Usable Analytical Expressions for Temperature Distribution Induced by Ultrafast Laser Pulses in Dielectric Solids

Abstract

:1. Introduction

“The underlying physical laws necessary for the mathematical theory of a large part of physics and the whole of chemistry are thus completely known, and the difficulty is only that the exact application of these laws leads to equations much too complicated to be soluble. It therefore becomes desirable that approximate practical methods of applying quantum mechanics should be developed, which can lead to an explanation of the main features of complex atomic systems without too much computation”.

- -

- The appearance of several regions in the heat-affected volume including change of the structure of a glass, crystallization, phase separation, thermal erasure while writing providing that energy endo or exo is negligible in front of the laser one;

- -

- The variations in the shape of the interaction volume according to the laser parameters like a change of laser track width, change of laser track morphology.

2. Starting Formulation

3. Final Temperatures at Steady State

3.1. At the Center

- -

- oscillates between a minimum () and a maximum () in each period between two pulses;

- -

- The oscillation amplitude seems to be the same, whatever ;

- -

- -

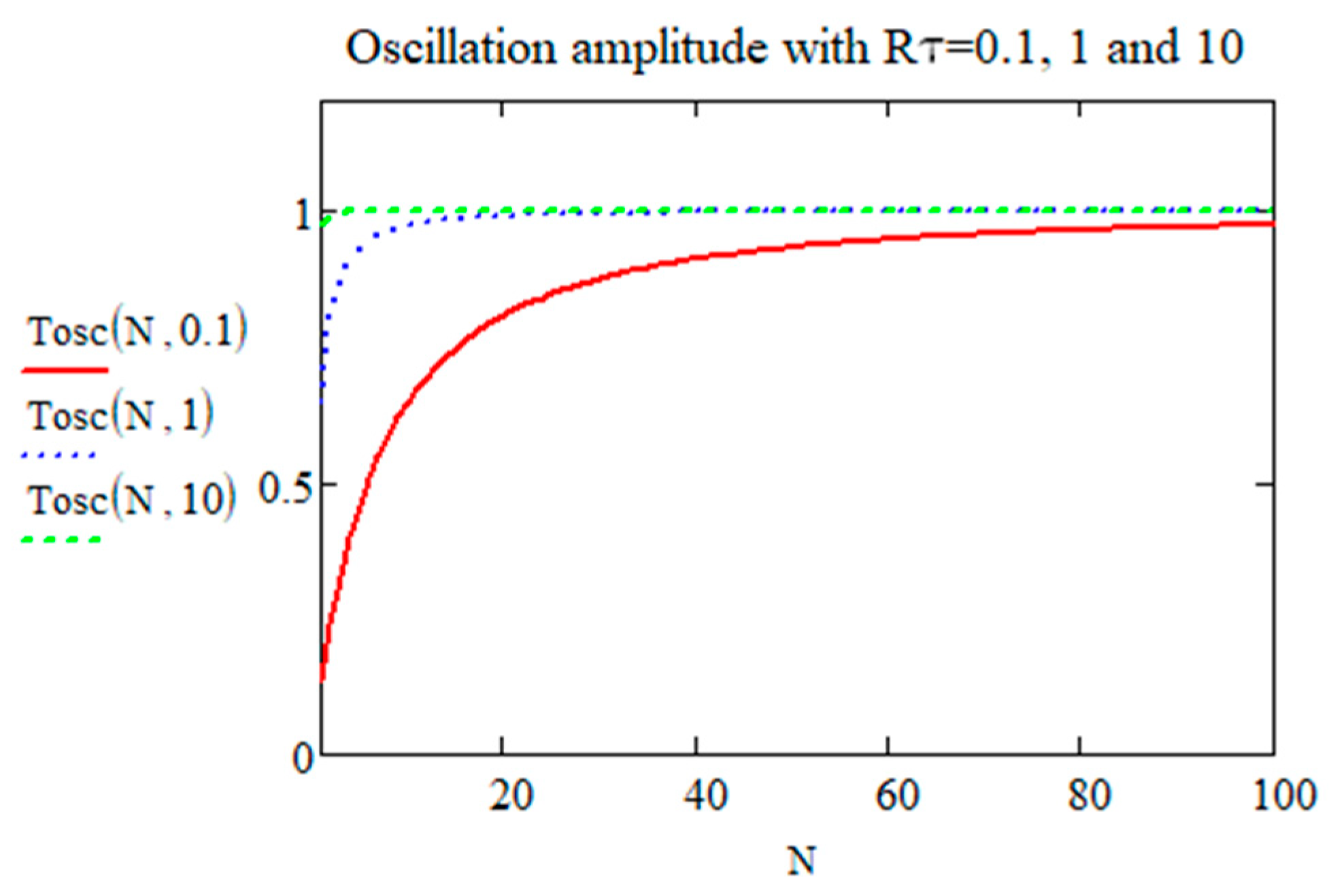

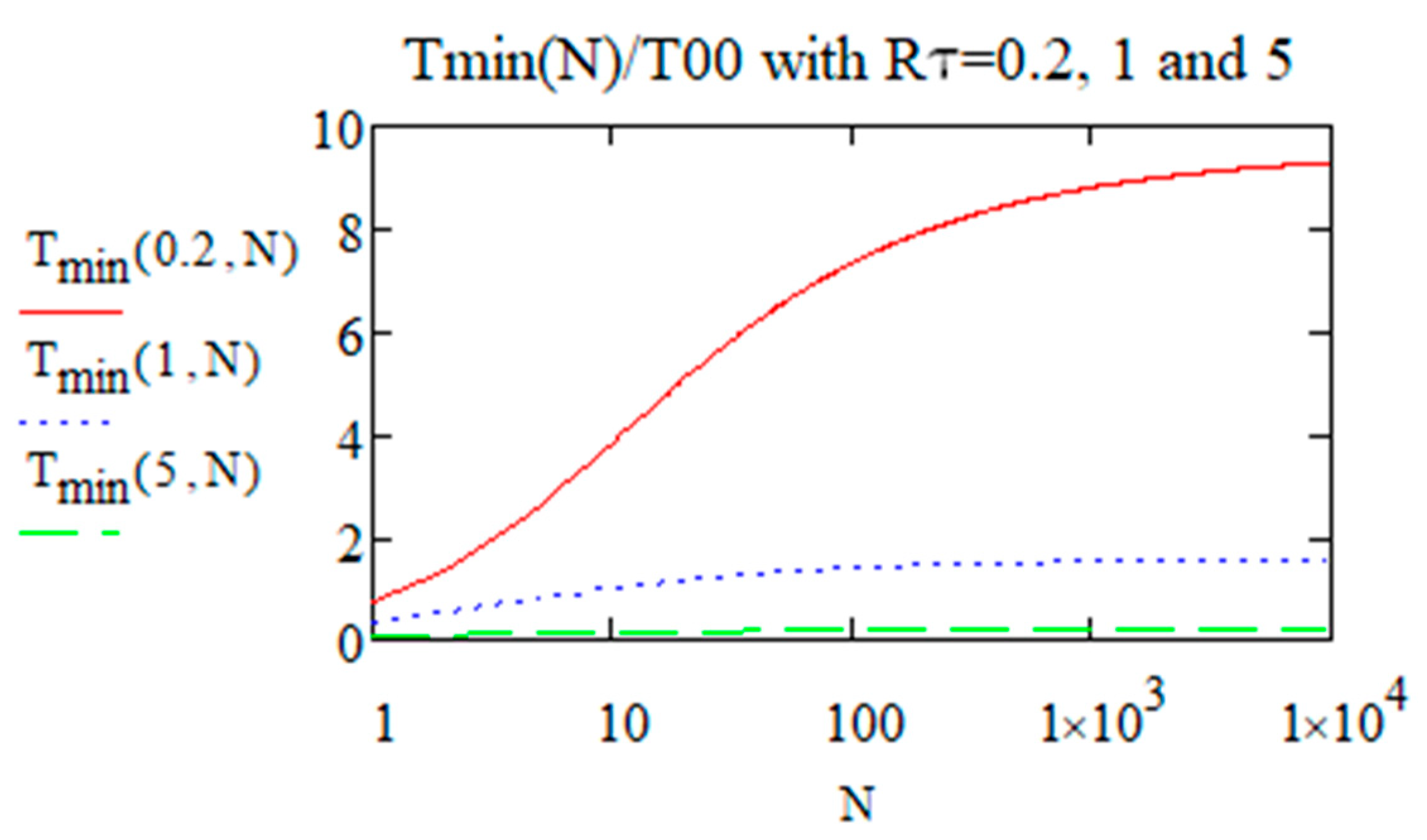

- The number of pulses to reach this ‘steady state’ appears very small for a large but larger for small values. For a larger , the temporal overlapping of temperature increase contributions from consecutive pulses is weaker, whereas it increases (heat accumulation) when is smaller.

3.1.1. The Oscillation Amplitude Tosc

The Limit of the Temperature Oscillation Amplitude after an Infinite Number of Pulses

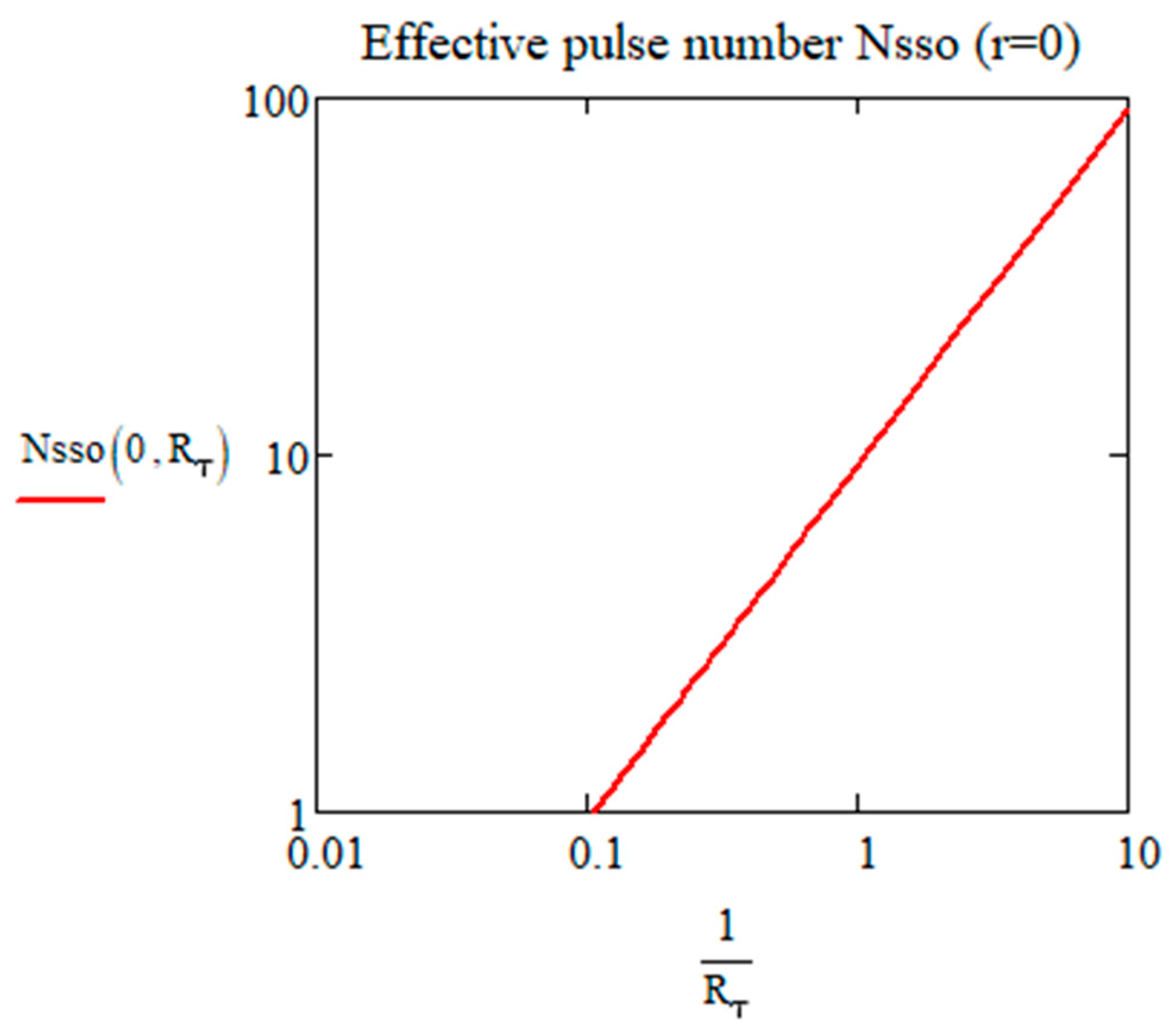

The Effective Number of Pulses for Reaching the Limit of Tosc()

Tmin and Tmax

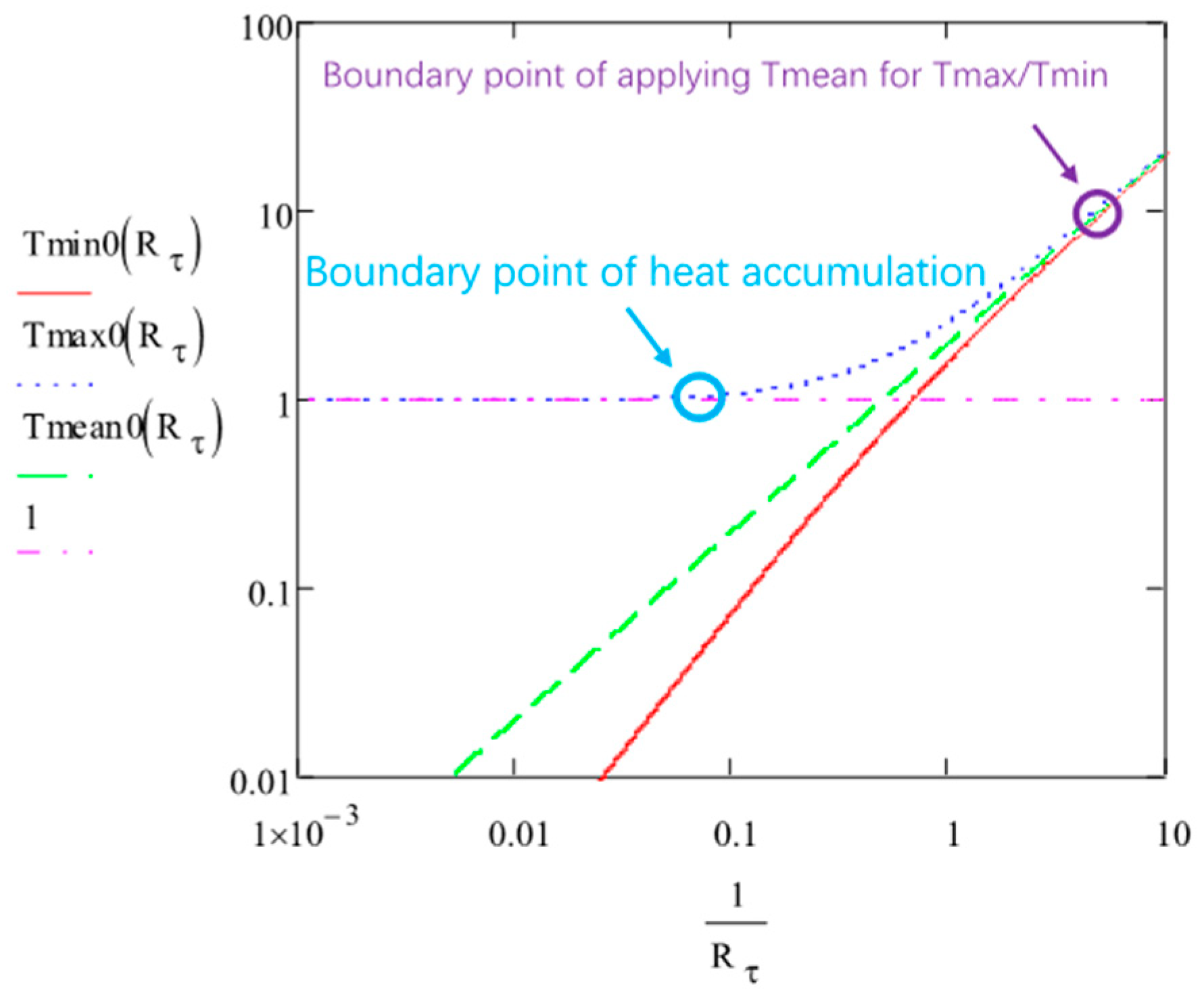

The Limit of Tmax and Tmin

The Effective Number of Pulses for Reaching the Limit of Tmin and Tmax (

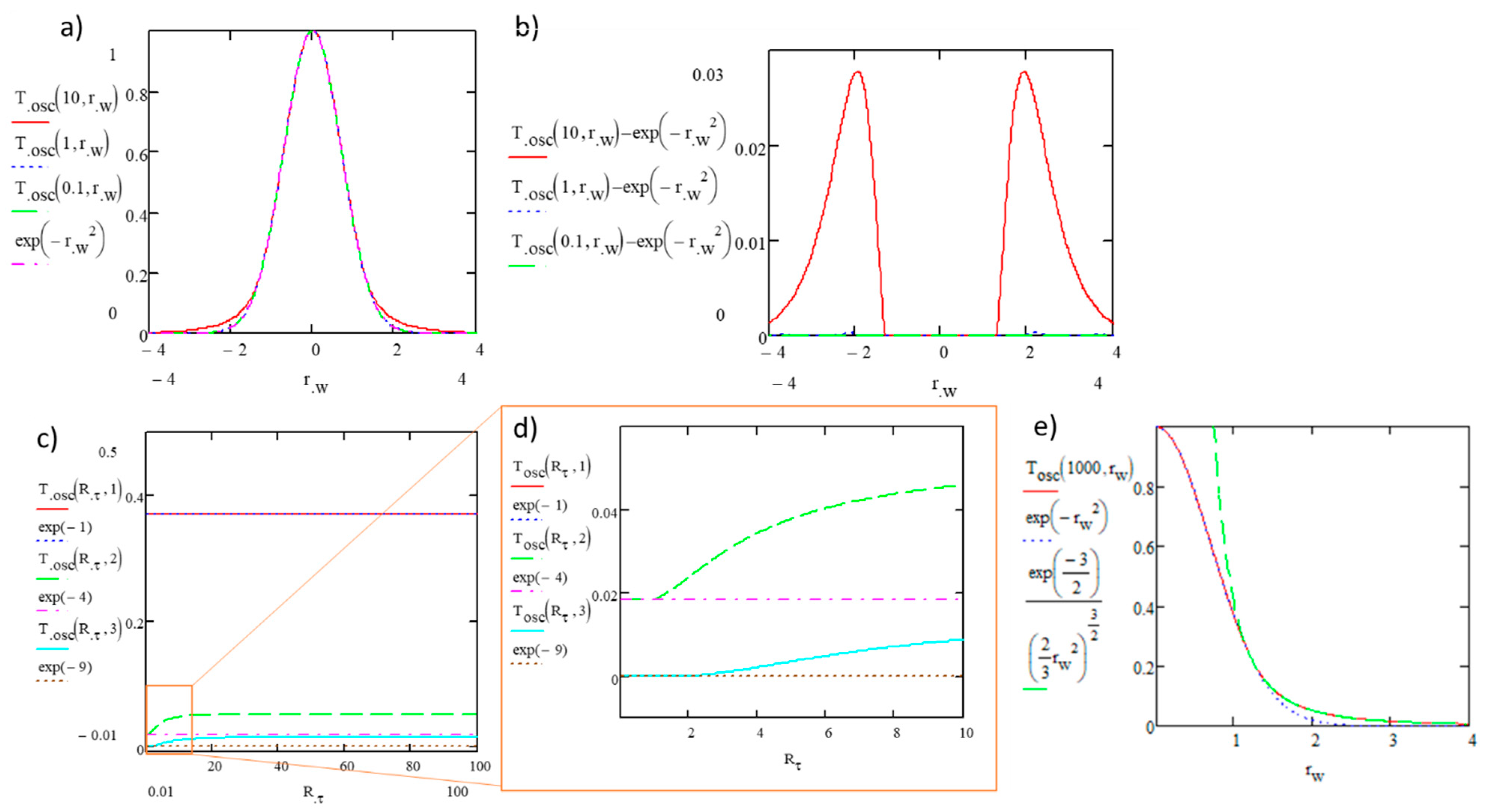

3.2. Time Behavior out of the Center ()

- -

- The amplitude of oscillation is less than 1 (in the unit of T00) for increasing radius;

- -

- The maximum temperature during a period is still at the beginning of the pulse deposition for = 1 with these three , while at = 2 the maximum temperature is no more at the beginning. That is because there is time for heat to diffuse from the center to . This renders the following calculation of Tmax for increasing radius to be more complex.

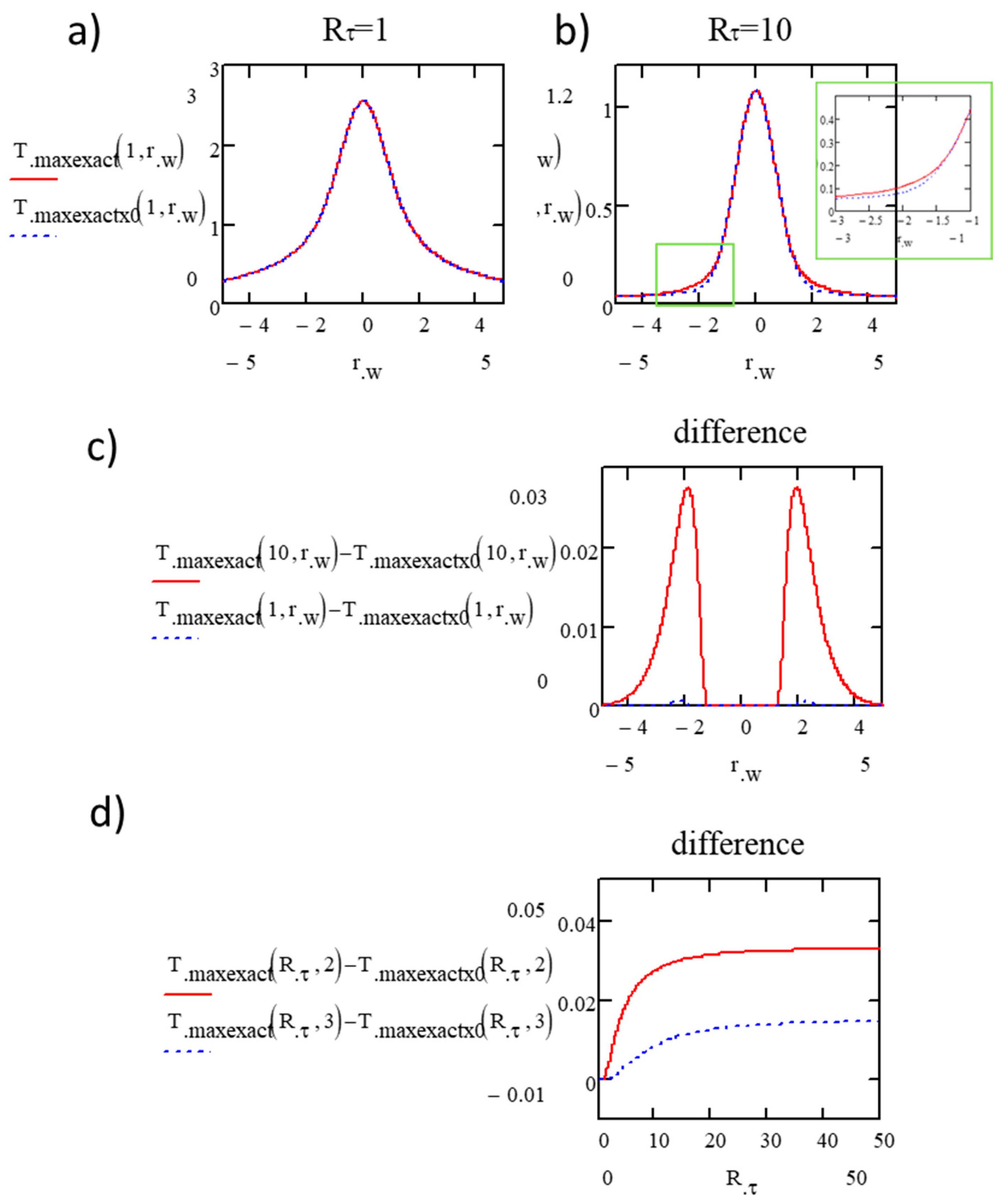

3.2.1. Tosc, Tmin, and Tmax

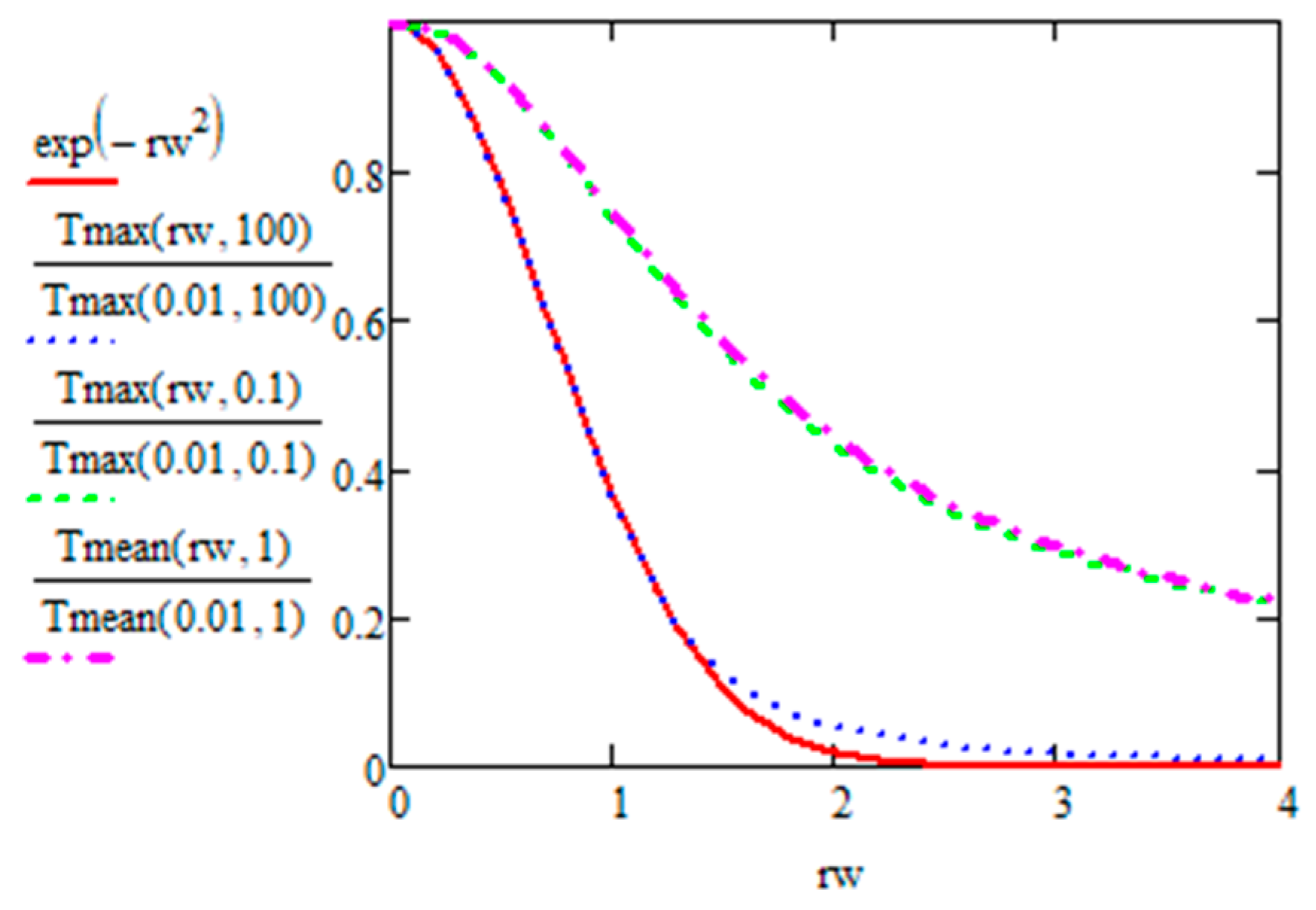

The Limit of Tmax and Tmin (when )

- (1)

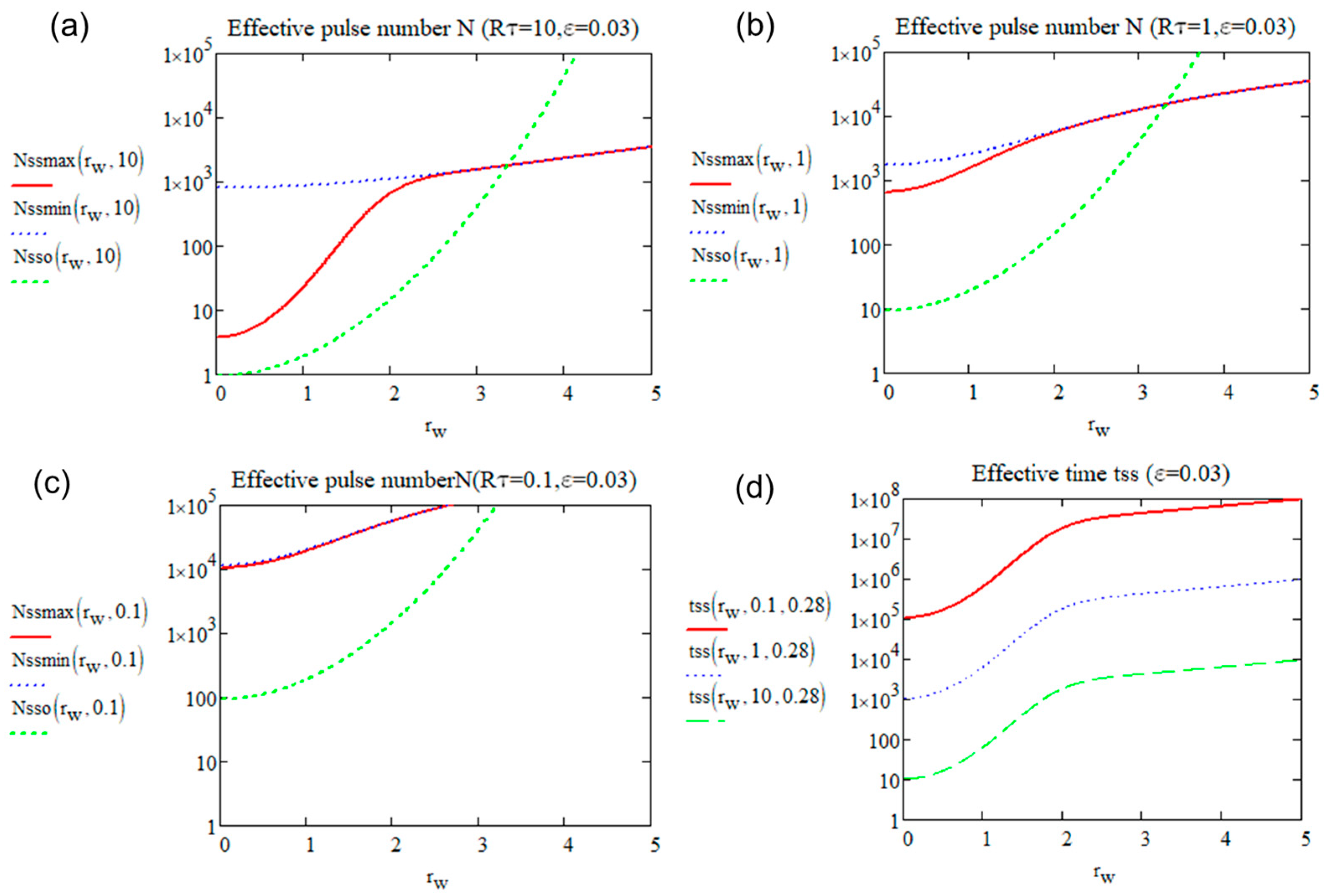

- In the intermediate cases around Rτ = 1, the center of the heat-affected zone experiences large temperature oscillations whereas the periphery temperature is not oscillating. This may induce differences in the modification structures along the radius. Specifically, the pedestal of the curve, borne by Tmin, increases in width with as ;

- (2)

- For smaller values, during the transient period (before Nss), the width of the temperature distribution starts with the beam waist (Gaussian) and then increases until a size which is defined by . It does not increase indefinitely over time. The order of magnitude is one w per two orders of magnitude on , e.g., the trace width at 1 MHz is twice the one at 10 kHz.

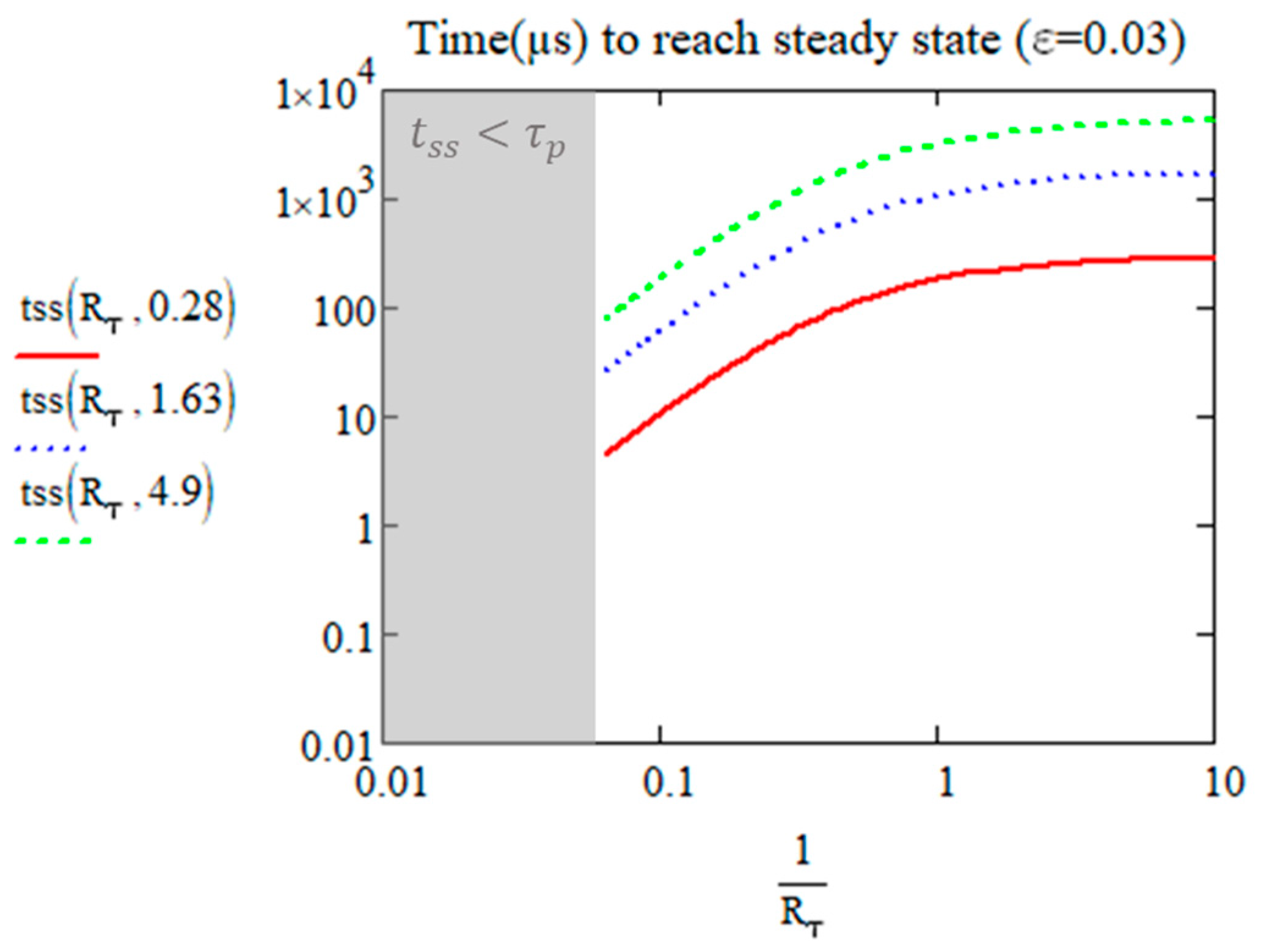

The Effective Number of Pulses for Reaching the Temperature Limits

4. The Mean Temperature in the Period between Two Pulses

4.1. Temperature at the Center ()

The Effective Number of Pulses for Reaching the Limit ()

4.2. Temperature out of the Focus Center ()

The Effective Number of Pulses for Reaching the Limit of Tmean ()

5. Application Examples

- -

- If a process is actually independent of RR, it does not depend on temperature (see [46]);

- -

- The number of pulses received by the material locally depends on the scanning speed. As the number of pulses for reaching a steady state is different at the center than at the periphery, it is possible that the appearance of the trace on the edge depends on the scanning speed during the transient stage;

- -

- However, the transient stage is not dependent on the pulse energy.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameters | Definitions | Units |

|---|---|---|

| Fraction of reflected light by the plasma | none | |

| Light absorption | μm−1 | |

| A small quantity of computational needs | none | |

| Period of the pulses | μs | |

| Heat diffusion time | μs | |

| none | ||

| Beam waist radius (at 1/e) | μm | |

| Thermal diffusivity | m2/s | |

| Thermal conductivity | W/(m·K) | |

| Pulse energy | J | |

| Pulse repetition rate | MHz | |

| Density | kg/m3 | |

| Specific heat capacity | J/(kg·K) |

| (kg/m3) | (J/(kg·K)) | (W/(m·K)) | (m2/s) | (µs) | Melting Point (K) | |

|---|---|---|---|---|---|---|

| STS glass | 3887 | 410 | 10.1 | 6.34 × 10−6 | 0.039 | 1585 |

| LNS glass | 3830 | 650 | 2.65 | 1.06 × 10−6 | 0.235 | 1530 |

| SiO2 (glass) | 2200 | 703 | 1.38 | 8.92 × 10−7 | 0.28 | 1983 |

| Borosilicate (Schott D263) [40] | 2510 | 820 | 0.96 | 4.66 × 10−7 | 0.534 | 1324 |

| Glycine | 1160.7 | 1266 | 1.3 [51] | 8.85 × 10−7 | 0.283 | 506 (decomp.) |

| Zeonex | 1010 | 1000 | 0.045 | 4.445 × 10−8 | 5.624 | 553 |

| Nifedipine | 1300 | 1000 | 0.2 | 1.54 × 10−7 | 1.63 | 446 |

| Sucrose | 1587 | 1243.1 | 0.1 | 5.07 × 10−8 | 4.93 | 458 (decomp.) |

Appendix B. The Existence of a Bound for Tmax and Tmin

Appendix C. Expression Approximation

Appendix D. About Situation 2 in Section 3.2.1: When the Tmax Is in the Middle of a Pulse Period

- (1)

- , for rw < or small enough (less than when ). In this situation, can be omitted from the expression.

- (2)

- , for rw > or when , will be appearing in the temperature expressions.

References

- Dirac, P.A.M. Quantum mechanics of many-electron systems. Proc. R. Soc. Lond. Ser. A Contain. Pap. Math. Phys. Character 1929, 123, 714–733. [Google Scholar]

- Schaffer, C.B.; Brodeur, A.; Mazur, E. Laser-induced breakdown and damage in bulk transparent materials induced by tightly focused femtosecond laser pulses. Meas. Sci. Technol. 2001, 12, 1784. [Google Scholar] [CrossRef]

- Bäuerle, D. Laser Processing and Chemistry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Seuthe, T.; Mermillod-Blondin, A.; Grehn, M.; Bonse, J.; Wondraczek, L.; Eberstein, M. Structural relaxation phenomena in silicate glasses modified by irradiation with femtosecond laser pulses. Sci. Rep. 2017, 7, 43815. [Google Scholar] [CrossRef]

- Chichkov, B.N.; Momma, C.; Nolte, S.; Von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Tan, D.; Sharafudeen, K.N.; Yue, Y.; Qiu, J. Femtosecond laser induced phenomena in transparent solid materials: Fundamentals and applications. Prog. Mater. Sci. 2016, 76, 154–228. [Google Scholar] [CrossRef]

- Gattass, R.R.; Mazur, E. Femtosecond laser micromachining in transparent materials. Nat. Photonics 2008, 2, 219–225. [Google Scholar] [CrossRef]

- Davis, K.M.; Miura, K.; Sugimoto, N.; Hirao, K. Writing waveguides in glass with a femtosecond laser. Opt. Lett. 1996, 21, 1729–1731. [Google Scholar] [CrossRef] [PubMed]

- Shimotsuma, Y.; Kazansky, P.G.; Qiu, J.; Hirao, K. Self-organized nanogratings in glass irradiated by ultrashort light pulses. Phys. Rev. Lett. 2003, 91, 247405. [Google Scholar] [CrossRef]

- Glezer, E.N.; Mazur, E. Ultrafast-laser driven micro-explosions in transparent materials. Appl. Phys. Lett. 1997, 71, 882–884. [Google Scholar] [CrossRef]

- Fernandez, T.; Sakakura, M.; Eaton, S.; Sotillo, B.; Siegel, J.; Solis, J.; Shimotsuma, Y.; Miura, K. Bespoke photonic devices using ultrafast laser driven ion migration in glasses. Prog. Mater. Sci. 2018, 94, 68–113. [Google Scholar] [CrossRef]

- Schaffer, C.B.; Brodeur, A.; García, J.F.; Mazur, E. Micromachining bulk glass by use of femtosecond laser pulses with nanojoule energy. Opt. Lett. 2001, 26, 93. [Google Scholar] [CrossRef] [PubMed]

- Minoshima, K.; Kowalevicz, A.M.; Hartl, I.; Ippen, E.P.; Fujimoto, J.G. Photonic device fabrication in glass by use of nonlinear materials processing with a femtosecond laser oscillator. Opt. Lett. 2001, 26, 1516–1518. [Google Scholar] [CrossRef]

- Schaffer, C.; García, J.; Mazur, E. Bulk heating of transparent materials using a high-repetition-rate femtosecond laser. Appl. Phys. A Mater. Sci. Process. 2003, 76, 351–354. [Google Scholar] [CrossRef]

- Eaton, S.M.; Zhang, H.; Herman, P.R.; Yoshino, F.; Shah, L.; Bovatsek, J.; Arai, A.Y. Heat accumulation effects in femtosecond laser-written waveguides with variable repetition rate. Opt. Express 2005, 13, 4708–4716. [Google Scholar] [CrossRef]

- Eaton, S.M.; Zhang, H.; Ng, M.L.; Li, J.; Chen, W.-J.; Ho, S.; Herman, P.R. Transition from thermal diffusion to heat accumulation in high repetition rate femtosecond laser writing of buried optical waveguides. Opt. Express 2008, 16, 9443–9458. [Google Scholar] [CrossRef]

- Bérubé, J.-P.; Bernier, M.; Vallée, R. Femtosecond laser-induced refractive index modifications in fluoride glass. Opt. Mater. Express 2013, 3, 598–611. [Google Scholar] [CrossRef]

- Sakakura, M.; Terazima, M.; Shimotsuma, Y.; Miura, K.; Hirao, K. Heating and rapid cooling of bulk glass after photoexcitation by a focused femtosecond laser pulse. Opt. Express 2007, 15, 16800–16807. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, B.; Wang, L.; Qiu, J.; Dai, Y.; Ma, H. Femtosecond laser induced coordination transformation and migration of ions in sodium borate glasses. Appl. Phys. Lett. 2008, 92, 121113. [Google Scholar] [CrossRef]

- Liu, Y.; Shimizu, M.; Zhu, B.; Dai, Y.; Qian, B.; Qiu, J.; Shimotsuma, Y.; Miura, K.; Hirao, K. Micromodification of element distribution in glass using femtosecond laser irradiation. Opt. Lett. 2009, 34, 136–138. [Google Scholar] [CrossRef]

- Shimizu, M.; Sakakura, M.; Kanehira, S.; Nishi, M.; Shimotsuma, Y.; Hirao, K.; Miura, K. Formation mechanism of element distribution in glass under femtosecond laser irradiation. Opt. Lett. 2011, 36, 2161–2163. [Google Scholar] [CrossRef]

- Zhu, B.; Dai, Y.; Ma, H.; Zhang, S.; Lin, G.; Qiu, J. Femtosecond laser induced space-selective precipitation of nonlinear optical crystals in rare-earth-doped glasses. Opt. Express 2007, 15, 6069–6074. [Google Scholar] [CrossRef]

- Dai, Y.; Zhu, B.; Qiu, J.; Ma, H.; Lu, B.; Cao, S.; Yu, B. Direct writing three-dimensional Ba2TiSi2O8 crystalline pattern in glass with ultrashort pulse laser. Appl. Phys. Lett. 2007, 90, 181109. [Google Scholar] [CrossRef]

- Zhang, B.; Tan, D.; Liu, X.; Tong, L.; Kazansky, P.G.; Qiu, J. Self-organized periodic crystallization in unconventional glass created by an ultrafast laser for optical attenuation in the broadband near-infrared region. Adv. Opt. Mater. 2019, 7, 1900593. [Google Scholar] [CrossRef]

- Miyamoto, I.; Cvecek, K.; Schmidt, M. Evaluation of nonlinear absorptivity in internal modification of bulk glass by ultrashort laser pulses. Opt. Express 2011, 19, 10714–10727. [Google Scholar] [CrossRef]

- Miyamoto, I.; Okamoto, Y.; Tanabe, R.; Ito, Y. Characterization of plasma in microwelding of glass using ultrashort laser pulse at high pulse repetition rates. Phys. Procedia 2014, 56, 973–982. [Google Scholar] [CrossRef]

- Lax, M. Temperature rise induced by a laser beam. J. Appl. Phys. 1977, 48, 3919–3924. [Google Scholar] [CrossRef]

- Sanders, D.J. Temperature distributions produced by scanning Gaussian laser beams. Appl. Opt. 1984, 23, 30–35. [Google Scholar] [CrossRef]

- Haba, B.; Hussey, B.W.; Gupta, A. Temperature distribution during heating using a high repetition rate pulsed laser. J. Appl. Phys. 1991, 69, 2871–2876. [Google Scholar] [CrossRef]

- Zhang, H.; Eaton, S.M.; Li, J.; Herman, P.R. Heat accumulation during high repetition rate ultrafast laser interaction: Waveguide writing in borosilicate glass. J. Phys. Conf. Ser. 2007, 59, 682–686. [Google Scholar] [CrossRef]

- Miyamoto, I.; Horn, A.; Gottmann, J.; Wortmann, D.; Yoshino, F. Fusion Welding of Glass Using Femtosecond Laser Pulses with High-repetition Rates. J. Laser Micro Nanoeng. 2007, 2, 57–63. [Google Scholar] [CrossRef]

- Beresna, M.; Gertus, T.; Tomašiūnas, R.; Misawa, H.; Juodkazis, S. Three-dimensional modeling of the heat-affected zone in laser machining applications. Laser Chem. 2008, 2008, 976205. [Google Scholar] [CrossRef]

- Shimizu, M.; Sakakura, M.; Ohnishi, M.; Yamaji, M.; Shimotsuma, Y.; Hirao, K.; Miura, K. Three-dimensional temperature distribution and modification mechanism in glass during ultrafast laser irradiation at high repetition rates. Opt. Express 2012, 20, 934–940. [Google Scholar] [CrossRef]

- Rahaman, A.; Kar, A.; Yu, X. Thermal effects of ultrafast laser interaction with polypropylene. Opt. Express 2019, 27, 5764–5783. [Google Scholar] [CrossRef]

- Rahaman, A.; Du, X.; Zhou, B.; Cheng, H.; Kar, A.; Yu, X. Absorption and temperature distribution during ultrafast laser microcutting of polymeric materials. J. Laser Appl. 2020, 32, 022044. [Google Scholar] [CrossRef]

- Lancry, M.; Groothoff, N.; Poumellec, B.; Guizard, S.; Fedorov, N.; Canning, J. Time-resolved plasma measurements in Ge-doped silica exposed to infrared femtosecond laser. Phys. Rev. B 2011, 84, 245103. [Google Scholar] [CrossRef]

- Miyamoto, I.; Horn, A.; Gottmann, J. Local Melting of Glass Material and Its Application to Direct Fusion Welding by Ps-laser Pulses. J. Laser Micro Nanoeng. 2007, 2, 7–14. [Google Scholar] [CrossRef]

- Neuville, D.R. From Glass to Crystal. Nucleation, Growth and Phase Separation: From Research to Applications; Chemistry/Materials; EDP Sciences: Les Ulis, France, 2017; 640p. [Google Scholar]

- Muzi, E.; Cavillon, M.; Lancry, M.; Brisset, F.; Que, R.; Pugliese, D.; Janner, D.; Poumellec, B. Towards a Rationalization of Ultrafast Laser-Induced Crystallization in Lithium Niobium Borosilicate Glasses: The Key Role of The Scanning Speed. Crystals 2021, 11, 290. [Google Scholar] [CrossRef]

- Couairon, A.; Sudrie, L.; Franco, M.; Prade, B.; Mysyrowicz, A. Filamentation and damage in fused silica induced by tightly focused femtosecond laser pulses. Phys. Rev. B 2005, 71, 125435. [Google Scholar] [CrossRef]

- Sudrie, L. Propagation Non-Linéaire des Impulsions Laser Femtosecondes Dans la Silice. Université de Paris Sud XI Orsay. 2002. Available online: http://www.ensta.fr/ilm/Archives/Theses_pdf/L_Sudrie (accessed on 1 January 2012).

- Bressel, L.; de Ligny, D.; Sonneville, C.; Martinez, V.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Femtosecond laser induced density changes in GeO2 and SiO2 glasses: Fictive temperature effect [Invited]. Opt. Mater. Express 2011, 1, 605–613. [Google Scholar] [CrossRef]

- Lancry, M.; Poumellec, B.; Chahid-Erraji, A.; Beresna, M.; Kazansky, P.G. Dependence of the femtosecond laser refractive index change thresholds on the chemical composition of doped-silica glasses. Opt. Mater. Express 2011, 1, 711–723. [Google Scholar] [CrossRef]

- Guerfa-Tamezait, D. Modifications d’une Couche Mince sur un Substrat, Induites par L’irradiation Mono-Impulsionnelle UV ns. Ph.D. Thesis, Université Paris-Saclay, Bures-sur-Yvette, France, 2022. [Google Scholar]

- Yao, H.; Xie, Q.; Cavillon, M.; Neuville, D.R.; Pugliese, D.; Janner, D.; Dai, Y.; Poumellec, B.; Lancry, M. Volume nanogratings inscribed by ultrafast IR laser in alumino-borosilicate glasses. Opt. Express 2023, 31, 15449–15460. [Google Scholar] [CrossRef]

- Xie, Q.; Cavillon, M.; Pugliese, D.; Janner, D.; Poumellec, B.; Lancry, M. On the Formation of Nanogratings in Commercial Oxide Glasses by Femtosecond Laser Direct Writing. Nanomaterials 2022, 12, 2986. [Google Scholar] [CrossRef]

- Cavillon, M.; Wang, Y.; Poumellec, B.; Brisset, F.; Lancry, M. Erasure of nanopores in silicate glasses induced by femtosecond laser irradiation in the Type II regime. Appl. Phys. A 2020, 126, 876. [Google Scholar] [CrossRef]

- Que, R.; Houel-Renault, L.; Temagoult, M.; Herrero, C.; Lancry, M.; Poumellec, B. Space-selective creation of photonics functions in a new organic material: Femtosecond laser direct writing in Zeonex glass of refractive index change and photoluminescence. Opt. Mater. 2022, 133, 112651. [Google Scholar] [CrossRef]

- He, X.; Liu, Q.; Lancry, M.; Brisset, F.; Poumellec, B. Space-Selective Control of Functional Crystals by Femtosecond Laser: A Comparison between SrO-TiO2-SiO2 and Li2O-Nb2O5-SiO2 Glasses. Crystals 2020, 10, 979. [Google Scholar] [CrossRef]

- Delullier, P.; Calvez, L.; Druart, G.; De La Barrière, F.; Humbert, C.; Poumellec, B.; Lancry, M. Photosensitivity of Infrared Glasses under Femtosecond Laser Direct Writing for mid-IR Applications. Appl. Sci. 2022, 12, 8813. [Google Scholar] [CrossRef]

- Simmons, J.A. Thermal Conductivity of Glycine. Nature 1967, 216, 1302. [Google Scholar] [CrossRef]

- Wang, X. Convergence-Divergence of p-Series. Coll. Math. J. 2002, 33, 314–316. [Google Scholar] [CrossRef]

- Weideman, J.A.C. Numerical integration of periodic functions: A few examples. Am. Math. Mon. 2002, 109, 21–36. [Google Scholar] [CrossRef]

- Atkinson, K.E. An Introduction to Numerical Analysis; John Wiley & Sons: Hoboken, NJ, USA, 2008. [Google Scholar]

| Laser Type | Mode | Geometry | Source Shape | Solving Method | Refs. |

|---|---|---|---|---|---|

| CW | static | cylindrical | Gaussian(r) Beer–Lambert(z) | analytical | Lax [27] |

| pulsed | scanning | three axes | Gaussian(x,y) Beer–Lambert(z) | analytical | Sanders [28] |

| pulsed | scanning | three axes | Gaussian(x,y) Beer–Lambert(z) | analytical | Haba [29] |

| pulsed | static | spherical | Gaussian(r) | finite difference | Eaton [15] or Zhang [30] |

| pulsed | quasi-static | cylindrical | Gaussian(r) Beer–Lambert(z) | analytical one pulse | Sakakura[18] |

| CW | scanning | three axes | uniform deposition in parallelepiped volume | analytical | Miyamoto [31] |

| pulsed | static | cylindrical | Gaussian(r,z) | analytical | Miyamoto[25] |

| pulsed | static | cylindrical | Gaussian(r) Gaussian(z) | numerical | Shimizu [33] |

| pulsed | scanning | cylindrical | Gaussian(r) surface absorption | analytical | Rahaman [34,35] |

| pulsed | quasi-static | spherical | Gaussian(r) | analytical | this work |

| SiO2 | LNS | STS | Glycine | Zeonex | Sucrose | Nifedipine | |

|---|---|---|---|---|---|---|---|

| (µs) | 0.28 | 0.235 | 0.04 | 0.28 | 0.42 | 4.9 | 1.63 |

| RR (kHz) | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| 18 | 21 | 125 | 18 | 12 | 1 | 3 | |

| Nssmax | 1 | 1 | 1 | 1 | 3 | 641 | 80 |

| rw = 0 | |||

| 1 | |||

| 1 + | 1 + | ||

| rw ≠ 0 * | |||

| + | |||

| rw = 0 | rw ≠ 0 * | |||

|---|---|---|---|---|

| 1 | * | |||

| 1 + | + | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Que, R.; Lancry, M.; Poumellec, B. Usable Analytical Expressions for Temperature Distribution Induced by Ultrafast Laser Pulses in Dielectric Solids. Micromachines 2024, 15, 196. https://doi.org/10.3390/mi15020196

Que R, Lancry M, Poumellec B. Usable Analytical Expressions for Temperature Distribution Induced by Ultrafast Laser Pulses in Dielectric Solids. Micromachines. 2024; 15(2):196. https://doi.org/10.3390/mi15020196

Chicago/Turabian StyleQue, Ruyue, Matthieu Lancry, and Bertrand Poumellec. 2024. "Usable Analytical Expressions for Temperature Distribution Induced by Ultrafast Laser Pulses in Dielectric Solids" Micromachines 15, no. 2: 196. https://doi.org/10.3390/mi15020196

APA StyleQue, R., Lancry, M., & Poumellec, B. (2024). Usable Analytical Expressions for Temperature Distribution Induced by Ultrafast Laser Pulses in Dielectric Solids. Micromachines, 15(2), 196. https://doi.org/10.3390/mi15020196