A Method of Realizing Adaptive Uniform Illumination by Pyramid Prism for PA-LiDAR

Abstract

:1. Introduction

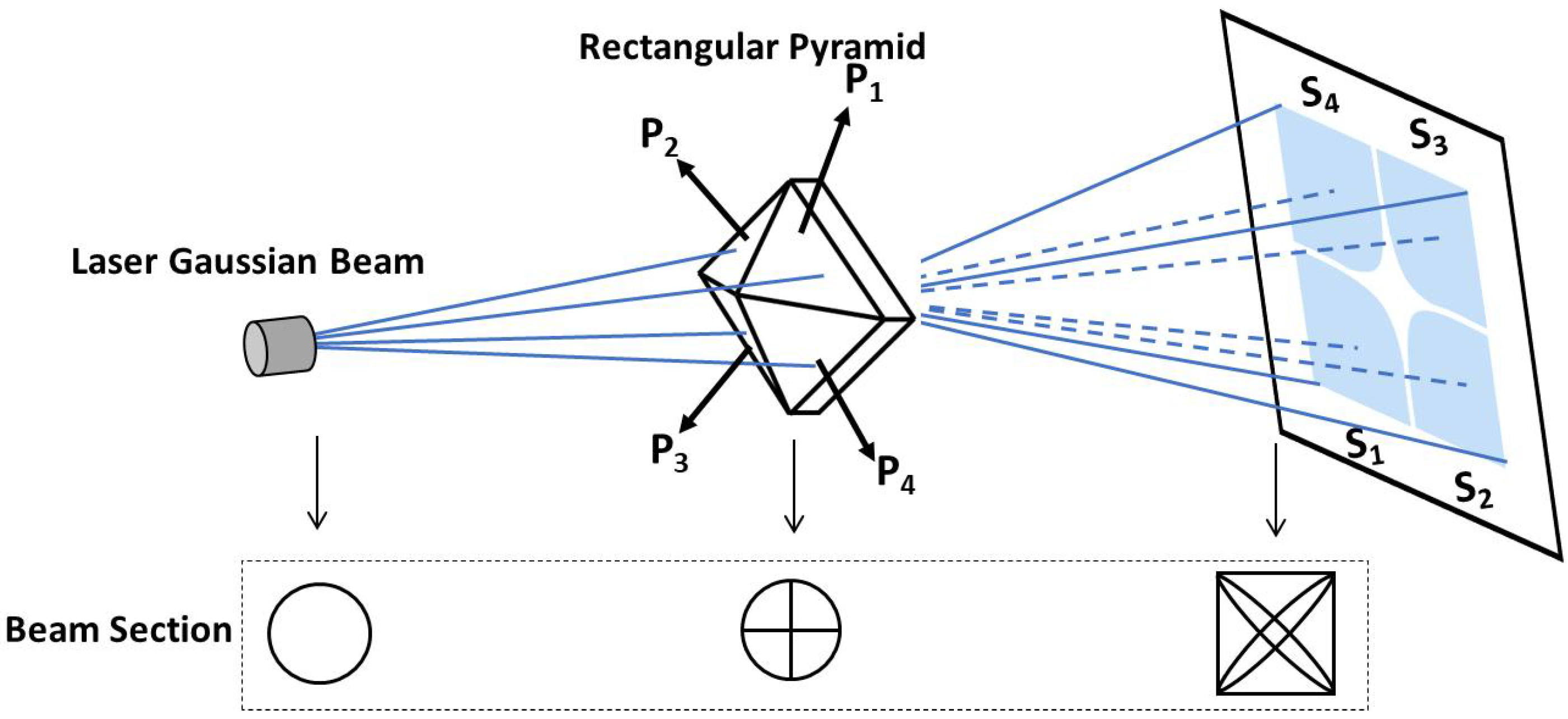

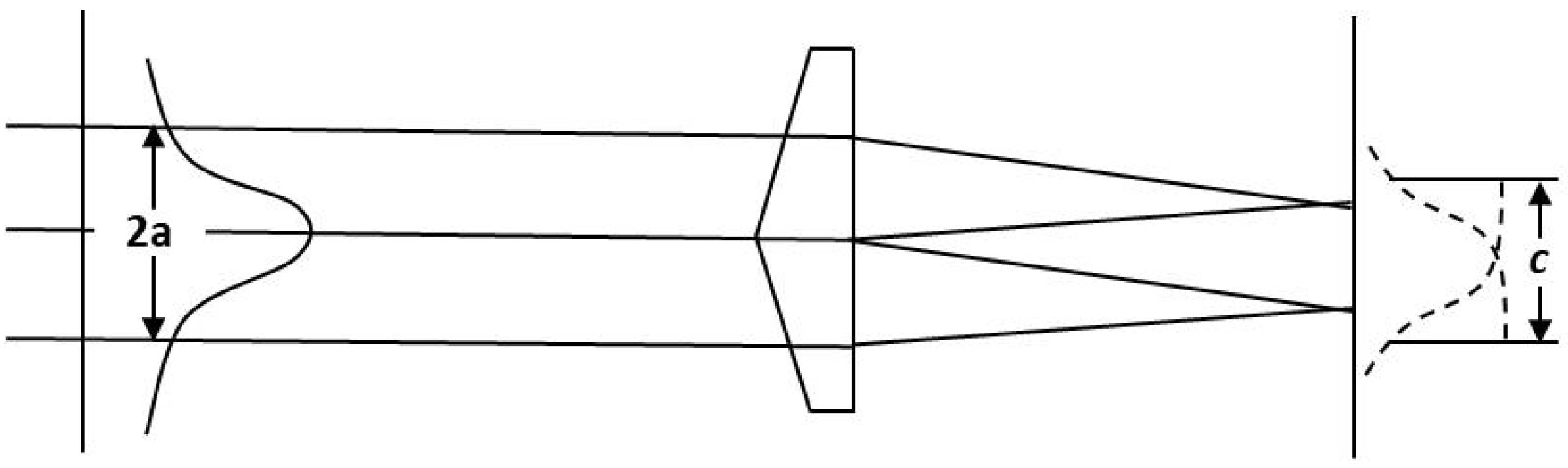

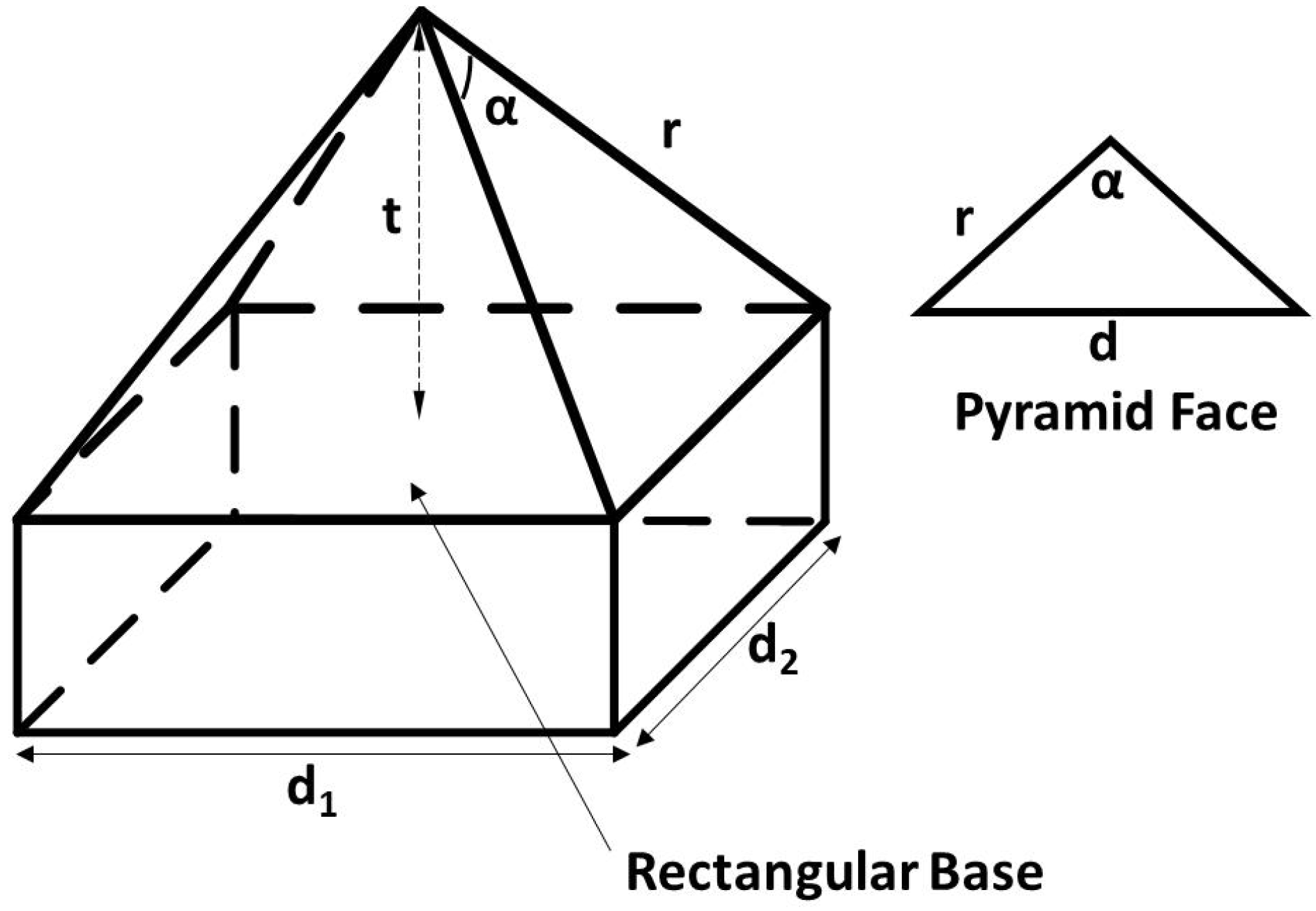

2. Description of Beam-Shaping Progress

2.1. Basic Principles of Operation

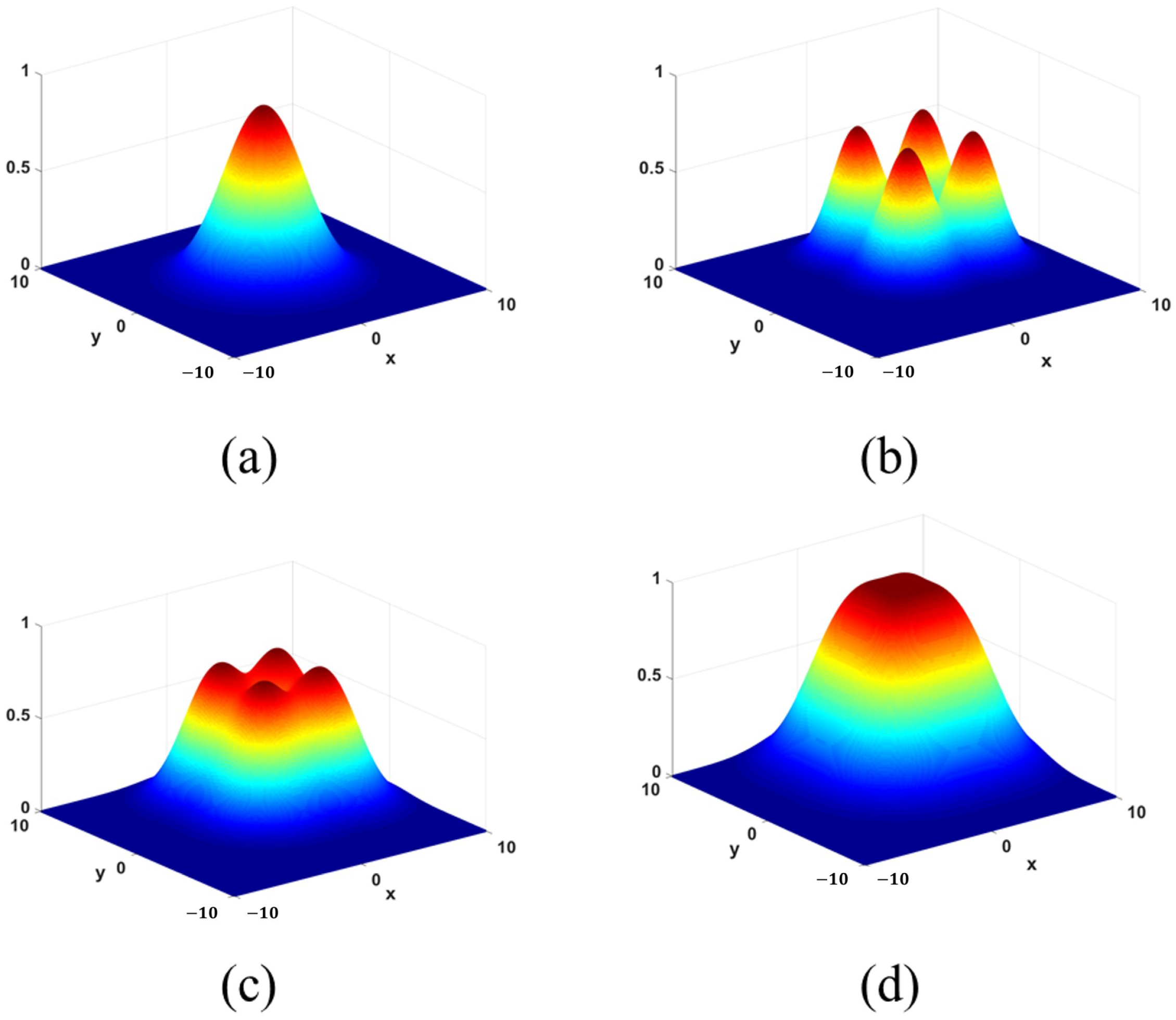

2.2. Numerical Simulation and Analysis

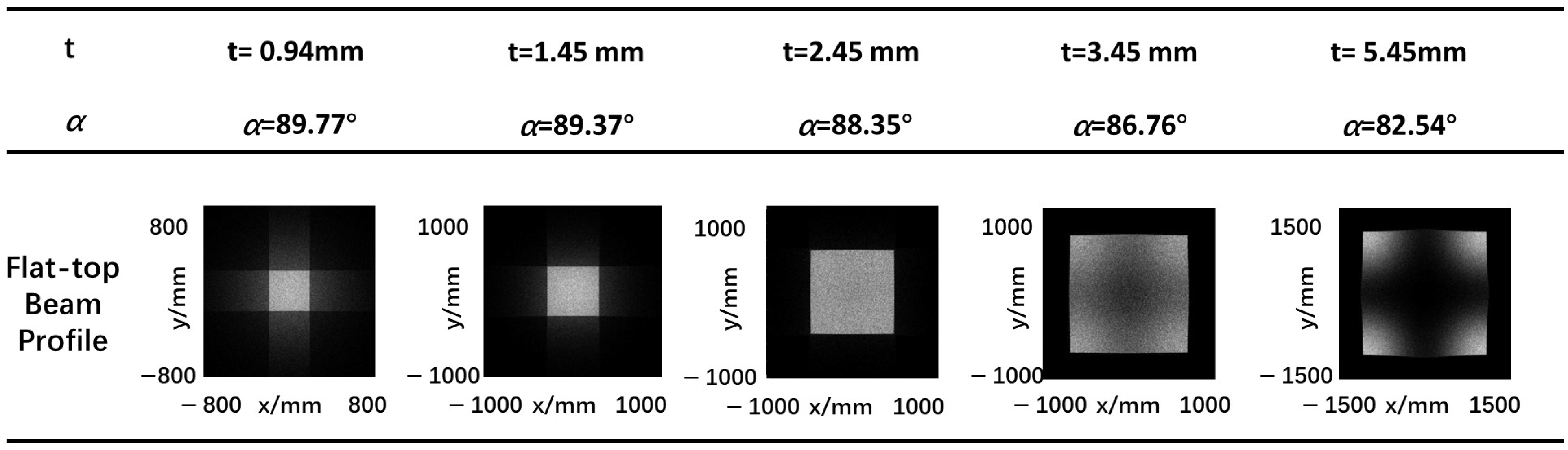

2.2.1. Included Angle

2.2.2. Incidence Angle of Laser Source

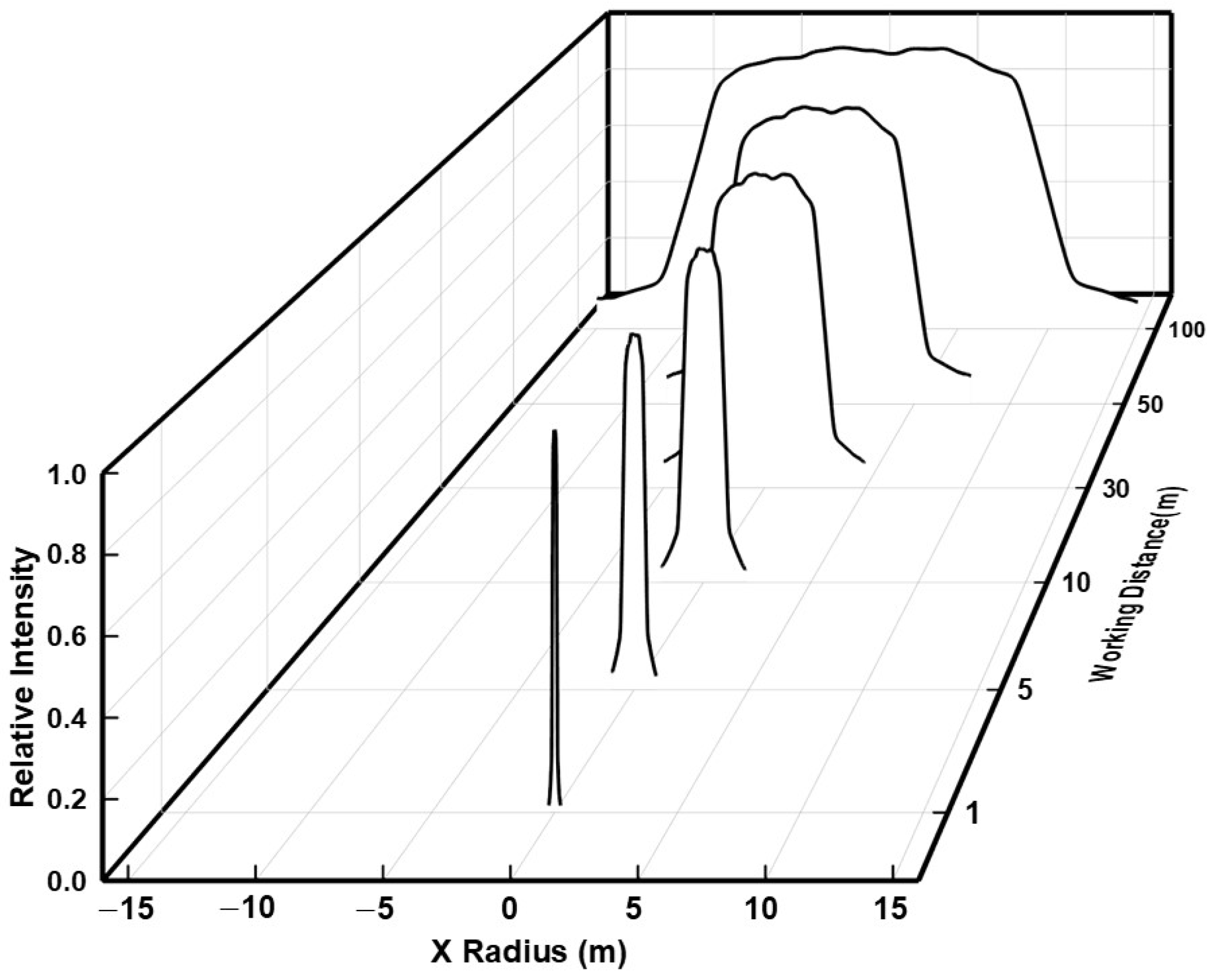

2.2.3. Propagation Characterization

3. PA-LiDAR Prototype Experiment

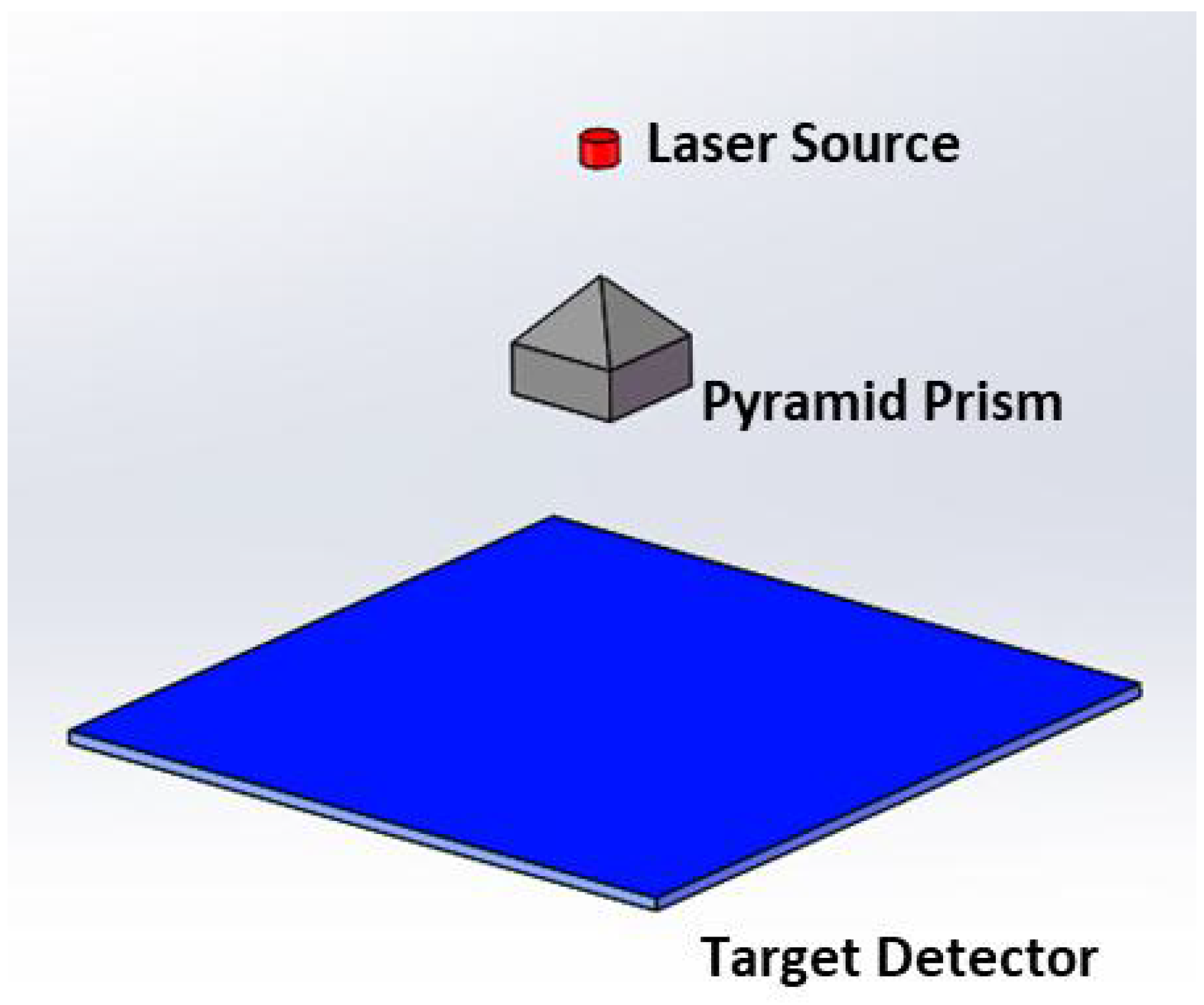

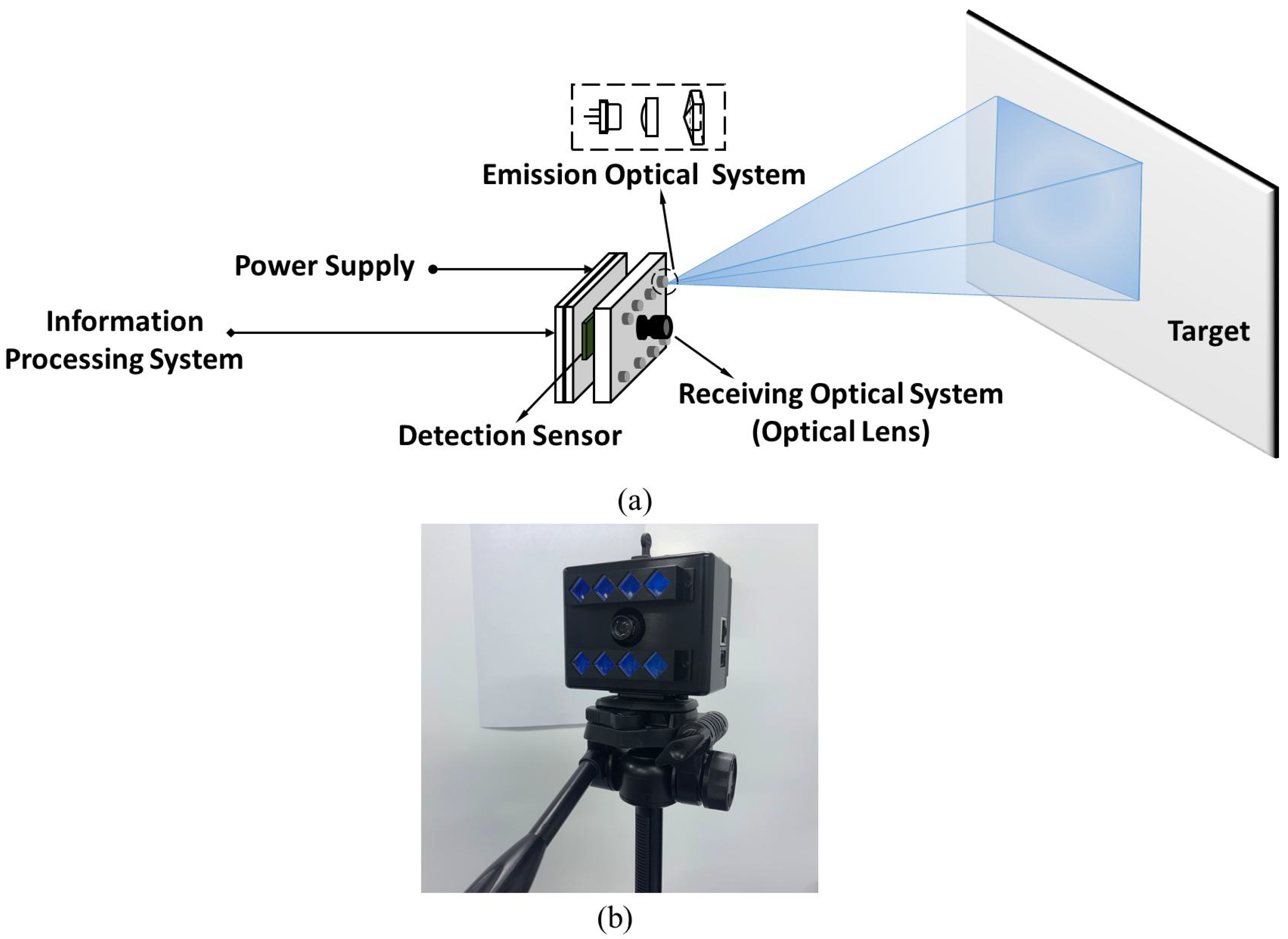

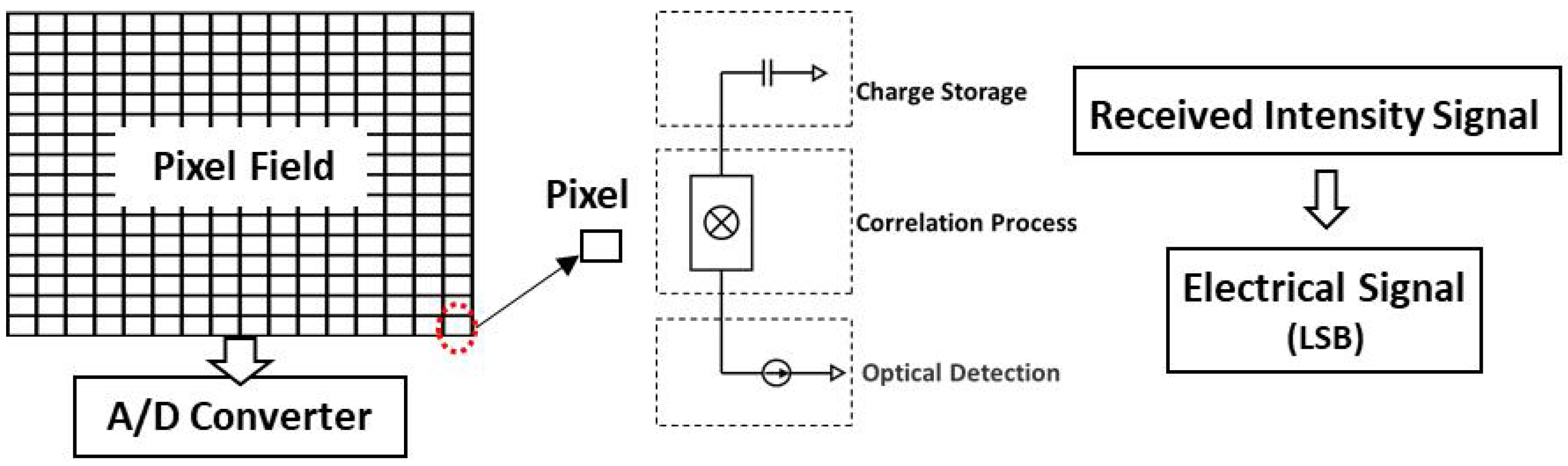

3.1. PA-LiDAR System

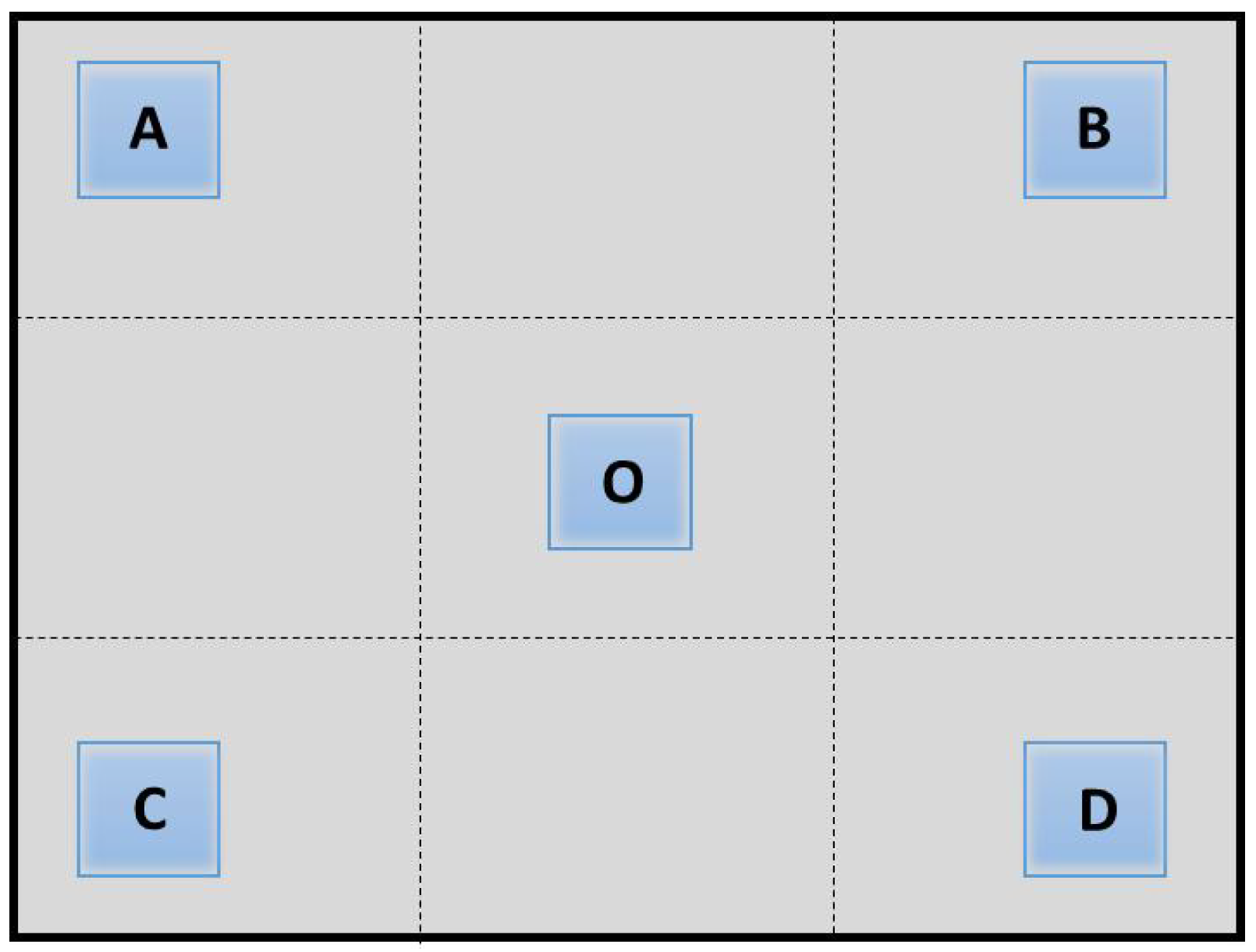

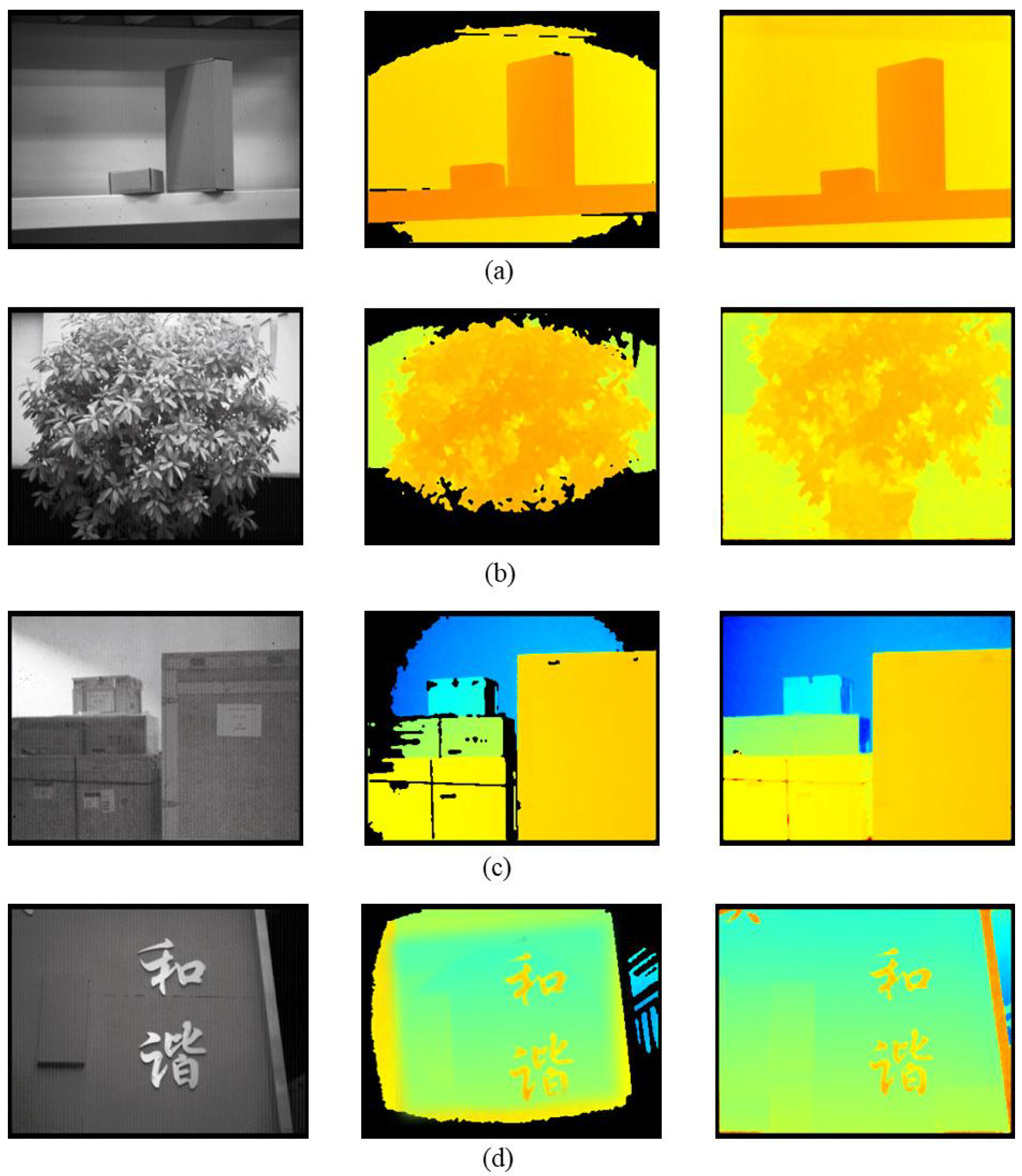

3.2. Experiment and Analysis of Illumination Uniformity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Bi, Y.; Sun, L.; Chen, Y. Method of improving the measurement accuracy of plane array imaging laser radar by pixel cascade. Appl. Opt. 2020, 59, 2541–2550. [Google Scholar] [CrossRef] [PubMed]

- Carmer, D.C.; Peterson, L.M. Laser radar in robotics. Proc. IEEE 1996, 84, 299–320. [Google Scholar] [CrossRef]

- Schwarz, B. Mapping the world in 3D. Nat. Photonics 2010, 4, 429–430. [Google Scholar] [CrossRef]

- Chatterjee, B.; Roy, A.; Banerjee, S.; Paul, P. Development of a low-cost photoelectric scanner system. IETE J. Res. 1980, 26, 195–197. [Google Scholar] [CrossRef]

- Wasenmüller, O.; Ansari, M.D.; Stricker, D. Dna-slam: Dense noise aware slam for tof rgb-d cameras. In Proceedings of the Computer Vision–ACCV 2016 Workshops: ACCV 2016 International Workshops, Taipei, Taiwan, 20–24 November 2016; Revised Selected Papers, Part I 13. Springer: Berlin/Heidelberg, Germany, 2017; pp. 613–629. [Google Scholar]

- Hewitt, R.A.; Marshall, J.A. Towards intensity-augmented SLAM with LiDAR and ToF sensors. In Proceedings of the 2015 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Hamburg, Germany, 28 September–3 October 2015; pp. 1956–1961. [Google Scholar]

- Kawakita, M.; Iizuka, K.; Nakamura, H.; Mizuno, I.; Kurita, T.; Aida, T.; Yamanouchi, Y.; Mitsumine, H.; Fukaya, T.; Kikuchi, H.; et al. High-definition real-time depth-mapping TV camera: HDTV Axi-Vision Camera. Opt. Express 2004, 12, 2781–2794. [Google Scholar] [CrossRef] [PubMed]

- Laurenzis, M.; Christnacher, F.; Monnin, D. Long-range three-dimensional active imaging with superresolution depth mapping. Opt. Lett. 2007, 32, 3146–3148. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yan, H.; Jiang, Y. Pulse-shape-free method for long-range three-dimensional active imaging with high linear accuracy. Opt. Lett. 2008, 33, 1219–1221. [Google Scholar]

- Way, F.C.; Crow, T.A. Beam shaping laser diode array output for optical pumping and illumination. In Proceedings of the 2000 IEEE Aerospace Conference. Proceedings (Cat. No. 00TH8484), Big Sky, MT, USA, 25 March 2000; Volune 3, pp. 61–65. [Google Scholar]

- Cullis, A.; Webber, H.; Bailey, P. A device for laser beam diffusion and homogenisation. J. Phys. E Sci. Instrum. 1979, 12, 688. [Google Scholar] [CrossRef]

- Veldkamp, W. Laser beam profile shaping with interlaced binary diffraction gratings. Appl. Opt. 1982, 21, 3209–3212. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Xuan, L.; Hu, L.; Cao, Z.; Li, D.; Mu, Q.; Lu, X. Investigation on the liquid crystal spatial light modulator with high precision and pure phase. Guangxue Xuebao (Acta Opt. Sin.) 2005, 25, 1682–1686. [Google Scholar]

- Lee, K.H.; Kim, D.; Kim, J.S.; Choi, S.S.; Chung, H.B.; Yoo, H.J.; Kim, B.W. Design of illumination system for ArF excimer laser step-and-scanner. In Proceedings of the Optical Microlithography XI. SPIE, Santa Clara, CA, USA, 29 June 1998; Volune 3334, pp. 997–1004. [Google Scholar]

- Zimmermann, M.; Lindlein, N.; Voelkel, R.; Weible, K.J. Microlens laser beam homogenizer: From theory to application. In Proceedings of the Laser Beam Shaping VIII. SPIE, San Diego, CA, USA, 26–30 August 2007; Volume 6663, pp. 9–21. [Google Scholar]

- Gao, X.; Ohashi, H.; Okamoto, H.; Takasaka, M.; Shinoda, K. Beam-shaping technique for improving the beam quality of a high-power laser-diode stack. Opt. Lett. 2006, 31, 1654–1656. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; An, Y. Coupling light from a laser diode into a multimode fiber. Appl. Opt. 2003, 42, 4427–4430. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; Cao, C.; An, Y. Asymmetrical prism for beam shaping of laser diode stacks. Appl. Opt. 2005, 44, 5408–5414. [Google Scholar] [CrossRef] [PubMed]

- Roth, M.; Heber, J.; Janschek, K. Modulating complex beams in amplitude and phase using fast tilt-micromirror arrays and phase masks. Opt. Lett. 2018, 43, 2860–2863. [Google Scholar] [CrossRef] [PubMed]

- Jia, W.; Wang, Y.; Huang, F.; Ying, Z.; Zhao, C. Application of fly’s eye lens in beam shaping laser diode array. Zhongguo Jiguang (Chin. J. Lasers) 2011, 38, 0202008. [Google Scholar] [CrossRef]

- Qiao, B.; Jiang, P.; Yang, H.; Ma, X.; Xu, M. The elliptical micro-lens array in the application of the LDA beam shaping. Optik 2014, 125, 7149–7153. [Google Scholar] [CrossRef]

- Dickey, F.M. Laser Beam Shaping: Theory and Techniques; CRC Press: Boca Raton, FL, USA, 2017; pp. 281–282. [Google Scholar]

- Ren, Y.X.; Lu, R.D.; Gong, L. Tailoring light with a digital micromirror device. Ann. Der Phys. 2015, 527, 447–470. [Google Scholar] [CrossRef]

- Tsuji, H.; Nakano, T.; Matsumoto, Y.; Kameyama, S. Flattop beam illumination for 3D imaging ladar with simple optical devices in the wide distance range. Opt. Rev. 2016, 23, 155–160. [Google Scholar] [CrossRef]

- Zheng, C.; Li, Q.; Rosengarten, G.; Hawkes, E.; Taylor, R.A. Compact, semi-passive beam steering prism array for solar concentrators. Appl. Opt. 2017, 56, 4158–4167. [Google Scholar] [CrossRef] [PubMed]

- Riccardi, A.; Bindi, N.; Ragazzoni, R.; Esposito, S.; Stefanini, P. Laboratory characterization of a Foucault-like wavefront sensor for adaptive optics. In Proceedings of the Adaptive Optical System Technologies. SPIE, Kona, HI, USA, 23–26 March 1998; Volume 3353, pp. 941–951. [Google Scholar]

| Beam Shaping Method | Descriptions |

|---|---|

| DOE | By means of diffractive optics, the laser beam with Gaussian intensity distribution is shaped into a spot with uniform intensity distribution. The spot shape can be circular, square, rectangular or straight. |

| This method can simply realize the flattop illumination, but the illumination pattern could not propagate like a laser beam. | |

| Binary Diffraction Gratings | It has the characteristics of high diffraction efficiency and adjustable spot profile, and can realize the functions of micro, array, integration and arbitrary wavefront. |

| The flatness of illumination was insufficient since the beam shape was expressed with the quasi-Sinc function and significantly different from a flattop one. | |

| LC-SLM | A real-time, adjustable method can be used to obtain the near-field beam with desired shape (such as square, circular) with flat top intensity distribution. |

| The laser damage threshold is low and the components are expensive. | |

| Fly-eye lens | The fly-eye lens subdivides and expands the non-uniform beam to the entire field of view and superimposes to obtain a uniform illumination area. |

| This kind of method has not been applied to long-distance active lighting, and the edge has a considerable proportion of non-uniform areas. | |

| Optical Fiber | The semiconductor laser is coupled to a multi-mode optical fiber, and the light mixing effect of multiple reflections of the optical fiber is used to obtain light intensity homogenization and mode symmetry at the fiber output end, and then project it to the illumination area through the optical system. |

| The method has high technical difficulty, low coupling efficiency and high coupling cost. | |

| Integrator Rod | Multiple reflections in the integrator rod are used to form the mixed light effect of multiple images overlapping. |

| This kind of method has not been applied to the design of long-distance imaging illumination system. |

| Distance | Non-Shaped Beam | Shaped Beam | ||||

|---|---|---|---|---|---|---|

| (LSB) | (LSB) | K | (LSB) | (LSB) | K | |

| 1.21 m | 629.28 | 1100.45 | 0.57 | 981.32 | 1011.08 | 0.91 |

| 3.75 m | 775.38 | 1384.49 | 0.56 | 1236.15 | 1357.96 | 0.92 |

| 7.79 m | 646.93 | 1457.89 | 0.44 | 1241.82 | 1420.02 | 0.89 |

| 18.71 m | 419.82 | 760.76 | 0.54 | 475.72 | 508.26 | 0.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Wu, B.; Bi, Y.; Gao, W. A Method of Realizing Adaptive Uniform Illumination by Pyramid Prism for PA-LiDAR. Micromachines 2024, 15, 1232. https://doi.org/10.3390/mi15101232

Zhang S, Wu B, Bi Y, Gao W. A Method of Realizing Adaptive Uniform Illumination by Pyramid Prism for PA-LiDAR. Micromachines. 2024; 15(10):1232. https://doi.org/10.3390/mi15101232

Chicago/Turabian StyleZhang, Shuo, Baiyang Wu, Yong Bi, and Weinan Gao. 2024. "A Method of Realizing Adaptive Uniform Illumination by Pyramid Prism for PA-LiDAR" Micromachines 15, no. 10: 1232. https://doi.org/10.3390/mi15101232