A Review of Ku-Band GaN HEMT Power Amplifiers Development

Abstract

1. Introduction

2. Ku-Band GaN HEMT HPA Technology

2.1. GaN HEMT Process

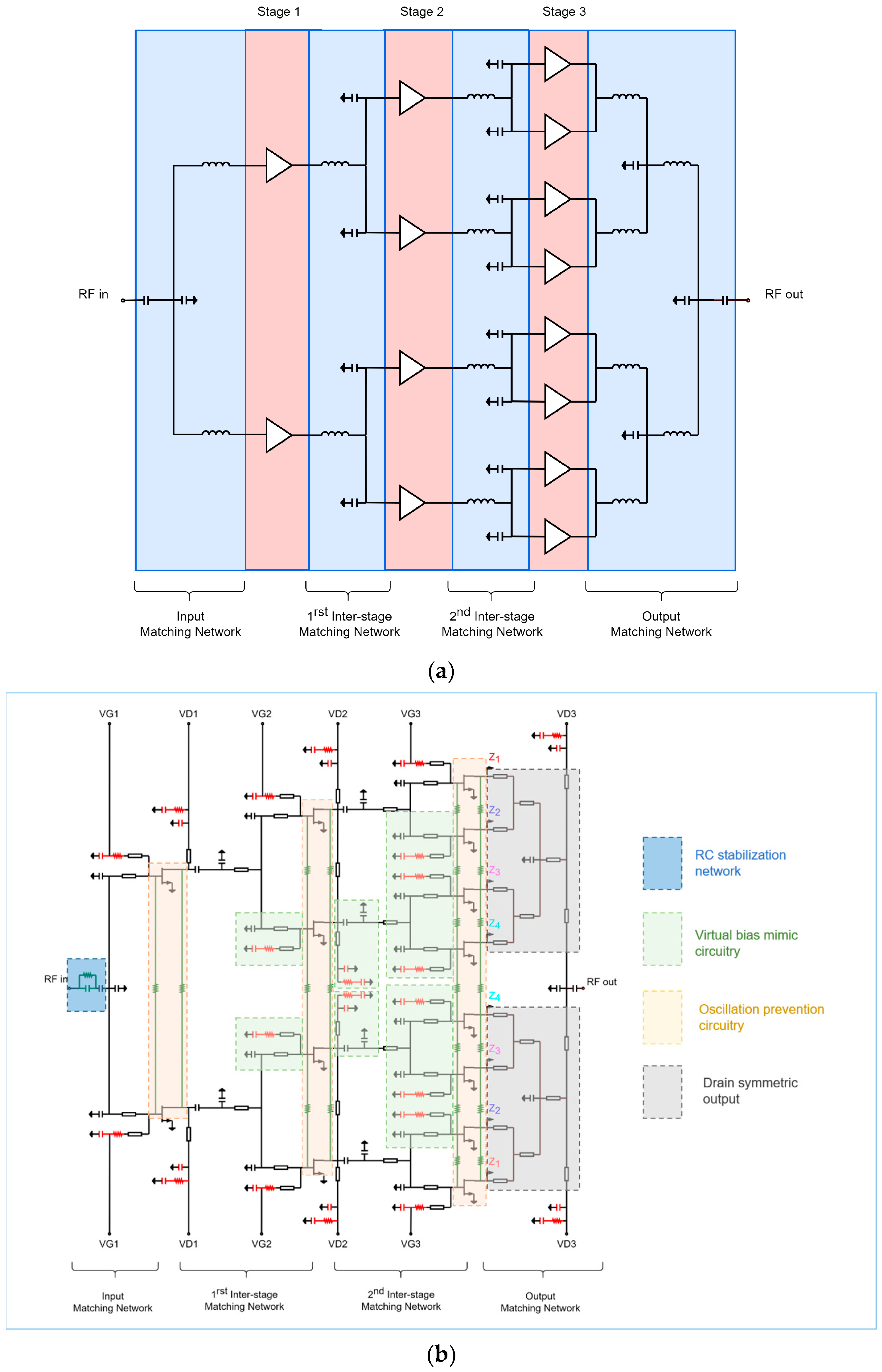

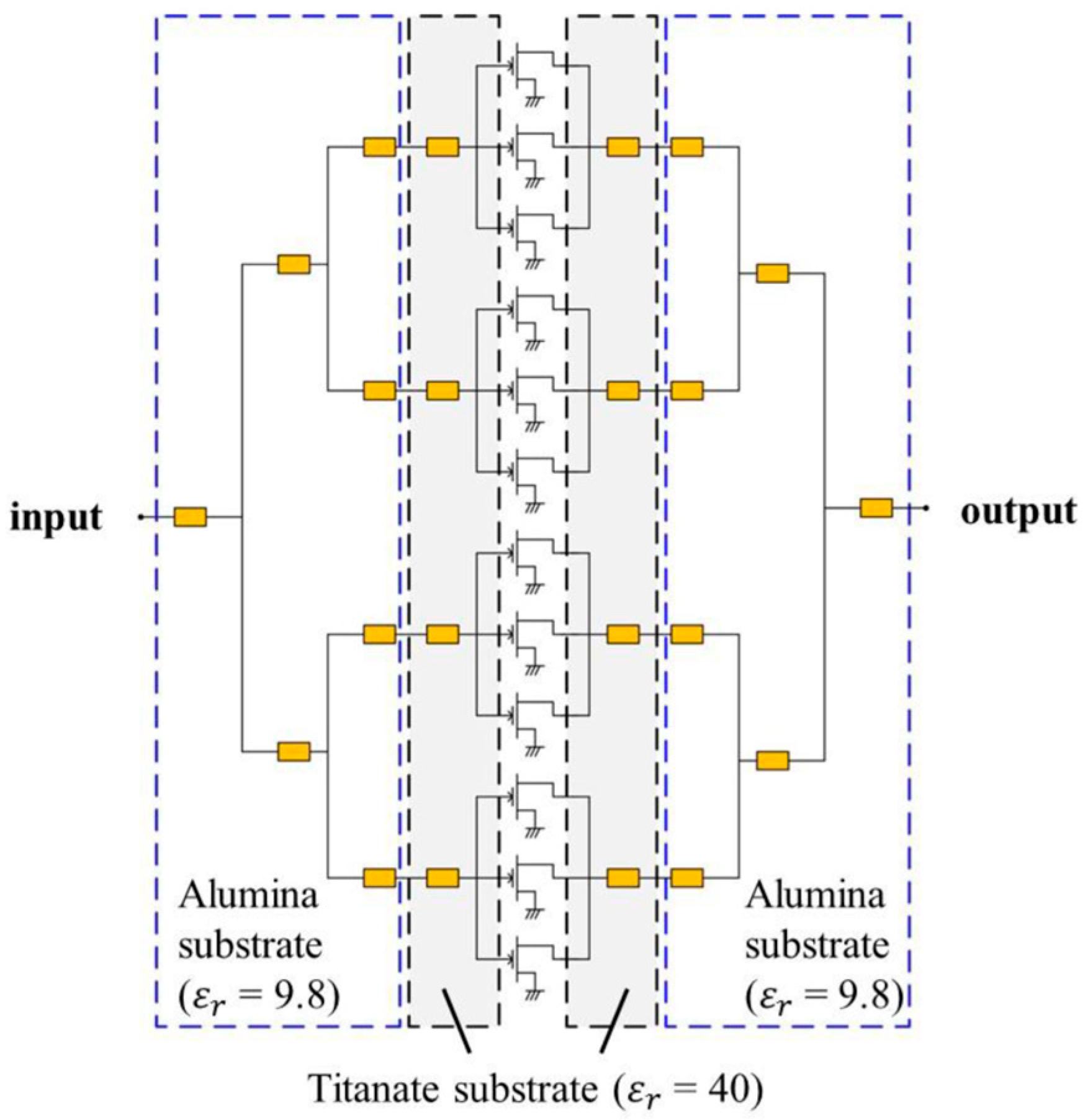

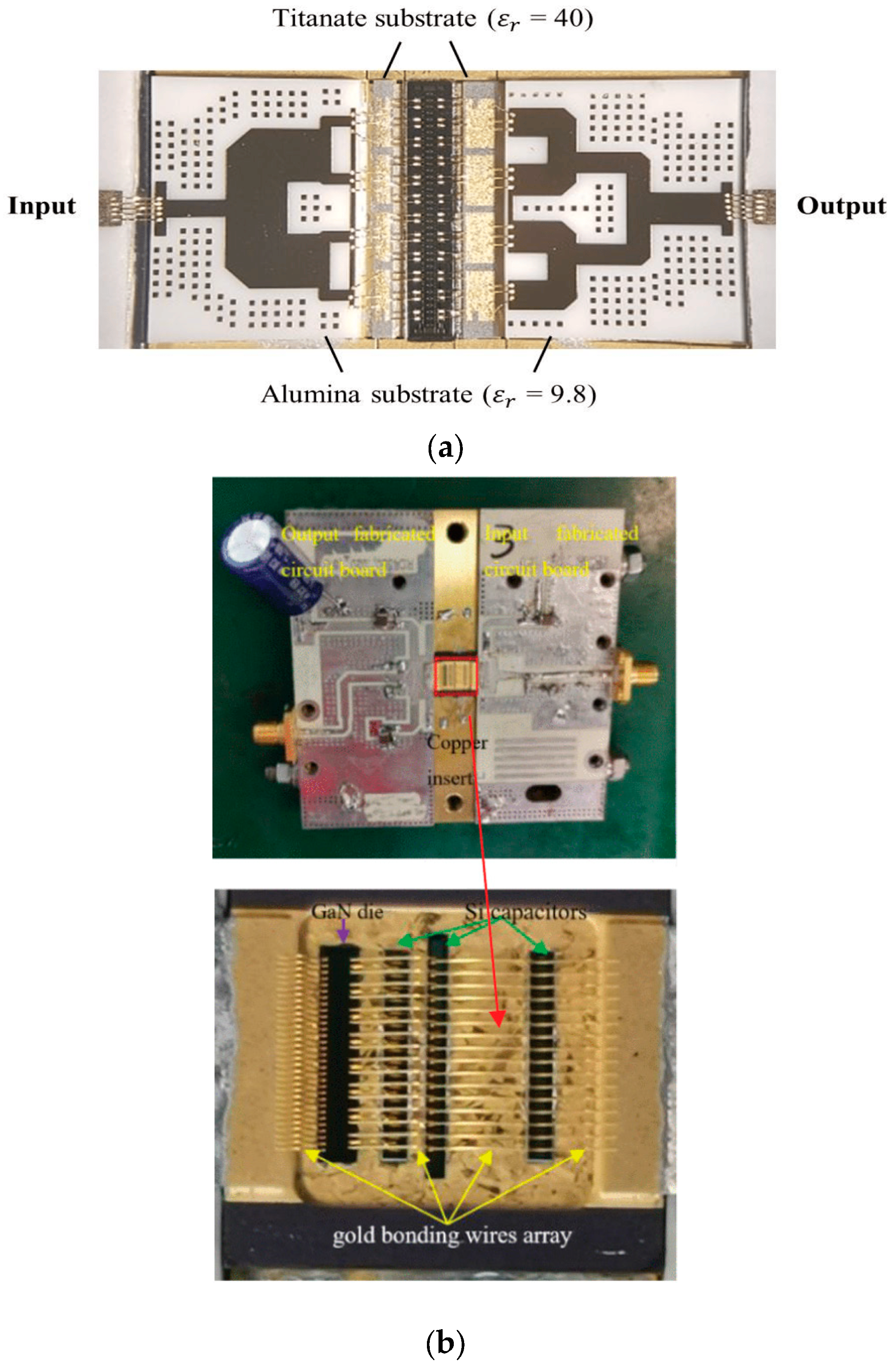

2.2. High Power Amplifier Design

2.3. Other Additional Design Techniques

3. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Nabeel, M.I.; Singh, K.; Afzal, M.U.; Thalakotuna, D.N.; Esselle, K.P. Dual-Band Passive Beam Steering Antenna Technologies for Satellite Communication and Modern Wireless Systems: A Review. Sensors 2024, 24, 6144. [Google Scholar] [CrossRef] [PubMed]

- Viasat. Satellite Communications in 2024: The Ins and Outs. Available online: https://news.viasat.com/blog/corporate/satellite-communications-in-2024-the-ins-and-outs (accessed on 31 July 2024).

- Delépaut, A.; Minetto, A.; Dovis, F. Code-Based Differential GNSS Ranging for Lunar Orbiters: Theoretical Review and Application to the NaviMoon Observables. Remote Sens. 2024, 16, 2755. [Google Scholar] [CrossRef]

- ShareTechnote. Communication Technology. Satellite Communication. Available online: https://www.sharetechnote.com/html/Communication_Satellite.html (accessed on 11 November 2024).

- Huang, C.; Li, Z.; An, H.; Sun, Z.; Wu, J.; Yang, J. Passive multistatic radar imaging of vessel target using GNSS satellites of opportunity. IEEE Trans. Geosci. Remote Sens. 2022, 60, 5116416. [Google Scholar] [CrossRef]

- Kozak, P.; Vrsecka, M. The use of drones in military conflict. In Proceedings of the 2023 International Conference on Military Technologies (ICMT), Brno, Czech Republic, 17–19 May 2023; pp. 1–6. [Google Scholar]

- Zolanvari, M.; Jain, R.; Salman, T. Potential data link candidates for civilian unmanned aircraft systems: A survey. IEEE Commun. Surv. Tutor. 2020, 22, 292–319. [Google Scholar] [CrossRef]

- Mishra, U.K.; Parikh, P.; Wu, Y.-F. AlGaN/GaN HEMTs—An overview of device operation and applications. Proc. IEEE 2002, 90, 1022–1031. [Google Scholar] [CrossRef]

- Shinohara, K.; Regan, D.C.; Tang, Y.; Corrion, A.L.; Brown, D.F.; Wong, J.C.; Robinson, J.F.; Fung, H.H.; Schmitz, A.; Oh, T.C.; et al. Scaling of GaN HEMTs and schottky diodes for submillimeter-wave MMIC applications. IEEE Trans. Electron Devices 2013, 60, 2982–2996. [Google Scholar] [CrossRef]

- Microwave Journal. WIN Semiconductors Releases Next Generation 0.1 μm GaAs pHEMT Technology. Available online: https://www.microwavejournal.com/articles/38436-win-semiconductors-releases-next-generation-01-m-gaas-phemt-technology (accessed on 11 November 2024).

- Dheeravath, R.; Joshi, S.; Kulkarni, S.; Tiwari, A. Model-Based Design for Solid State RF Power Transmitters for OFDM Applications. In Proceedings of the 2024 IEEE Space, Aerospace and Defence Conference (SPACE), Bangalore, India, 22–23 July 2024; pp. 1130–1137. [Google Scholar]

- Giofrè, R.; Cabrìa, L.; Leblanc, R.; López, M.; Vitobello, F.; Colantonio, P. An Efficient and Linear SSPA With Embedded Power Flexibility for Ka-Band Downlink SatCom Applications. IEEE Trans. Microw. Theory Techn. 2024, 72, 563–574. [Google Scholar] [CrossRef]

- Chiu, P.-H.; Tsao, Y.-F.; Hsu, H.-T. The Improvement of Device Linearity in AlGaN/GaN HEMTs at Millimeter-Wave Frequencies Using Dual-Gate Configuration. Results Phys. 2024, 59, 107612. [Google Scholar] [CrossRef]

- Qorvo. GaN Technology at Qorvo. Available online: https://www.qorvo.com/foundry (accessed on 3 October 2024).

- MACOM. GaN Foundry Services. Available online: https://www.macom.com/rfproducts/rf-foundry (accessed on 3 October 2024).

- GCS. GaN/SiC HEMT. Available online: http://www.gcsincorp.com/dedicated_pure_play_wafer_foundry/GaNSiC_HEMT_Technologies.php (accessed on 3 October 2024).

- UMS. Technology for RF and mm-Wave Applications. Available online: https://www.ums-rf.com/restricted-area/foundry/technologies/ (accessed on 3 October 2024).

- Win Semiconductor. Available online: https://www.winfoundry.com (accessed on 11 November 2024).

- Lerude, G. Survey of RF GaN Fabs: Successful Commercialization and Global Supply. Microw. J. 2021, 64, 36–45. [Google Scholar]

- Nikandish, R. GaN Integrated Circuit Power Amplifiers: Developments and Prospects. IEEE J. Microw. 2023, 3, 441–452. [Google Scholar] [CrossRef]

- Kim, Y.; Kwon, Y. Analysis and design of millimeter-wave power amplifier using stacked-FET structure. IEEE Trans. Microw. Theory Tech. 2015, 63, 691–702. [Google Scholar] [CrossRef]

- El-Aassar, O.; Rebeiz, G.M. Compact pMOS stacked-SOI distributed power amplifier with over 100-GHz bandwidth and up to 22-dBm saturated output power. IEEE J. Solid-State Circuits Lett. 2019, 2, 9–12. [Google Scholar] [CrossRef]

- Kanaya, K.; Sato, K.; Koyanagi, M.; Koyama, H.; Tsujioka, K.; Ohta, A. A Ku-band 20 W GaN-MMIC amplifier with built-in linearizer. In Proceedings of the 2014 IEEE MTT-S International Microwave Symposium (IMS 2014), Tampa, FL, USA, 1–6 June 2014; pp. 1–4. [Google Scholar]

- Qorvo. TGA2239 Data Sheet. Available online: https://www.qorvo.com/products/p/TGA2239 (accessed on 4 October 2024).

- Zhang, J.; Nie, L.; Chen, Y.; Ren, J.; Ma, S. A 6.5-mm² 10.5–to-15.5–GHz Differential GaN PA With Coupled-Line-Based Matching Networks Achieving 10-W Peak Psat and 42% PAE. IEEE Trans. Circuits Syst. II Express Briefs 2022, 69, 4268–4272. [Google Scholar]

- Gedela, S.K.; N’Gongo, S.; Bantupalli, K.; Suman, K. Ku-Band 25 W High Power Amplifier Using 0.25 µm GaN Technology. In Proceedings of the 2020 15th European Microwave Integrated Circuits Conference (EuMIC), Utrecht, The Netherlands, 11–12 January 2021; pp. 269–272. [Google Scholar]

- Imran, M.; Gupta, P.; Reeta; Mishra, M. GaN HEMT Based Ku-Band Power Amplifier MMIC. In Proceedings of the 2022 IEEE Microwaves, Antennas, and Propagation Conference (MAPCON), Bangalore, India, 12–16 December 2022; pp. 792–795. [Google Scholar]

- MACOM. CMPA1C1D060D: 10 W, 6–18 GHz GaN Power Amplifier. Available online: https://www.macom.com/products/product-detail/CMPA1C1D060D (accessed on 14 November 2024).

- Zhang, J.; Yan, X.; Luo, H.; Guo, Y. High Efficiency Ku-Band 13 W GaN HEMT HPA. In Proceedings of the 2022 IEEE MTT-S International Wireless Symposium (IWS), Harbin, China, 12–15 August 2022; pp. 1–3. [Google Scholar]

- Liu, Y.; Xiao, Z.; Zhu, S.; Wanq, H.; Mao, S.; Wu, Q.; Xu, R.; Yan, B.; Xu, Y. A Broadband 20W GaN High Power Amplifier for Ku-band Satellite Communication. In Proceedings of the 2022 IEEE International Conference on Integrated Circuits, Technologies and Applications (ICTA), Xi’an, China, 28–30 October 2022; pp. 94–95. [Google Scholar]

- Jin, H.; Yang, F.; Tao, H.; Xiao, W.; Zhou, Y.; Cai, L. A Ku-Band 100-W High-Power Amplifier MMIC Using 0.2-µm GaN Technology. IEEE Microw. Wirel. Technol. Lett. 2024, 34, 80–83. [Google Scholar] [CrossRef]

- Sim, T.; Lee, S.; Lee, D.; Choe, W.; Kim, M.; Kim, S.; Lee, Y.; Na, K.; Kim, J. A Ku-band High Gain 40 W GaN HPA MMIC for Satellite Systems in a 0.25-μm GaN Technology. In Proceedings of the 2024 IEEE Topical Conference on RF/Microwave Power Amplifiers for Radio and Wireless Applications (PAWR), San Antonio, TX, USA, 21–24 January 2024; pp. 31–34. [Google Scholar]

- del Pino, J.; Khemchandani, S.L.; Mayor-Duarte, D.; San-Miguel-Montesdeoca, M.; Mateos-Angulo, S.; de Arriba, F.; García, M. A Ku-Band GaN-on-Si MMIC Power Amplifier with an Asymmetrical Output Combiner. Sensors 2023, 23, 6377. [Google Scholar] [CrossRef]

- Duan, H.; Zhang, Z.; Gao, Y.; Zhang, J.; Wang, H. A 10 W, 35 % Power Added Efficiency 6 to 18 GHz GaN Power Amplifier. In Proceedings of the 2022 European Microwave Conference (EuMC), London, UK, 24–26 September 2022; pp. 1–4. [Google Scholar]

- Colantonio, P.; Lopez, M.; Cabria, L.; Vitobello, F.; Giofrè, R. 10 W High Efficiency GaN-Si MMIC Power Amplifier for 17.3–20.2 GHz Onboard Satellite Use. In Proceedings of the 2022 IEEE/MTT-S International Microwave Symposium (IMS), Denver, CO, USA, 19–24 June 2022; pp. 775–777. [Google Scholar]

- Zhu, S.; Liu, Y.; Xiao, Z.; Huang, L.; Wu, Q.; Mao, S.; Wang, H.; Xu, Y. A Ku-Band 40W GaN Power Amplifier MMIC for Satellite Communication. In Proceedings of the 2022 IEEE MTT-S International Microwave Workshop Series on Advanced Materials and Processes for RF and THz Applications (IMWS-AMP), Guangzhou, China, 27–29 November 2022; pp. 1–3. [Google Scholar]

- Brown, R. RF/Microwave Hybrids: Basics, Materials and Processes; Springer: New York, NY, USA, 2003. [Google Scholar]

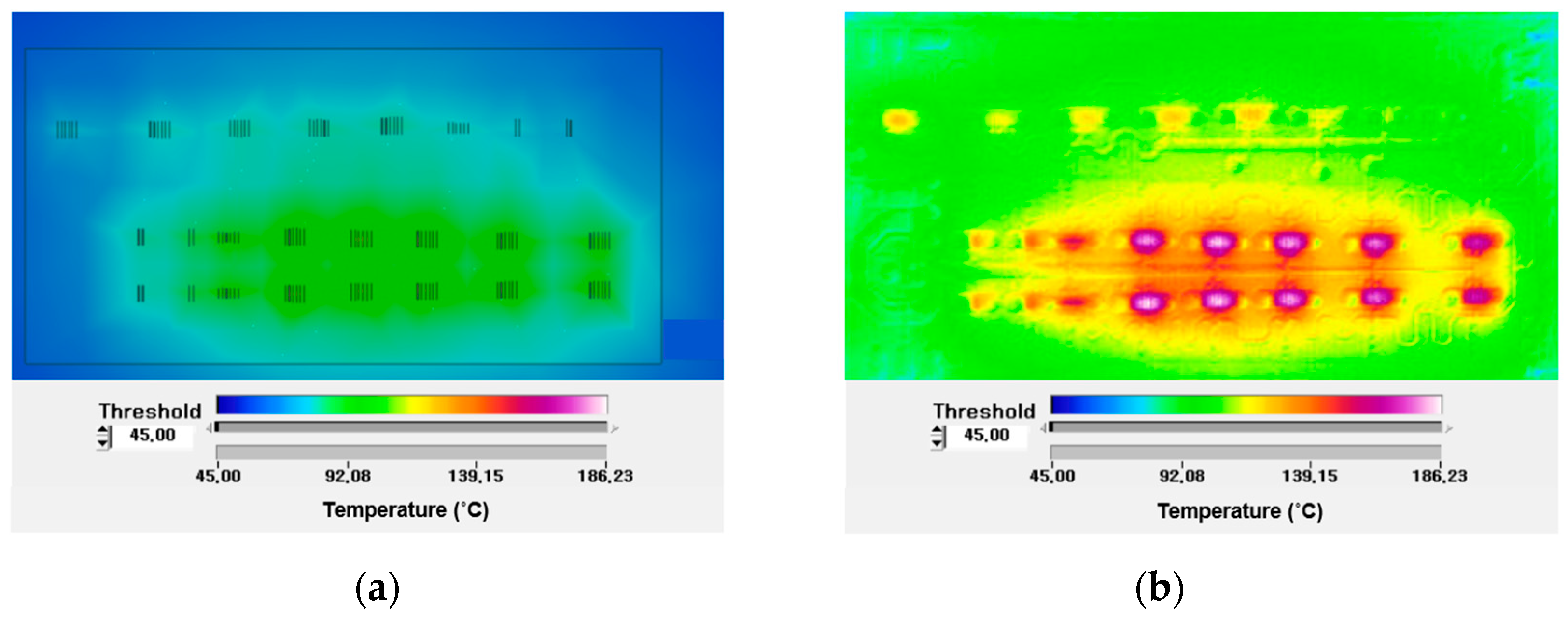

- Xie, H.; Du, S.; Pu, B.; Hu, J.; Zhang, Y.; Qi, W.; Liu, H.; Zhang, S.; Xiao, D. Electrothermal Responses of Bonding Wire Arrays in GaN Power Amplifier. IEEE Access 2023, 11, 57556–57563. [Google Scholar] [CrossRef]

- Sumitomo Electric Device Innovations. SGK1314-60A. GaN HEMT for Ku-Band. Sumitomo Electric. Available online: https://www.sedi.co.jp/data.jsp?version=en&database=wireless&id=6683&class=01010100 (accessed on 4 October 2024).

- Toshiba Global. Defense & Electronic Systems. Microwave Semiconductor GaN HEMTsTGI1314-50LA. Available online: https://www.global.toshiba/content/dam/toshiba/ww/products-solutions/defense/microwave-semiconductor/gan-hemt/pdf/tgi1213-50la_1_20220510_no1358.pdf (accessed on 14 November 2024).

- Yoshioka, T.; Harauchi, K.; Sugitani, T.; Maehara, H.; Yamasaki, T.; Ichinohe, H.; Miyashita, M.; Yamamoto, K.; Goto, S. Ku-Band 70-/30-W-Class Internally Matched GaN Power Amplifiers With Low IMD3 Over a Wide Offset Frequency Range of Up To 400 MHz. IEEE J. Solid-State Circuits 2021, 56, 2635–2646. [Google Scholar] [CrossRef]

- Maassen, D.; Rautschke, F.; Ohnimus, F.; Schenk, L.; Dalisda, U.; Boeck, G. 70 W GaN-HEMT Ku-Band Power Amplifier in MIC Technology. IEEE Trans. Microwave Theory Tech. 2017, 65, 1272–1283. [Google Scholar] [CrossRef]

- Kim, S.; Lee, M.-P.; Hong, S.-J.; Kim, D.-W. Ku-Band 50 W GaN HEMT Power Amplifier Using Asymmetric Power Combining of Transistor Cells. Micromachines 2018, 9, 619. [Google Scholar] [CrossRef]

- Park, Y.; Jeong, J.Y.; Kang, W.; Park, M.; Kim, D. A Ku-band Internally Matched 50W GaN HEMT Power Amplifier Using Advanced Cu-Mo-Cu Heat Sink. In Proceedings of the 2022 IEEE/MTT-S International Microwave Symposium (IMS), Washington, DC, USA, 16–21 June 2024. [Google Scholar]

- Torii, T.; Imai, S.; Maehara, H.; Miyashita, M.; Kunii, T.; Morimoto, T.; Inoue, A.; Ohta, A.; Katayama, H.; Yunoue, N.; et al. 60% PAE, 30W X-band and 33% PAE, 100W Ku-band PAs Utilizing 0.15 μm GaN HEMT Technology. In Proceedings of the 2016 46th European Microwave Conference (EuMC), London, UK, 3–7 October 2016; pp. 568–571. [Google Scholar]

- Imai, S.; Maehara, H.; Koyanagi, M.; Ohtsuka, H.; Ohta, A.; Yamanaka, K.; Inoue, A.; Fukumoto, H. An 80-W Packaged GaN High Power Amplifier for CW Operation in the 13.75–14.5 GHz Band. In Proceedings of the 2014 IEEE MTT-S International Microwave Symposium (IMS 2014), Tampa, FL, USA, 1–6 June 2014; pp. 1–4. [Google Scholar]

- Nagasaka, M.; Kojima, M.; Torii, T.; Utsumi, H.; Yamanaka, K.; Shinjo, S.; Shimozawa, M.; Sujikai, H. 120-W Ku-Band GaN SSPA with Diode Linearizer for Future Broadcasting Satellite. In Proceedings of the 2018 Asia-Pacific Microwave Conference (APMC), Kyoto, Japan, 6–9 November 2018; pp. 548–550. [Google Scholar]

- Kim, J.; Han, S.; Kim, B.-B.; Lee, M.-K.; Lee, B.-H. Millimeter-Wave GaN High-Power Amplifier MMIC Design Guideline Considering a Source via Effect. Electronics 2024, 13, 2616. [Google Scholar] [CrossRef]

- Nam, H.; Kim, J.; Jeon, J.; Jhon, H.; Kim, J. High-Performance RF Power Amplifier Module Using Optimum Chip-Level Packaging Structure. IEEE Trans. Ind. Electron. 2022, 69, 5660–5668. [Google Scholar] [CrossRef]

- Quaglia, R.; Camarchia, V.; Moreno Rubio, J.J.; Pirola, M.; Ghione, G. A 4-W Doherty Power Amplifier in GaN MMIC Technology for 15-GHz Applications. IEEE Microw. Wirel. Compon. Lett. 2017, 27, 365–367. [Google Scholar] [CrossRef]

| Property | Si | GaAs | SiC | GaN |

|---|---|---|---|---|

| Energy Bandgap (eV) | 1.11 | 1.43 | 3.2 | 3.4 |

| Critical Electric Field (MV/cm) | 0.3 | 0.5 | 3.0 | 3.5 |

| Charge Density (×1013/cm2) | 0.3 | 0.3 | 0.4 | 1 |

| Mobility (cm2/V/s) | 1350 | 8000 | 900 | 1500 |

| Saturation Velocity (×107 cm/V) | 1 | 1.4 | 2 | 2.7 |

| Foundry | VDD (V) | Substrate | Breakdown Voltage (V) | fT (GHz) | Pout @10 GHz (W/mm) | PAE @10 GHz (%) |

|---|---|---|---|---|---|---|

| Qorvo | 40 | SiC | 75 | 32 | 6 | >60 |

| MACOM (Wolfspeed) | 28/40 | SiC | >84 | − | 4.2/6.6 | >55 |

| GCS | 28/48 | SiC/Si | 200 | 23 | 4 1/10.8 | 45 1/65 |

| UMS | 30 | SiC | >120 | 25 | 4.5 2 | − |

| WIN semi | 28/40 | SiC | 120 | 23 | 5/10 | 65/60 |

| NXP | 50 | SiC | >150 | − | − | − |

| Foundry | VDD (V) | Substrate | Breakdown Voltage (V) | fT (GHz) | Pout @30 GHz (W/mm) | PAE @30 GHz (%) |

|---|---|---|---|---|---|---|

| Qorvo | 28 | SiC | 50 | 90 | 4.2 | >50 |

| MACOM (Wolfspeed) | 28 | SiC | 84 | − | 3.75 | >40 |

| GCS | 28 | SiC | 100 | 42 | 3 | 55 |

| UMS | 20–25 | SiC | >80 | − | 4.2 2 | 36 3 |

| WIN semi | 28 | SiC | 120 | 35 | 5 | 50 |

| NXP | 20–28 | SiC | >100 | − | − | − |

| MACOM/France (formerly OMMIC) 1 | 12 | Si | >50 | 150 | 4 2 | 48 2 |

| Reference | Gate Length (μm) | Substrate | VDD (V) | Pout (W) | PAE (%) |

|---|---|---|---|---|---|

| [23] | 0.25 | − | 24 | 20 | 16 |

| [24] | 0.15 | SiC | 28 | 47.5 | 36.2 |

| [25] | 0.25 | SiC | 25 | 7.2–9.5 | 35 |

| [26] | 0.25 | − | 30 | 25 | 26–30 |

| [27] | 0.15 | SiC | 25 | 7.9 | 35 |

| [28] | 0.25 | SiC | 40 | 63 | 30 |

| [29] | 0.15 | SiC | 28 | 8.3–13.2 | 35.7–45.4 |

| [30] | 0.15 | SiC | 28 | 16–25 | 30–40 1 |

| [31] | 0.20 | SiC | 28 | 79–93 | 28.7–31.5 |

| [32] | 0.25 | SiC | 28 | 40 | 17 |

| [33] | 0.1 | Si | 11 | 8.9 | 27 |

| [34] | 0.1 | Si | 12 | 8.9–15.8 | 30–41 1 |

| [35] | 0.1 | Si | 9 | 10 | 35 |

| [36] | 0.15 | − | 28 | 40–50 | 36 |

| Reference | BW (GHz) | Output Power (W) | # of GaN HEMTs in the Final Stage | Total Gate Width (mm) | # of Stages |

|---|---|---|---|---|---|

| [23] | 13.75–14.5 | 20 | 8 | 9.6 | 3 |

| [26] | 13–18 | 25 | 8 | 8.64 | 3 |

| [28] | 12.7–13.25 | 63 | 16 | − | 3 |

| [30] | 13–17 | 16–25 | 8 | 7.68 | 3 |

| [31] | 14–18 | 79–93 | 16 | 10.88 | 3 |

| [32] | 15.25–16.25 | 40 | 16 | 25.6 | 4 |

| [36] | 13–15.5 | 40–50 | 16 | 15.36 | 3 |

| Reference | Gate Length (μm) | Substrate | VDD (V) | Pout (W) | PAE (%) |

|---|---|---|---|---|---|

| [39] | − | − | 24 | 63 | 32 |

| [40] | − | − | 24 | 50 | 29 |

| [41] | 0.25 | SiC | 24 | 63 | 25 |

| [42] | 0.25 | SiC | 40 | 50 | 23 |

| [43] | 0.25 | SiC | 40 | 57–66 | − |

| [44] | 0.25 | SiC | 50 | 50 | − |

| [45] | 0.15 | − | 24 | 100 | 32 1 |

| [46] | − | − | 24 | 80 | 23–28 1 |

| [47] | 0.15 | − | 30 | 120 | 31 |

| Reference | BW (GHz) | Pout (W) | # of GaN HEMTs in the Final Stage | Total Gate Width (mm) | # of Stages |

|---|---|---|---|---|---|

| [41] 1 | 13.75–14.5 | 63 | 24 | 28.8 | 1 |

| [42] | 13.75–14.5 | 50 | 12 | 14.4 | 2 |

| [43] 2 | 16.2–16.8 | 57–66 | 12 | 14.4 | 1 |

| [44] 2 | 12.4–13.8 | 50 | 12 | 14.4 | 1 |

| [45] 1 | − | 100 | 48 | 28.8 | 1 |

| [46] 1 | 13.75–14.5 | 80 | 48 | − | 1 |

| [47] 1 | 11.7–12.2 | 120 | 64 | 30.72 3 | 1 |

| Composition | Thermal Conductivity (W/mK) |

|---|---|

| PbIn | 17 |

| AuGe | 44 |

| SnPb | 50 |

| AuSn | 57 |

| SnAg | 78 |

| Ag Sintering Epoxy | 100 |

| Composition | Thermal Conductivity (W/mK) |

|---|---|

| Mo | 140 |

| W | 170 |

| Al | 230 |

| Cu | 400 |

| CMC 1 | 270–320 |

| CVD Diamond | 1000–1800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J. A Review of Ku-Band GaN HEMT Power Amplifiers Development. Micromachines 2024, 15, 1381. https://doi.org/10.3390/mi15111381

Kim J. A Review of Ku-Band GaN HEMT Power Amplifiers Development. Micromachines. 2024; 15(11):1381. https://doi.org/10.3390/mi15111381

Chicago/Turabian StyleKim, Jihoon. 2024. "A Review of Ku-Band GaN HEMT Power Amplifiers Development" Micromachines 15, no. 11: 1381. https://doi.org/10.3390/mi15111381

APA StyleKim, J. (2024). A Review of Ku-Band GaN HEMT Power Amplifiers Development. Micromachines, 15(11), 1381. https://doi.org/10.3390/mi15111381