A Frequency Up-Conversion Piezoelectric Energy Harvester Shunted to a Synchronous Electric Charge Extraction Circuit

Abstract

:1. Introduction

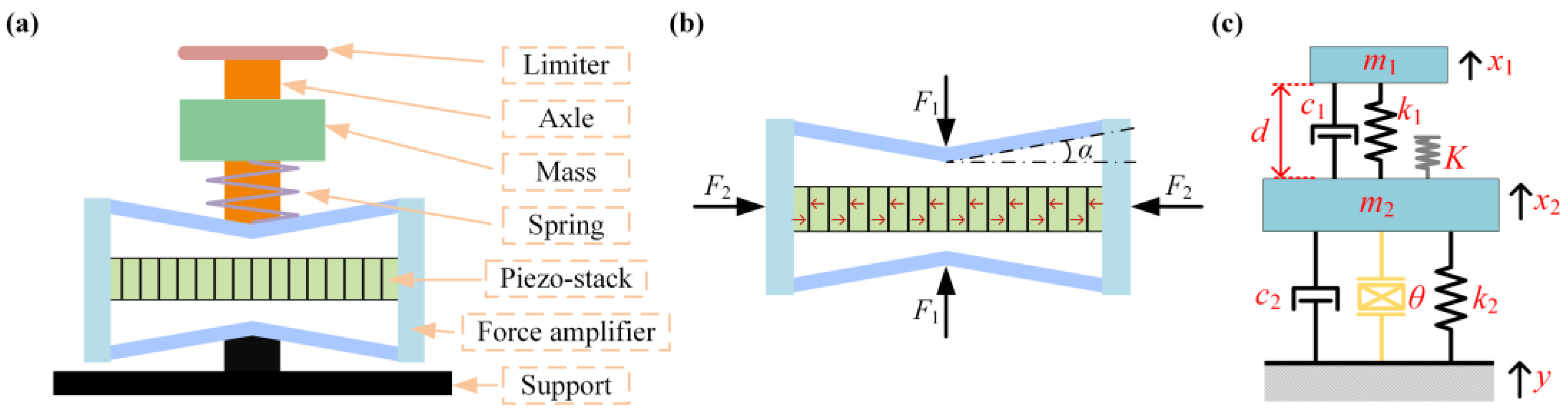

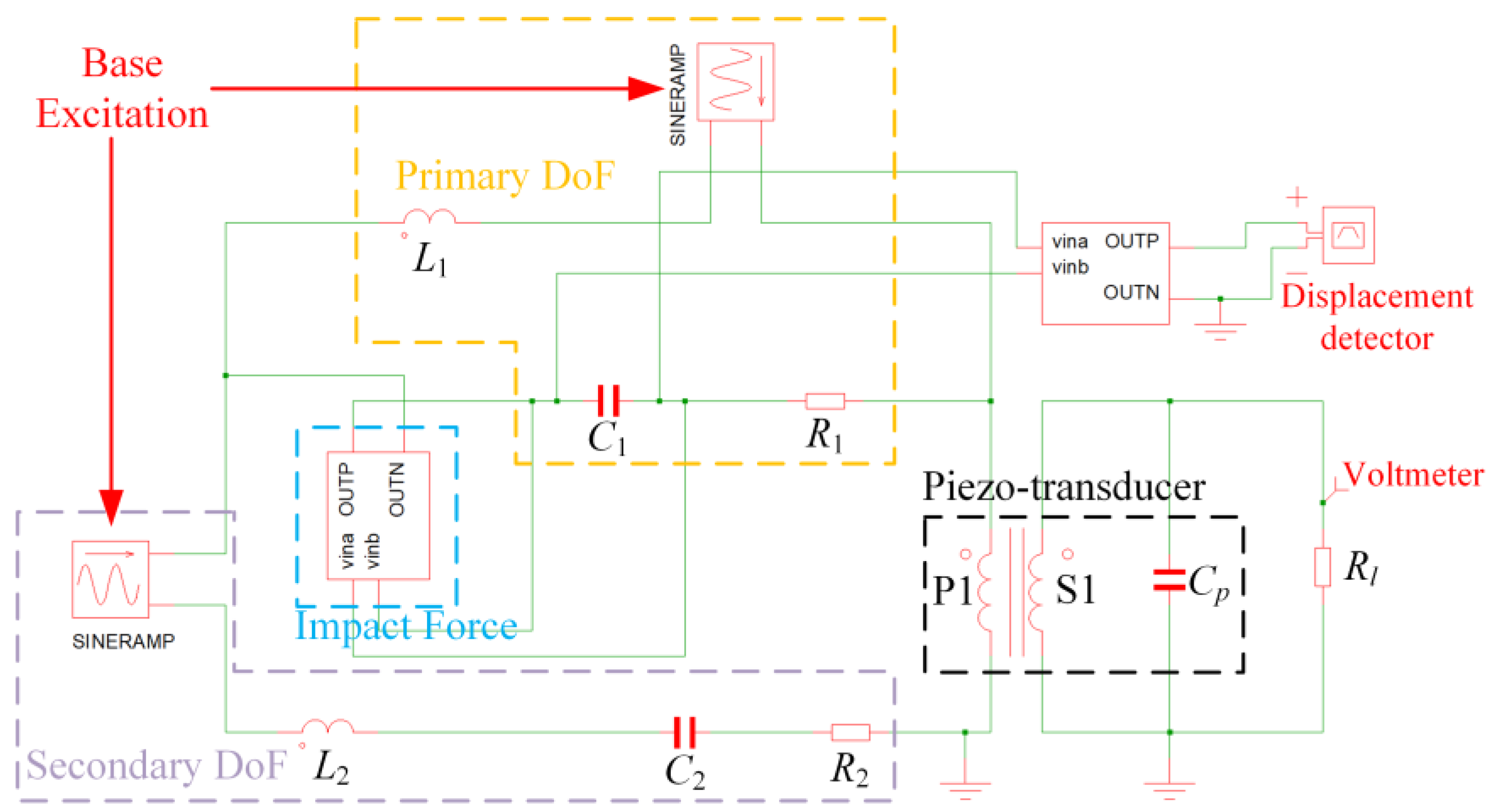

2. Materials and Methods

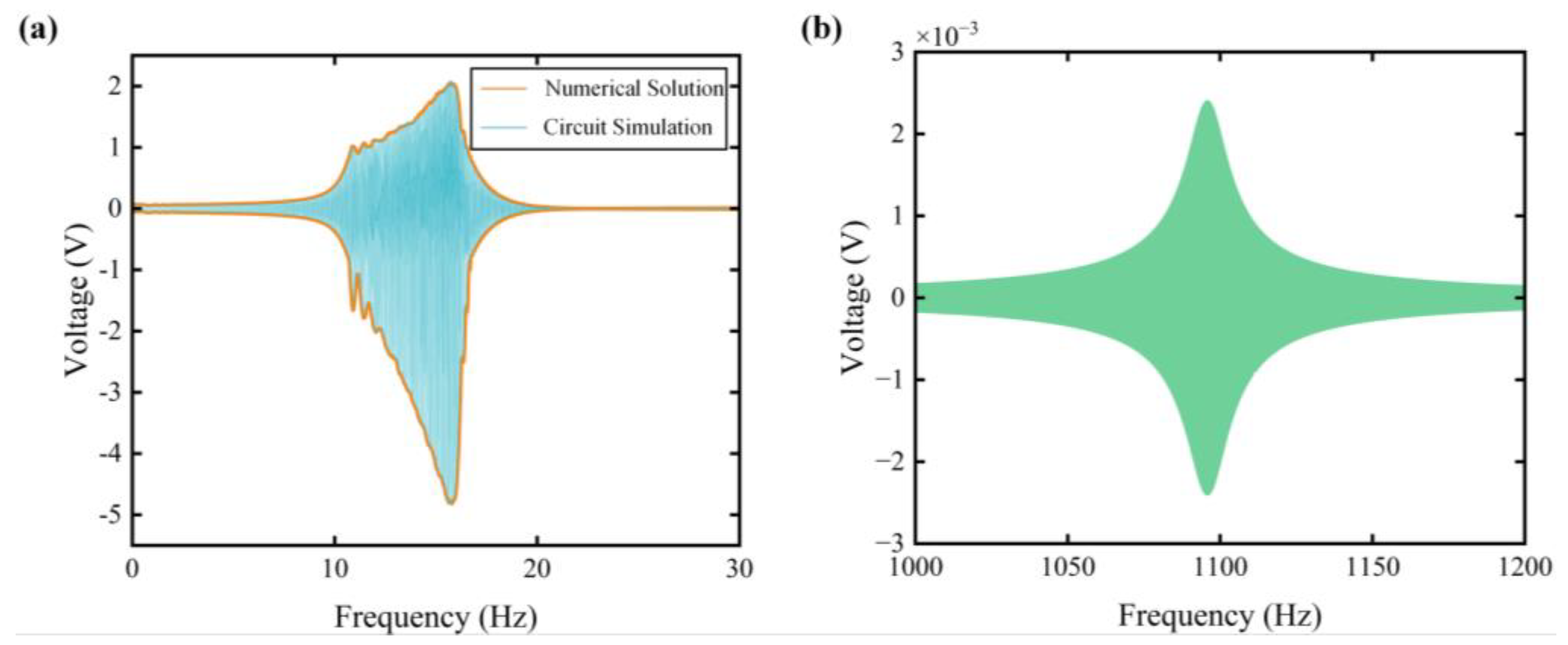

3. Results and Discussion

3.1. Parametric Study

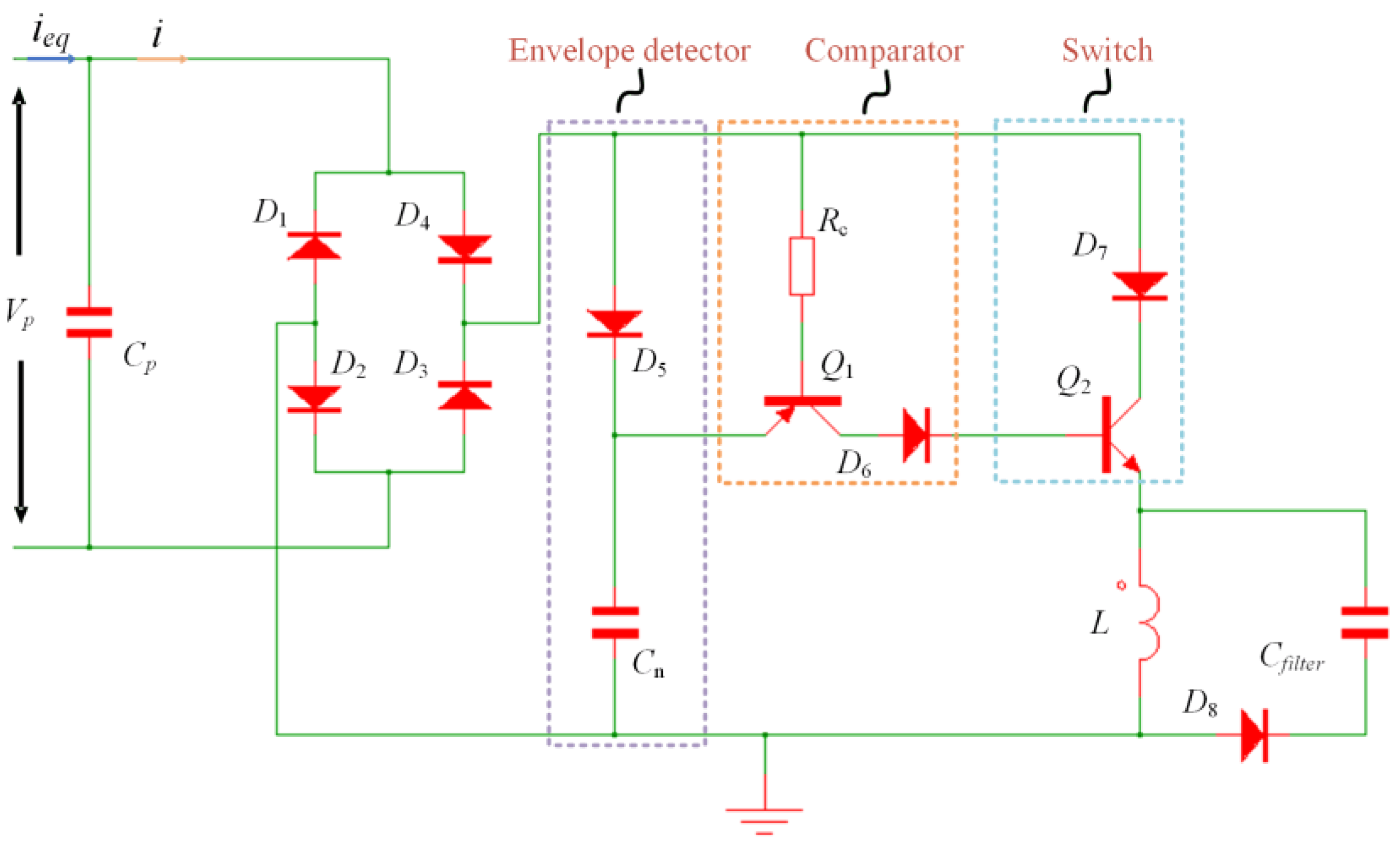

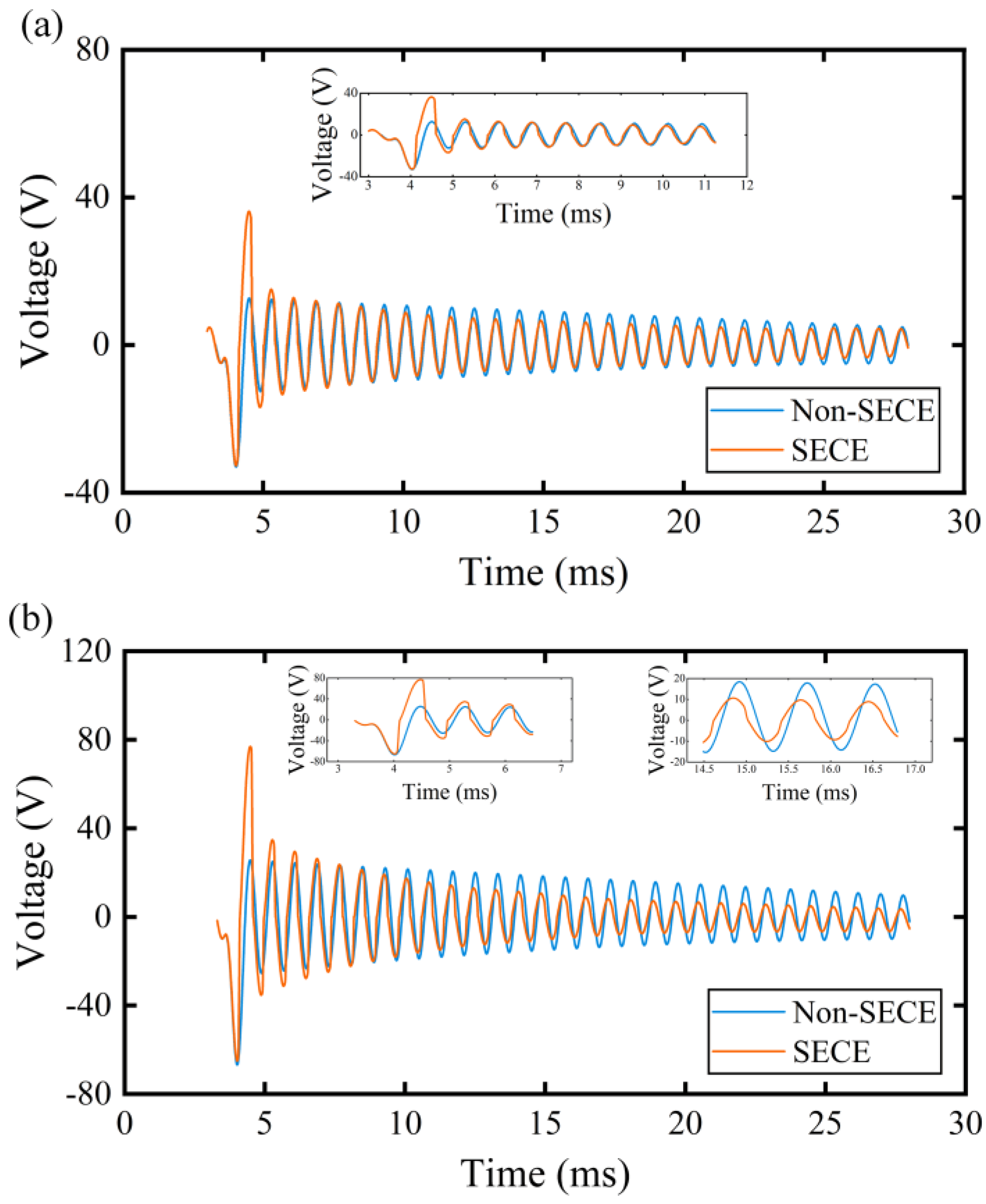

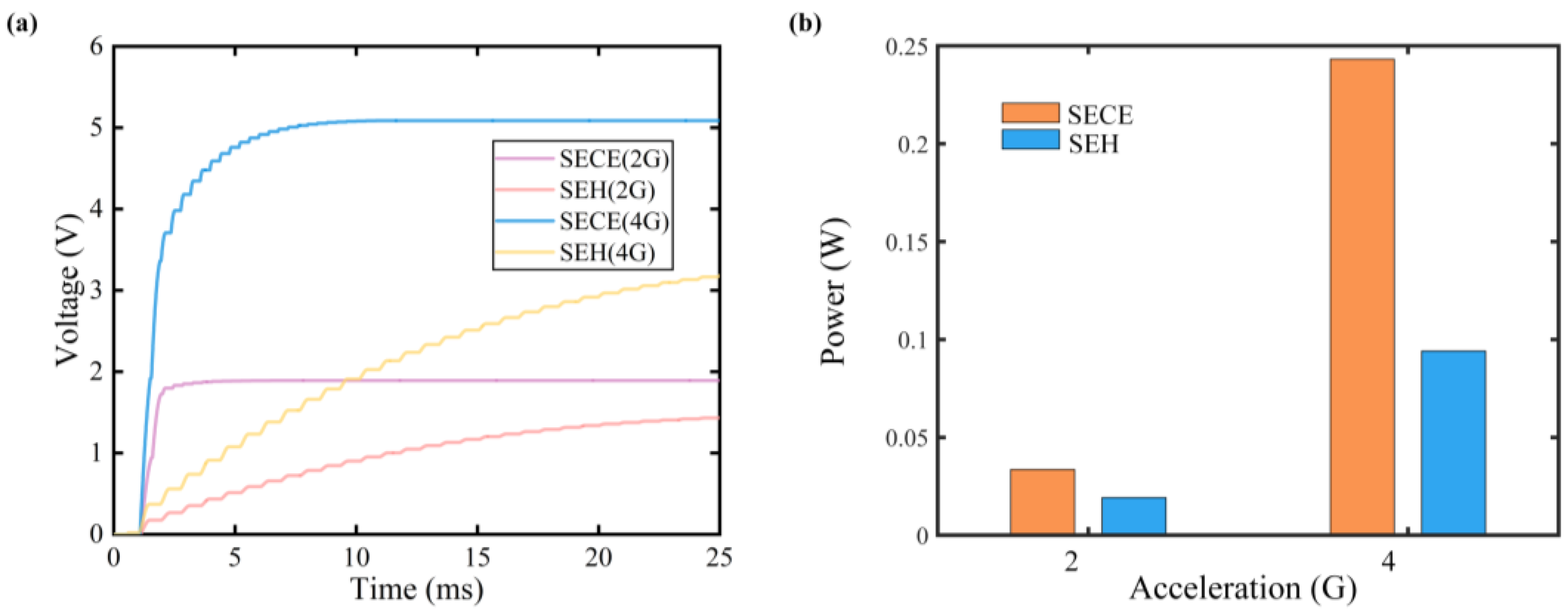

3.2. Integration of FUC-PEH and SECE Circuit

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, S.; Zhong, S.; Peng, Y.; Guo, H.; Shen, F.; Gong, Y.; Zhao, L.; Li, Z. Hand clappers inspired triboelectric nanogenerator based on magnetic coupling for harvesting rotational energy. Energy Convers. Manag. 2024, 313, 118559. [Google Scholar] [CrossRef]

- Peng, Y.; Liu, H.; Guo, H.; Gong, Y.; Shen, F.; Zhang, Q.; Li, Z. Toward Highly Sensitive Ocean-Wave Monitoring With Sliding-Triboelectric Effect: Modeling, Experimental Validation, and Demonstration. In IEEE/ASME Transactions on Mechatronics; IEEE: Piscataway, NJ, USA, 2024; pp. 1–10. [Google Scholar] [CrossRef]

- Tao, K.; Tang, L.; Wu, J.; Lye, S.W.; Chang, H.; Miao, J. Investigation of Multimodal Electret-Based MEMS Energy Harvester With Impact-Induced Nonlinearity. J. Microelectromechanical Syst. 2018, 27, 276–288. [Google Scholar] [CrossRef]

- Li, Z.; Peng, X.; Hu, G.; Zhang, D.; Xu, Z.; Peng, Y.; Xie, S. Towards real-time self-powered sensing with ample redundant charges by a piezostack-based frequency-converted generator from human motions. Energy Convers. Manag. 2022, 258, 115466. [Google Scholar] [CrossRef]

- Wang, M.; Liu, J.; Peng, Y.; Li, Z. Investigation of nonlinear magnetic stiffness based thin-layer stacked piezoelectric generators with a force-amplification structure. Thin-Walled Struct. 2024, 195, 111525. [Google Scholar] [CrossRef]

- Rezaei, M.; Talebitooti, R.; Liao, W.-H. Exploiting bi-stable magneto-piezoelastic absorber for simultaneous energy harvesting and vibration mitigation. Int. J. Mech. Sci. 2021, 207, 106618. [Google Scholar] [CrossRef]

- Li, Y.; Yan, P. A compliant mechanism based piezoelectric beam energy harvester with multi-mode frequency up conversion. Energy Rep. 2023, 10, 932–940. [Google Scholar] [CrossRef]

- Zhao, L.; Hu, G.; Zhou, S.; Peng, Y.; Xie, S.; Li, Z. Magnetic coupling and amplitude truncation based bistable energy harvester. Int. J. Mech. Sci. 2024, 273, 109228. [Google Scholar] [CrossRef]

- Rezaei, M.; Talebitooti, R. Wideband PZT energy harvesting from the wake of a bluff body in varying flow speeds. Int. J. Mech. Sci. 2019, 163, 105135. [Google Scholar] [CrossRef]

- Staaf, L.G.H.; Smith, A.D.; Lundgren, P.; Folkow, P.D.; Enoksson, P. Effective piezoelectric energy harvesting with bandwidth enhancement by assymetry augmented self-tuning of conjoined cantilevers. Int. J. Mech. Sci. 2019, 150, 1–11. [Google Scholar] [CrossRef]

- Li, Z.; Peng, X.; Hu, G.; Peng, Y. Theoretical, numerical, and experimental studies of a frequency up-conversion piezoelectric energy harvester. Int. J. Mech. Sci. 2022, 223, 107299. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, L.; Chang, Y.; Shan, G.; Gao, Y. Parameter optimization of magnetostrictive bistable vibration harvester with displacement amplifier. Int. J. Mech. Sci. 2022, 223, 107291. [Google Scholar] [CrossRef]

- Atmeh, M.; Ibrahim, A.; Ramini, A. Static and Dynamic Analysis of a Bistable Frequency Up-Converter Piezoelectric Energy Harvester. Micromachines 2023, 14, 261. [Google Scholar] [CrossRef] [PubMed]

- Norenberg, J.P.; Luo, R.; Lopes, V.G.; Peterson, J.V.L.L.; Cunha, A. Nonlinear dynamics of asymmetric bistable energy harvesters. Int. J. Mech. Sci. 2023, 257, 108542. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, W.; Yu, K.; Liao, B.; Zhao, R.; Liu, T. Gravity-induced bistable 2DOF piezoelectric vibration energy harvester for broadband low-frequency operation. Arch. Civ. Mech. Eng. 2023, 23, 208. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, Z.; Liao, W.-H.; Tan, J.; Ju, Y.; Li, Y. Characteristics of a tri-stable piezoelectric vibration energy harvester by considering geometric nonlinearity and gravitation effects. Mech. Syst. Signal Process. 2020, 138, 106571. [Google Scholar] [CrossRef]

- Sun, S.; Leng, Y.; Su, X.; Zhang, Y.; Chen, X.; Xu, J. Performance of a novel dual-magnet tri-stable piezoelectric energy harvester subjected to random excitation. Energy Convers. Manag. 2021, 239, 114246. [Google Scholar] [CrossRef]

- Mei, X.; Zhou, S.; Yang, Z.; Kaizuka, T.; Nakano, K. Enhancing energy harvesting in low-frequency rotational motion by a quad-stable energy harvester with time-varying potential wells. Mech. Syst. Signal Process. 2021, 148, 107167. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Q.; Wang, W.; Feng, J. A low-frequency, wideband quad-stable energy harvester using combined nonlinearity and frequency up-conversion by cantilever-surface contact. Mech. Syst. Signal Process. 2018, 112, 305–318. [Google Scholar] [CrossRef]

- Wang, H.; Tang, L. Modeling and experiment of bistable two-degree-of-freedom energy harvester with magnetic coupling. Mech. Syst. Signal Process. 2017, 86, 29–39. [Google Scholar] [CrossRef]

- Shao, N.; Xu, J.; Xu, X. Experimental study of a two-degree-of-freedom piezoelectric cantilever with a stopper for broadband vibration energy harvesting. Sens. Actuators A Phys. 2022, 344, 113742. [Google Scholar] [CrossRef]

- Zhang, B.; Li, H.; Zhou, S.; Liang, J.; Gao, J.; Yurchenko, D. Modeling and analysis of a three-degree-of-freedom piezoelectric vibration energy harvester for broadening bandwidth. Mech. Syst. Signal Process. 2022, 176, 109169. [Google Scholar] [CrossRef]

- Li, X.; Hu, G.; Guo, Z.; Wang, J.; Yang, Y.; Liang, J. Frequency Up-Conversion for Vibration Energy Harvesting: A Review. Symmetry 2022, 14, 631. [Google Scholar] [CrossRef]

- Liu, J.; Lu, Y.; Wang, Z.; Li, S.; Wu, Y. Three Frequency Up-Converting Piezoelectric Energy Harvesters Caused by Internal Resonance Mechanism: A Narrative Review. Micromachines 2022, 13, 210. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Liu, Z.; Jiang, X.; Peng, Y.; Zhu, C.; Li, Z. Experimental investigation on performance improvement of cantilever piezoelectric energy harvesters via escapement mechanism from extremely Low-Frequency excitations. Sustain. Energy Technol. Assess. 2022, 53, 102591. [Google Scholar] [CrossRef]

- Zhang, J.; Qin, L. A tunable frequency up-conversion wideband piezoelectric vibration energy harvester for low-frequency variable environment using a novel impact- and rope-driven hybrid mechanism. Appl. Energy 2019, 240, 26–34. [Google Scholar] [CrossRef]

- Panthongsy, P.; Isarakorn, D.; Janphuang, P.; Hamamoto, K. Fabrication and evaluation of energy harvesting floor using piezoelectric frequency up-converting mechanism. Sens. Actuators A Phys. 2018, 279, 321–330. [Google Scholar] [CrossRef]

- Aceti, P.; Rosso, M.; Ardito, R.; Pienazza, N.; Nastro, A.; Bau, M.; Ferrari, M.; Rouvala, M.; Ferrari, V.; Corigliano, A. Optimization of an Impact-Based Frequency Up-Converted Piezoelectric Vibration Energy Harvester for Wearable Devices. Sensors 2023, 23, 1391. [Google Scholar] [CrossRef]

- Wu, Y.; Li, S.; Fan, K.; Ji, H.; Qiu, J. Investigation of an ultra-low frequency piezoelectric energy harvester with high frequency up-conversion factor caused by internal resonance mechanism. Mech. Syst. Signal Process. 2022, 162, 108038. [Google Scholar] [CrossRef]

- Pyo, S.; Kwon, D.-S.; Ko, H.-J.; Eun, Y.; Kim, J. Frequency Up-Conversion Hybrid Energy Harvester Combining Piezoelectric and Electromagnetic Transduction Mechanisms. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 9, 241–251. [Google Scholar] [CrossRef]

- Ottman, G.K.; Hofmann, H.F.; Bhatt, A.C.; Lesieutre, G.A. Adaptive piezoelectric energy harvesting circuit for wireless remote power supply. IEEE Trans. Power Electron. 2002, 17, 669–676. [Google Scholar] [CrossRef]

- Guyomar, D.; Badel, A.; Lefeuvre, E.; Richard, C. Toward energy harvesting using active materials and conversion improvement by nonlinear processing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2005, 52, 584–595. [Google Scholar] [CrossRef]

- Badel, A.; Benayad, A.; Lefeuvre, E.; Lebrun, L.; Richard, C.; Guyomar, D. Single crystals and nonlinear process for outstanding vibration-powered electrical generators. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2006, 53, 673–684. [Google Scholar] [CrossRef]

- Lefeuvre, E.; Badel, A.; Richard, C.; Guyomar, D. Piezoelectric energy harvesting device optimization by synchronous electric charge extraction. J. Intell. Mater. Syst. Struct. 2005, 16, 865–876. [Google Scholar] [CrossRef]

- Zhou, W.; Zuo, L. A novel piezoelectric multilayer stack energy harvester with force amplification. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Portland, OR, USA, 4–7 August 2013; p. V008T013A095. [Google Scholar]

- Xu, T.-B.; Siochi, E.J.; Zuo, L.; Jiang, X.; Kang, J.H. Multistage Force Amplification of Piezoelectric Stacks; Patent and Trademark Office: Washington, DC, USA, 2015.

- Wang, L.; Chen, S.; Zhou, W.; Xu, T.-B.; Zuo, L. Piezoelectric vibration energy harvester with two-stage force amplification. J. Intell. Mater. Syst. Struct. 2016, 28, 1175–1187. [Google Scholar] [CrossRef]

- Kuang, Y.; Chew, Z.J.; Zhu, M. Strongly coupled piezoelectric energy harvesters: Finite element modelling and experimental validation. Energy Convers. Manag. 2020, 213, 112855. [Google Scholar] [CrossRef]

- Guo, Z.; Hu, G.; Sorokin, V.; Tang, L.; Yang, X.; Zhang, J. Low-frequency flexural wave attenuation in metamaterial sandwich beam with hourglass lattice truss core. Wave Motion 2021, 104, 102750. [Google Scholar] [CrossRef]

- Qian, F.; Xu, T.-B.; Zuo, L. Material equivalence, modeling and experimental validation of a piezoelectric boot energy harvester. Smart Mater. Struct. 2019, 28, 075018. [Google Scholar] [CrossRef]

- Lefeuvre, E.; Badel, A.; Brenes, A.; Seok, S.; Woytasik, M.; Yoo, C. Analysis of piezoelectric energy harvesting system with tunable SECE interface. Smart Mater. Struct. 2017, 26, 035065. [Google Scholar] [CrossRef]

- Liu, W.; Badel, A.; Formosa, F.; Zhu, Q.; Zhao, C.; Hu, G.-D. A comprehensive analysis and modeling of the self-powered synchronous switching harvesting circuit with electronic breakers. IEEE Trans. Ind. Electron. 2017, 65, 3899–3909. [Google Scholar] [CrossRef]

| Equivalent Circuit Parameters | Mechanical Counterparts |

|---|---|

| Charge: q | Displacement: u |

| Current: | Velocity: |

| Inductance: Li | Effective mass: mi |

| Resistance: Ri | Effective damping: ci |

| Capacitance: Ci | Reciprocal of effective stiffness: 1/ki |

| Ideal transformer turn ratio: N | Electromechanical coupling: θ |

| Mechanical Parameters | Values |

|---|---|

| Effective mass m1 (g) | 29.02 |

| Effective mass m2 (g) | 23.3 |

| Effective stiffness k1 (N/m) | 490 |

| Effective stiffness k2 (N/m) | 1.3756 × 106 |

| Damping coefficient c1 (Ns/m) | 0.0422 |

| Base excitation (m/s2) | 7.35 |

| Impact stiffness (N/m) | 3000 |

| Initial distance d (mm) | 14.4 |

| Load resistance Rl (Ω) | 1012 |

| Damping coefficient c2 (Ns/m) | 1.8916 |

| Description | Value | |

|---|---|---|

| Piezoelectric stack | Number of layers n | 180 |

| Piezoelectric constant e33 (10−3 Vm/N) | 12.5 | |

| Capacitance Cp (μF) | 1.732 | |

| Cross-sectional area A (mm2) | 25 | |

| Length L (mm) | 18 | |

| Rod in force amplifier | Intersection angle α (rad) | 0.3 |

| Young’s modulus Es (GPa) | 193 | |

| Cross-sectional area As (mm2) | 12 | |

| Length l (mm) | 8.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, X.; Tang, H.; Li, Z.; Liang, J.; Yu, L.; Hu, G. A Frequency Up-Conversion Piezoelectric Energy Harvester Shunted to a Synchronous Electric Charge Extraction Circuit. Micromachines 2024, 15, 842. https://doi.org/10.3390/mi15070842

Peng X, Tang H, Li Z, Liang J, Yu L, Hu G. A Frequency Up-Conversion Piezoelectric Energy Harvester Shunted to a Synchronous Electric Charge Extraction Circuit. Micromachines. 2024; 15(7):842. https://doi.org/10.3390/mi15070842

Chicago/Turabian StylePeng, Xuzhang, Hao Tang, Zhongjie Li, Junrui Liang, Liuding Yu, and Guobiao Hu. 2024. "A Frequency Up-Conversion Piezoelectric Energy Harvester Shunted to a Synchronous Electric Charge Extraction Circuit" Micromachines 15, no. 7: 842. https://doi.org/10.3390/mi15070842