Investigation of Piezoelectric Properties in Ca-Doped PbBa(Zr,Ti)O3 (PBZT) Ceramics

Abstract

1. Introduction

2. Materials and Methods

3. Results

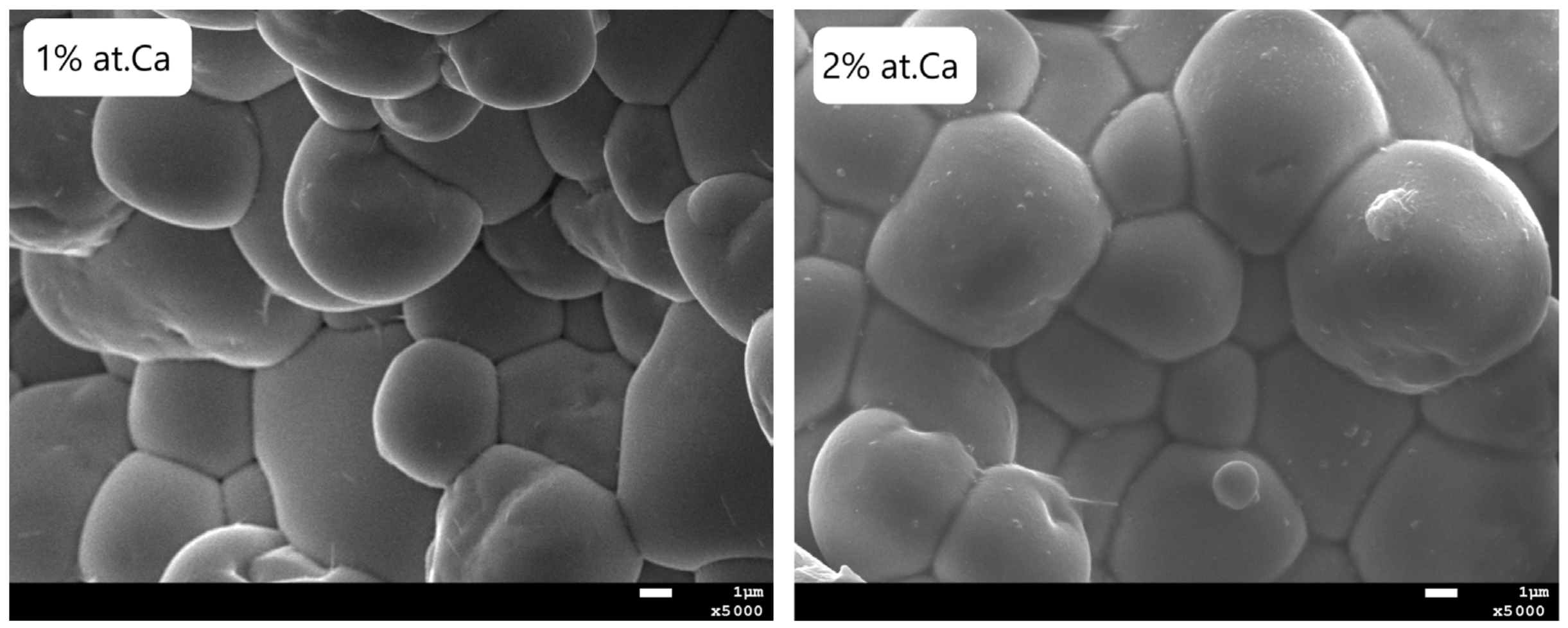

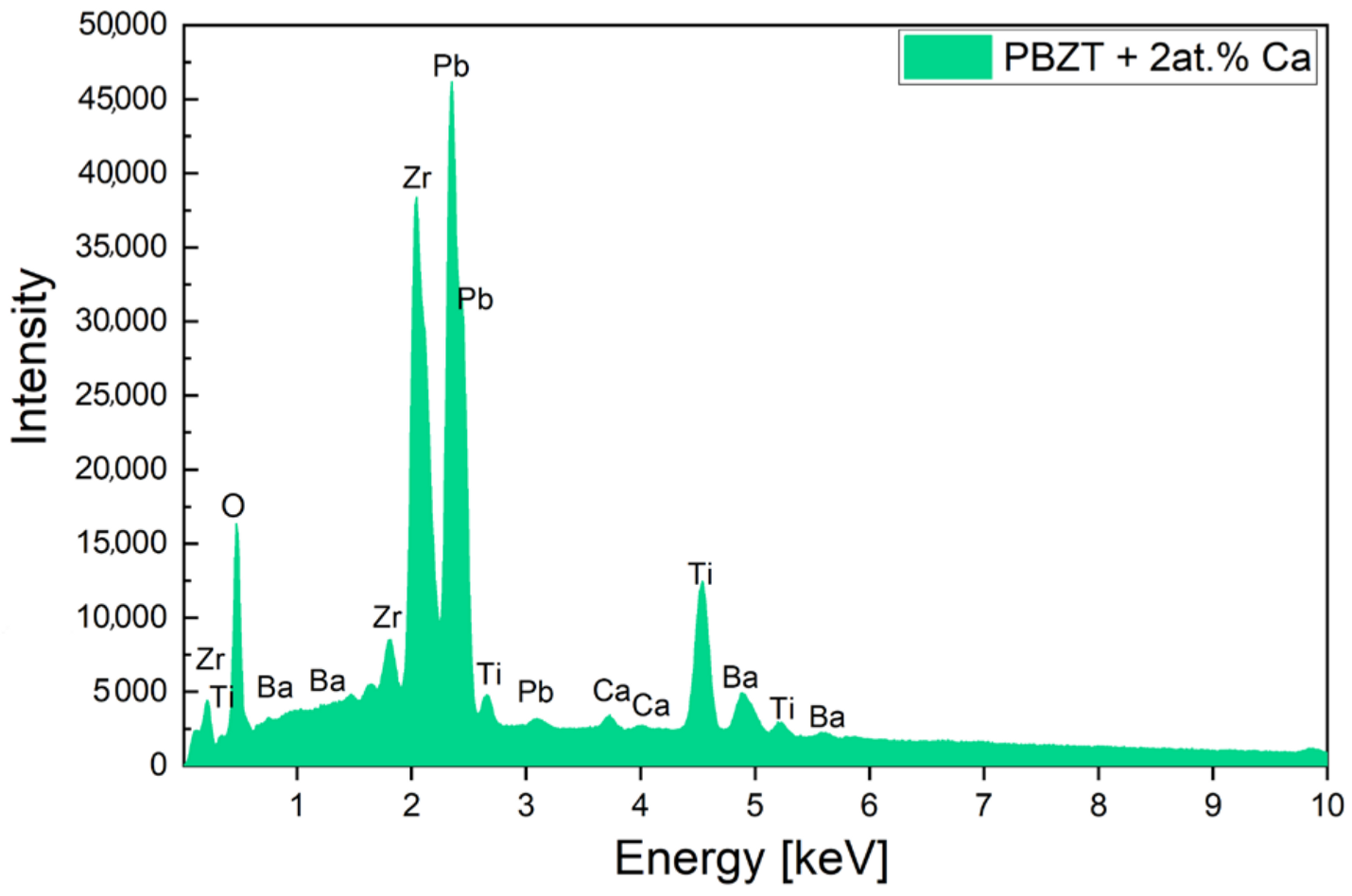

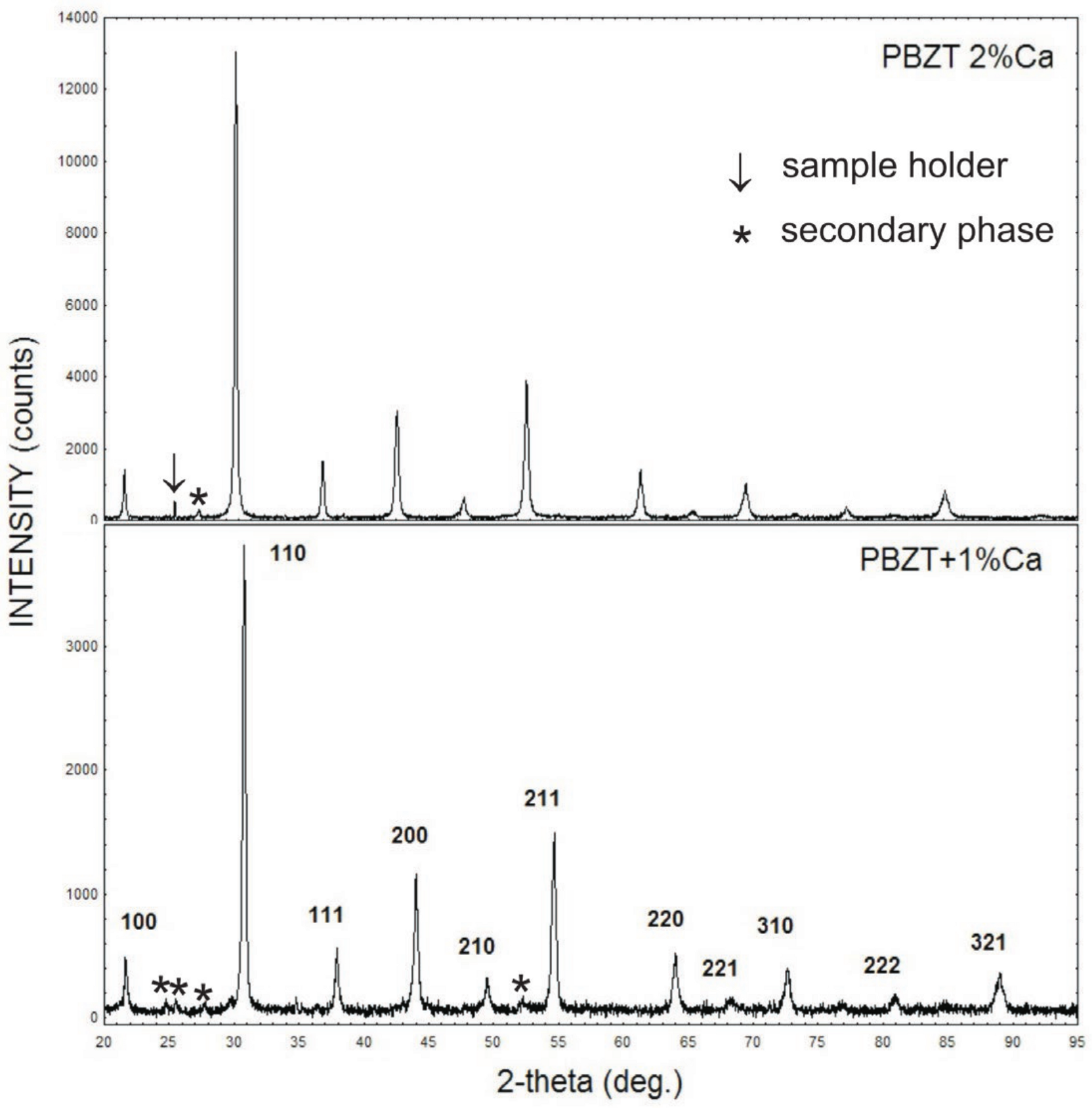

3.1. Scanning Electron Microscopy and X-ray Microanalysis (EDS)

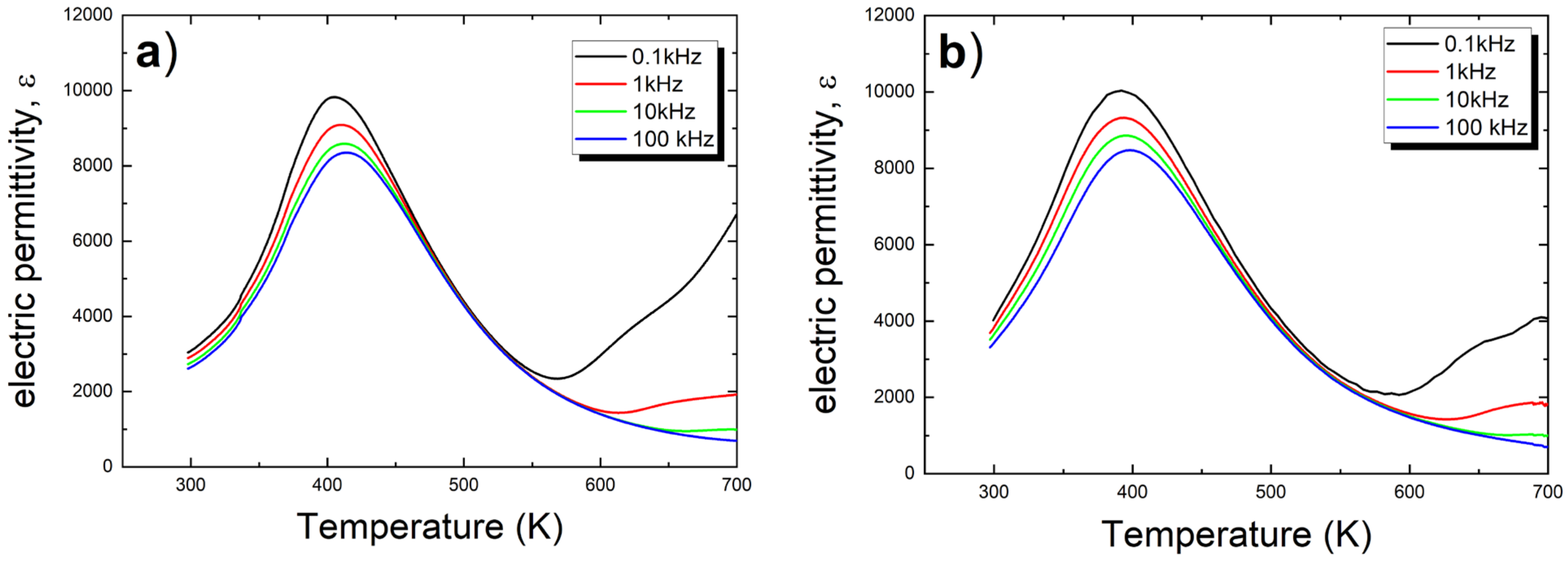

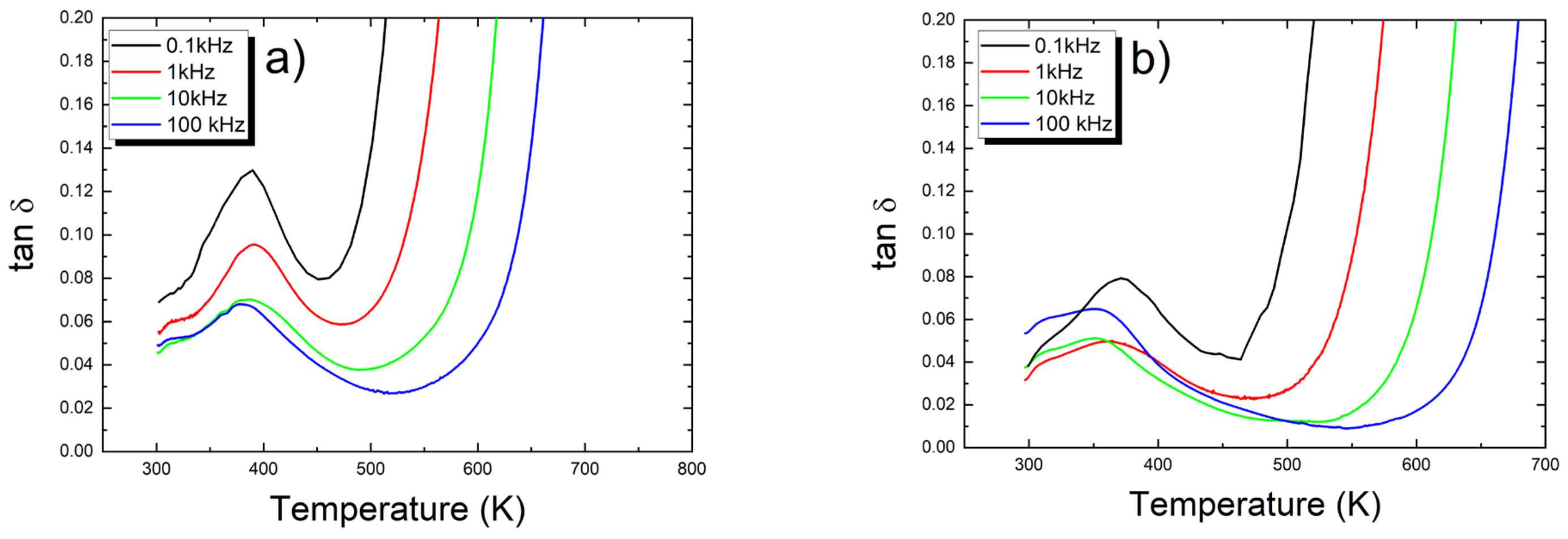

3.2. Dielectric Properties

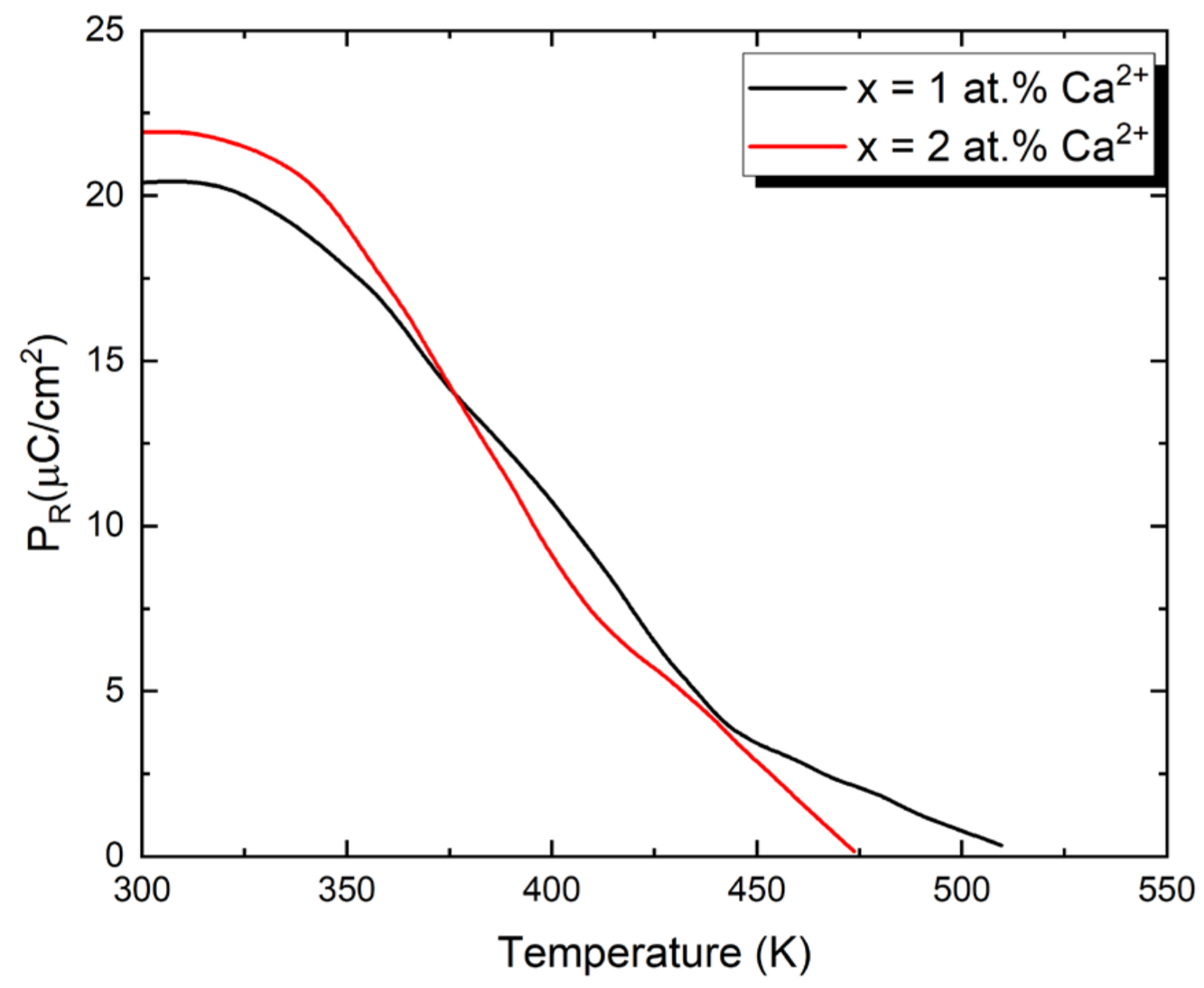

3.3. Hysteresis Loop Measurements

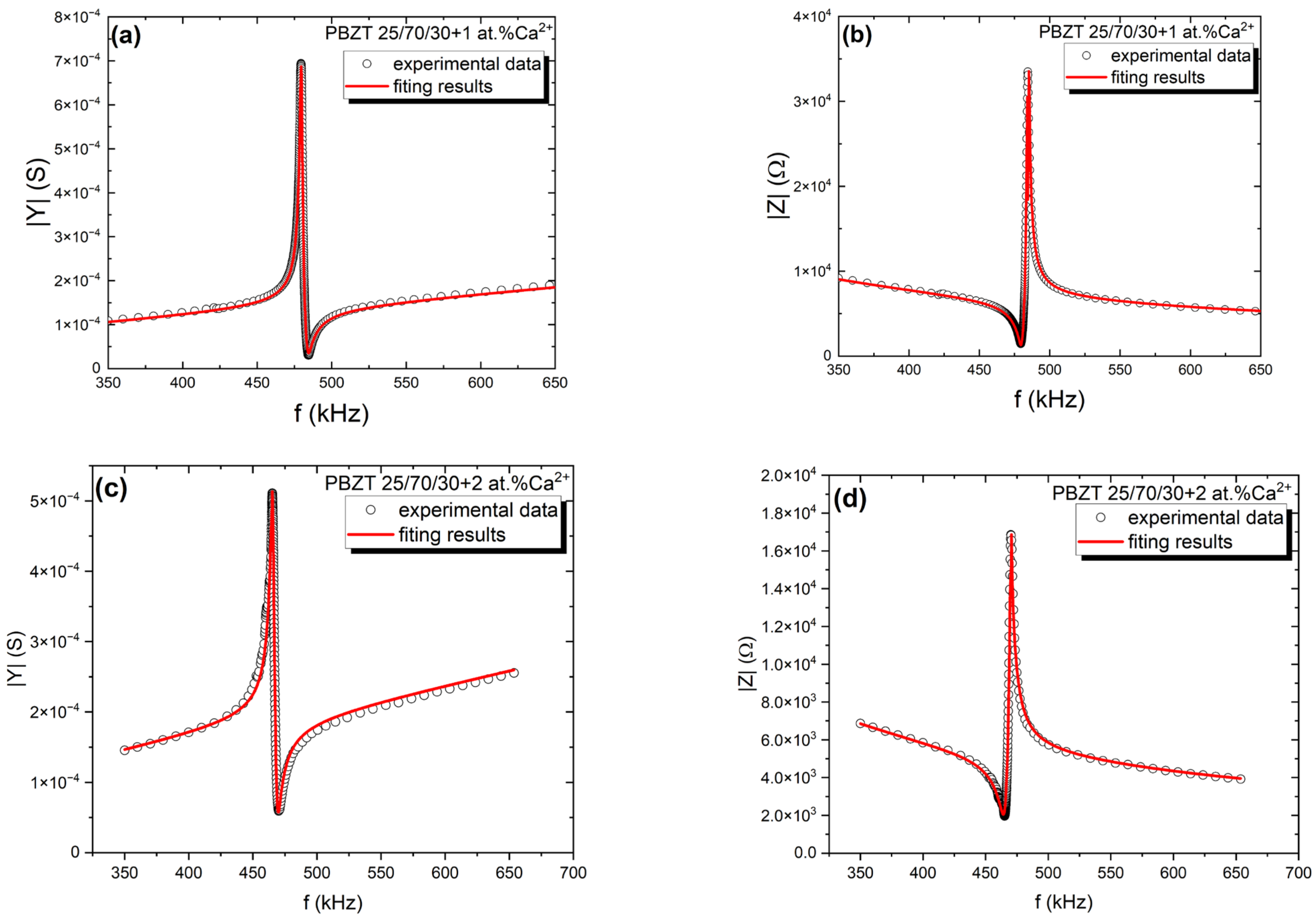

3.4. Piezoelectric Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hernández-García, M.; Durruthy-Rodríguez, M.D.; Costa-Marrero, J.; Calderón-Piñar, F.; Guerra, J.D.S.; Yañez-Limón, J.M. Photoluminescence in Pb0.95Sr0.05(Zr1−xTix)1−yCryO3 ferroelectric ceramic system. J. Appl. Phys. 2014, 116, 043510. [Google Scholar] [CrossRef]

- Butt, Z.; Pasha, R.A.; Qayyum, F.; Anjum, Z.; Ahmad, N.; Elahi, H. Generation of electrical energy using lead zirconate titanate (PZT-5A) piezoelectric material: Analytical, numerical and experimental verifications. J. Mech. Sci. Technol. 2016, 30, 3553–3558. [Google Scholar] [CrossRef]

- Bhugra, H. Piezoelectric MEMS Resonators; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Luo, C.; Cao, G.Z.; Shen, I.Y. Development of a lead-zirconate-titanate (PZT) thin-film microactuator probe for intracochlear applications. Sens. Actuators A Phys. 2013, 201, 1–9. [Google Scholar] [CrossRef]

- Suchanicz, J.; Kluczewska-Chmielarz, K.; Nowakowska-Malczyk, M.; Jagło, G.; Stachowski, G.; Kruzina, T.V. Thermal and electric field induced phase transitions of Na0.5Bi0.5TiO3 single crystals. J. Alloys Compd. 2022, 911, 165104. [Google Scholar] [CrossRef]

- Baasandorj, L.; Chen, Z. Recent Developments on Relaxor-PbTiO3 Ferroelectric Crystals. Crystals 2022, 12, 56. [Google Scholar] [CrossRef]

- Chen, Y.; Lam, K.-H.; Zhou, D.; Yue, Q.; Yu, Y.; Wu, J.; Qiu, W.; Sun, L.; Zhang, C.; Luo, H.; et al. High Performance Relaxor-Based Ferroelectric Single Crystals for Ultrasonic Transducer Applications. Sensors 2014, 14, 13730–13758. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Li, F.; Jiang, X.; Kim, J.; Luo, J.; Geng, X. Advantages and Challenges of Relaxor-PbTiO3 Ferroelectric Crystals for Electroacoustic Transducers—A Review. Prog. Mater. Sci. 2015, 68, 1–66. [Google Scholar] [CrossRef]

- Zhang, S.; Li, F.; Yu, F.; Jiang, X.; Lee, H.Y.; Luo, J.; Shrout, T.R. Recent Developments in Piezoelectric Crystals. J. Korean Ceram. Soc. 2018, 55, 419–439. [Google Scholar] [CrossRef]

- Trolier-McKinstry, S.; Zhang, S.; Bell, A.J.; Tan, X. High-Performance Piezoelectric Crystals, Ceramics, and Films. Annu. Rev. Mater. Res. 2018, 48, 191–217. [Google Scholar] [CrossRef]

- Bokov, A.A.; Ye, Z.-G. Recent progress in relaxor ferroelectrics with perovskite structure. J. Mater. Sci. 2006, 41, 31–52. [Google Scholar] [CrossRef]

- Zhou, K.; He, C.; Xu, G.; Deng, C.; Wang, H.; Dong, B.; Wang, F.; Lu, Y.; Li, Q. Huge piezoelectricity and electro-optic effects in rhombohedral relaxor ferroelectric single crystals by Sm3+ doping. J. Eur. Ceram. Soc. 2024, 44, 4111–4120. [Google Scholar] [CrossRef]

- Tang, Y.; Shen, Z.; Zhang, S.; Jiang, W.; Luo, J.; Shrout, T.R. Minimization of pyroelectric effects in relaxor-PbTiO3 crystals for piezoelectric sensors. Mater. Chem. Phys. 2014, 145, 135–140. [Google Scholar] [CrossRef]

- Kumar, A.; Kalyani, A.K.; Ranjan, R.; James Raju, K.C.; Ryu, J.; Park, N.; James, A.R. Evidence of Monoclinic Phase and Its Variation with Temperature at Morphotropic Phase Boundary of PLZT Ceramics. J. Alloys Compd. 2020, 816, 152613. [Google Scholar] [CrossRef]

- Verma, N.K.; Singh, A.K. Discovery of Ordered Tetragonal and Cubic Phases in the Morphotropic Phase Boundary Region of (1-x)Bi(Mg3/4W1/4)O3-xPbTiO3 Piezoceramics. Ceram. Int. 2019, 45, 17395–17408. [Google Scholar] [CrossRef]

- Li, Y.; Geng, W.; Zhang, L.; Yang, X.; Qiao, X.; Zheng, D.; Zhang, L.; He, J.; Hou, X.; Chou, X. Flexible PLZT Antiferroelectric Film Capacitor for Energy Storage in Wide Temperature Range. J. Alloys Compd. 2021, 868, 159129. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, Z.; Wang, X.; Lv, Z. Experimental Research on Response Characteristics of Optically Controlled Micro-Damping System Based on PLZT Ceramic-Electrorheological Fluid. Mater. Today Commun. 2024, 39, 109223. [Google Scholar] [CrossRef]

- Cross, L.E. Relaxor Ferroelectrics. Ferroelectrics 1987, 76, 241–267. [Google Scholar] [CrossRef]

- Uchino, K. Electrostrictive Actuators: Materials and Application. Bull. Am. Ceram. Soc. 1986, 65, 647. [Google Scholar]

- Bochenek, D.; Skulski, R.; Wawrzała, P.; Brzezińska, D. Dielectric Properties of Pb0.75Ba0.25(Zr0.65Ti0.35)1-zSnzO3 Ceramics. Ferroelectrics 2011, 418, 82–87. [Google Scholar] [CrossRef]

- Mesquita, A.; Michalowicz, A.; Moscovici, J.; Pizani, P.S.; Mastelaro, V.R. Relationship Between Ferroelectric Properties and Local Structure of Pb1-xBaxZr0.40Ti0.60O3 Ceramic Materials Studied by X-ray Absorption and Raman Spectroscopies. J. Solid State Chem. 2016, 240, 16–22. [Google Scholar] [CrossRef]

- Mesquita, A.; Michalowicz, A.; Mastelaro, V.R. Influence of Ba-Substitution on the Structural and Ferroelectric Properties of Pb1-xBaxZr0.40Ti0.60O3 Ceramic Materials. Phase Transit. 2012, 85, 8. [Google Scholar] [CrossRef]

- Smolenskii, G.A.; Agranovskaya, A.I.; Krainik, N. Segnetoelektricheskie svoistva tverdykh rastvorov BaTiO3-PbZrO3. Dokl. Nauk SSSR 1953, 91, 55. [Google Scholar]

- Ikeda, T.J. Studies on (Ba-Pb)(Ti-Zr)O3 System. Phys. Soc. Jpn 1958, 14, 1959. [Google Scholar] [CrossRef]

- Li, G.; Heartling, G.H. Dielectric, ferroelectric and electric field-induced strain properties of (Pb1-xBax)(Zr1-yTiy)O3 ceramics. Ferroelectrics 1995, 166, 31–45. [Google Scholar] [CrossRef]

- Handerek, J.; Adamczyk, M.; Ujma, Z. Dielectric and pyroelectric properties of (Pb1-xBax)(Zr0.70Ti0.30)O3 [x identical with 0.25 divided by 0.35], ceramics. Ferroelectrics 1999, 233, 253. [Google Scholar] [CrossRef]

- Ujma, Z.; Adamczyk, M.; Handerek, J. Relaxor properties of (Pb0.75Ba0.25)(Zr0.70Ti0.30)O3 ceramics. J. Eur. Ceram. Soc. 1998, 18, 2201–2207. [Google Scholar] [CrossRef]

- Adamczyk, M.; Ujma, Z.; Szymczak, L.; Koperski, J. Influence of post-sintering annealing on relaxor behaviour of (Pb0.75Ba0.25)(Zr0.70Ti0.30)O3 ceramics. Ceram. Int. 2005, 31, 791–794. [Google Scholar] [CrossRef]

- Lazar, I.; Adamczyk-Habrajska, M.; Pawełczyk, M.; Górny, M.; Zawada, A.; Roleder, K. Piezoelectric and elastic properties of relaxor-like PZT ceramics. J. Electroceram. 2018, 40, 203–210. [Google Scholar] [CrossRef]

- Yu, Z.; Ang, C.; Guo, R.; Bhalla, A.S. Piezoelectric and strain properties of Ceramics. J. Appl. Phys. 2002, 92, 1489–1493. [Google Scholar] [CrossRef]

- Yu, Z.; Ang, C.; Guo, R.; Bhalla, A.S. Dielectric properties of Ba(Ti1−xZrx)O3 solid solutions. Mater. Lett. 2006, 61, 326–329. [Google Scholar] [CrossRef]

- Roleder, K.; Majchrowski, A.; Lazar, I.; Whatmore, R.W.; Glazer, A.M.; Kajewski, D.; Koperski, J.; Soszynski, A. Monoclinic Domain Populations and Enhancement of Piezoelectric Properties in a PZT Single Crystal at the Morphotropic Phase Boundary. Phys. Rev. B 2022, 105, 144104. [Google Scholar] [CrossRef]

- Roleder, K.; Franke, I.; Glazer, A.M.; Thomas, P.A.; Miga, S.; Suchanicz, J. The Piezoelectric Effect in Na0.5Bi0.5TiO3 Ceramics. J. Phys. Condens. Matter 2002, 14, 5399–5406. [Google Scholar] [CrossRef]

- Bauer, A.; Buhling, D.; Gesemann, H.J.; Helke, G.; Schreckenbach, W. Technology and Application of Ferroelectrics; Akademische Verlagsgesellschaft Geest & Portig K.-G: Leipzig, Germany, 1976. [Google Scholar]

- Machnik, Z.; Bochenek, D.; Wodecka-Dus, B.; Adamczyk, M.; Osińska, K. Fabrication and dielectric properties of modified calcium (Pb0.75Ba0.25)(Zr0.7Ti0.3)O3 ceramics. Eur. Phys. J. B 2016, 89, 34. [Google Scholar] [CrossRef]

- Mir, M.; Mastelaro, V.R.; Neves, P.P.; Doriguetto, A.C.; Garcia, D.; Lente, M.H.; Eiras, J.A.; Mascarenhas, Y.P. X-ray powder diffraction structural characterization of Pb1−xBaxZr0.65Ti0.35O3 ceramic. Acta Cryst. B 2007, 63, 713. [Google Scholar] [CrossRef]

| Formula | Oxide Content by EDS Measurement [%] | Theoretical Content of Oxides [%] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| PbO | BaO | CaO | ZrO2 | TiO2 | PbO | BaO | CaO | ZrO2 | TiO2 | |

| PBZT + 1 at.%Ca | 52.7 | 12.07 | 0.18 | 27.43 | 7.62 | 53.02 | 11.95 | 0.16 | 27.23 | 7.64 |

| PBZT + 2 at.%Ca | 52.42 | 12.00 | 0.36 | 27.56 | 7.66 | 51.95 | 12.9 | 0.35 | 28.25 | 6.55 |

| εRT | εmax | Tm | tgδRT | tgδmax | Δεmax | ΔTm | |

|---|---|---|---|---|---|---|---|

| PBZT + 0 at.%Ca [c] | 430 | 5390 | 464 | 0.02 | 0.06 | 1420 | 14.1 |

| PBZT + 1 at.%Ca | 2897 | 9089 | 410 | 0.05 | 0.09 | 1111 | 12.68 |

| PBZT + 2 at.%Ca | 3688 | 9323 | 393 | 0.04 | 0.05 | 1033 | 9.46 |

| Sample | ε33 | s′11[m2/N] | s″11[m2/N] | k31 | d31[C/N] |

|---|---|---|---|---|---|

| PBZT 25/70/30 [29] | 433.4 | 1.32 × 10−11 | 3.79 × 10−14 | 0.08 | 1.80 × 10−11 |

| PBZT 25/70/30 + 1 at.% Ca2+ | 1042.7 | 1.09 × 10−11 | 2.19 × 10−14 | 0.16 | 4.92 × 10−11 |

| PBZT 25/70/30 + 2 at.% Ca2+ | 1443.6 | 1.15 × 10−11 | 7.86 × 10−14 | 0.16 | 6.09 × 10−11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makowska, J.; Pawełczyk, M.; Soszyński, A.; Pikula, T.; Adamczyk-Habrajska, M. Investigation of Piezoelectric Properties in Ca-Doped PbBa(Zr,Ti)O3 (PBZT) Ceramics. Micromachines 2024, 15, 1018. https://doi.org/10.3390/mi15081018

Makowska J, Pawełczyk M, Soszyński A, Pikula T, Adamczyk-Habrajska M. Investigation of Piezoelectric Properties in Ca-Doped PbBa(Zr,Ti)O3 (PBZT) Ceramics. Micromachines. 2024; 15(8):1018. https://doi.org/10.3390/mi15081018

Chicago/Turabian StyleMakowska, Jolanta, Marian Pawełczyk, Andrzej Soszyński, Tomasz Pikula, and Małgorzata Adamczyk-Habrajska. 2024. "Investigation of Piezoelectric Properties in Ca-Doped PbBa(Zr,Ti)O3 (PBZT) Ceramics" Micromachines 15, no. 8: 1018. https://doi.org/10.3390/mi15081018

APA StyleMakowska, J., Pawełczyk, M., Soszyński, A., Pikula, T., & Adamczyk-Habrajska, M. (2024). Investigation of Piezoelectric Properties in Ca-Doped PbBa(Zr,Ti)O3 (PBZT) Ceramics. Micromachines, 15(8), 1018. https://doi.org/10.3390/mi15081018