Design and Simulation of High-Temperature Micro-Hotplate for Synthesis of Graphene Using uCVD Method

Abstract

:1. Introduction

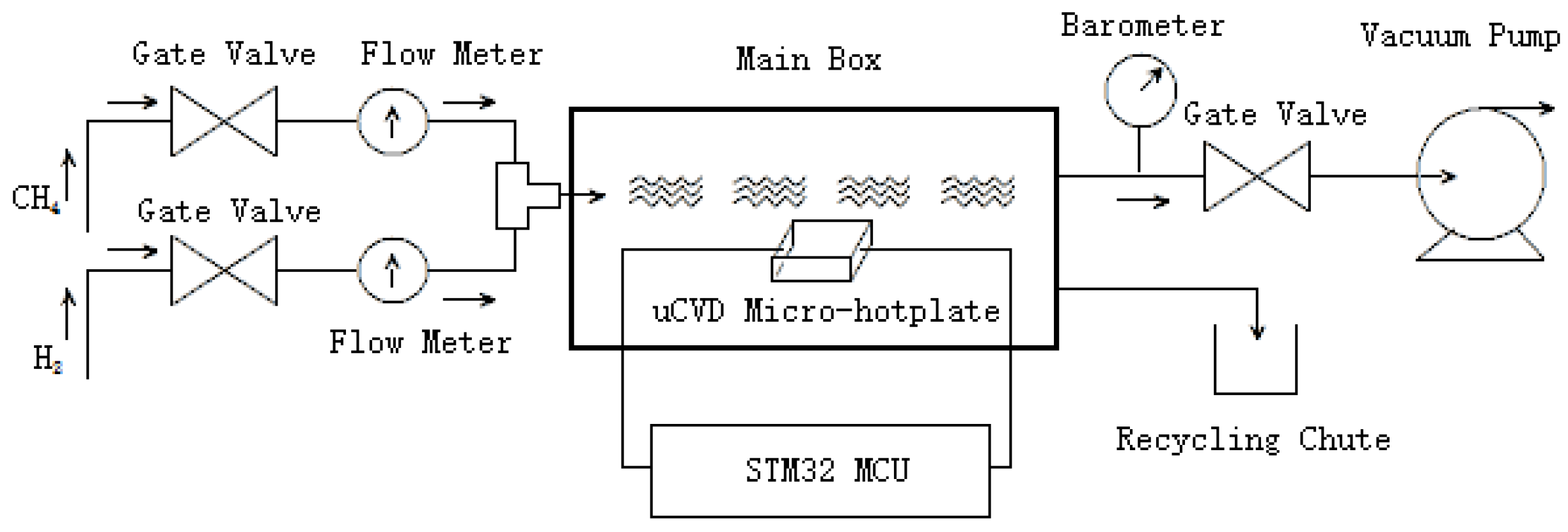

2. The uCVD Graphene Synthesis System

3. Analytical Models

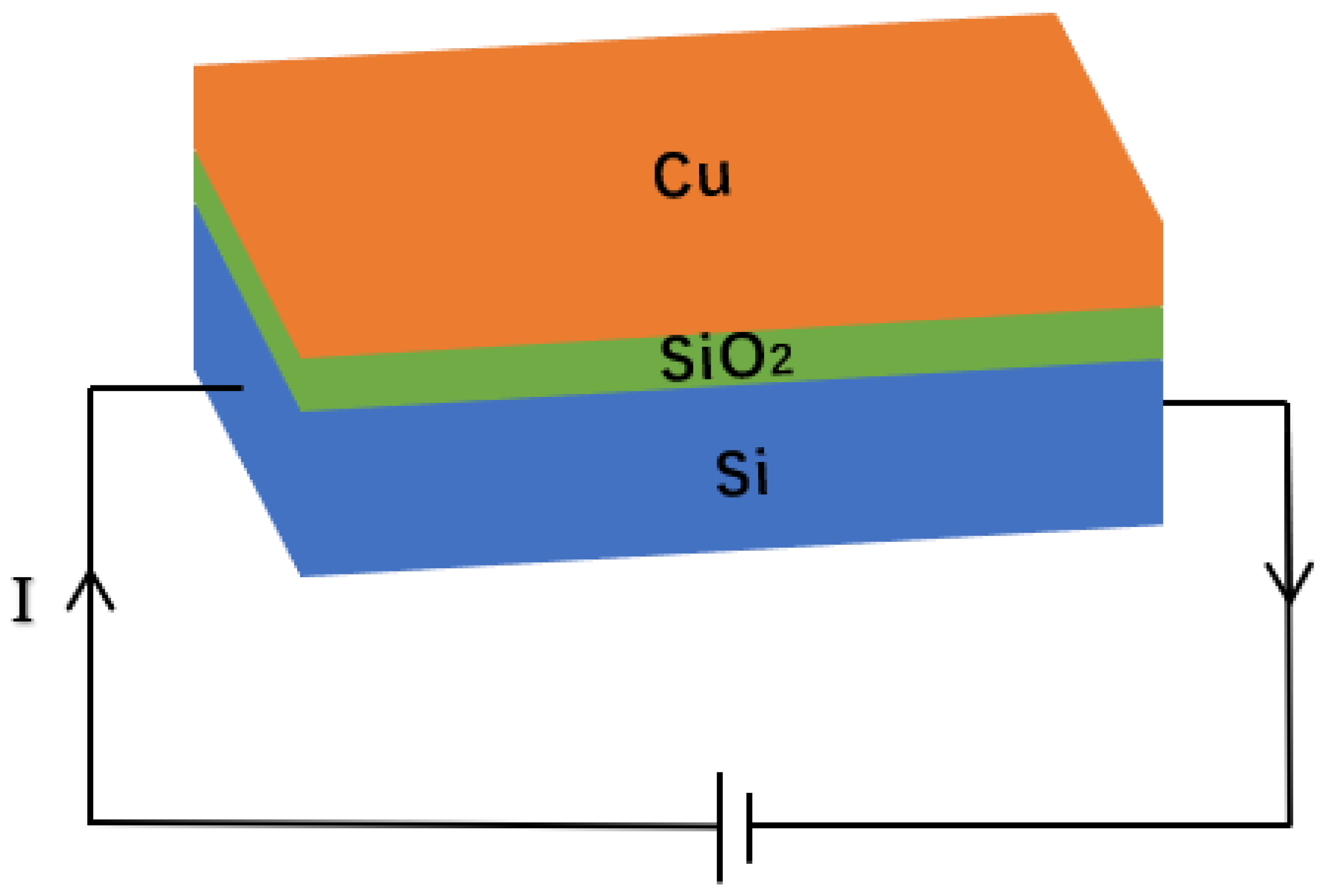

Electrothermal Model of the Micro-Hotplate in uCVD System

4. Simulation and Optimization

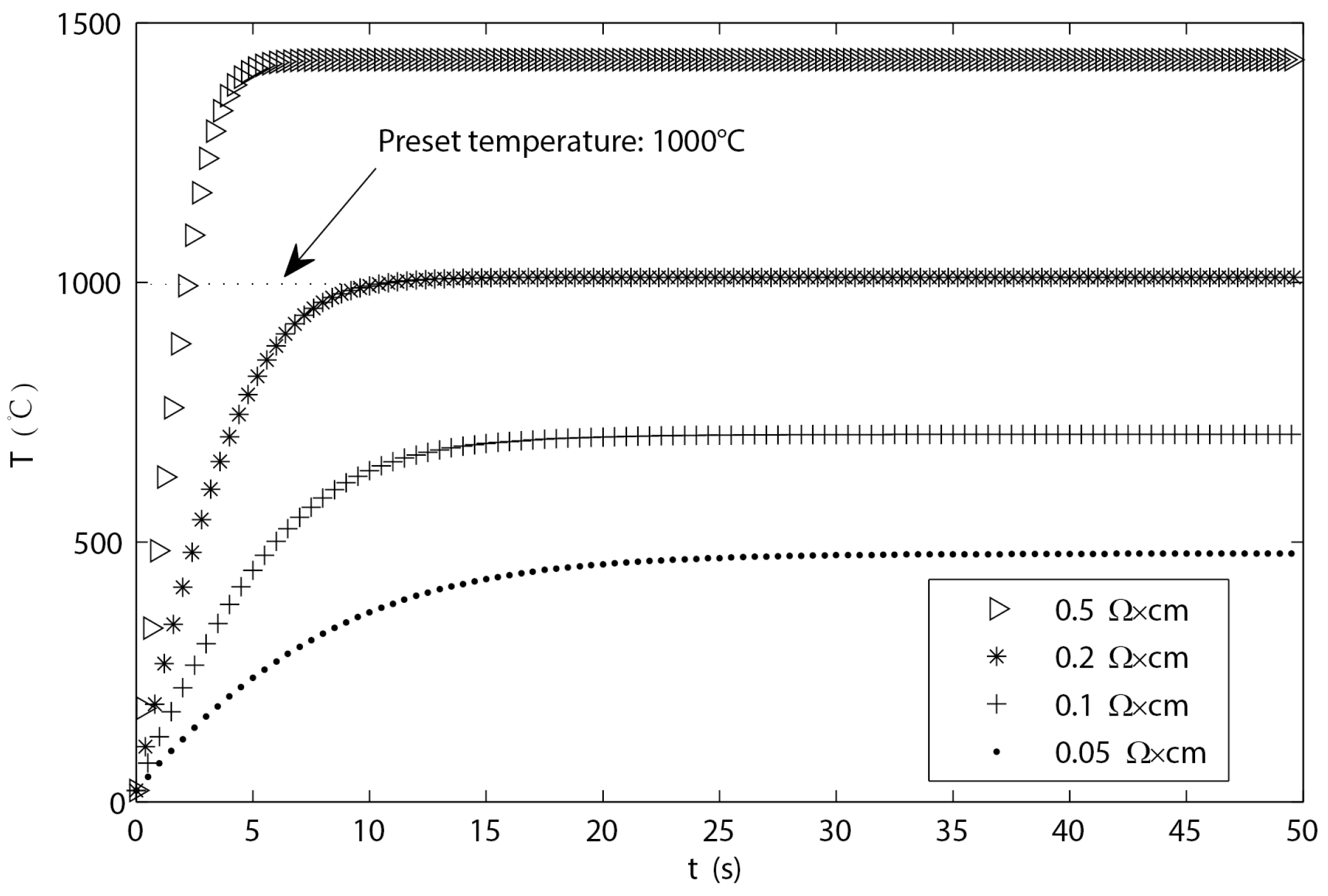

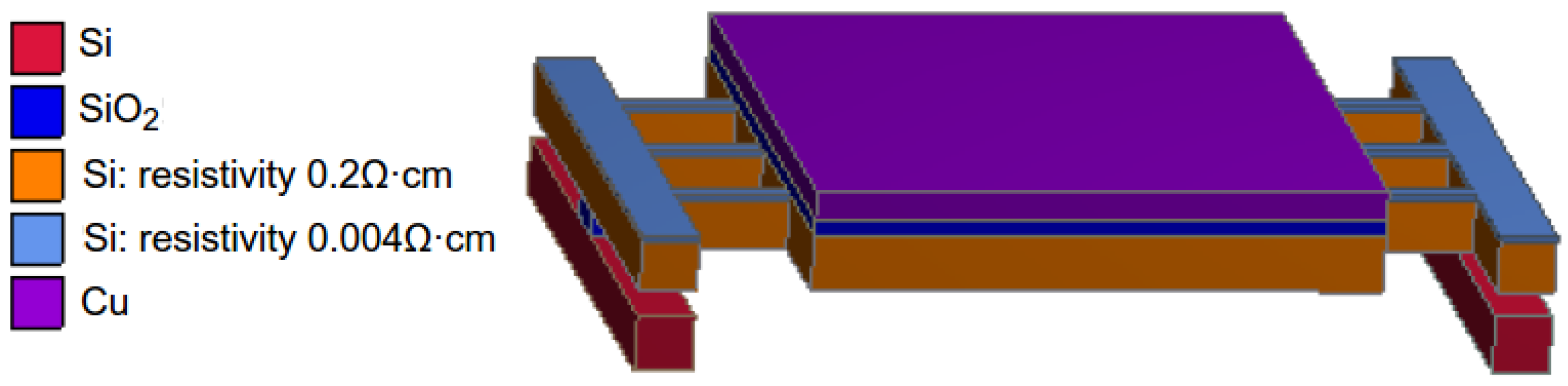

4.1. Effect of Silicon Resistivity on Heating

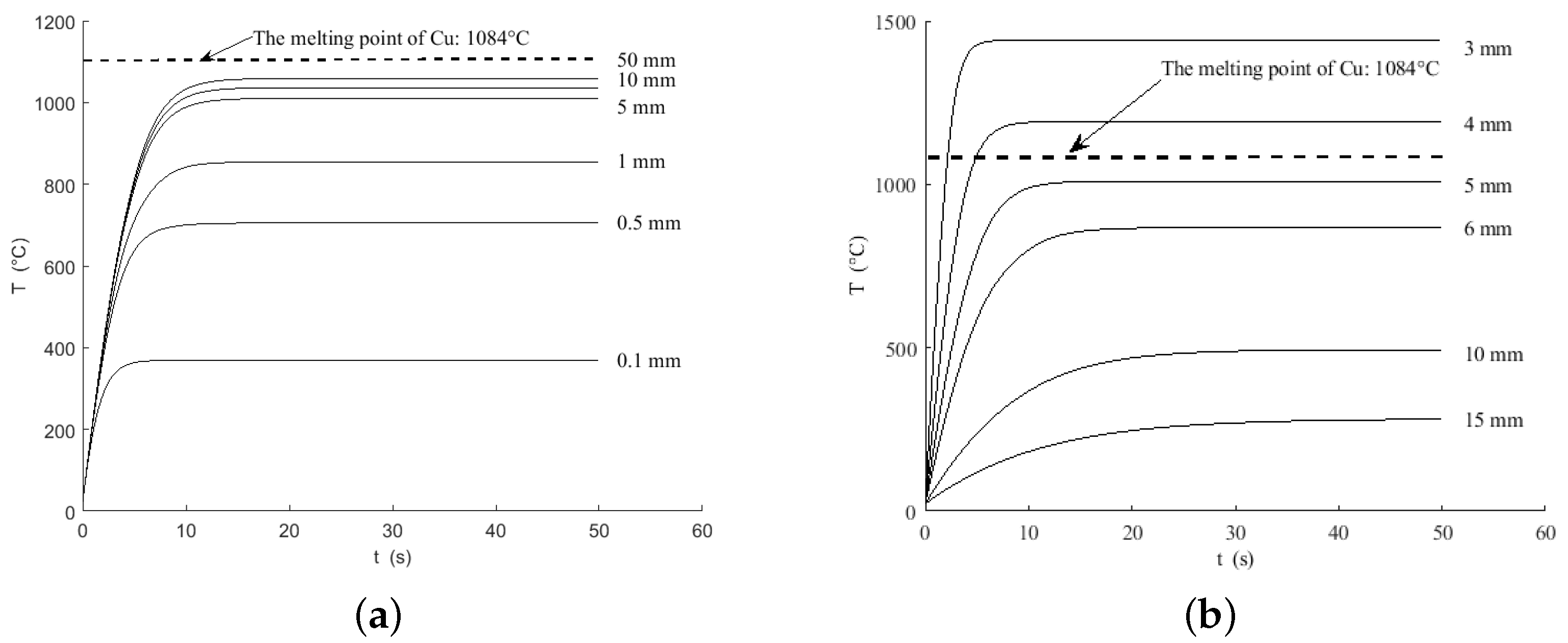

4.2. Effect of the Structural Parameters of Micro-Hotplate on Heating Performance

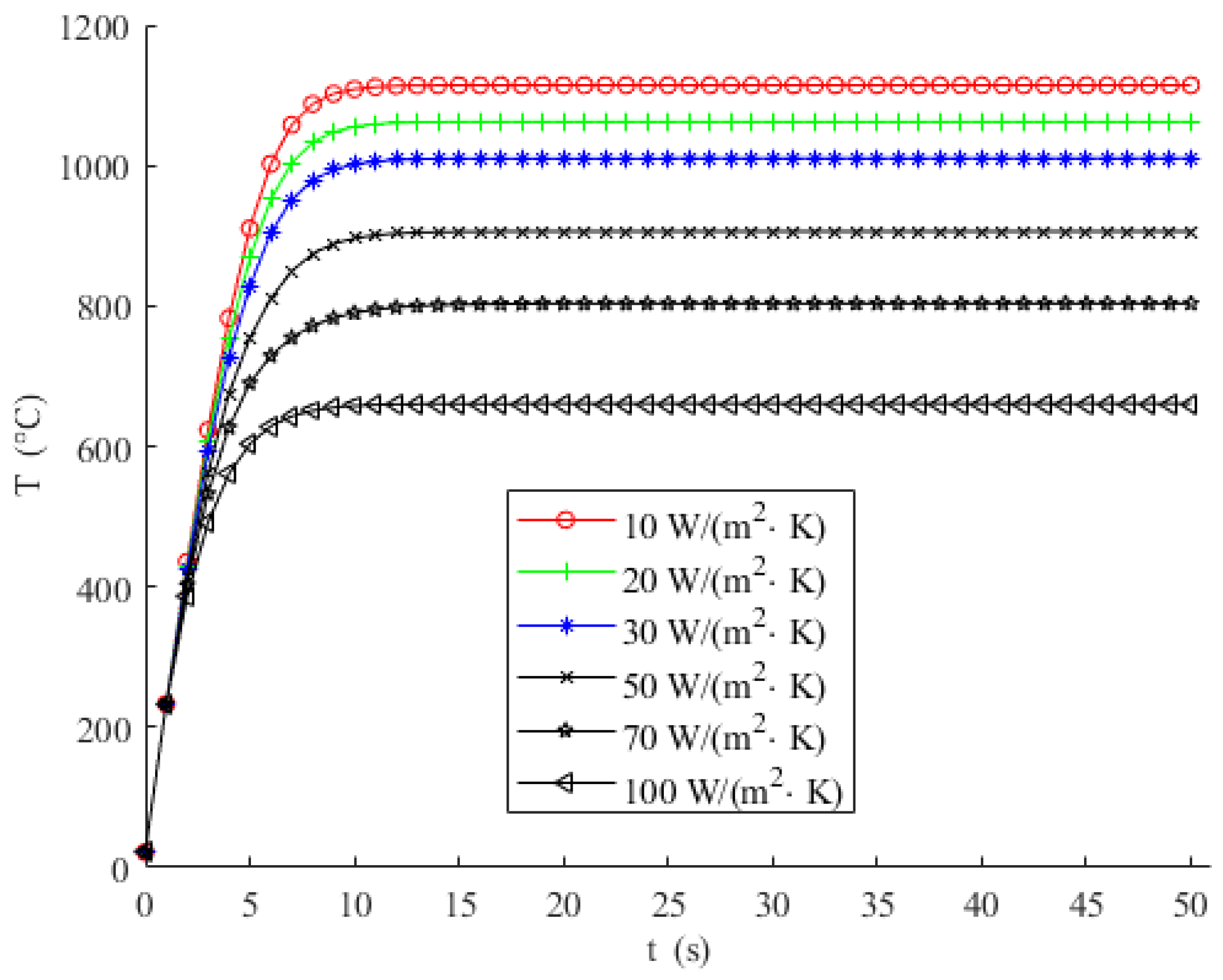

4.3. Effect of the Convective Heat Transfer Coefficient on Heating Performance

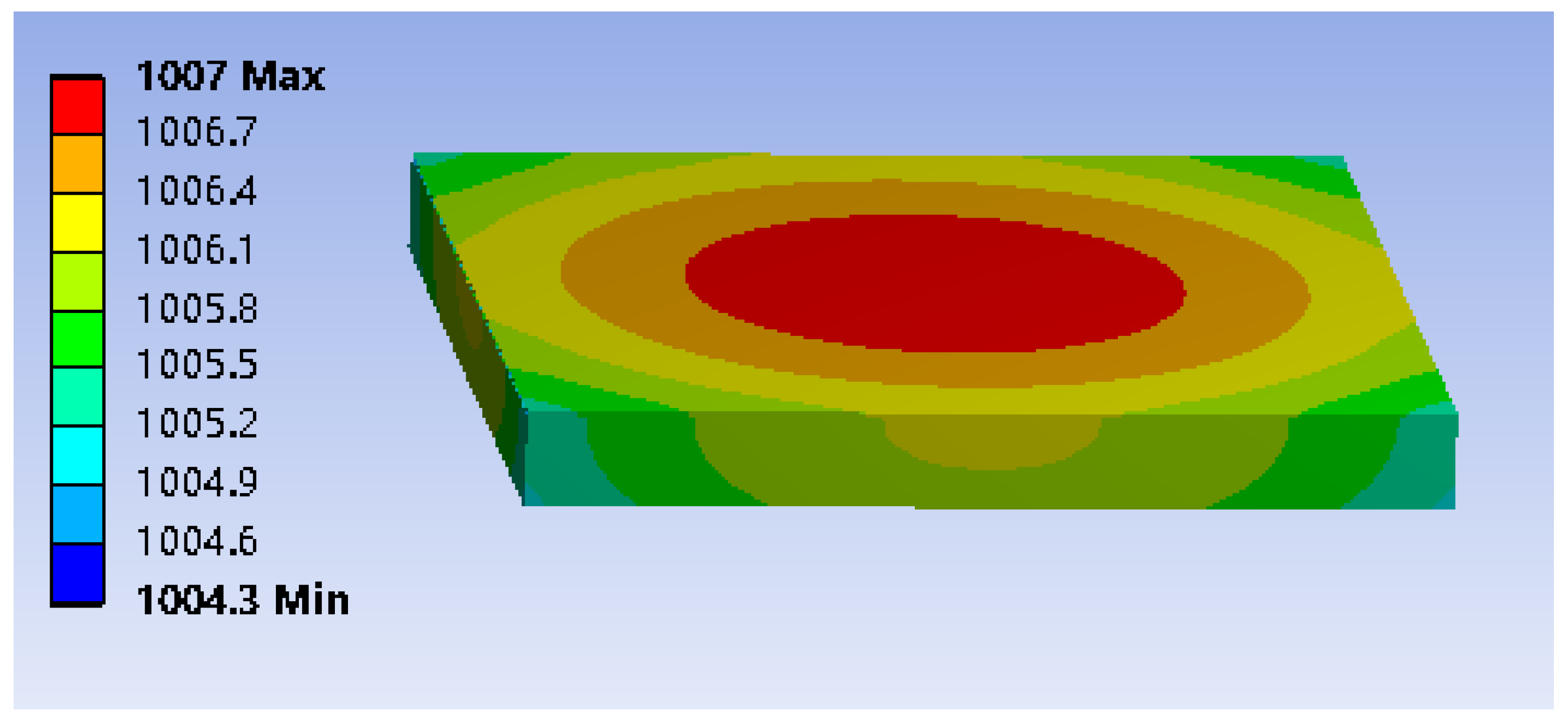

4.4. Structural Optimization

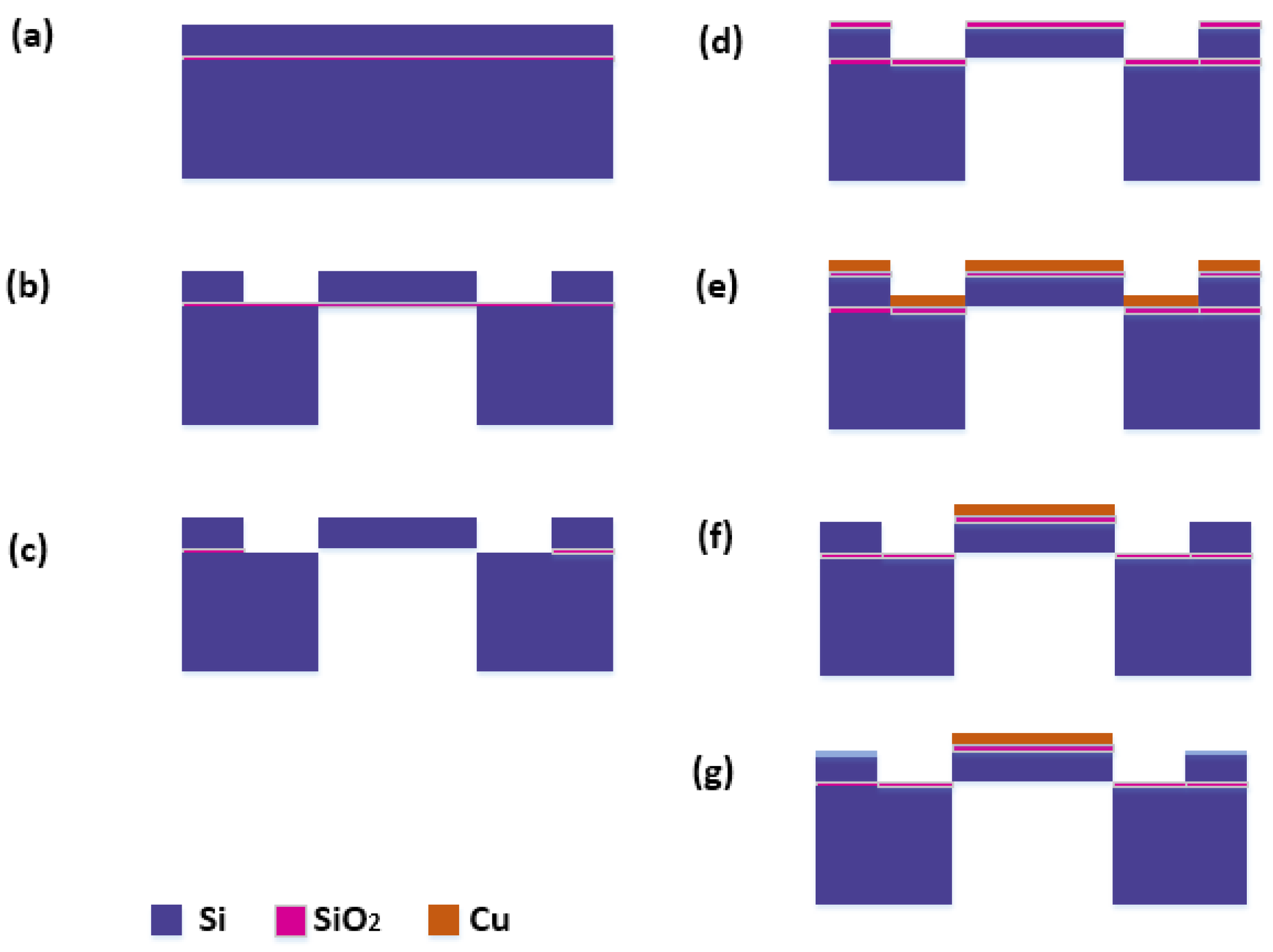

5. Fabrication Process of the Micro-Hotplate

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Armano, A.; Agnello, S. Two-dimensional carbon: A review of synthesis methods, and electronic, optical, and vibrational properties of single-layer graphene. C 2019, 5, 67. [Google Scholar] [CrossRef]

- Urade, A.R.; Lahiri, I.; Suresh, K.S. Graphene properties, synthesis and applications: A review. JOM 2023, 75, 614–630. [Google Scholar] [CrossRef]

- Medina-Rull, A.; Pasadas, F.; Marin, E.G.; Toral-Lopez, A.; Cuesta, J.; Godoy, A.; Jimenez, D.; Ruiz, F.G. A graphene field-effect transistor based analogue phase shifter for high-frequency applications. IEEE Access 2020, 8, 209055–209063. [Google Scholar] [CrossRef]

- Ma, J.; Wu, P.; Li, W.; Liang, S.; Shangguan, Q.; Cheng, S.; Tian, Y.; Fu, J.; Zhang, L. A five-peaks graphene absorber with multiple adjustable and high sensitivity in the far infrared band. Diam. Relat. Mater. 2023, 136, 109960. [Google Scholar] [CrossRef]

- Li, W.; Liu, M.; Cheng, S.; Zhang, H.; Yang, W.; Yi, Z.; Zeng, Q.; Tang, B.; Ahmad, S.; Sun, T. Polarization independent tunable bandwidth absorber based on single-layer graphene. Diam. Relat. Mater. 2024, 142, 110793. [Google Scholar] [CrossRef]

- Wei, Z.J.; Fu, Y.Y.; Liu, J.B.; Wang, Z.D.; Jia, Y.H.; Guo, J.; Ren, L.M.; Chen, Y.F.; Zhang, H.; Huang, R. Radio-frequency transistors from millimeter-scale graphene domains. Chin. Phys. B 2014, 23, 117201. [Google Scholar] [CrossRef]

- Xia, F.; Farmer, D.B.; Lin, Y.M.; Avouris, P. Graphene field-effect transistors with high on/off current ratio and large transport band gap at room temperature. Nano Lett. 2010, 10, 715–718. [Google Scholar] [CrossRef]

- Zhai, Y.; Xiang, Y.; Yuan, W.; Chen, G.; Shi, J.; Liang, G.; Wen, Z.; Wu, Y. Fabrication of graphene nanomesh FET terahertz detector. Micromachines 2021, 12, 641. [Google Scholar] [CrossRef]

- Saraswat, V.; Jacobberger, R.M.; Arnold, M.S. Materials science challenges to graphene nanoribbon electronics. ACS Nano 2021, 15, 3674–3708. [Google Scholar] [CrossRef]

- Shams, S.S.; Zhang, R.; Zhu, J. Graphene synthesis: A Review. Mater. Sci. 2015, 33, 566–578. [Google Scholar] [CrossRef]

- Warner, J.H.; Schaffel, F.; Rummeli, M.; Bachmatiuk, A. Graphene: Fundamentals and Emergent Applications, 1st ed.; Elsevier: Waltham, MA, USA, 2013; pp. 173–187. [Google Scholar]

- Saeed, M.; Alshammari, Y.; Majeed, S.A.; Al-Nasrallah, E. Chemical vapour deposition of graphene—Synthesis, characterisation, and applications: A review. Molecules 2020, 25, 3856. [Google Scholar] [CrossRef]

- Mattevi, C.; Kim, H.; Chhowalla, M. A review of chemical vapour deposition of graphene on copper. J. Mater. Chem. 2011, 21, 3324–3334. [Google Scholar] [CrossRef]

- Kim, K.S.; Zhao, Y.; Jang, H.; Lee, S.Y.; Kim, J.M.; Kim, K.S.; Ahn, J.H.; Kim, P.; Choi, J.Y.; Hong, B.H. Large-scale pattern growth of graphene films for stretchable transparent electrodes. Nature 2009, 457, 706–710. [Google Scholar] [CrossRef]

- Huang, M.; Bakharev, P.V.; Wang, Z.J.; Biswal, M.; Yang, Z.; Jin, S.; Wang, B.; Park, H.J.; Li, Y.; Qu, D.; et al. Large-area single-crystal AB-bilayer and ABA-trilayer graphene grown on a Cu/Ni (111) foil. Nat. Nanotechnol. 2020, 15, 289–295. [Google Scholar] [CrossRef]

- Han, L.Z.; Zhao, Z.X.; Ma, Z.Q. Process parameters of large single crystal graphene prepared by chemical vapor deposition. Acta Phys. Sin. 2014, 63, 248103. [Google Scholar]

- Zhou, Q.; Lin, L. Micro chemical vapor deposition system: Design and verification. In Proceedings of the IEEE 22nd International Conference on Micro Electro Mechanical Systems, Sorrento, Italy, 25–29 January 2009; pp. 72–75. [Google Scholar]

- Choi, W.; Lahiri, I.; Seelaboyina, R.; Kang, Y.S. Synthesis of graphene and its applications: A review. Crit. Rev. Solid State 2010, 35, 52–71. [Google Scholar] [CrossRef]

- Kumar, S.; McEvoy, N.; Kim, H.Y.; Lee, K.; Peltekis, N.; Rezvani, E.; Nolan, H.; Weidlich, A.; Daly, R.; Duesberg, G.S. CVD growth and processing of graphene for electronic applications. Phys. Status Solidi B 2011, 248, 2604–2608. [Google Scholar] [CrossRef]

- Oliveira, R.A.; Carreño, M.N.; Pereyra, I. Validation of MEMS Based New MicroLPCVD Technique for Thin Films Deposition. J. Integr. Circuits Syst. 2020, 15, 1–5. [Google Scholar] [CrossRef]

- Zhang, Q.; Geng, D.; Hu, W. Chemical vapor deposition for few-layer two-dimensional materials. SmartMat 2023, 4, e1177. [Google Scholar] [CrossRef]

- Ravindra, N.M.; Ravindra, K.; Mahendra, S.; Sopori, B.; Fiory, A.T. Modeling and simulation of emissivity of silicon-related materials and structures. J. Electron. Mater. 2003, 32, 1052–1058. [Google Scholar] [CrossRef]

- Zhang, K.; Hu, Q.; Yu, K.; Liu, Y. New Emissivity Measuring System with High Accuracy under Controlled Environment Conditions. Int. J. Thermophys. 2023, 44, 13. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bi, L.; Hu, B.; Lin, D.; Xie, S.; Yang, H.; Guo, D. Design and Simulation of High-Temperature Micro-Hotplate for Synthesis of Graphene Using uCVD Method. Micromachines 2024, 15, 445. https://doi.org/10.3390/mi15040445

Bi L, Hu B, Lin D, Xie S, Yang H, Guo D. Design and Simulation of High-Temperature Micro-Hotplate for Synthesis of Graphene Using uCVD Method. Micromachines. 2024; 15(4):445. https://doi.org/10.3390/mi15040445

Chicago/Turabian StyleBi, Lvqing, Bo Hu, Dehui Lin, Siqian Xie, Haiyan Yang, and Donghui Guo. 2024. "Design and Simulation of High-Temperature Micro-Hotplate for Synthesis of Graphene Using uCVD Method" Micromachines 15, no. 4: 445. https://doi.org/10.3390/mi15040445

APA StyleBi, L., Hu, B., Lin, D., Xie, S., Yang, H., & Guo, D. (2024). Design and Simulation of High-Temperature Micro-Hotplate for Synthesis of Graphene Using uCVD Method. Micromachines, 15(4), 445. https://doi.org/10.3390/mi15040445