Fabrication of Thin-Wall Structures with a Femtosecond Laser and Stainless Steel Powder †

Abstract

1. Introduction

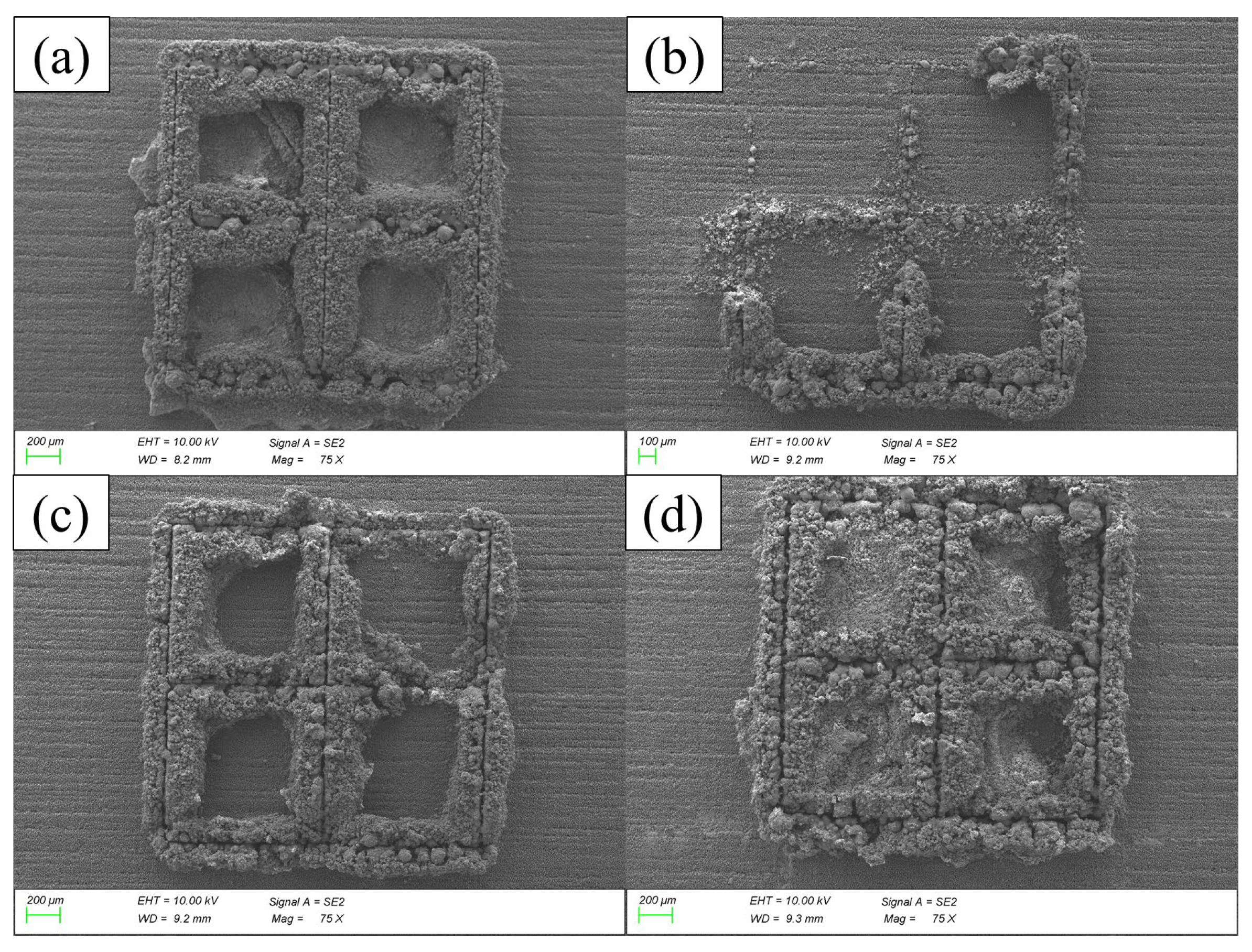

2. Materials and Methods

- A—Power: 0.78 W; Scanning Speed: 2.5 mm/s; Hatch Distance: 5 µm.

- B—Power: 0.85 W; Scanning Speed: 2.5 mm/s; Hatch Distance: 7.5 µm.

- Dump the powder on the substrate to allow it to fall with gravity;

- Vacuum up dust;

- Blow away the dust with varying degrees of strength, depending on the cleaning requirement.

3. Results

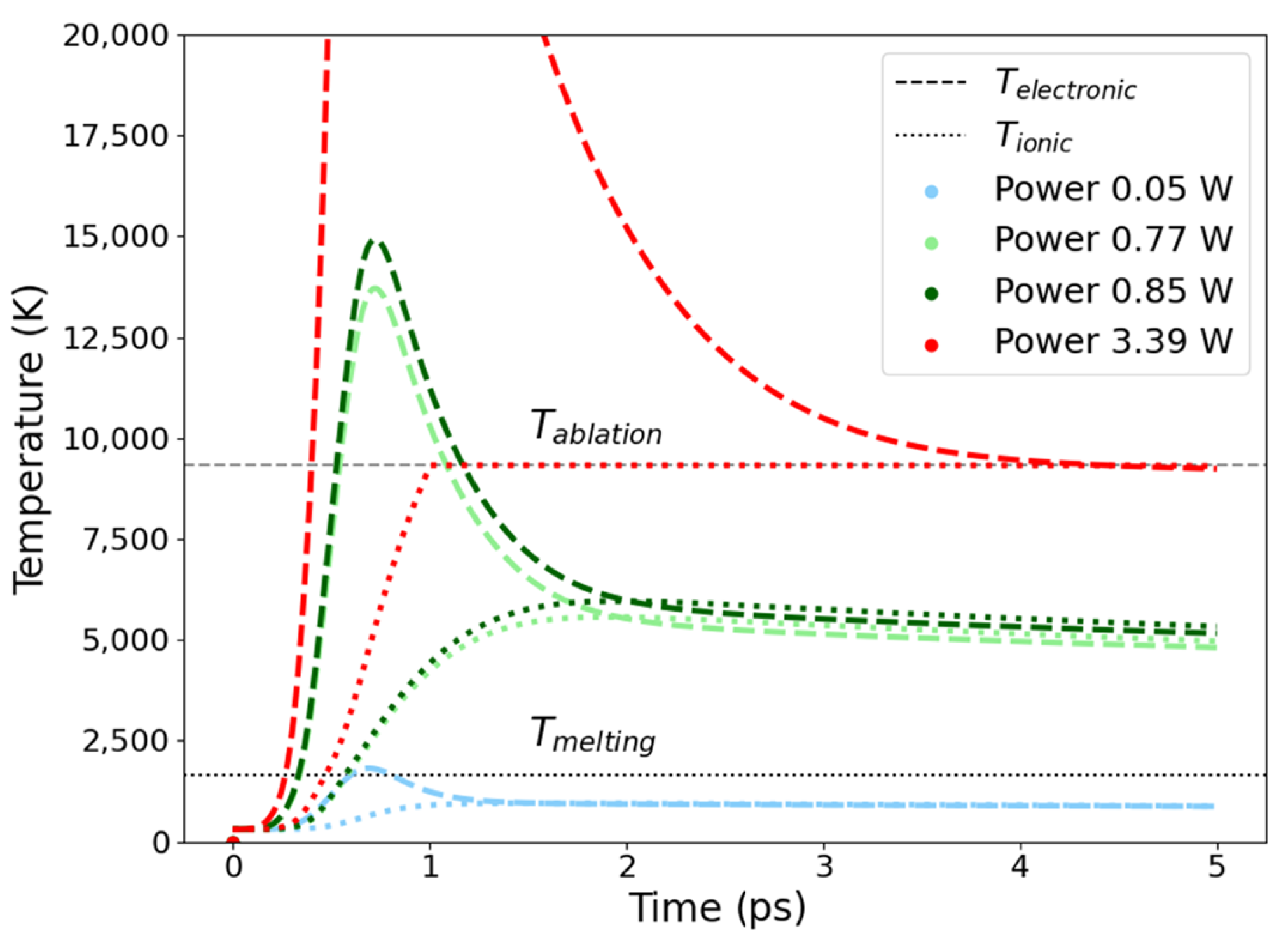

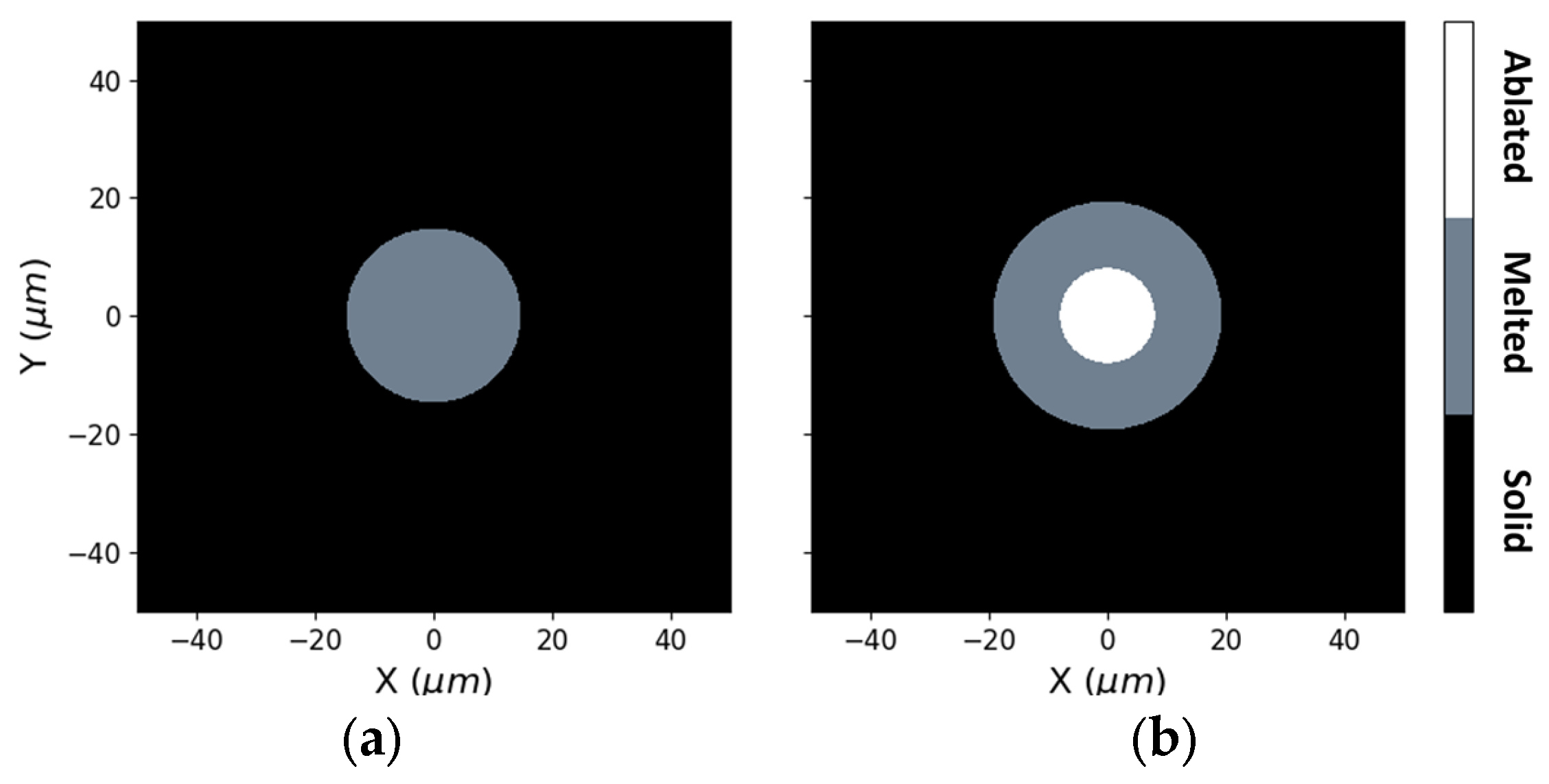

3.1. Two-Temperature Simulation

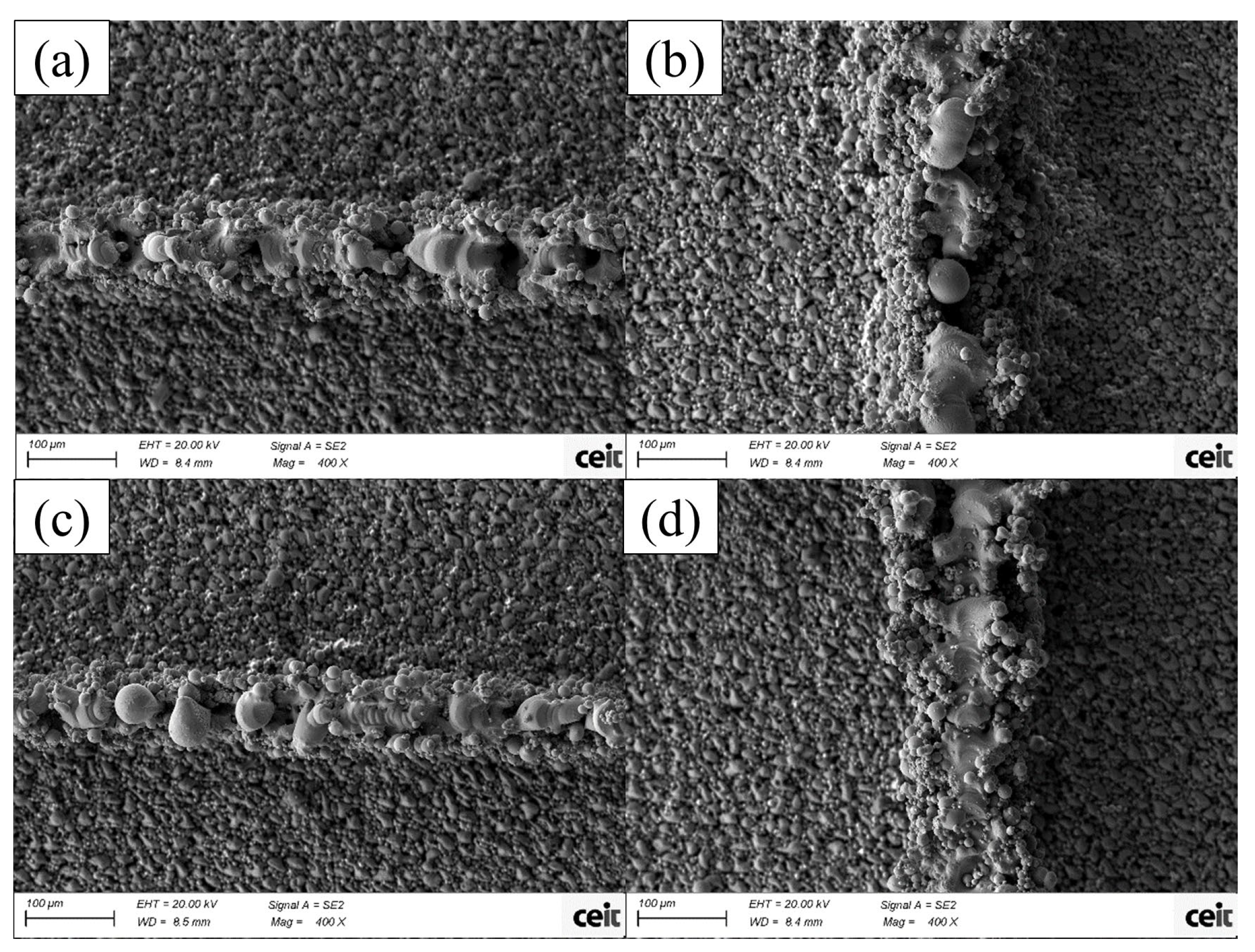

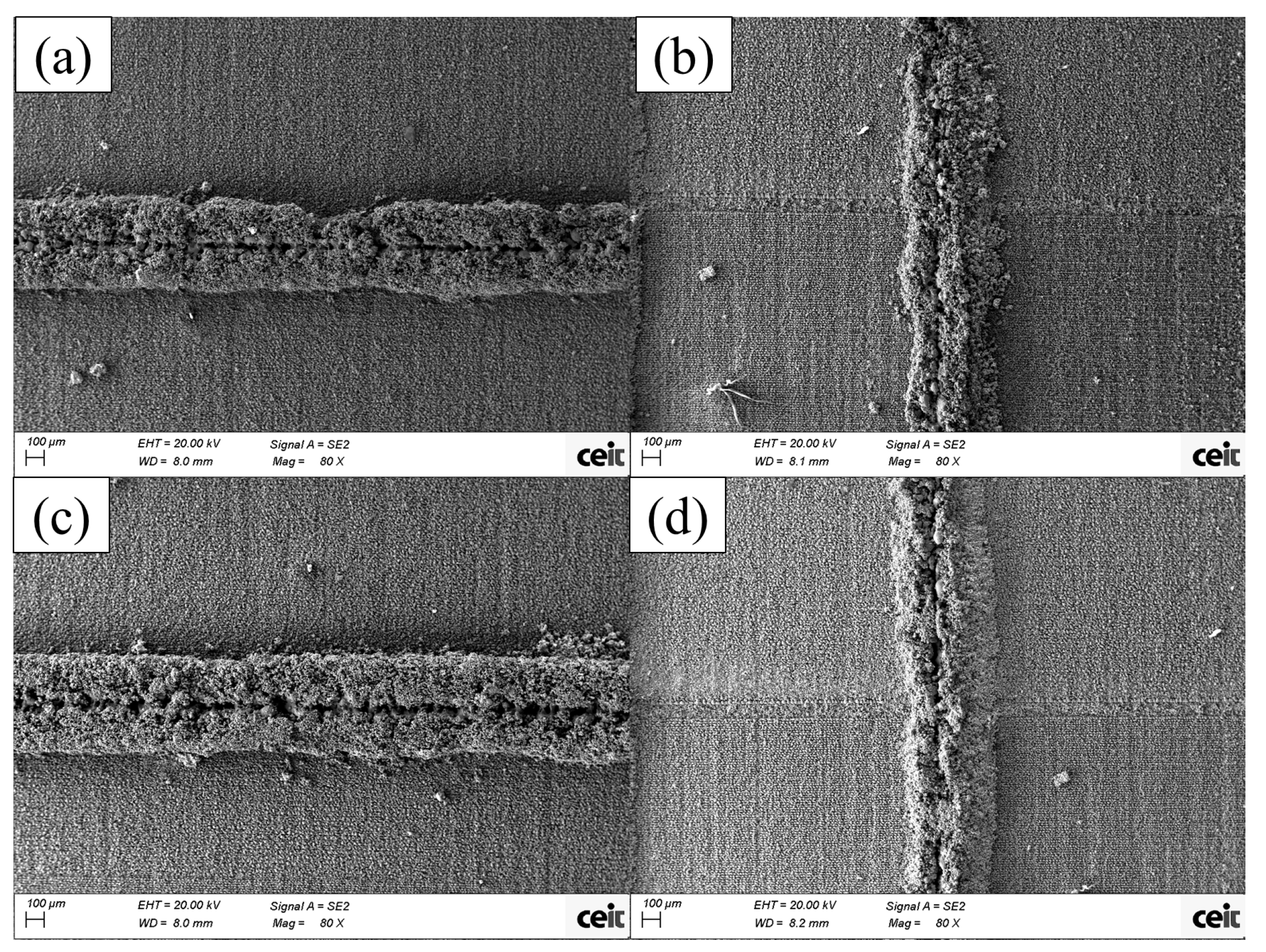

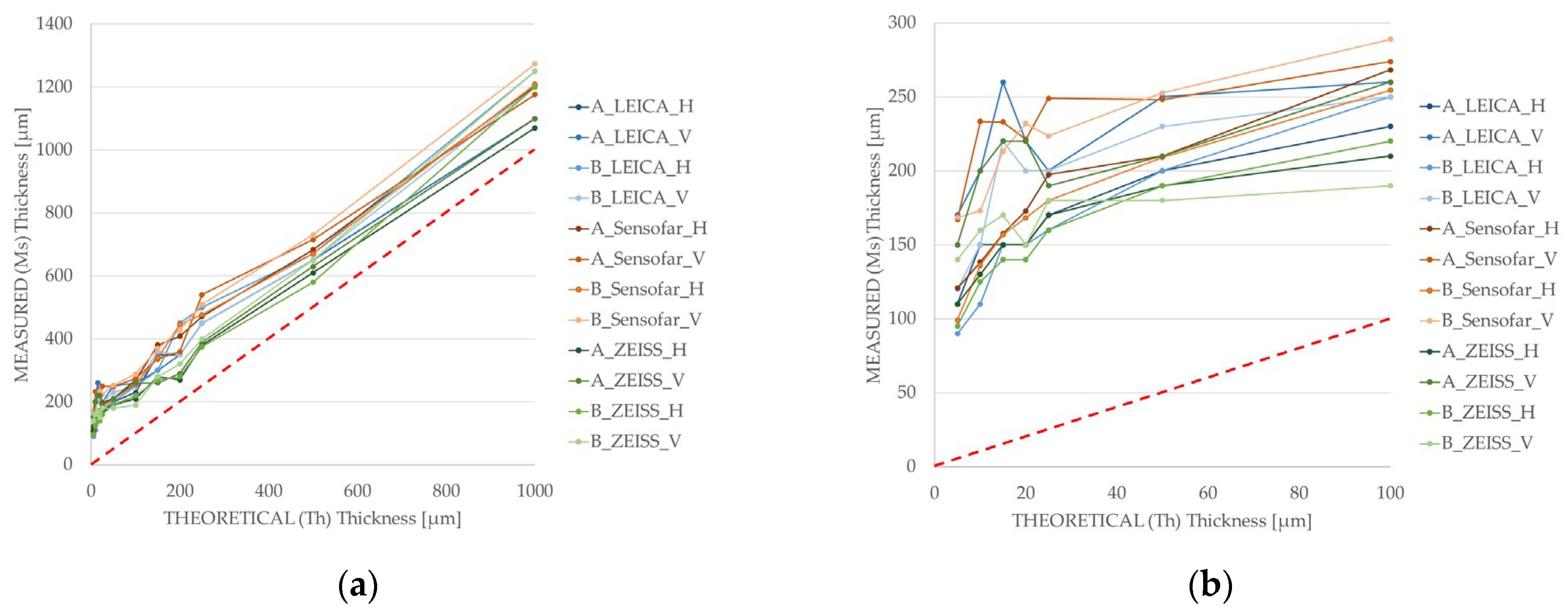

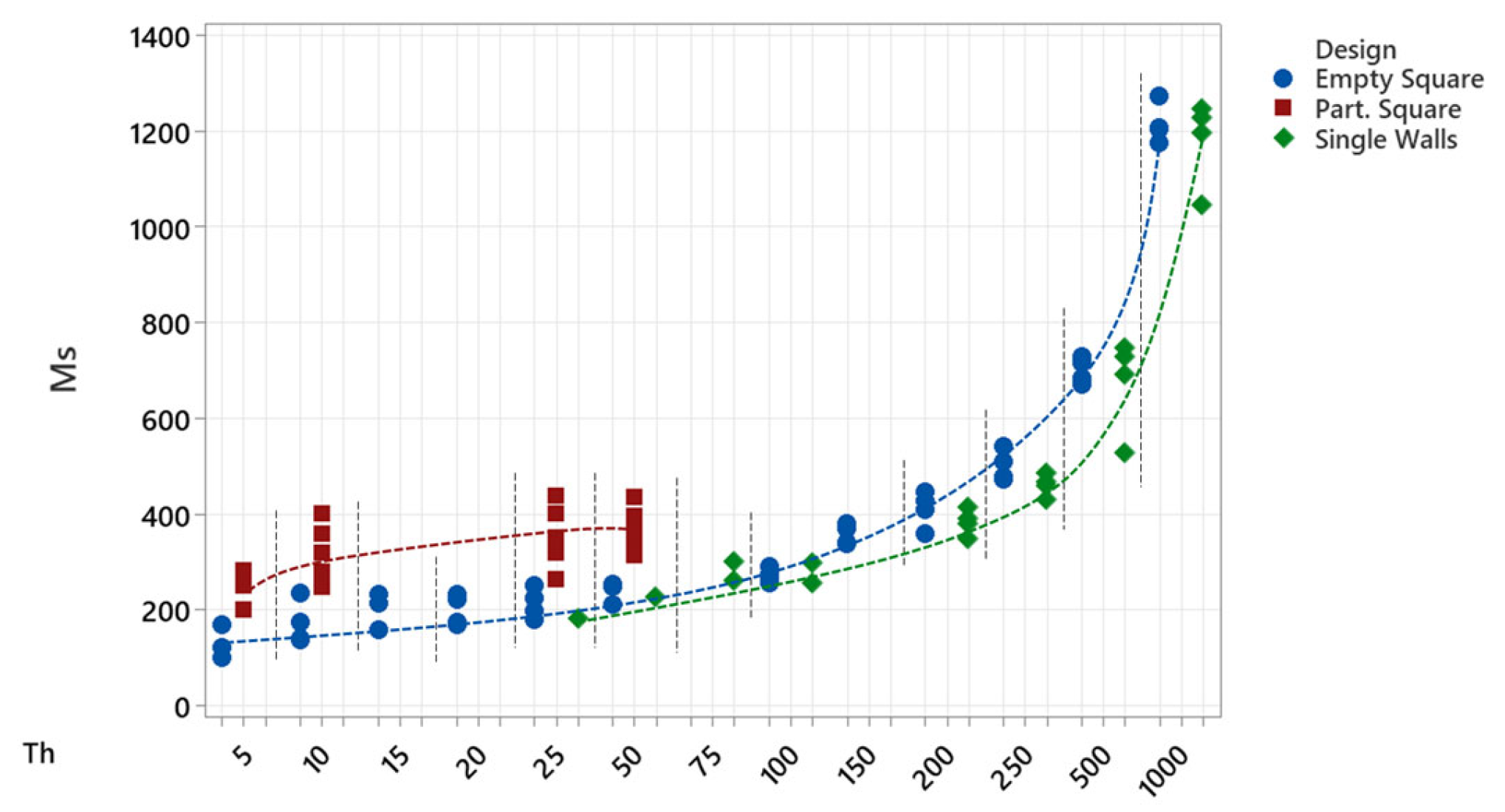

3.2. Thin-Wall Structure Thickness Analysis

4. Discussion

5. Conclusions

- After performing simulations with the set of reference parameters, it was found that femtosecond laser pulses are able to generate a small melt pool of the same size of the laser spot, indicating that there are no heat diffusion effects at the edges (considering a stainless-steel solid core).

- This study continues the work carried out in [6] and extends the information presented in [9], demonstrating that the femtosecond laser is not only valid for melting metal powder, but also for making complex profiles, and thanks to its controlled heat input, enables very thin profiles to be made, as thin or thinner than other similar techniques. Further research in this topic with higher pulse repetition may offer potential improvements in mAM using LPBF, a technique with a high maturity index.

- A scanning strategy has been found to be decisive in fabricating profiles with reduced thickness. For walls larger than 100 µm, where the thickness of the wall is much larger than the spot diameter, the scanning direction is not important, as the processing parameters are more influential; in contrast, when the wall is not much larger than the diameter spot, different scanning strategies strongly influence the results.

- Structure design is decisive with regard to the structural resistance to the cleaning process, a necessary step in all LPBF processes; the distribution of the walls in the structure also determines the amount of unmelted powder adhering to the structure, which in some cases hampers the measurements of the real wall thicknesses.

- The lowest measured wall thickness in the experiments was 90 µm, for a wall design of 5 µm; the rest of the measured thicknesses were at least around 90–100 µm higher that their theoretical value, denoting significant heat accumulation rates able to generate melting and/or sintering in an area wider than the laser spot.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chua, C.K.; Wong, C.H.; Young, W.Y. Introduction to 3D Printing or Additive Manufacturing, Standards, Quality Control, and Measurement Sciences in 3D Printing and Additive Manufacturing; Academic Press: Cambridge, MA, USA, 2017. [Google Scholar]

- Vaezi, M.; Seitz, H.; Yang, S. A review on 3D micro-additive manufacturing technologies. Int. J. Adv. Manuf. Technol. 2012, 67, 1721–1754. [Google Scholar] [CrossRef]

- Ostendorf, A.; Neumeister, A.; Dudziak, S.; Passinger, S.; Stampfl, J. Micro- and nano-parts generated by laser-based solid freeform fabrication. In Woodhead Publishing Series in Welding and Other Joining Technologies, Advances in Laser Materials Processing; Lawrence, J., Pou, J., Low, D.K.Y., Toyserkani, E., Eds.; Woodhead Publishing: Sawston, UK, 2010; pp. 695–734. [Google Scholar]

- Behera, D.; Chizari, S.; Shaw, L.A.; Porter, M.; Hensleigh, R.; Xu, Z.; Zheng, X.; Connolly, L.G.; Roy, N.K.; Panas, R.M.; et al. Current challenges and potential directions towards precision microscale additive manufacturing—Part IV: Future perspectives. Precis. Eng. 2020, 68, 197–205. [Google Scholar] [CrossRef]

- Presz, W. Ultrasonic Orbital Microforming—A New Possibility in the Forming of Microparts. Metals 2018, 8, 889. [Google Scholar] [CrossRef]

- Ramon-Conde, I.; Rodriguez, A.; Olaizola, S.M.; Gomez-Aranzadi, M. Study of the processing conditions for stainless steel additive manufacturing using femtosecond laser. Opt. Laser Technol. 2023, 161, 109232. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Additive manufacturing of cardiovascular CoCr stents by selective laser melting. Mater. Des. 2017, 119, 338–350. [Google Scholar] [CrossRef]

- Kaligar, A.B.; Kumar, H.A.; Ali, A.; Abuzaid, W.; Egilmez, M.; Alkhader, M.; Abed, F.; Alnaser, A.S. Femtosecond Laser-Based Additive Manufacturing: Current Status and Perspectives. Quantum Beam Sci. 2022, 6, 5. [Google Scholar] [CrossRef]

- Ramon-Conde, I.; Omeñaca, L.; Gomez-Aranzadi, M.; Castaño, E.; Ayerdi, I.; Olaizola, S.M. Fabrication of Thin-wall Structures with Femtosecond Laser and Stainless Steel Powder. In Proceedings of the 2023 IEEE International Conference on Manipulation, Manufacturing and Measurement on the Nanoscale (3M-NANO), Chengdu, China, 31 July–4 August 2023; pp. 249–252. [Google Scholar]

- Wu, Z.; Narra, S.P.; Rollett, A. Exploring the fabrication limits of thin-wall structures in a laser powder bed fusion process. Int. J. Adv. Manuf. Technol. 2020, 110, 191–207. [Google Scholar] [CrossRef]

- Wrobel, R.; Del Guidice, L.; Scheel, P.; Abando, N.; Maeder, X.; Vassiliou, M.; Hosseini, E.; Spolenak, R.; Leinenbach, C. Influence of wall thickness on microstructure and mechanical properties of thin-walled 316L stainless steel produced by laser powder bed fusion. Mater. Des. 2024, 238, 112652. [Google Scholar] [CrossRef]

- Calignano, F.; Cattano, G.; Manfredi, D. Manufacturing of thin wall structures in AlSi10Mg alloy by laser powder bed fusion through process parameters. J. Am. Acad. Dermatol. 2018, 255, 773–783. [Google Scholar] [CrossRef]

- Pasupathy, M.; Martín, J.M.; Rivas, A.; Iturriza, I.; Castro, F. Effect of the solidification time on the median particle size of powders produced by water atomisation. Powder Met. 2016, 59, 128–141. [Google Scholar] [CrossRef]

- Anisimov, S.I.; Kapeliovich, B.L.; Perelman, T.L. Electron emission from metal surfaces exposed to ultrashort laser pulses. Zh. Eksp. Teor. Fiz. 1974, 66, 375–377. [Google Scholar]

- Zhang, J.; Chen, Y.; Hu, M.; Chen, X. An improved three-dimensional two-temperature model for multi-pulse femtosecond laser ablation of aluminum. J. Appl. Phys. 2015, 117, 063104. [Google Scholar] [CrossRef]

- Shrestha, S.; Chou, K. Single track scanning experiment in laser powder bed fusion process. Procedia Manuf. 2018, 26, 857–864. [Google Scholar] [CrossRef]

- Kim, F.; Moylan, S. Literature review of metal additive manufacturing defects. In Advanced Manufacturing Series (NIST AMS); National Institute of Standards and Technology: Gaithersburg, MD, USA, 2024. [Google Scholar] [CrossRef]

- Wang, X.C.; Laoui, T.; Bonse, J.; Kruth, J.P.; Lauwers, B.; Froyen, L. Direct Selective Laser Sintering of Hard Metal Powders: Experimental Study and Simulation. Int. J. Adv. Manuf. Technol. 2002, 19, 351–357. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramon-Conde, I.; Omeñaca, L.; Gomez-Aranzadi, M.; Castaño, E.; Rodriguez, A.; Olaizola, S.M. Fabrication of Thin-Wall Structures with a Femtosecond Laser and Stainless Steel Powder. Micromachines 2024, 15, 444. https://doi.org/10.3390/mi15040444

Ramon-Conde I, Omeñaca L, Gomez-Aranzadi M, Castaño E, Rodriguez A, Olaizola SM. Fabrication of Thin-Wall Structures with a Femtosecond Laser and Stainless Steel Powder. Micromachines. 2024; 15(4):444. https://doi.org/10.3390/mi15040444

Chicago/Turabian StyleRamon-Conde, Iñigo, Luis Omeñaca, Mikel Gomez-Aranzadi, Enrique Castaño, Ainara Rodriguez, and Santiago M. Olaizola. 2024. "Fabrication of Thin-Wall Structures with a Femtosecond Laser and Stainless Steel Powder" Micromachines 15, no. 4: 444. https://doi.org/10.3390/mi15040444

APA StyleRamon-Conde, I., Omeñaca, L., Gomez-Aranzadi, M., Castaño, E., Rodriguez, A., & Olaizola, S. M. (2024). Fabrication of Thin-Wall Structures with a Femtosecond Laser and Stainless Steel Powder. Micromachines, 15(4), 444. https://doi.org/10.3390/mi15040444