Effect of Geometrical Parameters on the Mechanical Performance of Bamboo-Inspired Gradient Hollow-Strut Octet Lattice Structure Fabricated by Additive Manufacturing

Abstract

:1. Introduction

2. Structure Design, Materials and Methods

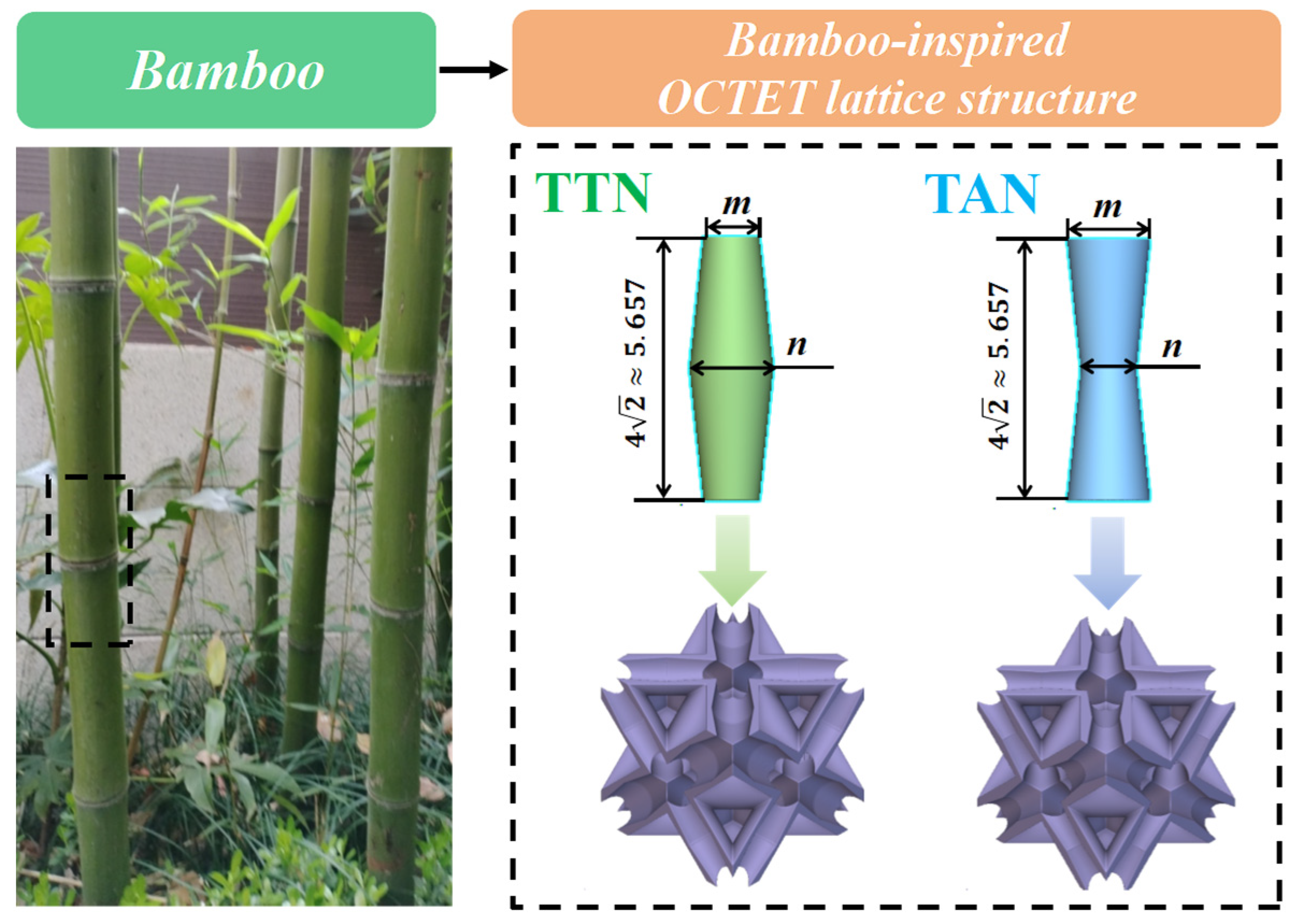

2.1. The Structure Design Strategy

2.2. Finite Element Analysis

2.3. Sample Preparation and Microstructural Observation

2.4. Mechanical Property Evaluation

3. Results and Discussion

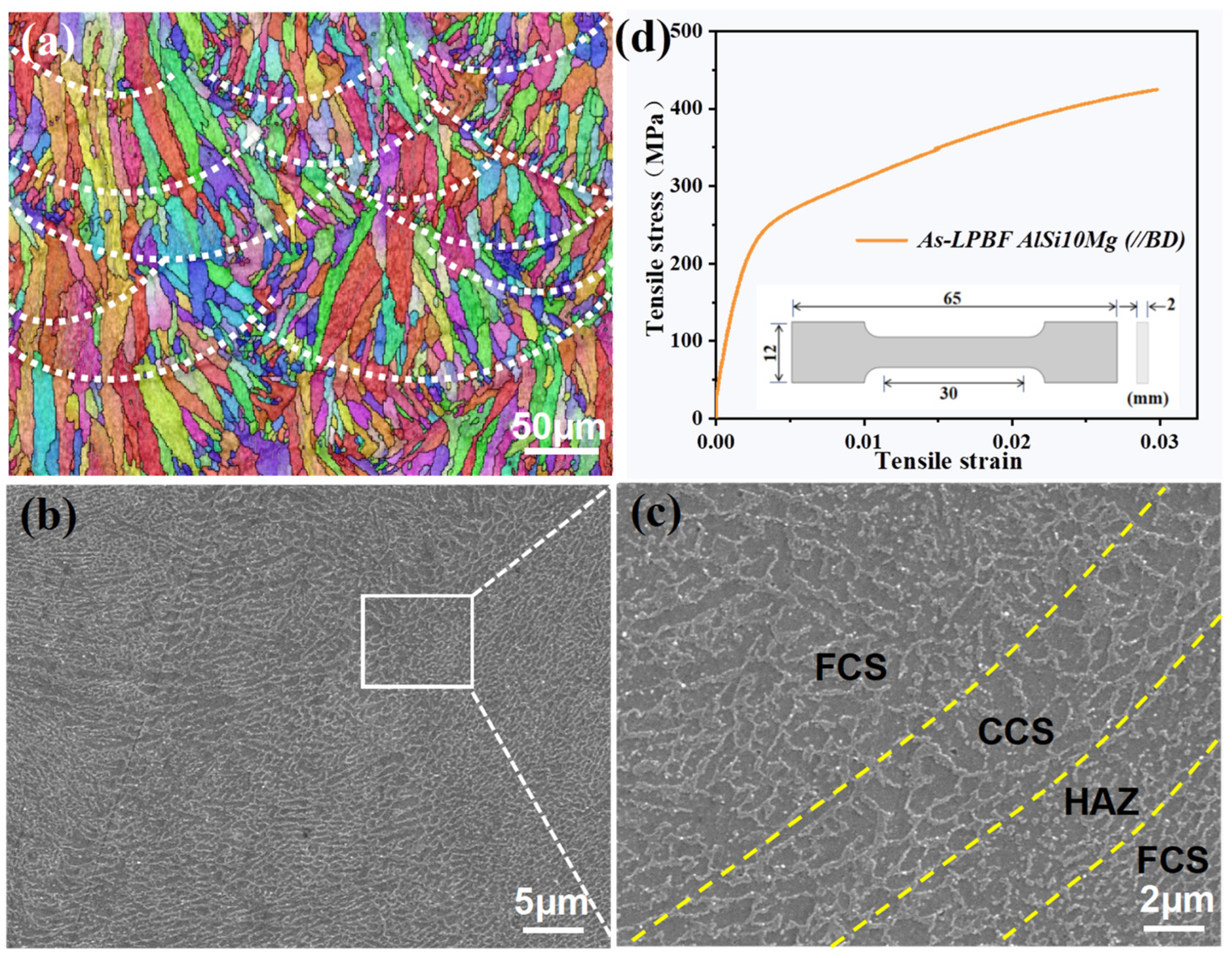

3.1. AlSi10Mg Sample Microstructure and Tensile Properties

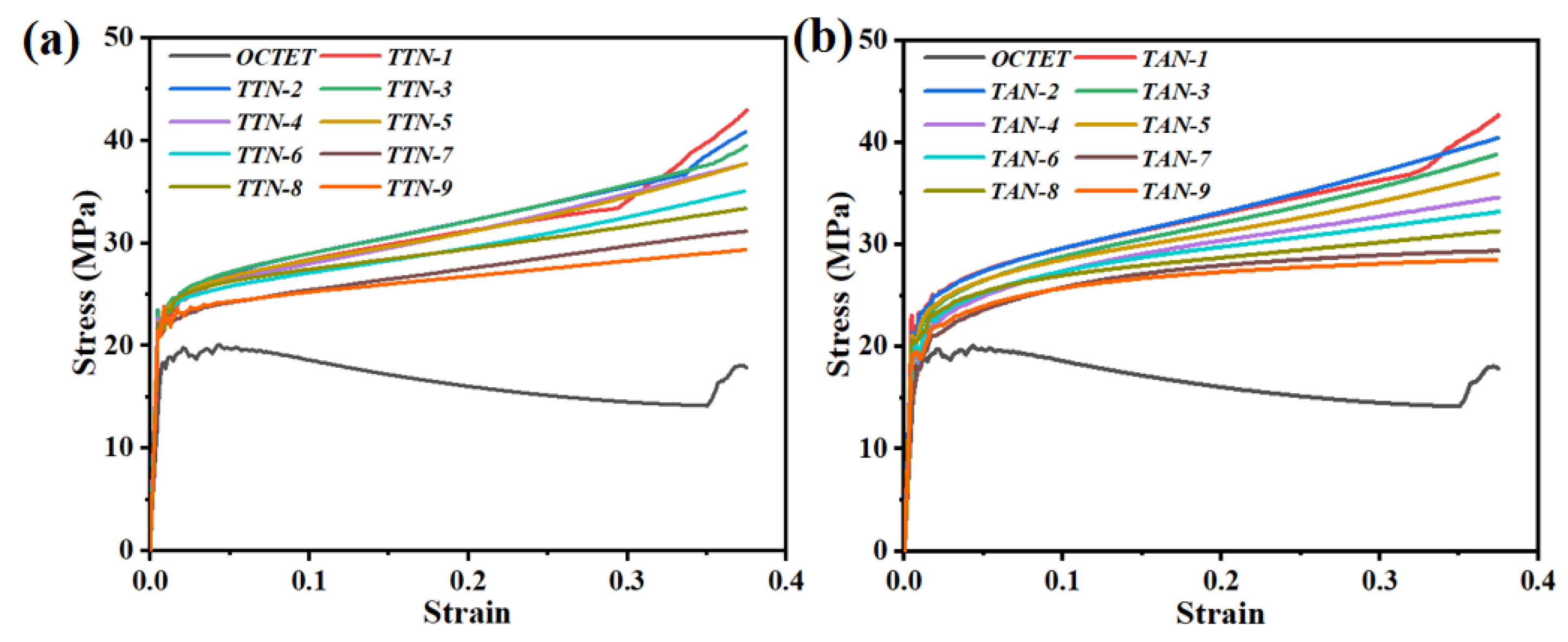

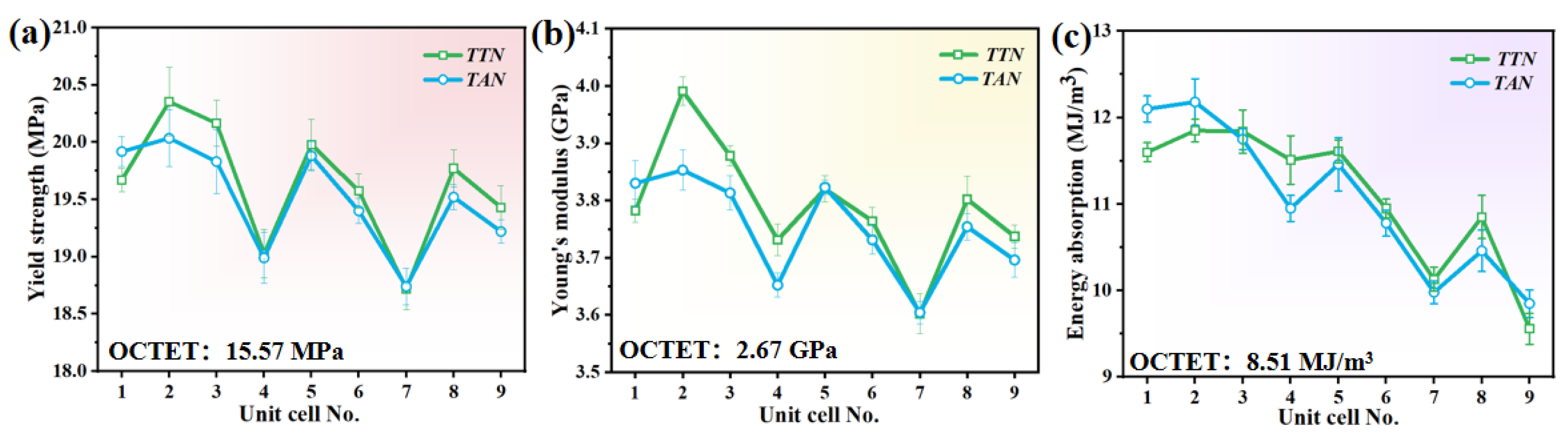

3.2. Structural Parameter Optimization of the Designed Unit Cells

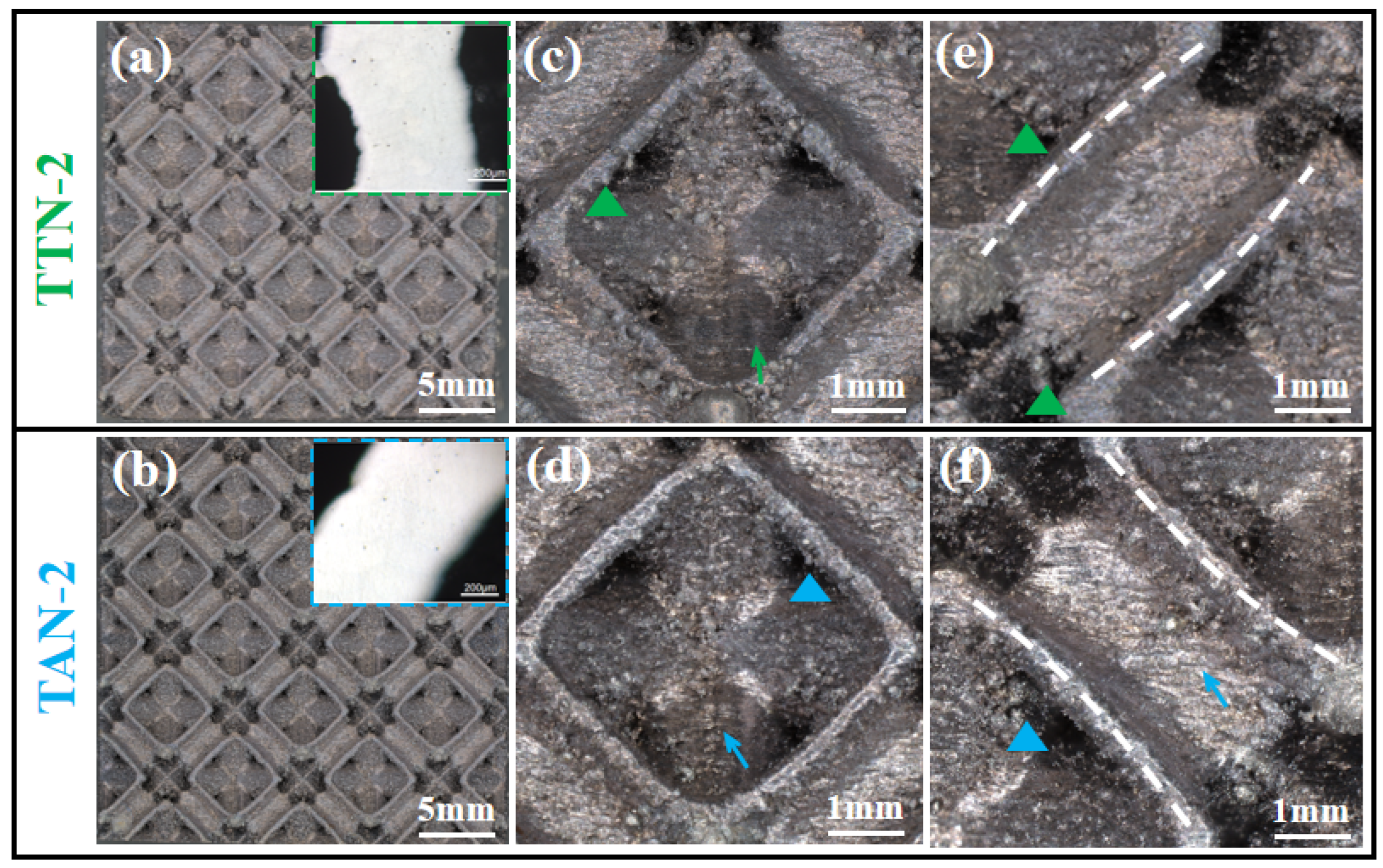

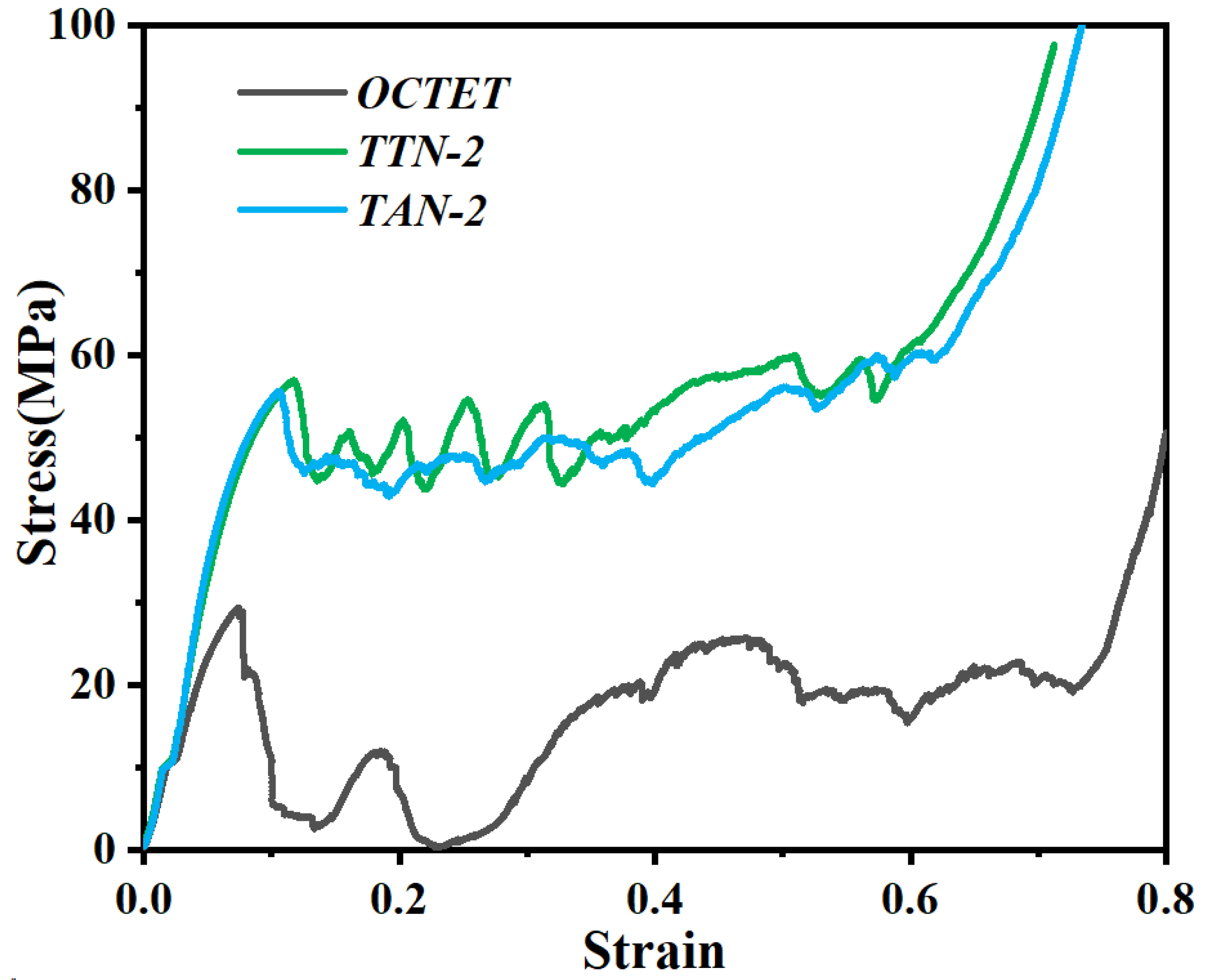

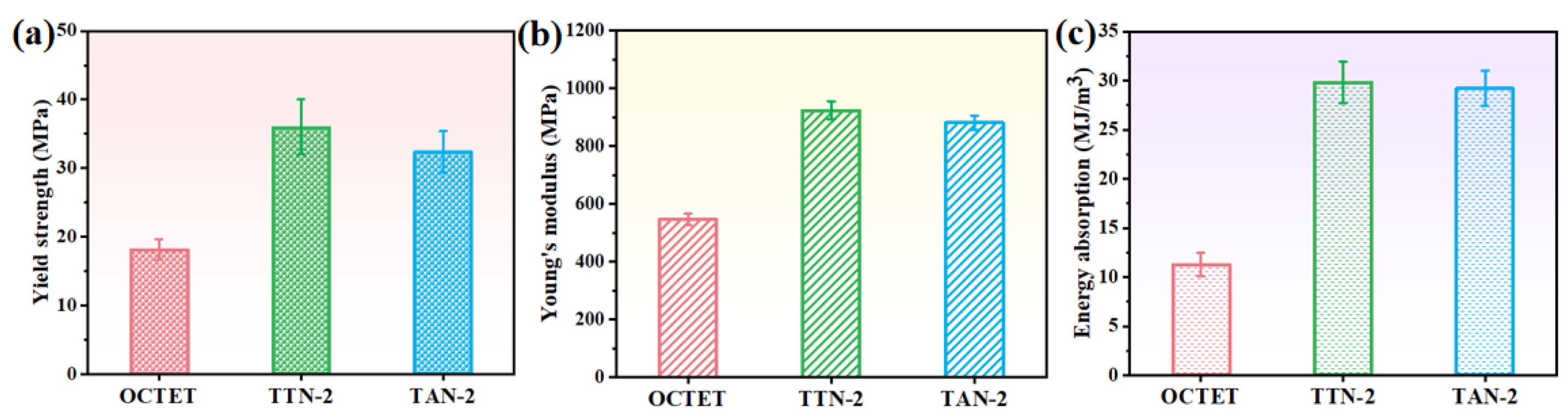

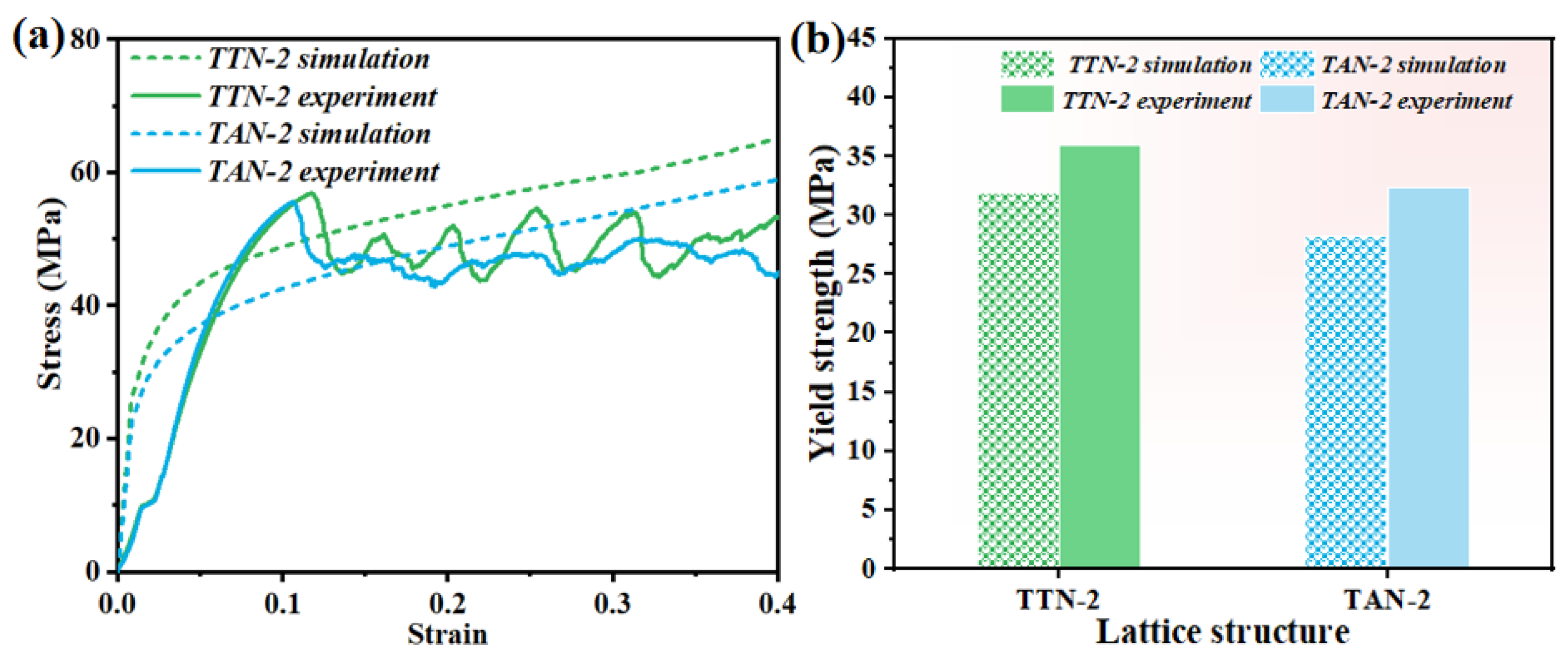

3.3. Experimental Evaluations of the LPBFed Lattice Structures

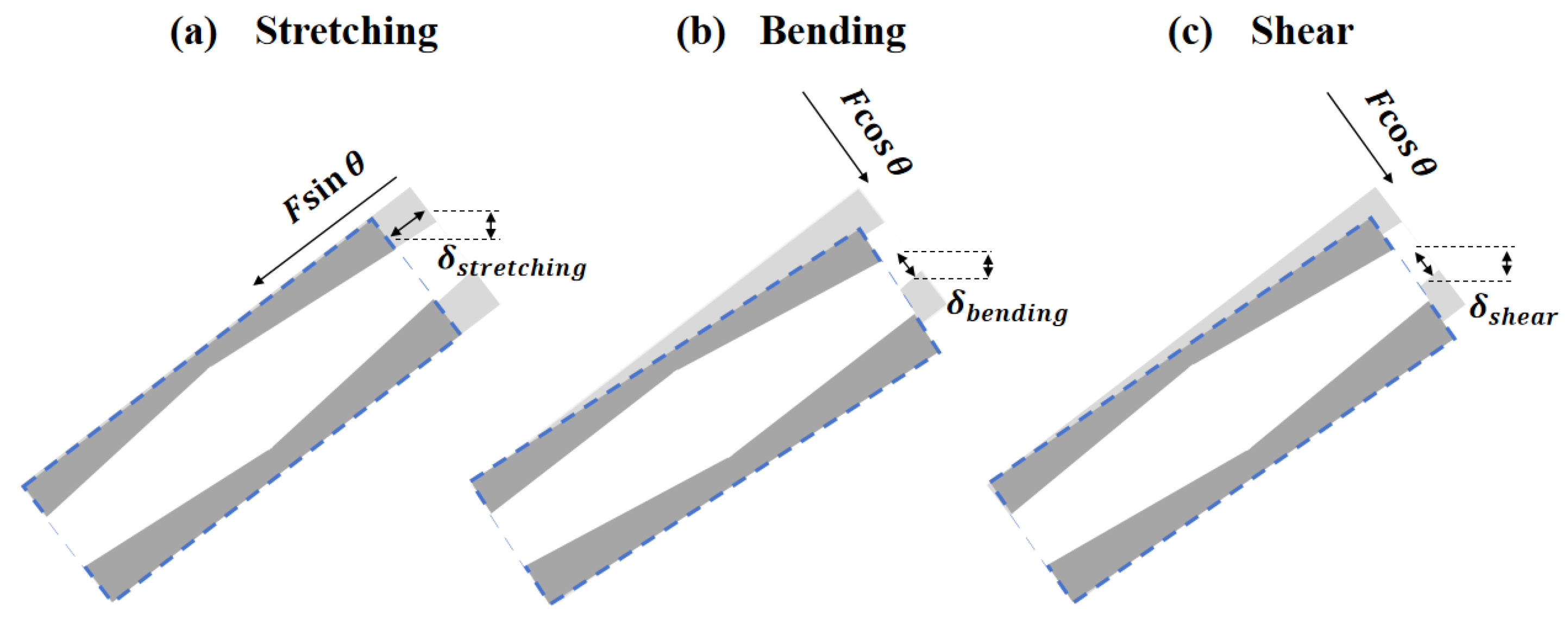

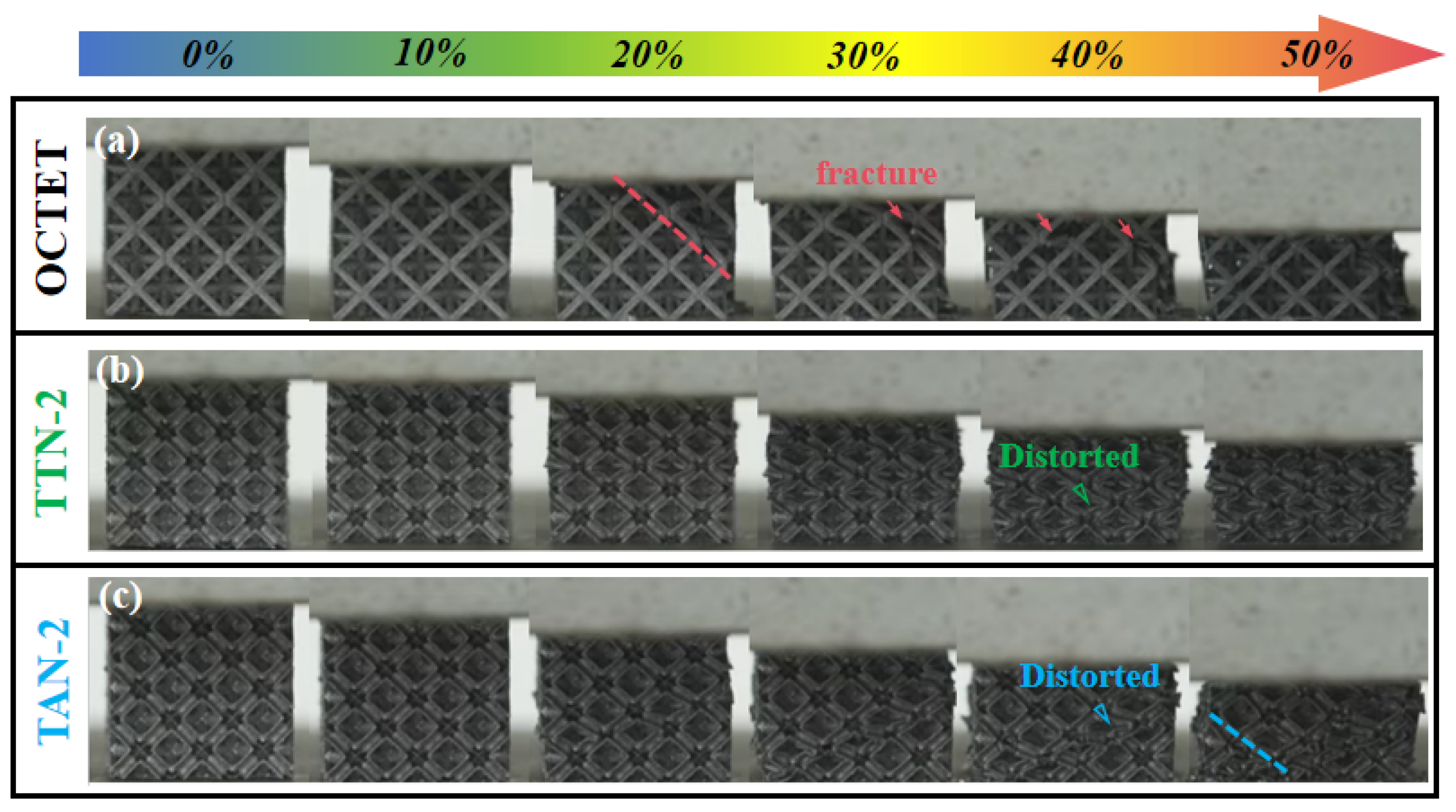

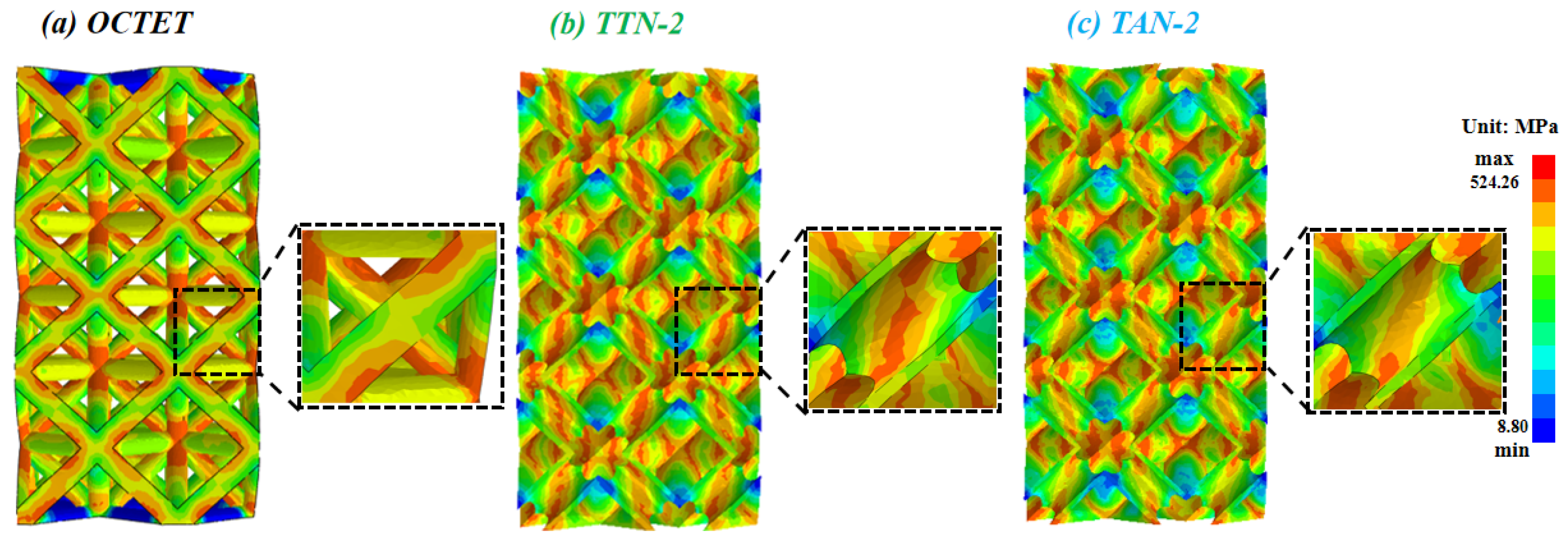

3.4. Deformation Mode Analysis

4. Conclusions

- (1)

- FEA analysis revealed that the higher yield strength, Young’s modulus and energy absorption for the designed octet unit cells were obtained when the shape parameter k equals 0.1. The optimized octet unit cells of TTN-2 and TAN-2 were redesigned into lattice structures for experimental studies.

- (2)

- The gradient hollow-strut lattice structure design significantly enhanced its mechanical properties as compared with the solid-strut lattice structures under the same relative density, while the TTN-2 structure exhibited slightly higher yield strength than the TAN-2 structure.

- (3)

- The deformation stability of the TTN-2 and TAN-2 structures was markedly enhanced by suppressing the typical shearing and local failure issues observed in the solid-strut octet lattice structure. Specifically, the TTN-2 structure displayed the best shape integrity even after 50% compression strain.

- (4)

- Deformation modes analysis revealed that the enhanced bending strength due to the gradient hollow strut design enhanced its mechanical performance as compared with the solid strut counterparts. On the other hand, the slight strut cross-section configuration variance contributed to the reasonable improvement in load-bearing capacity and deformation stability of the TTN-2 lattice structure.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Crupi, V.; Epasto, G.; Guglielmino, E. Comparison of aluminium sandwiches for lightweight ship structures: Honeycomb vs. foam. Mar. Struct. 2013, 30, 74–96. [Google Scholar] [CrossRef]

- Basha, H.S.; Goel, S.C. Special truss moment frames with Vierendeel middle panel. Eng. Struct. 1995, 17, 352–358. [Google Scholar] [CrossRef]

- Deshmukh, S.; Kumar, S.; Wagh, A.; Krishnan, S.; Ramamoorthy, S. Selection of periodic cellular structures for multifunctional applications directly based on their unit cell geometry. Int. J. Mech. Sci. 2022, 220, 107133. [Google Scholar] [CrossRef]

- Sahariah, B.J.; Namdeo, A.; Khanikar, P. Composite-inspired multilattice metamaterial structure: An auxetic lattice design with improved strength and energy absorption. Mater. Today Commun. 2022, 30, 103159. [Google Scholar] [CrossRef]

- Wang, C.; Zhu, J.; Wu, M.; Hou, J.; Zhou, H.; Meng, L.; Li, C.; Zhang, W. Multi-scale design and optimization for solid-lattice hybrid structures and their application to aerospace vehicle components. Chin. J. Aeronaut. 2021, 34, 386–398. [Google Scholar] [CrossRef]

- Zhao, M.; Zhang, D.Z.; Li, Z.; Zhang, T.; Zhou, H.; Ren, Z. Design, mechanical properties, and optimization of BCC lattice structures with taper struts. Compos. Struct. 2022, 295, 115830. [Google Scholar] [CrossRef]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Tran, P.; Harris, J.; Liu, Q.; Lu, G.; Ruan, D.; Faruque, O.; Brandt, M. The effect of topology on the quasi-static and dynamic behaviour of SLM AlSi10Mg lattice structures. Int. J. Adv. Manuf. Technol. 2022, 118, 4085–4104. [Google Scholar] [CrossRef]

- Tancogne-Dejean, T.; Spierings, A.B.; Mohr, D. Additively-manufactured metallic micro-lattice materials for high specific energy absorption under static and dynamic loading. Acta Mater. 2016, 116, 14–28. [Google Scholar] [CrossRef]

- Korshunova, N.; Alaimo, G.; Hosseini, S.; Carraturo, M.; Reali, A.; Niiranen, J.; Auricchio, F.; Rank, E.; Kollmannsberger, S. Image-based numerical characterization and experimental validation of tensile behavior of octet-truss lattice structures. Addit. Manuf. 2021, 41, 101949. [Google Scholar] [CrossRef]

- Dong, L.; Deshpande, V.; Wadley, H. Mechanical response of Ti–6Al–4V octet-truss lattice structures. Int. J. Solids Struct. 2015, 60, 107–124. [Google Scholar] [CrossRef]

- Elsayed, M.S.A.; Pasini, D. Multiscale structural design of columns made of regular octet-truss lattice material. Int. J. Solids Struct. 2010, 47, 1764–1774. [Google Scholar] [CrossRef]

- Noronha, J.; Qian, M.; Leary, M.; Kyriakou, E.; Brandt, M. Hollow-walled lattice materials by additive manufacturing: Design, manufacture, properties, applications and challenges. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100940. [Google Scholar] [CrossRef]

- Watts, S. Elastic response of hollow truss lattice micro-architectures. Int. J. Solids Struct. 2020, 206, 472–564. [Google Scholar] [CrossRef]

- Zhao, M.; Li, X.; Zhang, D.Z.; Zhai, W. Design, mechanical properties and optimization of lattice structures with hollow prismatic struts. Int. J. Mech. Sci. 2023, 238, 107842. [Google Scholar] [CrossRef]

- Noronha, J.; Rogers, J.; Leary, M.; Kyriakou, E.; Inverarity, S.; Das, R.; Brandt, M.; Qian, M. Ti-6Al-4V hollow-strut lattice materials by laser powder bed fusion. Addit. Manuf. 2023, 72, 103637. [Google Scholar] [CrossRef]

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser powder bed fusion additive manufacturing of metals; physics, computational, and materials challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Ti6Al4V lightweight lattice structures manufactured by laser powder bed fusion for load-bearing applications. Opt. Laser Technol. 2018, 108, 521–528. [Google Scholar] [CrossRef]

- Yang, Y.; Großmann, A.; Kühn, P.; Mölleney, J.; Kropholler, L.; Mittelstedt, C.; Xu, B.-X. Validated dimensionless scaling law for melt pool width in laser powder bed fusion. J. Am. Acad. Dermatol. 2022, 299, 117316. [Google Scholar] [CrossRef]

- Großmann, A.; Mölleney, J.; Frölich, T.; Merschroth, H.; Felger, J.; Weigold, M.; Sielaff, A.; Mittelstedt, C. Dimensionless process development for lattice structure design in laser powder bed fusion. Mater. Des. 2020, 194, 108952. [Google Scholar] [CrossRef]

- Sun, S.-B.; Zheng, L.-J.; Liu, J.-H.; Zhang, H. Microstructure, cracking behavior and control of Al-Fe-V-Si alloy produced by selective laser melting. Rare Met. 2023, 42, 1353–1362. [Google Scholar] [CrossRef]

- Wang, J.; Zhu, R.; Liu, Y.; Zhang, L. Understanding melt pool characteristics in laser powder bed fusion: An overview of single- and multi-track melt pools for process optimization. Adv. Powder Mater. 2023, 2, 100137. [Google Scholar] [CrossRef]

- Wu, Z.Y.; Liu, Y.J.; Wu, X.; Liu, X.; Wang, J.C.; Wang, Q. Fatigue performance of beta titanium alloy topological porous structures fabricated by laser powder bed fusion. J. Mater. Res. Technol. 2024, 29, 4772–4780. [Google Scholar] [CrossRef]

- Chen, H.; Liu, Y.; Lu, Y.; Zhang, A.; Yang, W.; Han, Q.; Wang, J. Bamboo-Inspired Porous Scaffolds for Advanced Orthopedic Implants: Design, Mechanical Properties, and Fluid Characteristics. ACS Biomater. Sci. Eng. 2024, 10, 1173–1189. [Google Scholar] [CrossRef]

- Sun, H.; Li, H.; Dauletbek, A.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. Review on materials and structures inspired by bamboo. Constr. Build. Mater. 2022, 325, 126656. [Google Scholar] [CrossRef]

- Hadadzadeh, A.; Amirkhiz, B.S.; Li, J.; Mohammadi, M. Columnar to equiaxed transition during direct metal laser sintering of AlSi10Mg alloy: Effect of building direction. Addit. Manuf. 2018, 23, 121–131. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Microstructure and mechanical properties of AlSi10Mg parts produced by the laser beam additive manufacturing (AM) technology. Met. Microstruct. Anal. 2014, 3, 448–453. [Google Scholar] [CrossRef]

- Chen, S.; Tan, X.; Hu, J.; Zhu, S.; Wang, B.; Wang, L.; Jin, Y.; Wu, L. A novel gradient negative stiffness honeycomb for recoverable energy absorption. Compos. Part B Eng. 2021, 215, 108745. [Google Scholar] [CrossRef]

- Xiao, L.; Song, W.; Wang, C.; Tang, H.; Fan, Q.; Liu, N.; Wang, J. Mechanical properties of open-cell rhombic dodecahedron titanium alloy lattice structure manufactured using electron beam melting under dynamic loading. Int. J. Impact Eng. 2017, 100, 75–89. [Google Scholar] [CrossRef]

- Zhong, H.; Song, T.; Li, C.; Das, R.; Gu, J.; Qian, M. The Gibson-Ashby model for additively manufactured metal lattice materials: Its theoretical basis, limitations and new insights from remedies. Curr. Opin. Solid State Mater. Sci. 2023, 27, 101081. [Google Scholar] [CrossRef]

- Zhong, H.Z.; Song, T.; Li, C.W.; Das, R.; Gu, J.F.; Qian, M. Understanding the superior mechanical properties of hollow-strut metal lattice materials. Scr. Mater. 2023, 228, 115341. [Google Scholar] [CrossRef]

- Kotzem, D.; Arold, T.; Bleicher, K.; Raveendran, R.; Niendorf, T.; Walther, F. Ti6Al4V lattice structures manufactured by electron beam powder bed fusion—Microstructural and mechanical characterization based on advanced in situ techniques. J. Mater. Res. Technol. 2023, 22, 2111–2130. [Google Scholar] [CrossRef]

| Unit Cell | m (mm) | n (mm) | |m − n| |

|---|---|---|---|

| TTN-1 | 0.9 | 1.0 | 0.1 |

| TTN-2 | 0.8 | 0.9 | 0.1 |

| TTN-3 | 0.7 | 0.9 | 0.2 |

| TTN-4 | 0.6 | 0.9 | 0.3 |

| TTN-5 | 0.7 | 0.8 | 0.1 |

| TTN-6 | 0.6 | 0.8 | 0.2 |

| TTN-7 | 0.5 | 0.8 | 0.3 |

| TTN-8 | 0.6 | 0.7 | 0.1 |

| TTN-9 | 0.5 | 0.7 | 0.2 |

| Unit Cell | m (mm) | n (mm) | |m − n| |

|---|---|---|---|

| TAN-1 | 1.0 | 0.9 | 0.1 |

| TAN-2 | 0.9 | 0.8 | 0.1 |

| TAN-3 | 0.9 | 0.7 | 0.2 |

| TAN-4 | 0.9 | 0.6 | 0.3 |

| TAN-5 | 0.8 | 0.7 | 0.1 |

| TAN-6 | 0.8 | 0.6 | 0.2 |

| TAN-7 | 0.8 | 0.5 | 0.3 |

| TAN-8 | 0.7 | 0.6 | 0.1 |

| TAN-9 | 0.7 | 0.5 | 0.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, J.; Song, Y.; Chen, Z.; Zhuo, Y.; Wei, T.; Ge, C.; Cheng, Y.; Liu, M.; Jia, Q. Effect of Geometrical Parameters on the Mechanical Performance of Bamboo-Inspired Gradient Hollow-Strut Octet Lattice Structure Fabricated by Additive Manufacturing. Micromachines 2024, 15, 583. https://doi.org/10.3390/mi15050583

Ge J, Song Y, Chen Z, Zhuo Y, Wei T, Ge C, Cheng Y, Liu M, Jia Q. Effect of Geometrical Parameters on the Mechanical Performance of Bamboo-Inspired Gradient Hollow-Strut Octet Lattice Structure Fabricated by Additive Manufacturing. Micromachines. 2024; 15(5):583. https://doi.org/10.3390/mi15050583

Chicago/Turabian StyleGe, Junxian, Yu Song, Zhenyu Chen, Yuhao Zhuo, Tongzheng Wei, Chen Ge, Yuang Cheng, Ming Liu, and Qingbo Jia. 2024. "Effect of Geometrical Parameters on the Mechanical Performance of Bamboo-Inspired Gradient Hollow-Strut Octet Lattice Structure Fabricated by Additive Manufacturing" Micromachines 15, no. 5: 583. https://doi.org/10.3390/mi15050583

APA StyleGe, J., Song, Y., Chen, Z., Zhuo, Y., Wei, T., Ge, C., Cheng, Y., Liu, M., & Jia, Q. (2024). Effect of Geometrical Parameters on the Mechanical Performance of Bamboo-Inspired Gradient Hollow-Strut Octet Lattice Structure Fabricated by Additive Manufacturing. Micromachines, 15(5), 583. https://doi.org/10.3390/mi15050583