Micro-Electro-Mechanical Systems Microphones: A Brief Review Emphasizing Recent Advances in Audible Spectrum Applications

Abstract

1. Introduction

2. MEMS Microphone Transduction Mechanism

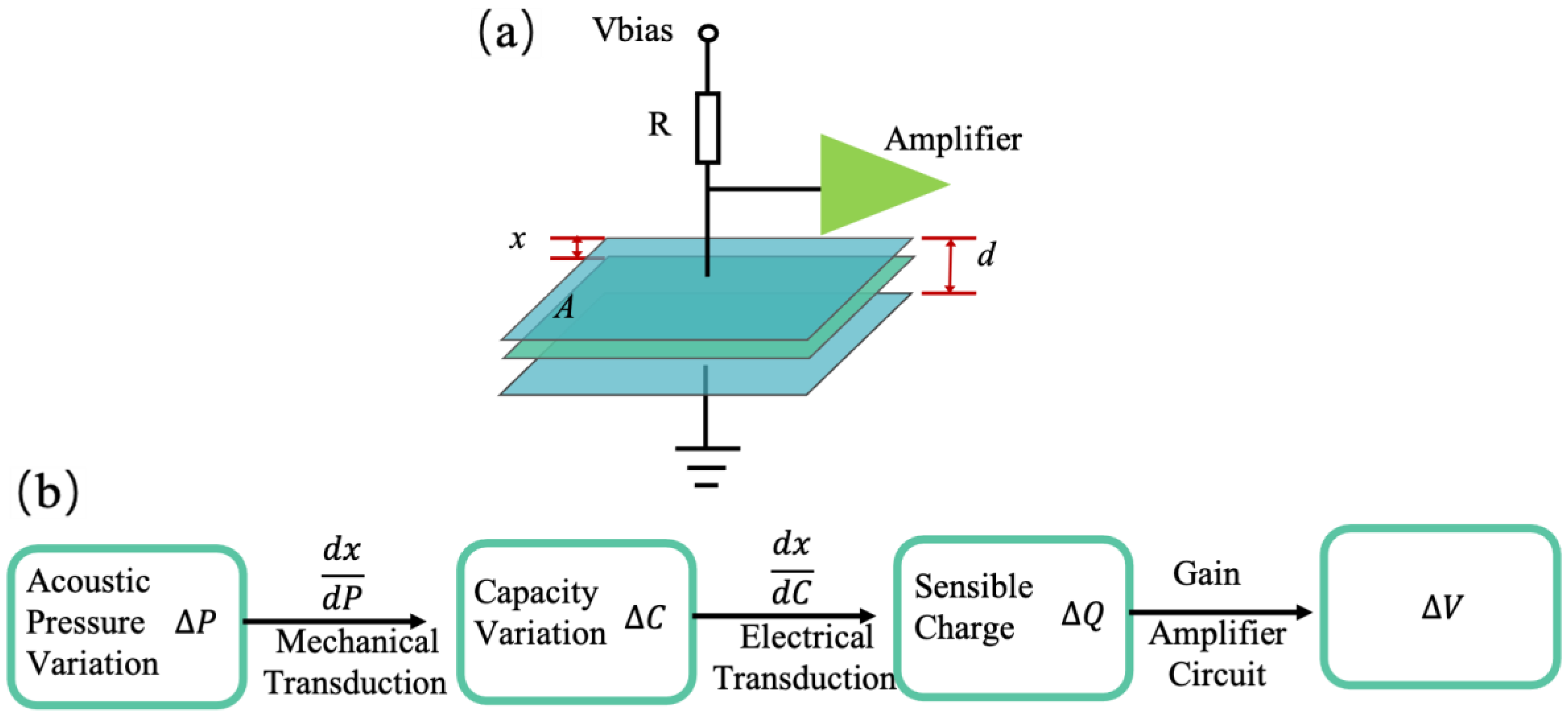

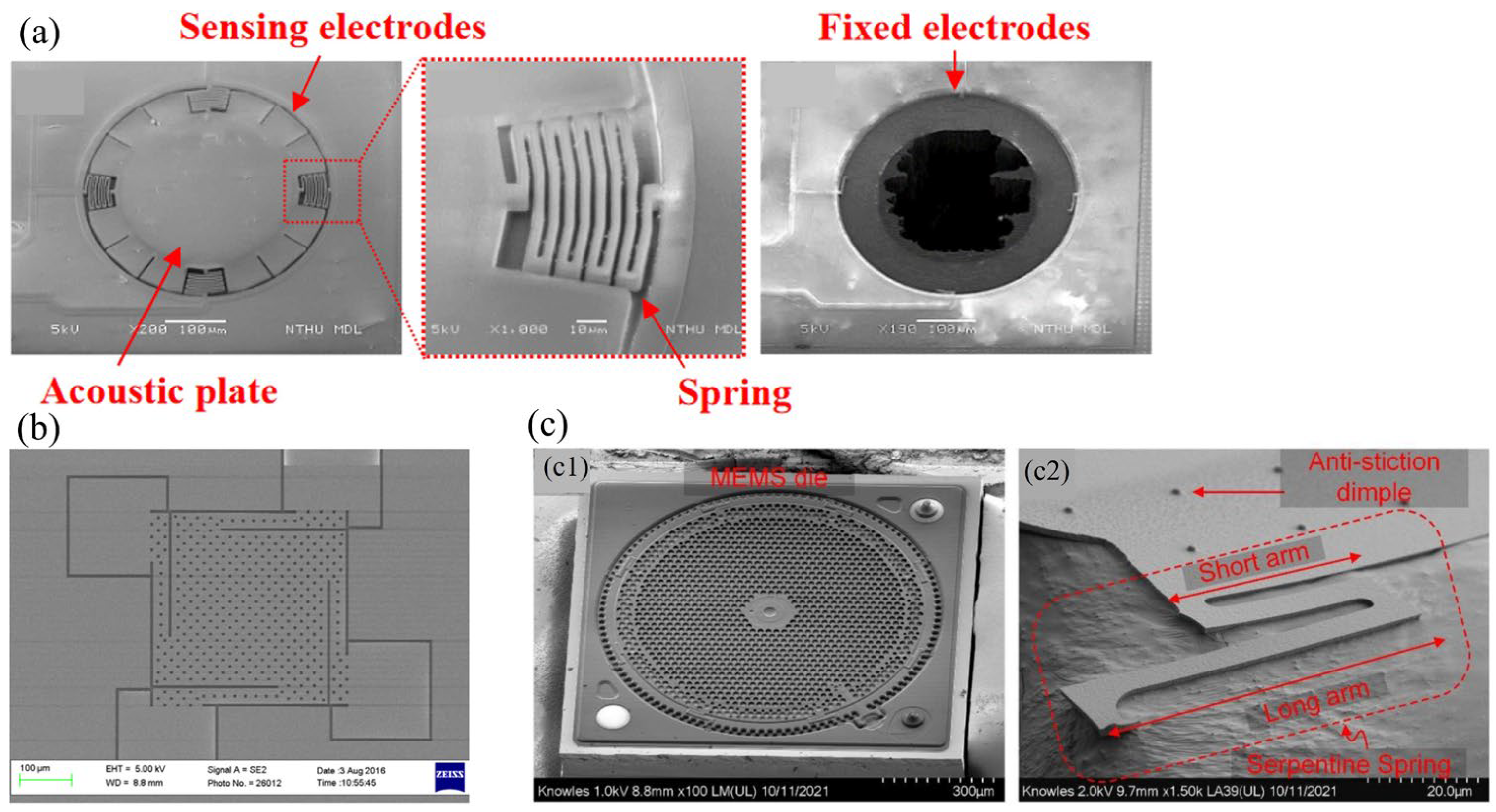

2.1. Capacitive Transducer

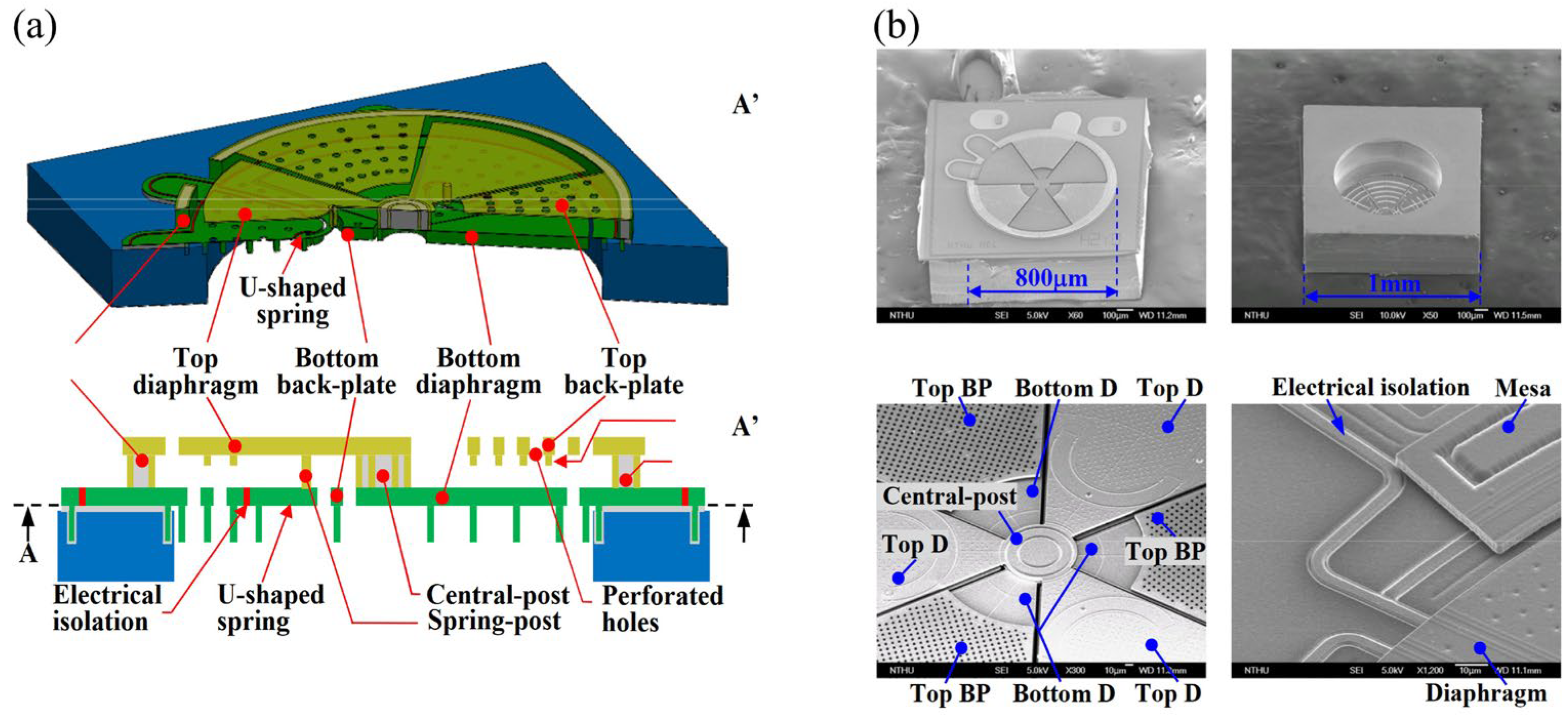

2.1.1. Expanding the Effective Diaphragm Area

2.1.2. Diaphragm Compliance

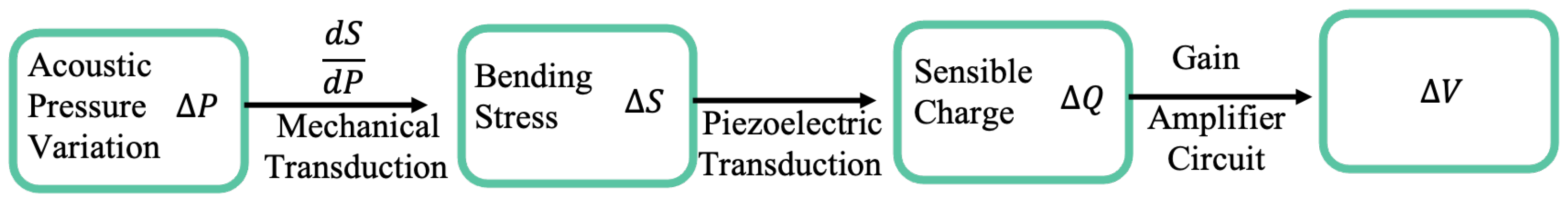

2.2. Piezoelectrical Transducer

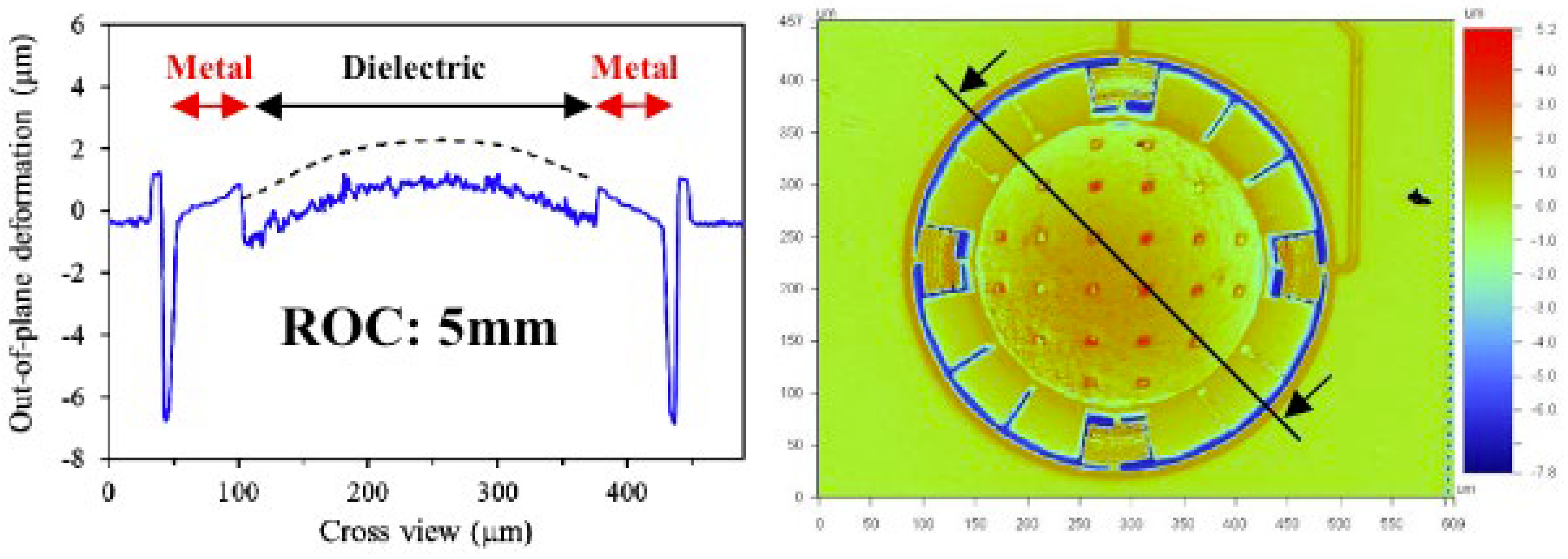

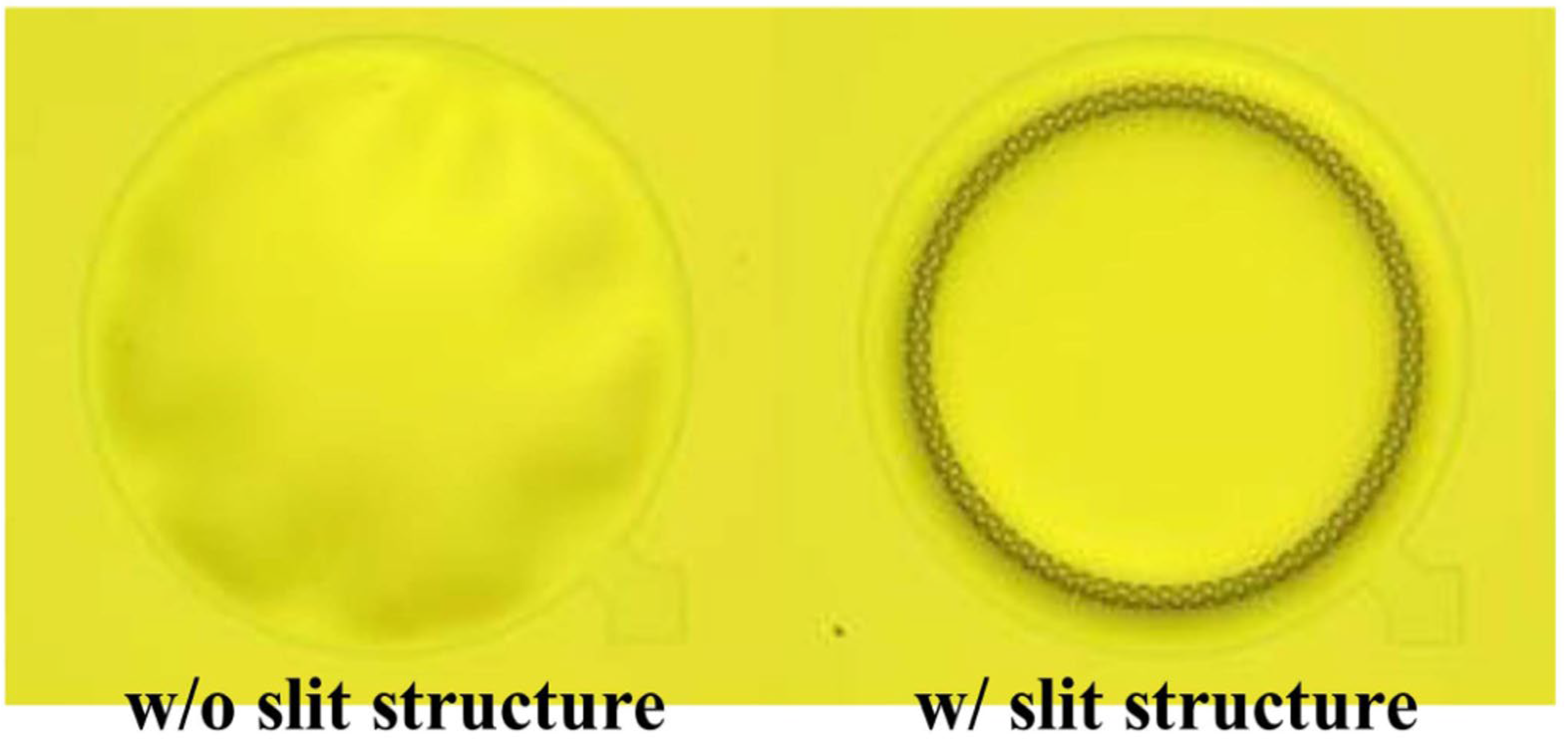

2.2.1. The Reduction of Residual Stress

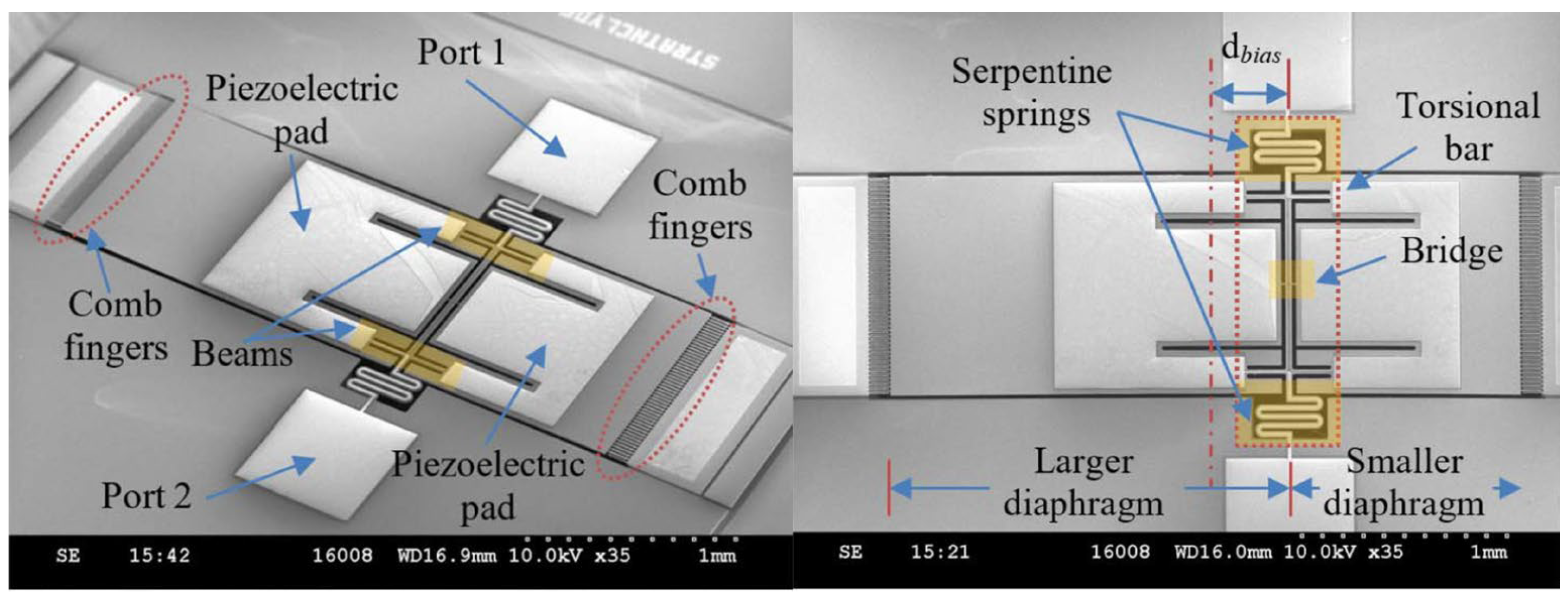

2.2.2. Cantilever

3. Denoising Techniques for High-Performance MEMS Microphones

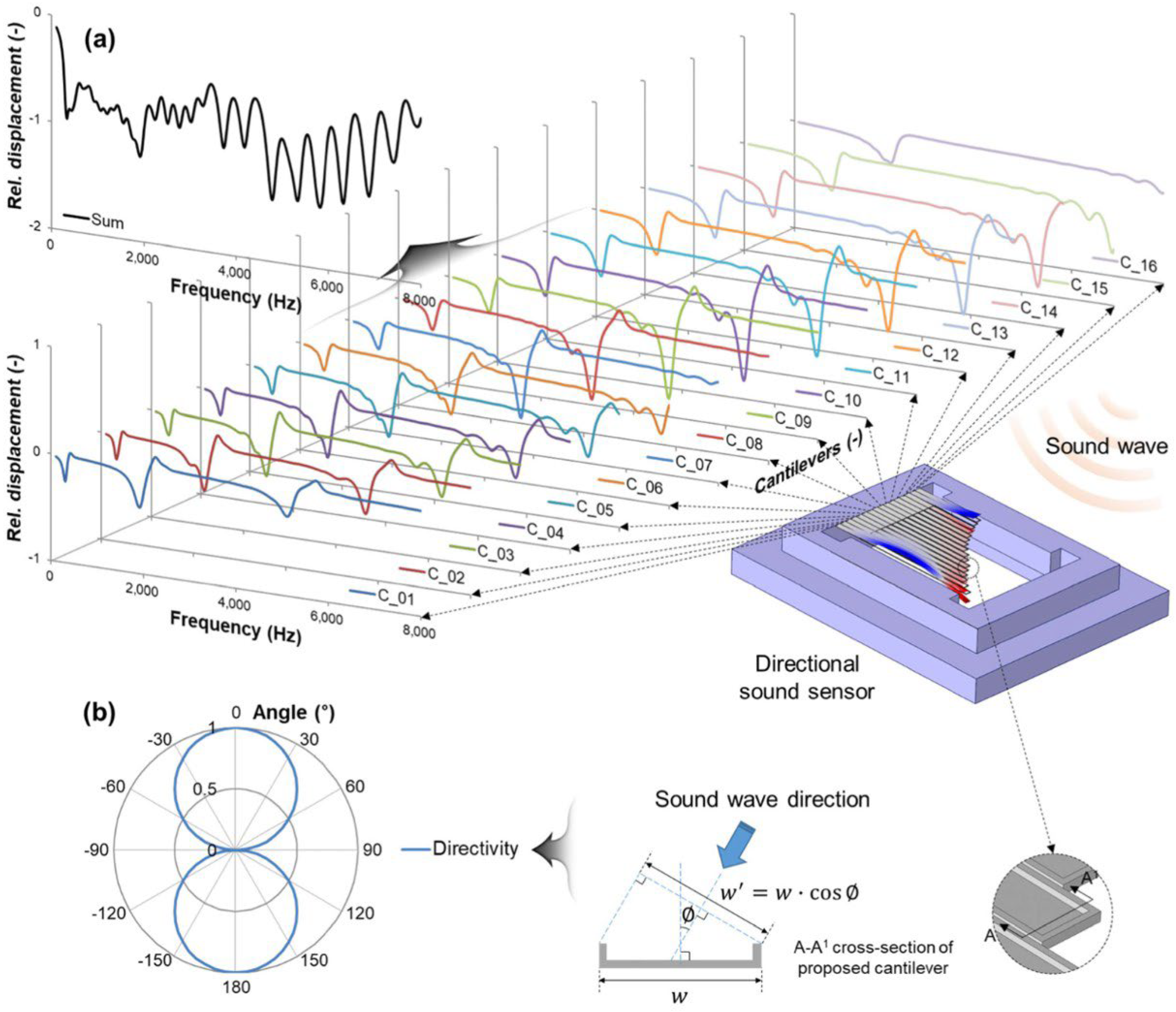

3.1. Utilizing the Resonant Responses of Membranes

3.2. Utilizing BF-Compliant Directional Microphones

3.3. Other Applications in Noise Cancelation

4. Discussions and Conclusions

- Presently, the primary bottleneck affecting microphone sensitivity and reliability remains within the manufacturing process. Stabilizing residual stress within thin film processing stands as a crucial means to significantly improve microphone performance and concurrently reduce production costs;

- The dynamic range of microphone devices presently hinges on both the mechanical structure and the noise floor. Thermal noise, circuit noise, and packaging noise collectively dictate the microphone noise performance. Integrating backend circuits with front-end sensors in a synergistic design approach will substantially diminish the overall noise and expand the available bandwidth;

- Sound source localization (SSL) technology predominantly relies on omnidirectional microphones. However, there is limited ongoing research on real-time sound source localization using directional microphones. Future developments should focus on merging MEMS multi-directional microphones with SSL algorithms to enable advanced applications like the real-time pinpointing of low-frequency noise and active noise cancellation.

Author Contributions

Funding

Conflicts of Interest

References

- Hohm, D. An integrated silicon-electret-condenser microphone. In Proceedings of the 11th International Congress on Acoustics, Paris, France, 19–27 July 1983; Volume 6, pp. 29–32. [Google Scholar]

- Wang, L.; Wang, C.; Wang, Y.; Quan, A.; Keshavarz, M.; Madeira, B.P.; Zhang, H.; Wang, C.; Kraft, M. A review on coupled bulk acoustic wave mems resonators. Sensors 2022, 22, 3857. [Google Scholar] [CrossRef]

- MEMS Microphones Market: Growth Potential of US$ 3.97 Billion. Maximize Market Research. Available online: https://www.maximizemarketresearch.com/market-report/mems-microphones-market/186923/ (accessed on 29 November 2023).

- Papila, M.; Haftka, R.T.; Nishida, T.; Sheplak, M. Piezoresistive Microphone Design Pareto Optimization: Tradeoff between Sensitivity and Noise Floor. J. Microelectromechan. Syst. 2006, 15, 1632–1643. [Google Scholar] [CrossRef]

- Pinto, R.M.R.; Gund, V.; Dias, R.A.; Nagaraja, K.K.; Vinayakumar, K.B. CMOS-Integrated Aluminum Nitride MEMS: A Review. J. Microelectromechan. Syst. 2022, 31, 500–523. [Google Scholar] [CrossRef]

- Fraga, M.A.; Furlan, H.; Pessoa, R.S.; Massi, M. Wide bandgap semiconductor thin films for piezoelectric and piezoresistive MEMS sensors applied at high temperatures: An overview. Microsyst. Technol. 2014, 20, 9–21. [Google Scholar] [CrossRef]

- Ishfaque, A.; Kim, B. Fly Ormia Ochracea Inspired MEMS Directional Microphone: A Review. IEEE Sens. J. 2018, 18, 1778–1789. [Google Scholar] [CrossRef]

- Shah, M.A.; Shah, I.A.; Lee, D.-G.; Hur, S. Design approaches of MEMS microphones for enhanced performance. J. Sens. 2019, 2019, 9294528. [Google Scholar] [CrossRef]

- Zawawi, S.A.; Hamzah, A.A.; Majlis, B.Y.; Mohd-Yasin, F. A Review of MEMS Capacitive Microphones. Micromachines 2020, 11, 484. [Google Scholar] [CrossRef]

- Kumar, A.; Varghese, A.; Sharma, A.; Prasad, M.; Janyani, V.; Yadav, R.; Elgaid, K. Recent development and futuristic applications of MEMS based piezoelectric microphones. Sens. Actuators A Phys. 2022, 347, 113887. [Google Scholar] [CrossRef]

- Gemelli, A.; Tambussi, M.; Fusetto, S.; Aprile, A.; Moisello, E.; Bonizzoni, E.; Malcovati, P. Recent Trends in Structures and Interfaces of MEMS Transducers for Audio Applications: A Review. Micromachines 2023, 14, 847. [Google Scholar] [CrossRef] [PubMed]

- Shubham, S.; Seo, Y.; Naderyan, V.; Song, X.; Frank, A.J.; Johnson, J.T.M.G.; da Silva, M.; Pedersen, M. A Novel MEMS Capacitive Microphone with Semiconstrained Diaphragm Supported with Center and Peripheral Backplate Protrusions. Micromachines 2021, 13, 22. [Google Scholar] [CrossRef]

- Füldner, M.; Dehé, A. Dual back plate silicon MEMS microphone: Balancing high performance. In Proceedings of the DAGA 2015, Nuremberg, Germany, 16–19 March 2015; pp. 41–43. [Google Scholar]

- Martin, D.; Kadirvel, K.; Liu, J.; Fox, R.; Sheplak, M.; Nishida, T. Surface and bulk micromachined dual back-plate condenser microphone. In Proceedings of the 18th IEEE International Conference on Micro Electro Mechanical Systems, 2005. MEMS 2005, Miami Beach, FL, USA, 30 January–3 February 2005; pp. 319–322. [Google Scholar] [CrossRef]

- Kadirvel, K.; Martin, D.T.; Liu, J.; Fox, R.; Sheplak, M.; Cattafesta, L.N.; Nishida, T. Design, Modeling and Simulation of a Closed-Loop Controller for a Dual Backplate MEMS Capacitive Microphone. In Proceedings of the 2007 IEEE Sensors, Atlanta, GA, USA, 28–31 October 2007; pp. 87–90. [Google Scholar] [CrossRef]

- Martin, D.T.; Liu, J.; Kadirvel, K.; Fox, R.M.; Sheplak, M.; Nishida, T. A Micromachined Dual-Backplate Capacitive Microphone for Aeroacoustic Measurements. J. Microelectromechan. Syst. 2007, 16, 1289–1302. [Google Scholar] [CrossRef]

- Peña-García, N.N.; Aguilera-Cortés, L.A.; González-Palacios, M.A.; Raskin, J.-P.; Herrera-May, A.L. Design and Modeling of a MEMS Dual-Backplate Capacitive Microphone with Spring-Supported Diaphragm for Mobile Device Applications. Sensors 2018, 18, 3545. [Google Scholar] [CrossRef]

- Saadatmand, M.; Kook, J. Multi-objective optimization of a circular dual back-plate MEMS microphone: Tradeoff between pull-in voltage, sensitivity and resonance frequency. Microsyst. Technol. 2019, 25, 2937–2947. [Google Scholar] [CrossRef]

- Sant, L.; Fuldner, M.; Bach, E.; Conzatti, F.; Caspani, A.; Gaggl, R.; Baschirotto, A.; Wiesbauer, A. A 130dB SPL 72dB SNR MEMS Microphone Using a Sealed-Dual Membrane Transducer and a Power-Scaling Read-Out ASIC. IEEE Sens. J. 2022, 22, 7825–7833. [Google Scholar] [CrossRef]

- Klein, W.; Angelopoulos, E.; Barzen, S.; Fueldner, M.; Geissler, S.; Herrmann, M.F.; Krumbein, U.; Tkachuk, K.; Tosolini, G.; Wagner, J. Membrane Support for Dual Backplate Transducers. U.S. Patent US10981780B2, 20 April 2021. [Google Scholar]

- Shubham, S.; Guo, J. Dual-Diaphragm MEMS Transducers with High Effective Area. U.S. Patent US20230388713A1, 30 November 2023. [Google Scholar]

- Scheeper, P.; Olthuis, W.; Bergveld, P. The design, fabrication, and testing of corrugated silicon nitride diaphragms. J. Microelectromechan. Syst. 1994, 3, 36–42. [Google Scholar] [CrossRef]

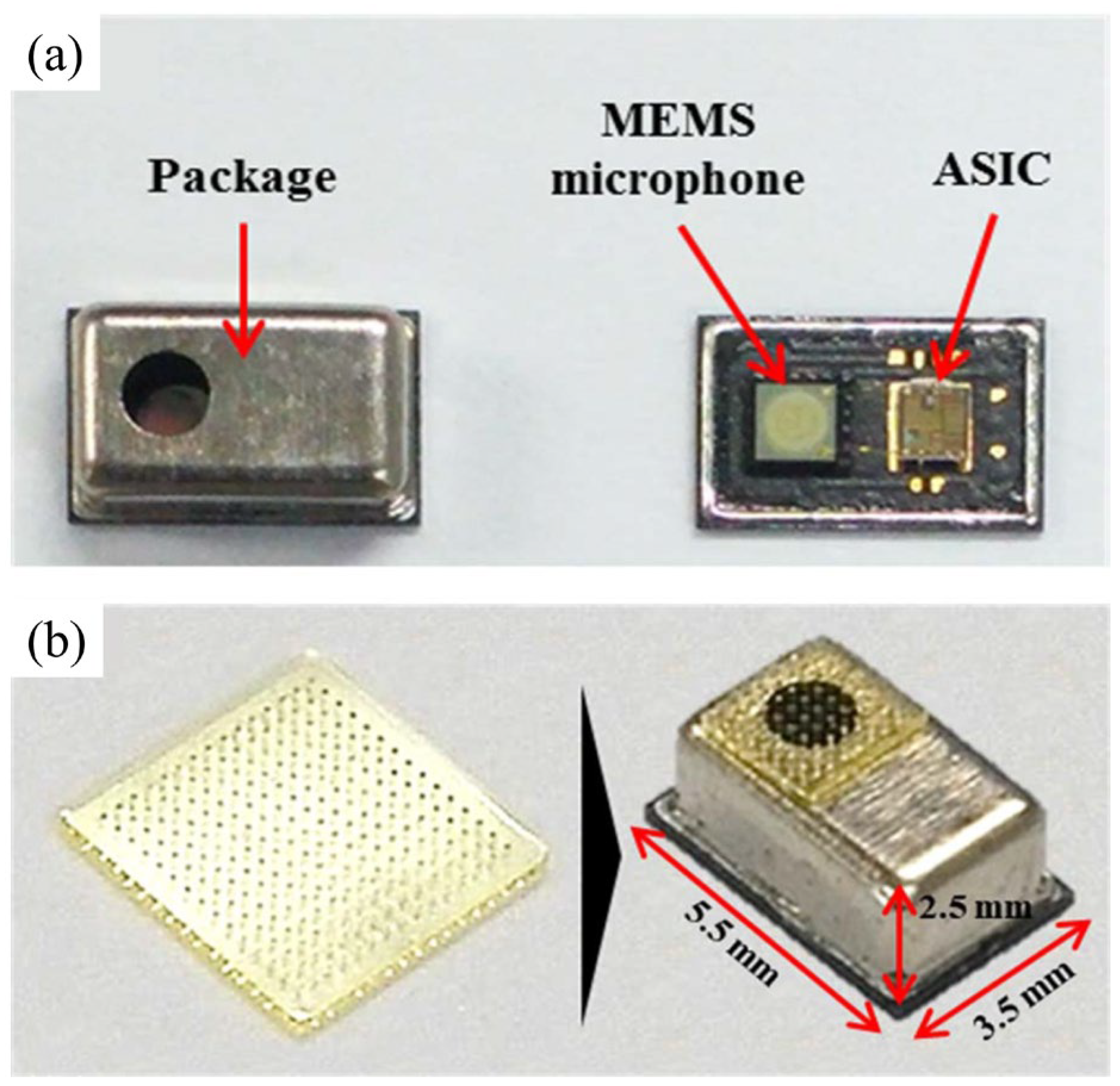

- Yoo, I.; Kim, H.; Yang, S.; Kim, D.; Kwon, D.-S.; Lee, J.; Jeong, T. Development of Directional MEMS Microphone Single Module for High Directivity and SNR. IEEE Sens. J. 2022, 22, 6329–6335. [Google Scholar] [CrossRef]

- Lo, S.-C.; Lai, W.-C.; Chang, C.-I.; Lo, Y.-Y.; Wang, C.; Bai, M.R.; Fang, W. Development of a no-back-plate SOI MEMS condenser microphone. In Proceedings of the 2015 Transducers—2015 18th International Solid-State Sensors, Actuators and Microsystems Conference, Anchorage, AK, USA, 21–25 June 2015; pp. 1085–1088. [Google Scholar] [CrossRef]

- Jerman, J. The fabrication and use of micromachined corrugated silicon diaphragms. Sens. Actuators A Phys. 1990, 23, 988–992. [Google Scholar] [CrossRef]

- Spiering, V.L.; Bouwstra, S.; Spiering, R.M. On-chip decoupling zone for package-stress reduction. Sens. Actuators A Phys. 1993, 39, 149–156. [Google Scholar] [CrossRef]

- Dehe, A.; Barzen, S.; Friza, W.; Klein, W. Semiconductor Devices Having a Membrane Layer with Smooth Stress-Relieving Corrugations and Methods of Fabrication Thereof. U.S. Patent US20150145079A1, 3 September 2019. [Google Scholar]

- Lo, S.-C.; Chan, C.-K.; Lee, Y.-C.; Wu, M.; Fang, W. Implementation of Two-Poly Differential MEMS Microphones for SNR and Sensing Range Enhancement. In Proceedings of the 2019 IEEE 32nd International Conference on Micro Electro Mechanical Systems (MEMS), Seoul, Republic of Korea, 27–31 January 2019; pp. 775–778. [Google Scholar] [CrossRef]

- Lo, S.-C.; Yeh, S.-K.; Wang, J.-J.; Wu, M.; Chen, R.; Fang, W. Bandwidth and SNR enhancement of MEMS microphones using two poly-Si micromachining processes. In Proceedings of the 2018 IEEE Micro Electro Mechanical Systems (MEMS), Belfast, UK, 21–25 January 2018; pp. 1064–1067. [Google Scholar] [CrossRef]

- Mao, W.-J.; Cheng, C.-L.; Lo, S.-C.; Chen, Y.-S.; Fang, W. Design and implementation of a CMOS-MEMS microphone without the back-plate. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 1037–1040. [Google Scholar] [CrossRef]

- Ganji, B.A.; Sedaghat, S.B.; Roncaglia, A.; Belsito, L. Design and fabrication of very small MEMS microphone with silicon diaphragm supported by Z-shape arms using SOI wafer. Solid-State Electron. 2018, 148, 27–34. [Google Scholar] [CrossRef]

- Weigold, J.; Brosnihan, T.; Bergeron, J.; Zhang, X. A MEMS Condenser Microphone for Consumer Applications. In Proceedings of the 19th IEEE International Conference on Micro Electro Mechanical Systems, Istanbul, Turkey, 22–26 January 2006; pp. 86–89. [Google Scholar] [CrossRef]

- Loeppert, P.V. Mems Structure with Stiffening Member. U.S. Patent US20220417670A1, 29 November 2022. [Google Scholar]

- Touse, M.; Sinibaldi, J.; Simsek, K.; Catterlin, J.; Harrison, S.; Karunasiri, G. Fabrication of a microelectromechanical directional sound sensor with electronic readout using comb fingers. Appl. Phys. Lett. 2010, 96, 173701. [Google Scholar] [CrossRef]

- Liu, H.; Currano, L.; Gee, D.; Helms, T.; Yu, M. Understanding and mimicking the dual optimality of the fly ear. Sci. Rep. 2013, 3, 2489. [Google Scholar] [CrossRef]

- Kuntzman, M.L.; Kim, D.; Hall, N.A. Microfabrication and Experimental Evaluation of a Rotational Capacitive Micromachined Ultrasonic Transducer. J. Microelectromechan. Syst. 2015, 24, 404–413. [Google Scholar] [CrossRef]

- Miles, R.N.; Cui, W.; Su, Q.T.; Homentcovschi, D. A MEMS Low-Noise Sound Pressure Gradient Microphone with Capacitive Sensing. J. Microelectromechan. Syst. 2015, 24, 241–248. [Google Scholar] [CrossRef]

- Rombach, P.; Müllenborn, M.; Klein, U.; Rasmussen, K. The first low voltage, low noise differential silicon microphone, technology development and measurement results. Sens. Actuators A Phys. 2002, 95, 196–201. [Google Scholar] [CrossRef]

- Hake, A.E.; Zhao, C.; Ping, L.; Grosh, K. Ultraminiature AlN diaphragm acoustic transducer. Appl. Phys. Lett. 2020, 117, 143504. [Google Scholar] [CrossRef]

- Williams, M.D.; Griffin, B.A.; Reagan, T.N.; Underbrink, J.R.; Sheplak, M. An AlN MEMS Piezoelectric Microphone for Aeroacoustic Applications. J. Microelectromechan. Syst. 2012, 21, 270–283. [Google Scholar] [CrossRef]

- Littrell, R.J. High Performance Piezoelectric MEMS Microphones. Ph.D. Thesis, University of Michigan, Ann Arbor, MI, USA, 2010. [Google Scholar]

- Ullmann, P.; Bretthauer, C.; Schneider, M.; Schmid, U. Stress analysis of circular membrane-type MEMS microphones with piezoelectric read-out. Sens. Actuators A Phys. 2023, 349, 114003. [Google Scholar] [CrossRef]

- Lee, S.S.; Ried, R.P.; White, R.M. Piezoelectric cantilever microphone and microspeaker. J. Microelectromechan. Syst. 1996, 5, 238–242. [Google Scholar] [CrossRef]

- Kuchiji, H.; Masumoto, N.; Baba, A. Piezoelectric MEMS wideband acoustic sensor coated by organic film. Jpn. J. Appl. Phys. 2023, 62, SG1021. [Google Scholar] [CrossRef]

- Wang, T.; Lee, C. Zero-Bending Piezoelectric Micromachined Ultrasonic Transducer (pMUT) with Enhanced Transmitting Performance. J. Microelectromechan. Syst. 2015, 24, 2083–2091. [Google Scholar] [CrossRef]

- Muralt, P.; Ledermann, N.; Baborowski, J.; Barzegar, A.; Gentil, S.; Belgacem, B.; Petitgrand, S.; Bosseboeuf, A.; Setter, N. Piezoelectric micromachined ultrasonic transducers based on PZT thin films. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 2276–2288. [Google Scholar] [CrossRef]

- Kuenzig, T.; Schrag, G.; Dehe, A.; Wachutka, G. Performance and noise analysis of capacitive silicon microphones using tailored system-level simulation. In Proceedings of the 2015 Transducers-2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 2192–2195. [Google Scholar] [CrossRef]

- Littrell, R.; Grosh, K. Modeling and Characterization of Cantilever-Based MEMS Piezoelectric Sensors and Actuators. J. Microelectromechan. Syst. 2012, 21, 406–413. [Google Scholar] [CrossRef]

- Baumgartel, L.; Vafanejad, A.; Chen, S.-J.; Kim, E.S. Resonance-Enhanced Piezoelectric Microphone Array for Broadband or Prefiltered Acoustic Sensing. J. Microelectromechan. Syst. 2013, 22, 107–114. [Google Scholar] [CrossRef]

- Shkel, A.A.; Baumgartel, L.; Kim, E.S. A resonant piezoelectric microphone array for detection of acoustic signatures in noisy environments. In Proceedings of the 2015 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 917–920. [Google Scholar] [CrossRef]

- Tseng, S.-H.; Lo, S.-C.; Chen, Y.-C.; Lee, Y.-C.; Wu, M.; Fang, W. Implementation of Piezoelectric MEMS Microphone for Sensitivity and Sensing Range Enhancement. In Proceedings of the 2020 IEEE 33rd International Conference on Micro Electro Mechanical Systems (MEMS), Vancouver, BC, Canada, 18–22 January 2020; pp. 845–848. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Lo, S.-C.; Cheng, H.-H.; Wu, M.; Huang, I.-Y.; Fang, W. Design of Cantilever Diaphragm Array Piezoelectric MEMS Microphone for Signal-To-Noise Ratio Enhancement. In Proceedings of the 2019 IEEE Sensors, Montreal, QC, Canada, 27–30 October 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Ledermann, N.; Muralt, P.; Baborowski, J.; Forster, M.; Pellaux, J.-P. Piezoelectric Pb(Zrx, Ti1−x)O3 thin film cantilever and bridge acoustic sensors for miniaturized photoacoustic gas detectors. J. Micromechan. Microeng. 2004, 14, 1650–1658. [Google Scholar] [CrossRef]

- Wang, S.-D.; Chen, Y.-C.; Lo, S.-C.; Wang, Y.-J.; Wu, M.; Fang, W. On The Performance Enhancement of Cantilever Diaphragm Piezoelectric Microphone. In Proceedings of the 2021 IEEE Sensors, Sydney, Australia, 31 October–4 November 2021; pp. 1–4. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Lo, S.-C.; Wang, S.-D.; Wang, Y.-J.; Wu, M.; Fang, W. On the PZT/Si unimorph cantilever design for the signal-to-noise ratio enhancement of piezoelectric MEMS microphone. J. Micromechan. Microeng. 2021, 31, 105003. [Google Scholar] [CrossRef]

- Hu, B.; Liu, W.; Yang, C.; Lu, L.; Wang, Z.; Liu, Y.; Cai, Y.; Wang, J.; Guo, S.; Sun, C. A ScAlN-Based Piezoelectric MEMS Microphone with Sector-Connected Cantilevers. J. Microelectromechan. Syst. 2023, 32, 638–644. [Google Scholar] [CrossRef]

- Yang, C.; Hu, B.; Lu, L.; Wang, Y.; Cai, Y.; Liu, Y.; Liu, W.; Sun, C. Bimorph Piezoelectric MEMS Microphone with Tractive Structure. In Proceedings of the 2022 IEEE International Ultrasonics Symposium (IUS), Venice, Italy, 10–13 October 2022; pp. 1–4. [Google Scholar]

- Gong, Y.; Zhang, M.; Sun, S.; Guo, W.; Sun, C.; Pang, W. Piezoelectric Micromachined Ultrasonic Transducers with Superior Frequency Control. J. Microelectromechan. Syst. 2023, 32, 513–515. [Google Scholar] [CrossRef]

- Ho, C.-Y.; Shyu, K.-K.; Chang, C.-Y.; Kuo, S.M. Integrated active noise control for open-fit hearing aids with customized filter. Appl. Acoust. 2018, 137, 1–8. [Google Scholar] [CrossRef]

- Reger, R.W.; Clews, P.J.; Bryan, G.M.; Keane, C.A.; Henry, M.D.; Griffin, B.A. Aluminum nitride piezoelectric microphones as zero-power passive acoustic filters. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 2207–2210. [Google Scholar] [CrossRef]

- Cai, X.; Guo, Q.; Hu, G.; Yang, J. Ultrathin low-frequency sound absorbing panels based on coplanar spiral tubes or coplanar Helmholtz resonators. Appl. Phys. Lett. 2014, 105, 121901. [Google Scholar] [CrossRef]

- Kusano, Y.; Segovia-Fernandez, J.; Sonmezoglu, S.; Amirtharajah, R.; Horsley, D.A. Frequency selective mems microphone based on a bioinspired spiral-shaped acoustic resonator. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017; pp. 71–74. [Google Scholar] [CrossRef]

- Wilmott, D.; Alves, F.; Karunasiri, G. Bio-Inspired Miniature Direction Finding Acoustic Sensor. Sci. Rep. 2016, 6, 29957. [Google Scholar] [CrossRef]

- Miles, R.N.; Robert, D.; Hoy, R.R. Mechanically coupled ears for directional hearing in the parasitoid fly Ormia ochracea. J. Acoust. Soc. Am. 1995, 98, 3059–3070. [Google Scholar] [CrossRef]

- Miles, R.N.; Su, Q.; Cui, W.; Shetye, M.; Degertekin, F.L.; Bicen, B.; Garcia, C.; Jones, S.; Hall, N. A low-noise differential microphone inspired by the ears of the parasitoid fly Ormia ochracea. J. Acoust. Soc. Am. 2009, 125, 2013–2026. [Google Scholar] [CrossRef] [PubMed]

- Miles, R.N.; Gibbons, C.; Gao, J.; Yoo, K.; Su, Q.; Cui, W. A silicon nitride microphone diaphragm inspired by the ears of the parasitoid fly Ormia ochracea. J. Acoust. Soc. Am. 2001, 110, 2645. [Google Scholar] [CrossRef]

- Tan, L.; Miles, R.N.; Weinstein, M.G.; Miller, R.A.; Su, Q.; Cui, W.; Gao, J. Response of a biologically inspired MEMS differential microphone diaphragm. In Unattended Ground Sensor Technologies and Applications IV; SPIE: Bellingham, WA, USA, 2002; pp. 91–98. [Google Scholar] [CrossRef]

- Touse, M.; Sinibaldi, J.; Karunasiri, G. MEMS directional sound sensor with simultaneous detection of two frequency bands. In Proceedings of the 2010 Ninth IEEE Sensors Conference (SENSORS 2010), Waikoloa, HI, USA, 1–4 November 2010; pp. 2422–2425. [Google Scholar] [CrossRef]

- Downey, R.H.; Karunasiri, G. Reduced residual stress curvature and branched comb fingers increase sensitivity of MEMS acoustic sensor. J. Microelectromechan. Syst. 2013, 23, 417–423. [Google Scholar] [CrossRef]

- Bicen, B. Micromachined Diffraction Based Optical Microphones and Intensity Probes with Electrostatic Force Feedback. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2010. [Google Scholar]

- Ang, L.Y.L.; Koh, Y.K.; Lee, H.P. Plate-type acoustic metamaterials: Experimental evaluation of a modular large-scale design for low-frequency noise con-trol. Acoustics 2019, 1, 354–368. [Google Scholar] [CrossRef]

- Zhang, Y.; Bauer, R.; Jackson, J.C.; Whitmer, W.M.; Windmill, J.F.C.; Uttamchandani, D. A Low-Frequency Dual-Band Operational Microphone Mimicking the Hearing Property of Ormia Ochracea. J. Microelectromechan. Syst. 2018, 27, 667–676. [Google Scholar] [CrossRef]

- Ren, D.; Liu, X.; Zhang, M.; Gao, R.; Qi, Z.-M. Low-Frequency Bi-Directional Microphone Based on a Combination of Bionic MEMS Diaphragm and Fiber Acousto-Optic Transducer. IEEE Sens. J. 2021, 21, 14655–14665. [Google Scholar] [CrossRef]

- Baumhauer, J.C., Jr.; Fengyuan, L.; Marcus, L.A.; Michel, A.D.; Reese, M. Gradient Micro-Electro-Mechanical Systems (MEMS) Microphone. U.S. Patent US10154330B2, 11 December 2018. [Google Scholar]

- Kang, S.; Hong, H.-K.; Rhee, C.-H.; Yoon, Y.; Kim, C.-H. Directional Sound Sensor with Consistent Directivity and Sensitivity in the Audible Range. J. Microelectromechan. Syst. 2021, 30, 471–479. [Google Scholar] [CrossRef]

- Chung, K. Challenges and Recent Developments in Hearing Aids: Part II. Feedback and Occlusion Effect Reduction Strategies, Laser Shell Manufacturing Processes, and Other Signal Processing Technologies. Trends Amplif. 2004, 8, 125–164. [Google Scholar] [CrossRef]

- Liu, H.; Liu, S.; Shkel, A.A.; Kim, E.S. Active Noise Cancellation with MEMS Resonant Microphone Array. J. Microelectromechan. Syst. 2020, 29, 839–845. [Google Scholar] [CrossRef]

| Ref. | Chip Size | Sensitivity 1 | Bandwidth | SNR |

|---|---|---|---|---|

| [38] | 2 mm × 2 mm | −37.7 dBV/Pa | 20 Hz–10 kHz | N/A |

| [14] | 460 μm diameter * | −71 dBV/Pa ** | 300 Hz–20 kHz | N/A |

| [16] | 512 μm diameter * | −68 dBV/Pa ** | 300 Hz–20 kHz | N/A |

| [17] | 1.2 mm diameter * | −29.4 dBV/Pa | 31 Hz–27 kHz | 61.7 dB |

| [19] | 5 mm × 4 mm | −38 dBFS/Pa | 20 Hz–20 kHz | 72 dB |

| [30] | 300 μm diameter * | −64 dBV/Pa ** | 200 Hz–10 kHz | N/A |

| [23] | 1.5 mm diameter * | −3.4 dBV/Pa | 100 Hz–12 kHz | 62.4 dB |

| [28] | 1 mm × 1 mm | −40.5 dBV/Pa | 50 Hz–20 kHz | 57.8 dB |

| [29] | 1.3 mm × 1.3 mm | −38 dBV/Pa | 50 Hz–20 kHz | 54 dB |

| [24] | 1.2 mm diameter * | −60.1 dBV/Pa | 1 kHz–20 kHz | N/A |

| [32] | 0.3 mm × 0.3 mm * | −52 dBV/Pa | 1 Hz–20 kHz | N/A |

| [12] 4 | 3.25 mm × 1.9 mm | −38 dBV/Pa | 35 Hz–10 kHz | 67 dB |

| [37] | 1 mm × 3 mm * | −10.4 dBV/Pa 3 | 10 Hz–10 kHz | N/A |

| [36] | 500 μm × 400 μm * | −111.3 dBV/Pa 2 ** | 20 Hz–250 kHz | N/A |

| Ref. | Chip Size | Sensitivity 1 | Bandwidth | SNR |

|---|---|---|---|---|

| [42] | 1/1.6 mm diameter * | −66.7 dBV/Pa | 10 Hz–10 kHz | 27/31 dB |

| [48] | 30 μm × 369 μm 2 | −79.1 dBV/Pa ** | 20 Hz–19 kHz | N/A |

| [49] | 4 mm × 11 mm | −52 dBV/Pa | 240 Hz–6.5 kHz | N/A |

| [51] | 1080 μm × 1080 μm | −37.54 dBV/Pa | 20 Hz–20 kHz | 48.9 dB |

| [52] | 800 μm × 800 μm | −35.9 dBV/Pa | 100 Hz–10 kHz | 70.1 dB |

| [54] | 1.08 mm2 | −32.1 dBV/Pa | 1.4 Hz–10 kHz | 77.2 dB |

| [55] | 800 μm × 800 μm | −33.2 dBV/Pa | 10 Hz–10 kHz | 82.4 dB |

| [56] | 800 μm diameter * | −73.7 dBV/Pa ** | 100 Hz–20 kHz | 54.2 dB |

| [58] | 170 μm diameter 3 | −76.5 dBV/Pa ** | 20 Hz–6.3 kHz | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Z.; Wang, C.; Wang, L.; Ji, Z.; Song, X.; Mak, P.-I.; Liu, H.; Wang, Y. Micro-Electro-Mechanical Systems Microphones: A Brief Review Emphasizing Recent Advances in Audible Spectrum Applications. Micromachines 2024, 15, 352. https://doi.org/10.3390/mi15030352

Zheng Z, Wang C, Wang L, Ji Z, Song X, Mak P-I, Liu H, Wang Y. Micro-Electro-Mechanical Systems Microphones: A Brief Review Emphasizing Recent Advances in Audible Spectrum Applications. Micromachines. 2024; 15(3):352. https://doi.org/10.3390/mi15030352

Chicago/Turabian StyleZheng, Zhuoyue, Chen Wang, Linlin Wang, Zeyu Ji, Xiaoxiao Song, Pui-In Mak, Huafeng Liu, and Yuan Wang. 2024. "Micro-Electro-Mechanical Systems Microphones: A Brief Review Emphasizing Recent Advances in Audible Spectrum Applications" Micromachines 15, no. 3: 352. https://doi.org/10.3390/mi15030352

APA StyleZheng, Z., Wang, C., Wang, L., Ji, Z., Song, X., Mak, P.-I., Liu, H., & Wang, Y. (2024). Micro-Electro-Mechanical Systems Microphones: A Brief Review Emphasizing Recent Advances in Audible Spectrum Applications. Micromachines, 15(3), 352. https://doi.org/10.3390/mi15030352