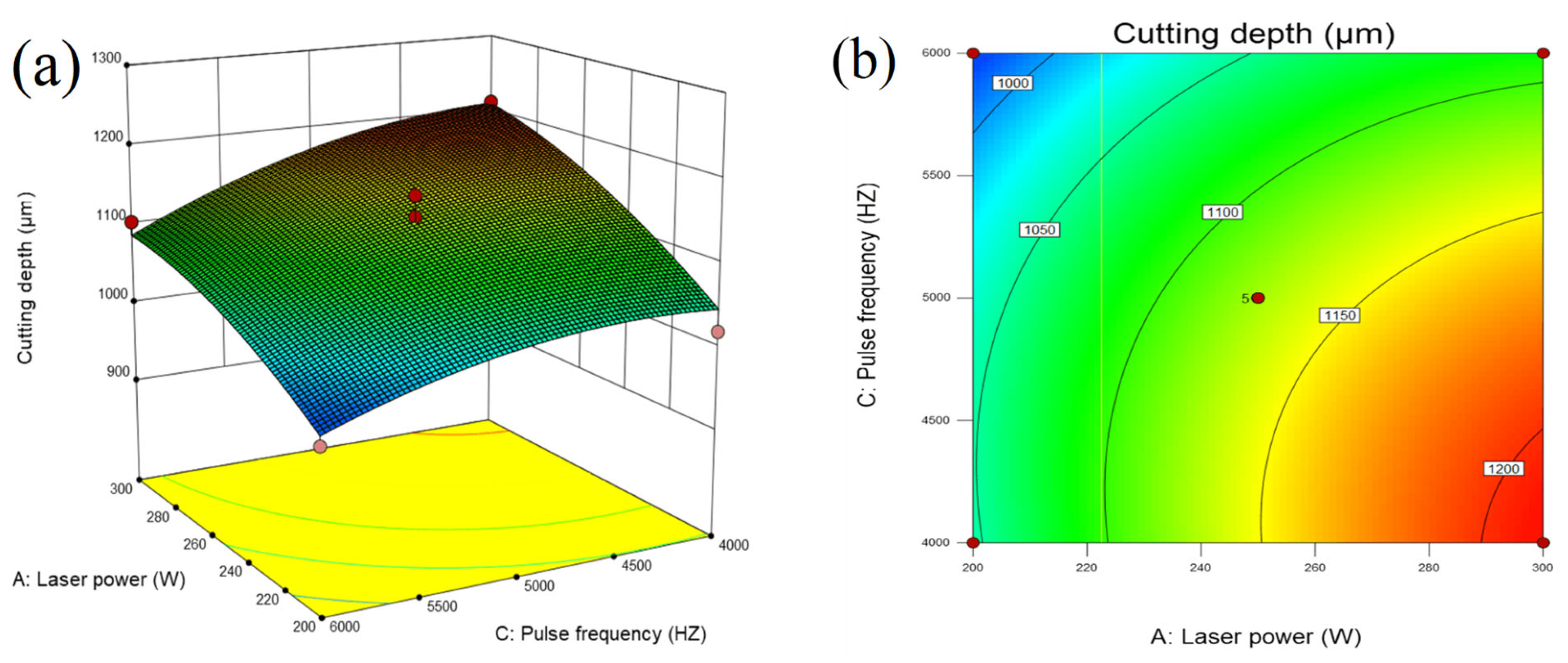

5.2.2. Response Surface Analysis of Laser Power and Pulse Frequency

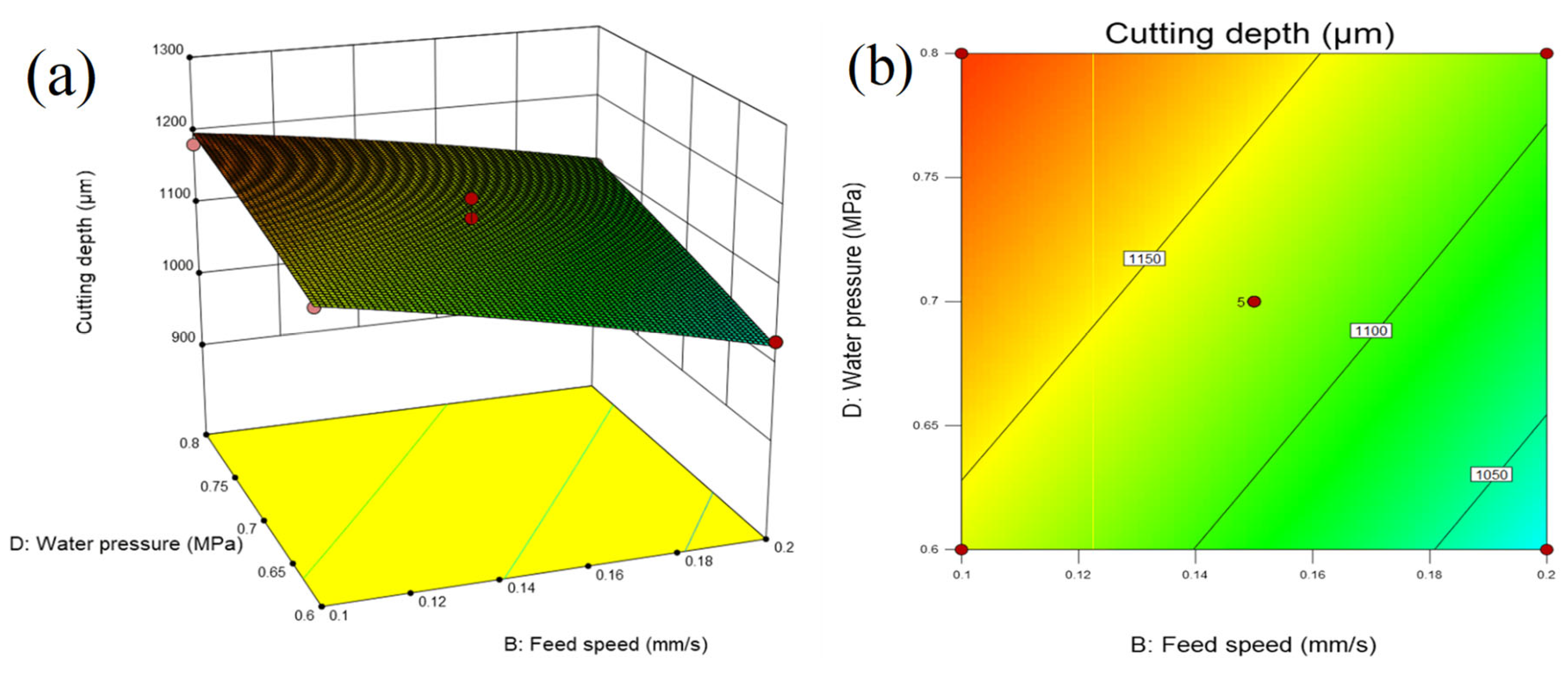

5.2.3. Response Surface Analysis of Feed Speed and Water Pressure

5.3. Process Parameter Optimization and Experimental Verification

6. Conclusions

- The single-factor test results show that the laser power, feed rate, pulse frequency, and water-jet pressure have a significant effect on the cutting depth. However, improper selection of process parameters will cause adverse effects such as a too large heat-affected zone. In the experiment of water-guided laser cutting of CFRPs, the laser power determines the energy of a single pulse, so it has the greatest influence on the cutting depth. The experimental results show that when the laser power is 200~300 W, the feed speed is 0.1~0.2 mm/s, the laser frequency is 4000~6000 Hz, and the water-jet pressure is 0.6~0.8 MPa, the cutting effect is promoted.

- The response surface test scheme of four factors and three levels was developed with the cutting depth as the evaluation standard by the response surface method. The regression model of the influence of laser power, feed rate, pulse frequency, and water-jet pressure on the cutting depth is established. The results show that the model has a response value of 93.91%, and its good fitting effect is verified by variance analysis, which has a high reference value. In addition, the level of influence of each of the parameters on the cutting depth is laser power > pulse frequency > feed rate > water-jet pressure.

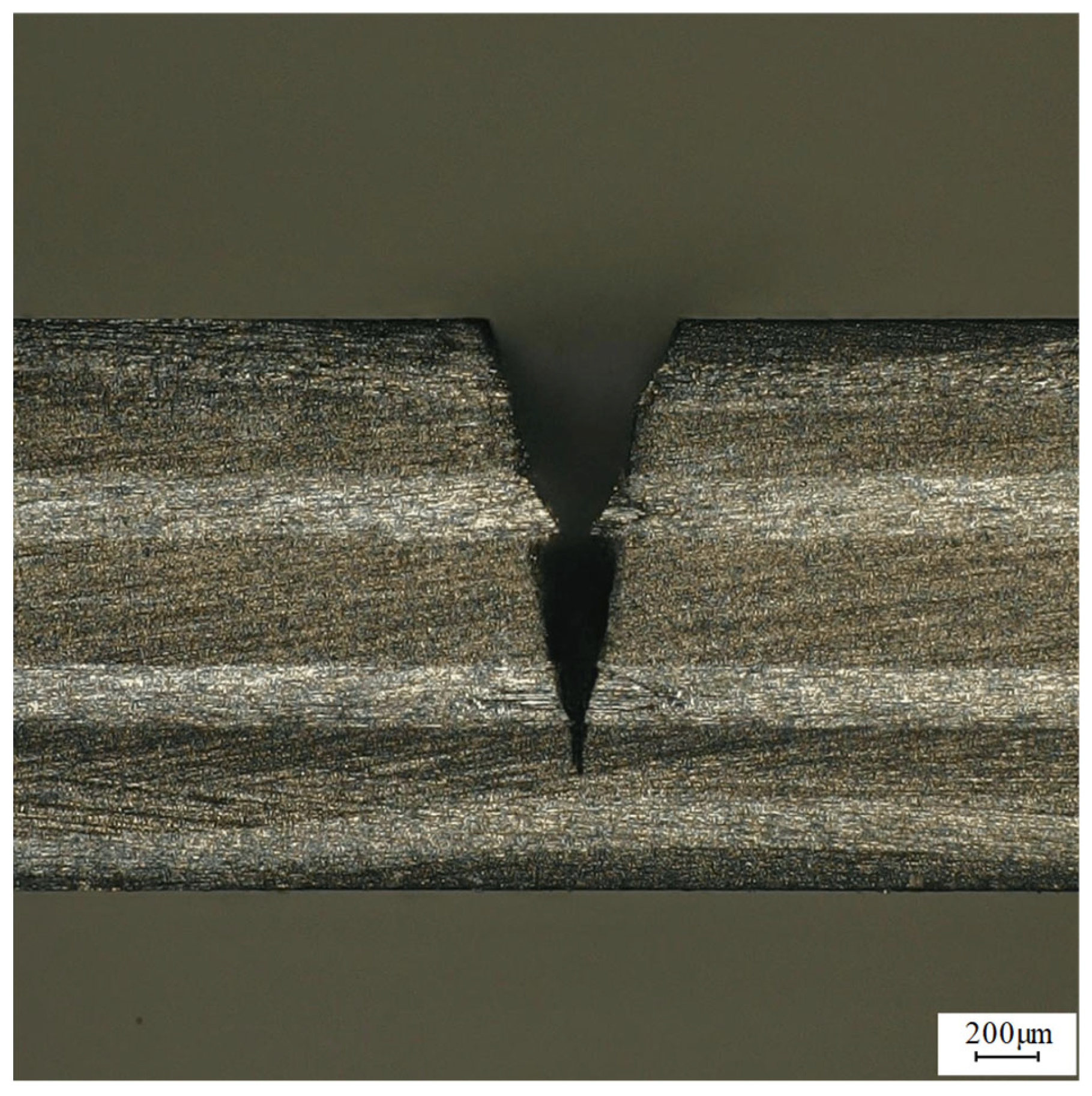

- The response surface optimization results show that the process parameters are a laser power of 271.49 W, a feed rate of 0.149 mm/s, a pulse frequency of 4048.24 Hz, a water-jet pressure of 0.799 MPa, and a predicted depth of 1212.257 mm. Finally, the cutting experiment is carried out by using the optimized parameters to verify the predicted value. The cutting depth is 1189.97 mm, and the error is only 1.84%, which proves that the model has a high reference value.

- There are many factors affecting the quality of water-guided laser processing. In this paper, only some process parameters are selected to explore the processing quality. Subsequently, water-jet diameter, processing distance, CFRP material thickness, and other factors can be selected for further experimental research.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ou, Y.; Zhu, D.; Zhang, H.; Yao, Y.; Mobasher, B.; Huang, L. Mechanical properties and failure characteristics of CFRP under intermediate strain rates and varying temperatures. Compos. Part B Eng. 2016, 95, 123–136. [Google Scholar] [CrossRef]

- Geier, N.; Davim, J.P.; Szalay, T. Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105552. [Google Scholar] [CrossRef]

- Oh, S.; Lee, I.; Park, Y.-B.; Ki, H. Investigation of cut quality in fiber laser cutting of CFRP. Opt. Laser Technol. 2019, 113, 129–140. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, H.; Zhao, J.; Cao, Z.; Yu, Y. Numerical simulation of water jet–guided laser micromachining of CFRP. Mater. Today Commun. 2020, 25, 101456. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Mechanical properties and failure behaviour of carbon fibre-reinforced polymer composites under the influence of moisture. Compos. Part A Appl. Sci. Manuf. 1997, 28, 595–604. [Google Scholar] [CrossRef]

- Xu, W.-X.; Zhang, L.-C. Ultrasonic vibration-assisted machining: Principle, design and application. Adv. Manuf. 2015, 3, 173–192. [Google Scholar] [CrossRef]

- Chen, Y.; Liang, Y.; Xu, J.; Hu, A. Ultrasonic vibration assisted grinding of CFRP composites: Effect of fiber orientation and vibration velocity on grinding forces and surface quality. Int. J. Light. Mater. Manuf. 2018, 1, 189–196. [Google Scholar] [CrossRef]

- George, P.M.; Raghunath, B.K.; Manocha, L.M.; Warrier, A.M. EDM machining of carbon–carbon composite—A Taguchi approach. J. Mater. Process. Technol. 2004, 145, 66–71. [Google Scholar] [CrossRef]

- Lau, W.S.; Wang, M.; Lee, W.B. Electrical discharge machining of carbon fibre composite materials. Int. J. Mach. Tools Manuf. 1990, 30, 297–308. [Google Scholar] [CrossRef]

- Freitag, C.; Wiedenmann, M.; Negel, J.P.; Loescher, A.; Onuseit, V.; Weber, R.; Ahmed, M.A.; Graf, T. High-quality processing of CFRP with a 1.1-kW picosecond laser. Appl. Phys. A 2015, 119, 1237–1243. [Google Scholar] [CrossRef]

- Salama, A.; Li, L.; Mativenga, P.; Whitehead, D. TEA CO2 laser machining of CFRP composite. Appl. Phys. A 2016, 122, 497. [Google Scholar] [CrossRef]

- Riveiro, A.; Quintero, F.; Lusquiños, F.; del Val, J.; Comesaña, R.; Boutinguiza, M.; Pou, J. Experimental study on the CO2 laser cutting of carbon fiber reinforced plastic composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1400–1409. [Google Scholar] [CrossRef]

- Sander, R.; Poesl, H.; Frank, F.; Meister, P.; Strobel, M.; Spuhler, A. An Nd:YAG laser with a water-guided laser beam—A new transmission system. Gastrointest. Endosc. 1988, 34, 336–338. [Google Scholar] [CrossRef]

- Hock, K.; Adelmann, B.; Hellmann, R. Comparative Study of Remote Fiber Laser and Water-Jet Guided Laser Cutting of Thin Metal Sheets. Phys. Procedia 2012, 39, 225–231. [Google Scholar] [CrossRef]

- Wagner, F.R.; Boillat, C.; Buchilly, J.M.; Spiegel, A.; Vago, N.; Richerzhagen, B. High-speed cutting of thin materials with a Q-switched laser in a water-jet vs. conventional laser cutting with a free running laser. High-Power Lasers Appl. 2003, 4977, 70–74. [Google Scholar]

- Perrottet, D.; Housh, R.; Richerzhagen, B.; Manley, J. Heat damage-free Laser-Microjet cutting achieves highest die fracture strength. Photon Process. Microelectron. Photonics IV 2005, 5713, 285–292. [Google Scholar]

- Sun, D.; Han, F.; Ying, W.; Jin, C. Surface integrity of water jet guided laser machining of CFRP. Procedia CIRP 2018, 71, 71–74. [Google Scholar] [CrossRef]

- Tabie, V.M.; Koranteng, M.O.; Yunus, A.; Kuuyine, F. Water-Jet Guided Laser Cutting Technology—An Overview. Lasers Manuf. Mater. Process. 2019, 6, 189–203. [Google Scholar] [CrossRef]

- Adalarasan, R.; Santhanakumar, M. Application of Taguchi based Response Surface Method (TRSM) for Optimization of Multi Responses in Drilling Al/SiC/Al2O3 Hybrid Composite. J. Inst. Eng. (India) Ser. C 2015, 96, 65–71. [Google Scholar] [CrossRef]

- Freitag, C.; Kononenko, T.V.; Weber, R.; Konov, V.I.; Graf, T. Influence of pulse repetition rate and pulse energy on the heat accumulation between subsequent laser pulses during laser processing of CFRP with ps pulses. Appl. Phys. A 2018, 124, 479. [Google Scholar] [CrossRef]

- Porter, J.A.; Louhisalmi, Y.A.; Karjalainen, J.A.; Füger, S. Cutting thin sheet metal with a water jet guided laser using various cutting distances, feed speeds and angles of incidence. Int. J. Adv. Manuf. Technol. 2007, 33, 961–967. [Google Scholar] [CrossRef]

| Density | Melting Temperature | Thermal Conductivity |

|---|---|---|

| Kg/m3 | °C | (W/(m·K)) |

| 1500 ± 15 | 3300 | 32(0°), 5(90°) |

| Test Factors | Laser Power (A) | Feed Speed (B) | Pulse Frequency (C) | Water Pressure (D) |

|---|---|---|---|---|

| Unit | W | mm/s | Hz | MPa |

| 1 | 200 | 0.1 | 4000 | 0.6 |

| 2 | 250 | 0.15 | 5000 | 0.7 |

| 3 | 300 | 0.2 | 6000 | 0.8 |

| Test Factors | Laser Power (A) | Feed Speed (B) | Pulse Frequency (C) | Water Pressure (D) | Cutting Depth (H) |

|---|---|---|---|---|---|

| Unit | W | mm/s | Hz | MPa | μm |

| 1 | 200 | 4000 | 0.15 | 0.7 | 1018.6 |

| 2 | 250 | 5000 | 0.15 | 0.7 | 1121.4 |

| 3 | 250 | 5000 | 0.2 | 0.8 | 1102.2 |

| 4 | 250 | 4000 | 0.2 | 0.7 | 1106.5 |

| 5 | 250 | 5000 | 0.2 | 0.6 | 1029.3 |

| 6 | 250 | 6000 | 0.2 | 0.7 | 989.1 |

| 7 | 250 | 6000 | 0.15 | 0.8 | 1088.8 |

| 8 | 250 | 5000 | 0.15 | 0.7 | 1133 |

| 9 | 300 | 5000 | 0.15 | 0.8 | 1206.1 |

| 10 | 300 | 4000 | 0.15 | 0.7 | 1211.1 |

| 11 | 300 | 6000 | 0.15 | 0.7 | 1103.7 |

| 12 | 300 | 5000 | 0.15 | 0.6 | 1143.2 |

| 13 | 250 | 6000 | 0.1 | 0.7 | 1099.9 |

| 14 | 200 | 5000 | 0.15 | 0.8 | 1084.2 |

| 15 | 200 | 5000 | 0.15 | 0.6 | 1001.9 |

| 16 | 250 | 4000 | 0.15 | 0.8 | 1189.1 |

| 17 | 250 | 5000 | 0.15 | 0.7 | 1107.7 |

| 18 | 250 | 4000 | 0.15 | 0.6 | 1102.3 |

| 19 | 200 | 5000 | 0.1 | 0.7 | 1095.5 |

| 20 | 250 | 6000 | 0.15 | 0.6 | 1005.2 |

| 21 | 300 | 5000 | 0.1 | 0.7 | 1207 |

| 22 | 250 | 5000 | 0.1 | 0.6 | 1139.2 |

| 23 | 250 | 4000 | 0.1 | 0.7 | 1206.5 |

| 24 | 250 | 5000 | 0.1 | 0.8 | 1182.3 |

| 25 | 200 | 6000 | 0.15 | 0.7 | 961.8 |

| 26 | 250 | 5000 | 0.15 | 0.7 | 1113.7 |

| 27 | 300 | 5000 | 0.2 | 0.7 | 1107.2 |

| 28 | 200 | 5000 | 0.2 | 0.7 | 985.9 |

| 29 | 250 | 5000 | 0.15 | 0.7 | 1159.1 |

| Source | Some of Squares | df | Mean Square | F-Value | p-Value Prob > F | |

|---|---|---|---|---|---|---|

| Model | 1.402 × 105 | 14 | 10,014.33 | 31.84 | <0.0001 | Significant |

| A-Laser power | 57,463.68 | 1 | 57,463.68 | 182.73 | <0.0001 | |

| B-Feed speed | 31,028.67 | 1 | 31,028.67 | 90.67 | <0.0001 | |

| C-Pulse frequency | 28,577.28 | 1 | 28,577.28 | 98.87 | <0.0001 | |

| D-Water pressure | 15,523.21 | 1 | 15,523.21 | 49.36 | <0.0001 | |

| AB | 24.01 | 1 | 24.01 | 0.076 | 0.7863 | |

| AC | 640.09 | 1 | 640.09 | 2.04 | 0.1756 | |

| AD | 94.09 | 1 | 94.09 | 0.30 | 0.5930 | |

| BC | 29.16 | 1 | 29.16 | 0.093 | 0.7652 | |

| BD | 222.01 | 1 | 222.01 | 0.71 | 0.4149 | |

| CD | 2.56 | 1 | 2.56 | 8.140 × 10−3 | 0.9294 | |

| A2 | 2949.31 | 1 | 2949.31 | 9.38 | 0.0084 | |

| B2 | 216.20 | 1 | 216.20 | 0.69 | 0.4209 | |

| C2 | 4649.59 | 1 | 4649.59 | 14.79 | 0.0018 | |

| D2 | 53.55 | 1 | 53.55 | 0.17 | 0.6861 | |

| Residual | 4402.71 | 14 | 314.48 | |||

| Lack of Fit | 2755.56 | 10 | 275.56 | 0.67 | 0.7243 | Not significant |

| Pure Error | 1647.15 | 4 | 411.79 | |||

| Cor Total | 1.446 × 105 | 28 | ||||

| R-Squared = 0.9696 | Adj R-Squared = 0.9391 | |||||

| Laser Power (A) | Feed Speed (B) | Pulse Frequency (C) | Water Pressure (D) | Prediction Depth | Actual Depth | Error |

|---|---|---|---|---|---|---|

| W | mm/s | HZ | MPa | μm | μm | % |

| 271.49 | 0.149 | 4048.24 | 0.799 | 1212.257 | 1189.97 | 1.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, S.; Zhao, Y.; Zhao, D.; Zhao, C.; Tang, Y.; Li, Z.; Yu, H.; Liu, G.; Cao, C.; Meng, J. Experimental Study on Carbon Fiber-Reinforced Polymer Groove Machining by High-Power Water-Jet-Guided Laser. Micromachines 2023, 14, 1721. https://doi.org/10.3390/mi14091721

Meng S, Zhao Y, Zhao D, Zhao C, Tang Y, Li Z, Yu H, Liu G, Cao C, Meng J. Experimental Study on Carbon Fiber-Reinforced Polymer Groove Machining by High-Power Water-Jet-Guided Laser. Micromachines. 2023; 14(9):1721. https://doi.org/10.3390/mi14091721

Chicago/Turabian StyleMeng, Shuo, Yugang Zhao, Dandan Zhao, Chuang Zhao, Yu Tang, Zhihao Li, Hanlin Yu, Guangxin Liu, Chen Cao, and Jianbing Meng. 2023. "Experimental Study on Carbon Fiber-Reinforced Polymer Groove Machining by High-Power Water-Jet-Guided Laser" Micromachines 14, no. 9: 1721. https://doi.org/10.3390/mi14091721

APA StyleMeng, S., Zhao, Y., Zhao, D., Zhao, C., Tang, Y., Li, Z., Yu, H., Liu, G., Cao, C., & Meng, J. (2023). Experimental Study on Carbon Fiber-Reinforced Polymer Groove Machining by High-Power Water-Jet-Guided Laser. Micromachines, 14(9), 1721. https://doi.org/10.3390/mi14091721