Performance-Enhanced Piezoelectric Micromachined Ultrasonic Transducers by PDMS Acoustic Lens Design

Abstract

:1. Introduction

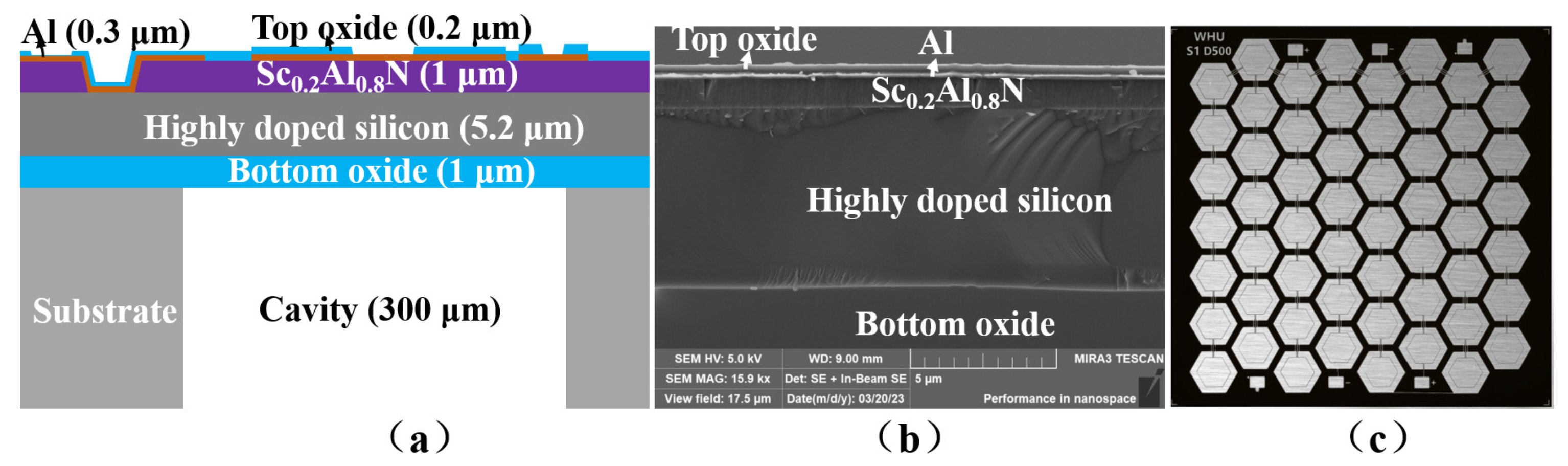

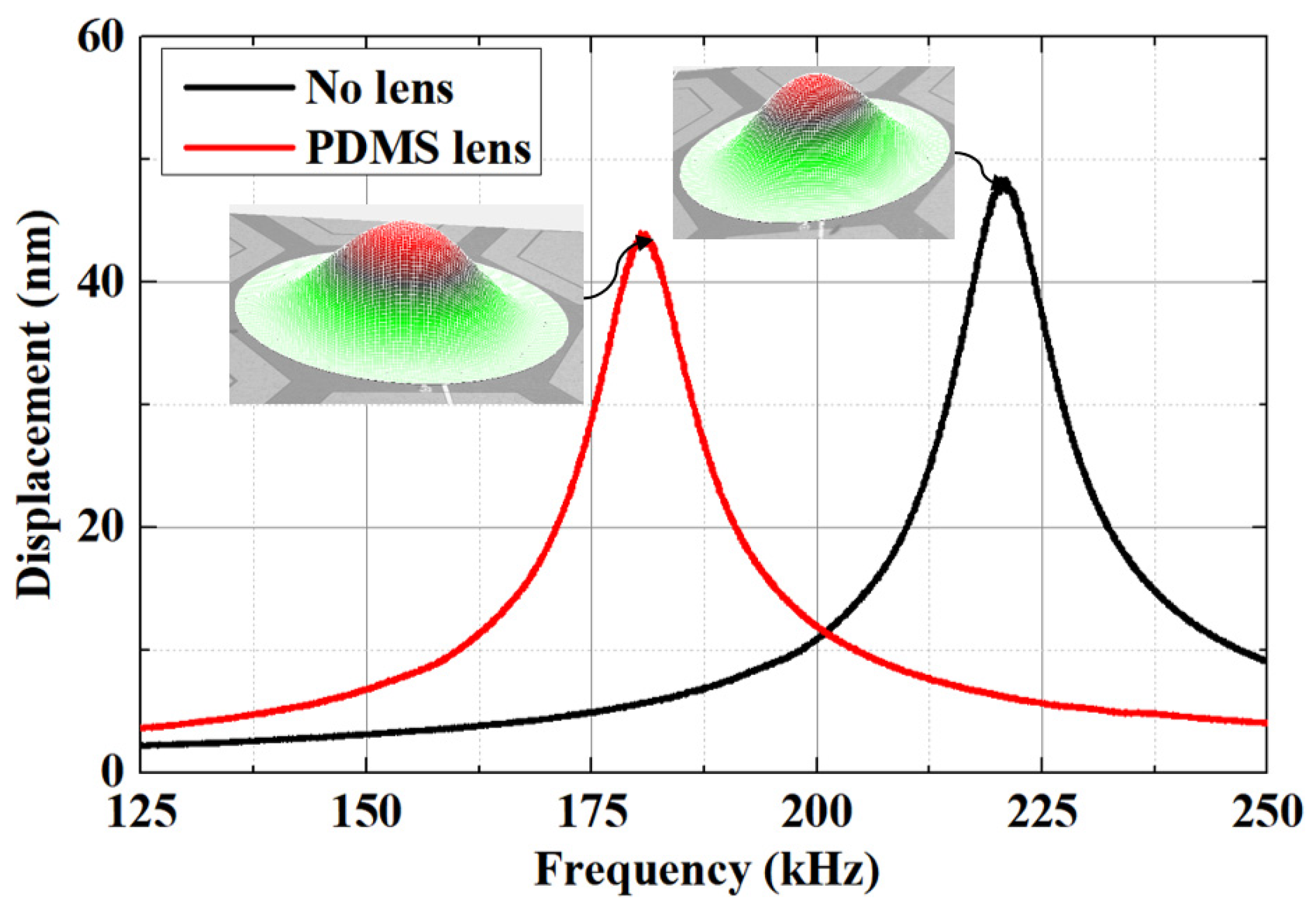

2. PMUT Array Design

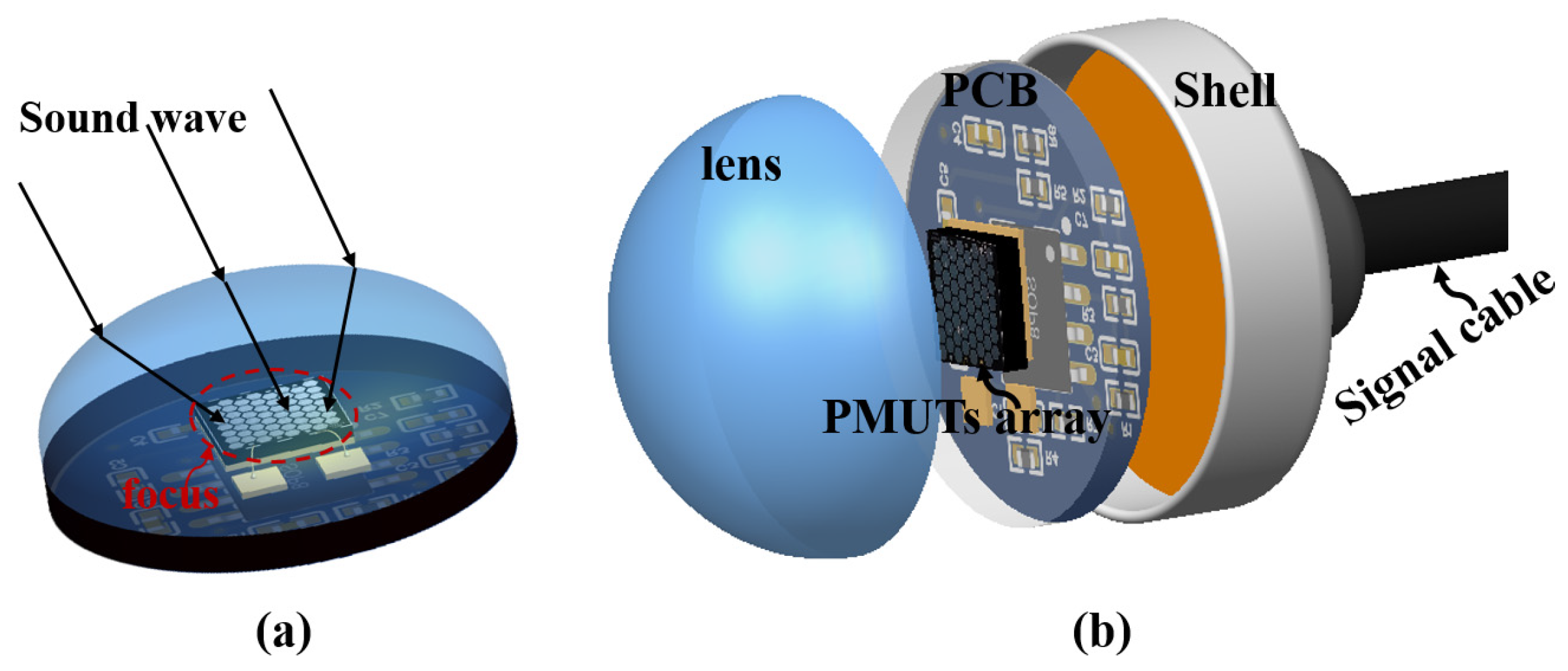

3. Lens Design

4. Lens Fabrication

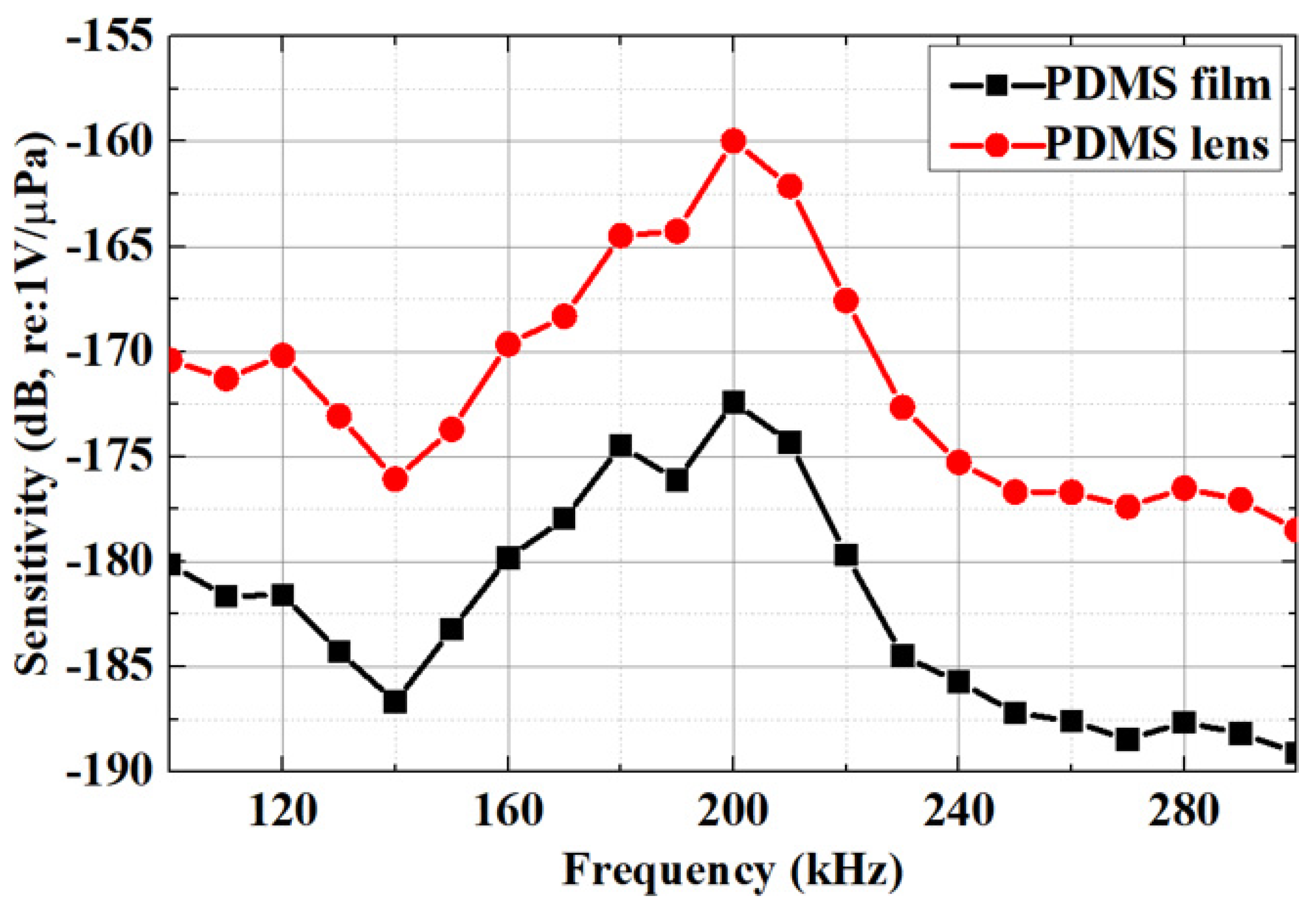

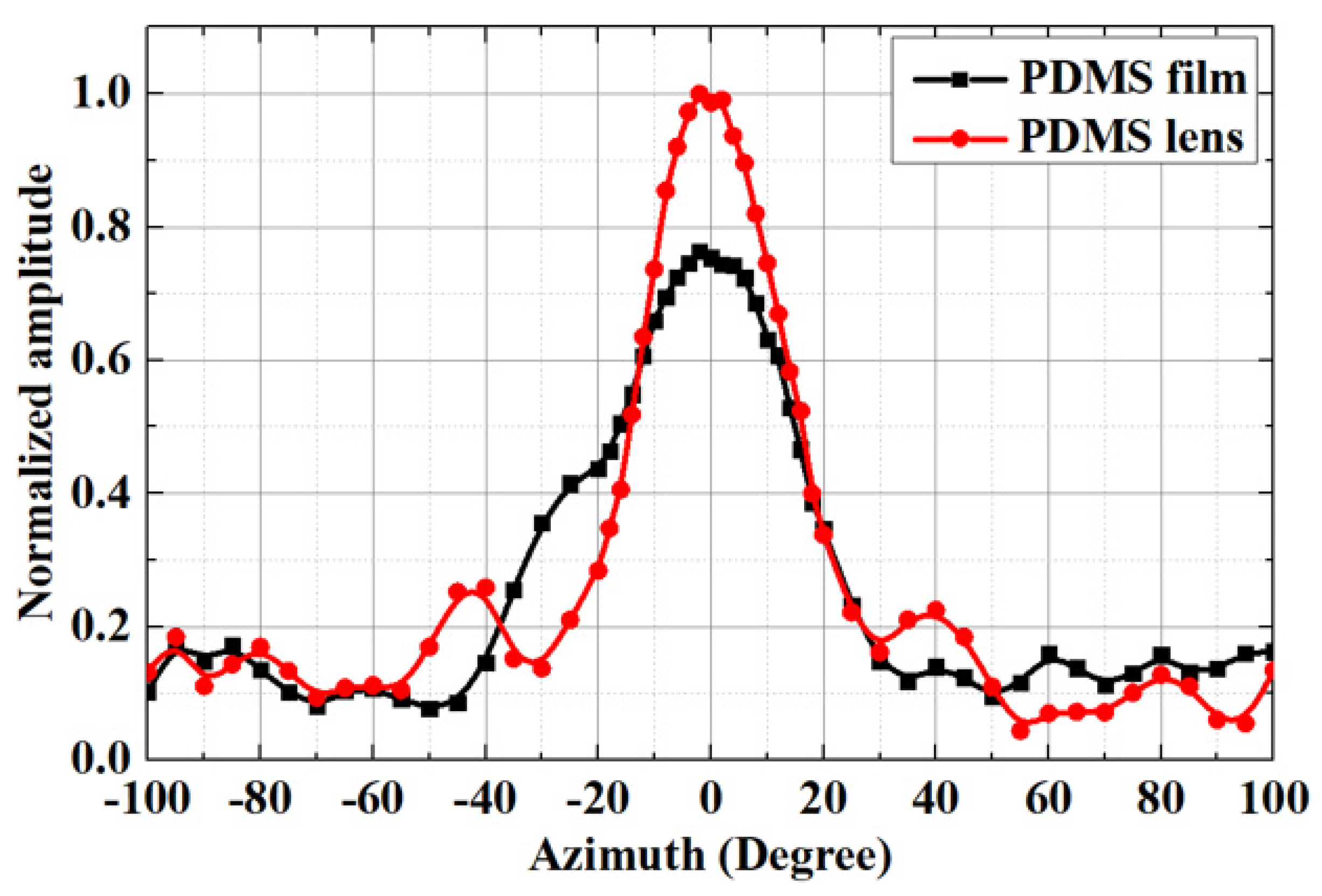

5. Performance Characterization

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ingraham, J.M.; Deng, Z.D.; Martinez, J.J.; Trumbo, B.A.; Mueller, R.P.; Weiland, M.A. Feasibility of tracking fish with acoustic transmitters in the ice harbor dam tailrace. Sci. Rep. 2014, 4, 4090. [Google Scholar] [CrossRef] [PubMed]

- Herrera, B.; Pop, F.; Cassella, C.; Rinaldi, M. Miniaturized PMUT-based receiver for underwater acoustic networking. J. Microelectromech. Syst. 2020, 29, 832–838. [Google Scholar] [CrossRef]

- Yang, D.; Yang, L.; Chen, X.; Qu, M.; Zhu, K.; Ding, H.; Li, D.; Bai, Y.; Ling, J.; Xu, J.; et al. A piezoelectric AlN MEMS hydrophone with high sensitivity and low noise density. Sens. Actuators A 2021, 318, 112493. [Google Scholar] [CrossRef]

- Liu, X.; Chen, D.; Yang, D.; Chen, X.; Le, X.; Xie, J. A computational piezoelectric micro-machined ultrasonic transducer toward acoustic communication. IEEE Electron Device Lett. 2019, 40, 965–968. [Google Scholar] [CrossRef]

- Przybyla, R.; Flynn, A.; Jain, V.; Shelton, S.; Guedes, A.; Izyumin, I.; Horsley, D.; Boser, B. A micromechanical ultrasonic distance sensor with >1 meter range. In Proceedings of the 2011 16th International Solid-State Sensors, Actuators and Microsystems Conference, Beijing, China, 5–9 June 2011; pp. 2070–2073. [Google Scholar]

- Almeida, R.; Cruz, N.; Matos, A. Synchronized intelligent buoy network for underwater positioning. In Proceedings of the OCEANS 2010 MTS/IEEE SEATTLE, Seattle, WA, USA, 20–23 September 2010; pp. 1–6. [Google Scholar]

- Benthowave Instrument Inc. Product Datasheet. Available online: https://www.benthowave.com/products/BII-7150Hydrophone.html (accessed on 6 June 2024).

- DolphinEar Hydrophones, Product Datasheet. Available online: http://www.dolphinear.com/de200.html (accessed on 6 June 2024).

- H2a Hydrophone User’s Guide; Aquarian Audio: Anacortes, WA, USA; Available online: https://www.aquarianaudio.com/ (accessed on 6 June 2024).

- Brüel&Kjær, “Hydrophones-Types 8103, 8104, 8105 and 8106”. September 2017. Available online: https://www.bksv.com/zh/transducers/acoustic/microphones/hydrophones/ (accessed on 6 June 2024).

- Jia, L.; Shi, L.; Sun, C.; Liu, S.; Wu, G. AlN based piezoelectric micromachined ultrasonic transducers for continuous monitoring of the mechano-acoustic cardiopulmonary signals. In Proceedings of the 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS), Gainesville, FL, USA, 25–29 January 2021; pp. 426–429. [Google Scholar]

- Jia, L.; Shi, L.; Liu, C.; Sun, C.; Wu, G. Enhancement of transmitting sensitivity of piezoelectric micromachined ultrasonic transducers by electrode design. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2021, 68, 3371–3377. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Lu, Y.; Tang, H.Y.; Tsai, J.M.; Ng, E.J.; Daneman, M.J.; Boser, B.E.; Horsley, D.A. Monolithic ultrasound fingerprint sensor. Microsyst. Nanoeng. 2017, 3, 17059. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Sawada, R.; Lee, C. A piezoelectric, micromachined ultrasonic transducer using piston-like membrane motion. IEEE Electron Device Lett. 2015, 36, 957–959. [Google Scholar] [CrossRef]

- Muralt, P. PZT thin films for microsensors and actuators: Where do we stand? IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2000, 47, 903–915. [Google Scholar] [CrossRef] [PubMed]

- Ledesma, E.; Zamora, I.; Uranga, A.; Barniol, N. 9.5% Scandium doped ALN PMUT compatible with pre-processed CMOS substrates. In Proceedings of the 2021 IEEE 34th International Conference on Micro Electro Mechanical Systems (MEMS), Gainesville, FL, USA, 25–29 January 2021; pp. 887–890. [Google Scholar]

- Xu, J.; Zhang, X.; Fernando, S.N.; Chai, K.T.; Gu, Y. AlN-on-SOI platform-based micro-machined hydrophone. Appl. Phys. Lett. 2016, 109, 032902. [Google Scholar] [CrossRef]

- Xu, J.; Chai, K.T.; Wu, G.; Han, B.; Wai, E.L.; Li, W.; Yeo, J.; Nijhof, E.; Gu, Y. Low-cost, tiny-sized MEMS hydrophone sensor for water pipeline leak detection. IEEE Trans. Ind. Electron. 2018, 66, 6374–6382. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, Y.; Randles, A. Enhancement of the transmission of piezoelectric micromachined ultrasonic transducer with an isolation trench. J. Microelectromech. Syst. 2016, 25, 691–700. [Google Scholar] [CrossRef]

- Chen, X.; Chen, D.; Liu, X.; Yang, D.; Pang, J.; Xie, J. Transmitting sensitivity enhancement of piezoelectric micromachined ultrasonic trans-ducers via residual stress localization by stiffness modification. IEEE Electron Device Lett. 2019, 40, 796–799. [Google Scholar] [CrossRef]

- Liang, Y.; Eovino, B.; Lin, L. Piezoelectric micromachined ultrasonic transducers with pinned boundary structure. J. Microelectromech. Syst. 2020, 29, 585–591. [Google Scholar] [CrossRef]

- Akhbari, S.; Sammoura, F.; Eovino, B.; Yang, C.; Lin, L. Bimorph piezoelectric micromachined ultrasonic transducers. J. Microelectromech. Syst. 2016, 25, 326–336. [Google Scholar] [CrossRef]

- Akhbari, S.; Sammoura, F.; Yang, C.; Mahmoud, M.; Aqab, N.; Lin, L. Bimorph pMUT with dual electrodes. In Proceedings of the 28th IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Estoril, Portugal, 18–22 January 2015; pp. 928–931. [Google Scholar]

| Parameter | Value |

|---|---|

| Array length | 4 mm |

| Array width | 4 mm |

| Piezoelectric layer thickness | 1 μm |

| Diaphragm characteristic size | 500 μm |

| Electrode thickness | 0.3 μm |

| Top Oxide layer thickness | 0.2 μm |

| Bottom Oxide layer thickness | 1 μm |

| Gap height | 300 μm |

| Characteristic size | 500 μm |

| Number of cells per array | 56 |

| Property | No Lens (Water) | PDMS Film | PDMS Lens | |

|---|---|---|---|---|

| Lens Material | (m/s) | 1480 | 930 | 930 |

| (kg/m−3) | ||||

| Z (MRayl) | 1.48 | 0.9 | 0.9 | |

| at 6 MHz (dB/cm) | 0.0022 | 31.0 | 31.0 | |

| (dB/cm/MHz) | − | 7.6 | 7.6 | |

| Lens Geometry | Shape | − | No lens | Convex |

| Radius (mm) | − | 42.64 | 42.64 | |

| Thickness (mm) | − | 4 | 4 | |

| Response | Resonance frequency (kHz) | 221 | 183 | 183 |

| Sensitivity (re: 1 V/μPa) | −163 | −168 | −160 |

| Hydrophone | Technology | Encapsulation | Lens | Size | Sensitivity (dB, re: 1 V/μPa) |

|---|---|---|---|---|---|

| DophinEar DE200 [8] | Piezoceramic | Polyurethane | No | cm level | −209 ± 1.5 |

| Aquarian H2a [9] | Piezoceramic | Polyurethane | No | cm level | −180 ± 4 |

| Brüel&Kjær 8103 [10] | Piezoceramic | Polyurethane | No | cm level | −211 ± 2 |

| Ref. [17] | AlN | Polyurethane | No | 3.5 mm × 3.5 mm | −182 ± 0.3 |

| This work | ScAlN | PDMS | No | 4 mm × 4 mm | −168 |

| This work | ScAlN | PDMS | Yes | 4 mm × 4 mm | −160 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, L.; Liang, Y.; Meng, F.; Zhang, G.; Wang, R.; He, C.; Yang, Y.; Cui, J.; Zhang, W.; Wu, G. Performance-Enhanced Piezoelectric Micromachined Ultrasonic Transducers by PDMS Acoustic Lens Design. Micromachines 2024, 15, 795. https://doi.org/10.3390/mi15060795

Jia L, Liang Y, Meng F, Zhang G, Wang R, He C, Yang Y, Cui J, Zhang W, Wu G. Performance-Enhanced Piezoelectric Micromachined Ultrasonic Transducers by PDMS Acoustic Lens Design. Micromachines. 2024; 15(6):795. https://doi.org/10.3390/mi15060795

Chicago/Turabian StyleJia, Licheng, Yong Liang, Fansheng Meng, Guojun Zhang, Renxin Wang, Changde He, Yuhua Yang, Jiangong Cui, Wendong Zhang, and Guoqiang Wu. 2024. "Performance-Enhanced Piezoelectric Micromachined Ultrasonic Transducers by PDMS Acoustic Lens Design" Micromachines 15, no. 6: 795. https://doi.org/10.3390/mi15060795