Piezoelectric Micromachined Ultrasonic Transducers with Micro-Hole Inter-Etch and Sealing Process on (111) Silicon Wafer

Abstract

1. Introduction

2. Materials and Methods

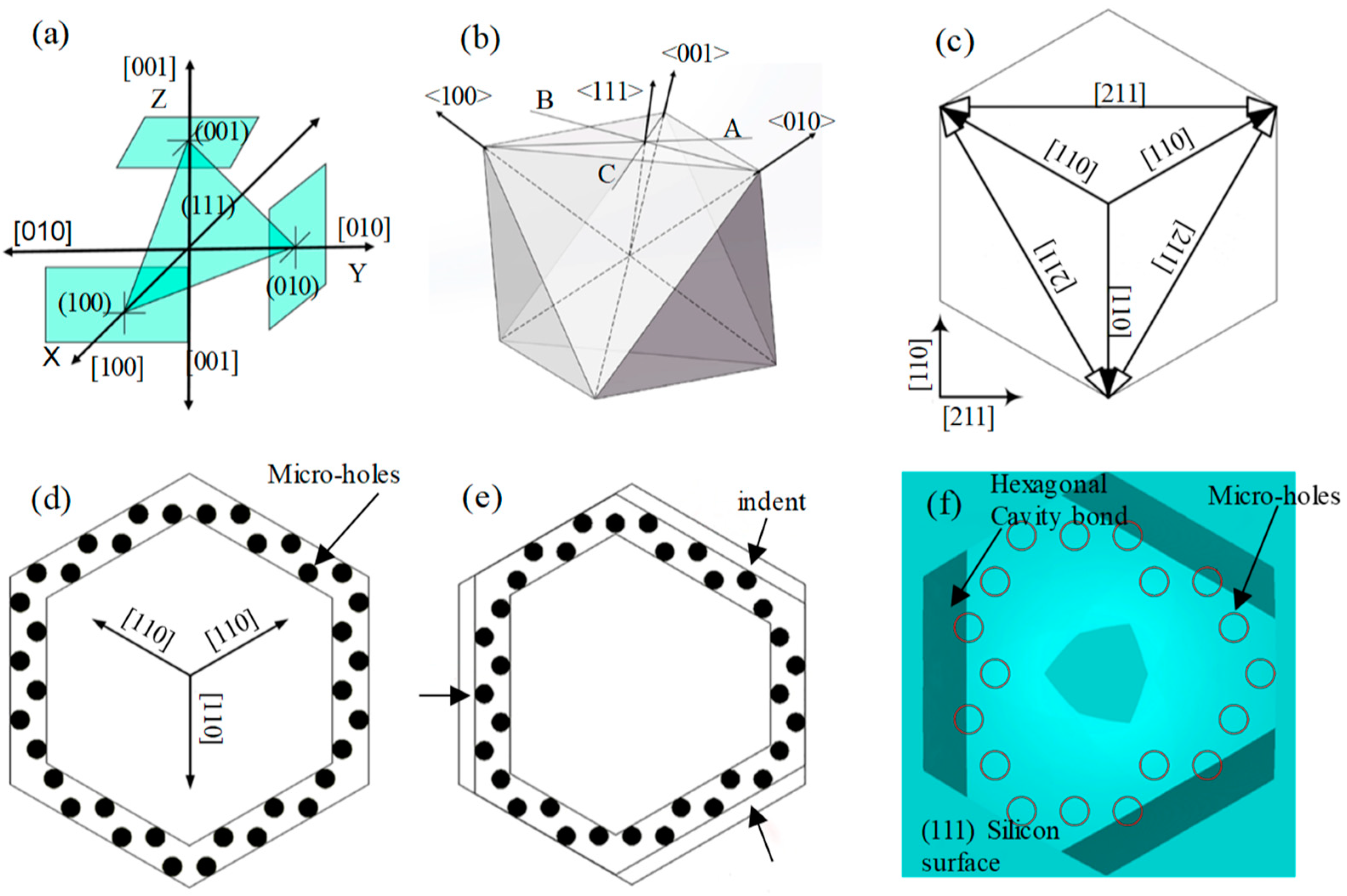

2.1. Anisotropic Corrosion Mechanism of Silicon

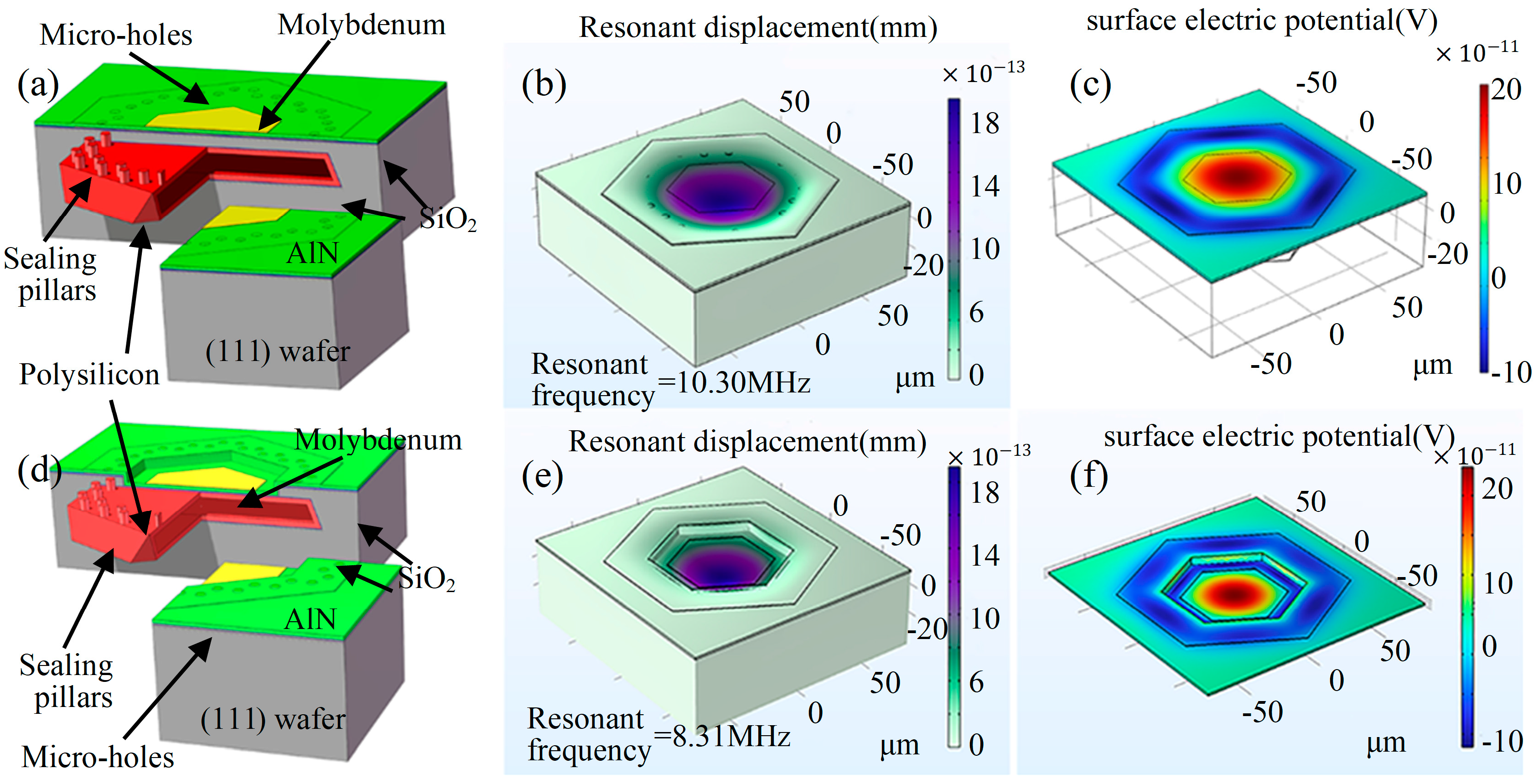

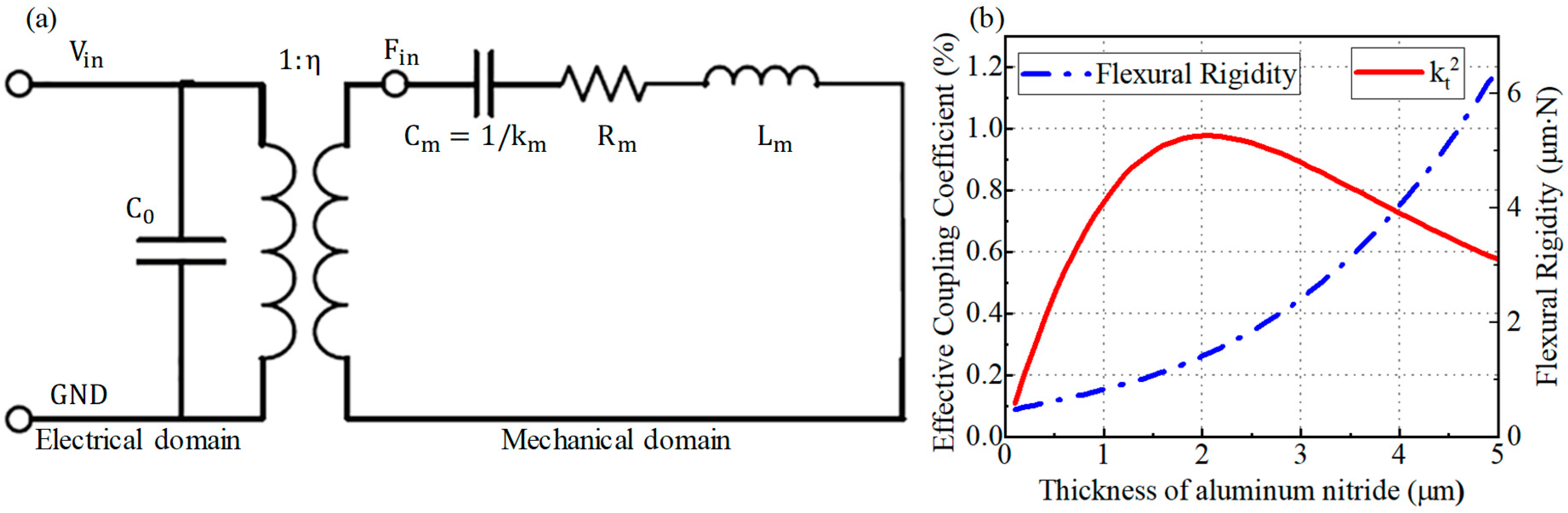

2.2. PMUT Cell and Array

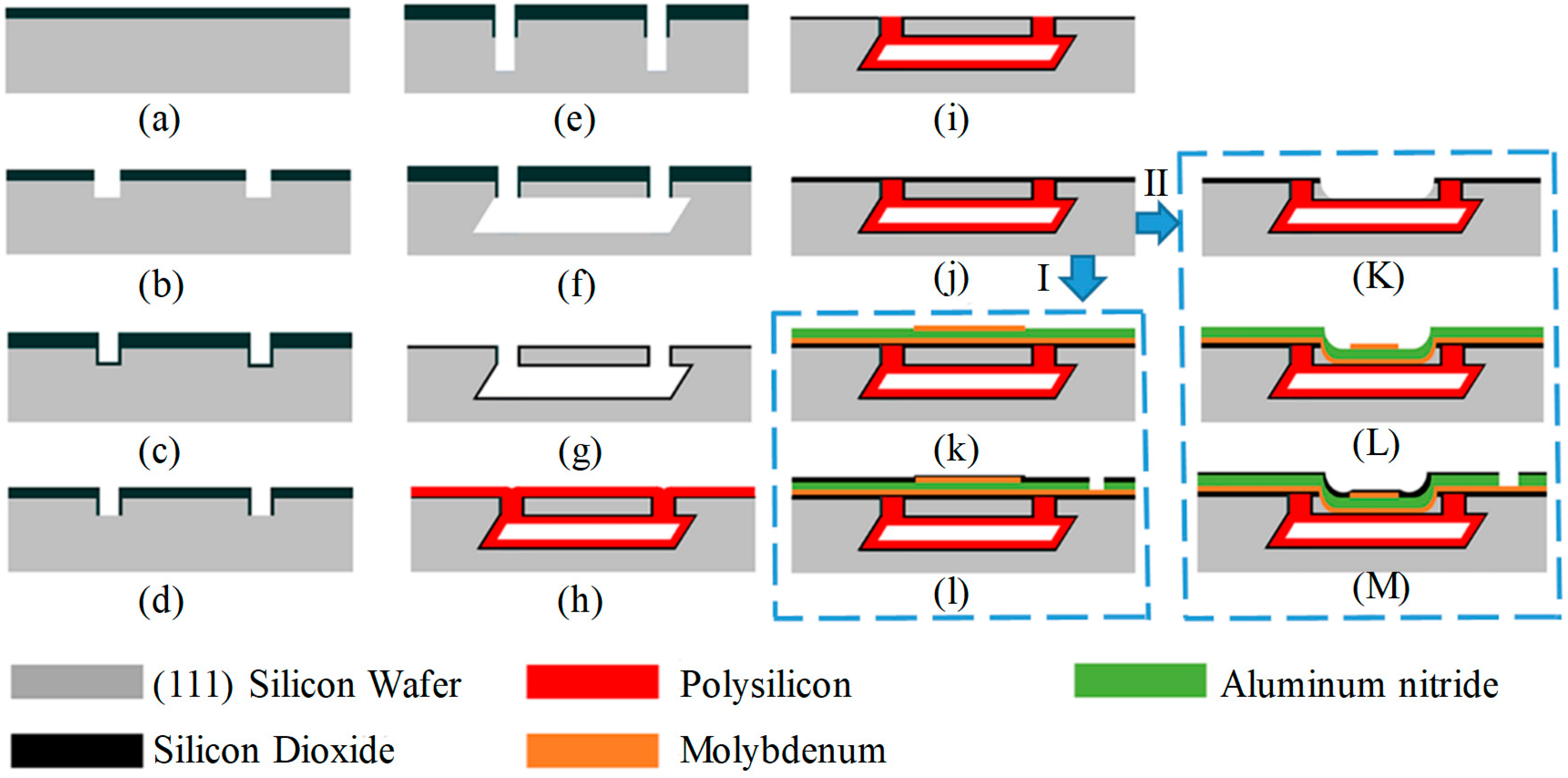

3. Fabrication

- A thin thermal dioxide (200 nm) layer is grown on the wafer to facilitate better adhesion of a 1 μm thick layer of TEOS-based silicon dioxide via low-pressure chemical vapor deposition (LPCVD). The dioxide layer is used as a self-aligned mask in the following procedures.

- The dioxide layer is subjected to dry etching by reactive ion etching (RIE) and another deep RIE process is applied to confine the diaphragm thickness.

- A 0.4 μm thick layer of TEOS-based silicon dioxide is deposited using LPCVD to cover the hole surface for protecting the vertical surface of the micro-hole sidewalls from the following anisotropic wet etching.

- Then the dioxide on the bottom of micro-holes is anisotropically dry etched using RIE to expose monocrystalline silicon at the bottom surface of the holes, while the silicon oxide on the vertical sidewalls is retained.

- Silicon deep RIE is then performed again to deepen the holes. The etching depth is increased by 12~14 μm; this etching depth determines the cavity height, which needs to be controlled within the range of 12~28 μm.

- By leveraging the high selectivity of silicon wet etching in an alkaline solution, the lateral interconnection of micro-holes is generated in a 25% aqueous tetramethylammonium hydroxide (TMAH) solution, which forms the diaphragm-on-cavity structure.

- The dioxide mask is removed in a buffered HF solution, and a thermal dioxide thin layer of 300 nm is grown on the surface of the wafer.

- A 4 μm thick polysilicon layer is deposited on the wafer via LPCVD for vacuum cavity sealing. At this point, the wafer surface has 0.3 μm of silicon oxide and 4 μm of polysilicon.

- Then the top surface polysilicon is etched via RIE; the stop layer is 0.3 μm silicon oxide.

- A high-quality electrical insulation layer of LPCVD TEOS-based silicon dioxide is deposited before the bottom electrode is transferred.

- A layer of molybdenum metal is sputtered and patterned as the bottom electrode with a thickness of 0.3 μm on the wafer surface using a lift-off process, followed by sputtering of a 2 μm aluminum nitride thin film as the piezoelectric layer and then sputtering and patterning of 0.3 μm molybdenum metal as the top electrode.

- The process of sputtering and patterning a layer of 0.3 μm PECVD silicon oxide on the wafer surface serves as a mask for TMAH etching of aluminum nitride, which takes about 30 min etching time for 2 μm aluminum nitride, and an additional 10 min etching time helps to completely eliminate residual aluminum nitride pyramid-shaped particles in the window.

4. Characterization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jung, J.; Lee, W.; Kang, W.; Shin, E.; Ryu, J.; Choi, H. Review of piezoelectric micromachined ultrasonic transducers and their applications. J. Micromech. Microeng. 2017, 27, 113001. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; He, C.; Xue, C. Design and Performance Analysis of Capacitive Micromachined Ultrasonic Transducer Linear Array. Micromachines 2014, 5, 420–431. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Kwon, Y.E. Review of magnetostrictive patch transducers and applications in ultrasonic nondestructive testing of waveguides. Ultrasonics 2015, 62, 3–19. [Google Scholar] [CrossRef] [PubMed]

- Bachu, V.S.; Kedda, J.; Suk, I.; Green, J.J.; Tyler, B. High-Intensity Focused Ultrasound: A Review of Mechanisms and Clinical Applications. Ann. Biomed. Eng. 2021, 49, 1975–1991. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Tong, Z.; Wu, Z.; Lou, L. An Ultrasonic Target Detection System Based on Piezoelectric Micromachined Ultrasonic Transducers. Micromachines 2023, 14, 683. [Google Scholar] [CrossRef] [PubMed]

- Cai, J.; Wang, Y.; Jiang, D.; Zhang, S.; Gu, Y.A.; Lou, L.; Gao, F.; Wu, T. Beyond fundamental resonance mode: High-order multi-band ALN PMUT for in vivo photoacoustic imaging. Microsyst. Nanoeng. 2022, 8, 116. [Google Scholar] [CrossRef] [PubMed]

- Abdalla, O.M.O.; Massimino, G.; Quaglia, F.; Passoni, M.; Corigliano, A. PMUTs Arrays for Structural Health Monitoring of Bolted-Joints. Micromachines 2023, 14, 311. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Gigliotti, J.; Wallace, M.; Griggio, F.; Demore, C.; Cochran, S.; Trolier-McKinstry, S. Piezoelectric Micromachined Ultrasound Transducer (PMUT) Arrays for Integrated Sensing, Actuation and Imaging. Sensors 2015, 15, 8020–8041. [Google Scholar] [CrossRef]

- Lu, Y.; Heidari, A.; Horsley, D.A. A High Fill-Factor Annular Array of High Frequency Piezoelectric Micromachined Ultrasonic Transducers. J. Microelectromechanical Syst. 2015, 24, 904–913. [Google Scholar] [CrossRef]

- Cai, J.; Wang, Y.; Jiang, D.; Gu, Y.; Lou, L.; Gao, F.; Wu, T. Photoacoustic Imaging Based on Broadened Bandwidth Aluminum Nitride Piezoelectric Micromachined Ultrasound Transducers. IEEE Sens. Lett. 2023, 7, 1–4. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Cai, J.; Wang, B.; Gu, Y.A.; Lou, L.; Wang, X.; Wu, T. Microwave-Induced Thermoacoustic Imaging Using Aluminum Nitride PMUT. In Proceedings of the 2023 IEEE 36th International Conference on Micro Electro Mechanical Systems (MEMS), Munich, Germany, 15–19 January 2023; pp. 413–416. [Google Scholar]

- Qu, M.; Lv, D.; Zhou, J.; Wang, Z.; Zheng, Y.; Zhang, G.; Xie, J. Sensing and Controlling Strategy for Upper Extremity Prosthetics Based on Piezoelectric Micromachined Ultrasound Transducer. IEEE Trans. Biomed. Eng. 2024, 71, 1161–1169. [Google Scholar] [CrossRef]

- Roy, K.; Mandal, A.; Ashok, A.; Gupta, H.; Shastri, V.; Pratap, R. A Single Cell PMUT as a Bio-Fluid Density Sensor. In Proceedings of the 2020 IEEE International Ultrasonics Symposium (IUS), Las Vegas, NV, USA, 7–11 September 2020; pp. 1–4. [Google Scholar]

- Cai, J.; Liu, K.; Lou, L.; Zhang, S.; Gu, Y.A.; Wu, T. Increasing Ranging Accuracy of Aluminum Nitride Pmuts by Circuit Coupling. In Proceedings of the 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS), Gainesville, FL, USA, 25–29 January 2021; pp. 740–743. [Google Scholar]

- Wang, Y.; Zhang, L.; Wang, B.; Cai, J.; Gu, Y.A.; Lou, L.; Wang, X.; Wu, T. Microwave-induced thermoacoustic imaging with a multi-cell AlScN piezoelectric micromachined ultrasonic transducer. Appl. Phys. Lett. 2023, 122, 133702. [Google Scholar] [CrossRef]

- Jiao, D.; Ni, Z.; Wang, J.; Li, X. High Fill Factor Array of Piezoelectric Micromachined Ultrasonic Transducers with Large Quality Factor. Sens. Mater. 2020, 32, 1785–1795. [Google Scholar] [CrossRef]

- Shao, Z.; Peng, Y.; Pala, S.; Liang, Y.; Lin, L. 3D Ultrasonic Object Detections with >1 Meter Range. In Proceedings of the 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS), Virtual, 25–29 January 2021; pp. 386–389. [Google Scholar]

- Sadeghpour, S.; Lips, B.; Kraft, M.; Puers, R. Flexible Soi-Based Piezoelectric Micromachined Ultrasound Transducer (PMUT) Arrays. In Proceedings of the International Conference on Solid-State Sensors, Actuators and Microsystems, Berlin, Germany, 23–27 June 2019; Eurosensors: Cambridge, UK, 2019. [Google Scholar]

- Choong, D.S.W.; Chen, D.S.-H.; Goh, D.J.; Liu, J.; Ghosh, S.; Koh, Y.; Sharma, J.; Merugu, S.; Quaglia, F.; Ferrera, M.; et al. Silicon-On-Nothing ScAlN pMUTs. In Proceedings of the 2021 IEEE International Ultrasonics Symposium (IUS), Virtual, 11–16 September 2021; pp. 1–4. [Google Scholar]

- Li, P.; Li, W.; Chen, C.; Sun, K.; Liu, M.; Ni, Z.; Wang, J.; Li, X. Ultra-small high-temperature pressure sensor chips fabricated in single-layer (111) SOI wafers. J. Micromech. Microeng. 2023, 33, 085003. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J.; Li, X. Fully front-side bulk-micromachined single-chip micro flow sensors for bare-chipSMT(surface mounting technology) packaging. J. Micromech. Microeng. 2012, 22, 035020. [Google Scholar] [CrossRef]

- Wu, S.; Li, W.; Shao, S.; Yang, H.; Wu, T.; Li, X. PMUT Structure Design with a Scar-Free Minimally Invasive Surgery Process on (111) Silicon Wafer. In Proceedings of the 2022 IEEE International Ultrasonics Symposium (IUS), Venice, Italy, 10–13 October 2022; pp. 1–4. [Google Scholar]

- Wu, S.; Li, W.; Jiao, D.; Yang, H.; Wu, T.; Li, X. An Aluminum-Nitride PMUT with Pre-Concaved Membrane for Large Deformation and High Quality-Factor Performance. In Proceedings of the 2021 21st International Conference on Solid-State Sensors, Actuators and Microsystems (Transducers), Orlando, FL, USA, 20–24 June 2021; pp. 46–49. [Google Scholar]

- Zhou, J.; Cheng, C.; Qu, M.; Lv, D.; Liu, W.; Xie, J. Continuous and Non-Invasive Monitoring of Blood Pressure Based on Wearable Piezoelectric Micromachined Ultrasonic Transducers Array. J. Microelectromechanical Syst. 2023, 32, 437–444. [Google Scholar] [CrossRef]

- Cai, J.; Wang, Y.; Lou, L.; Zhang, S.; Gu, Y.; Gao, F.; Wu, T. Photoacoustic and Ultrosound Dual-Modality Endoscopic Imaging Based on ALN Pmut Array. In Proceedings of the 2022 IEEE 35th International Conference on Micro Electro Mechanical Systems Conference (MEMS), Tokyo, Japan, 9–13 January 2022; pp. 412–415. [Google Scholar]

- Li, D.; Shang, Z.; She, Y.; Wen, Z. Investigation of Au/Si Eutectic Wafer Bonding for MEMS Accelerometers. Micromachines 2017, 8, 158. [Google Scholar] [CrossRef]

- Hopcroft, M.A.; Nix, W.D.; Kenny, T.W. What is the Young’s Modulus of Silicon? J. Microelectromechanical Syst. 2010, 19, 229–238. [Google Scholar] [CrossRef]

- Oosterbroek, R.E.; Berenschot, J.W.E.; Jansen, H.V.; Nijdam, A.J.; Elwenspoek, M.C. Etching methodologies in <111>-oriented silicon wafers. J. Microelectromechanical Syst. 2000, 9, 390–398. [Google Scholar]

- Zubel, I.; Kramkowska, M.; Rola, K. Silicon anisotropic etching in TMAH solutions containing alcohol and surfactant additives. Sens. Actuators A Phys. 2012, 178, 126–135. [Google Scholar] [CrossRef]

- Ni, Z.; Jiao, D.; Zou, H.; Wang, J.; Li, X. 0.4mm×0.4mm barometer sensor-chip fabricated by a scar-free ‘MIS’ (minimally invasive surgery) process for 0.01US$/die product. In Proceedings of the 2017 19th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Kaohsiung, Taiwan, 18–22 June 2017. [Google Scholar]

- Bhugra, H.; Piazza, G. Piezoelectric MEMS Resonators; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Pandey, A.; Dutta, S.; Prakash, R.; Dalal, S.; Raman, R.; Kapoor, A.K.; Kaur, D. Growth and evolution of residual stress of AlN films on silicon (100) wafer. Mater. Sci. Semicond. Process. 2016, 52, 16–23. [Google Scholar] [CrossRef]

- Terai, Y.; Haraguchi, K.; Ichinose, R.; Oota, H.; Yonezawa, K. Structural and piezoelectric properties of AlN thin films grown by pressure gradient sputtering. Jpn. J. Appl. Phys. 2023, 62, SA1003. [Google Scholar] [CrossRef]

| The Number of Etching Holes | Hexagonal Cavity Area (μm) |

|---|---|

| 33 | 38 |

| 39 | 42 |

| 42 | 47 |

| 45 | 51 |

| Material Layer | Material | Thickness (μm) |

|---|---|---|

| Elastic layer | Polysilicon | 4 |

| Elastic layer | (111) Silicon | 6 |

| Insulation layer | TEOS–silicon oxide | 0.3 |

| Electrode layer | Molybdenum | 0.3 |

| Piezoelectric layer | Aluminum nitride | 2 |

| Etching mask layer | PECVD silicon oxide | 0.3 |

| PMUT Device (μm) | Resonant Frequency (MHz) | Quality Factor | Displacement Sensitivity (nm/V) |

|---|---|---|---|

| Flat diaphragm of R-38 | 11.99 | 110 | 1.8 |

| Etched diaphragm of R-38 | 9.04 | 139 | 0.78 |

| Flat diaphragm of R-42 | 9.86 | 107.5 | 3.67 |

| Etched diaphragm of R-42 | 8.29 | 193 | 6.23 |

| flat diaphragm of R-47 | 8.37 | 204.8 | 7.26 |

| Etched diaphragm of R-47 | 7.38 | 211.2 | 5.93 |

| Flat diaphragm of R-51 | 7.37 | 217 | 18.49 |

| Etched diaphragm of R-51 | 6.28 | 251 | 9.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wu, S.; Wang, W.; Wu, T.; Li, X. Piezoelectric Micromachined Ultrasonic Transducers with Micro-Hole Inter-Etch and Sealing Process on (111) Silicon Wafer. Micromachines 2024, 15, 482. https://doi.org/10.3390/mi15040482

Wang Y, Wu S, Wang W, Wu T, Li X. Piezoelectric Micromachined Ultrasonic Transducers with Micro-Hole Inter-Etch and Sealing Process on (111) Silicon Wafer. Micromachines. 2024; 15(4):482. https://doi.org/10.3390/mi15040482

Chicago/Turabian StyleWang, Yunhao, Sheng Wu, Wenjing Wang, Tao Wu, and Xinxin Li. 2024. "Piezoelectric Micromachined Ultrasonic Transducers with Micro-Hole Inter-Etch and Sealing Process on (111) Silicon Wafer" Micromachines 15, no. 4: 482. https://doi.org/10.3390/mi15040482

APA StyleWang, Y., Wu, S., Wang, W., Wu, T., & Li, X. (2024). Piezoelectric Micromachined Ultrasonic Transducers with Micro-Hole Inter-Etch and Sealing Process on (111) Silicon Wafer. Micromachines, 15(4), 482. https://doi.org/10.3390/mi15040482