Understanding Melt Pool Behavior of 316L Stainless Steel in Laser Powder Bed Fusion Additive Manufacturing

Abstract

1. Introduction

2. Experimental and Modeling Methods

2.1. Experimental Procedure

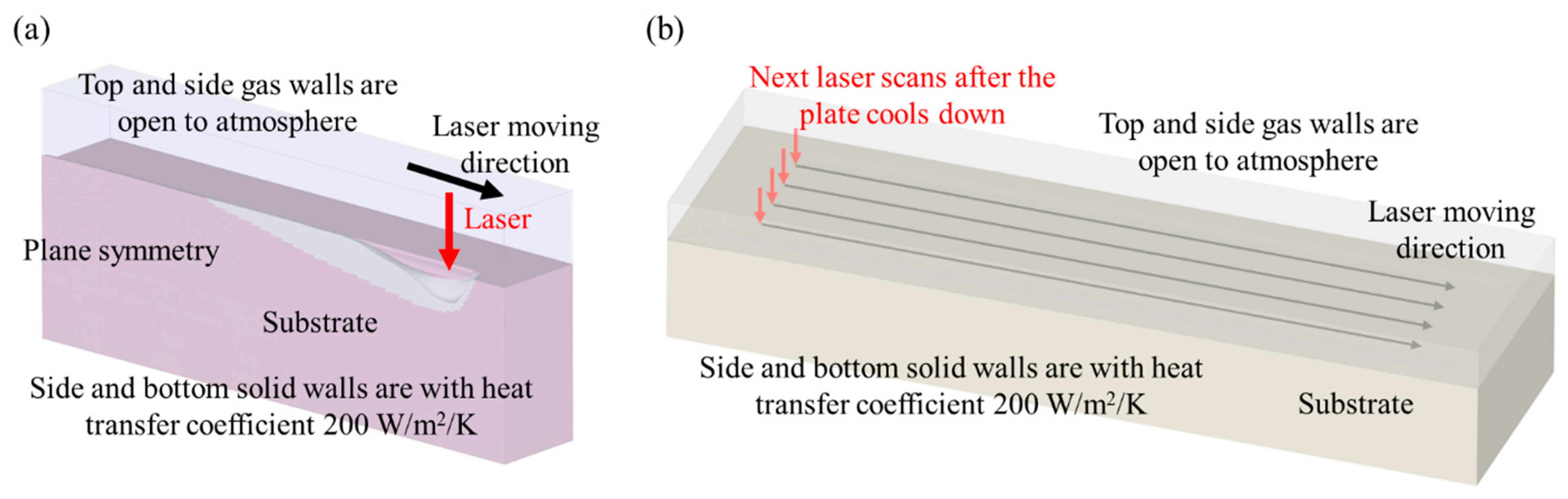

2.2. Modeling Method

2.2.1. Governing Equations

2.2.2. Simulation Setup and Material Properties

3. Results and Discussion

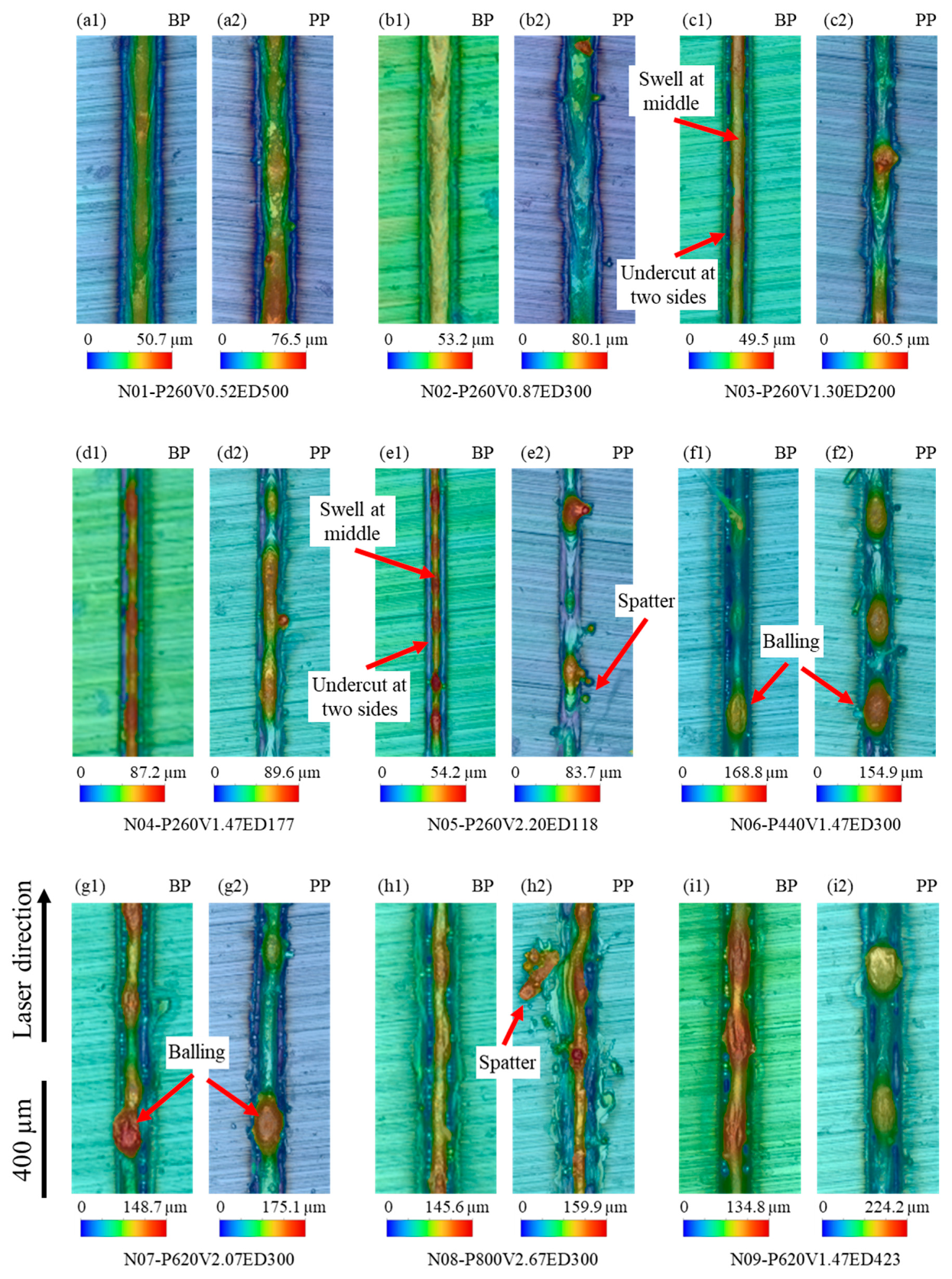

3.1. Melt Pool Surface Topography and Dimensions in the Single-Track Experiments

3.2. Numerical Analysis of Single-Track Laser Scanning

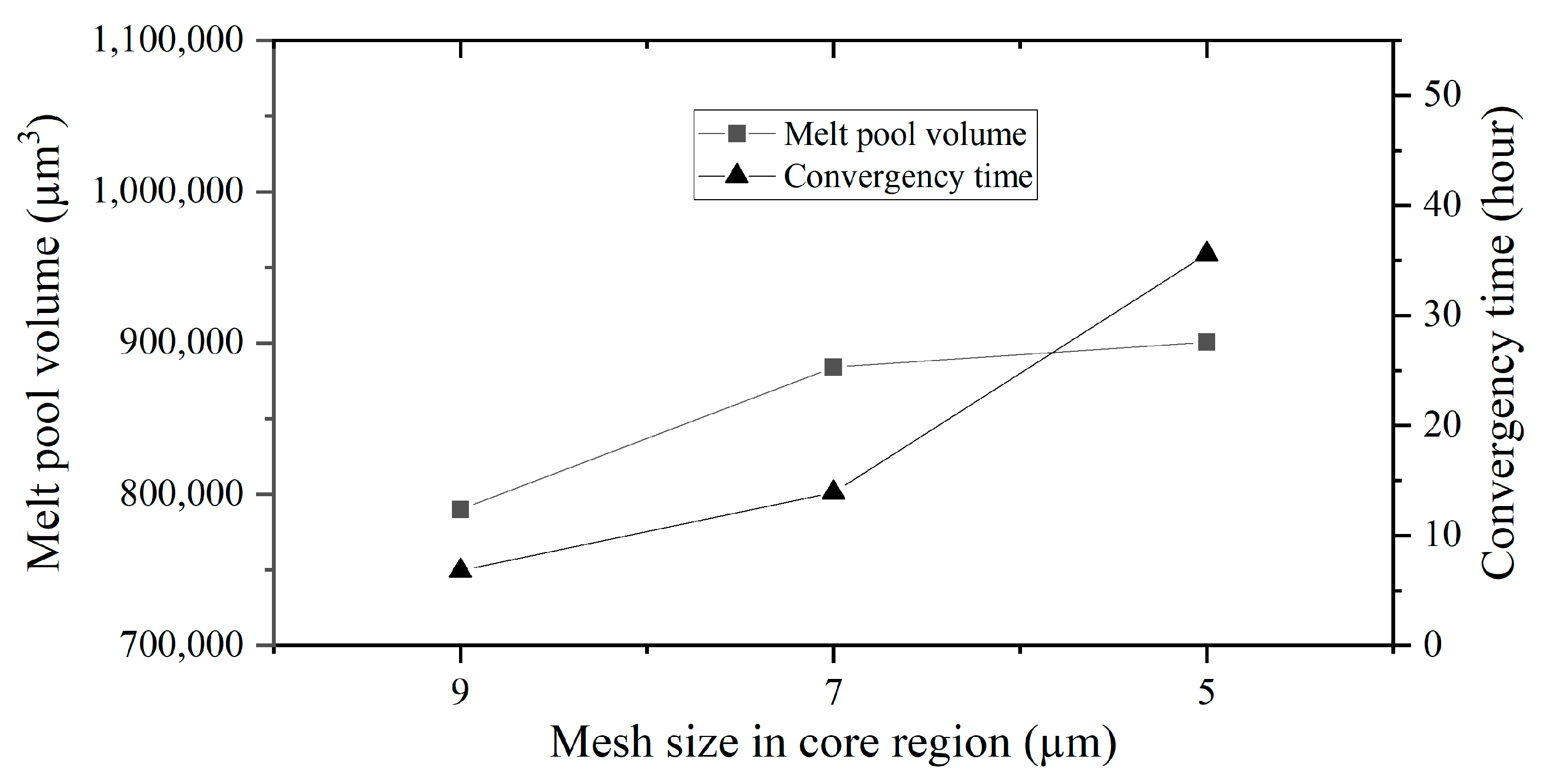

3.2.1. Mesh Sensitivity and Model Validation

3.2.2. Physical Mechanisms of Swell-Undercut Formation

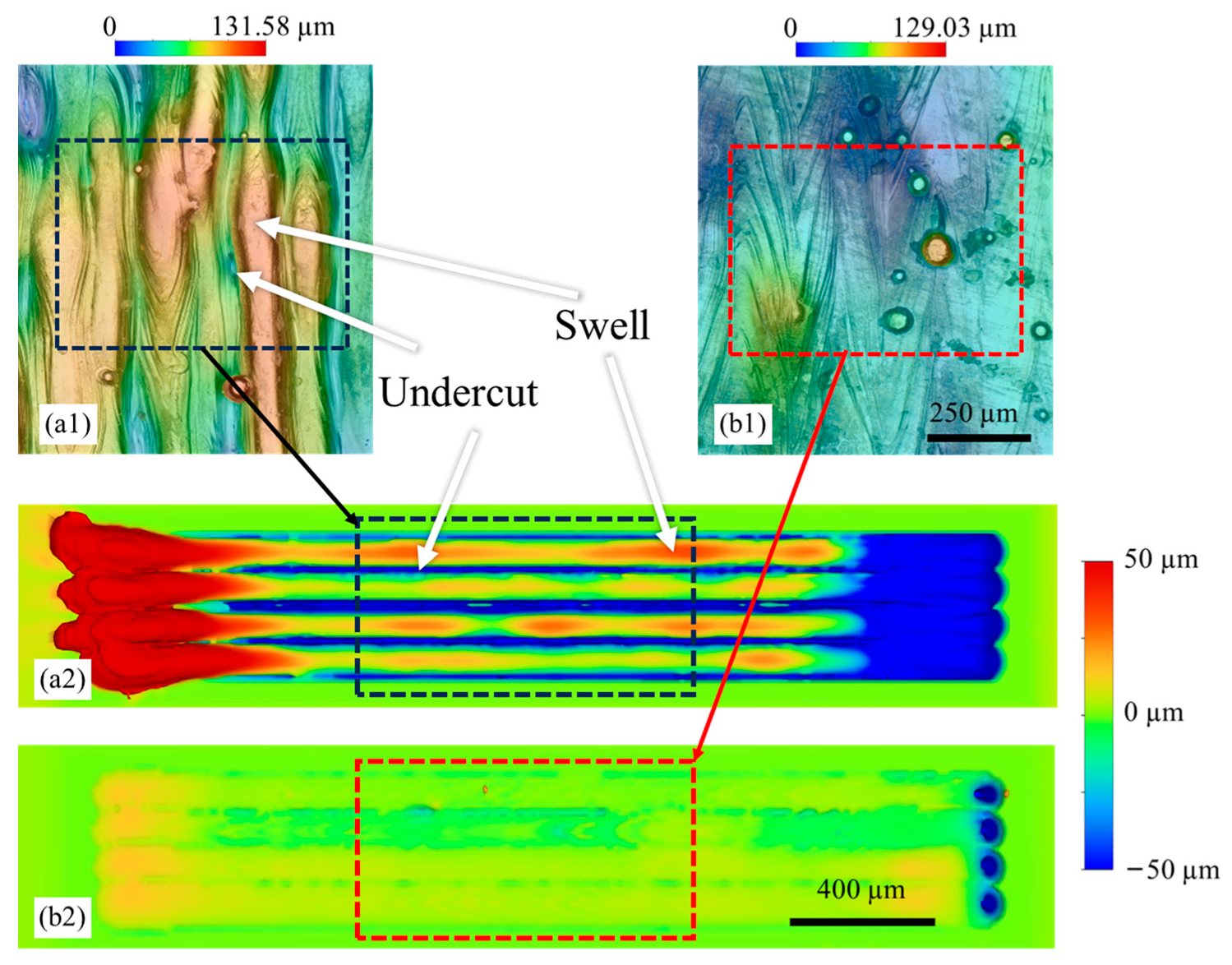

3.3. Surface Topography of Cubic Samples and Multiple-Track Simulation

4. Conclusions

- At a low power of 260 W, the width and depth of the melt pool decrease with increasing laser speed in single-track scanning, both with and without a powder layer. Swell-undercut appears when the speed exceeds 1.30 m/s. At a higher power and a laser speed of 1.47 m/s, the melt pool expands, resulting in significant balling.

- Increasing laser power and speed at a linear energy density of 300 J/m leads to an increase in melt pool width and depth, transitioning from shallow and wide to deep and narrow and then back to a shallow and wide melt pool. Balling and swell-undercut phenomena emerge beyond 440 W and 1.47 m/s, with additional spattering observed beyond 620 W and 2.67 m/s.

- The laser–matter interaction on the bare plate or powder plate does not alter the melt pool characteristics. However, the fluctuation of melt track height on a powder plate is consistently higher than on a bare plate in the laser moving direction, due to increased laser energy absorptivity and additional mass from loose powder, worsening melt pool irregularity.

- The formation of swell-undercut, revealed by the numerical model, is owing to the large void space created by high intense recoil pressure and insufficient liquid refilling due to momentum damping in the semisolid zone and rapid solidification at high laser power and high-speed conditions. In contrast, a lower laser power and speed provide adequate heat transfer time and energy deposition, reducing swell-undercut and surface roughness.

- Cubic samples under high laser power and speed exhibit swell-undercut and increased height fluctuation, while lower laser power and speed result in smoother surfaces due to enhanced heat transfer and energy deposition. These characteristics align with findings from multiple-track scanning simulations, highlighting the influence of insufficient energy deposition and reduced heat transfer time on surface topography.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Elambasseril, J.; Rogers, J.; Wallbrink, C.; Munk, D.; Leary, M.; Qian, M. Laser Powder Bed Fusion Additive Manufacturing (LPBF-AM): The Influence of Design Features and LPBF Variables on Surface Topography and Effect on Fatigue Properties. Crit. Rev. Solid State Mater. Sci. 2023, 48, 132–168. [Google Scholar] [CrossRef]

- Narasimharaju, S.R.; Zeng, W.; See, T.L.; Zhu, Z.; Scott, P.; Jiang, X.; Lou, S. A Comprehensive Review on Laser Powder Bed Fusion of Steels: Processing, Microstructure, Defects and Control Methods, Mechanical Properties, Current Challenges and Future Trends. J. Manuf. Process 2022, 75, 375–414. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Nzeukou, R.A.; Onawale, O.T.; Matizamhuka, W.R. Laser Powder Bed Fusion of Potential Superalloys: A Review. Metals 2020, 11, 58. [Google Scholar] [CrossRef]

- Abd-Elaziem, W.; Elkatatny, S.; Abd-Elaziem, A.E.; Khedr, M.; Abd El-Baky, M.A.; Hassan, M.A.; Abu-Okail, M.; Mohammed, M.; Järvenpää, A.; Allam, T.; et al. On the Current Research Progress of Metallic Materials Fabricated by Laser Powder Bed Fusion Process: A Review. J. Mater. Res. Technol. 2022, 20, 681–707. [Google Scholar] [CrossRef]

- Yin, H.; Yang, J.; Fischer, R.D.; Zhang, Z.; Prorok, B.; Yuan, L.; Lou, X. Pulsed Laser Additive Manufacturing for 316L Stainless Steel: A New Approach to Control Subgrain Cellular Structure. JOM 2023, 75, 5027–5036. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive Manufacturing: Scientific and Technological Challenges, Market Uptake and Opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Chowdhury, S.; Yadaiah, N.; Prakash, C.; Ramakrishna, S.; Dixit, S.; Gupta, L.R.; Buddhi, D. Laser Powder Bed Fusion: A State-of-the-Art Review of the Technology, Materials, Properties & Defects, and Numerical Modelling. J. Mater. Res. Technol. 2022, 20, 2109–2172. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Yuan, L.; Sabau, A.S.; Yan, W.; Kao, A. Editorial: Advances in Computational Modeling of Additive Manufacturing Processes. Front. Mater. 2022, 9, 980825. [Google Scholar] [CrossRef]

- Jin, J.; Wu, S.; Yang, L.; Zhang, C.; Li, Y.; Cai, C.; Yan, C.; Shi, Y. Ni–Ti Multicell Interlacing Gyroid Lattice Structures with Ultra-High Hyperelastic Response Fabricated by Laser Powder Bed Fusion. Int. J. Mach. Tools Manuf. 2024, 195, 104099. [Google Scholar] [CrossRef]

- Agrawal, A.K.; Rankouhi, B.; Thoma, D.J. Predictive Process Mapping for Laser Powder Bed Fusion: A Review of Existing Analytical Solutions. Curr. Opin. Solid State Mater. Sci. 2022, 26, 101024. [Google Scholar] [CrossRef]

- Wang, W.; Ning, J.; Liang, S.Y. Analytical Prediction of Keyhole Porosity in Laser Powder Bed Fusion. Int. J. Adv. Manuf. Technol. 2022, 119, 6995–7002. [Google Scholar] [CrossRef]

- Yeung, H.; Kim, F.H.; Donmez, M.A.; Neira, J. Keyhole Pores Reduction in Laser Powder Bed Fusion Additive Manufacturing of Nickel Alloy 625. Int. J. Mach. Tools Manuf. 2022, 183, 103957. [Google Scholar] [CrossRef]

- Yang, X.; Li, Y.; Li, B. Formation Mechanisms of Lack of Fusion and Keyhole-Induced Pore Defects in Laser Powder Bed Fusion Process: A Numerical Study. Int. J. Therm. Sci. 2023, 188, 108221. [Google Scholar] [CrossRef]

- Shrestha, S.; Chou, K. Formation of Keyhole and Lack of Fusion Pores during the Laser Powder Bed Fusion Process. Manuf. Lett. 2022, 32, 19–23. [Google Scholar] [CrossRef]

- Tang, C.; Le, K.Q.; Wong, C.H. Physics of Humping Formation in Laser Powder Bed Fusion. Int. J. Heat. Mass. Transf. 2020, 149, 119172. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, R.; Wei, X.; Xiao, M.; Yin, Y.; Qu, Y.; Li, H.; Liu, P.; Qiu, X.; Guo, T. An Investigation on the Oxidation Behavior of Spatters Generated during the Laser Powder Bed Fusion of 316L Stainless Steel. Appl. Surf. Sci. 2022, 586, 152796. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, Y.; Wang, D.; Chen, Z.; Yan, W. Correlation between the Scan Strategy, Residing Spatter Distribution, and Parts Quality in Laser Powder Bed Fusion. Mater. Des. 2023, 234, 112317. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, Y.; Han, C.; Zhou, H.; Zhou, H.; Wang, M.; Liu, L.; Wang, H.; Bai, Y.; Wang, D. Effects of Gas Flow Parameters on Droplet Spatter Features and Dynamics during Large-Scale Laser Powder Bed Fusion. Mater. Des. 2023, 225, 111534. [Google Scholar] [CrossRef]

- Schultz, V.; Woizeschke, P. High Seam Surface Quality in Keyhole Laser Welding: Buttonhole Welding. J. Manuf. Mater. Process. 2018, 2, 78. [Google Scholar] [CrossRef]

- Bitharas, I.; Parab, N.; Zhao, C.; Sun, T.; Rollett, A.D.; Moore, A.J. The Interplay between Vapour, Liquid, and Solid Phases in Laser Powder Bed Fusion. Nat. Commun. 2022, 13, 2959. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Tang, G.; Clark, S.J.; Meshkov, A.; Roychowdhury, S.; Gould, B.; Ostroverkhov, V.; Adcock, T.; Duclos, S.J.; Fezzaa, K.; et al. High Frequency Beam Oscillation Keyhole Dynamics in Laser Melting Revealed by In-Situ x-Ray Imaging. Commun. Mater. 2023, 4, 5. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole Threshold and Morphology in Laser Melting Revealed by Ultrahigh-Speed x-Ray Imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Garcia, D.; Kamath, R.R.; Dou, C.; Ma, X.; Shen, B.; Choo, H.; Fezzaa, K.; Yu, H.Z.; Kong, Z. In Situ Melt Pool Measurements for Laser Powder Bed Fusion Using Multi Sensing and Correlation Analysis. Sci. Rep. 2022, 12, 13716. [Google Scholar] [CrossRef]

- Caprio, L.; Demir, A.G.; Previtali, B. Application Notes-Illumination Lasers-High-Speed Imaging Additive Manufacturing Observing Molten Pool Surface Oscillations During Keyhole Processing in Laser Powder Bed Fusion. Addit. Manuf. 2020, 36, 101470. [Google Scholar] [CrossRef]

- Sun, T.; Tan, W.; Chen, L.; Rollett, A. In Situ/Operando Synchrotron x-Ray Studies of Metal Additive Manufacturing. MRS Bull. 2020, 45, 927–933. [Google Scholar] [CrossRef]

- Zhao, C.; Fezzaa, K.; Cunningham, R.W.; Wen, H.; de Carlo, F.; Chen, L.; Rollett, A.D.; Sun, T. Real-Time Monitoring of Laser Powder Bed Fusion Process Using High-Speed X-ray Imaging and Diffraction. Sci. Rep. 2017, 7, 3602. [Google Scholar] [CrossRef]

- Yin, J.; Wang, D.; Yang, L.; Wei, H.; Dong, P.; Ke, L.; Wang, G.; Zhu, H.; Zeng, X. Correlation between Forming Quality and Spatter Dynamics in Laser Powder Bed Fusion. Addit. Manuf. 2020, 31, 100958. [Google Scholar] [CrossRef]

- Guo, Q.; Zhao, C.; Qu, M.; Xiong, L.; Escano, L.I.; Hojjatzadeh, S.M.H.; Parab, N.D.; Fezzaa, K.; Everhart, W.; Sun, T.; et al. In-Situ Characterization and Quantification of Melt Pool Variation under Constant Input Energy Density in Laser Powder Bed Fusion Additive Manufacturing Process. Addit. Manuf. 2019, 28, 600–609. [Google Scholar] [CrossRef]

- Leung, C.L.A.; Marussi, S.; Atwood, R.C.; Towrie, M.; Withers, P.J.; Lee, P.D. In Situ X-ray Imaging of Defect and Molten Pool Dynamics in Laser Additive Manufacturing. Nat. Commun. 2018, 9, 1355. [Google Scholar] [CrossRef]

- Zheng, M.; Wei, L.; Chen, J.; Zhang, Q.; Zhong, C.; Lin, X.; Huang, W. A Novel Method for the Molten Pool and Porosity Formation Modelling in Selective Laser Melting. Int. J. Heat. Mass. Transf. 2019, 140, 1091–1105. [Google Scholar] [CrossRef]

- Lee, Y.S.; Zhang, W. Modeling of Heat Transfer, Fluid Flow and Solidification Microstructure of Nickel-Base Superalloy Fabricated by Laser Powder Bed Fusion. Addit. Manuf. 2016, 12, 178–188. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser Powder-Bed Fusion Additive Manufacturing: Physics of Complex Melt Flow and Formation Mechanisms of Pores, Spatter, and Denudation Zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A. Mesoscopic Simulation Model of Selective Laser Melting of Stainless Steel Powder. J. Mater. Process Technol. 2014, 214, 2627–2636. [Google Scholar] [CrossRef]

- Azadi Tinat, M.R.; Uddagiri, M.; Steinbach, I.; López-Galilea, I. Numerical Simulations to Predict the Melt Pool Dynamics and Heat Transfer during Single-Track Laser Melting of Ni-Based Superalloy (CMSX-4). Metals 2023, 13, 1091. [Google Scholar] [CrossRef]

- Li, E.; Zhou, Z.; Wang, L.; Zheng, Q.; Zou, R.; Yu, A. Melt Pool Dynamics and Pores Formation in Multi-Track Studies in Laser Powder Bed Fusion Process. Powder Technol. 2022, 405, 117533. [Google Scholar] [CrossRef]

- Sabau, A.S.; Yuan, L.; Raghavan, N.; Bement, M.; Simunovic, S.; Turner, J.A.; Gupta, V.K. Fluid Dynamics Effects on Microstructure Prediction in Single-Laser Tracks for Additive Manufacturing of IN625. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2020, 51, 1263–1281. [Google Scholar] [CrossRef]

- Tangestani, R.; Sabiston, T.; Chakraborty, A.; Muhammad, W.; Yuan, L.; Martin, É. An Efficient Track-Scale Model for Laser Powder Bed Fusion Additive Manufacturing: Part 1—Thermal Model. Front. Mater. 2021, 8, 753040. [Google Scholar] [CrossRef]

- Tangestani, R.; Sabiston, T.; Chakraborty, A.; Yuan, L.; Krutz, N.; Martin, É. An Efficient Track-Scale Model for Laser Powder Bed Fusion Additive Manufacturing: Part 2—Mechanical Model. Front. Mater. 2021, 8, 759669. [Google Scholar] [CrossRef]

- Cho, W.I.; Na, S.J.; Thomy, C.; Vollertsen, F. Numerical Simulation of Molten Pool Dynamics in High Power Disk Laser Welding. J. Mater. Process Technol. 2012, 212, 262–275. [Google Scholar] [CrossRef]

- Saldi, Z.S.; Kidess, A.; Kenjereš, S.; Zhao, C.; Richardson, I.M.; Kleijn, C.R. Effect of Enhanced Heat and Mass Transport and Flow Reversal during Cool down on Weld Pool Shapes in Laser Spot Welding of Steel. Int. J. Heat. Mass. Transf. 2013, 66, 879–888. [Google Scholar] [CrossRef]

- Zhao, C.X.; Kwakernaak, C.; Pan, Y.; Richardson, I.M.; Saldi, Z.; Kenjeres, S.; Kleijn, C.R. The Effect of Oxygen on Transitional Marangoni Flow in Laser Spot Welding. Acta Mater. 2010, 58, 6345–6357. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Yin, J.; Li, Y.; Nie, Z.; Li, X.; You, D.; Guan, K.; Duan, W.; Cao, L.; et al. A Review of Spatter in Laser Powder Bed Fusion Additive Manufacturing: In Situ Detection, Generation, Effects, and Countermeasures. Micromachines 2022, 13, 1366. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Li, H.; Lang, L.; Gong, S.; Ge, Y. Effects of Scan Speed on Vapor Plume Behavior and Spatter Generation in Laser Powder Bed Fusion Additive Manufacturing. J. Manuf. Process 2018, 36, 60–67. [Google Scholar] [CrossRef]

- Cho, W.I.; Na, S.J.; Cho, M.H.; Lee, J.S. Numerical Study of Alloying Element Distribution in CO2 Laser–GMA Hybrid Welding. Comput. Mater. Sci. 2010, 49, 792–800. [Google Scholar] [CrossRef]

- Ren, Z.; Wei, D.; Wang, S.; Zhang, D.Z.; Mao, S. On the Role of Pre- and Post-Contour Scanning in Laser Powder Bed Fusion: Thermal-Fluid Dynamics and Laser Reflections. Int. J. Mech. Sci. 2022, 226, 107389. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, W.G.; Qin, Q.H.; Tu, Z.X.; Li, D.S. Particle-Scale Computational Fluid Dynamics Study on Surface Morphology of GH4169 Superalloy during Multi-Laser Powder Bed Fusion with Low Energy Density. J. Manuf. Process 2023, 92, 287–296. [Google Scholar] [CrossRef]

- Dai, K.; He, X.; Kong, D.; Dong, C. Multi-Physical Field Simulation to Yield Defect-Free IN718 Alloy Fabricated by Laser Powder Bed Fusion. Mater. Lett. 2024, 355, 135437. [Google Scholar] [CrossRef]

- Zhang, T.; Yuan, L. Understanding Surface Roughness on Vertical Surfaces of 316 L Stainless Steel in Laser Powder Bed Fusion Additive Manufacturing. Powder Technol. 2022, 411, 117957. [Google Scholar] [CrossRef]

- Calignano, F.; Minetola, P. Influence of Process Parameters on the Porosity, Accuracy, Roughness, and Support Structures of Hastelloy X Produced by Laser Powder Bed Fusion. Materials 2019, 12, 3178. [Google Scholar] [CrossRef]

- Baciu, A.M.; Bejinariu, C.; Corăbieru, A.; Mihalache, E.; Lupu-Poliac, M.; Baciu, C.; Baciu, E.R. Influence of Process Parameters for Selective Laser Melting on the Roughness of 3D Printed Surfaces in Co-Cr Dental Alloy Powder. IOP Conf. Ser. Mater. Sci. Eng. 2019, 572, 012054. [Google Scholar] [CrossRef]

- Artzt, K.; Mishurova, T.; Bauer, P.P.; Gussone, J.; Barriobero-Vila, P.; Evsevleev, S.; Bruno, G.; Requena, G.; Haubrich, J. Pandora’s Box–Influence of Contour Parameters on Roughness and Subsurface Residual Stresses in Laser Powder Bed Fusion of Ti-6Al-4V. Materials 2020, 13, 3348. [Google Scholar] [CrossRef] [PubMed]

- Guo, C.; Li, S.; Shi, S.; Li, X.; Hu, X.; Zhu, Q.; Ward, R.M. Effect of Processing Parameters on Surface Roughness, Porosity and Cracking of as-Built IN738LC Parts Fabricated by Laser Powder Bed Fusion. J. Mater. Process Technol. 2020, 285, 116788. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the Role of Melt Flow into the Surface Structure and Porosity Development during Selective Laser Melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef]

- Yang, J.; Han, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Role of Molten Pool Mode on Formability, Microstructure and Mechanical Properties of Selective Laser Melted Ti-6Al-4V Alloy. Mater. Des. 2016, 110, 558–570. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of Process Parameters on Surface Roughness of Aluminum Parts Produced by DMLS. Int. J. Adv. Manuf. Technol. 2013, 67, 2743–2751. [Google Scholar] [CrossRef]

- Megahed, M.; Mindt, H.W.; Willems, J.; Dionne, P.; Jacquemetton, L.; Craig, J.; Ranade, P.; Peralta, A. LPBF Right the First Time—The Right Mix Between Modeling and Experiments. Integr. Mater. Manuf. Innov. 2019, 8, 194–216. [Google Scholar] [CrossRef]

- Ansys® Fluent, Release 2022 R1; Fluent Theory Guide, Chapter 1. Basic Fluid Flow; ANSYS, Inc.: Canonsburg, PA, USA, 2022. Available online: https://www.ansys.com/services/ansys-learning-hub (accessed on 16 January 2024).

- Ezzat, Y.; Sakr, R.Y.; Abdel-Rehim, A.A. Numerical Investigation of the Effect of Thermal Expansion Coefficient and Mushy Zone Constant on Modelling of the Phase Change Process to Provide Reliable Selection Criteria of Modelling Parameters. J. Energy Storage 2023, 72, 108771. [Google Scholar] [CrossRef]

- Katagiri, J.; Kusano, M.; Nomoto, S.; Watanabe, M. Influence of Recoil Pressure, Mushy Zone Flow Resistance and Reflectivity on Melt Pool Shape in Laser Powder Bed Fusion Simulation. Case Stud. Therm. Eng. 2023, 50, 103477. [Google Scholar] [CrossRef]

- He, Q.; Xia, H.; Liu, J.; Ao, X.; Lin, S. Modeling and Numerical Studies of Selective Laser Melting: Multiphase Flow, Solidification and Heat Transfer. Mater. Des. 2020, 196, 109115. [Google Scholar] [CrossRef]

- Makoana, N.W.; Yadroitsava, I.; Möller, H.; Yadroitsev, I. Characterization of 17-4PH Single Tracks Produced at Different Parametric Conditions towards Increased Productivity of LPBF Systems—The Effect of Laser Power and Spot Size Upscaling. Metals 2018, 8, 475. [Google Scholar] [CrossRef]

- Guo, L.; Wang, H.; Liu, H.; Huang, Y.; Wei, Q.; Leung, C.L.A.; Wu, Y.; Wang, H. Understanding Keyhole Induced-Porosities in Laser Powder Bed Fusion of Aluminum and Elimination Strategy. Int. J. Mach. Tools Manuf. 2023, 184, 103977. [Google Scholar] [CrossRef]

| Case Name | Laser Power, W | Laser Speed, m/s | Laser Energy Density, J/m |

|---|---|---|---|

| N01 | 260 | 0.52 | 500 |

| N02 | 260 | 0.87 | 300 |

| N03 | 260 | 1.30 | 200 |

| N04 | 260 | 1.47 | 177 |

| N05 | 260 | 2.20 | 118 |

| N06 | 440 | 1.47 | 300 |

| N07 | 620 | 2.07 | 300 |

| N08 | 800 | 2.67 | 300 |

| N09 | 620 | 1.47 | 423 |

| Properties | Symbol | Value | Unit |

|---|---|---|---|

| Density of solid phase | 7950 | kg/m3 | |

| Density of liquid phase | 8200 − 0.77T | kg/m3 | |

| Density of gas phase | 1.22 | kg/m3 | |

| Specific heat of solid phase | 415 + 0.1838T | J/kg/K | |

| Specific heat of liquid phase | 830 | J/kg/K | |

| Specific heat of gas phase | 1006.43 | J/kg/K | |

| Thermal conductivity of solid phase | 9.23 + 0.0139T | W/m/K | |

| Thermal conductivity of liquid phase | 5.5 + 0.0133T | W/m/K | |

| Thermal conductivity of gas phase | 0.02 | W/m/K | |

| Solidus temperature | 1658 | K | |

| Liquidus temperature | 1723 | K | |

| Evaporation temperature | 3090 | K | |

| Latent heat of melting | 2.6 × 105 | J/kg | |

| Latent heat of vaporization | 7.45 × 106 | J/kg | |

| Viscosity of metallic phase | 0.006 | N/m2 | |

| Viscosity of gas phase | 1.85 × 10−5 | N/m2 | |

| Mushy zone constant | 1 × 109 | kg/m3/s | |

| Molar mass | 0.05593 | kg/mol | |

| Ambient pressure | 1.013 × 105 | Pa | |

| Universal gas constant | 8.314 | kgm2/s2/K/mol | |

| Stefan–Boltzmann constant | 5.67 × 10−8 | kg/s3/K4 | |

| Emissivity | 0.5 | ||

| Coefficient of evaporation energy loss | 0.5 | ||

| Recoil pressure coefficient | 0.6 | ||

| Laser absorptivity | 0.5 | ||

| Laser spot radius | 50 | µm |

| Experimental Melt Pool Size on Bare Plate | Numerical Melt Pool Size on Bare Plate | Error of Simulation | ||||

|---|---|---|---|---|---|---|

| Width | Depth | Width | Depth | Width | Depth | |

| N01-P260V0.52 | 114 µm | 180 µm | 119 µm | 168 µm | 4.20% | 7.14% |

| N04-P260V1.47 | 94 µm | 61 µm | 99 µm | 62 µm | 5.05% | 1.61% |

| N05-P260V2.20 | 83 µm | 41 µm | 92 µm | 48.3 µm | 9.78% | 15.11% |

| N06-P440V1.47 | 98 µm | 104 µm | 105 µm | 108 µm | 6.67% | 3.70% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhang, T.; Sun, C.; Karna, S.; Yuan, L. Understanding Melt Pool Behavior of 316L Stainless Steel in Laser Powder Bed Fusion Additive Manufacturing. Micromachines 2024, 15, 170. https://doi.org/10.3390/mi15020170

Zhang Z, Zhang T, Sun C, Karna S, Yuan L. Understanding Melt Pool Behavior of 316L Stainless Steel in Laser Powder Bed Fusion Additive Manufacturing. Micromachines. 2024; 15(2):170. https://doi.org/10.3390/mi15020170

Chicago/Turabian StyleZhang, Zilong, Tianyu Zhang, Can Sun, Sivaji Karna, and Lang Yuan. 2024. "Understanding Melt Pool Behavior of 316L Stainless Steel in Laser Powder Bed Fusion Additive Manufacturing" Micromachines 15, no. 2: 170. https://doi.org/10.3390/mi15020170

APA StyleZhang, Z., Zhang, T., Sun, C., Karna, S., & Yuan, L. (2024). Understanding Melt Pool Behavior of 316L Stainless Steel in Laser Powder Bed Fusion Additive Manufacturing. Micromachines, 15(2), 170. https://doi.org/10.3390/mi15020170