Effect of Ga Doping on the Stability and Optoelectronic Properties of ZnSnO Thin Film Transistor

Abstract

1. Introduction

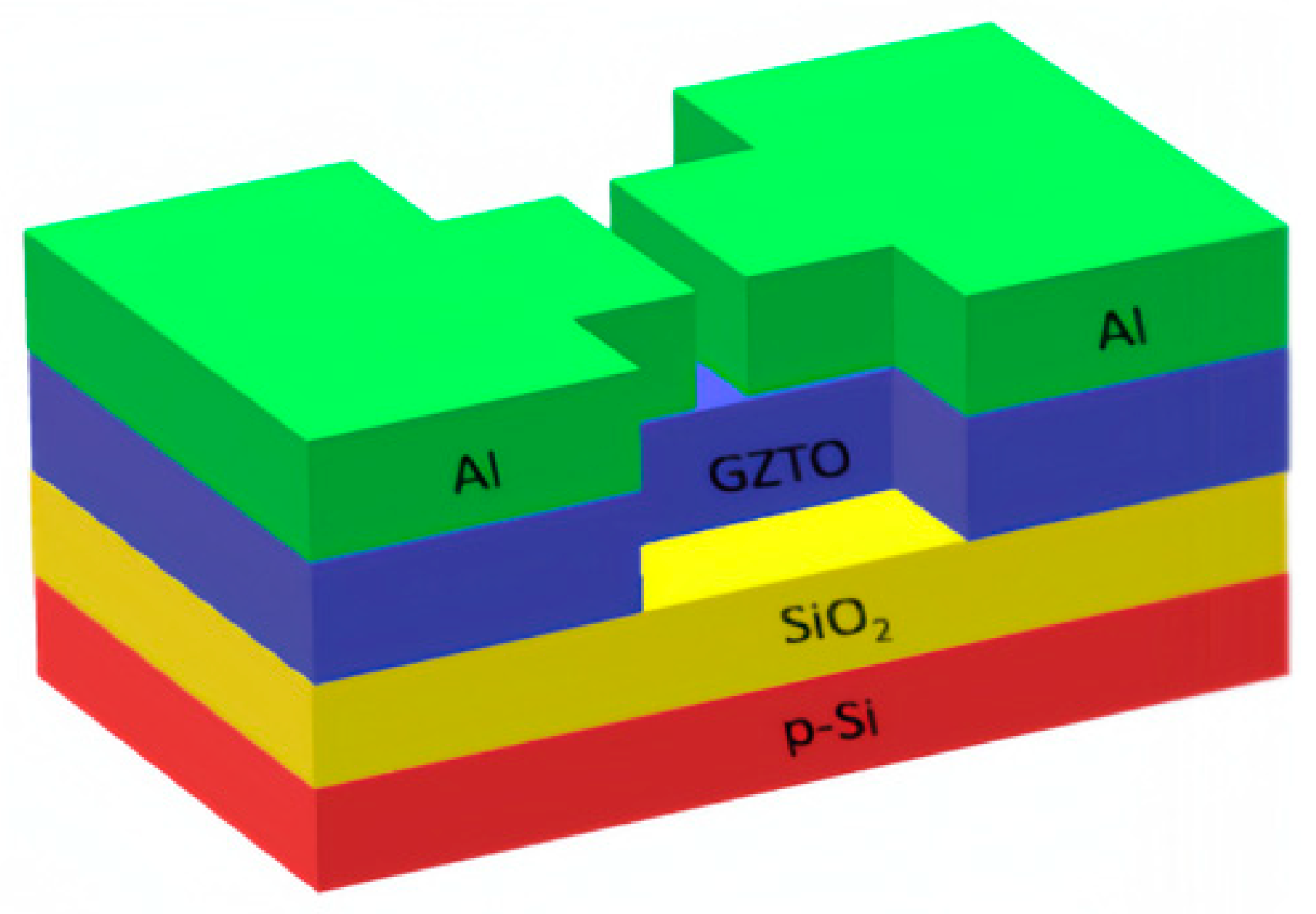

2. Experimental

3. Results and Discussion

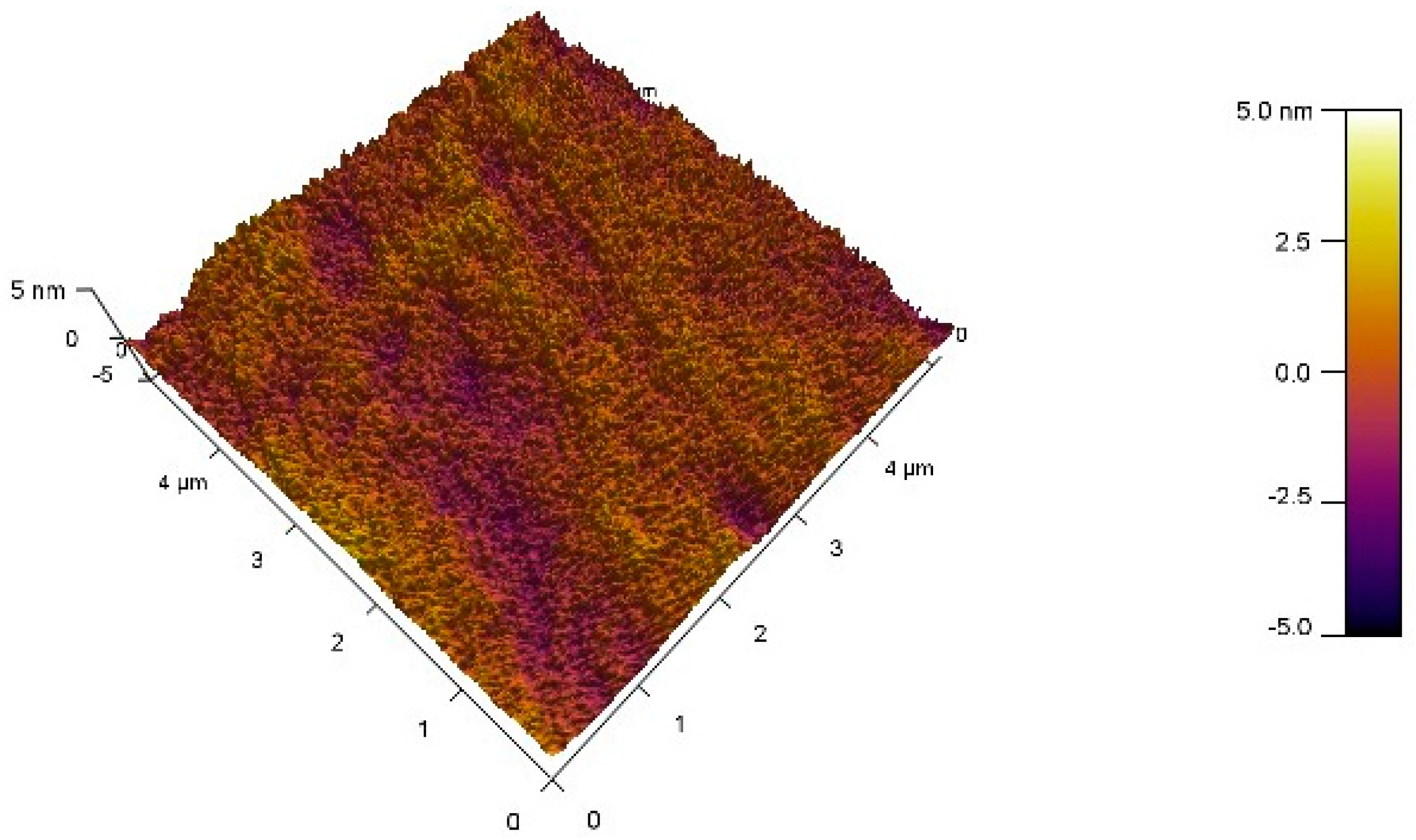

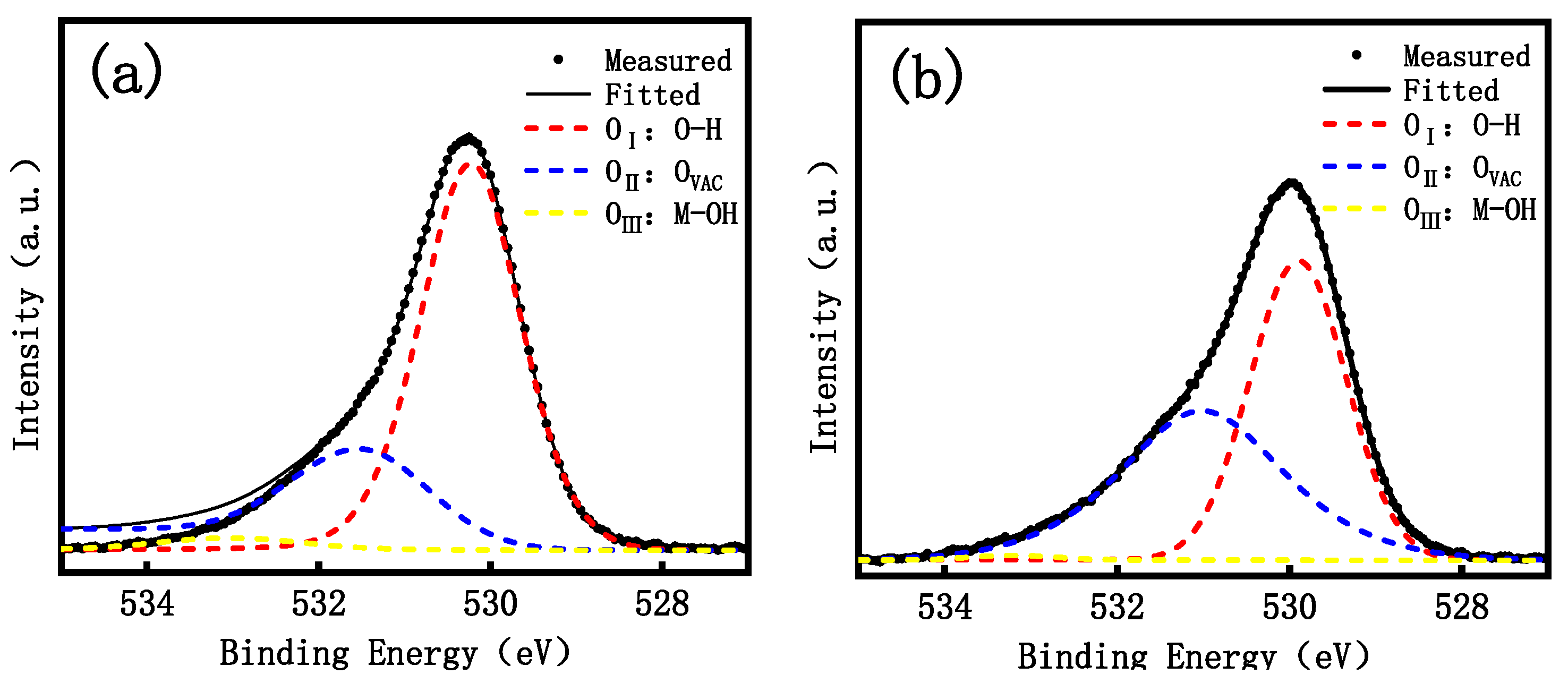

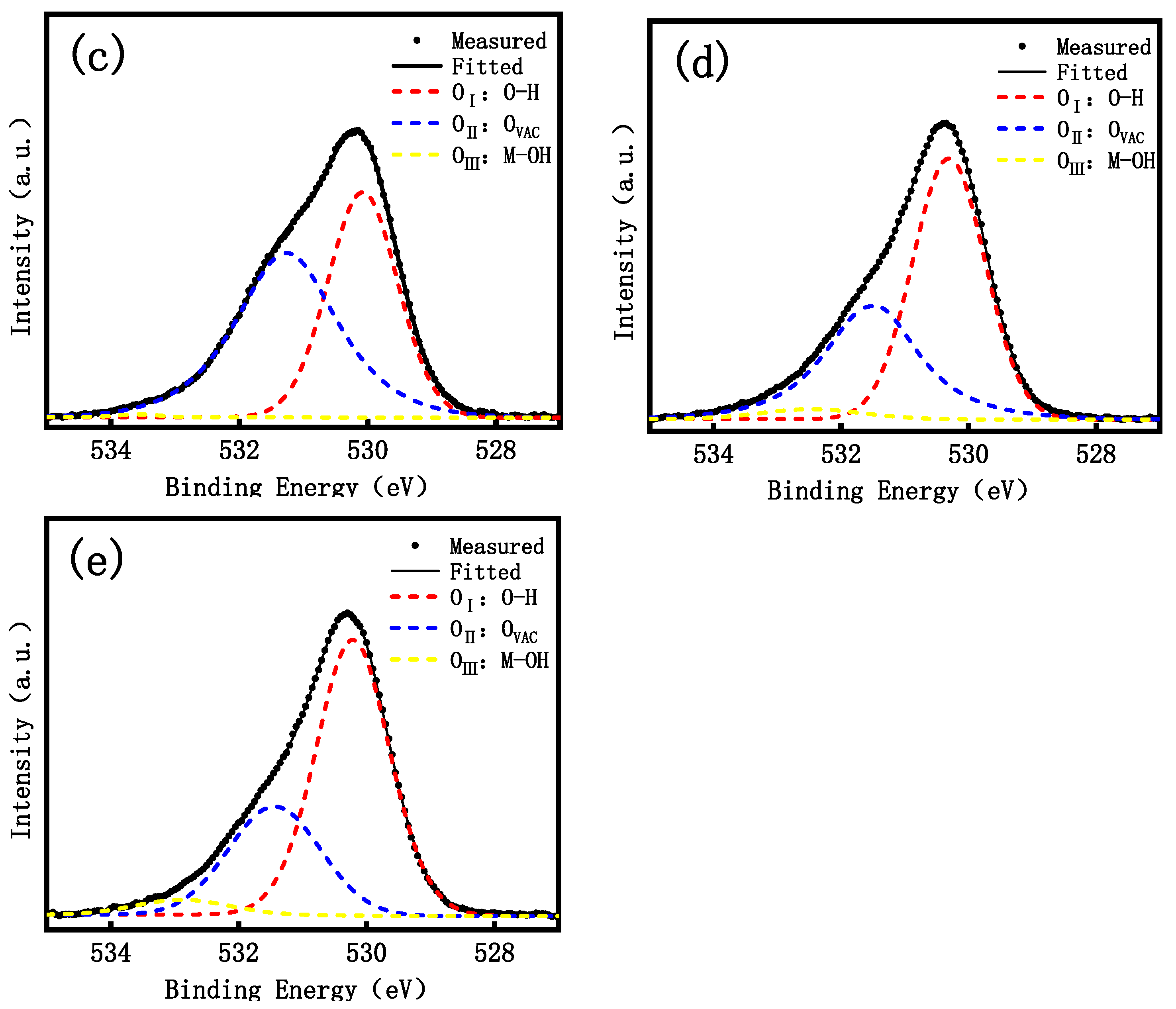

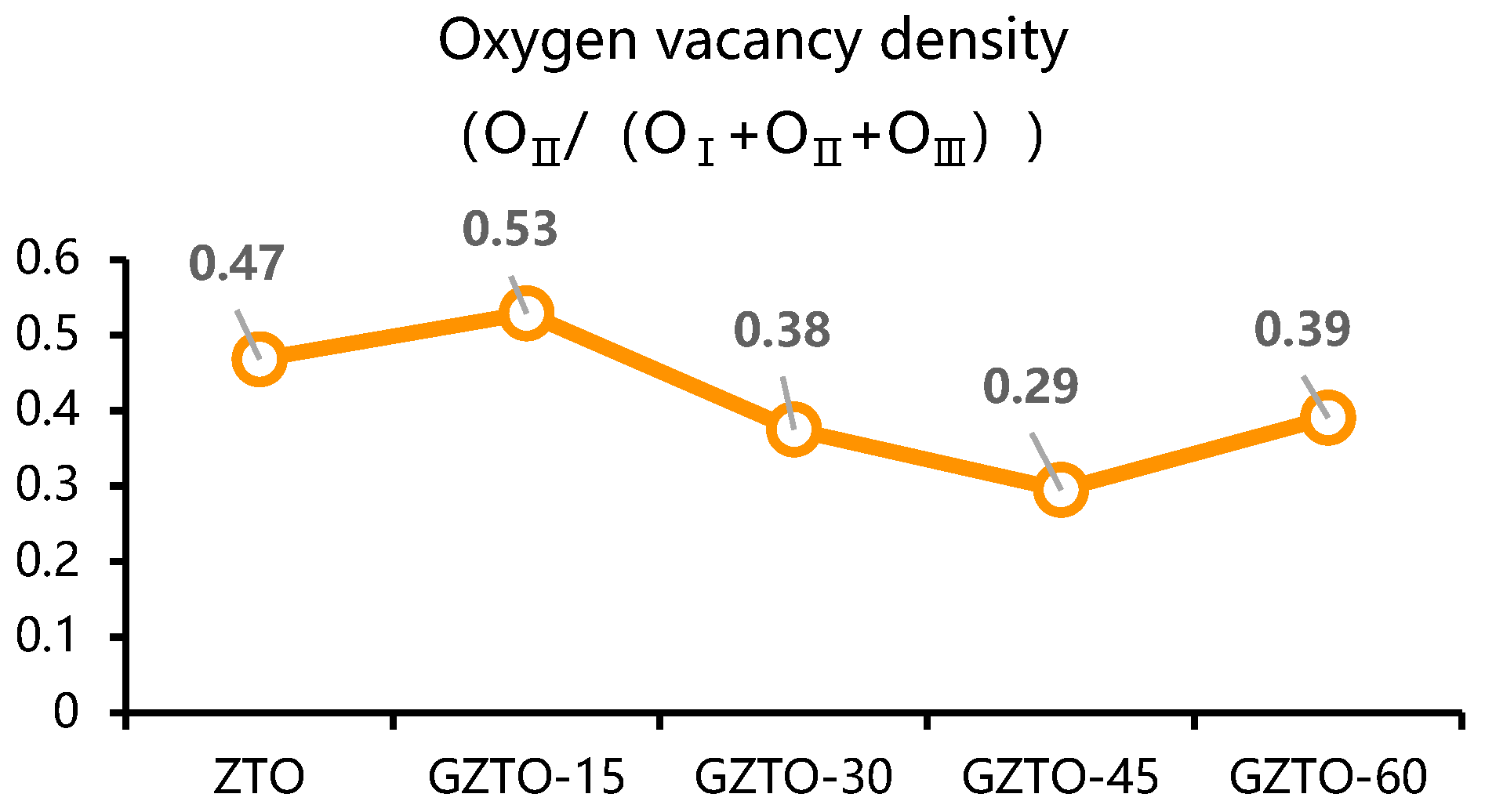

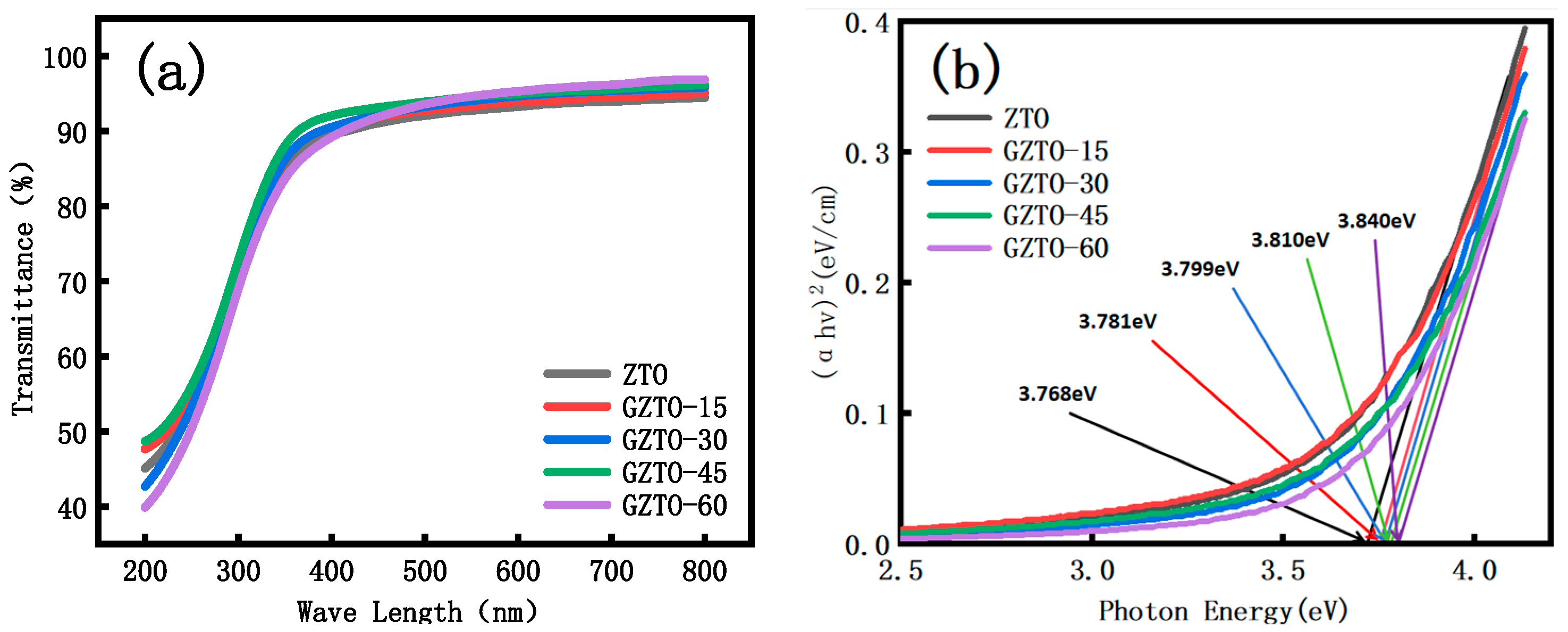

3.1. Thin Film Properties

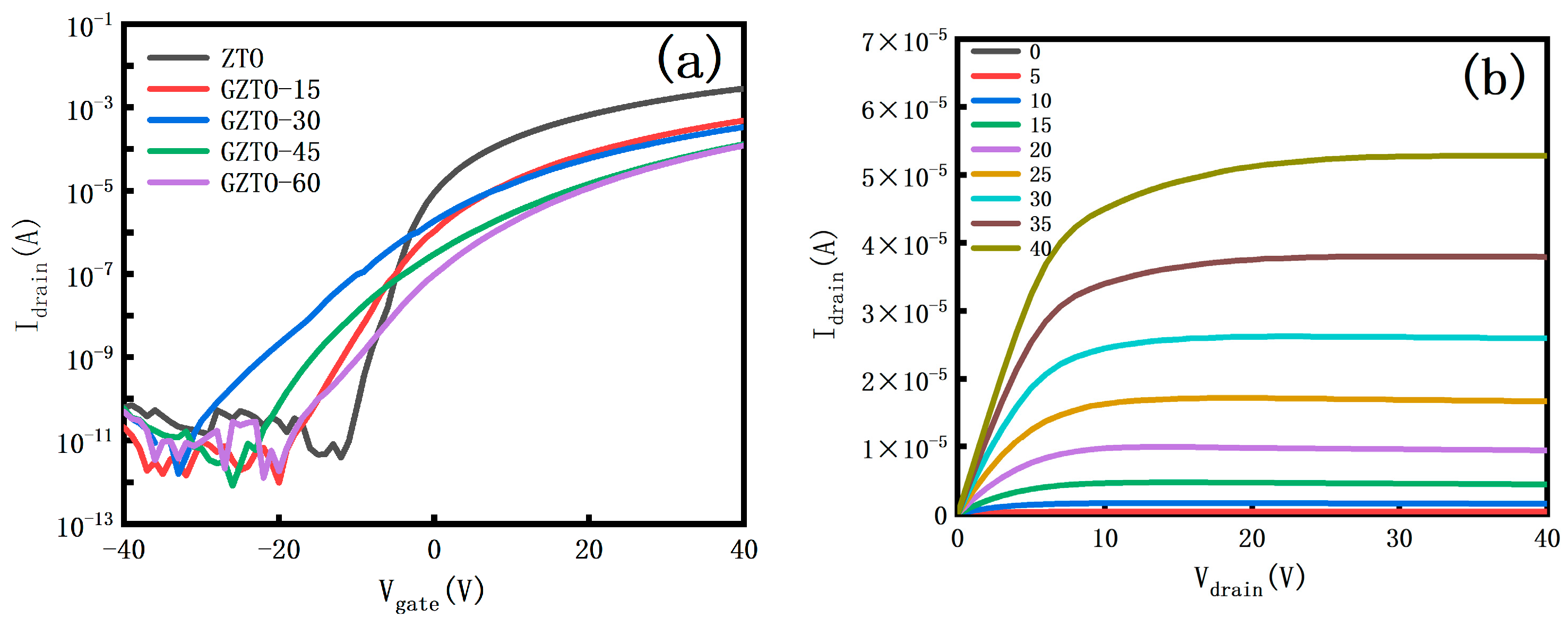

3.2. Electrical Performance

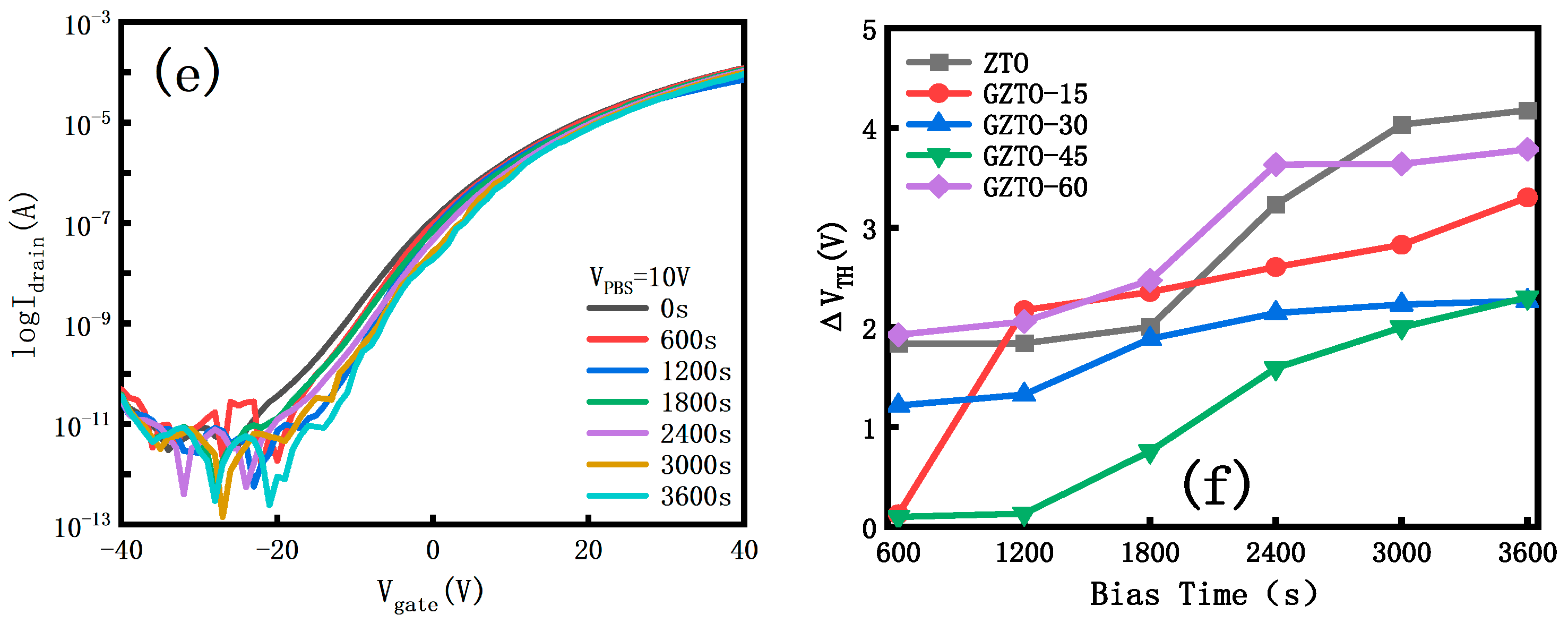

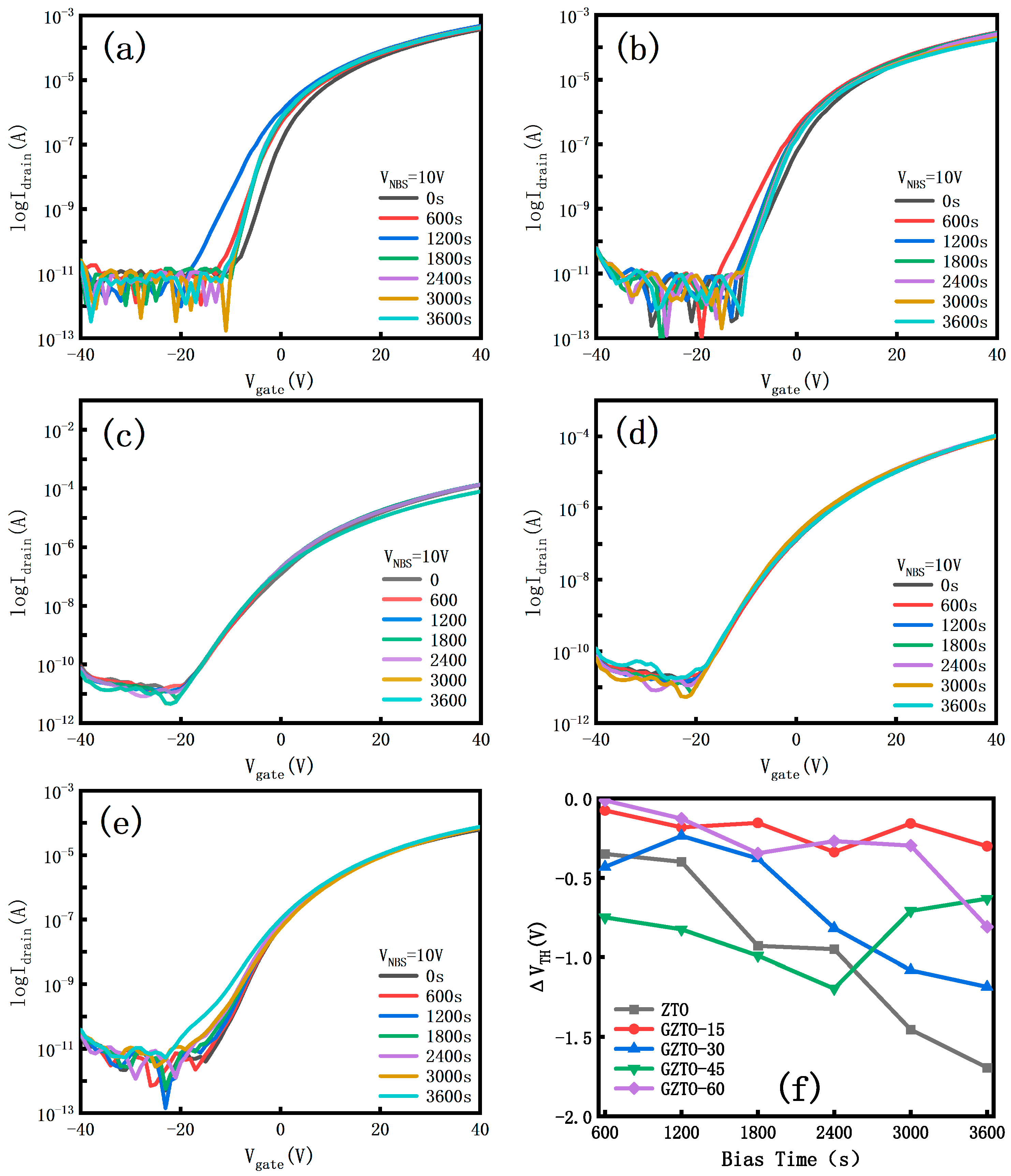

3.3. Stability

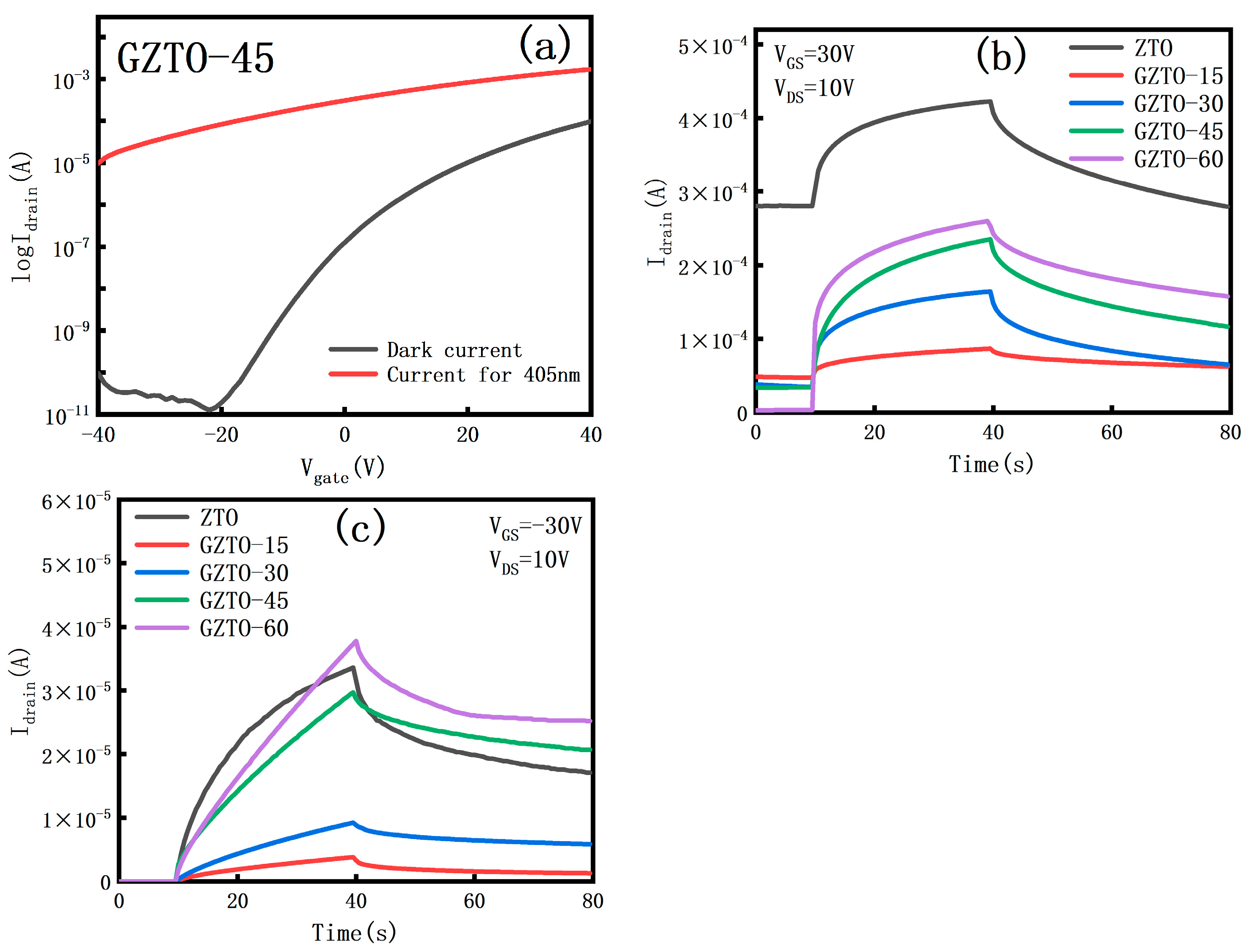

3.4. UV Photoelectric Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Q.; Dong, J.; Han, D.; Xu, D.; Wang, J.; Wang, Y. Structural engineering effects on hump characteristics of ZnO/InSnO heterojunction thin-film transistors. Nanomaterials 2022, 12, 1167. [Google Scholar] [CrossRef] [PubMed]

- Ji, D.; Jang, J.; Park, J.H.; Kim, D.; Rim, Y.S.; Hwang, D.K.; Noh, Y.Y. Recent progress in the development of backplane thin film transistors for information displays. J. Inf. Disp. 2021, 22, 159–168. [Google Scholar] [CrossRef]

- Kamiya, T.; Nomura, K.; Hosono, H. Present status of amorphous In–Ga–Zn–O thin-film transistors. Sci. Technol. Adv. Mater. 2010, 11, 044305. [Google Scholar] [CrossRef] [PubMed]

- Fuh, C.S.; Liu, P.T.; Huang, W.H.; Sze, S.M. Effect of annealing on defect elimination for high mobility amorphous indium-zinc-tin-oxide thin-film transistor. IEEE Electron. Device Lett. 2014, 35, 1103–1105. [Google Scholar] [CrossRef]

- Li, J.; Huang, C.X.; Fu, Y.Z.; Zhang, J.H.; Jiang, X.Y.; Zhang, Z. Amorphous LaZnSnO thin films by a combustion solution process and application in thin film transistors. Electron. Mater. Lett. 2016, 12, 76–81. [Google Scholar] [CrossRef]

- Dai, S.; Wang, T.; Li, R.; Zhou, D.; Peng, Y.; Wang, H.; Zhang, X.; Wang, Y. Preparation and effects of post-annealing temperature on the electrical characteristics of Li–N co-doped ZnSnO thin film transistors. Ceram. Int. 2017, 43, 4926–4929. [Google Scholar] [CrossRef]

- Lei, M.; Guo, L.; Wang, C.; Wang, C.; Chu, X.; Yang, F.; Gao, X.; Wang, H.; Chi, Y.; Yang, X. Analysis of the valence state of tin in ZnSnOx thin-film transistors. J. Mater. Sci. Mater. Electron. 2022, 33, 24785–24793. [Google Scholar] [CrossRef]

- Parthiban, S.; Kwon, J.Y. Role of dopants as a carrier suppressor and strong oxygen binder in amorphous indium-oxide-based field effect transistor. J. Mater. Res. 2014, 29, 1585–1596. [Google Scholar] [CrossRef]

- Kim, S.J.; Yoon, S.; Kim, H.J. Review of solution-processed oxide thin-film transistors. Jpn. J. Appl. Phys. 2014, 53, 02BA02. [Google Scholar] [CrossRef]

- Pearton, S.J.; Yang, J.; Cary, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar] [CrossRef]

- Lim, W.; Wang, Y.L.; Ren, F.; Norton, D.P.; Kravchenko, I.I.; Zavada, J.M.; Pearton, S.J. Indium zinc oxide thin films deposited by sputtering at room temperature. Appl. Surf. Sci. 2008, 254, 2878–2881. [Google Scholar] [CrossRef]

- Peng, C.; Yang, S.; Pan, C.; Li, X.; Zhang, J. Effect of two-step annealing on high stability of a-IGZO thin-film transistor. IEEE Trans. Electron. Devices 2020, 67, 4262–4268. [Google Scholar] [CrossRef]

- Lim, H.S.; Rim, Y.S.; Kim, D.L.; Jeong, W.H.; Kim, H.J. Carrier-suppressing effect of Mg in solution-processed Zn-Sn-O thin-film transistors. Electrochem. Solid-State Lett. 2012, 15, H78. [Google Scholar] [CrossRef]

- Ide, K.; Kikuchi, Y.; Nomura, K.; Kimura, M.; Kamiya, T.; Hosono, H. Effects of excess oxygen on operation characteristics of amorphous In-Ga-Zn-O thin-film transistors. Appl. Phys. Lett. 2011, 99, 093507. [Google Scholar] [CrossRef]

- Qian, L.X.; Wang, Y.; Wu, Z.H.; Sheng, T.; Liu, X.Z. β-Ga2O3 solar-blind deep-ultraviolet photodetector based on annealed sapphire substrate. Vacuum 2017, 140, 106–110. [Google Scholar] [CrossRef]

- Kim, H.R.; Park, J.; Lee, S.H.; Lee, G.H.; Song, P.G.; Kang, Y.C.; Kim, D.H. Effects of Ga concentration on electrical and physical properties of amorphous Ga-Zn-Sn-O semiconductor thin films. Electrochem. Solid-State Lett. 2011, 14, H411. [Google Scholar] [CrossRef]

- Pei, Y.; Liang, L.; Wang, X.; Wang, Z.; Zhang, H.; Ren, J.; Cao, H. Low-temperature-crystallized Ga2O3 thin films and their TFT-type solar-blind photodetectors. J. Phys. Chem. Lett. 2022, 13, 7243–7251. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, H.; Cao, J.; Shen, J.; Zhang, Q.; Yang, Y.; Dong, Z.; Zhou, T.; Zhang, Y.; Tang, W.; et al. Ultrahigh gain solar blind avalanche photodetector using an amorphous Ga2O3-based heterojunction. ACS Nano 2021, 15, 16654–16663. [Google Scholar] [CrossRef]

- Chen, J.; Ouyang, W.; Yang, W.; He, J.H.; Fang, X. Recent progress of heterojunction ultraviolet photodetectors: Materials, integrations, and applications. Adv. Funct. Mater. 2020, 30, 1909909. [Google Scholar] [CrossRef]

- Min Song, S.; Yong Kim, T.; Jae Sul, O.; Cheol Shin, W.; Jin Cho, B. Semiconducting properties of amorphous GaZnSnO thin film based on combinatorial electronic structures. Appl. Phys. Lett. 2014, 104, 182106. [Google Scholar]

- Kim, J.; Park, J.; Yoon, G.; Khushabu, A.; Kim, J.S.; Pae, S.; Cho, E.C.; Yi, J. Effect of IGZO thin films fabricated by Pulsed-DC and RF sputtering on TFT characteristics. Mater. Sci. Semicond. Process. 2020, 120, 105264. [Google Scholar] [CrossRef]

- Yu, E.S.; Kim, S.G.; Moon, S.J.; Bae, B.S. Improving the electrical stability of a-IGZO TFT through gate surround structures. Electron. Lett. 2023, 59, e12977. [Google Scholar] [CrossRef]

- Lee, H.; Lee, S.; Kim, Y.; Siddik, A.B.; Billah, M.M.; Lee, J.; Jang, J. Improvement of stability and performance of amorphous indium gallium zinc oxide thin film transistor by zinc-tin-oxide spray coating. IEEE Electron. Device Lett. 2020, 41, 1520–1523. [Google Scholar] [CrossRef]

- Nomura, K.; Ohta, H.; Ueda, K.; Kamiya, T.; Hirano, M.; Hosono, H. Thin-film transistor fabricated in single-crystalline transparent oxide semiconductor. Science 2003, 300, 1269–1272. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Liang, L.; Pei, Y.; Yu, J.; Duan, H.; Chang, T.C.; Cao, H. Solution-processed amorphous Ga2O3: CdO TFT-type deep-UV photodetectors. Appl. Phys. Lett. 2020, 116, 192102. [Google Scholar] [CrossRef]

- Kim, S.M.; Song, E.B.; Lee, S.; Seo, S.; Seo, D.H.; Hwang, Y.; Candler, R.; Wang, K.L. Improved negative bias illumination instability of sol-gel gallium zinc tin oxide thin film transistors. Appl. Phys. Lett. 2011, 99, 152102. [Google Scholar]

- Cui, S.J.; Mei, Z.X.; Hou, Y.N.; Chen, Q.S.; Liang, H.L.; Zhang, Y.H.; Huo, W.X.; Du, X.L. Enhanced photoresponse performance in Ga/Ga2O3 nanocomposite solar-blind ultraviolet photodetectors. Chin. Phys. B 2018, 27, 067301. [Google Scholar] [CrossRef]

- Qian, L.X.; Wu, Z.H.; Zhang, Y.Y.; Lai, P.T.; Liu, X.Z.; Li, Y.R. Ultrahigh-responsivity, rapid-recovery, solar-blind photodetector based on highly nonstoichiometric amorphous gallium oxide. ACS Photonics 2017, 4, 2203–2211. [Google Scholar] [CrossRef]

- Ko, R.M.; Chen, W.T.; Cheng, H.C.; Wu, C.H.; Chang, C.Y.; Wang, S.J. Ultraviolet photodetectors based on Si-Zn-SnO thin film transistors with a stacked channel structure and a patterned NiO capping layer. Jpn. J. Appl. Phys. 2022, 62, SC1006. [Google Scholar] [CrossRef]

- Liang, H.; Cui, S.; Su, R.; Guan, P.; He, Y.; Yang, L.; Chen, L.; Zhang, Y.; Mei, Z.; Du, X. Flexible X-ray detectors based on amorphous Ga2O3 thin films. ACS Photonics 2018, 6, 351–359. [Google Scholar] [CrossRef]

| TFT | RMS (nm) |

|---|---|

| GZTO TFT-unannealed | 0.94 |

| ZTO TFT 300 °C | 0.71 |

| GZTO-15 TFT 300 °C | 0.62 |

| GZTO-30 TFT 300 °C | 0.55 |

| GZTO-45 TFT 300 °C | 0.66 |

| GZTO-60 TFT 300 °C | 0.79 |

| TFT | Ga3d (%) | Zn2p (%) | Sn3d (%) | O1s (%) |

|---|---|---|---|---|

| ZTO | 0 | 19.17 | 18.04 | 62.79 |

| GZTO-15 | 1.08 | 18.62 | 16.33 | 63.99 |

| GZTO-30 | 1.72 | 17.42 | 17.88 | 62.98 |

| GZTO-45 | 2.22 | 16.33 | 17.95 | 63.48 |

| GZTO-60 | 2.81 | 18.97 | 17.00 | 61.21 |

| TFT | μFE (cm2/vs) | VTH (V) | SS (V/dec) | ION (A) | IOFF (A) | ION/IOFF |

|---|---|---|---|---|---|---|

| ZTO | 10.82 | 1.82 | 2.31 | 2.84 × 10−3 | 5.63 × 10−11 | 5.04 × 107 |

| GZTO-15 | 2.80 | 9.19 | 3.08 | 4.83 × 10−4 | 5.86 × 10−12 | 8.25× 107 |

| GZTO-30 | 1.92 | 8.93 | 2.15 | 3.37 × 10−4 | 1.59 × 10−12 | 2.12 × 108 |

| GZTO-45 | 1.24 | 15.93 | 1.99 | 1.31 × 10−4 | 8.27 × 10−13 | 1.59 × 108 |

| GZTO-60 | 1.16 | 16.09 | 2.14 | 1.21 × 10−4 | 1.28 × 10−12 | 9.43 × 107 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, L.; Wang, Q.; Wang, C.; Chu, X.; Hao, Y.; Chi, Y.; Yang, X. Effect of Ga Doping on the Stability and Optoelectronic Properties of ZnSnO Thin Film Transistor. Micromachines 2024, 15, 1445. https://doi.org/10.3390/mi15121445

Guo L, Wang Q, Wang C, Chu X, Hao Y, Chi Y, Yang X. Effect of Ga Doping on the Stability and Optoelectronic Properties of ZnSnO Thin Film Transistor. Micromachines. 2024; 15(12):1445. https://doi.org/10.3390/mi15121445

Chicago/Turabian StyleGuo, Liang, Qing Wang, Chao Wang, Xuefeng Chu, Yunpeng Hao, Yaodan Chi, and Xiaotian Yang. 2024. "Effect of Ga Doping on the Stability and Optoelectronic Properties of ZnSnO Thin Film Transistor" Micromachines 15, no. 12: 1445. https://doi.org/10.3390/mi15121445

APA StyleGuo, L., Wang, Q., Wang, C., Chu, X., Hao, Y., Chi, Y., & Yang, X. (2024). Effect of Ga Doping on the Stability and Optoelectronic Properties of ZnSnO Thin Film Transistor. Micromachines, 15(12), 1445. https://doi.org/10.3390/mi15121445