Mixing Performance Analysis and Optimal Design of a Novel Passive Baffle Micromixer

Abstract

1. Introduction

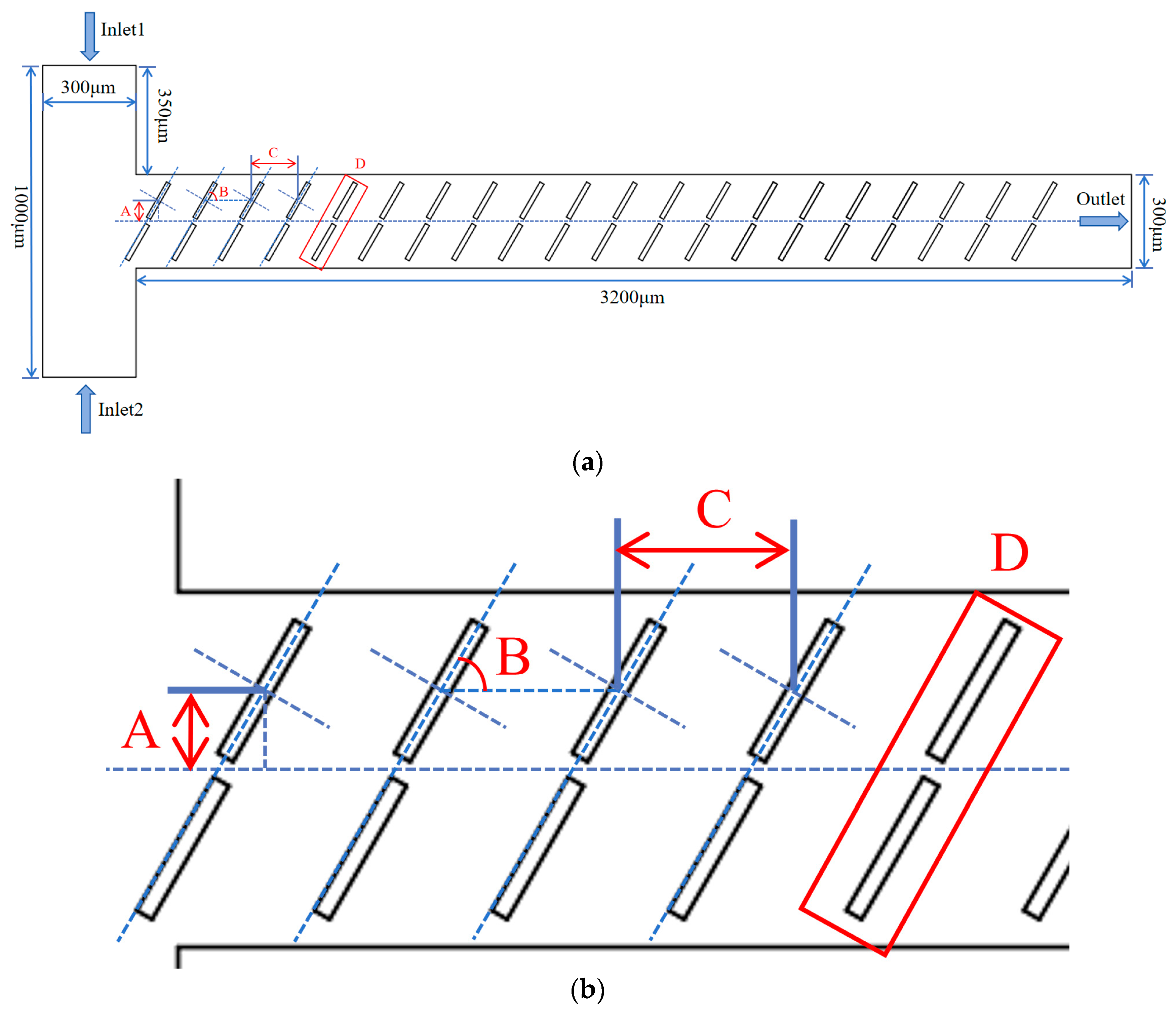

2. Physical Model

3. Research Methods and Feasibility Verification

3.1. The Fundamental Control Equations for Microfluidic Mixing

3.2. Numerical Simulation Methods and Boundary Condition Settings

3.3. Mesh Independence Verification

4. Results and Discussion

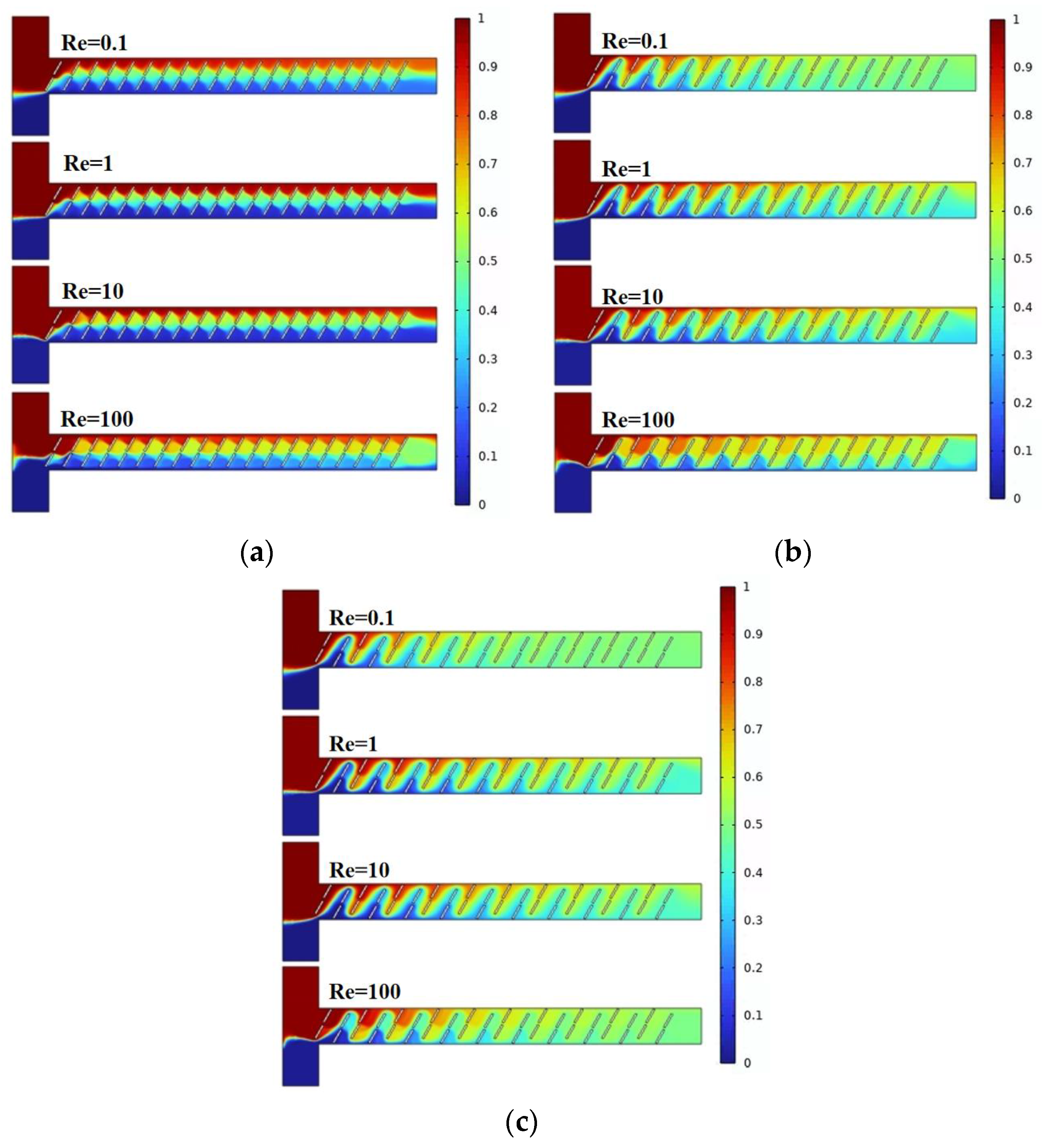

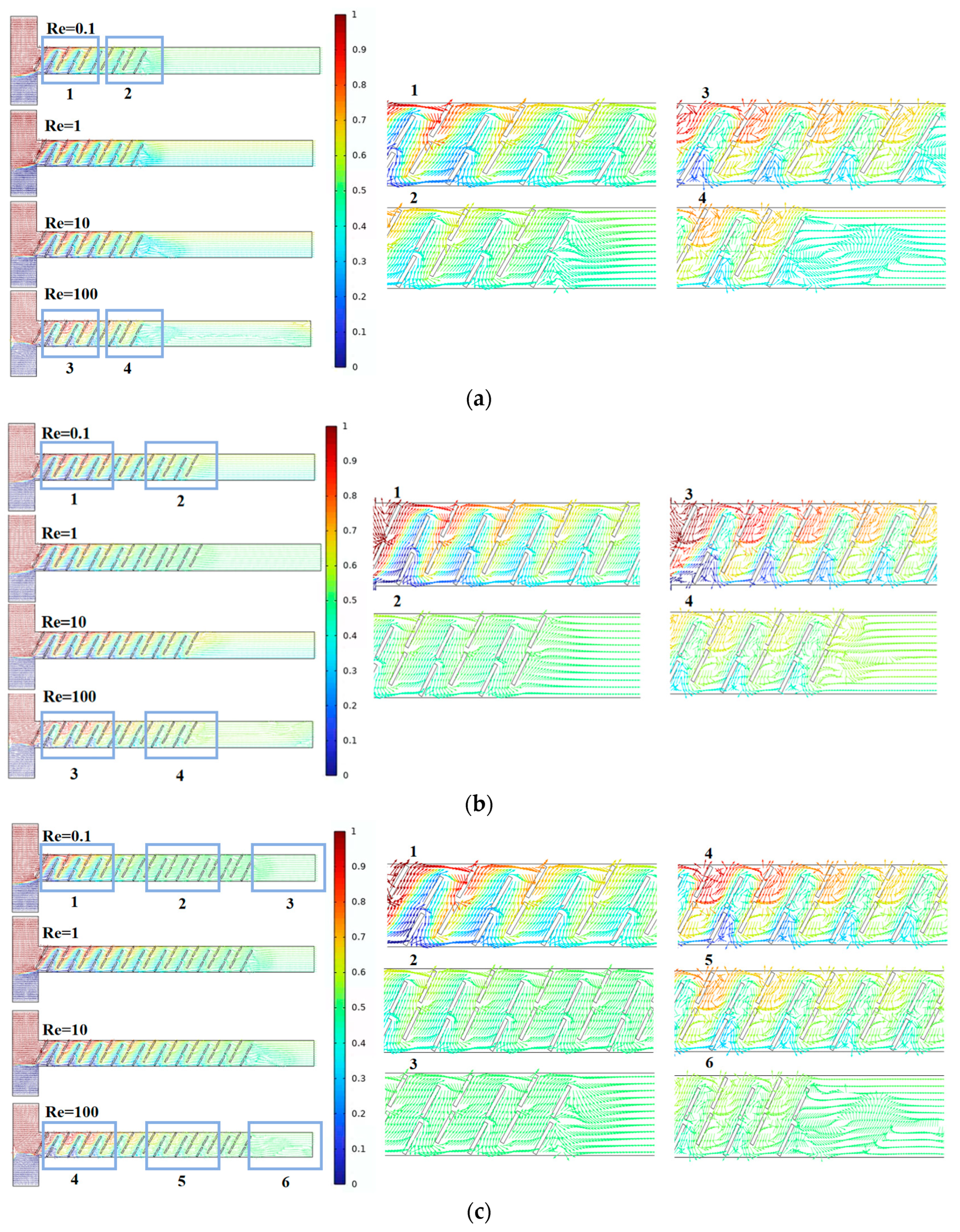

4.1. The Impact of the Vertical Displacement of Baffles on the Mixing and Flow Characteristics of the Solution

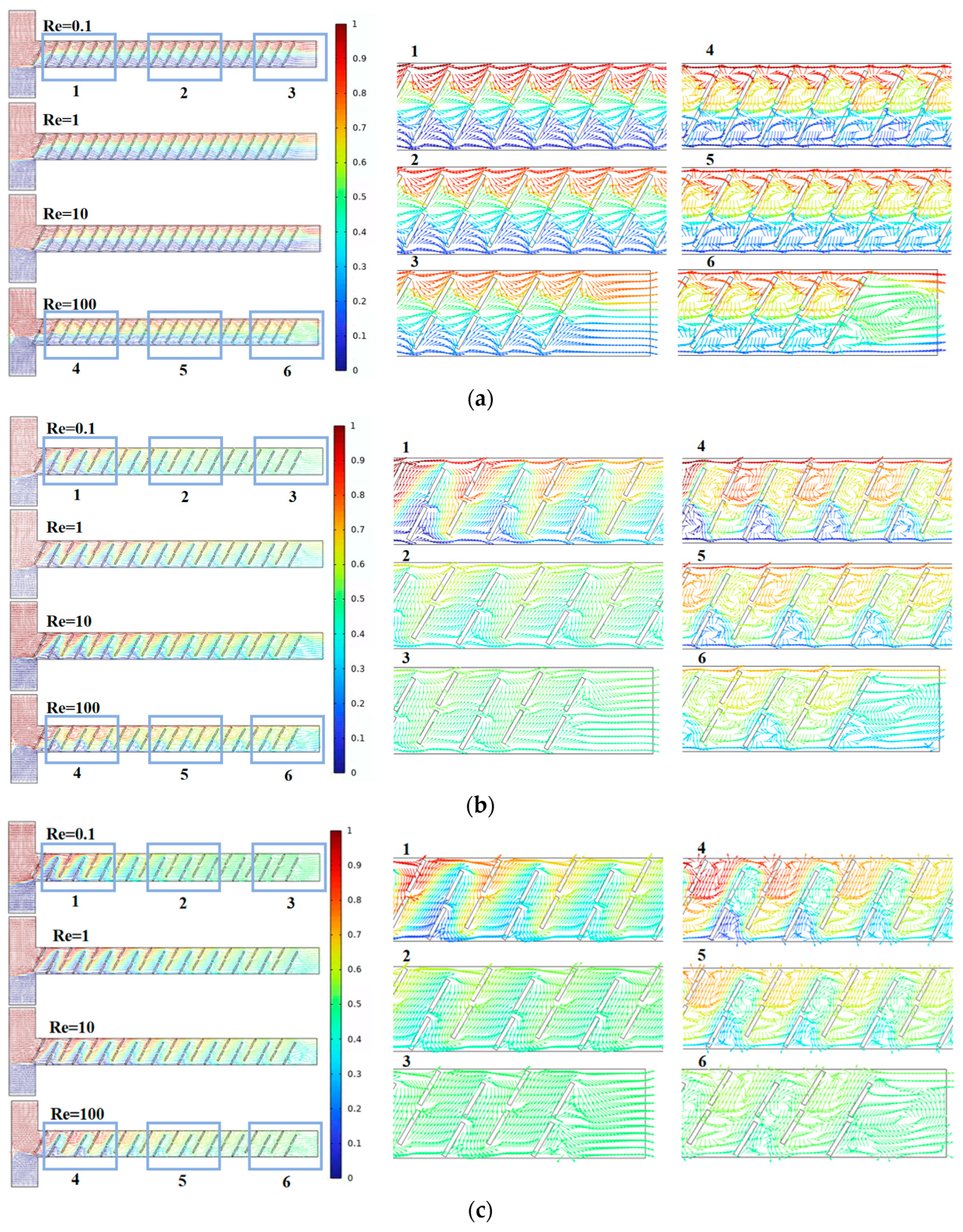

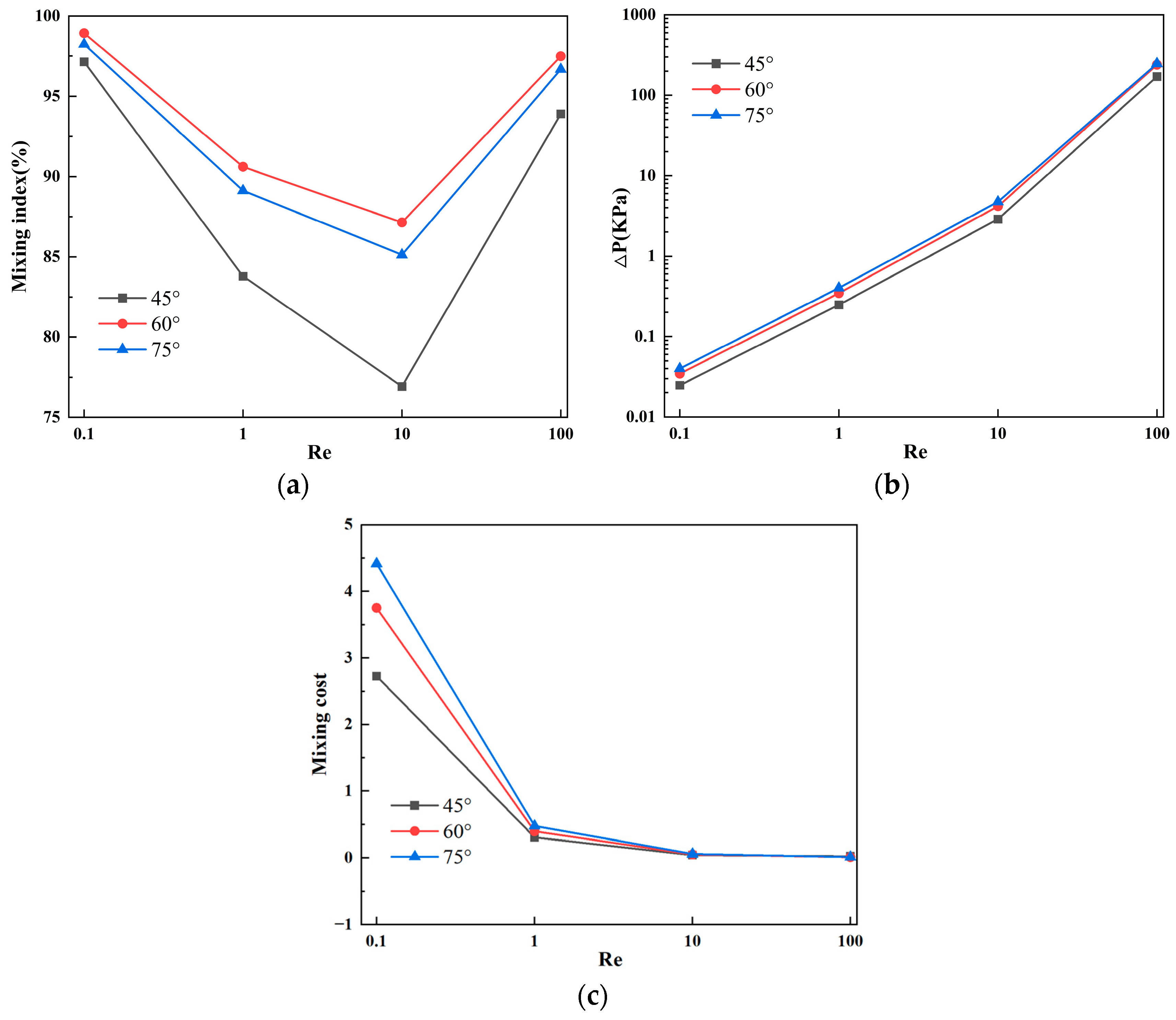

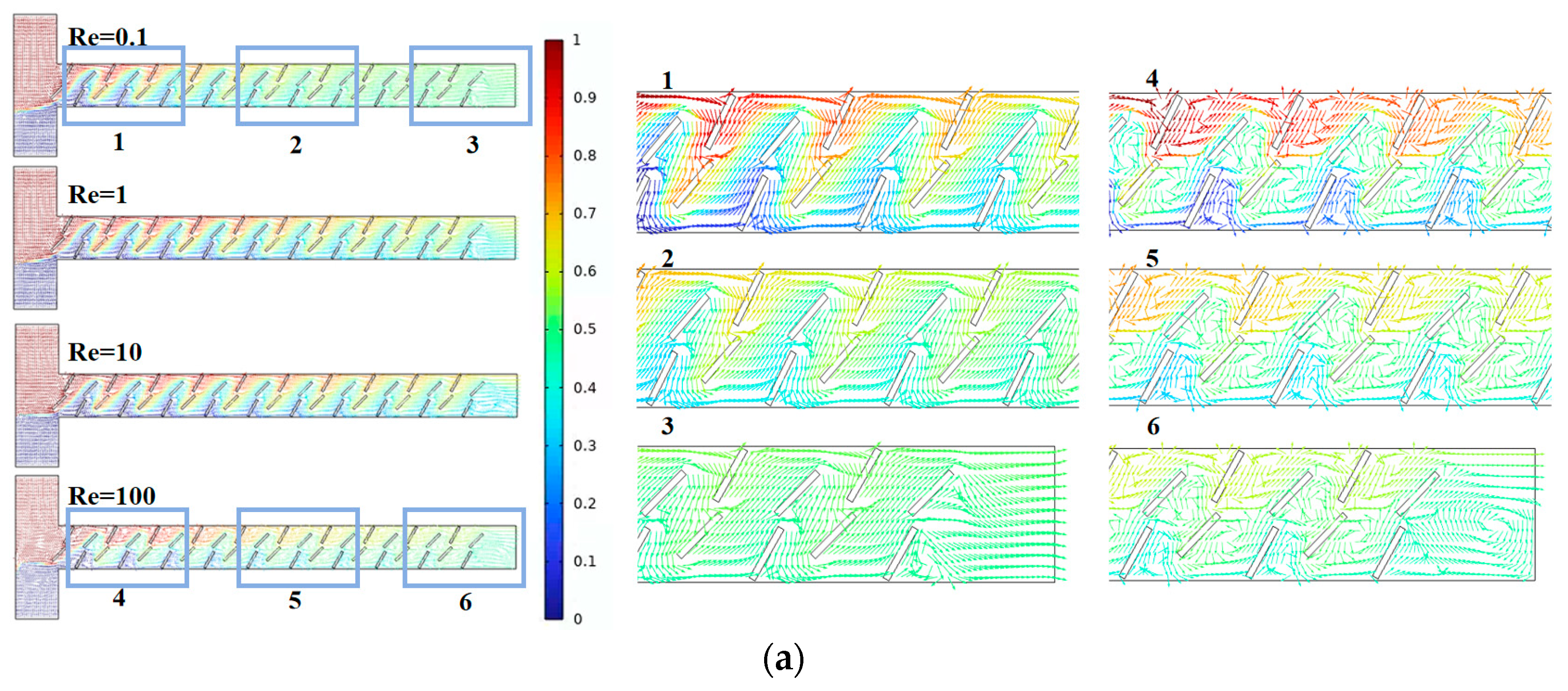

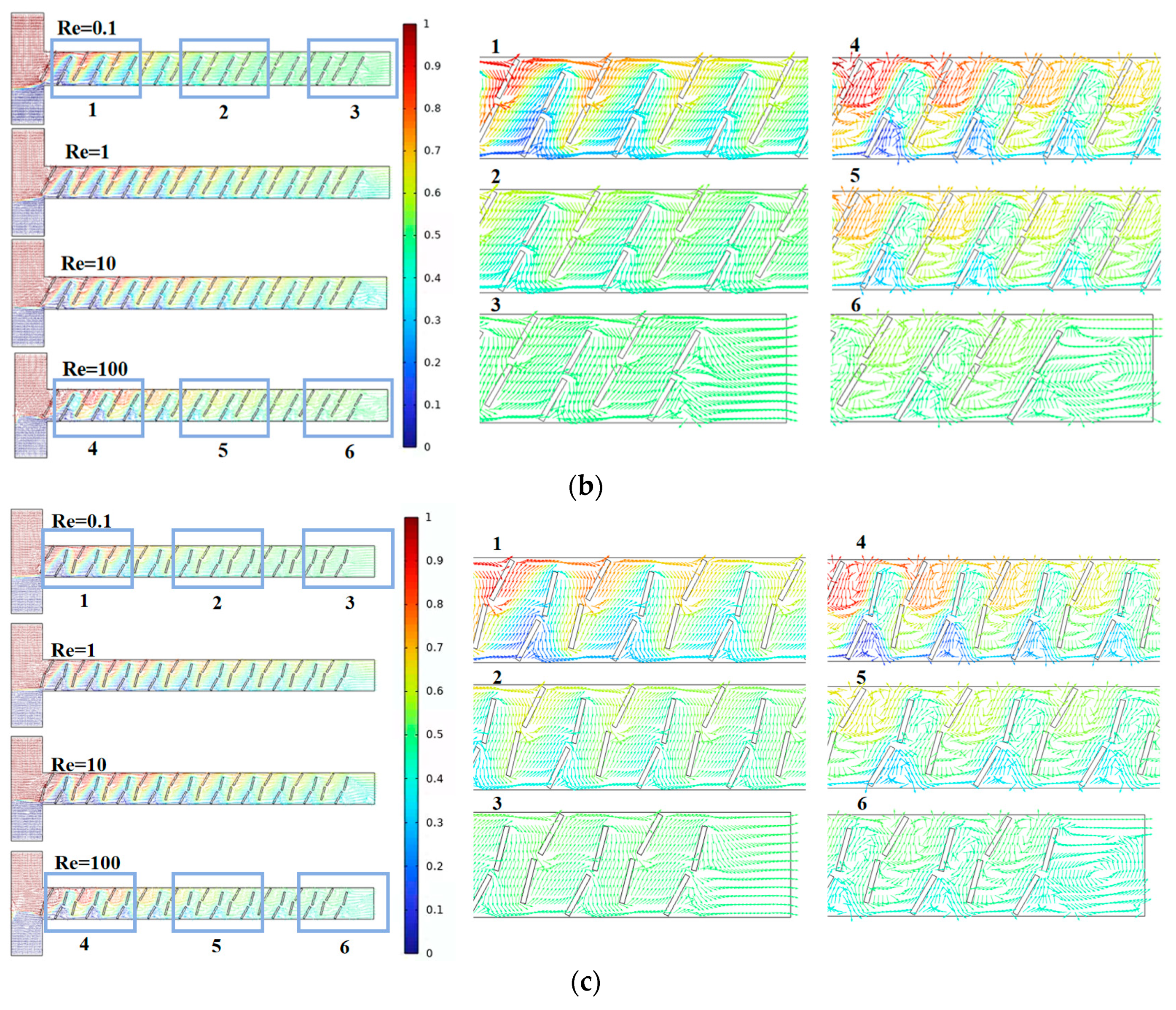

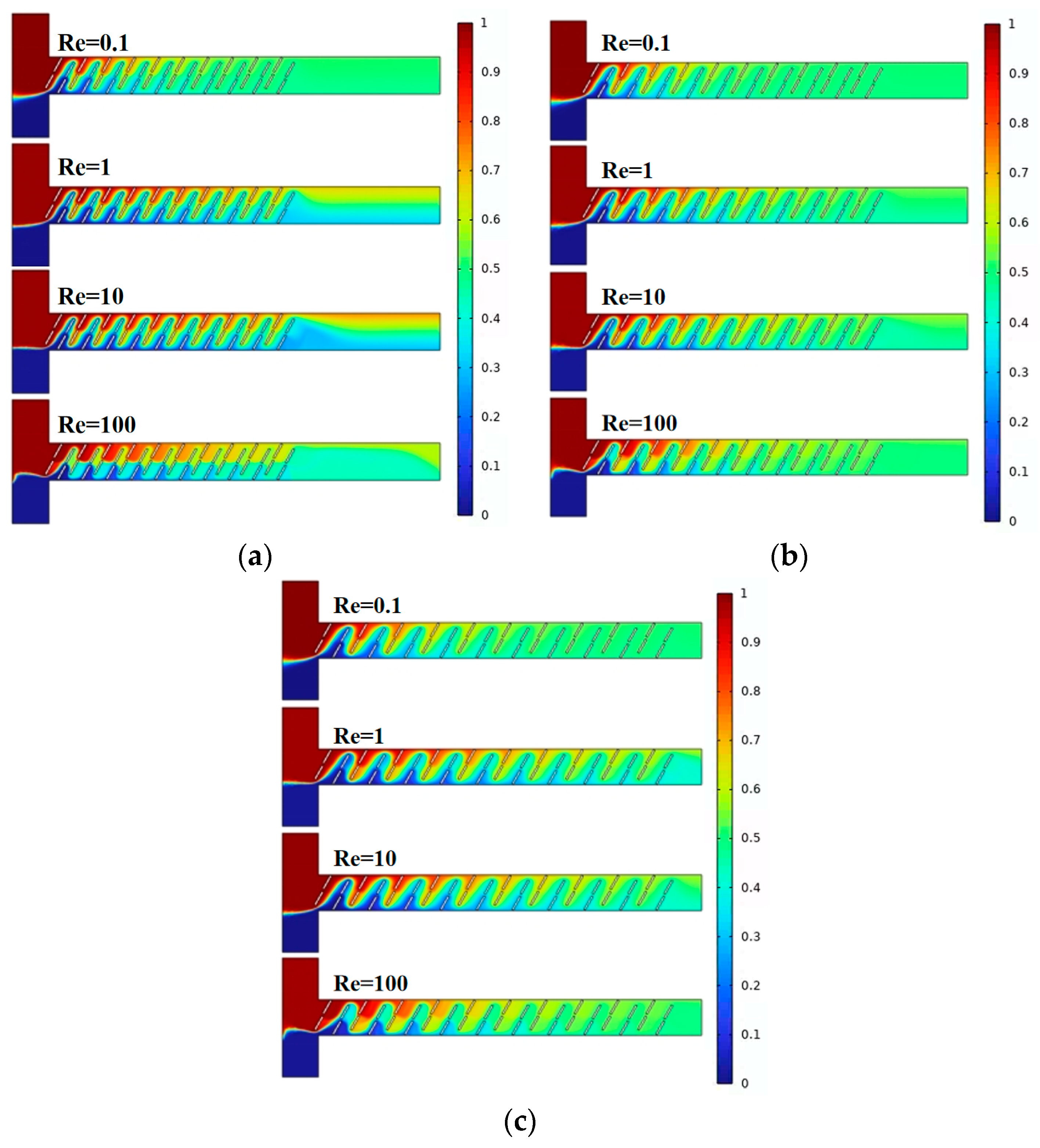

4.2. Effect of Baffle Rotation Angle on Solution Mixing and Flow Characteristics

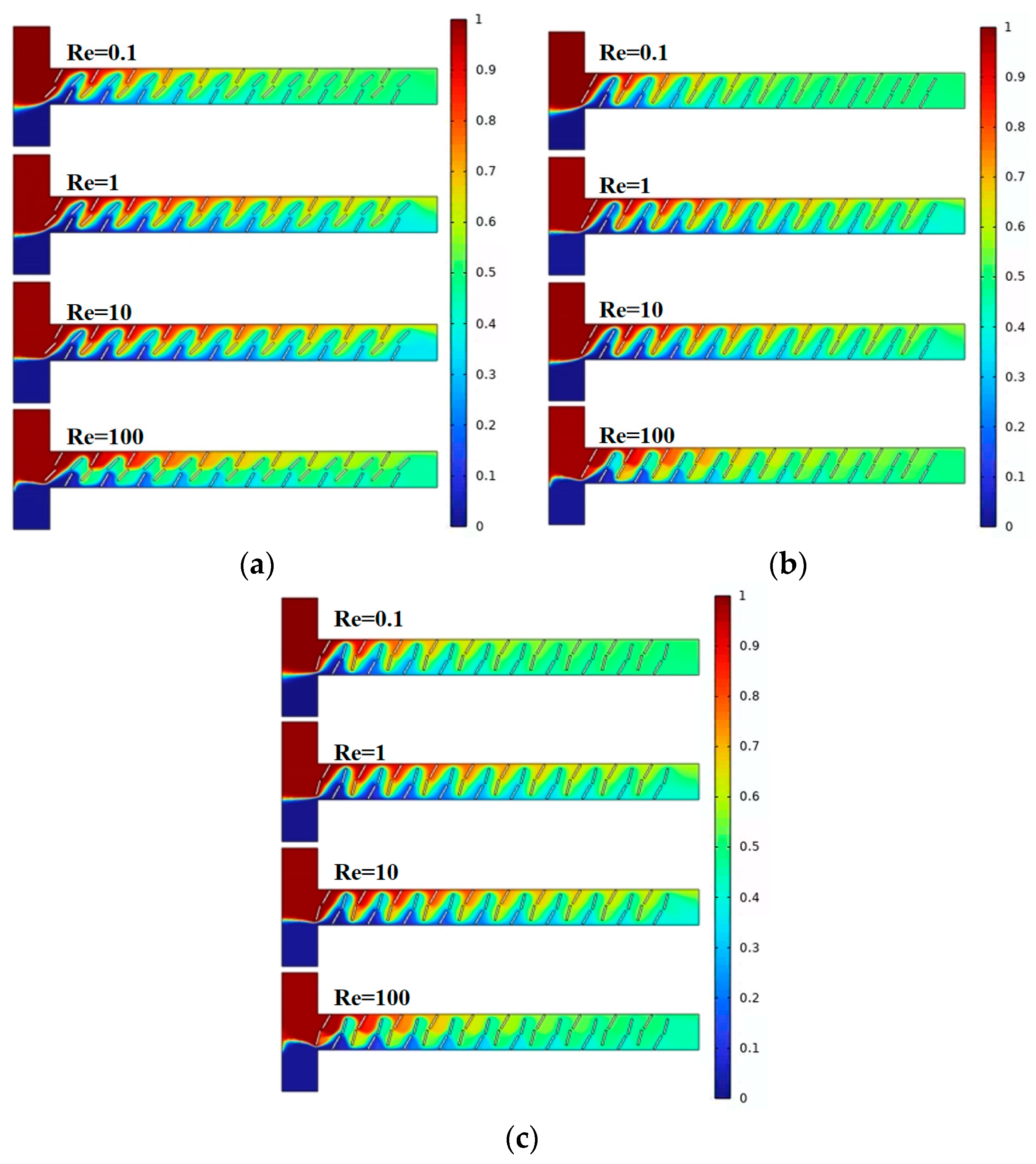

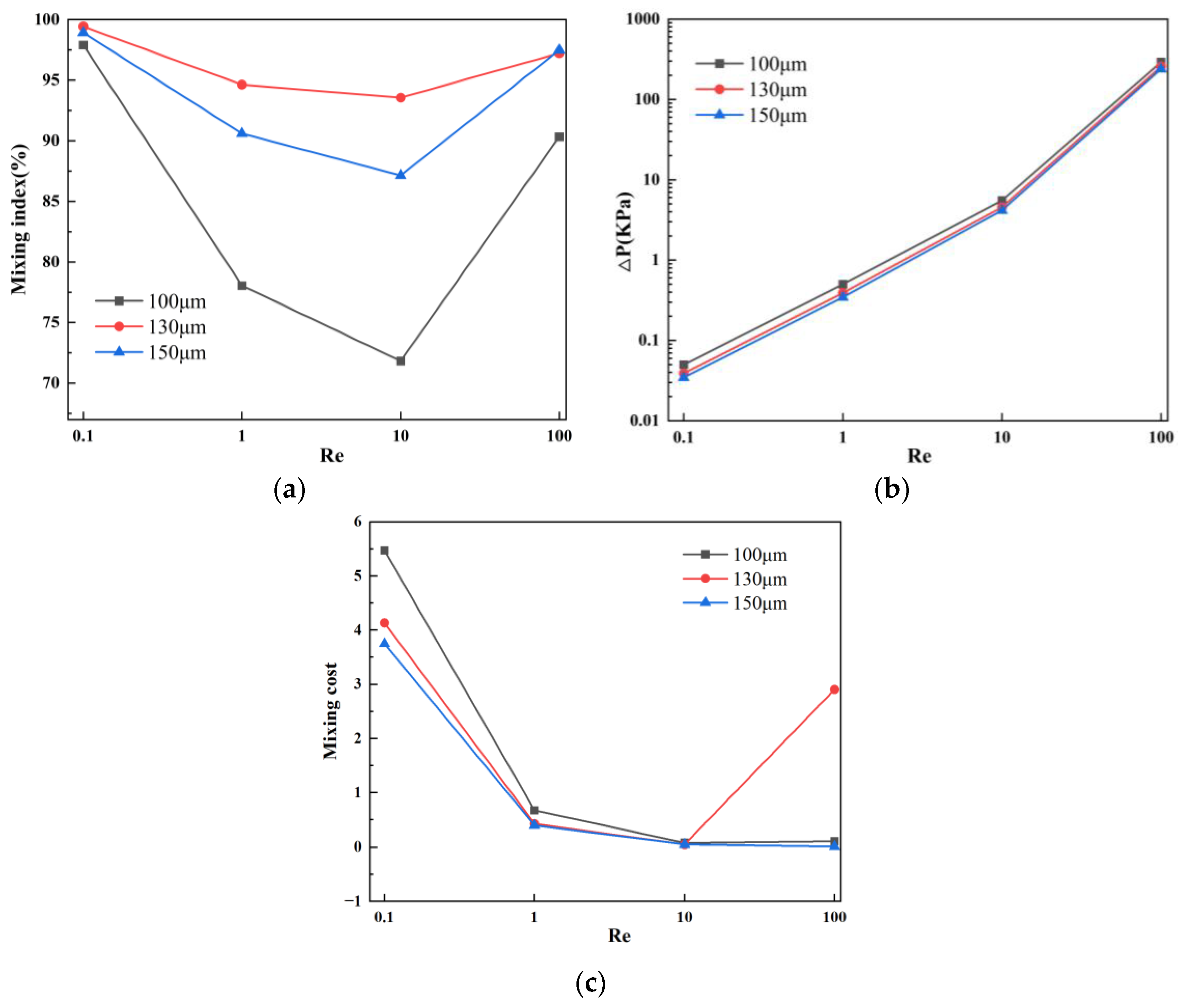

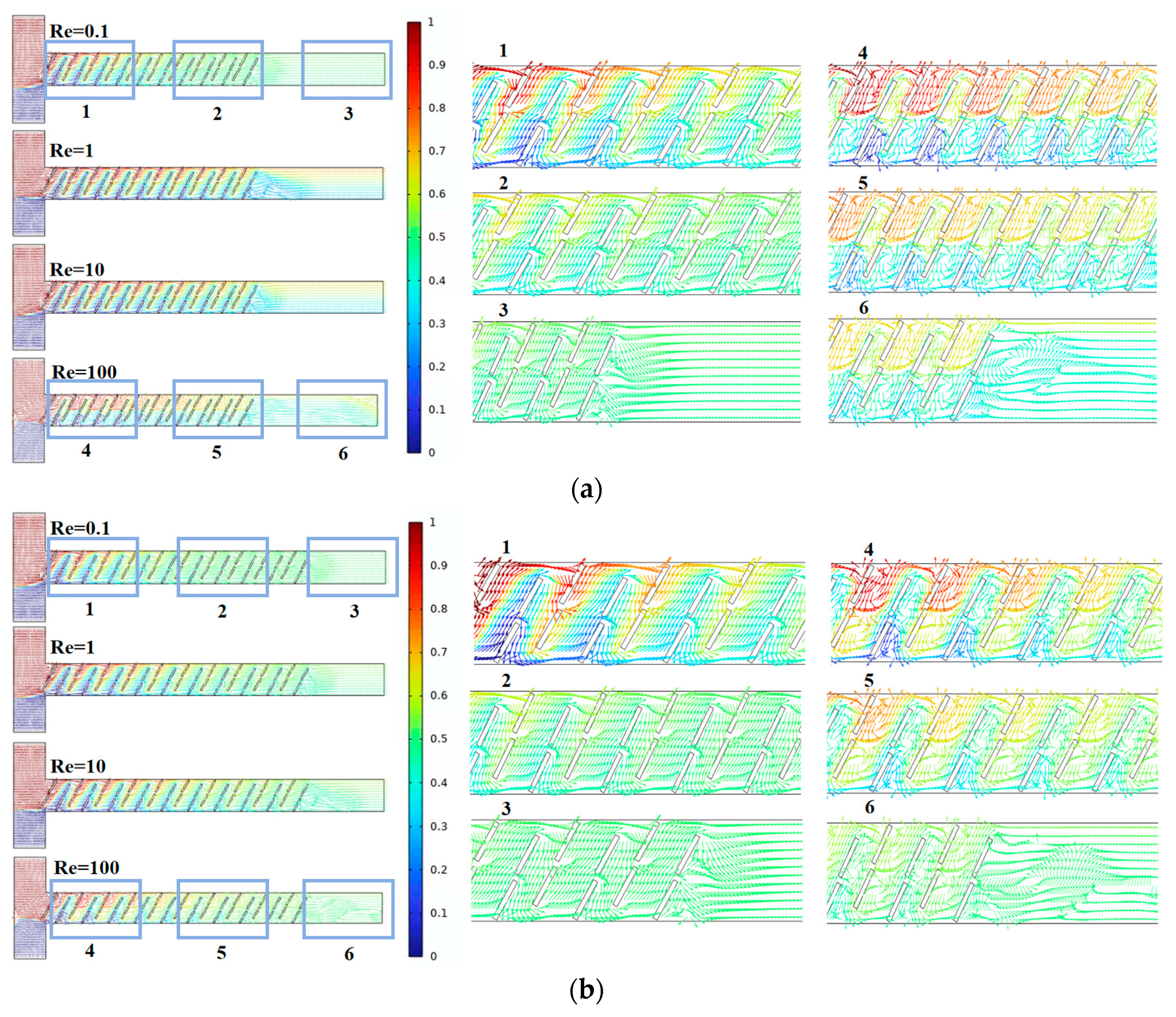

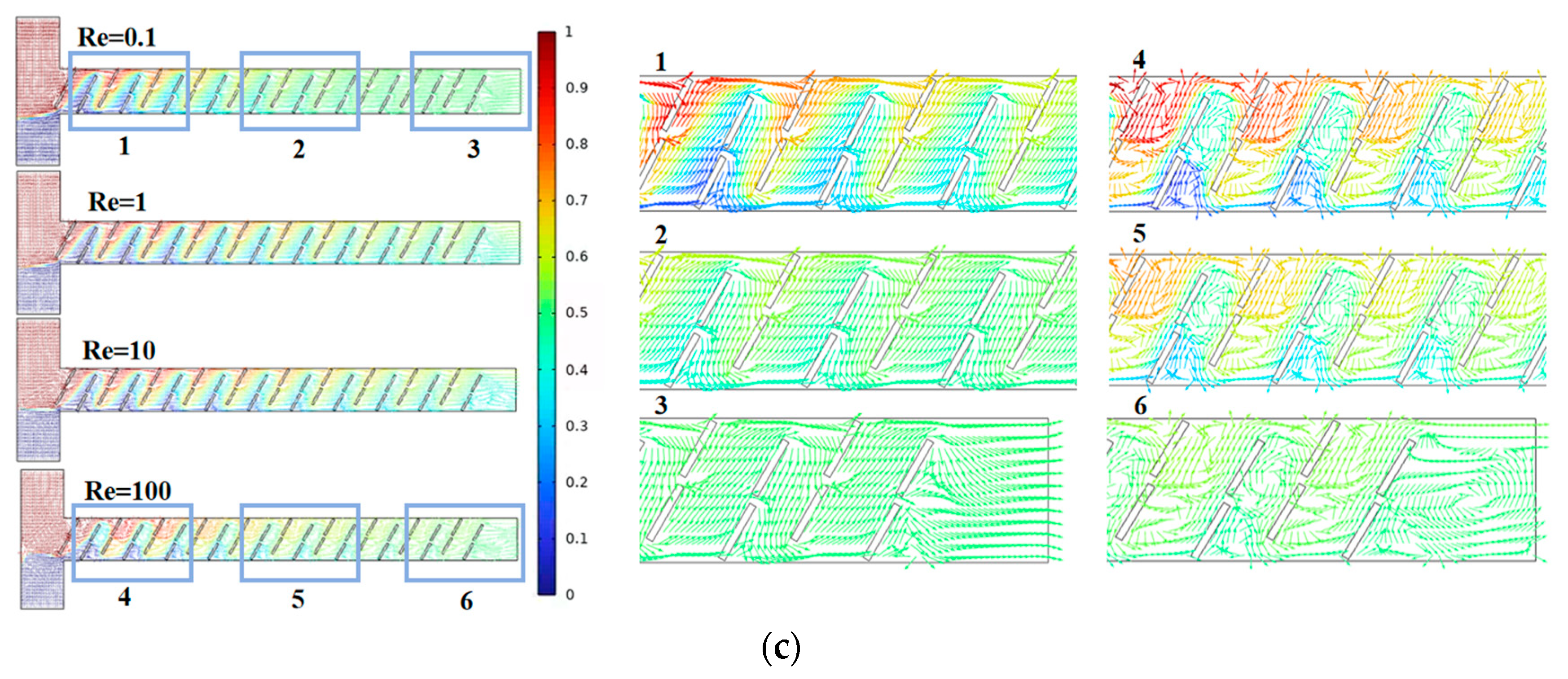

4.3. Effect of Baffle Horizontal Spacing on Solution Mixing and Flow Characteristics

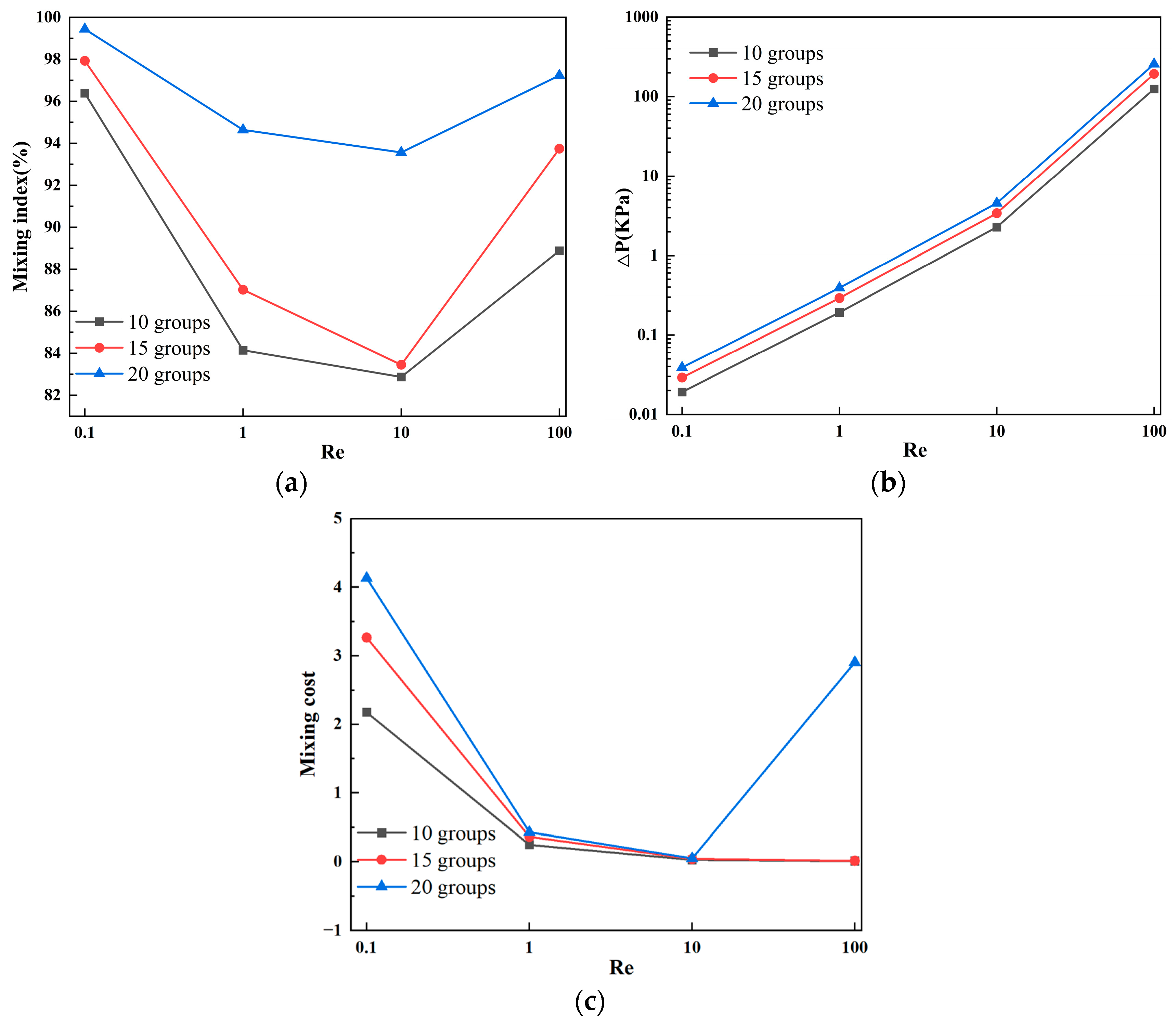

4.4. Effect of Baffle Logarithm on Solution Mixing and Flow Characteristics

5. Conclusions

- (1)

- The optimal mixing effect is achieved when the baffle vertical displacement is 90 μm, the baffle angle is 60°, horizontal spacing is 130 μm, and the number of baffles is 20 groups. At Re = 0.1, the mixing efficiency reaches 99.4%, and, at Re = 100, the mixing efficiency is 97.2%.

- (2)

- With the gradual increase of Re, the mixing efficiency shows a trend of decreasing first, and then increasing. When Re = 0.1, the dominant mode of fluid diffusion in the micromixer is molecular diffusion, and the mixing efficiency is related to the total path of fluid flow in the microchannel. As Re increases to 100, the area and velocity of the double vortex micro-eddies distributed along the main flow channel increase, enhancing chaotic convection in the micromixer and resulting in a more uniform concentration distribution of fluids.

- (3)

- The increase in mixing efficiency does not necessarily lead to a proportional increase in pressure drop in the micromixer. This finding suggests a new approach to structural optimization, enabling a high mixing efficiency while maintaining a relatively small pressure drop. This insight provides a reference for the design and development of micromixers with efficient mixing functionality for the preprocessing part in microfluidic analysis and micro-total analysis.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cui, W.; Zhao, P.; Wang, J.; Qin, N.; Ho, E.A.; Ren, C.L. Reagent free detection of SARS-CoV-2 using an antibody-based microwave sensor in a microfluidic platform. Lab Chip 2022, 22, 2307–2314. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.K.; Singha, P.; Dai, Y.; Sreejith, K.R.; Phan, H.P.; Nguyen, N.T.; Ooi, C.H. Controllable high-performance liquid marble micromixer. Lab Chip 2022, 22, 1508–1518. [Google Scholar] [CrossRef] [PubMed]

- Yin, B.; Wan, X.; Qian, C.; Sohan, A.M.; Zhou, T.; Yue, W. Enzyme method-based microfluidic chip for the rapid detection of copper ions. Micromachines 2021, 12, 1380. [Google Scholar] [CrossRef] [PubMed]

- Yin, B.; Wan, X.; Qian, C.; Sohan AM, F.; Zhou, T.; Yue, W. A review on micromixers. Micromachines 2017, 8, 274. [Google Scholar]

- Juraeva, M.; Kang, D.J. Mixing Performance of a Passive Micromixer Based on Multiple Baffles and Submergence Scheme. Micromachines 2023, 14, 1078. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, T. A novel passive micromixer designed by applying an optimization algorithm to the zigzag microchannel. Chem. Eng. J. 2017, 313, 1406–1414. [Google Scholar] [CrossRef]

- Chen, X.; Li, T.; Zeng, H.; Hu, Z.; Fu, B. Numerical and experimental investigation on micromixers with serpentine microchannels. Int. J. Heat Mass Transf. 2016, 98, 131–140. [Google Scholar] [CrossRef]

- Liu, G.; Wang, M.; Dong, L.; Zhu, D.; Wang, C.; Jia, Y.; Li, X.; Wang, J. A novel design for split-and-recombine micromixer with double-layer Y-shaped mixing units. Sens. Actuators A Phys. 2022, 341, 113569. [Google Scholar] [CrossRef]

- Dong, X.; Yaji, K.; Liu, X. Optimum design of micromixer for a non-Newtonian fluid by topology optimization. Chem. Eng. J. 2022, 428, 131367. [Google Scholar] [CrossRef]

- Ye, Z.; Jia, X.; Lou, M.; Huang, H.; Lu, P.; Ye, G.; Gong, X.; Zhu, Y.; Yan, B. Surface-enhanced Raman scattering substrates prepared by controlled synthesis of gold nanobipyramids in microchannels. Microfluid. Nanofluidics 2022, 26, 28. [Google Scholar] [CrossRef]

- Shi, H.; Nie, K.; Dong, B.; Chao, L.; Gao, F.; Ma, M.; Long, M.; Liu, Z. Mixing enhancement via a serpentine micromixer for real-time activation of carboxyl. Chem. Eng. J. 2020, 392, 123642. [Google Scholar] [CrossRef]

- Niu, D.; Chen, J.; Xiong, M.; Cao, Y.; He, C.; Chen, J.; Liu, H. Numerical investigation of multiscale lateral microstructures enhancing passive micromixing efficiency via secondary vortex flow. Phys. Fluids 2022, 34, 092006. [Google Scholar] [CrossRef]

- de Oliveira Maionchi, D.; Ainstein, L.; dos Santos, F.P.; de Souza Júnior, M.B. Computational fluid dynamics and machine learning as tools for optimization of micromixers geometry. Int. J. Heat Mass Transf. 2022, 194, 123110. [Google Scholar] [CrossRef]

- Fu, Q.; Liu, Z.; Cao, S.; Wang, Z.; Liu, G. Topology-Optimized Micromixer Design with Enhanced Reverse Flow to Increase Mixing Efficiency. Micromachines 2023, 14, 1599. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Chen, X. A novel passive micromixer based on Koch fractal principle. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 487. [Google Scholar] [CrossRef]

- Nikpour, M.; Mohebbi, A. Optimization of micromixer with different baffle shapes using CFD, DOE, meta-heuristic algorithms and multi-criteria decision making. Chem. Eng. Process.-Process Intensif. 2022, 170, 108713. [Google Scholar] [CrossRef]

- Hossain, S.; Kim, K.Y. Mixing analysis of passive micromixer with unbalanced three-split rhombic sub-channels. Micromachines 2014, 5, 913–928. [Google Scholar] [CrossRef]

- Yuan, S.; Jiang, B.; Peng, T.; Zhou, M.; Drummer, D. Investigation of efficient mixing enhancement in planar micromixers with short mixing length. Chem. Eng. Process.-Process Intensif. 2022, 171, 108747. [Google Scholar] [CrossRef]

- Nai, J.; Zhang, F.; Dong, P.; Bai, F.; Fu, T.; Wang, J.; Ge, A. Effect of Multiple Structural Parameters on the Performance of a Micromixer with Baffles, Obstacles, and Gaps. Micromachines 2023, 14, 1750. [Google Scholar] [CrossRef]

- Rho, H.S.; Hanke, A.T.; Ottens, M.; Gardeniers, H.J.G.E. A microfluidic chip with a staircase pH gradient generator, a packed column and a fraction collector for chromatofocusing of proteins. Electrophoresis 2018, 39, 1031–1039. [Google Scholar] [CrossRef]

- Xie, H.; Wang, L.; Chen, X. Insight Into An Efficient Micromixer with Stagger Abreast Baffles. Surf. Rev. Lett. 2022, 29, 2250112. [Google Scholar] [CrossRef]

- Zhao, S.; Wei, Y.; Yu, P.; Nie, Y.; Hu, R.; He, W.; Zhu, N.; Li, Y.; Ji, D.; Guo, K. High throughput millifluidics mixer with double triangle baffle for improvement of mixing performance and reduction of flow resistance designed by grey relational analysis. Chem. Eng. Process.-Process Intensif. 2022, 181, 109166. [Google Scholar] [CrossRef]

- Ansari, M.A.; Kim, K.Y.; Kim, S.M. Numerical and experimental study on mixing performances of simple and vortex micro T-mixers. Micromachines 2018, 9, 204. [Google Scholar] [CrossRef]

- Ahmadi, V.E.; Butun, I.; Altay, R.; Bazaz, S.R.; Alijani, H.; Celik, S.; Warkiani, M.E.; Koşar, A. The effects of baffle configuration and number on inertial mixing in a curved serpentine micromixer: Experimental and numerical study. Chem. Eng. Res. Des. 2021, 168, 490–498. [Google Scholar] [CrossRef]

- Agarwal, T.; Wang, L. Numerical analysis of vortex T micromixer with diffuser plates and baffle micromixers. Therm. Sci. Eng. Prog. 2022, 28, 101156. [Google Scholar] [CrossRef]

- Gidde, R.R. On the computational analysis of short mixing length planar split and recombine micromixers for microfluidic applications. Int. J. Environ. Anal. Chem. 2021, 101, 79–94. [Google Scholar] [CrossRef]

- Rudyak, V.; Minakov, A. Modeling and optimization of Y-type micromixers. Micromachines 2014, 5, 886–912. [Google Scholar] [CrossRef]

- Arockiam, S.; Cheng, Y.H.; Armenante, P.M.; Basuray, S. Experimental determination and computational prediction of the mixing efficiency of a simple, continuous, serpentine-channel microdevice. Chem. Eng. Res. Des. 2021, 167, 303–317. [Google Scholar] [CrossRef]

- Mehta, S.K.; Mondal, P.K. Vortex-assisted electroosmotic mixing of Carreau fluid in a microchannel. Electrophoresis 2023, 44, 1629–1636. [Google Scholar] [CrossRef]

- Lee, C.Y.; Wang, W.T.; Liu, C.C.; Fu, L.M. Passive mixers in microfluidic systems: A review. Chem. Eng. J. 2016, 288, 146–160. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.; Liu, Y.; Tang, C.; Liu, B.; Zou, H.; Li, W.; Zhang, H. Mixing Performance Analysis and Optimal Design of a Novel Passive Baffle Micromixer. Micromachines 2024, 15, 182. https://doi.org/10.3390/mi15020182

Zheng Y, Liu Y, Tang C, Liu B, Zou H, Li W, Zhang H. Mixing Performance Analysis and Optimal Design of a Novel Passive Baffle Micromixer. Micromachines. 2024; 15(2):182. https://doi.org/10.3390/mi15020182

Chicago/Turabian StyleZheng, Yiwen, Yu Liu, Chaojun Tang, Bo Liu, Hongyuan Zou, Wei Li, and Hongpeng Zhang. 2024. "Mixing Performance Analysis and Optimal Design of a Novel Passive Baffle Micromixer" Micromachines 15, no. 2: 182. https://doi.org/10.3390/mi15020182

APA StyleZheng, Y., Liu, Y., Tang, C., Liu, B., Zou, H., Li, W., & Zhang, H. (2024). Mixing Performance Analysis and Optimal Design of a Novel Passive Baffle Micromixer. Micromachines, 15(2), 182. https://doi.org/10.3390/mi15020182