A Novel 6500 V SiC Trench MOSFET with Integrated Unipolar Diode for Improved Third Quadrant and Switching Characteristics

Abstract

:1. Introduction

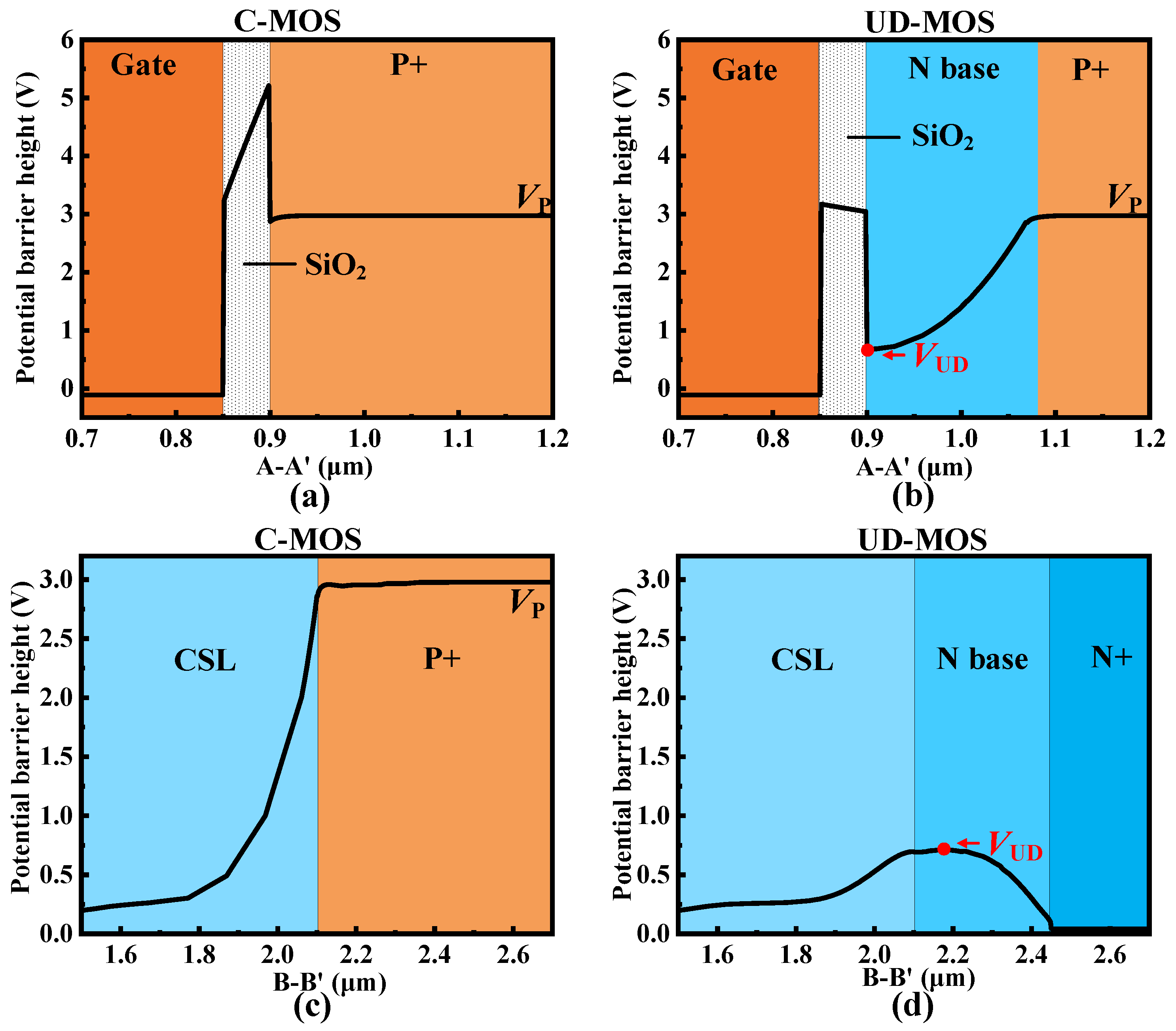

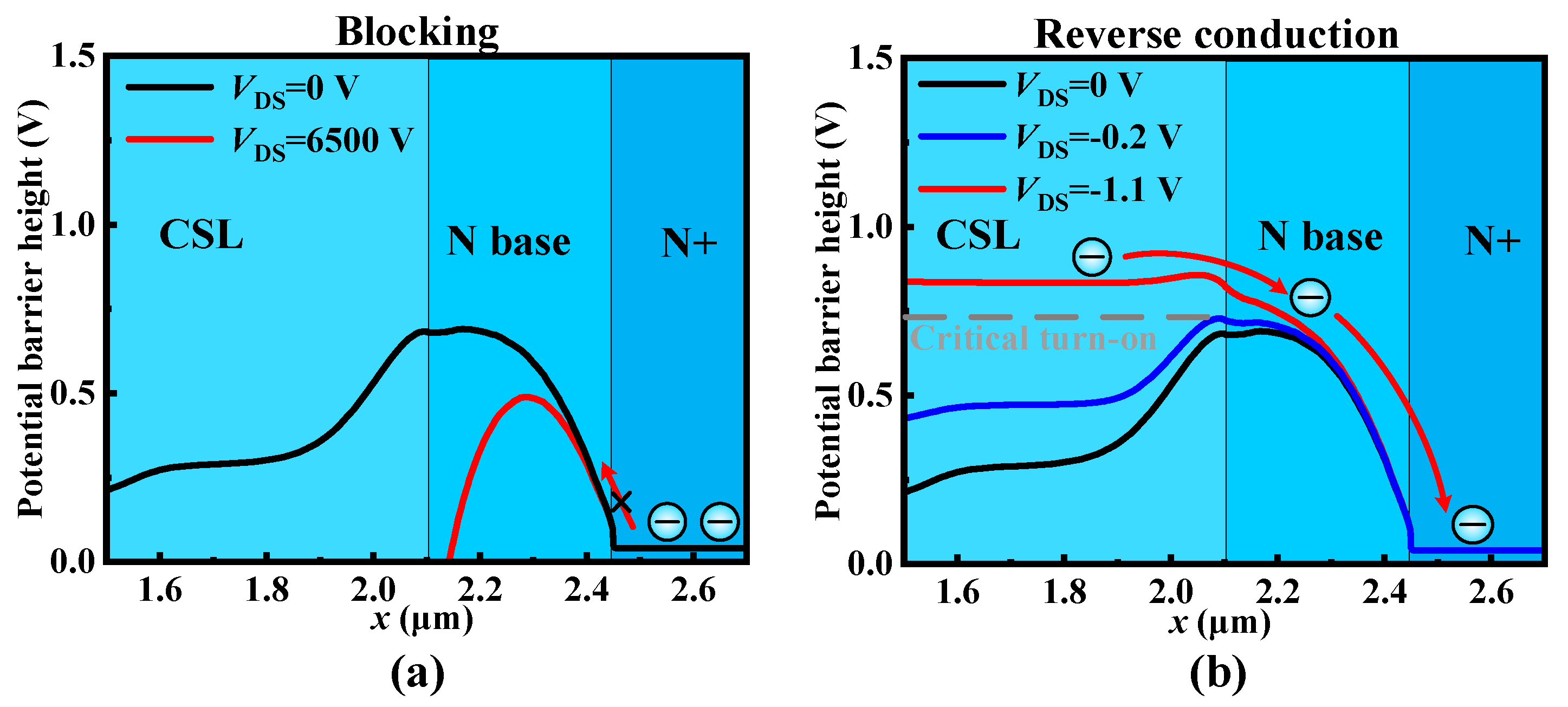

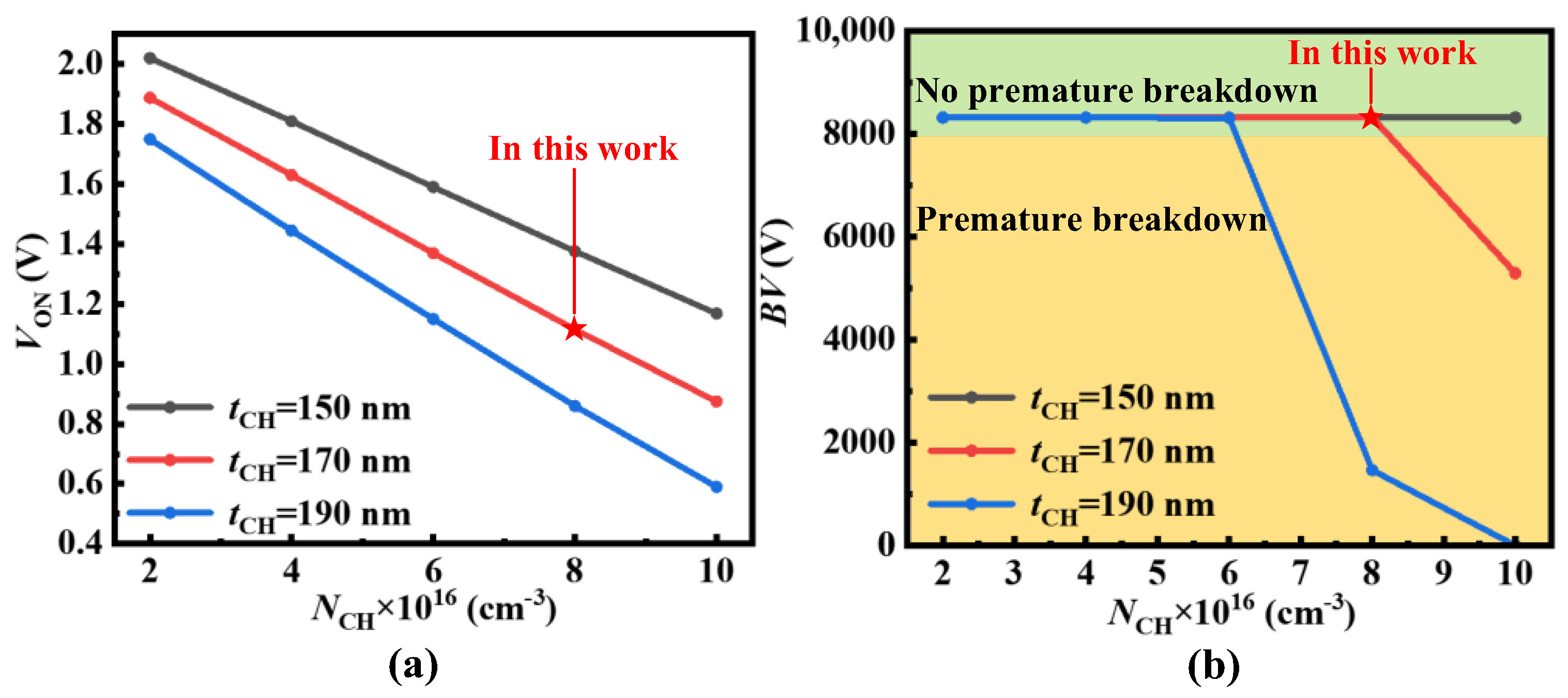

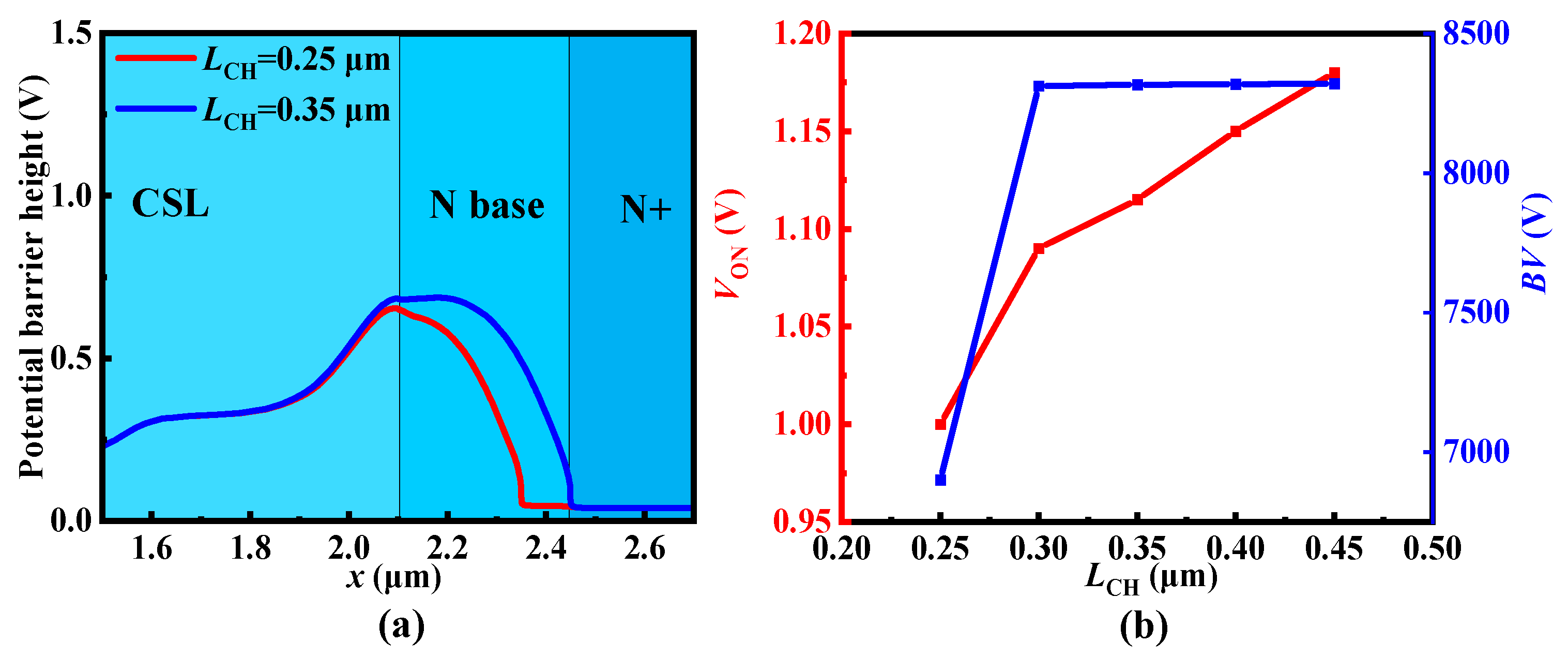

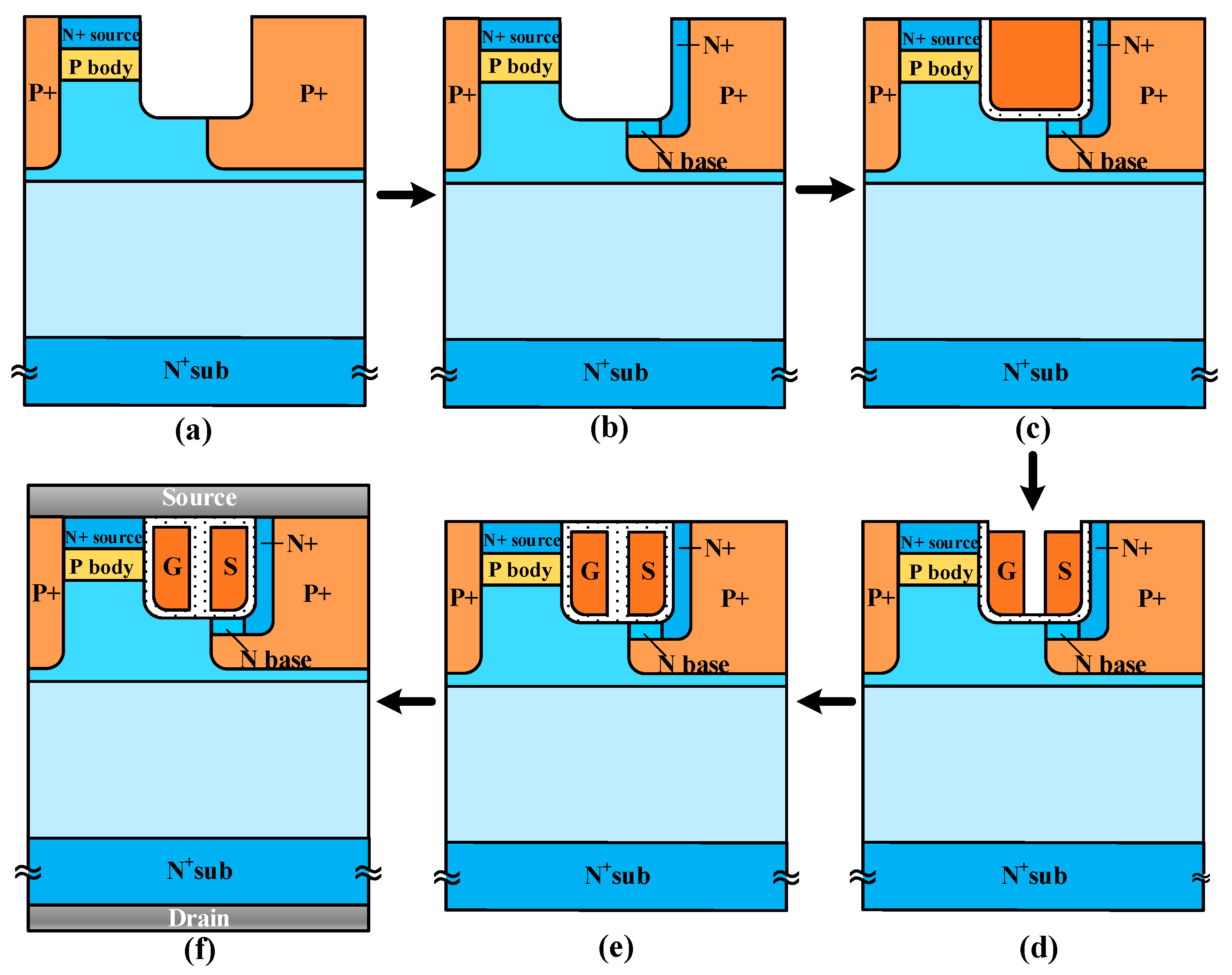

2. Device Structure and Mechanism

3. Results and Discussion

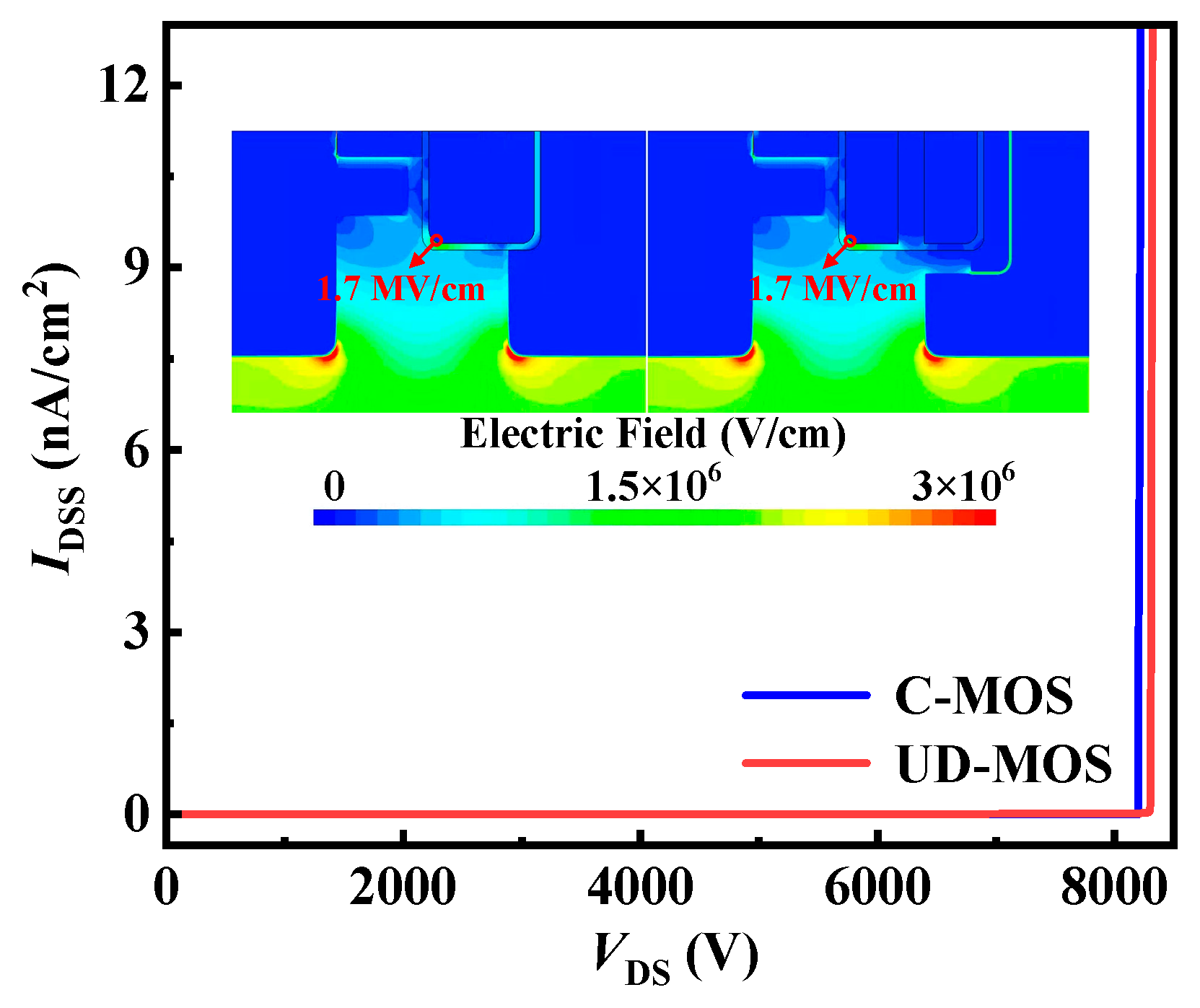

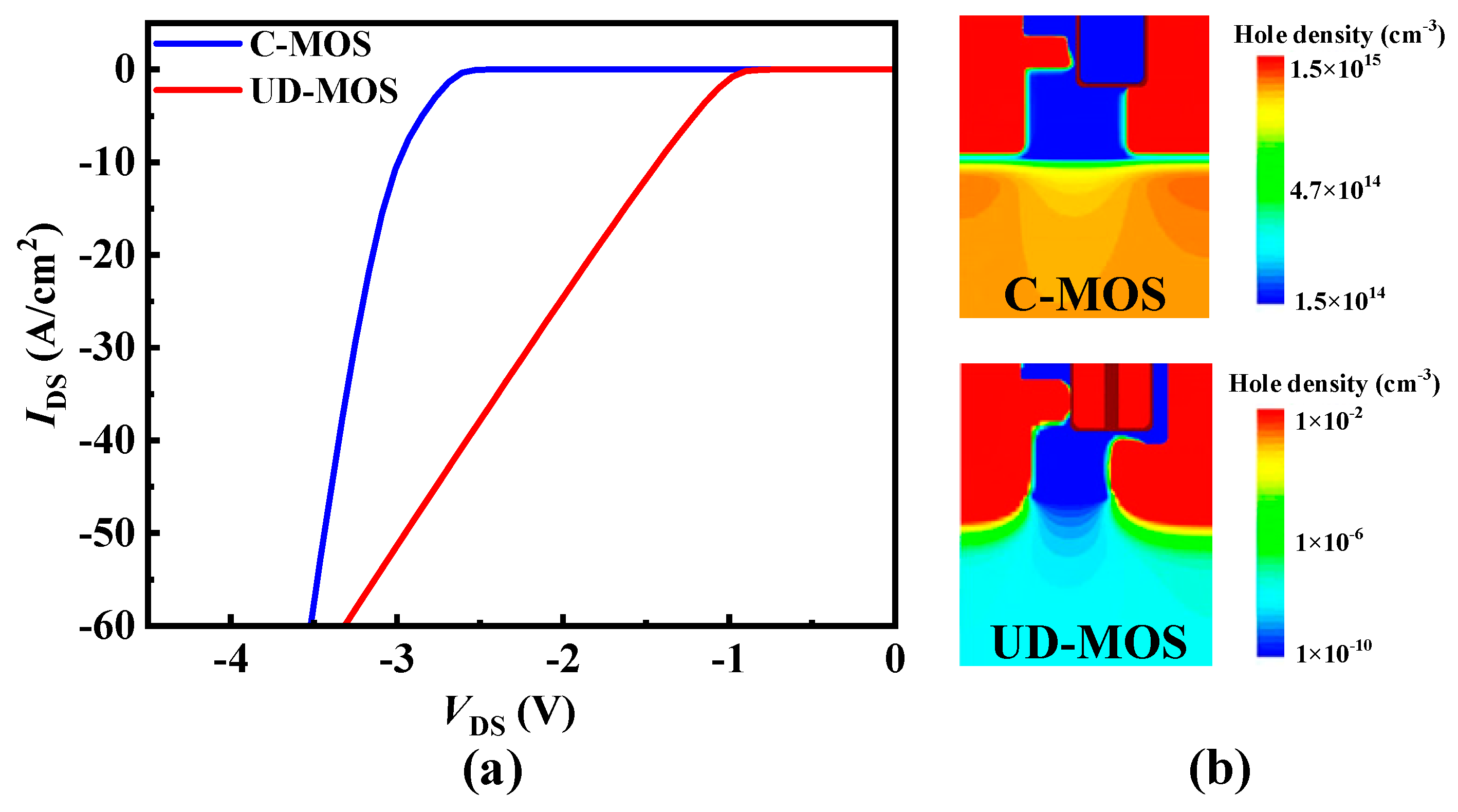

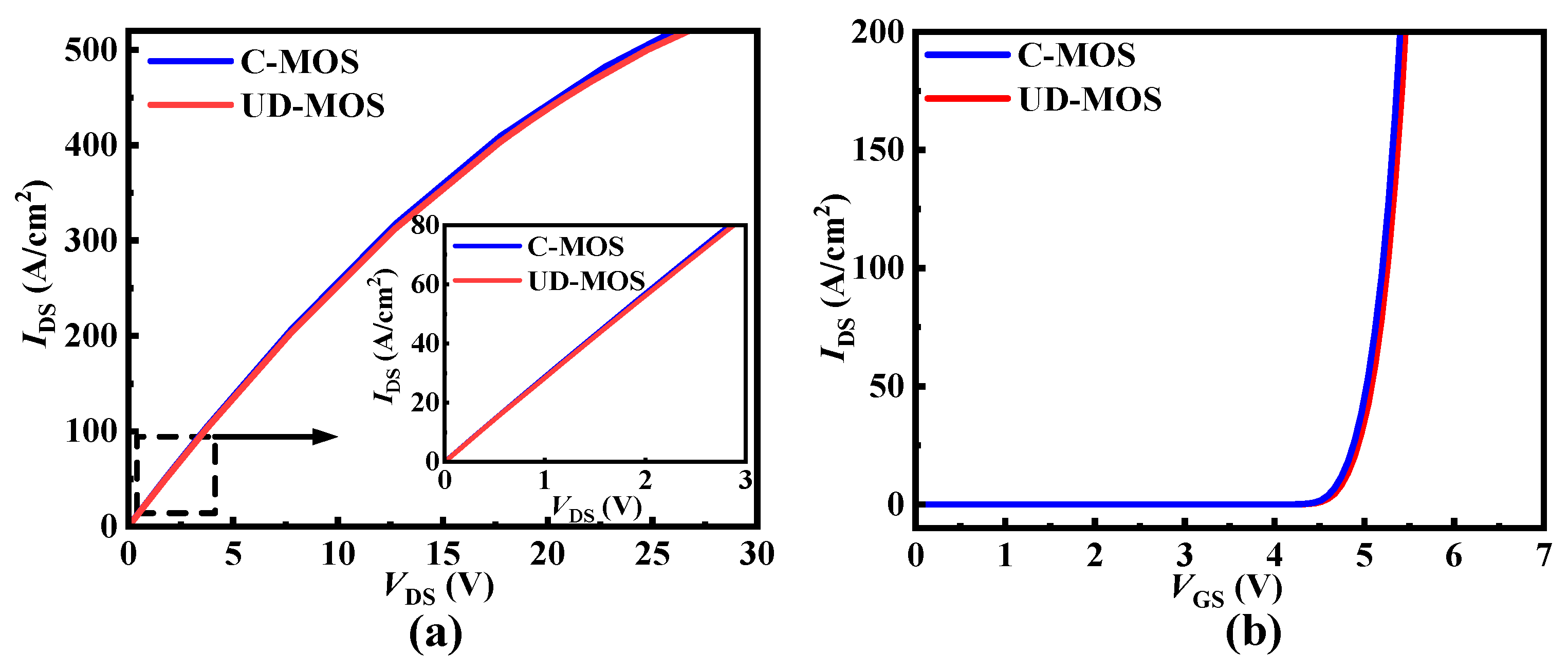

3.1. Static Characteristics

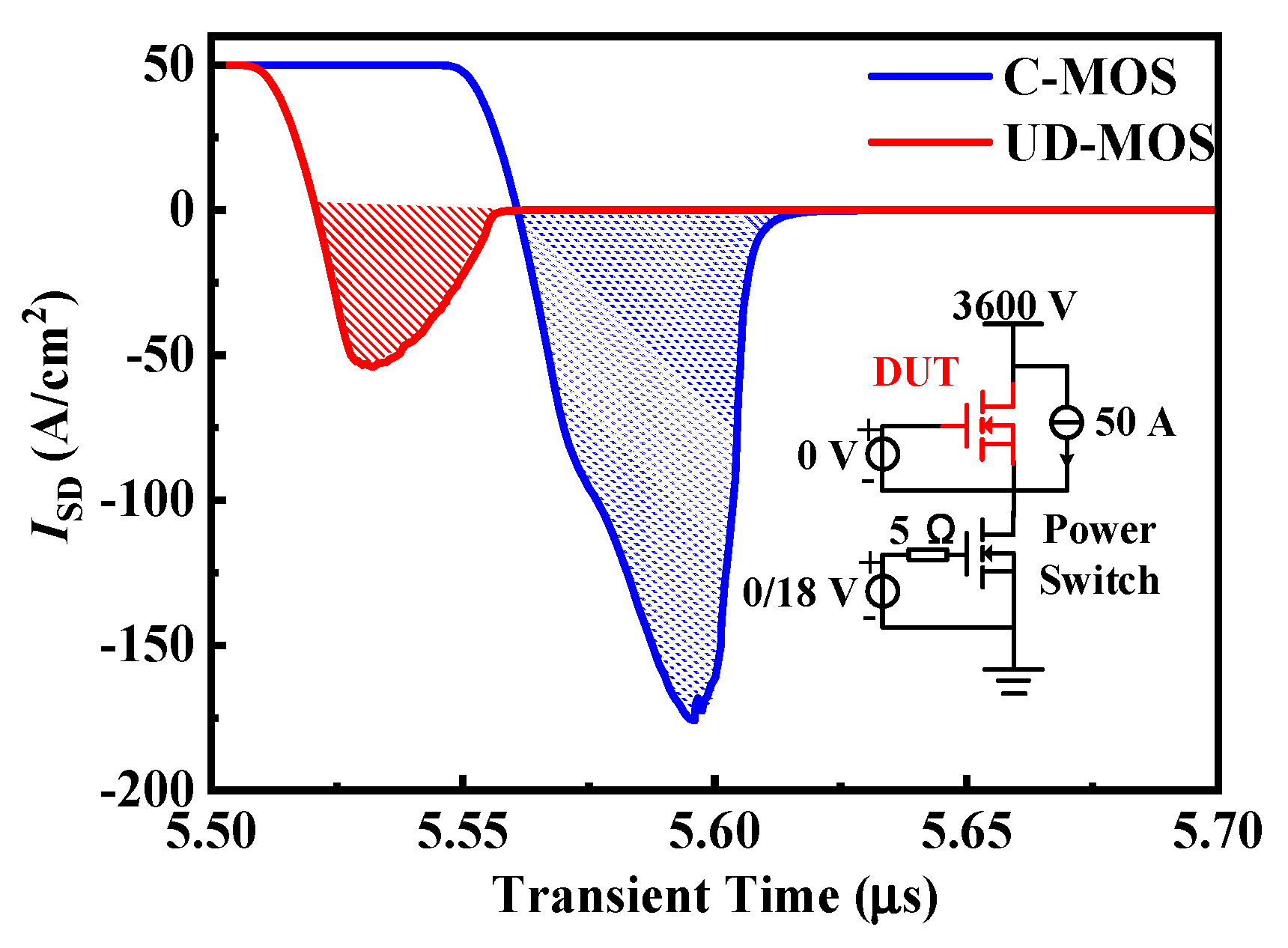

3.2. Dynamic Characteristics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Spaziani, L.; Lu, L. Silicon, GaN and SiC: There’s room for all: An application space overview of device considerations. In Proceedings of the 2018 IEEE 30th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Chicago, IL, USA, 13–17 May 2018; pp. 8–11. [Google Scholar] [CrossRef]

- Ghosh, R.; Mondal, S.; Ghorui, S.K. SiC MOSFET Based VSC Used in HVDC Transmission with DC Fault Protection Scheme. In Proceedings of the2017 International Conference on Computer, Electrical & Communication Engineering (ICCECE), Kolkata, India, 22–23 December 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Li, X.; Jiang, J.; Huang, A.Q.; Guo, S.; Deng, X.; Zhang, B.; She, X. A SiC Power MOSFET Loss Model Suitable for High-Frequency Applications. IEEE Trans. Ind. Electron. 2017, 64, 8268–8276. [Google Scholar] [CrossRef]

- Kimoto, T.; Iijima, A.; Tsuchida, H.; Miyazawa, T.; Tawara, T.; Otsuki, A.; Kato, T.; Yonezawa, Y. Understanding and reduction of degradation phenomena in SiC power devices. In Proceedings of the 2017 IEEE International Reliability Physics Symposium (IRPS), Monterey, CA, USA, 2–6 April 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 2A-1.1–2A-1.7. [Google Scholar]

- Agarwal, A.; Fatima, H.; Haney, S.; Ryu, S.-H. A New Degradation Mechanism in High-Voltage SiC Power MOSFETs. IEEE Electron. Device Lett. 2007, 28, 587–589. [Google Scholar] [CrossRef]

- Ishigaki, T.; Murata, T.; Kinoshita, K.; Morikawa, T.; Oda, T.; Fujita, R.; Konishi, K.; Mori, Y.; Shima, A. Analysis of Degradation Phenomena in Bipolar Degradation Screening Process for SiC-MOSFETs. In Proceedings of the 2019 31st International Symposium on Power Semiconductor Devices and ICs (ISPSD), Shanghai, China, 19–23 May 2019; pp. 259–262. [Google Scholar] [CrossRef]

- Jiang, H.; Wei, J.; Dai, X.; Zheng, C.; Ke, M.; Deng, X.; Sharma, Y.; Deviny, I.; Mawby, P. SiC MOSFET with built-in SBD for reduction of reverse recovery charge and switching loss in 10-kV applications. In Proceedings of the 2017 29th International Symposium on Power Semiconductor Devices and IC’s (ISPSD), Sapporo, Japan, 28 May–1 June 2017; pp. 49–52. [Google Scholar] [CrossRef]

- Saito, K.; Miyoshi, T.; Kawase, D.; Hayakawa, S.; Masuda, T.; Sasajima, Y. Simplified Model Analysis of Self-Excited Oscillation and Its Suppression in a High-Voltage Common Package for Si-IGBT and SiC-MOS. IEEE Trans. Electron. Devices 2018, 65, 1063–1071. [Google Scholar] [CrossRef]

- Sung, W.; Baliga, B.J. On developing one-chip integration of 1.2 kV SiC MOSFET and JBS diode (JBSFET). IEEE Trans. Ind. Electron. 2017, 64, 8206–8212. [Google Scholar] [CrossRef]

- Sundaresan, S.; Park, J.; Mulpuri, V.; Singh, R. Performance and Robustness of 6500 V SiC DMOSFETs with Integrated MPS diodes. In Proceedings of the 2021 33rd International Symposium on Power Semiconductor Devices and ICs (ISPSD), Nagoya, Japan, 30 May–3 June 2021; pp. 235–238. [Google Scholar] [CrossRef]

- Kawahara, K.; Hino, S.; Sadamatsu, K.; Nakao, Y.; Yamashiro, Y.; Yamamoto, Y.; Iwamatsu, T.; Nakata, S.; Tomohisa, S.; Yamakawa, S. 6.5 kV schottky-barrier-diode-embedded SiC-MOSFET for compact full-unipolar module. In Proceedings of the 2017 29th International Symposium on Power Semiconductor Devices and IC’s (ISPSD), Sapporo, Japan, 28 May–1 June 2017; pp. 41–44. [Google Scholar] [CrossRef]

- Zhou, X.; Pang, H.; Jia, Y.; Hu, D.; Wu, Y.; Tang, Y.; Xia, T.; Gong, H.; Zhao, Y. SiC Double-Trench MOSFETs With Embedded MOS-Channel Diode. IEEE Trans. Electron. Devices 2020, 67, 582–587. [Google Scholar] [CrossRef]

- Zhou, X.; Gong, H.; Jia, Y.; Hu, D.; Wu, Y.; Xia, T.; Pang, H.; Zhao, Y. SiC Planar MOSFETs With Built-In Reverse MOS-Channel Diode for Enhanced Performance. IEEE J. Electron. Devices Soc. 2020, 8, 619–625. [Google Scholar] [CrossRef]

- Zhu, L.; Chow, T.; Jones, K.; Agarwal, A. Design, fabrication, and characterization of low forward drop, low leakage, 1-kV 4H-SiC JBS rectifiers. IEEE Trans. Electron. Devices 2006, 53, 363–368. [Google Scholar] [CrossRef]

- Bodeker, C.; Vogt, T.; Silber, D.; Kaminski, N. Criterion for the Stability Against Thermal Runaway During Blocking Operation and Its Application to SiC Diodes. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 970–977. [Google Scholar] [CrossRef]

- Li, X.; Tong, X.; Huang, A.Q.; Tao, H.; Zhou, K.; Jiang, Y.; Jiang, J.; Deng, X.; She, X.; Zhang, B.; et al. SiC Trench MOSFET with Integrated Self-Assembled Three-Level Protection Schottky Barrier Diode. IEEE Trans. Electron. Devices 2018, 65, 347–351. [Google Scholar] [CrossRef]

- Beier-Moebius, M.; Lutz, J. Breakdown of gate oxide of 1.2 kV SiC-MOSFETs under high temperature and high gate voltage. In Proceedings of the PCIM Europe 2016—International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2016; pp. 1–8. [Google Scholar]

- Ohoka, A.; Uchida, M.; Kiyosawa, T.; Horikawa, N.; Saitou, K.; Kanzawa, Y.; Sorada, H.; Sawada, K.; Ueda, T. Reduction of RonA retaining high threshold voltage in SiC DioMOS by improved channel design. In Proceedings of the 2018 IEEE 30th International Symposium on Power Semiconductor Devices and ICs (ISPSD), Chicago, IL, USA, 13–17 May 2018; pp. 52–55. [Google Scholar] [CrossRef]

- Uchida, M.; Horikawa, N.; Tanaka, K.; Takahashi, K.; Kiyosawa, T.; Hayashi, M.; Niwayama, M.; Kusumoto, O.; Adachi, K.; Kudou, C.; et al. Novel SiC power MOSFET with integrated unipolar internal inverse MOS-channel diode. In Proceedings of the 2011 International Electron Devices Meeting, Washington, DC, USA, 5–7 December 2011; pp. 26.6.1–26.6.4. [Google Scholar] [CrossRef]

- Ohoka, A.; Horikawa, N.; Kiyosawa, T.; Sorada, H.; Uchida, M.; Kanzawa, Y.; Sawada, K.; Ueda, T.; Fujii, E. 40 mΩ/1700 V DioMOS (Diode in SiC MOSFET) for High Power Switching Applications. Mater. Sci. Forum 2014, 778–780, 911–914. [Google Scholar] [CrossRef]

- Huang, A. New Unipolar Switching Power Device Figures of Merit. IEEE Electron. Device Lett. 2004, 25, 298–301. [Google Scholar] [CrossRef]

| Parameters | UD-MOS | C-MOS |

|---|---|---|

| cell pitch (μm) | 3.35 | 3.15 |

| drift region thickness (μm) | 60 | 60 |

| drift region doping (cm−3) | 1.2 × 1015 | 1.2 × 1015 |

| polysilicon width (μm) | 0.8 | 0.8 |

| trench depth (μm) | 0.9 | 0.9 |

| trench width (μm) | 1.1 | 0.9 |

| oxide thickness (nm) | 50 | 50 |

| CSL doping (cm−3) | 3 × 1016 | 3 × 1016 |

| JFET width (μm) | 1.3 | 1.3 |

| P+ region thickness (μm) | 1.7 | 1.7 |

| P+ region doping (cm−3) | 1 × 1019 | 1 × 1019 |

| N base length (μm) | 0.35 | − |

| N base thickness (nm) | 170 | − |

| N base doping (cm−3) | 8 × 1016 | − |

| Parameters | UD-MOS | C-MOS |

|---|---|---|

| RON (mΩ·cm2) | 35.48 | 34.99 |

| VON (V) | −1.11 | −2.77 |

| BV (V) | 8317 | 8217 |

| VTH (V) | 5.2 | 5.2 |

| IRRM (A/cm2) | 54 | 176 |

| CGS (nF/cm2) | 18.1 | 37.9 |

| CDS (pF/cm2) | 149 | 149 |

| CGD (pF/cm2) | 4.01 | 4.43 |

| QRR (μC/cm2) | 1.22 | 5.01 |

| QG (nC/cm2) | 566 | 970 |

| QGD (nC/cm2) | 109 | 121 |

| RON × QGD (mΩ·μC) | 3.87 | 4.24 |

| EON (mJ/cm2) | 3.8 | 5.71 |

| EOFF (mJ/cm2) | 3.36 | 4.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Li, X.; Deng, X.; Wu, Y.; Ding, J.; Peng, W.; Zhang, B. A Novel 6500 V SiC Trench MOSFET with Integrated Unipolar Diode for Improved Third Quadrant and Switching Characteristics. Micromachines 2024, 15, 92. https://doi.org/10.3390/mi15010092

Wu H, Li X, Deng X, Wu Y, Ding J, Peng W, Zhang B. A Novel 6500 V SiC Trench MOSFET with Integrated Unipolar Diode for Improved Third Quadrant and Switching Characteristics. Micromachines. 2024; 15(1):92. https://doi.org/10.3390/mi15010092

Chicago/Turabian StyleWu, Hao, Xuan Li, Xiaochuan Deng, Yangyang Wu, Jiawei Ding, Wensong Peng, and Bo Zhang. 2024. "A Novel 6500 V SiC Trench MOSFET with Integrated Unipolar Diode for Improved Third Quadrant and Switching Characteristics" Micromachines 15, no. 1: 92. https://doi.org/10.3390/mi15010092

APA StyleWu, H., Li, X., Deng, X., Wu, Y., Ding, J., Peng, W., & Zhang, B. (2024). A Novel 6500 V SiC Trench MOSFET with Integrated Unipolar Diode for Improved Third Quadrant and Switching Characteristics. Micromachines, 15(1), 92. https://doi.org/10.3390/mi15010092